Diesel DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 678 of 2895

²Washer Pump/Motor- The electric washer

pump/motor unit is located in a dedicated hole on the

rearward facing surface of the washer reservoir in

the engine compartment.

²Washer Reservoir- On all models except those

with an optional V-10 or diesel engine, the washer

reservoir is secured by integral mounting tabs and a

snap feature to slots in the right side of the cooling

module shroud in the engine compartment. On mod-

els with an optional V-10 or diesel engine, the washer

reservoir is secured by screws to the back of the

upright left vertical member of the radiator support

in the engine compartment. The washer reservoir

filler neck is accessed from the engine compartment.

²Wiper Arm- The two wiper arms are secured

with integral latches to the serrated ends of the two

wiper pivot shafts, which extend through the cowl

plenum cover/grille panel located near the base of the

windshield.

²Wiper Blade- The two wiper blades are

secured to the two wiper arms with an integral latch,

and are parked on the glass near the bottom of the

windshield when the wiper system is not in opera-

tion.

²Wiper High/Low Relay- The wiper high/low

relay is an International Standards Organization

(ISO) micro relay located in the Integrated Power

Module (IPM) in the engine compartment near the

battery.

²Wiper Module- The wiper pivot shafts are the

only visible components of the wiper module. The

remainder of the module is concealed within the cowl

plenum area beneath the cowl plenum cover/grille

panel. The wiper module includes the wiper module

bracket, four rubber-isolated wiper module mounts,

the wiper motor, the wiper motor crank arm, the two

wiper drive links, and the two wiper pivots.

²Wiper On/Off Relay- The wiper on/off relay is

an International Standards Organization (ISO) micro

relay located in the Integrated Power Module (IPM)

in the engine compartment near the battery.

Hard wired circuitry connects the wiper and

washer system components to the electrical system of

the vehicle. These hard wired circuits are integral to

several wire harnesses, which are routed throughout

the vehicle and retained by many different methods.

These circuits may be connected to each other, to the

vehicle electrical system and to the wiper and washer

system components through the use of a combination

of soldered splices, splice block connectors, and many

different types of wire harness terminal connectors

and insulators. Refer to the appropriate wiring infor-

mation. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

further details on wire harness routing and reten-tion, as well as pin-out and location views for the

various wire harness connectors, splices and grounds.

OPERATING MODES

The components of the wiper and washer system

are designed to work in concert to provide the follow-

ing operating modes:

²Continuous Wipe Mode- The control knob on

the control stalk of the multi-function switch has two

continuous wipe positions, Low and High. When

selected, these switch positions will cause the two-

speed wiper motor to operate in a continuous low or

high speed cycle.

²Intermittent Wipe Mode- The control knob on

the control stalk of the multi-function switch has five

minor detent intermittent wipe positions. When

selected, these switch positions will cause the wiper

system to operate with one of five delay intervals

between complete wipe cycles. The intermittent wipe

delay intervals are speed sensitive and will be dou-

bled when the vehicle speed is about sixteen kilome-

ters-per-hour (ten miles-per-hour) or less.

²Pulse Wipe Mode- When the control knob on

the control stalk of the multi-function switch is

depressed to the momentary Wash position for less

than about one-half second, the wiper system will

operate the wipers for one complete low speed cycle,

then will park the wiper blades near the base of the

windshield.

²Washer Mode- When the control knob on the

control stalk of the multi-function switch is

depressed to the momentary Wash position for more

than about one-half second with the wiper system

turned Off, the washer pump/motor and the wipers

will operate for as long as the washer switch is held

closed up to about thirty seconds, then the wipe-af-

ter-wash mode is invoked when the control knob is

released. When the Wash position is selected with

the wiper system operating in a continuous wipe

mode, washer fluid will be dispensed onto the wind-

shield glass through the washer nozzles for as long

as the washer switch is held closed up to about thirty

seconds. When the Wash position is selected with the

wiper system operating in an intermittent wipe

mode, washer fluid is still dispensed until the control

knob is released; however, the wipers will operate in

a low speed continuous cycle from the time the

washer switch is closed until several wipe cycles

after the switch is released, before returning to the

selected intermittent wipe interval. If the control

knob is held in the depressed Wash position for more

than about thirty seconds, washer system operation

will be suspended until the control knob is released

for about two seconds then cycled back to the Wash

position.

DRWIPERS/WASHERS 8R - 3

WIPERS/WASHERS (Continued)

Page 685 of 2895

The washer fluid level switch is connected to the

vehicle electrical system through a dedicated take

out and connector of the right (except V-10 and diesel

engines) or left (V-10 and diesel engines only) head-

lamp and dash wire harness. The switch is connected

in series between a clean ground output of the Front

Control Module (FCM) on a sensor return circuit and

the washer fluid switch sense input to the FCM.

When the switch closes, the FMC senses the ground

on the washer fluid switch sense circuit. The FMC is

programmed to respond to this input by sending an

electronic washer fluid indicator lamp-on message to

the instrument cluster over the Programmable Com-

munications Interface (PCI) data bus. The instru-

ment cluster responds to this message by

illuminating the washer fluid indicator and by sound-

ing an audible chime tone warning.

The washer fluid level switch may be diagnosed

and tested using conventional diagnostic tools and

procedures. However, conventional diagnostic meth-

ods may not prove conclusive in the diagnosis of the

instrument cluster, the Front Control Module (FCM),

or the electronic message inputs to or outputs from

the instrument cluster and the FCM that control the

operation of the washer fluid visual and/or audible

indicators. The most reliable, efficient, and accurate

means to diagnose the washer fluid level indicator,

the instrument cluster, the FCM, or the electronic

message inputs and outputs related to the washer

fluid indicator requires the use of a DRBIIItscan

tool. Refer to the appropriate diagnostic information.

REMOVAL

The washer fluid level switch can be removed from

the washer reservoir without removing the reservoir

from the vehicle.

(1) Unlatch and open the hood.

(2) Disconnect and isolate the battery negative

cable.

(3) Disconnect the washer hose from the barbed

outlet nipple of the washer pump/motor unit and

allow the washer fluid to drain into a clean container

for reuse.

