Vacuum DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2852 of 2895

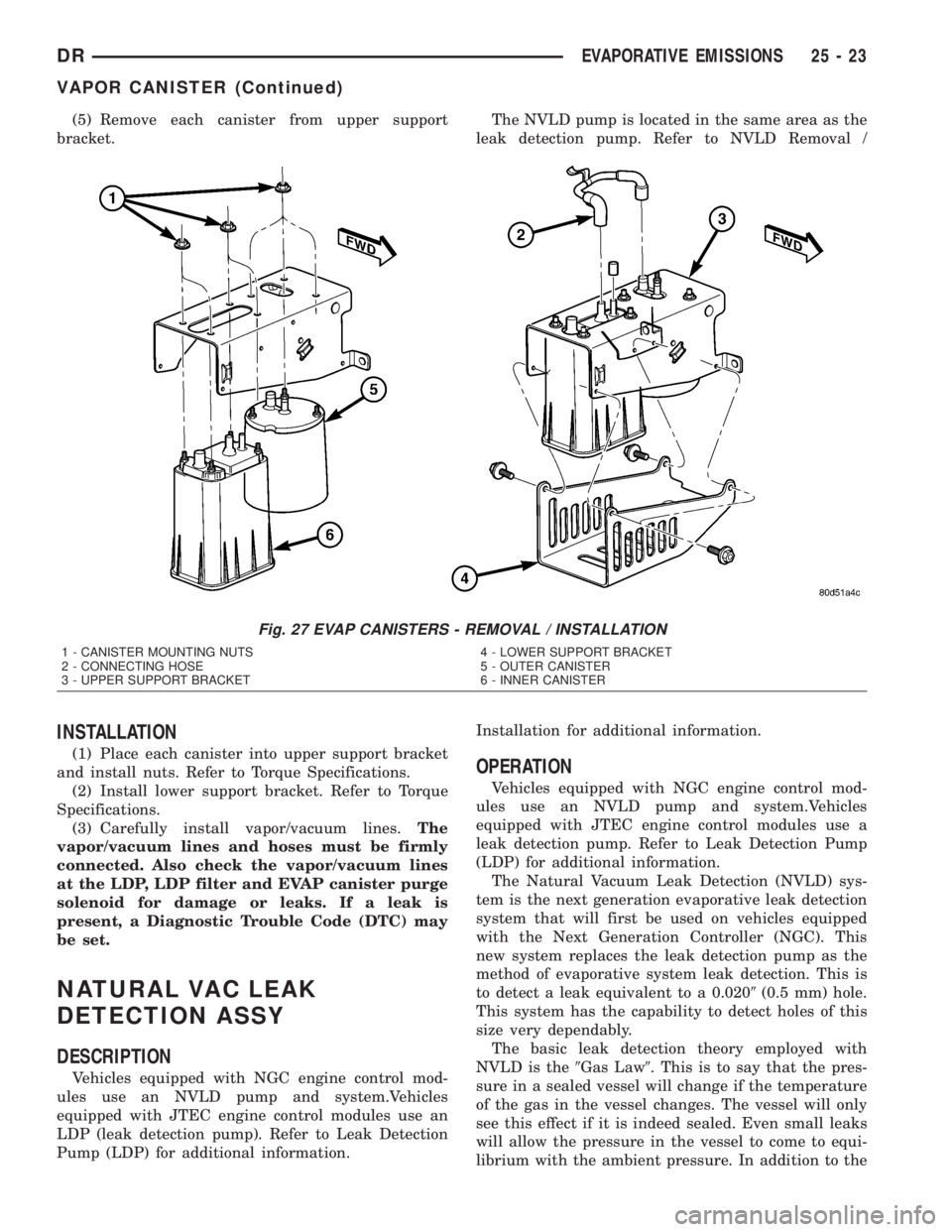

(5) Remove each canister from upper support

bracket.

INSTALLATION

(1) Place each canister into upper support bracket

and install nuts. Refer to Torque Specifications.

(2) Install lower support bracket. Refer to Torque

Specifications.

(3) Carefully install vapor/vacuum lines.The

vapor/vacuum lines and hoses must be firmly

connected. Also check the vapor/vacuum lines

at the LDP, LDP filter and EVAP canister purge

solenoid for damage or leaks. If a leak is

present, a Diagnostic Trouble Code (DTC) may

be set.

NATURAL VAC LEAK

DETECTION ASSY

DESCRIPTION

Vehicles equipped with NGC engine control mod-

ules use an NVLD pump and system.Vehicles

equipped with JTEC engine control modules use an

LDP (leak detection pump). Refer to Leak Detection

Pump (LDP) for additional information.The NVLD pump is located in the same area as the

leak detection pump. Refer to NVLD Removal /

Installation for additional information.

OPERATION

Vehicles equipped with NGC engine control mod-

ules use an NVLD pump and system.Vehicles

equipped with JTEC engine control modules use a

leak detection pump. Refer to Leak Detection Pump

(LDP) for additional information.

The Natural Vacuum Leak Detection (NVLD) sys-

tem is the next generation evaporative leak detection

system that will first be used on vehicles equipped

with the Next Generation Controller (NGC). This

new system replaces the leak detection pump as the

method of evaporative system leak detection. This is

to detect a leak equivalent to a 0.0209(0.5 mm) hole.

This system has the capability to detect holes of this

size very dependably.

The basic leak detection theory employed with

NVLD is the9Gas Law9. This is to say that the pres-

sure in a sealed vessel will change if the temperature

of the gas in the vessel changes. The vessel will only

see this effect if it is indeed sealed. Even small leaks

will allow the pressure in the vessel to come to equi-

librium with the ambient pressure. In addition to the

Fig. 27 EVAP CANISTERS - REMOVAL / INSTALLATION

1 - CANISTER MOUNTING NUTS

2 - CONNECTING HOSE

3 - UPPER SUPPORT BRACKET4 - LOWER SUPPORT BRACKET

5 - OUTER CANISTER

6 - INNER CANISTER

DREVAPORATIVE EMISSIONS 25 - 23

VAPOR CANISTER (Continued)

Page 2853 of 2895

detection of very small leaks, this system has the

capability of detecting medium as well as large evap-

orative system leaks.

A vent valve seals the canister vent during engine

off conditions. If the vapor system has a leak of less

than the failure threshold, the evaporative system

will be pulled into a vacuum, either due to the cool

down from operating temperature or diurnal ambient

temperature cycling. The diurnal effect is considered

one of the primary contributors to the leak determi-

nation by this diagnostic. When the vacuum in the

system exceeds about 19H2O (0.25 KPA), a vacuum

switch closes. The switch closure sends a signal to

the NGC. The NGC, via appropriate logic strategies,

utilizes the switch signal, or lack thereof, to make a

determination of whether a leak is present.

The NVLD device is designed with a normally open

vacuum switch, a normally closed solenoid, and a

seal, which is actuated by both the solenoid and a

diaphragm. The NVLD is located on the atmospheric

vent side of the canister. The NVLD assembly may

be mounted on top of the canister outlet, or in-line

between the canister and atmospheric vent filter. The

normally open vacuum switch will close with about 19

H2O (0.25 KPA) vacuum in the evaporative system.

The diaphragm actuates the switch. This is above the

opening point of the fuel inlet check valve in the fill

tube so cap off leaks can be detected. Submerged fill

systems must have recirculation lines that do not

have the in-line normally closed check valve that pro-

tects the system from failed nozzle liquid ingestion,

in order to detect cap off conditions.

The normally closed valve in the NVLD is intended

to maintain the seal on the evaporative system dur-

ing the engine off condition. If vacuum in the evapo-

rative system exceeds 39to 69H2O (0.75 to 1.5 KPA),

the valve will be pulled off the seat, opening the seal.

This will protect the system from excessive vacuum

as well as allowing sufficient purge flow in the event

that the solenoid was to become inoperative.

The solenoid actuates the valve to unseal the can-

ister vent while the engine is running. It also will be

used to close the vent during the medium and large

leak tests and during the purge flow check. This sole-

noid requires initial 1.5 amps of current to pull the

valve open but after 100 ms. will be duty cycled down

to an average of about 150 mA for the remainder of

the drive cycle.

Another feature in the device is a diaphragm that

will open the seal in the NVLD with pressure in the

evaporative system. The device will9blow off9at

about 0.59H2O (0.12 KPA) pressure to permit the

venting of vapors during refueling. An added benefit

to this is that it will also allow the tank to9breathe9

during increasing temperatures, thus limiting the

pressure in the tank to this low level. This is benefi-cial because the induced vacuum during a subse-

quent declining temperature will achieve the switch

closed (pass threshold) sooner than if the tank had to

decay from a built up pressure.

The device itself has 3 wires: Switch sense, sole-

noid driver and ground. It also includes a resistor to

protect the switch from a short to battery or a short

to ground. The NGC utilizes a high-side driver to

energize and duty-cycle the solenoid.

