Ignition switch DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1241 of 2895

SPECIAL TOOLS

POWER DISTRIBUTION SYSTEMS

CIGAR LIGHTER OUTLET

DESCRIPTION

On models equipped a cigar lighter outlet is

installed to the left of the center stack area in the

lower instrument panel. The cigar lighter outlet is

secured by a snap fit within the bezel.

The cigar lighter outlet, plastic cap and the knob

and heating element unit are available for service

replacement. These components cannot be repaired

and, if faulty or damaged, they must be replaced.

OPERATION

The cigar lighter consists of two major components:

a knob and heating element unit, and the cigar

lighter base or outlet shell. The receptacle shell is

connected to ground, and an insulated contact in the

bottom of the shell is connected to battery current.

The cigar lighter receives battery voltage from a fuse

in the junction block when the ignition switch is in

the Accessory or Run positions.

The cigar lighter knob and heating element are

encased within a spring-loaded housing, which also

features a sliding protective heat shield. When the

knob and heating element are inserted in the outlet

shell, the heating element resistor coil is grounded

through its housing to the outlet shell. If the cigar

lighter knob is pushed inward, the heat shield slides

up toward the knob exposing the heating element,

and the heating element extends from the housing

toward the insulated contact in the bottom of the

outlet shell.

Two small spring-clip retainers are located on

either side of the insulated contact inside the bottom

of the outlet shell. These clips engage and hold the

heating element against the insulated contact longenough for the resistor coil to heat up. When the

heating element is engaged with the contact, battery

current can flow through the resistor coil to ground,

causing the resistor coil to heat.

When the resistor coil becomes sufficiently heated,

excess heat radiates from the heating element caus-

ing the spring-clips to expand. Once the spring-clips

expand far enough to release the heating element,

the spring-loaded housing forces the knob and heat-

ing element to pop back outward to their relaxed

position. When the cigar lighter knob and element

are pulled out of the outlet shell, the protective heat

shield slides downward on the housing so that the

heating element is recessed and shielded around its

circumference for safety.

DIAGNOSIS AND TESTING - CIGAR LIGHTER

OUTLET

For complete circuit diagrams, refer toWiring

Diagrams.

(1) Check the fused B(+) fuse in the integrated

power module. If OK, go to Step 2. If not OK, repair

the shorted circuit or component as required and

replace the faulty fuse.

(2) Turn the ignition switch to the Run position.

Check for battery voltage at the fused B(+) fuse in

the integrated power module. If OK, go to Step 3. If

not OK, repair the open or short as required.

(3) Remove the cigar lighter knob and element

from the cigar lighter outlet shell. Check for continu-

ity between the inside circumference of the cigar

lighter outlet shell and a good ground. there should

be continuity. If OK, go to Step 4. If not OK, go to

Step 5.

(4) Turn the ignition switch to the Run position.

Check for battery voltage at the insulated contact

located at the back of the cigar lighter outlet shell. If

OK, replace the faulty cigar lighter knob and ele-

ment. If not OK, go to Step 5.

(5) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Check for continuity between the ground circuit cav-

ity of the cigar lighter wire harness connector and a

good ground. There should be continuity. If OK, go to

Step 6. If not OK, repair the open ground circuit to

ground as required.

(6) Connect the battery negative cable. Turn the

ignition switch to the Accessory or Run positions.

Check for battery voltage at the fused B(+) circuit

cavity of the cigar lighter wire harness connector. If

OK, replace the faulty cigar lighter outlet. If not OK,

repair the open fused B(+) circuit to the integrated

power module fuse as required.Terminal Pick Kit 6680

8W - 97 - 2 8W-97 POWER DISTRIBUTIONDR

POWER DISTRIBUTION (Continued)

Page 1244 of 2895

tery and provides the primary means of circuit pro-

tection and power distribution for all vehicle

electrical systems. The front control module controls

power to some of these vehicle systems electrical and

electromechanical loads based on inputs received

from hard wired switch inputs and data received on

the PCI bus circuit (J1850).