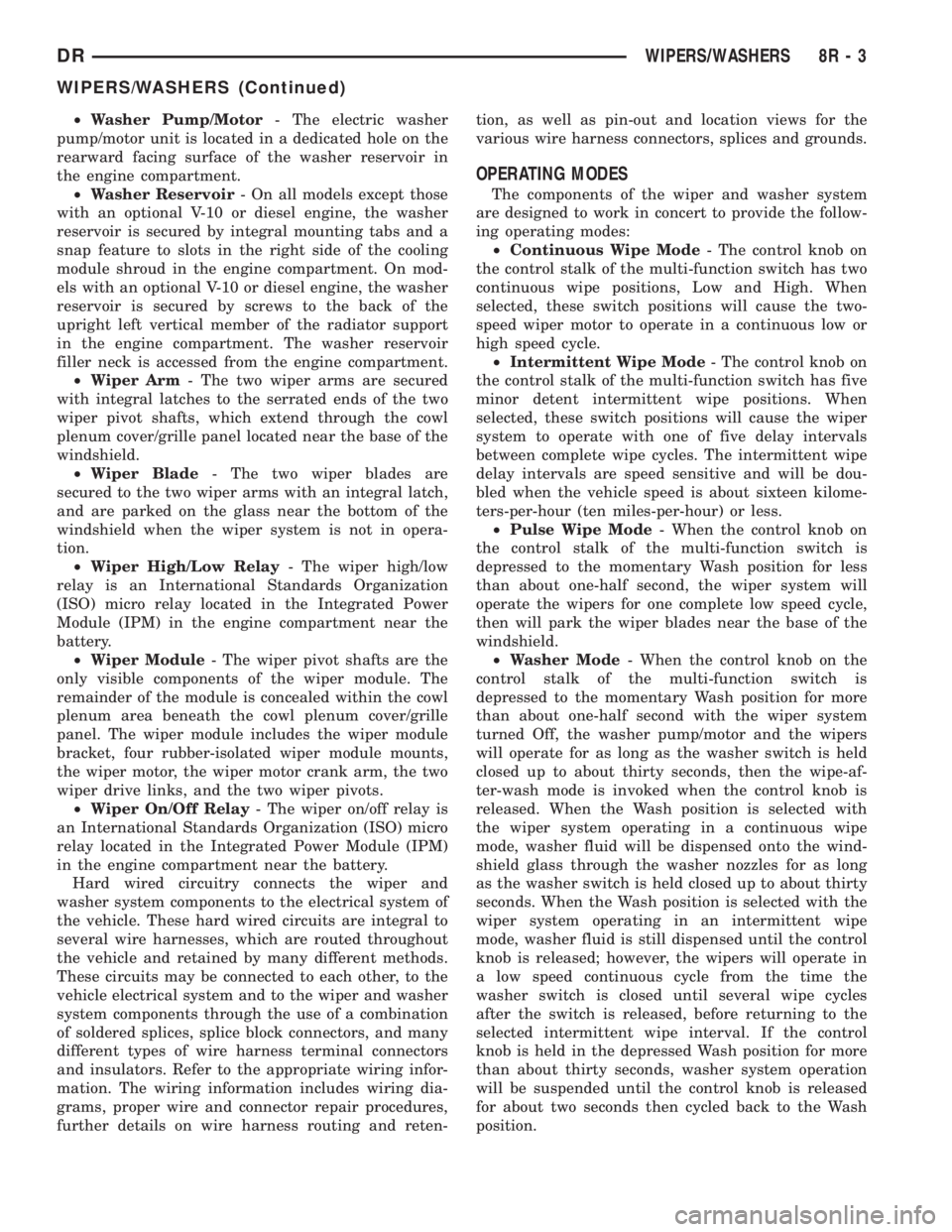

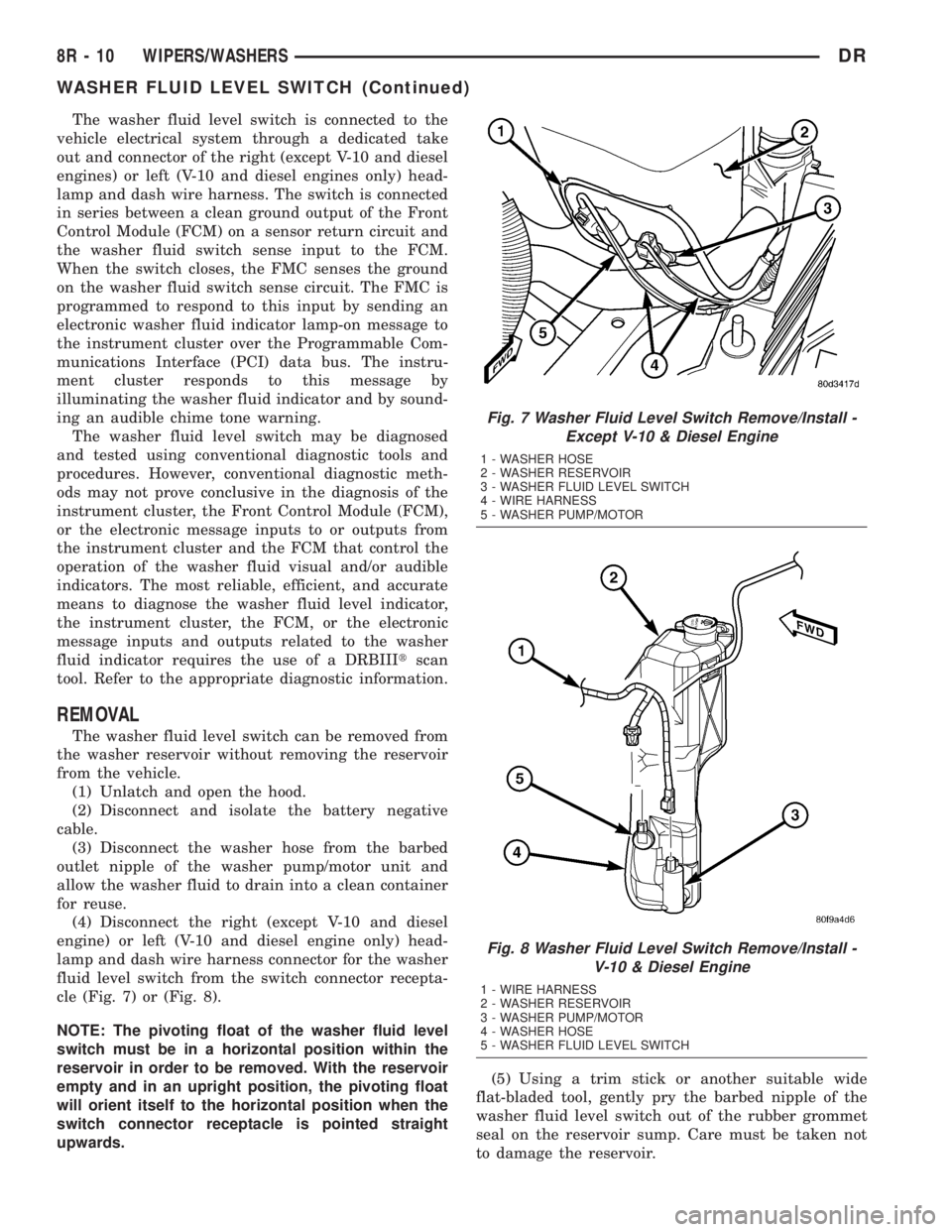

(4) Disconnect the right (except V-10 and diesel

engine) or left (V-10 and diesel engine only) head-

lamp and dash wire harness connector for the washer

fluid level switch from the switch connector recepta-

cle (Fig. 7) or (Fig. 8).

NOTE: The pivoting float of the washer fluid level

switch must be in a horizontal position within the

reservoir in order to be removed. With the reservoir

empty and in an upright position, the pivoting float

will orient itself to the horizontal position when the

switch connector receptacle is pointed straight

upwards.(5) Using a trim stick or another suitable wide

flat-bladed tool, gently pry the barbed nipple of the

washer fluid level switch out of the rubber grommet

seal on the reservoir sump. Care must be taken not

to damage the reservoir.

Fig. 7 Washer Fluid Level Switch Remove/Install -

Except V-10 & Diesel Engine

1 - WASHER HOSE

2 - WASHER RESERVOIR

3 - WASHER FLUID LEVEL SWITCH

4 - WIRE HARNESS

5 - WASHER PUMP/MOTOR

Fig. 8 Washer Fluid Level Switch Remove/Install -

V-10 & Diesel Engine

1 - WIRE HARNESS

2 - WASHER RESERVOIR

3 - WASHER PUMP/MOTOR

4 - WASHER HOSE

5 - WASHER FLUID LEVEL SWITCH

8R - 10 WIPERS/WASHERSDR

WASHER FLUID LEVEL SWITCH (Continued)

Page 686 of 2895

(6) Remove the washer fluid level switch from the

washer reservoir.

(7) Remove the rubber grommet seal from the

washer fluid level switch mounting hole in the

washer reservoir and discard.

INSTALLATION

(1) Install a new rubber grommet seal into the

washer fluid level switch mounting hole in the

washer reservoir. Always use a new rubber grommet

seal on the reservoir.

(2) Insert the float of the washer fluid level switch

through the rubber grommet seal and into the

washer reservoir. The connector receptacle of the

washer fluid level switch should be pointed upward.

(3) Using hand pressure, press firmly and evenly

on the washer fluid level switch mounting flange

until the barbed nipple is fully seated in the rubber

grommet seal in the washer reservoir mounting hole.

(4) Reconnect the right (except V-10 and diesel

engine) or left (V-10 and diesel engine only) head-

lamp and dash wire harness connector for the washer

fluid level switch to the switch connector receptacle

(Fig. 7) or (Fig. 8).

(5) Reconnect the removed washer hose to the

barbed outlet nipple of the washer pump/motor unit.

(6) Refill the washer reservoir with the washer

fluid drained from the reservoir during the removal

procedure.

(7) Reconnect the battery negative cable.

(8) Close and latch the hood.