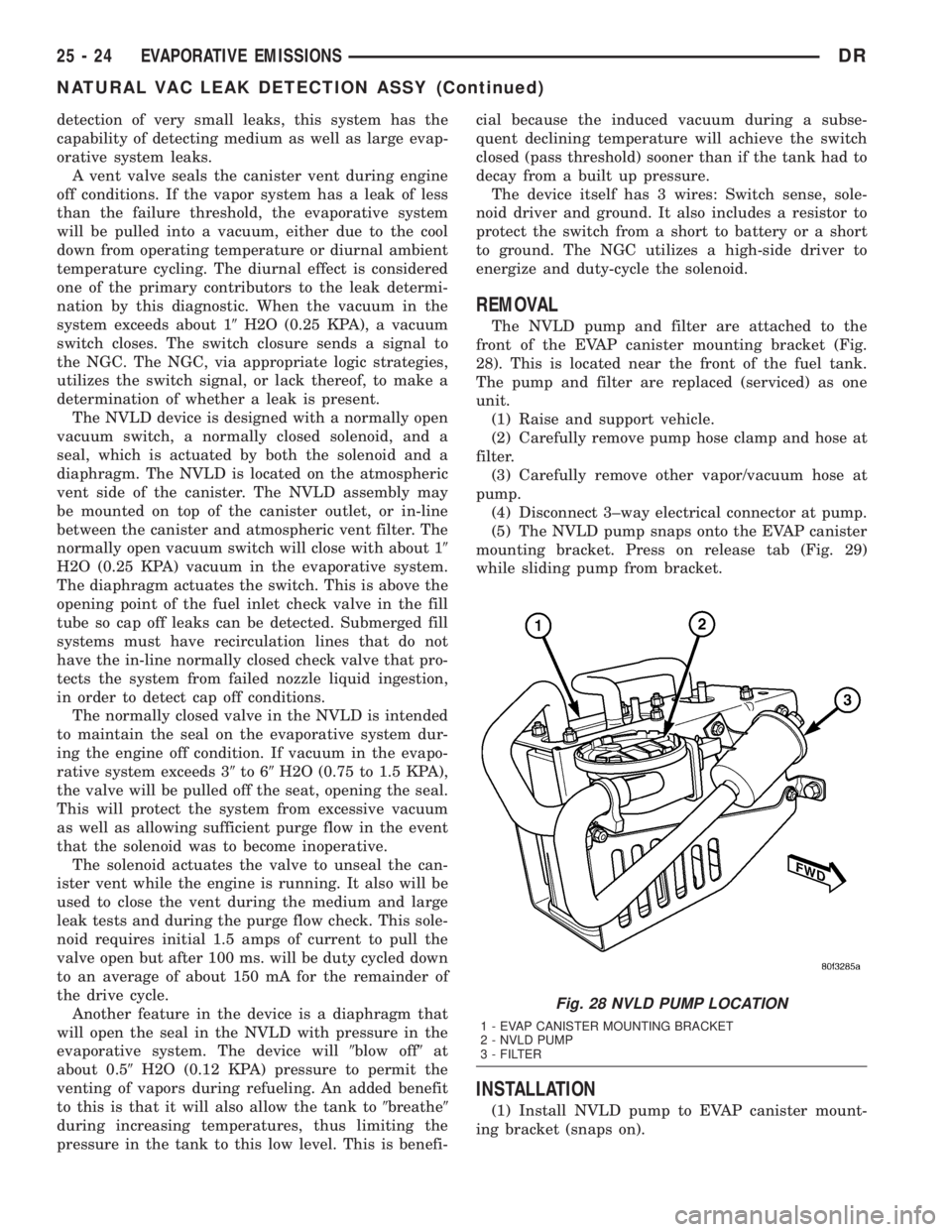

REMOVAL

The NVLD pump and filter are attached to the

front of the EVAP canister mounting bracket (Fig.

28). This is located near the front of the fuel tank.

The pump and filter are replaced (serviced) as one

unit.

(1) Raise and support vehicle.

(2) Carefully remove pump hose clamp and hose at

filter.

(3) Carefully remove other vapor/vacuum hose at

pump.

(4) Disconnect 3±way electrical connector at pump.

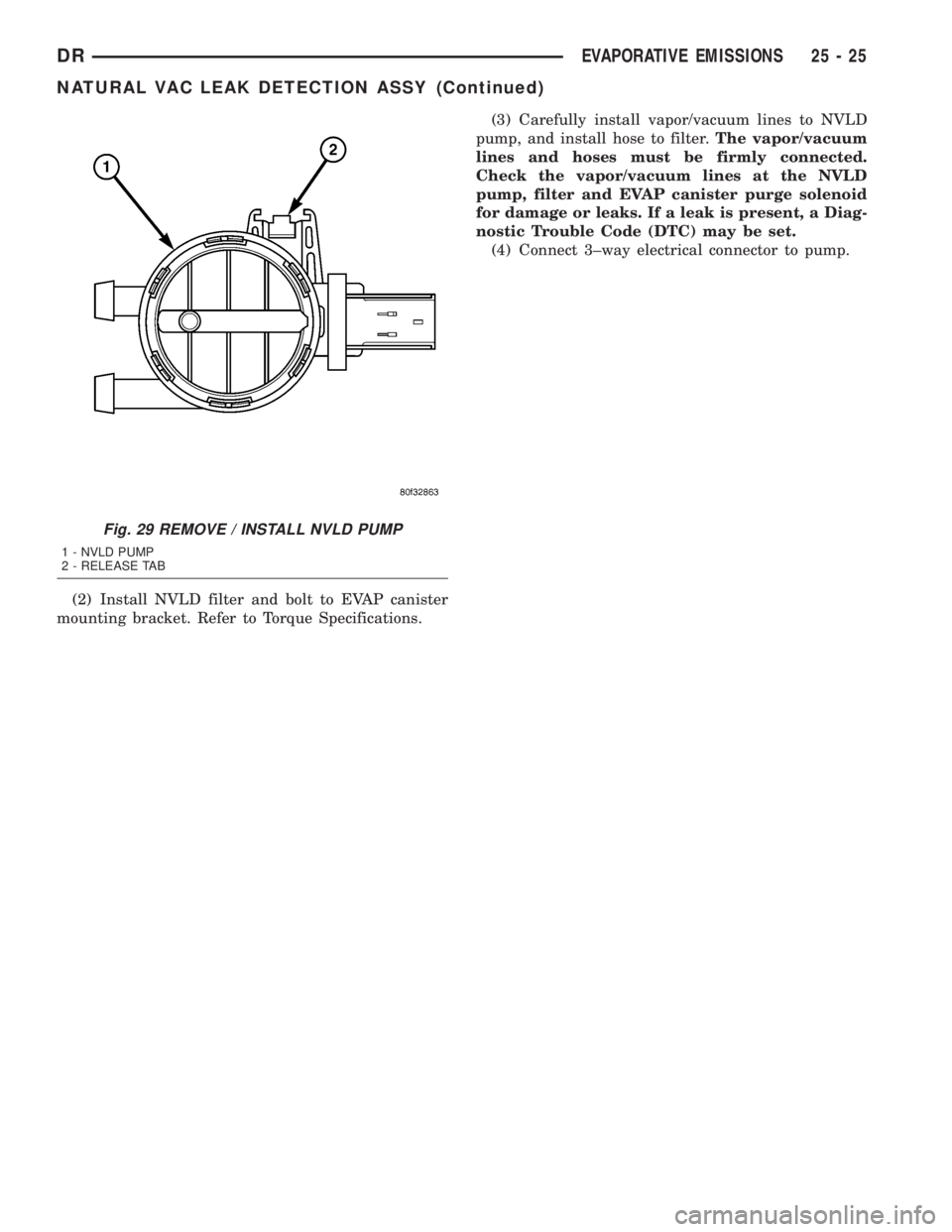

(5) The NVLD pump snaps onto the EVAP canister

mounting bracket. Press on release tab (Fig. 29)

while sliding pump from bracket.

INSTALLATION

(1) Install NVLD pump to EVAP canister mount-

ing bracket (snaps on).

Fig. 28 NVLD PUMP LOCATION

1 - EVAP CANISTER MOUNTING BRACKET

2 - NVLD PUMP

3 - FILTER

25 - 24 EVAPORATIVE EMISSIONSDR

NATURAL VAC LEAK DETECTION ASSY (Continued)

Page 2854 of 2895

(2) Install NVLD filter and bolt to EVAP canister

mounting bracket. Refer to Torque Specifications.(3) Carefully install vapor/vacuum lines to NVLD

pump, and install hose to filter.The vapor/vacuum

lines and hoses must be firmly connected.

Check the vapor/vacuum lines at the NVLD

pump, filter and EVAP canister purge solenoid

for damage or leaks. If a leak is present, a Diag-

nostic Trouble Code (DTC) may be set.

(4) Connect 3±way electrical connector to pump.

Fig. 29 REMOVE / INSTALL NVLD PUMP

1 - NVLD PUMP

2 - RELEASE TAB

DREVAPORATIVE EMISSIONS 25 - 25

NATURAL VAC LEAK DETECTION ASSY (Continued)