For information on theIntegrated Power Mod-

ule Refer to the Power Distribution Sectionof

the service manual.

OPERATION

As messages are sent over the PCI bus circuit, the

front control module reads these messages and con-

trols power to some of the vehicles electrical systems

by completing the circuit to ground (low side driver)

or completing the circuit to 12 volt power (high side

driver). The following functions areControlledby

the Front Control Module:

²Headlamp Power with Voltage Regulation

²Windshield Wiper ªON/OFFº Relay Actuation

²Windshield Wiper ªHI/LOº Relay Actuation

²Windshield Washer Pump Motor

²Fog Lamp Relay Actuation

²Park Lamp Relay Actuation

²Horn Relay Actuation

The following inputs areReceived/Monitoredby

the Front Control Module:

²B+ Connection Detection²Power Ground

²Ambient Temperature Sensing

²Ignition Switch Run

²Washer Fluid Level Switch

²Windshield Wiper Park Switch

²PCI Bus Circuit

DIAGNOSIS AND TESTING - FRONT CONTROL

MODULE

The front control module is a printed circuit board

based module with a on-board micro-processor. The

front control module interfaces with other electronic

modules in the vehicle via the Programmable Com-

munications Interface (PCI) data bus (J1850). In

order to obtain conclusive testing the Programmable

Communications Interface (PCI) data bus network

and all of the electronic modules that provide inputs

to, or receive outputs from the front control module

must be checked. All PCI (J1850) communication

faults must be resolved prior to further diagnosing

any front control module related issues.

The front control module was designed to be diag-

nosed with an appropriate diagnostic scan tool, such

as the DRB IIIt. The most reliable, efficient, and

accurate means to diagnose the front control module

requires the use of a DRB IIItscan tool and the

proper Body Diagnostic Procedures manual.

Before any testing of the front control module is

attempted, the battery should be fully charged and

all wire harness and ground connections inspected

around the affected areas on the vehicle.

REMOVAL

(1) Disconnect the positive and negative battery

cables from the battery.

(2) Partially remove the integrated power module

from the engine compartment (Refer to 8 - ELECTRI-

CAL/POWER DISTRIBUTION/INTEGRATED

POWER MODULE - REMOVAL).

(3)

Remove the front control module retaining

screws.

(4) Using both hands, pull the front control module

straightfrom the integrated power module assembly

to disconnect the 49-way electrical connector and

remove the front control module from the vehicle.

INSTALLATION

(1) Install the front control module on the inte-

grated power module assembly by pushing the

49-way electrical connector straight in.

(2) Install the front control module retaining

screws. Torque the screws to 7 in. lbs.

(3) Install the integrated power module (Refer to 8

- ELECTRICAL/POWER DISTRIBUTION/INTE-

GRATED POWER MODULE - INSTALLATION).

(4)

Connect the positive and negative battery cables.