WASHER HOSES/TUBES

DESCRIPTION

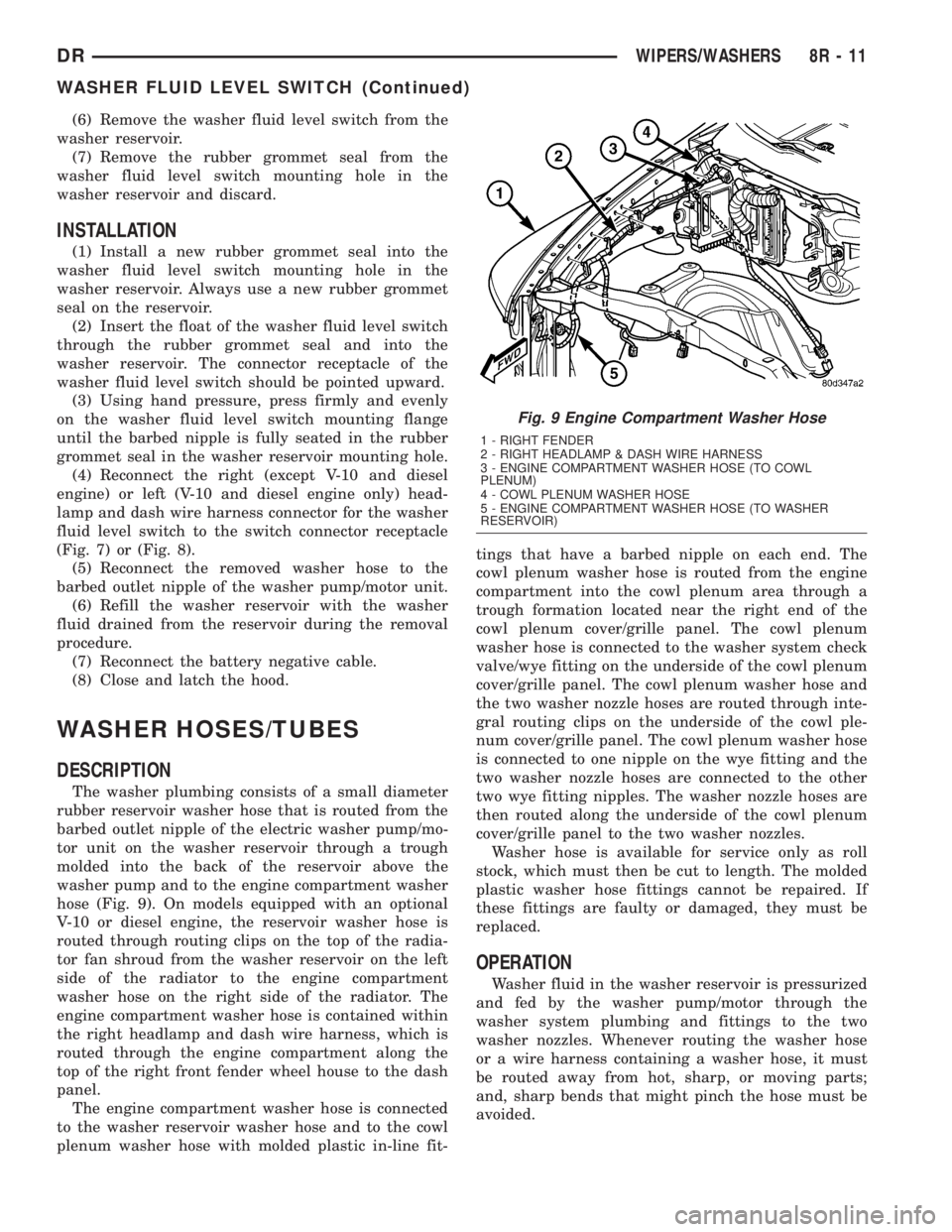

The washer plumbing consists of a small diameter

rubber reservoir washer hose that is routed from the

barbed outlet nipple of the electric washer pump/mo-

tor unit on the washer reservoir through a trough

molded into the back of the reservoir above the

washer pump and to the engine compartment washer

hose (Fig. 9). On models equipped with an optional

V-10 or diesel engine, the reservoir washer hose is

routed through routing clips on the top of the radia-

tor fan shroud from the washer reservoir on the left

side of the radiator to the engine compartment

washer hose on the right side of the radiator. The

engine compartment washer hose is contained within

the right headlamp and dash wire harness, which is

routed through the engine compartment along the

top of the right front fender wheel house to the dash

panel.

The engine compartment washer hose is connected

to the washer reservoir washer hose and to the cowl

plenum washer hose with molded plastic in-line fit-tings that have a barbed nipple on each end. The

cowl plenum washer hose is routed from the engine

compartment into the cowl plenum area through a

trough formation located near the right end of the

cowl plenum cover/grille panel. The cowl plenum

washer hose is connected to the washer system check

valve/wye fitting on the underside of the cowl plenum

cover/grille panel. The cowl plenum washer hose and

the two washer nozzle hoses are routed through inte-

gral routing clips on the underside of the cowl ple-

num cover/grille panel. The cowl plenum washer hose

is connected to one nipple on the wye fitting and the

two washer nozzle hoses are connected to the other

two wye fitting nipples. The washer nozzle hoses are

then routed along the underside of the cowl plenum

cover/grille panel to the two washer nozzles.

Washer hose is available for service only as roll

stock, which must then be cut to length. The molded

plastic washer hose fittings cannot be repaired. If

these fittings are faulty or damaged, they must be

replaced.

OPERATION

Washer fluid in the washer reservoir is pressurized

and fed by the washer pump/motor through the

washer system plumbing and fittings to the two

washer nozzles. Whenever routing the washer hose

or a wire harness containing a washer hose, it must

be routed away from hot, sharp, or moving parts;

and, sharp bends that might pinch the hose must be

avoided.

Fig. 9 Engine Compartment Washer Hose

1 - RIGHT FENDER

2 - RIGHT HEADLAMP & DASH WIRE HARNESS

3 - ENGINE COMPARTMENT WASHER HOSE (TO COWL

PLENUM)

4 - COWL PLENUM WASHER HOSE

5 - ENGINE COMPARTMENT WASHER HOSE (TO WASHER

RESERVOIR)

DRWIPERS/WASHERS 8R - 11

WASHER FLUID LEVEL SWITCH (Continued)

Page 688 of 2895

(4) Reinstall the washer hose for the washer noz-

zle into its routing clips on the underside of the cowl

plenum cover/grille panel.

(5) Reinstall the cowl plenum cover/grille panel

over the cowl plenum. (Refer to 23 - BODY/EXTERI-

OR/COWL GRILLE - INSTALLATION).

(6) Close and latch the hood.

(7) Reinstall both wiper arms onto the wiper piv-

ots. (Refer to 8 - ELECTRICAL/WIPERS/WASHERS/

WIPER ARM - INSTALLATION).

WASHER PUMP/MOTOR

DESCRIPTION

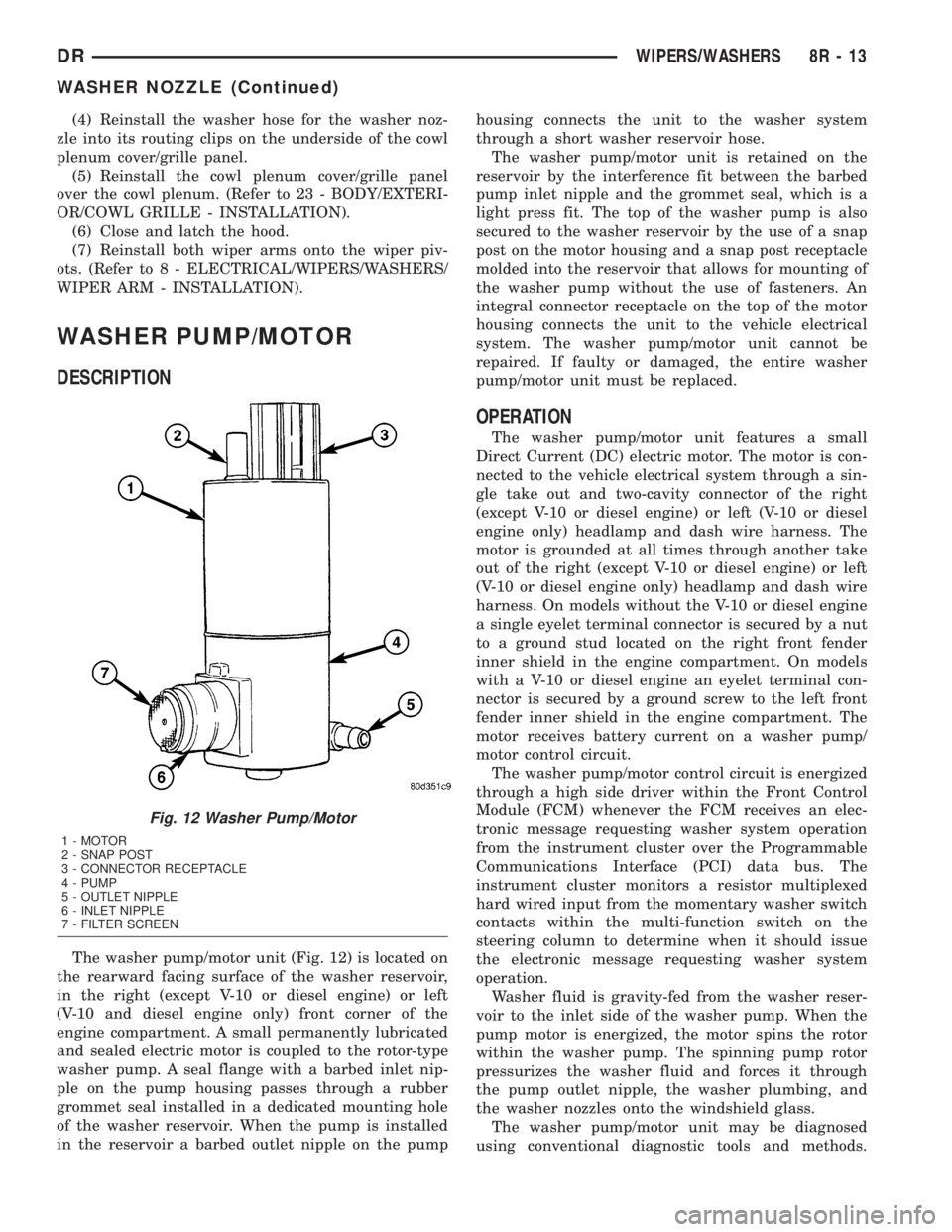

The washer pump/motor unit (Fig. 12) is located on

the rearward facing surface of the washer reservoir,

in the right (except V-10 or diesel engine) or left

(V-10 and diesel engine only) front corner of the

engine compartment. A small permanently lubricated

and sealed electric motor is coupled to the rotor-type

washer pump. A seal flange with a barbed inlet nip-

ple on the pump housing passes through a rubber

grommet seal installed in a dedicated mounting hole

of the washer reservoir. When the pump is installed

in the reservoir a barbed outlet nipple on the pumphousing connects the unit to the washer system

through a short washer reservoir hose.

The washer pump/motor unit is retained on the

reservoir by the interference fit between the barbed

pump inlet nipple and the grommet seal, which is a

light press fit. The top of the washer pump is also

secured to the washer reservoir by the use of a snap

post on the motor housing and a snap post receptacle

molded into the reservoir that allows for mounting of

the washer pump without the use of fasteners. An

integral connector receptacle on the top of the motor

housing connects the unit to the vehicle electrical

system. The washer pump/motor unit cannot be

repaired. If faulty or damaged, the entire washer

pump/motor unit must be replaced.

OPERATION

The washer pump/motor unit features a small

Direct Current (DC) electric motor. The motor is con-

nected to the vehicle electrical system through a sin-

gle take out and two-cavity connector of the right

(except V-10 or diesel engine) or left (V-10 or diesel

engine only) headlamp and dash wire harness. The

motor is grounded at all times through another take

out of the right (except V-10 or diesel engine) or left

(V-10 or diesel engine only) headlamp and dash wire

harness. On models without the V-10 or diesel engine

a single eyelet terminal connector is secured by a nut

to a ground stud located on the right front fender

inner shield in the engine compartment. On models

with a V-10 or diesel engine an eyelet terminal con-

nector is secured by a ground screw to the left front

fender inner shield in the engine compartment. The

motor receives battery current on a washer pump/

motor control circuit.