Page 2875 of 2895

LEVEL - STANDARD PROCEDURE,

REFRIGERANT OIL...................24-54

LEVEL CHECK - STANDARD

PROCEDURE, COOLANT................7-17

LEVEL CHECK - STANDARD

PROCEDURE, FLUID.....21-201,21-381,21-542

LEVEL CHECKING - STANDARD

PROCEDURE, POWER STEERING FLUID . . . 19-42

LEVEL SENDING UNIT / SENSOR -

DESCRIPTION, FUEL..............14-68,14-7

LEVEL SENDING UNIT / SENSOR -

INSTALLATION, FUEL..................14-8

LEVEL SENDING UNIT / SENSOR -

OPERATION, FUEL................14-68,14-7

LEVEL SENDING UNIT / SENSOR -

REMOVAL, FUEL......................14-7

LEVEL SWITCH - DESCRIPTION,

WASHER FLUID......................8R-9

LEVEL SWITCH - INSTALLATION,

WASHER FLUID.....................8R-11

LEVEL SWITCH - OPERATION, WASHER

FLUID..............................8R-9

LEVEL SWITCH - REMOVAL, WASHER

FLUID.............................8R-10

LEVER - ADJUSTMENT, SHIFT . . . 21-622,21-657

LEVER - INSTALLATION, GEAR SHIFT.....19-12

LEVER - INSTALLATION, SHIFT . . . 21-621,21-656

LEVER - REMOVAL, GEAR SHIFT........19-12

LEVER - REMOVAL, SHIFT......21-620,21-655

LICENSE PLATE LAMP - INSTALLATION . . . 8L-16

LICENSE PLATE LAMP - REMOVAL.......8L-16

LICENSE PLATE LAMP UNIT -

INSTALLATION.......................8L-16

LICENSE PLATE LAMP UNIT - REMOVAL . . 8L-16

LID - INSTALLATION, CENTER SEAT

BACK..............................23-80

LID - REMOVAL, CENTER SEAT BACK....23-80

LIFTERS - CLEANING, HYDRAULIC . . 9-260,9-388

LIFTERS - INSTALLATION, HYDRAULIC . . . 9-260,

9-388

LIFTERS - REMOVAL, HYDRAULIC . . 9-259,9-387

LIFTERS/TAPPETS - CLEANING, SOLID....9-328

LIFTERS/TAPPETS - INSPECTION, SOLID . . 9-328

LIFTERS/TAPPETS - INSTALLATION,

SOLID.............................9-328

LIFTERS/TAPPETS - REMOVAL, SOLID....9-327

LIGHT DUTY FRONT FRAME RAIL TIP

REPLACEMENT - STANDARD

PROCEDURE.........................13-4

LIGHTER OUTLET - DESCRIPTION,

CIGAR...........................8W-97-2

LIGHTER OUTLET - DIAGNOSIS AND

TESTING, CIGAR...................8W-97-2

LIGHTER OUTLET - OPERATION, CIGAR . 8W-97-2

LIMITING VALVE - DESCRIPTION, FUEL

PRESSURE.........................14-72

LIMITING VALVE - INSTALLATION, FUEL

PRESSURE.........................14-73

LIMITING VALVE - OPERATION, FUEL

PRESSURE.........................14-72

LIMITING VALVE - REMOVAL, FUEL

PRESSURE.........................14-72

LINE - DESCRIPTION, REFRIGERANT.....24-32

LINE - INSTALLATION, LIQUID..........24-45

LINE - REMOVAL, LIQUID..............24-45

LINE COUPLER - DESCRIPTION,

REFRIGERANT.......................24-52

LINE COUPLER - INSTALLATION,

REFRIGERANT.......................24-53

LINE COUPLER - OPERATION,

REFRIGERANT.......................24-52

LINE COUPLER - REMOVAL,

REFRIGERANT.......................24-52

LINE LEAKS - DIAGNOSIS AND TESTING,

HIGH-PRESSURE FUEL................14-69

LINE PRESSURE (LP) SENSOR -

DESCRIPTION......................21-559

LINE PRESSURE (LP) SENSOR -

INSTALLATION......................21-560

LINE PRESSURE (LP) SENSOR -

OPERATION........................21-559

LINE PRESSURE (LP) SENSOR -

REMOVAL.........................21-559

LINES - DESCRIPTION, FUEL

.......14-69,14-8

LINES - DESCRIPTION, VACUUM

........25-22

LINES - INSTALLATION, FUEL

...........14-71

LINES - OPERATION, FUEL

.............14-69

LINES - OPERATION, REFRIGERANT

......24-32LINES - REMOVAL, FUEL..............14-69

LINK - INSTALLATION, DRAG...........19-35

LINK - REMOVAL, DRAG...............19-35

LINK CONNECTOR - DESCRIPTION, DATA . . 8E-3

LINK CONNECTOR - OPERATION, DATA....8E-3

LINKAGE - INSTALLATION...............6-13

LINKAGE - LINK/COIL - DESCRIPTION....19-33

LINKAGE - REMOVAL..................6-13

LINKAGE, SPECIAL TOOLS - STEERING . . . 19-35

LINK/COIL - DESCRIPTION, GEAR........19-19

LINK/COIL - DESCRIPTION, LINKAGE.....19-33

LINK/COIL - INSTALLATION, GEAR.......19-20

LINK/COIL - OPERATION, GEAR.........19-19

LINK/COIL - REMOVAL, GEAR...........19-19

LINK/COIL SUSPENSION - STANDARD

PROCEDURE, ALIGNMENT...............2-5

LIQUID LINE - INSTALLATION...........24-45

LIQUID LINE - REMOVAL..............24-45

LOAD FLOOR - INSTALLATION..........23-73

LOAD FLOOR - REMOVAL..............23-73

LOAD FLOOR SUPPORT CYLINDER -

INSTALLATION.......................23-73

LOAD FLOOR SUPPORT CYLINDER -

REMOVAL..........................23-73

LOADS - STANDARD PROCEDURE,

TESTING FOR A SHORT TO GROUND

ON FUSES POWERING SEVERAL.....8W-01-10

LOCATION - DESCRIPTION, CONNECTOR/

GROUND/SPLICE...................8W-91-1

LOCATIONS - SPECIFICATIONS, SEALER . 23-103

LOCATIONS - SPECIFICATIONS,

STRUCTURAL ADHESIVE..............23-113

LOCATIONS - SPECIFICATIONS, WELD . . . 23-122

LOCK - STANDARD PROCEDURE,

HYDROSTATIC........9-186,9-232,9-290,9-361

LOCK CYLINDER - DIAGNOSIS AND

TESTING, IGNITION SWITCH AND KEY....19-11

LOCK CYLINDER - INSTALLATION.......23-24

LOCK CYLINDER - REMOVAL...........23-24

LOCK MOTOR - DESCRIPTION, DOOR.....8N-5

LOCK MOTOR - DIAGNOSIS AND

TESTING, DOOR......................8N-5

LOCK MOTOR - OPERATION, DOOR.......8N-5

LOCK SWITCH - DIAGNOSIS AND

TESTING, POWER.....................8N-4

LOCK SWITCH - INSTALLATION, POWER . . . 8N-4

LOCK SWITCH - REMOVAL, POWER......8N-4

LOCKING RETRACTOR - DESCRIPTION,

AUTOMATIC........................8O-13

LOCKING RETRACTOR - OPERATION,

AUTOMATIC........................8O-14

LOCKS - DESCRIPTION, POWER.........8N-1

LOCKS - DIAGNOSIS AND TESTING,

POWER.............................8N-3

LOCKS - OPERATION, POWER...........8N-2

LOOP ADJUSTER - INSTALLATION, SEAT

BELT TURNING......................8O-50

LOOP ADJUSTER - REMOVAL, SEAT

BELT TURNING......................8O-50

LOOP BRACKETS - INSTALLATION, SEAT

BACK REAR - FOOTMANS..............23-85

LOOP BRACKETS - REMOVAL, SEAT

BACK REAR - FOOTMANS..............23-85

LOW FUEL INDICATOR - DESCRIPTION . . . 8J-29

LOW FUEL INDICATOR - OPERATION.....8J-29

LOWER BALL JOINT - DIAGNOSIS AND

TESTING............................2-18

LOWER BALL JOINT - INSTALLATION . 2-19,2-33

LOWER BALL JOINT - REMOVAL.....2-18,2-32

LOWER CONTROL ARM BUSHINGS -

2WD (LD) - INSTALLATION..............2-14

LOWER CONTROL ARM BUSHINGS -

2WD (LD) - REMOVAL.................2-12

LOWER CONTROL ARM BUSHINGS -

4WD (LD) - INSTALLATION..............2-13

LOWER CONTROL ARM BUSHINGS -

4WD (LD) - REMOVAL.................2-12

LOWER SURROUND - INSTALLATION,

INSTRUMENT PANEL..................23-60

LOWER SURROUND - REMOVAL,

INSTRUMENT PANEL

..................23-60

LOWER SUSPENSION ARM -

INSTALLATION

........................2-35

LOWER SUSPENSION ARM - REMOVAL

....2-35

LOWER TRIM - INSTALLATION,

B-PILLAR

...........................23-65

LOWER TRIM - INSTALLATION,

C-PILLAR

...........................23-68LOWER TRIM - REMOVAL, B-PILLAR.....23-64

LOWER TRIM - REMOVAL, C-PILLAR.....23-67

LOW/REVERSE CLUTCH - ASSEMBLY....21-561

LOW/REVERSE CLUTCH - CLEANING....21-561

LOW/REVERSE CLUTCH - DISASSEMBLY . 21-560

LOW/REVERSE CLUTCH - INSPECTION . . 21-561

LUBRICANTS - DESCRIPTION, ENGINE

OIL .................................0-2

LUBRICATION - DESCRIPTION.....9-148,9-214,

9-267,9-337,9-393,9-60

LUBRICATION - DIAGNOSIS AND

TESTING, ENGINE DIAGNOSIS.....9-183,9-230,

9-358,9-7

LUBRICATION - OPERATION . 9-148,9-267,9-337,

9-393,9-60

LUBRICATION - STANDARD PROCEDURE . . 19-34

LUBRICATION - STANDARD PROCEDURE,

BODY...............................23-3

LUMBAR CONTROL SWITCH -

DESCRIPTION.......................8N-19

LUMBAR CONTROL SWITCH -

OPERATION.........................8N-19

LUMBAR CONTROL SWITCH - REMOVAL . 8N-19

LUMBAR MOTOR - DESCRIPTION.......8N-19

LUMBAR MOTOR - DIAGNOSIS AND

TESTING...........................8N-20

LUMBAR MOTOR - OPERATION.........8N-20

MAIN BEARING - FITTING - STANDARD

PROCEDURE, CRANKSHAFT.......9-133,9-202

MAIN BEARING CLEARANCE -

STANDARD PROCEDURE................9-322

MAIN BEARING FITTING - STANDARD

PROCEDURE, CRANKSHAFT............9-253

MAIN BEARING FITTING, STANDARD

PROCEDURE.........................9-43

MAIN BEARINGS - DESCRIPTION,

CRANKSHAFT.......................9-253

MAIN BEARINGS - INSPECTION,

CRANKSHAFT..................9-133,9-203

MAIN BEARINGS - INSTALLATION,

CRANKSHAFT..................9-254,9-383

MAIN BEARINGS - OPERATION,