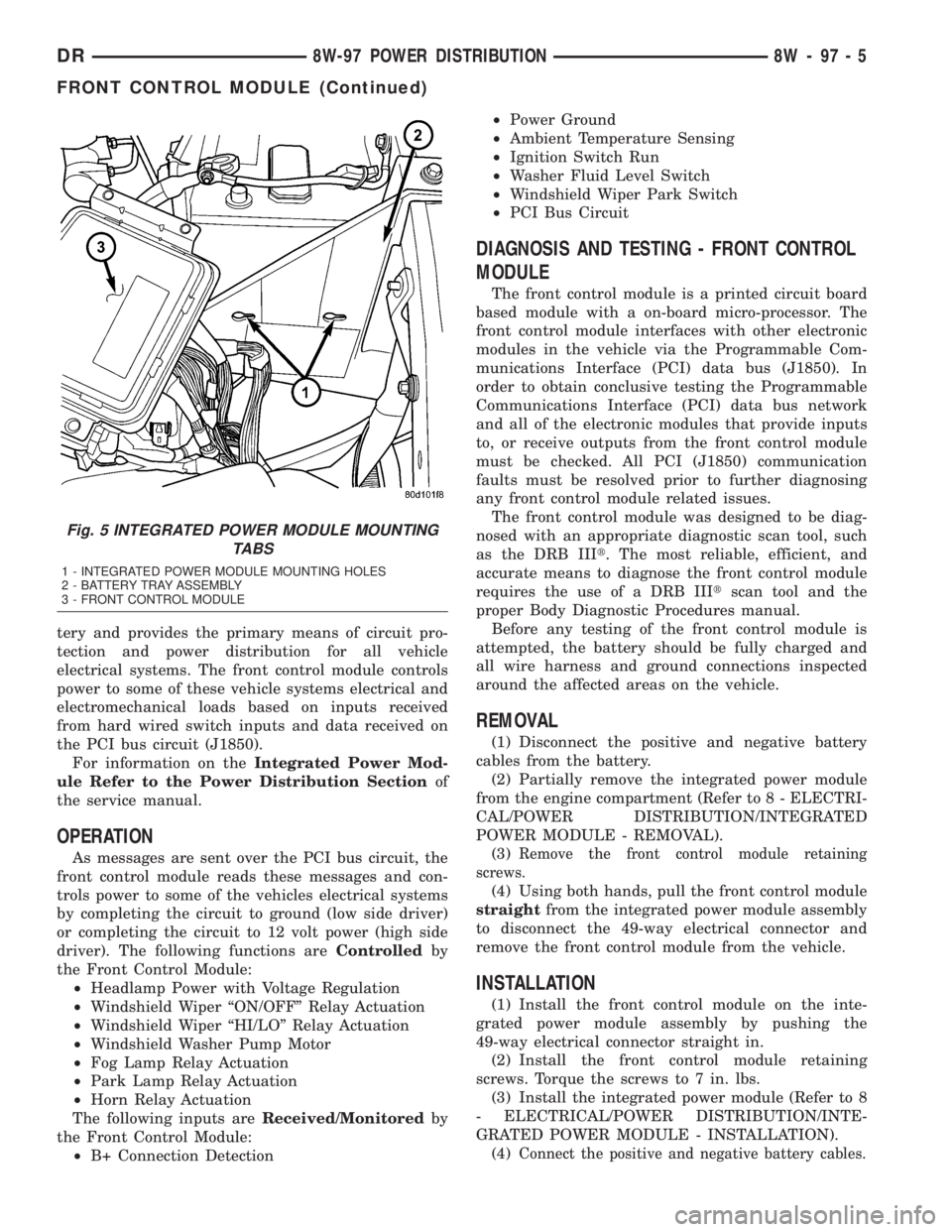

Fig. 5 INTEGRATED POWER MODULE MOUNTING

TABS

1 - INTEGRATED POWER MODULE MOUNTING HOLES

2 - BATTERY TRAY ASSEMBLY

3 - FRONT CONTROL MODULE

DR8W-97 POWER DISTRIBUTION 8W - 97 - 5

FRONT CONTROL MODULE (Continued)