The washer pump/motor control circuit is energized

through a high side driver within the Front Control

Module (FCM) whenever the FCM receives an elec-

tronic message requesting washer system operation

from the instrument cluster over the Programmable

Communications Interface (PCI) data bus. The

instrument cluster monitors a resistor multiplexed

hard wired input from the momentary washer switch

contacts within the multi-function switch on the

steering column to determine when it should issue

the electronic message requesting washer system

operation.

Washer fluid is gravity-fed from the washer reser-

voir to the inlet side of the washer pump. When the

pump motor is energized, the motor spins the rotor

within the washer pump. The spinning pump rotor

pressurizes the washer fluid and forces it through

the pump outlet nipple, the washer plumbing, and

the washer nozzles onto the windshield glass.

The washer pump/motor unit may be diagnosed

using conventional diagnostic tools and methods.

Fig. 12 Washer Pump/Motor

1 - MOTOR

2 - SNAP POST

3 - CONNECTOR RECEPTACLE

4 - PUMP

5 - OUTLET NIPPLE

6 - INLET NIPPLE

7 - FILTER SCREEN

DRWIPERS/WASHERS 8R - 13

WASHER NOZZLE (Continued)

Page 689 of 2895

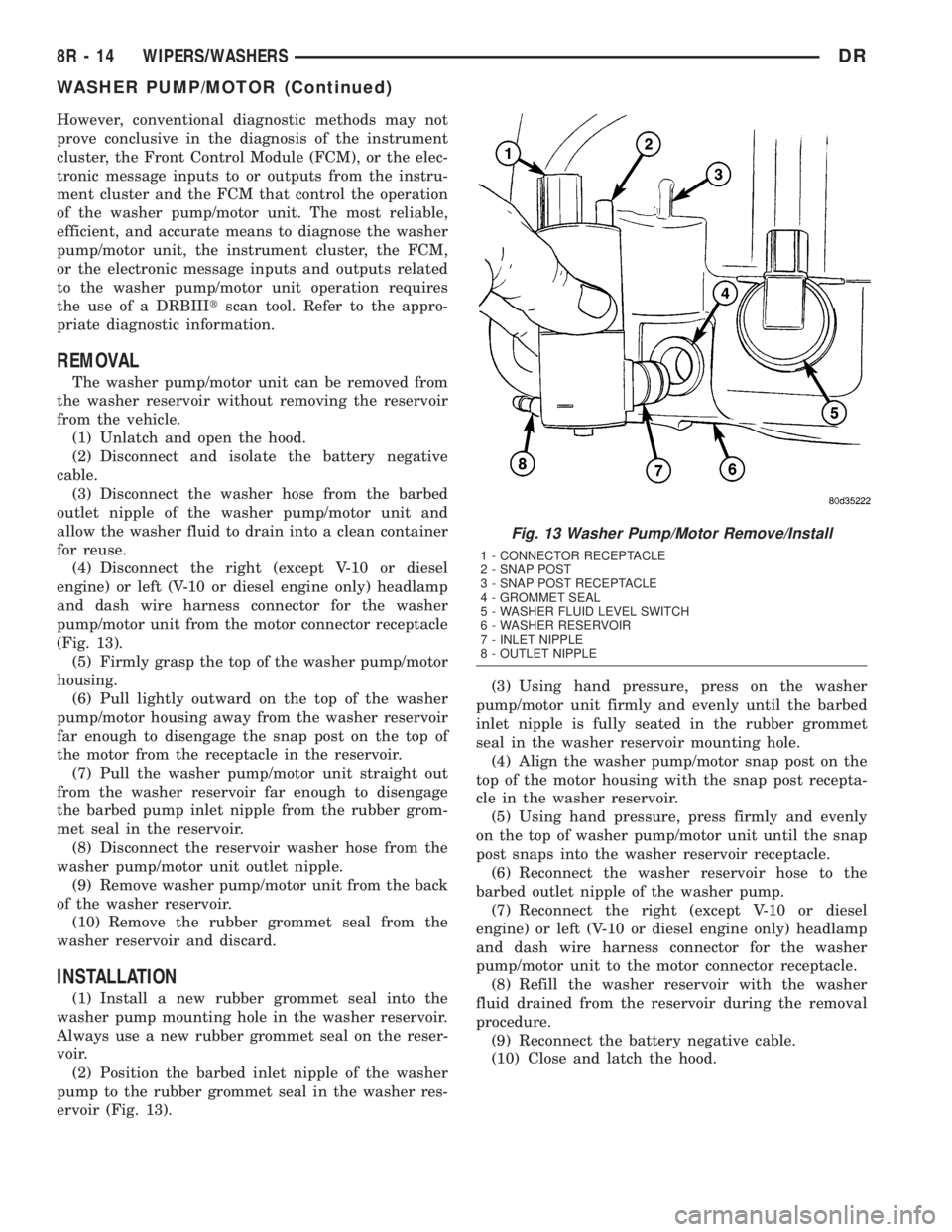

However, conventional diagnostic methods may not

prove conclusive in the diagnosis of the instrument

cluster, the Front Control Module (FCM), or the elec-

tronic message inputs to or outputs from the instru-

ment cluster and the FCM that control the operation

of the washer pump/motor unit. The most reliable,

efficient, and accurate means to diagnose the washer

pump/motor unit, the instrument cluster, the FCM,

or the electronic message inputs and outputs related

to the washer pump/motor unit operation requires

the use of a DRBIIItscan tool. Refer to the appro-

priate diagnostic information.

REMOVAL

The washer pump/motor unit can be removed from

the washer reservoir without removing the reservoir

from the vehicle.

(1) Unlatch and open the hood.

(2) Disconnect and isolate the battery negative

cable.

(3) Disconnect the washer hose from the barbed

outlet nipple of the washer pump/motor unit and

allow the washer fluid to drain into a clean container

for reuse.

(4) Disconnect the right (except V-10 or diesel

engine) or left (V-10 or diesel engine only) headlamp

and dash wire harness connector for the washer

pump/motor unit from the motor connector receptacle

(Fig. 13).

(5) Firmly grasp the top of the washer pump/motor

housing.

(6) Pull lightly outward on the top of the washer

pump/motor housing away from the washer reservoir

far enough to disengage the snap post on the top of

the motor from the receptacle in the reservoir.

(7) Pull the washer pump/motor unit straight out

from the washer reservoir far enough to disengage

the barbed pump inlet nipple from the rubber grom-

met seal in the reservoir.

(8) Disconnect the reservoir washer hose from the

washer pump/motor unit outlet nipple.

(9) Remove washer pump/motor unit from the back

of the washer reservoir.

(10) Remove the rubber grommet seal from the

washer reservoir and discard.

INSTALLATION

(1) Install a new rubber grommet seal into the

washer pump mounting hole in the washer reservoir.

Always use a new rubber grommet seal on the reser-

voir.

(2) Position the barbed inlet nipple of the washer

pump to the rubber grommet seal in the washer res-

ervoir (Fig. 13).(3) Using hand pressure, press on the washer

pump/motor unit firmly and evenly until the barbed

inlet nipple is fully seated in the rubber grommet

seal in the washer reservoir mounting hole.

(4) Align the washer pump/motor snap post on the

top of the motor housing with the snap post recepta-

cle in the washer reservoir.

(5) Using hand pressure, press firmly and evenly

on the top of washer pump/motor unit until the snap

post snaps into the washer reservoir receptacle.

(6) Reconnect the washer reservoir hose to the

barbed outlet nipple of the washer pump.

(7) Reconnect the right (except V-10 or diesel

engine) or left (V-10 or diesel engine only) headlamp

and dash wire harness connector for the washer

pump/motor unit to the motor connector receptacle.

(8) Refill the washer reservoir with the washer

fluid drained from the reservoir during the removal

procedure.

(9) Reconnect the battery negative cable.

(10) Close and latch the hood.

Fig. 13 Washer Pump/Motor Remove/Install

1 - CONNECTOR RECEPTACLE

2 - SNAP POST

3 - SNAP POST RECEPTACLE

4 - GROMMET SEAL

5 - WASHER FLUID LEVEL SWITCH

6 - WASHER RESERVOIR

7 - INLET NIPPLE

8 - OUTLET NIPPLE

8R - 14 WIPERS/WASHERSDR

WASHER PUMP/MOTOR (Continued)