CRANKSHAFT.......................9-253

MAIN BEARINGS - REMOVAL,

CRANKSHAFT..................9-254,9-383

MAIN BEARINGS - STANDARD

PROCEDURE, FITTING CRANKSHAFT.....9-383

MAINTENANCE SCHEDULES -

DESCRIPTION.........................0-6

MALFUNCTION INDICATOR LAMP (MIL) -

DESCRIPTION.......................8J-30

MALFUNCTION INDICATOR LAMP (MIL) -

OPERATION.........................8J-30

MANAGER - DESCRIPTION, TASK.........25-1

MANAGER - OPERATION, TASK..........25-5

MANIFOLD - CLEANING, EXHAUST . 9-161,9-220,

9-277,9-347,9-404

MANIFOLD - CLEANING, INTAKE . . . 9-158,9-219,

9-275,9-346,9-402

MANIFOLD - DESCRIPTION, EXHAUST . . . 9-159,

9-220,9-277,9-403,9-73

MANIFOLD - DESCRIPTION, INTAKE.....9-157,

9-219,9-274,9-401,9-71

MANIFOLD - INSPECTION, EXHAUST.....9-161,

9-220,9-277,9-347,9-404

MANIFOLD - INSPECTION, INTAKE . 9-158,9-219,

9-275,9-346,9-402

MANIFOLD - INSTALLATION, EXHAUST . . . 9-162,

9-220,9-277,9-347,9-404,9-74

MANIFOLD - INSTALLATION, INTAKE.....9-158,

9-219,9-275,9-346,9-402,9-72

MANIFOLD - OPERATION, EXHAUST.....9-220,

9-277,9-403

MANIFOLD - OPERATION, INTAKE........9-274

MANIFOLD - REMOVAL, EXHAUST . . 9-159,9-220,

9-277,9-347,9-404,9-73

MANIFOLD - REMOVAL, INTAKE . . . 9-157,9-219,

9-275,9-345,9-401,9-72

MANIFOLD LEAKAGE - DIAGNOSIS AND

TESTING, INTAKE

.....9-157,9-219,9-274,9-401

MANIFOLD LEAKS - DIAGNOSIS AND

TESTING, INTAKE

.....................9-71

MANUAL - INSTALLATION, WINDOW

REGULATOR

...................23-26,23-35

MANUAL - REMOVAL, WINDOW

REGULATOR

...................23-26,23-35

MANUAL BLEEDING - STANDARD

PROCEDURE

..........................5-5

20 INDEXDR

Description Group-Page Description Group-Page Description Group-Page

Page 2883 of 2895

REGULATOR - MANUAL - INSTALLATION,

WINDOW......................23-26,23-35

REGULATOR - MANUAL - REMOVAL,

WINDOW......................23-26,23-35

REGULATOR - OPERATION, FUEL

FILTER/PRESSURE.....................14-6

REGULATOR - OPERATION, VOLTAGE.....8F-27

REGULATOR - POWER - INSTALLATION,

WINDOW......................23-25,23-34

REGULATOR - POWER - REMOVAL,

WINDOW......................23-25,23-34

RELAY - DESCRIPTION..............8W-97-8

RELAY - DESCRIPTION, A/C

COMPRESSOR CLUTCH...............24-13

RELAY - DESCRIPTION, FOG LAMP......8L-11

RELAY - DESCRIPTION, FUEL HEATER....14-64

RELAY - DESCRIPTION, FUEL PUMP.....14-33

RELAY - DESCRIPTION, INTAKE AIR

HEATER ............................14-92

RELAY - DESCRIPTION, MICRO.......8W-97-9

RELAY - DESCRIPTION, PARK LAMP.....8L-19

RELAY - DESCRIPTION, STARTER

MOTOR............................8F-38

RELAY - DESCRIPTION, TRANSMISSION

CONTROL.........................21-581

RELAY - DESCRIPTION, WIPER

HIGH/LOW..........................8R-20

RELAY - DESCRIPTION, WIPER ON/OFF . . . 8R-25

RELAY - DIAGNOSIS AND TESTING....8W-97-8

RELAY - DIAGNOSIS AND TESTING,

COMPRESSOR CLUTCH.................24-13

RELAY - DIAGNOSIS AND TESTING,

FRONT FOG LAMP....................8L-12

RELAY - DIAGNOSIS AND TESTING,

PARK LAMP.........................8L-20

RELAY - DIAGNOSIS AND TESTING,

STARTER ...........................8F-38

RELAY - DIAGNOSIS AND TESTING,

WIPER HIGH/LOW...................8R-21

RELAY - DIAGNOSIS AND TESTING,

WIPER ON/OFF......................8R-26

RELAY - INSTALLATION.............8W-97-9

RELAY - INSTALLATION, A/C

COMPRESSOR CLUTCH...............24-14

RELAY - INSTALLATION, FOG LAMP......8L-13

RELAY - INSTALLATION, FUEL HEATER . . . 14-64

RELAY - INSTALLATION, FUEL PUMP.....14-33

RELAY - INSTALLATION, INTAKE AIR

HEATER ............................14-93

RELAY - INSTALLATION, MICRO......8W-97-10

RELAY - INSTALLATION, PARK LAMP.....8L-21

RELAY - INSTALLATION, STARTER

MOTOR............................8F-39

RELAY - INSTALLATION, WIPER

HIGH/LOW..........................8R-21

RELAY - INSTALLATION, WIPER ON/OFF . . 8R-26

RELAY - OPERATION................8W-97-8

RELAY - OPERATION, A/C COMPRESSOR

CLUTCH............................24-13

RELAY - OPERATION, FOG LAMP........8L-12

RELAY - OPERATION, FUEL HEATER......14-64

RELAY - OPERATION, FUEL PUMP.......14-33

RELAY - OPERATION, INTAKE AIR

HEATER ............................14-92

RELAY - OPERATION, MICRO.........8W-97-9

RELAY - OPERATION, PARK LAMP.......8L-19

RELAY - OPERATION, STARTER MOTOR . . . 8F-38

RELAY - OPERATION, TRANSMISSION

CONTROL.........................21-581

RELAY - OPERATION, WIPER HIGH/LOW . . 8R-20

RELAY - OPERATION, WIPER ON/OFF....8R-25

RELAY - REMOVAL

.................8W-97-9

RELAY - REMOVAL, A/C COMPRESSOR

CLUTCH

............................24-14

RELAY - REMOVAL, FOG LAMP

.........8L-13

RELAY - REMOVAL, FUEL HEATER

.......14-64

RELAY - REMOVAL, FUEL PUMP

........14-33

RELAY - REMOVAL, INTAKE AIR HEATER

. . 14-93

RELAY - REMOVAL, MICRO

.........8W-97-10

RELAY - REMOVAL, PARK LAMP

........8L-20

RELAY - REMOVAL, STARTER MOTOR

....8F-39

RELAY - REMOVAL, WIPER HIGH/LOW

. . . 8R-21

RELAY - REMOVAL, WIPER ON/OFF

......8R-26

RELAYS - DIAGNOSIS AND TESTING,

ASD AND FUEL PUMP

..................8I-7

RELEASE - STANDARD PROCEDURE,

FUEL SYSTEM PRESSURE

..............14-2RELEASE BEARING - INSTALLATION,

CLUTCH.............................6-11

RELEASE BEARING - REMOVAL, CLUTCH . . . 6-11

RELEASE CABLE/HANDLE ASSEMBLY -

INSTALLATION, LATCH................23-47

RELEASE CABLE/HANDLE ASSEMBLY -

REMOVAL, LATCH....................23-47

RELEASE HANDLE - INSTALLATION.......5-38

RELEASE HANDLE - REMOVAL...........5-38

RELEASE HANDLE/LATCH REMOTE -

INSTALLATION.......................23-17

RELEASE HANDLE/LATCH REMOTE -

REMOVAL..........................23-17

RELIEF VALVE - CLEANING, OIL

PRESSURE.........................9-343

RELIEF VALVE - DESCRIPTION, HIGH

PRESSURE.........................24-35

RELIEF VALVE - INSPECTION, OIL

PRESSURE.........................9-343

RELIEF VALVE - INSTALLATION, OIL

PRESSURE.........................9-343

RELIEF VALVE - OPERATION, HIGH

PRESSURE.........................24-36

RELIEF VALVE - REMOVAL, OIL

PRESSURE.........................9-343

REMOTE - INSTALLATION, RELEASE

HANDLE/LATCH......................23-17

REMOTE - REMOVAL, RELEASE

HANDLE/LATCH......................23-17

REMOTE KEYLESS ENTRY MODULE -

DESCRIPTION........................8N-7

REMOTE KEYLESS ENTRY MODULE -

DIAGNOSIS AND TESTING................8N-8

REMOTE KEYLESS ENTRY MODULE -

INSTALLATION.......................8N-8

REMOTE KEYLESS ENTRY MODULE -

OPERATION..........................8N-8

REMOTE KEYLESS ENTRY MODULE -

REMOVAL...........................8N-8

REMOTE KEYLESS ENTRY

TRANSMITTER - DIAGNOSIS AND

TESTING............................8N-8

REMOTE KEYLESS ENTRY

TRANSMITTER - SPECIFICATIONS.......8N-10

REMOTE SWITCHES - DESCRIPTION.....8A-10

REMOTE SWITCHES - DIAGNOSIS AND

TESTING...........................8A-11

REMOTE SWITCHES - INSTALLATION.....8A-12

REMOTE SWITCHES - OPERATION.......8A-10

REMOTE SWITCHES - REMOVAL........8A-12

REMOVAL/INSTALLATION, REMOVAL.....25-13

REMOVAL/INSTALLATION, REMOVAL.....14-64,

14-68,14-77

REPAIR - DESCRIPTION, THREADED

HOLE.............................Intro.-9

REPAIR - STANDARD PROCEDURE,

ALUMINUM THREAD.....21-156,21-337,21-495

REPAIR - STANDARD PROCEDURE, CAM

BORE..............................9-315

REPAIR - STANDARD PROCEDURE,

CYLINDER BORE.....................9-313

REPAIR - STANDARD PROCEDURE,

HYDROFORM FENDER RAIL............13-12

REPAIR - STANDARD PROCEDURE,

PLASTIC BODY PANEL.................23-3

REPAIR DAMAGED OR WORN THREADS

- STANDARD PROCEDURE . . . 9-186,9-232,9-289,

9-361,9-9,9-93

REPAIRING LEAKS - STANDARD

PROCEDURE........................22-10

REQUIREMENTS - DESCRIPTION,

COOLING SYSTEM....................24-1

REQUIREMENTS - DIESEL ENGINE -

DESCRIPTION, FUEL....................0-1

RESERVOIR - DESCRIPTION, VACUUM....8P-9

RESERVOIR - DESCRIPTION, WASHER . . . 8R-15

RESERVOIR - DIAGNOSIS AND TESTING,

VACUUM............................8P-9

RESERVOIR - INSTALLATION...........19-46

RESERVOIR - INSTALLATION, FLUID......5-19

RESERVOIR - INSTALLATION, VACUUM . . . 8P-10

RESERVOIR - OPERATION, VACUUM......8P-9

RESERVOIR - OPERATION, WASHER

.....8R-15

RESERVOIR - REMOVAL

...............19-46

RESERVOIR - REMOVAL, FLUID