Page 690 of 2895

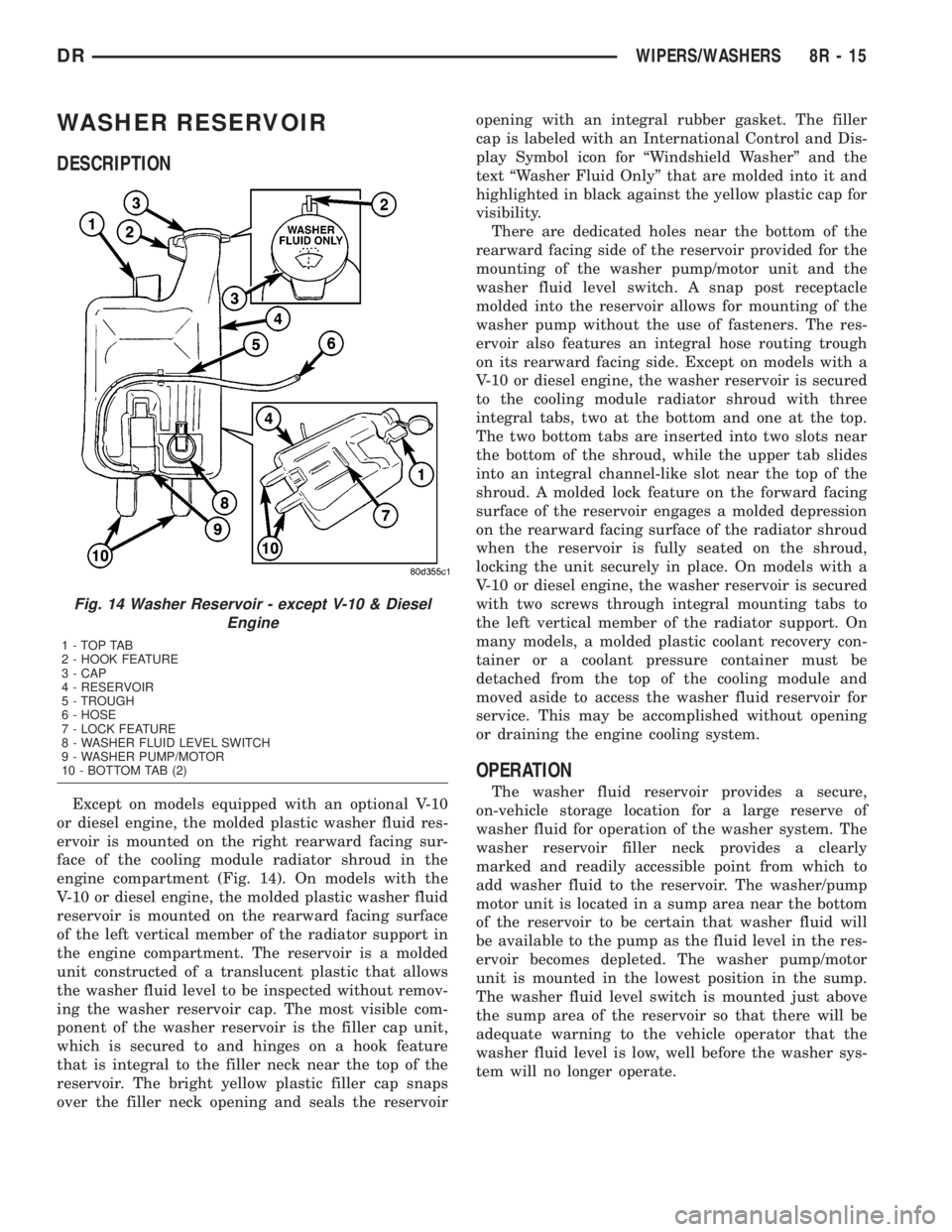

WASHER RESERVOIR

DESCRIPTION

Except on models equipped with an optional V-10

or diesel engine, the molded plastic washer fluid res-

ervoir is mounted on the right rearward facing sur-

face of the cooling module radiator shroud in the

engine compartment (Fig. 14). On models with the

V-10 or diesel engine, the molded plastic washer fluid

reservoir is mounted on the rearward facing surface

of the left vertical member of the radiator support in

the engine compartment. The reservoir is a molded

unit constructed of a translucent plastic that allows

the washer fluid level to be inspected without remov-

ing the washer reservoir cap. The most visible com-

ponent of the washer reservoir is the filler cap unit,

which is secured to and hinges on a hook feature

that is integral to the filler neck near the top of the

reservoir. The bright yellow plastic filler cap snaps

over the filler neck opening and seals the reservoiropening with an integral rubber gasket. The filler

cap is labeled with an International Control and Dis-

play Symbol icon for ªWindshield Washerº and the

text ªWasher Fluid Onlyº that are molded into it and

highlighted in black against the yellow plastic cap for

visibility.

There are dedicated holes near the bottom of the

rearward facing side of the reservoir provided for the

mounting of the washer pump/motor unit and the

washer fluid level switch. A snap post receptacle

molded into the reservoir allows for mounting of the

washer pump without the use of fasteners. The res-

ervoir also features an integral hose routing trough

on its rearward facing side. Except on models with a

V-10 or diesel engine, the washer reservoir is secured

to the cooling module radiator shroud with three

integral tabs, two at the bottom and one at the top.

The two bottom tabs are inserted into two slots near

the bottom of the shroud, while the upper tab slides

into an integral channel-like slot near the top of the

shroud. A molded lock feature on the forward facing

surface of the reservoir engages a molded depression

on the rearward facing surface of the radiator shroud

when the reservoir is fully seated on the shroud,

locking the unit securely in place. On models with a

V-10 or diesel engine, the washer reservoir is secured

with two screws through integral mounting tabs to

the left vertical member of the radiator support. On

many models, a molded plastic coolant recovery con-

tainer or a coolant pressure container must be

detached from the top of the cooling module and

moved aside to access the washer fluid reservoir for

service. This may be accomplished without opening

or draining the engine cooling system.

OPERATION

The washer fluid reservoir provides a secure,

on-vehicle storage location for a large reserve of

washer fluid for operation of the washer system. The

washer reservoir filler neck provides a clearly

marked and readily accessible point from which to

add washer fluid to the reservoir. The washer/pump

motor unit is located in a sump area near the bottom

of the reservoir to be certain that washer fluid will

be available to the pump as the fluid level in the res-

ervoir becomes depleted. The washer pump/motor

unit is mounted in the lowest position in the sump.

The washer fluid level switch is mounted just above

the sump area of the reservoir so that there will be

adequate warning to the vehicle operator that the

washer fluid level is low, well before the washer sys-

tem will no longer operate.

Fig. 14 Washer Reservoir - except V-10 & Diesel

Engine

1-TOPTAB

2 - HOOK FEATURE

3 - CAP

4 - RESERVOIR

5 - TROUGH

6 - HOSE

7 - LOCK FEATURE

8 - WASHER FLUID LEVEL SWITCH

9 - WASHER PUMP/MOTOR

10 - BOTTOM TAB (2)

DRWIPERS/WASHERS 8R - 15

Page 691 of 2895

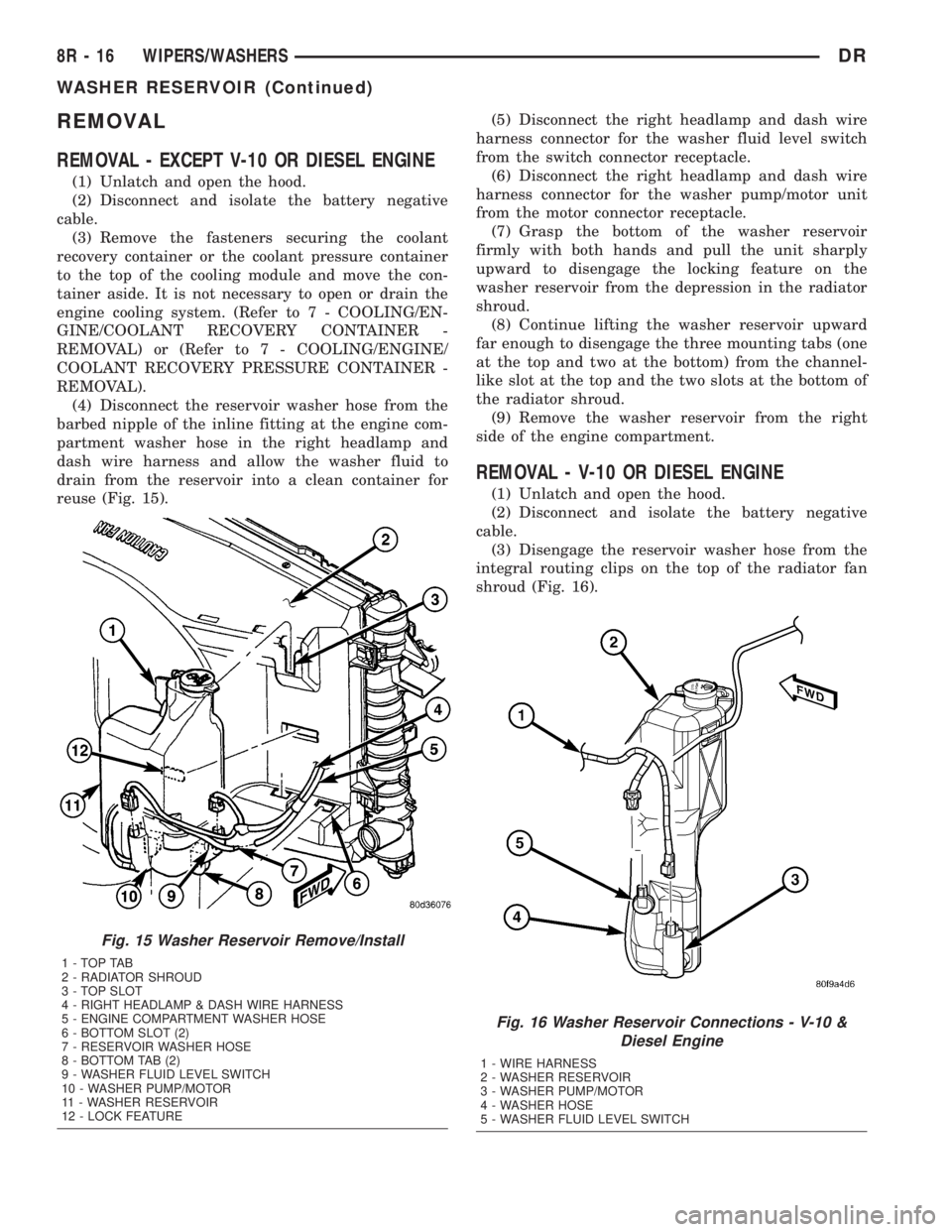

REMOVAL

REMOVAL - EXCEPT V-10 OR DIESEL ENGINE

(1) Unlatch and open the hood.