..........5-19

RESERVOIR - REMOVAL, VACUUM

.......8P-10

RESERVOIR TO COOLER -

INSTALLATION, RETURN HOSE

.....19-43,19-44RESERVOIR TO COOLER - REMOVAL,

RETURN HOSE.................19-43,19-44

RESISTANCE, 3.7L V-6 - IGNITION COIL....8I-6

RESISTANCE, 4.7L V-8 - IGNITION COIL....8I-6

RESISTANCE, 5.7L V-8 - IGNITION COIL....8I-6

RESISTANCE, 5.9L - IGNITION COIL.......8I-6

RESISTANCE, 8.0L V-10 ENGINE -

IGNITION COIL........................8I-6

RESISTANCE, SPECIFICATIONS - SPARK

PLUG CABLE.........................8I-5

RESISTOR - DIAGNOSIS AND TESTING,

BLOWER MOTOR....................24-18

RESISTOR BLOCK - DESCRIPTION,

BLOWER MOTOR....................24-17

RESISTOR BLOCK - INSTALLATION,

BLOWER MOTOR....................24-18

RESISTOR BLOCK - OPERATION,

BLOWER MOTOR....................24-17

RESISTOR BLOCK - REMOVAL, BLOWER

MOTOR............................24-18

RESTRAINT ANCHOR - DESCRIPTION,

CHILD.............................8O-14

RESTRAINT ANCHOR - INSTALLATION,

CHILD.............................8O-17

RESTRAINT ANCHOR - OPERATION,

CHILD.............................8O-16

RESTRAINT ANCHOR - REMOVAL, CHILD . 8O-16

RESTRAINT DEPLOYMENT - STANDARD

PROCEDURE, SERVICE AFTER A

SUPPLEMENTAL......................8O-7

RESTRAINT SYSTEM - DIAGNOSIS AND

TESTING, SUPPLEMENTAL..............8O-6

RESTRAINT SYSTEM - WARNINGS.......8O-5

RESTRAINTS - DESCRIPTION............8O-2

RESTRAINTS - OPERATION.............8O-4

RESTRAINTS - STANDARD PROCEDURE,

HANDLING NON-DEPLOYED

SUPPLEMENTAL......................8O-6

RETAINER - ASSEMBLY, OVERRUNNING

CLUTCH CAM/OVERDRIVE PISTON.....21-239,

21-416

RETAINER - CLEANING, OVERRUNNING

CLUTCH CAM/OVERDRIVE PISTON.....21-238,

21-416

RETAINER - DESCRIPTION,

OVERRUNNING CLUTCH CAM/

OVERDRIVE PISTON...........21-237,21-415

RETAINER - DISASSEMBLY,

OVERRUNNING CLUTCH CAM/

OVERDRIVE PISTON...........21-238,21-415

RETAINER - INSPECTION,

OVERRUNNING CLUTCH CAM/

OVERDRIVE PISTON...........21-238,21-416

RETAINER - INSTALLATION, A-PILLAR

WEATHERSTRIP.....................23-91

RETAINER - INSTALLATION,

CRANKSHAFT REAR OIL SEAL.....9-205,9-326,

9-386

RETAINER - INSTALLATION, DRIP RAIL

WEATHERSTRIP.....................23-92

RETAINER - OPERATION, OVERRUNNING

CLUTCH CAM/OVERDRIVE PISTON.....21-237,

21-415

RETAINER - REMOVAL, A-PILLAR

WEATHERSTRIP.....................23-91

RETAINER - REMOVAL, CRANKSHAFT

REAR OIL SEAL............9-204,9-326,9-386

RETAINER - REMOVAL, DRIP RAIL

WEATHERSTRIP.....................23-92

RETAINER/BULKHEAD - ASSEMBLY, 4C . . 21-538

RETAINER/BULKHEAD - DISASSEMBLY,

4C ...............................21-538

RETRACTOR - DESCRIPTION,

AUTOMATIC LOCKING.................8O-13

RETRACTOR - INSTALLATION, FRONT

CENTER SEAT BELT..................8O-26

RETRACTOR - INSTALLATION, REAR

CENTER SEAT BELT..................8O-40

RETRACTOR - INSTALLATION, REAR

OUTBOARD SEAT BELT

................8O-42

RETRACTOR - OPERATION, AUTOMATIC

LOCKING

...........................8O-14

RETRACTOR - REMOVAL, FRONT

CENTER SEAT BELT

..................8O-25

RETRACTOR - REMOVAL, REAR CENTER

SEAT BELT

.........................8O-39

RETRACTOR - REMOVAL, REAR

OUTBOARD SEAT BELT

................8O-41

28 INDEXDR

Description Group-Page Description Group-Page Description Group-Page

Page 2888 of 2895

STEM SEALS - REMOVAL, VALVE........9-377

STOP LAMP - INSTALLATION, CENTER

HIGH MOUNTED.....................8L-10

STOP LAMP - REMOVAL, CENTER HIGH

MOUNTED..........................8L-10

STOP LAMP UNIT - INSTALLATION,

CENTER HIGH MOUNTED..............8L-10

STOP LAMP UNIT - REMOVAL, CENTER

HIGH MOUNTED.....................8L-10

STORAGE BIN - INSTALLATION..........23-62

STORAGE BIN - INSTALLATION, UNDER

SEAT ..............................23-81

STORAGE BIN - REMOVAL.............23-62

STORAGE BIN - REMOVAL, UNDER SEAT . . 23-81

STORAGE BIN COVERING -

INSTALLATION, UNDER SEAT...........23-81

STORAGE BIN COVERING - REMOVAL,

UNDER SEAT........................23-81

STORAGE BIN LATCH - INSTALLATION,

UNDER SEAT........................23-81

STORAGE BIN LATCH - REMOVAL,

UNDER SEAT........................23-81

STRAP - DESCRIPTION, RADIO NOISE

SUPPRESSION GROUND................8A-8

STRAP - INSTALLATION, RADIO NOISE

SUPPRESSION GROUND...............8A-10

STRAP - OPERATION, RADIO NOISE

SUPPRESSION GROUND................8A-8

STRAP - REMOVAL, RADIO NOISE

SUPPRESSION GROUND................8A-9

STRETCH - INSPECTION, MEASURING

TIMING CHAIN.................9-279,9-405

STRIKER - INSTALLATION, LATCH . . 23-17,23-24,

23-33

STRIKER - REMOVAL, LATCH . 23-17,23-24,23-33

STRIKER / SECONDARY CATCH -

INSTALLATION, LATCH................23-48

STRIKER / SECONDARY CATCH -

REMOVAL, LATCH....................23-48

STRUCTURAL ADHESIVE LOCATIONS -

SPECIFICATIONS....................23-113

STRUCTURAL COVER - DESCRIPTION....9-143,

9-210,9-56

STRUCTURAL COVER - INSTALLATION . . . 9-143,

9-210,9-56

STRUCTURAL COVER - OPERATION.....9-143,

9-210,9-56

STRUCTURAL COVER - REMOVAL . . 9-143,9-210,

9-56

STUDS - INSTALLATION...............22-14

STUDS - REMOVAL...................22-14

SUN VISOR - INSTALLATION...........23-71

SUN VISOR - REMOVAL...............23-71

SUN VISOR SUPPORT - INSTALLATION . . . 23-72

SUN VISOR SUPPORT - REMOVAL.......23-72

SUPPLEMENTAL RESTRAINT

DEPLOYMENT - STANDARD

PROCEDURE, SERVICE AFTER A.........8O-7

SUPPLEMENTAL RESTRAINT SYSTEM -

DIAGNOSIS AND TESTING..............8O-6

SUPPLEMENTAL RESTRAINTS -

STANDARD PROCEDURE, HANDLING

NON-DEPLOYED......................8O-6

SUPPLIES - DESCRIPTION, 5 VOLT......8E-10

SUPPLIES - OPERATION, 5 VOLT........8E-11

SUPPLY TEST - DIAGNOSIS AND

TESTING, VACUUM....................8P-2

SUPPORT - INSTALLATION, SUN VISOR

. . . 23-72

SUPPORT - REMOVAL, SUN VISOR

......23-72

SUPPORT BRACKET - INSTALLATION,

REARVIEW MIRROR

..................23-71

SUPPORT BRACKET - INSTALLATION,

STEERING COLUMN OPENING

..........23-62

SUPPORT BRACKET - REMOVAL,

STEERING COLUMN OPENING

..........23-61

SUPPORT CYLINDER - INSTALLATION

....23-49

SUPPORT CYLINDER - INSTALLATION,

LOAD FLOOR

........................23-73

SUPPORT CYLINDER - REMOVAL

........23-48

SUPPORT CYLINDER - REMOVAL, LOAD

FLOOR

.............................23-73

SUPPORT PLATE - INSTALLATION

........5-29

SUPPORT PLATE - REMOVAL

............5-29

SUPPRESSION GROUND STRAP -

DESCRIPTION, RADIO NOISE

............8A-8

SUPPRESSION GROUND STRAP -

INSTALLATION, RADIO NOISE

...........8A-10SUPPRESSION GROUND STRAP -

OPERATION, RADIO NOISE..............8A-8

SUPPRESSION GROUND STRAP -

REMOVAL, RADIO NOISE...............8A-9

SURFACE PREPARATION - STANDARD

PROCEDURE, ENGINE GASKET...........9-10

SURROUND - INSTALLATION,

INSTRUMENT PANEL LOWER...........23-60

SURROUND - REMOVAL, INSTRUMENT

PANEL LOWER......................23-60

SUSPENSION - DESCRIPTION, GEAR -

INDEPENDENT FRONT.................19-16

SUSPENSION - INSTALLATION, GEAR -

INDEPENDENT FRONT.................19-17

SUSPENSION - REMOVAL, GEAR -

INDEPENDENT FRONT.................19-16

SUSPENSION - STANDARD PROCEDURE,

ALIGNMENT LINK/COIL..................2-5

SUSPENSION ARM - INSTALLATION,

LOWER.............................2-35

SUSPENSION ARM - REMOVAL, LOWER . . . 2-35

SUSPENSION, SPECIAL TOOLS - FRONT . . . 2-11

SWITCH - DESCRIPTION................8P-8

SWITCH - DESCRIPTION, BACKUP LAMP . . . 8L-7

SWITCH - DESCRIPTION, BLOWER

MOTOR............................24-18

SWITCH - DESCRIPTION, BRAKE LAMP....8L-8

SWITCH - DESCRIPTION, CLUTCH

PEDAL POSITION.....................6-14

SWITCH - DESCRIPTION, DOOR AJAR....8L-25

SWITCH - DESCRIPTION, DRIVER SEAT . . . 8N-15

SWITCH - DESCRIPTION, HAZARD.......8L-13

SWITCH - DESCRIPTION, HEADLAMP....8L-14

SWITCH - DESCRIPTION, HEATED SEAT . . . 8G-7

SWITCH - DESCRIPTION, HORN..........8H-2

SWITCH - DESCRIPTION, IGNITION.......19-9

SWITCH - DESCRIPTION, KEY-IN

IGNITION...........................19-11

SWITCH - DESCRIPTION, LUMBAR

CONTROL..........................8N-19

SWITCH - DESCRIPTION, OVERDRIVE . . . 21-218,

21-397,21-568

SWITCH - DESCRIPTION, PASSENGER

AIRBAG ON/OFF.....................8O-38

SWITCH - DESCRIPTION, PASSENGER

SEAT ..............................8N-16

SWITCH - DESCRIPTION, POWER

STEERING PRESSURE.................19-45

SWITCH - DESCRIPTION, SEAT BELT.....8O-46

SWITCH - DESCRIPTION, SELECTOR....21-685,

21-719

SWITCH - DESCRIPTION, WASHER

FLUID LEVEL.........................8R-9

SWITCH - DIAGNOSIS AND TESTING,

BACKUP LAMP.......................8L-8

SWITCH - DIAGNOSIS AND TESTING,

BLOWER MOTOR....................24-18

SWITCH - DIAGNOSIS AND TESTING,

BRAKE LAMP........................8L-9

SWITCH - DIAGNOSIS AND TESTING,

CLUTCH PEDAL POSITION..............6-14

SWITCH - DIAGNOSIS AND TESTING,

DRIVER SEAT.......................8N-15

SWITCH - DIAGNOSIS AND TESTING,

HEATED SEAT ........................8G-8

SWITCH - DIAGNOSIS AND TESTING,

HORN..............................8H-2

SWITCH - DIAGNOSIS AND TESTING,

IGNITION............................19-9

SWITCH - DIAGNOSIS AND TESTING,

MULTI-FUNCTION....................8L-18

SWITCH - DIAGNOSIS AND TESTING,

PASSENGER SEAT....................8N-17

SWITCH - DIAGNOSIS AND TESTING,

POWER LOCK........................8N-4

SWITCH - DIAGNOSIS AND TESTING,

POWER MIRROR....................8N-13

SWITCH - DIAGNOSIS AND TESTING,

SEAT BELT .........................8O-47

SWITCH - DIAGNOSIS AND TESTING,

WINDOW...........................8N-22

SWITCH - INSTALLATION

...............8P-9

SWITCH - INSTALLATION, ADJUSTABLE

PEDAL

...............................5-6

SWITCH - INSTALLATION, BLOWER

MOTOR

............................24-19

SWITCH - INSTALLATION, BRAKE LAMP

. . 8L-10

SWITCH - INSTALLATION, DRIVER SEAT

. . 8N-16SWITCH - INSTALLATION, HEADLAMP....8L-14

SWITCH - INSTALLATION, HEATED SEAT . . . 8G-9

SWITCH - INSTALLATION, IGNITION......19-11

SWITCH - INSTALLATION, MULTI-

FUNCTION..........................8L-19

SWITCH - INSTALLATION, OVERDRIVE . . 21-219,

21-397,21-569

SWITCH - INSTALLATION, PASSENGER

AIRBAG ON/OFF.....................8O-39

SWITCH - INSTALLATION, PASSENGER

SEAT ..............................8N-18

SWITCH - INSTALLATION, POWER LOCK . . . 8N-4

SWITCH - INSTALLATION, WASHER

FLUID LEVEL........................8R-11

SWITCH - INSTALLATION, WINDOW.....8N-23

SWITCH - OPERATION.................8P-8

SWITCH - OPERATION, BACKUP LAMP....8L-8

SWITCH - OPERATION, BLOWER MOTOR . . 24-18

SWITCH - OPERATION, BRAKE LAMP......8L-8

SWITCH - OPERATION, CLUTCH PEDAL

POSITION...........................6-14

SWITCH - OPERATION, DOOR AJAR......8L-25

SWITCH - OPERATION, DRIVER SEAT....8N-15

SWITCH - OPERATION, HAZARD.........8L-13

SWITCH - OPERATION, HEADLAMP......8L-14

SWITCH - OPERATION, HEATED SEAT.....8G-8

SWITCH - OPERATION, IGNITION.........19-9

SWITCH - OPERATION, LUMBAR

CONTROL............................8N-19

SWITCH - OPERATION, OVERDRIVE....21-218,

21-397,21-568

SWITCH - OPERATION, PASSENGER

AIRBAG ON/OFF.....................8O-38

SWITCH - OPERATION, PASSENGER

SEAT ..............................8N-17

SWITCH - OPERATION, POWER

STEERING PRESSURE.................19-45

SWITCH - OPERATION, SEAT BELT.......8O-46

SWITCH - OPERATION, SELECTOR.....21-685,

21-719

SWITCH - OPERATION, WASHER FLUID

LEVEL..............................8R-9

SWITCH - REMOVAL...................8P-9

SWITCH - REMOVAL, ADJUSTABLE

PEDAL...............................5-6

SWITCH - REMOVAL, BLOWER MOTOR . . . 24-19

SWITCH - REMOVAL, BRAKE LAMP.......8L-9

SWITCH - REMOVAL, DRIVER SEAT......8N-16

SWITCH - REMOVAL, HEADLAMP........8L-14

SWITCH - REMOVAL, HEATED SEAT.......8G-9

SWITCH - REMOVAL, IGNITION.........19-10

SWITCH - REMOVAL, LUMBAR

CONTROL..........................8N-19

SWITCH - REMOVAL, MULTI-FUNCTION . . . 8L-18

SWITCH - REMOVAL, OVERDRIVE......21-219,

21-397,21-568

SWITCH - REMOVAL, PASSENGER

AIRBAG ON/OFF.....................8O-39

SWITCH - REMOVAL, PASSENGER SEAT . . 8N-17

SWITCH - REMOVAL, POWER LOCK......8N-4

SWITCH - REMOVAL, POWER MIRROR . . . 8N-13

SWITCH - REMOVAL, WASHER FLUID

LEVEL.............................8R-10

SWITCH - REMOVAL, WINDOW.........8N-23

SWITCH AND KEY LOCK CYLINDER -

DIAGNOSIS AND TESTING, IGNITION.....19-11

SWITCH BEZEL - INSTALLATION,

INSTRUMENT PANEL HEADLAMP........23-57

SWITCH BEZEL - REMOVAL,

INSTRUMENT PANEL HEADLAMP........23-57

SWITCH OPERATING MODES,

STANDARD PROCEDURE -

CONFIGURING A NEW MODULE..........8Q-3

SWITCH VALVE - DESCRIPTION,

SOLENOID.........................21-574

SWITCH VALVE - OPERATION, SOLENOID . 21-574

SWITCHES - DESCRIPTION, REMOTE.....8A-10

SWITCHES - DIAGNOSIS AND TESTING,

REMOTE...........................8A-11

SWITCHES - INSTALLATION, REMOTE....8A-12

SWITCHES - OPERATION, REMOTE

......8A-10

SWITCHES - REMOVAL, REMOTE

........8A-12

SYMBOLS - DESCRIPTION,

INTERNATIONAL

....................Intro.-6

SYMBOLS - DESCRIPTION,

INTERNATIONAL

.......................0-1

TABLE, SPECIFICATIONS - A/C

APPLICATION

........................24-7

DRINDEX 33

Description Group-Page Description Group-Page Description Group-Page

Page 2889 of 2895

TACHOMETER - DESCRIPTION..........8J-37

TACHOMETER - OPERATION............8J-37

TAIL LAMP - INSTALLATION............8L-21

TAIL LAMP - REMOVAL................8L-21

TAIL LAMP UNIT - INSTALLATION.......8L-21

TAIL LAMP UNIT - REMOVAL...........8L-21

TAILGATE - INSTALLATION.............23-17

TAILGATE - REMOVAL.................23-17

TAILPIPE - 5.9L DIESEL - INSPECTION....11-9

TAILPIPE - 5.9L DIESEL - INSTALLATION . . . 11-9

TAILPIPE - 5.9L DIESEL - REMOVAL......11-9

TAILPIPE - INSPECTION...............11-10

TAILPIPE - INSTALLATION..............11-10

TAILPIPE - REMOVAL.................11-10

TANK - DESCRIPTION, FUEL............14-20

TANK - OPERATION, FUEL..............14-20

TANK MODULE - DESCRIPTION, FUEL....14-75

TANK MODULE - INSTALLATION, FUEL....14-75

TANK MODULE - OPERATION, FUEL......14-75

TANK MODULE - REMOVAL, FUEL.......14-75

TAPPETS - DIAGNOSIS AND TESTING,

HYDRAULIC....................9-258,9-386

TASK MANAGER - DESCRIPTION.........25-1

TASK MANAGER - OPERATION...........25-5

TCM QUICK LEARN - STANDARD

PROCEDURE........................8E-21

TEMP INDICATOR - DESCRIPTION,

TRANS.............................8J-38

TEMP INDICATOR - OPERATION, TRANS . . 8J-38

TEMP SENSOR - DESCRIPTION,

AMBIENT..........................8M-10

TEMP SENSOR - OPERATION, AMBIENT . . 8M-10

TEMPERATURE GAUGE - DESCRIPTION,

ENGINE............................8J-23

TEMPERATURE GAUGE - OPERATION,

ENGINE............................8J-23

TEMPERATURE SENSOR - DESCRIPTION,

BATTERY...........................8F-21

TEMPERATURE SENSOR - DESCRIPTION,

ENGINE COOLANT.....................7-44

TEMPERATURE SENSOR - DESCRIPTION,

INTAKE AIR .........................14-36

TEMPERATURE SENSOR - DESCRIPTION,

TRANSMISSION.........21-267,21-445,21-583

TEMPERATURE SENSOR - DIAGNOSIS

AND TESTING, AMBIENT..............8M-11

TEMPERATURE SENSOR -

INSTALLATION, BATTERY..............8F-21

TEMPERATURE SENSOR -

INSTALLATION, ENGINE COOLANT........7-47

TEMPERATURE SENSOR -

INSTALLATION, INTAKE AIR............14-38

TEMPERATURE SENSOR - OPERATION,

BATTERY...........................8F-21

TEMPERATURE SENSOR - OPERATION,

ENGINE COOLANT.....................7-44

TEMPERATURE SENSOR - OPERATION,

INTAKE AIR .........................14-36

TEMPERATURE SENSOR - OPERATION,

TRANSMISSION.........21-267,21-445,21-583

TEMPERATURE SENSOR - REMOVAL,

BATTERY...........................8F-21

TEMPERATURE SENSOR - REMOVAL,

ENGINE COOLANT.....................7-44

TEMPERATURE SENSOR - REMOVAL,

INTAKE AIR .........................14-36

TEMPERATURE SENSOR CIRCUIT -

DIAGNOSIS AND TESTING, AMBIENT....8M-11

TEMPERATURE SENSOR/MAP SENSOR -

DESCRIPTION, INTAKE AIR.............14-93

TEMPERATURE SENSOR/MAP SENSOR -

INSTALLATION, INTAKE AIR............14-94

TEMPERATURE SENSOR/MAP SENSOR -

OPERATION, INTAKE AIR...............14-93

TEMPERATURE SENSOR/MAP SENSOR -

REMOVAL, INTAKE AIR................14-93

TEMPERATURE SENSOR/PRESSURE

SENSOR - DESCRIPTION, INLET AIR.....14-90

TEMPERATURE SENSOR/PRESSURE

SENSOR - INSTALLATION, INLET AIR

.....14-90

TEMPERATURE SENSOR/PRESSURE

SENSOR - OPERATION, INLET AIR

.......14-90

TEMPERATURE SENSOR/PRESSURE

SENSOR - REMOVAL, INLET AIR

........14-90

TEMPORARY - DESCRIPTION, SPARE

TIRE

................................22-5

TEMPORARY TIRE - DESCRIPTION,