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the fasteners securing the coolant

recovery container or the coolant pressure container

to the top of the cooling module and move the con-

tainer aside. It is not necessary to open or drain the

engine cooling system. (Refer to 7 - COOLING/EN-

GINE/COOLANT RECOVERY CONTAINER -

REMOVAL) or (Refer to 7 - COOLING/ENGINE/

COOLANT RECOVERY PRESSURE CONTAINER -

REMOVAL).

(4) Disconnect the reservoir washer hose from the

barbed nipple of the inline fitting at the engine com-

partment washer hose in the right headlamp and

dash wire harness and allow the washer fluid to

drain from the reservoir into a clean container for

reuse (Fig. 15).(5) Disconnect the right headlamp and dash wire

harness connector for the washer fluid level switch

from the switch connector receptacle.

(6) Disconnect the right headlamp and dash wire

harness connector for the washer pump/motor unit

from the motor connector receptacle.

(7) Grasp the bottom of the washer reservoir

firmly with both hands and pull the unit sharply

upward to disengage the locking feature on the

washer reservoir from the depression in the radiator

shroud.

(8) Continue lifting the washer reservoir upward

far enough to disengage the three mounting tabs (one

at the top and two at the bottom) from the channel-

like slot at the top and the two slots at the bottom of

the radiator shroud.

(9) Remove the washer reservoir from the right

side of the engine compartment.

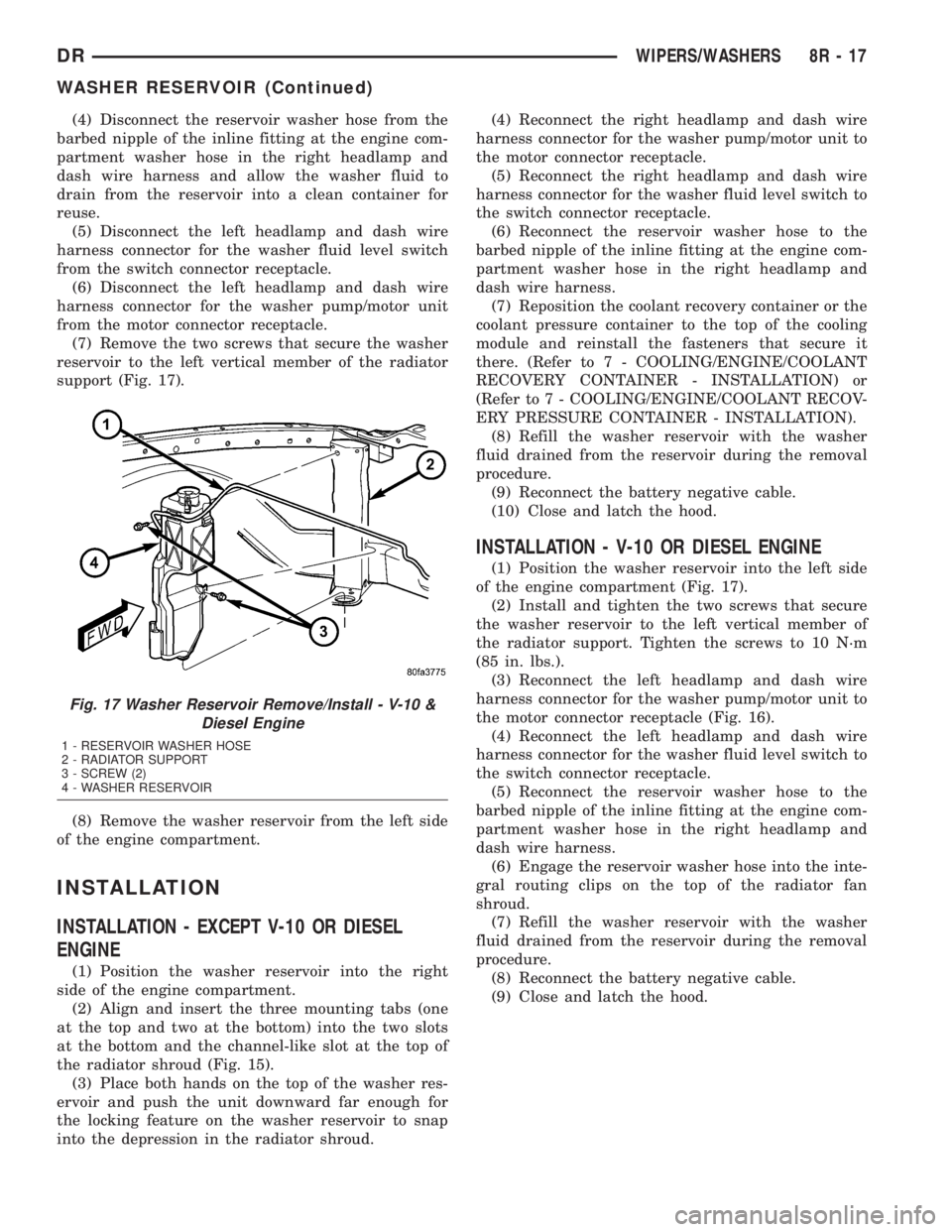

REMOVAL - V-10 OR DIESEL ENGINE

(1) Unlatch and open the hood.

(2) Disconnect and isolate the battery negative

cable.

(3) Disengage the reservoir washer hose from the

integral routing clips on the top of the radiator fan

shroud (Fig. 16).

Fig. 15 Washer Reservoir Remove/Install

1-TOPTAB

2 - RADIATOR SHROUD

3 - TOP SLOT

4 - RIGHT HEADLAMP & DASH WIRE HARNESS

5 - ENGINE COMPARTMENT WASHER HOSE

6 - BOTTOM SLOT (2)

7 - RESERVOIR WASHER HOSE

8 - BOTTOM TAB (2)

9 - WASHER FLUID LEVEL SWITCH

10 - WASHER PUMP/MOTOR

11 - WASHER RESERVOIR

12 - LOCK FEATURE

Fig. 16 Washer Reservoir Connections - V-10 &

Diesel Engine

1 - WIRE HARNESS

2 - WASHER RESERVOIR

3 - WASHER PUMP/MOTOR

4 - WASHER HOSE

5 - WASHER FLUID LEVEL SWITCH

8R - 16 WIPERS/WASHERSDR

WASHER RESERVOIR (Continued)

Page 692 of 2895

(4) Disconnect the reservoir washer hose from the

barbed nipple of the inline fitting at the engine com-

partment washer hose in the right headlamp and

dash wire harness and allow the washer fluid to

drain from the reservoir into a clean container for

reuse.

(5) Disconnect the left headlamp and dash wire

harness connector for the washer fluid level switch

from the switch connector receptacle.

(6) Disconnect the left headlamp and dash wire

harness connector for the washer pump/motor unit

from the motor connector receptacle.

(7) Remove the two screws that secure the washer

reservoir to the left vertical member of the radiator

support (Fig. 17).

(8) Remove the washer reservoir from the left side

of the engine compartment.

INSTALLATION

INSTALLATION - EXCEPT V-10 OR DIESEL

ENGINE

(1) Position the washer reservoir into the right

side of the engine compartment.

(2) Align and insert the three mounting tabs (one

at the top and two at the bottom) into the two slots

at the bottom and the channel-like slot at the top of

the radiator shroud (Fig. 15).

(3) Place both hands on the top of the washer res-

ervoir and push the unit downward far enough for

the locking feature on the washer reservoir to snap

into the depression in the radiator shroud.(4) Reconnect the right headlamp and dash wire

harness connector for the washer pump/motor unit to

the motor connector receptacle.

(5) Reconnect the right headlamp and dash wire

harness connector for the washer fluid level switch to

the switch connector receptacle.

(6) Reconnect the reservoir washer hose to the

barbed nipple of the inline fitting at the engine com-

partment washer hose in the right headlamp and

dash wire harness.

(7) Reposition the coolant recovery container or the

coolant pressure container to the top of the cooling

module and reinstall the fasteners that secure it

there. (Refer to 7 - COOLING/ENGINE/COOLANT

RECOVERY CONTAINER - INSTALLATION) or

(Refer to 7 - COOLING/ENGINE/COOLANT RECOV-

ERY PRESSURE CONTAINER - INSTALLATION).

(8) Refill the washer reservoir with the washer

fluid drained from the reservoir during the removal

procedure.

(9) Reconnect the battery negative cable.

(10) Close and latch the hood.

INSTALLATION - V-10 OR DIESEL ENGINE

(1) Position the washer reservoir into the left side

of the engine compartment (Fig. 17).

(2) Install and tighten the two screws that secure

the washer reservoir to the left vertical member of

the radiator support. Tighten the screws to 10 N´m

(85 in. lbs.).

(3) Reconnect the left headlamp and dash wire

harness connector for the washer pump/motor unit to

the motor connector receptacle (Fig. 16).

(4) Reconnect the left headlamp and dash wire

harness connector for the washer fluid level switch to

the switch connector receptacle.

(5) Reconnect the reservoir washer hose to the

barbed nipple of the inline fitting at the engine com-

partment washer hose in the right headlamp and

dash wire harness.