SPARE

.............................22-15TENSION REDUCER - DESCRIPTION,

SEAT BELT .........................8O-48

TENSION REDUCER - DIAGNOSIS AND

TESTING, SEAT BELT.................8O-49

TENSION REDUCER - OPERATION, SEAT

BELT ..............................8O-49

TENSIONER - DESCRIPTION, SEAT BELT . . 8O-47

TENSIONER - OPERATION, SEAT BELT....8O-48

TENSIONERS - 3.7L / 4.7L -

DESCRIPTION, BELT...................7-22

TENSIONERS - 3.7L / 4.7L -

INSTALLATION, BELT...................7-23

TENSIONERS - 3.7L / 4.7L - OPERATION,

BELT ...............................7-22

TENSIONERS - 3.7L / 4.7L - REMOVAL,

BELT ...............................7-22

TENSIONERS - 5.9L - DESCRIPTION,

BELT ...............................7-23

TENSIONERS - 5.9L - INSTALLATION,

BELT ...............................7-24

TENSIONERS - 5.9L - OPERATION, BELT . . . 7-23

TENSIONERS - 5.9L - REMOVAL, BELT.....7-23

TENSIONERS - 5.9L DIESEL -

DESCRIPTION, BELT...................7-24

TENSIONERS - 5.9L DIESEL -

INSTALLATION, BELT...................7-25

TENSIONERS - 5.9L DIESEL -

OPERATION, BELT.....................7-24

TENSIONERS - 5.9L DIESEL - REMOVAL,

BELT ...............................7-25

TERMINAL - INSTALLATION.........8W-01-14

TERMINAL - REMOVAL..............8W-01-14

TEST - DIAGNOSIS AND TESTING,

HYDRAULIC PRESSURE . . 21-140,21-321,21-493

TEST - DIAGNOSIS AND TESTING, ROAD . . . 8P-3

TEST - DIAGNOSIS AND TESTING,

VACUUM SUPPLY.....................8P-2

TEST - STANDARD PROCEDURE,

BUILT-IN INDICATOR..................8F-10

TEST - STANDARD PROCEDURE,

IGNITION-OFF DRAW..................8F-11

TEST - STANDARD PROCEDURE,

OPEN-CIRCUIT VOLTAGE...............8F-10

TEST - STANDARD PROCEDURE,

VERIFICATION........................8O-8

TEST MODE - DESCRIPTION, CIRCUIT

ACTUATION..........................25-1

TEST MODE - DESCRIPTION, STATE

DISPLAY............................25-1

TESTER - STANDARD PROCEDURE,

USING MICRO 420 BATTERY............8F-12

TESTS - DIAGNOSIS AND TESTING,

CYLINDER COMPRESSION/LEAKAGE.....9-288

THEFT SECURITY SYSTEM, DIAGNOSIS

AND TESTING - VEHICLE...............8Q-3

THERMOSTAT - 3.7L/4.7L -

DESCRIPTION, ENGINE COOLANT.........7-50

THERMOSTAT - 3.7L/4.7L -

INSTALLATION, ENGINE COOLANT........7-51

THERMOSTAT - 3.7L/4.7L - OPERATION,

ENGINE COOLANT.....................7-51

THERMOSTAT - 3.7L/4.7L - REMOVAL,

ENGINE COOLANT.....................7-51

THERMOSTAT - 5.9L DIESEL -

DESCRIPTION, ENGINE COOLANT.........7-52

THERMOSTAT - 5.9L DIESEL -

INSTALLATION, ENGINE COOLANT........7-53

THERMOSTAT - 5.9L DIESEL -

OPERATION, ENGINE COOLANT..........7-52

THERMOSTAT - 5.9L DIESEL -

REMOVAL, ENGINE COOLANT............7-53

THERMOSTAT - DIAGNOSIS AND

TESTING....................7-48,7-51,7-52

THERMOSTAT-5.7L/5.9L - DESCRIPTION,

ENGINE COOLANT.....................7-47

THERMOSTAT-5.7L/5.9L -

INSTALLATION, ENGINE COOLANT........7-49

THERMOSTAT-5.7L/5.9L - OPERATION,

ENGINE COOLANT

.....................7-48

THERMOSTAT-5.7L/5.9L - REMOVAL,

ENGINE COOLANT

.....................7-48

THREAD REPAIR - STANDARD

PROCEDURE, ALUMINUM

. 21-156,21-337,21-495

THREADED HOLE REPAIR -

DESCRIPTION

......................Intro.-9

THREADS - STANDARD PROCEDURE,

REPAIR DAMAGED OR WORN

.....9-186,9-232,

9-289,9-361,9-9,9-93THROTTLE BODY - DESCRIPTION........14-45

THROTTLE BODY - INSTALLATION.......14-47

THROTTLE BODY - OPERATION.........14-45

THROTTLE BODY - REMOVAL...........14-45

THROTTLE CONTROL CABLE -

INSTALLATION..................14-51,14-96

THROTTLE CONTROL CABLE - REMOVAL . 14-49,

14-94

THROTTLE POSITION SENSOR -

DESCRIPTION.......................14-52

THROTTLE POSITION SENSOR -

INSTALLATION.......................14-54

THROTTLE POSITION SENSOR -

OPERATION.........................14-52

THROTTLE POSITION SENSOR -

REMOVAL..........................14-53

THROTTLE VALVE CABLE -

ADJUSTMENTS...............21-255,21-432

THROTTLE VALVE CABLE -

DESCRIPTION................21-254,21-432

TIE DOWN - INSTALLATION, CARGO BOX . 23-37

TIE DOWN - REMOVAL, CARGO BOX.....23-37

TIE ROD END - DIAGNOSIS AND

TESTING, OUTER.....................19-31

TIE ROD END - INSTALLATION..........19-37

TIE ROD END - INSTALLATION, OUTER . . . 19-32

TIE ROD END - REMOVAL..............19-36

TIE ROD END - REMOVAL, OUTER.......19-31

TIMING - DESCRIPTION, VALVE..........9-75

TIMING - DIAGNOSIS AND TESTING,

FUEL INJECTION PUMP...............14-65

TIMING - OPERATION, VALVE............9-75

TIMING - VERIFICATION - STANDARD

PROCEDURE, ENGINE.................9-165

TIMING BELT / CHAIN COVER(S) -

INSTALLATION........9-169,9-278,9-404,9-81

TIMING BELT / CHAIN COVER(S) -

REMOVAL............9-168,9-278,9-404,9-80

TIMING BELT/CHAIN AND SPROCKETS -

INSPECTION....................9-171,9-83

TIMING BELT/CHAIN AND SPROCKETS -

INSTALLATION........9-172,9-279,9-406,9-84

TIMING BELT/CHAIN AND SPROCKETS -

REMOVAL............9-169,9-279,9-405,9-81

TIMING CHAIN STRETCH - INSPECTION,

MEASURING...................9-279,9-405

TIMING CHAIN WEAR - STANDARD

PROCEDURE, MEASURING.............9-165

TIMING CHAIN WEAR, STANDARD

PROCEDURE - MEASURING.............9-76

TIMING CHAIN/TENSIONER -

DESCRIPTION.......................9-222

TIMING CHAIN/TENSIONER - OPERATION . 9-222

TIMING DRIVE SYSTEM - DESCRIPTION . . 9-164

TIMING DRIVE SYSTEM - OPERATION....9-164

TIMING, SPECIFICATIONS - IGNITION......8I-6

TIMING VERIFICATION - SERVICE

PROCEDURE.........................9-76

TIMING VERIFICATION - STANDARD

PROCEDURE........................9-348

TIMING/CHAIN AND SPROCKETS -

INSTALLATION.......................9-222

TIMING/CHAIN AND SPROCKETS -

REMOVAL..........................9-221

TIMING/CHAIN COVER - INSTALLATION

. . . 9-221

TIMING/CHAIN COVER - REMOVAL

.......9-220

TIP INSERTS - INSTALLATION, SPRING

....2-42

TIP INSERTS - REMOVAL, SPRING

........2-41

TIP REPLACEMENT - STANDARD

PROCEDURE, LIGHT DUTY FRONT

FRAME RAIL

.........................13-4

TIRE - DESCRIPTION, FULL SIZE, SPARE

WHEEL WITH MATCHING

..............22-15

TIRE - DESCRIPTION, SPARE /

TEMPORARY

........................22-15

TIRE / TEMPORARY - DESCRIPTION,

SPARE

..............................22-5

TIRE AND WHEEL BALANCE -

STANDARD PROCEDURE

................22-4

TIRE AND WHEEL RUNOUT - DIAGNOSIS

AND TESTING

........................22-1

TIRE INFLATION PRESSURES -

DESCRIPTION

........................22-6

TIRE NOISE OR VIBRATION - DIAGNOSIS

AND TESTING

........................22-7

TIRE PRESSURE FOR HIGH SPEEDS -

DESCRIPTION

........................22-6

34 INDEXDR

Description Group-Page Description Group-Page Description Group-Page

Page 2892 of 2895

UPPER RADIATOR CROSSMEMBER -

INSTALLATION.......................23-42

UPPER RADIATOR CROSSMEMBER -

REMOVAL..........................23-42

UPPER STEERING COUPLING -

INSTALLATION.......................19-14

UPPER STEERING COUPLING -

REMOVAL..........................19-13

UPPER TRIM - INSTALLATION, B-PILLAR . . 23-65

UPPER TRIM - INSTALLATION, C-PILLAR . . 23-68

UPPER TRIM - REMOVAL, B-PILLAR.....23-65

UPPER TRIM - REMOVAL, C-PILLAR.....23-68

UPSHIFT INDICATOR - DESCRIPTION.....8J-40

UPSHIFT INDICATOR - OPERATION.......8J-40

USAGE - DESCRIPTION, FASTENER.....Intro.-9

USE WIRING DIAGRAMS -

DESCRIPTION, HOW TO.............8W-01-1

USING MICRO 420 BATTERY TESTER -

STANDARD PROCEDURE...............8F-12

V-10 - DESCRIPTION, 8.0L.............25-12

V-10 - OPERATION, 8.0L...............25-12

V-10 ENGINE - IGNITION COIL

RESISTANCE, 8.0L.....................8I-6

V-10 ENGINE - SPARK PLUG CABLE

ORDER, 8.0L.........................8I-5

V-10 OR DIESEL ENGINE -

INSTALLATION......................8R-17

V-10 OR DIESEL ENGINE -

INSTALLATION, EXCEPT...............8R-17

V-10 OR DIESEL ENGINE - REMOVAL....8R-16

V-10 OR DIESEL ENGINE - REMOVAL,

EXCEPT............................8R-16

V-6 - ENGINE FIRING ORDER, 3.7L........8I-4

V-6 - IGNITION COIL RESISTANCE, 3.7L....8I-6

V-6/ 4.7L V-8 - DIAGNOSIS AND

TESTING, PCV VALVE - 3.7L............25-19

V-8 - DIAGNOSIS AND TESTING,

DISTRIBUTOR CAP - 5.9L..............8I-18

V-8 - DIAGNOSIS AND TESTING,

DISTRIBUTOR ROTOR - 5.9L............8I-19

V-8 - DIAGNOSIS AND TESTING, PCV

VALVE - 3.7L V-6/ 4.7L................25-19