(6) Engage the reservoir washer hose into the inte-

gral routing clips on the top of the radiator fan

shroud.

(7) Refill the washer reservoir with the washer

fluid drained from the reservoir during the removal

procedure.

(8) Reconnect the battery negative cable.

(9) Close and latch the hood.

Fig. 17 Washer Reservoir Remove/Install - V-10 &

Diesel Engine

1 - RESERVOIR WASHER HOSE

2 - RADIATOR SUPPORT

3 - SCREW (2)

4 - WASHER RESERVOIR

DRWIPERS/WASHERS 8R - 17

WASHER RESERVOIR (Continued)

Page 1068 of 2895

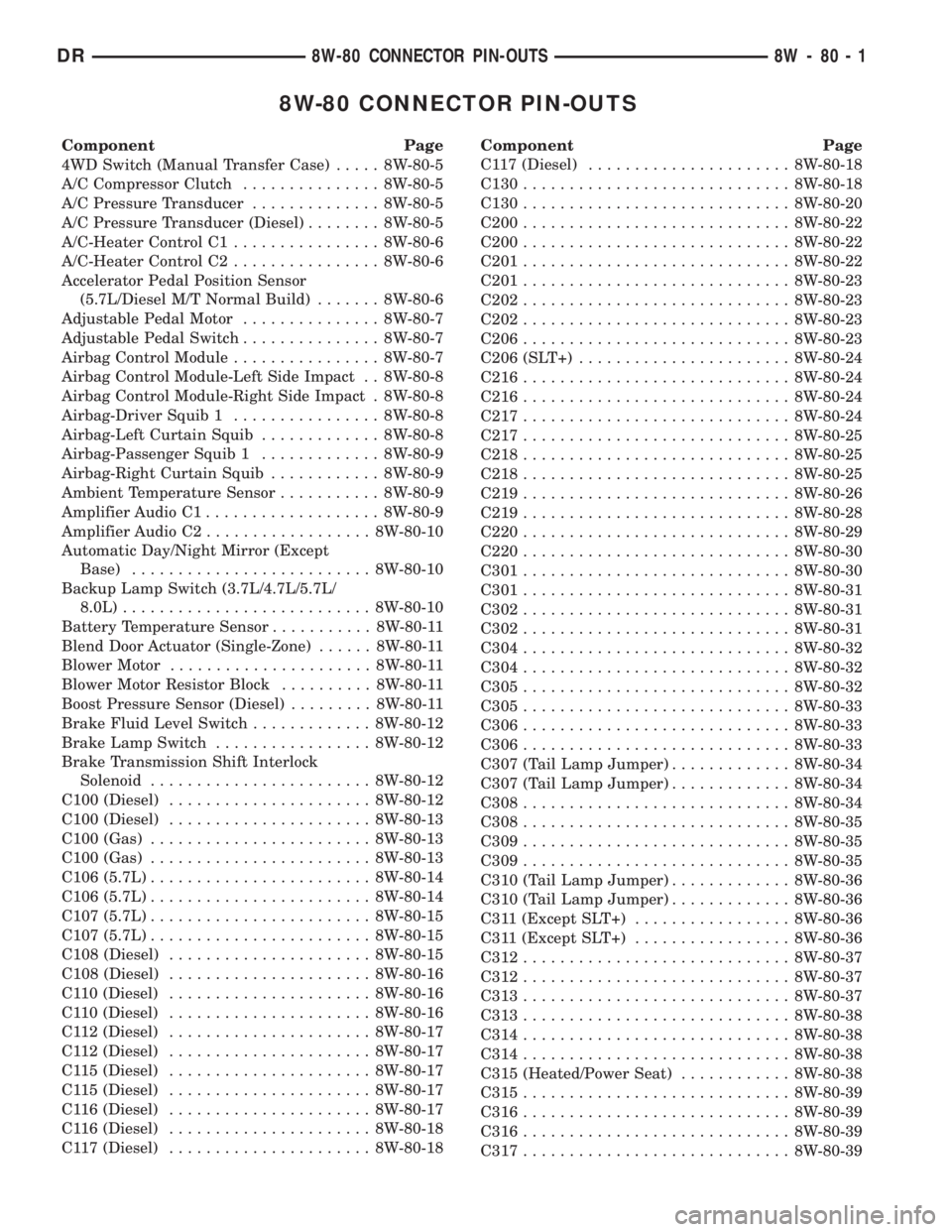

8W-80 CONNECTOR PIN-OUTS

Component Page

4WD Switch (Manual Transfer Case)..... 8W-80-5

A/C Compressor Clutch............... 8W-80-5

A/C Pressure Transducer.............. 8W-80-5

A/C Pressure Transducer (Diesel)........ 8W-80-5

A/C-Heater Control C1................ 8W-80-6

A/C-Heater Control C2................ 8W-80-6

Accelerator Pedal Position Sensor

(5.7L/Diesel M/T Normal Build)....... 8W-80-6

Adjustable Pedal Motor............... 8W-80-7

Adjustable Pedal Switch............... 8W-80-7

Airbag Control Module................ 8W-80-7

Airbag Control Module-Left Side Impact . . 8W-80-8

Airbag Control Module-Right Side Impact . 8W-80-8

Airbag-Driver Squib 1................ 8W-80-8

Airbag-Left Curtain Squib............. 8W-80-8

Airbag-Passenger Squib 1............. 8W-80-9

Airbag-Right Curtain Squib............ 8W-80-9

Ambient Temperature Sensor........... 8W-80-9

Amplifier Audio C1................... 8W-80-9

Amplifier Audio C2.................. 8W-80-10

Automatic Day/Night Mirror (Except

Base).......................... 8W-80-10

Backup Lamp Switch (3.7L/4.7L/5.7L/

8.0L)........................... 8W-80-10

Battery Temperature Sensor........... 8W-80-11

Blend Door Actuator (Single-Zone)...... 8W-80-11

Blower Motor...................... 8W-80-11

Blower Motor Resistor Block.......... 8W-80-11

Boost Pressure Sensor (Diesel)......... 8W-80-11

Brake Fluid Level Switch............. 8W-80-12

Brake Lamp Switch................. 8W-80-12

Brake Transmission Shift Interlock

Solenoid........................ 8W-80-12

C100 (Diesel)...................... 8W-80-12

C100 (Diesel)...................... 8W-80-13

C100 (Gas)........................ 8W-80-13

C100 (Gas)........................ 8W-80-13

C106 (5.7L)........................ 8W-80-14

C106 (5.7L)........................ 8W-80-14

C107 (5.7L)........................ 8W-80-15

C107 (5.7L)........................ 8W-80-15

C108 (Diesel)...................... 8W-80-15

C108 (Diesel)...................... 8W-80-16

C110 (Diesel)...................... 8W-80-16

C110 (Diesel)...................... 8W-80-16

C112 (Diesel)...................... 8W-80-17

C112 (Diesel)...................... 8W-80-17

C115 (Diesel)...................... 8W-80-17

C115 (Diesel)...................... 8W-80-17

C116 (Diesel)...................... 8W-80-17

C116 (Diesel)...................... 8W-80-18

C117 (Diesel)...................... 8W-80-18Component Page

C117 (Diesel)...................... 8W-80-18

C130............................. 8W-80-18

C130............................. 8W-80-20

C200............................. 8W-80-22

C200............................. 8W-80-22

C201............................. 8W-80-22

C201............................. 8W-80-23

C202............................. 8W-80-23

C202............................. 8W-80-23

C206............................. 8W-80-23

C206 (SLT+)....................... 8W-80-24

C216............................. 8W-80-24

C216............................. 8W-80-24

C217............................. 8W-80-24

C217............................. 8W-80-25

C218............................. 8W-80-25

C218............................. 8W-80-25

C219............................. 8W-80-26

C219............................. 8W-80-28

C220............................. 8W-80-29

C220............................. 8W-80-30

C301............................. 8W-80-30

C301............................. 8W-80-31

C302............................. 8W-80-31

C302............................. 8W-80-31

C304............................. 8W-80-32

C304............................. 8W-80-32

C305............................. 8W-80-32

C305............................. 8W-80-33

C306............................. 8W-80-33

C306............................. 8W-80-33

C307 (Tail Lamp Jumper)............. 8W-80-34

C307 (Tail Lamp Jumper)............. 8W-80-34

C308............................. 8W-80-34

C308............................. 8W-80-35

C309............................. 8W-80-35

C309............................. 8W-80-35

C310 (Tail Lamp Jumper)............. 8W-80-36

C310 (Tail Lamp Jumper)............. 8W-80-36

C311 (Except SLT+)................. 8W-80-36

C311 (Except SLT+)................. 8W-80-36

C312............................. 8W-80-37

C312............................. 8W-80-37

C313............................. 8W-80-37

C313............................. 8W-80-38

C314............................. 8W-80-38

C314............................. 8W-80-38

C315 (Heated/Power Seat)............ 8W-80-38

C315............................. 8W-80-39

C316............................. 8W-80-39