V-8 - DIAGNOSIS AND TESTING, PCV

VALVE - 5.9L........................25-19

V-8 - ENGINE FIRING ORDER, 4.7L........8I-4

V-8 - ENGINE FIRING ORDER, 5.9L........8I-4

V-8 - IGNITION COIL RESISTANCE, 4.7L....8I-6

V-8 - IGNITION COIL RESISTANCE, 5.7L....8I-6

V-8 ENGINE - FIRING ORDER / CABLE

ROUTING, 5.7L........................8I-4

VAC LEAK DETECTION ASSY -

DESCRIPTION, NATURAL..............25-23

VAC LEAK DETECTION ASSY -

INSTALLATION, NATURAL..............25-24

VAC LEAK DETECTION ASSY -

OPERATION, NATURAL................25-23

VAC LEAK DETECTION ASSY -

REMOVAL, NATURAL..................25-24

VACUUM LINES - DESCRIPTION.........25-22

VACUUM RESERVOIR - DESCRIPTION.....8P-9

VACUUM RESERVOIR - DIAGNOSIS AND

TESTING............................8P-9

VACUUM RESERVOIR - INSTALLATION . . . 8P-10

VACUUM RESERVOIR - OPERATION.......8P-9

VACUUM RESERVOIR - REMOVAL.......8P-10

VACUUM SUPPLY TEST - DIAGNOSIS

AND TESTING........................8P-2

VALVE - 3.7L V-6/ 4.7L V-8 - DIAGNOSIS

AND TESTING, PCV...................25-19

VALVE - 5.9L V-8 - DIAGNOSIS AND

TESTING, PCV.......................25-19

VALVE - CLEANING, OIL PRESSURE

RELIEF.............................9-343

VALVE - DESCRIPTION, CASCADE

OVERFLOW.........................14-77

VALVE - DESCRIPTION, CHECK..........8R-8

VALVE - DESCRIPTION, FUEL PRESSURE

LIMITING...........................14-72

VALVE - DESCRIPTION, HIGH PRESSURE

RELIEF.............................24-35

VALVE - DESCRIPTION, PCV

............25-16

VALVE - DESCRIPTION, RWAL

...........5-44

VALVE - DESCRIPTION, SOLENOID

SWITCH

...........................21-574

VALVE - DESCRIPTION, TORQUE

CONVERTER DRAINBACK

.......21-262,21-440

VALVE - INSPECTION, OIL PRESSURE

RELIEF

.............................9-343VALVE - INSTALLATION, CHECK..........8R-9

VALVE - INSTALLATION, FUEL

PRESSURE LIMITING.................14-73

VALVE - INSTALLATION, OIL PRESSURE

RELIEF.............................9-343

VALVE - INSTALLATION, RWAL...........5-45

VALVE - OPERATION, CASCADE

OVERFLOW.........................14-77

VALVE - OPERATION, CHECK............8R-8

VALVE - OPERATION, FUEL PRESSURE

LIMITING...........................14-72

VALVE - OPERATION, HIGH PRESSURE

RELIEF.............................24-36

VALVE - OPERATION, PCV..............25-17

VALVE - OPERATION, RWAL.............5-44

VALVE - OPERATION, SOLENOID SWITCH . 21-574

VALVE - OPERATION, TORQUE

CONVERTER DRAINBACK.......21-262,21-440

VALVE - REMOVAL, CHECK..............8R-8

VALVE - REMOVAL, FUEL PRESSURE

LIMITING...........................14-72

VALVE - REMOVAL, OIL PRESSURE

RELIEF.............................9-343

VALVE - REMOVAL, RWAL..............5-45

VALVE - STANDARD PROCEDURE,

TORQUE CONVERTER DRAINBACK.....21-262,

21-440

VALVE BODY - ADJUSTMENTS . . . 21-308,21-487

VALVE BODY - ASSEMBLY......21-299,21-477,

21-590

VALVE BODY - CLEANING . . 21-298,21-476,21-588

VALVE BODY - DESCRIPTION....21-267,21-445,

21-584

VALVE BODY - DISASSEMBLY . . . 21-287,21-465,

21-586

VALVE BODY - INSPECTION.....21-298,21-476,

21-588

VALVE BODY - INSTALLATION . . . 21-307,21-486,

21-590

VALVE BODY - OPERATION.....21-272,21-450,

21-585

VALVE BODY - REMOVAL . 21-286,21-464,21-585

VALVE CABLE - ADJUSTMENTS,

THROTTLE...................21-255,21-432

VALVE CABLE - DESCRIPTION,

THROTTLE...................21-254,21-432

VALVE GUIDE SEALS - DESCRIPTION . . 9-31,9-36

VALVE GUIDES - DESCRIPTION....9-106,9-197

VALVE LASH ADJUSTMENT AND

VERIFICATION - STANDARD

PROCEDURE........................9-308

VALVE SERVICE, STANDARD

PROCEDURE........................9-375

VALVE SPRINGS - DESCRIPTION....9-125,9-31,

9-36

VALVE SPRINGS - INSTALLATION . . 9-126,9-199,

9-31,9-37

VALVE SPRINGS - INSTALLATION,

VALVES ............................9-379

VALVE SPRINGS - REMOVAL . . 9-125,9-199,9-31,

9-37

VALVE SPRINGS - REMOVAL, VALVES....9-377

VALVE SPRINGS AND SEALS - REMOVAL . 9-308

VALVE STEM SEAL - INSTALLATION......9-378

VALVE STEM SEALS - DESCRIPTION.....9-126,

9-198

VALVE STEM SEALS - REMOVAL........9-377

VALVE TIMING - DESCRIPTION...........9-75

VALVE TIMING - OPERATION............9-75

VALVES & SEATS - CLEANING,

INTAKE/EXHAUST....................9-248

VALVES & SEATS - DESCRIPTION,

INTAKE/EXHAUST . 9-122,9-246,9-27,9-305,9-375

VALVES & SEATS - INSPECTION,

INTAKE/EXHAUST....................9-248

VALVES & SEATS - INSTALLATION,

INTAKE/EXHAUST...........9-123,9-248,9-29

VALVES & SEATS - REMOVAL,

INTAKE/EXHAUST...........9-122,9-248,9-28

VALVES AND VALVE SPRINGS -

INSTALLATION.......................9-379

VALVES AND VALVE SPRINGS -

REMOVAL

..........................9-377

VALVES, GUIDES AND SPRINGS -

STANDARD PROCEDURE

..........9-246,9-305

VAPOR CANISTER - DESCRIPTION

.......25-22

VAPOR CANISTER - INSTALLATION

......25-23

VAPOR CANISTER - OPERATION

.........25-22VAPOR CANISTER - REMOVAL..........25-22

VARIABLE BRAKE PROPORTIONING -

DESCRIPTION, ELECTRONIC.............5-43

VARIABLE BRAKE PROPORTIONING -

OPERATION, ELECTRONIC...............5-43

VARIATION ADJUSTMENT - STANDARD

PROCEDURE, COMPASS...............8M-4

VEHICLE EMISSION CONTROL

INFORMATION (VECI) - DESCRIPTION . . . Intro.-3

VEHICLE IDENTIFICATION NUMBER -

DESCRIPTION......................Intro.-2

VEHICLE INFO CENTER - DESCRIPTION,

ELECTRONIC........................8M-7

VEHICLE INFO CENTER - INSTALLATION,

ELECTRONIC.......................8M-10

VEHICLE INFO CENTER - OPERATION,

ELECTRONIC........................8M-8

VEHICLE INFO CENTER - REMOVAL,

ELECTRONIC.......................8M-10

VEHICLE INFORMATION CENTER -

DIAGNOSIS AND TESTING,

ELECTRONIC........................8M-8

VEHICLE INFORMATION CENTER

PROGRAMMING - STANDARD

PROCEDURE, ELECTRONIC.............8M-8

VEHICLE SAFETY CERTIFICATION LABEL

- DESCRIPTION.....................Intro.-1

VEHICLE THEFT SECURITY SYSTEM,

DIAGNOSIS AND TESTING..............8Q-3

VENT - INSTALLATION, BODY...........23-72

VENT - REMOVAL, BODY..............23-72

VENT GLASS - INSTALLATION, BACKLITE . 23-87

VENT GLASS - REMOVAL, BACKLITE.......23-87

VERIFICATION - SERVICE PROCEDURE,

TIMING.............................9-76

VERIFICATION - STANDARD

PROCEDURE, ENGINE TIMING..........9-165

VERIFICATION - STANDARD

PROCEDURE, TIMING.................9-348

VERIFICATION - STANDARD

PROCEDURE, VALVE LASH

ADJUSTMENT.......................9-308

VERIFICATION TEST - STANDARD

PROCEDURE.........................8O-8

VIBRATION - DIAGNOSIS AND TESTING,

TIRE NOISE OR.......................22-7

VIBRATION DAMPER - INSPECTION......9-335

VIBRATION DAMPER - INSTALLATION....9-142,

9-209,9-263,9-335,9-392,9-55

VIBRATION DAMPER - REMOVAL . . 9-141,9-209,

9-263,9-335,9-392,9-54

VIEW MIRROR - INSTALLATION, SIDE....23-41

VIEW MIRROR - REMOVAL, REAR.......23-71

VIEW MIRROR - REMOVAL, SIDE........23-41

VIEW MIRROR FLAG - INSTALLATION,

SIDE..............................23-27

VIEW MIRROR FLAG - REMOVAL, SIDE . . . 23-27

VIEW MIRROR GLASS - INSTALLATION,

SIDE..............................23-44

VIEW MIRROR GLASS - REMOVAL, SIDE . . 23-42

VISCOUS CLUTCH - 5.9L DIESEL -

DESCRIPTION, FAN DRIVE..............7-55

VISCOUS CLUTCH - 5.9L DIESEL -

OPERATION, FAN DRIVE................7-55

VISCOUS CLUTCH - DESCRIPTION, FAN

DRIVE..............................7-54

VISCOUS CLUTCH - OPERATION, FAN

DRIVE..............................7-54

VISCOUS FAN DRIVE - DIAGNOSIS AND

TESTING............................7-54

VISCOUS FAN DRIVE - DIAGNOSIS AND

TESTING, ELECTRONICLY CONTOLLED.....7-56

VISOR - INSTALLATION, SUN...........23-71

VISOR - REMOVAL, SUN...............23-71

VISOR SUPPORT - INSTALLATION, SUN . . . 23-72

VISOR SUPPORT - REMOVAL, SUN......23-72

VOLT SUPPLIES - DESCRIPTION, 5......8E-10

VOLT SUPPLIES - OPERATION, 5........8E-11

VOLTAGE DROP - STANDARD

PROCEDURE, TESTING FOR A.......8W-01-10

VOLTAGE GAUGE - DESCRIPTION........8J-40

VOLTAGE GAUGE - OPERATION

..........8J-41

VOLTAGE POTENTIAL - STANDARD

PROCEDURE, TESTING OF

...........8W-01-9

VOLTAGE REGULATOR - DESCRIPTION

....8F-27

VOLTAGE REGULATOR - OPERATION

.....8F-27

VOLTAGE TEST - STANDARD

PROCEDURE, OPEN-CIRCUIT

...........8F-10

DRINDEX 37

Description Group-Page Description Group-Page Description Group-Page