C316............................. 8W-80-39

C317............................. 8W-80-39

DR8W-80 CONNECTOR PIN-OUTS 8W - 80 - 1

Page 1069 of 2895

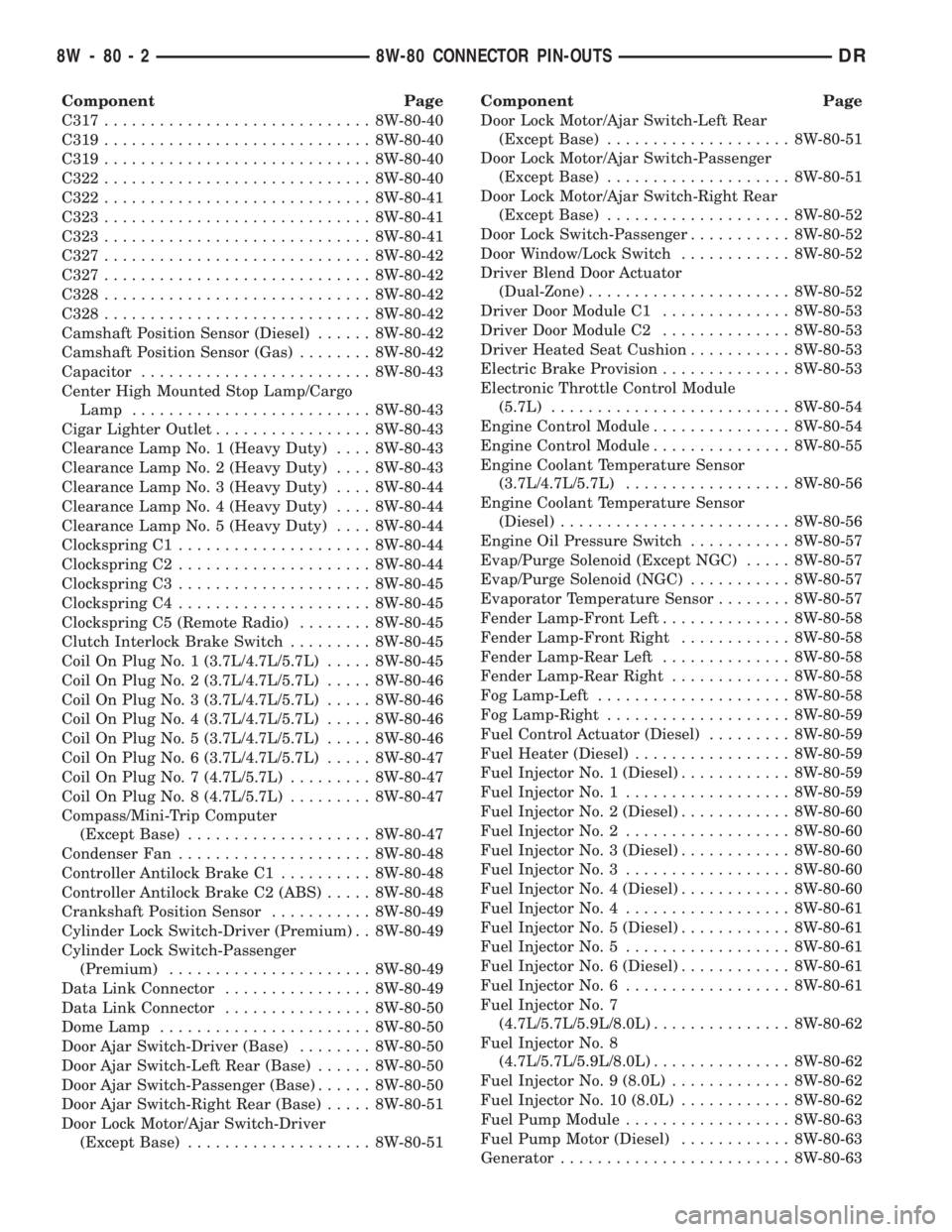

Component Page

C317............................. 8W-80-40

C319............................. 8W-80-40

C319............................. 8W-80-40

C322............................. 8W-80-40

C322............................. 8W-80-41

C323............................. 8W-80-41

C323............................. 8W-80-41

C327............................. 8W-80-42

C327............................. 8W-80-42

C328............................. 8W-80-42

C328............................. 8W-80-42

Camshaft Position Sensor (Diesel)...... 8W-80-42

Camshaft Position Sensor (Gas)........ 8W-80-42

Capacitor......................... 8W-80-43

Center High Mounted Stop Lamp/Cargo

Lamp.......................... 8W-80-43

Cigar Lighter Outlet................. 8W-80-43

Clearance Lamp No. 1 (Heavy Duty).... 8W-80-43

Clearance Lamp No. 2 (Heavy Duty).... 8W-80-43

Clearance Lamp No. 3 (Heavy Duty).... 8W-80-44

Clearance Lamp No. 4 (Heavy Duty).... 8W-80-44

Clearance Lamp No. 5 (Heavy Duty).... 8W-80-44

Clockspring C1..................... 8W-80-44

Clockspring C2..................... 8W-80-44

Clockspring C3..................... 8W-80-45

Clockspring C4..................... 8W-80-45

Clockspring C5 (Remote Radio)........ 8W-80-45

Clutch Interlock Brake Switch......... 8W-80-45

Coil On Plug No. 1 (3.7L/4.7L/5.7L)..... 8W-80-45

Coil On Plug No. 2 (3.7L/4.7L/5.7L)..... 8W-80-46

Coil On Plug No. 3 (3.7L/4.7L/5.7L)..... 8W-80-46

Coil On Plug No. 4 (3.7L/4.7L/5.7L)..... 8W-80-46

Coil On Plug No. 5 (3.7L/4.7L/5.7L)..... 8W-80-46

Coil On Plug No. 6 (3.7L/4.7L/5.7L)..... 8W-80-47

Coil On Plug No. 7 (4.7L/5.7L)......... 8W-80-47

Coil On Plug No. 8 (4.7L/5.7L)......... 8W-80-47

Compass/Mini-Trip Computer

(Except Base).................... 8W-80-47

Condenser Fan..................... 8W-80-48

Controller Antilock Brake C1.......... 8W-80-48

Controller Antilock Brake C2 (ABS)..... 8W-80-48

Crankshaft Position Sensor........... 8W-80-49

Cylinder Lock Switch-Driver (Premium) . . 8W-80-49

Cylinder Lock Switch-Passenger

(Premium)...................... 8W-80-49

Data Link Connector................ 8W-80-49

Data Link Connector................ 8W-80-50

Dome Lamp....................... 8W-80-50

Door Ajar Switch-Driver (Base)........ 8W-80-50

Door Ajar Switch-Left Rear (Base)...... 8W-80-50

Door Ajar Switch-Passenger (Base)...... 8W-80-50

Door Ajar Switch-Right Rear (Base)..... 8W-80-51

Door Lock Motor/Ajar Switch-Driver

(Except Base).................... 8W-80-51Component Page

Door Lock Motor/Ajar Switch-Left Rear

(Except Base).................... 8W-80-51

Door Lock Motor/Ajar Switch-Passenger

(Except Base).................... 8W-80-51

Door Lock Motor/Ajar Switch-Right Rear

(Except Base).................... 8W-80-52

Door Lock Switch-Passenger........... 8W-80-52

Door Window/Lock Switch............ 8W-80-52

Driver Blend Door Actuator

(Dual-Zone)...................... 8W-80-52

Driver Door Module C1.............. 8W-80-53

Driver Door Module C2.............. 8W-80-53

Driver Heated Seat Cushion........... 8W-80-53

Electric Brake Provision.............. 8W-80-53

Electronic Throttle Control Module

(5.7L).......................... 8W-80-54

Engine Control Module............... 8W-80-54

Engine Control Module............... 8W-80-55

Engine Coolant Temperature Sensor

(3.7L/4.7L/5.7L).................. 8W-80-56

Engine Coolant Temperature Sensor

(Diesel)......................... 8W-80-56

Engine Oil Pressure Switch........... 8W-80-57

Evap/Purge Solenoid (Except NGC)..... 8W-80-57

Evap/Purge Solenoid (NGC)........... 8W-80-57

Evaporator Temperature Sensor........ 8W-80-57

Fender Lamp-Front Left.............. 8W-80-58

Fender Lamp-Front Right............ 8W-80-58

Fender Lamp-Rear Left.............. 8W-80-58

Fender Lamp-Rear Right............. 8W-80-58

Fog Lamp-Left..................... 8W-80-58

Fog Lamp-Right.................... 8W-80-59

Fuel Control Actuator (Diesel)......... 8W-80-59

Fuel Heater (Diesel)................. 8W-80-59

Fuel Injector No. 1 (Diesel)............ 8W-80-59

Fuel Injector No. 1.................. 8W-80-59

Fuel Injector No. 2 (Diesel)............ 8W-80-60

Fuel Injector No. 2.................. 8W-80-60

Fuel Injector No. 3 (Diesel)............ 8W-80-60

Fuel Injector No. 3.................. 8W-80-60

Fuel Injector No. 4 (Diesel)............ 8W-80-60

Fuel Injector No. 4.................. 8W-80-61

Fuel Injector No. 5 (Diesel)............ 8W-80-61

Fuel Injector No. 5.................. 8W-80-61

Fuel Injector No. 6 (Diesel)............ 8W-80-61

Fuel Injector No. 6.................. 8W-80-61

Fuel Injector No. 7

(4.7L/5.7L/5.9L/8.0L)............... 8W-80-62

Fuel Injector No. 8

(4.7L/5.7L/5.9L/8.0L)............... 8W-80-62

Fuel Injector No. 9 (8.0L)............. 8W-80-62

Fuel Injector No. 10 (8.0L)............ 8W-80-62

Fuel Pump Module.................. 8W-80-63

Fuel Pump Motor (Diesel)............ 8W-80-63

Generator......................... 8W-80-63

8W - 80 - 2 8W-80 CONNECTOR PIN-OUTSDR