Page 1245 of 2895

IOD FUSE

DESCRIPTION

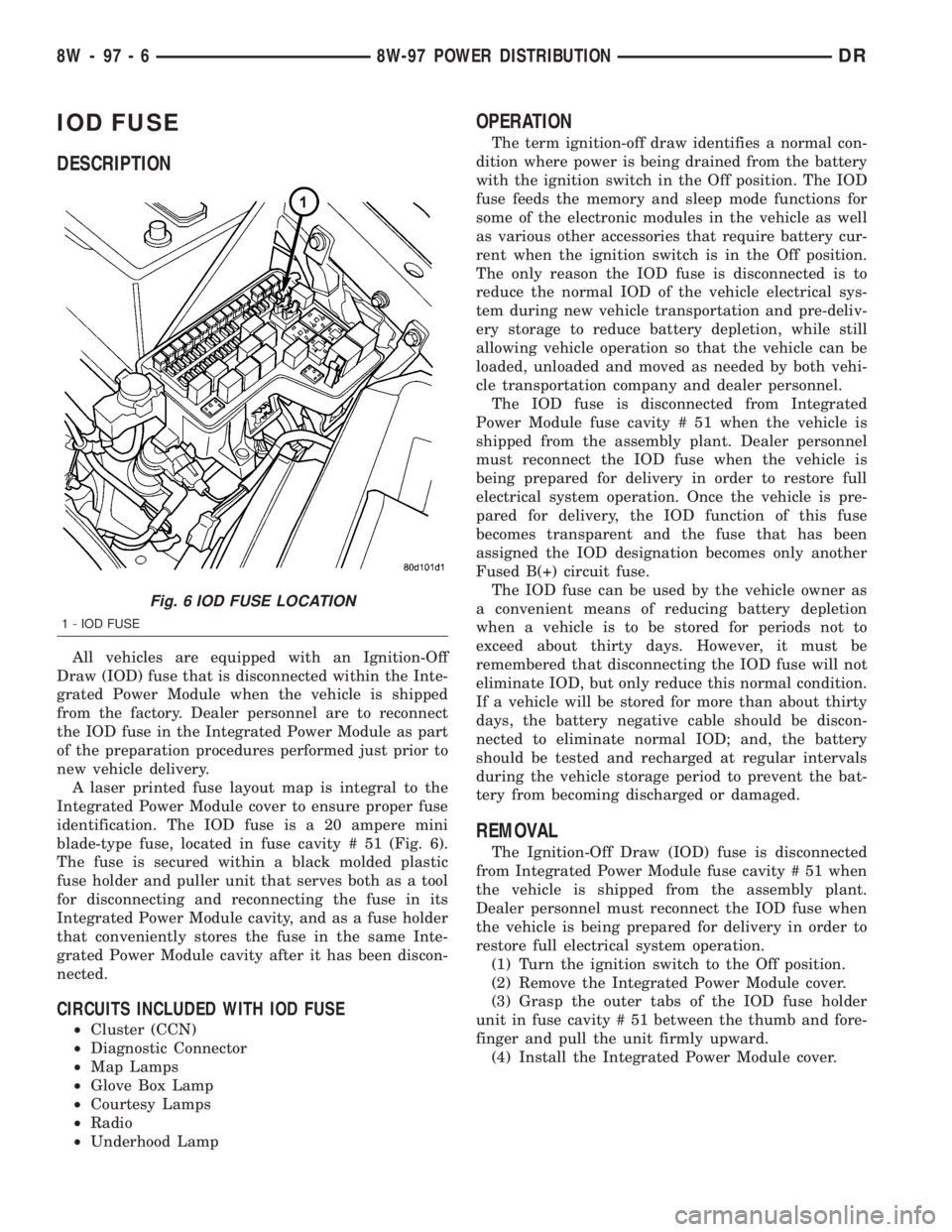

All vehicles are equipped with an Ignition-Off

Draw (IOD) fuse that is disconnected within the Inte-

grated Power Module when the vehicle is shipped

from the factory. Dealer personnel are to reconnect

the IOD fuse in the Integrated Power Module as part

of the preparation procedures performed just prior to

new vehicle delivery.

A laser printed fuse layout map is integral to the

Integrated Power Module cover to ensure proper fuse

identification. The IOD fuse is a 20 ampere mini

blade-type fuse, located in fuse cavity # 51 (Fig. 6).

The fuse is secured within a black molded plastic

fuse holder and puller unit that serves both as a tool

for disconnecting and reconnecting the fuse in its

Integrated Power Module cavity, and as a fuse holder

that conveniently stores the fuse in the same Inte-

grated Power Module cavity after it has been discon-

nected.

CIRCUITS INCLUDED WITH IOD FUSE

²Cluster (CCN)

²Diagnostic Connector

²Map Lamps

²Glove Box Lamp

²Courtesy Lamps

²Radio

²Underhood Lamp

OPERATION

The term ignition-off draw identifies a normal con-

dition where power is being drained from the battery

with the ignition switch in the Off position. The IOD

fuse feeds the memory and sleep mode functions for

some of the electronic modules in the vehicle as well

as various other accessories that require battery cur-

rent when the ignition switch is in the Off position.

The only reason the IOD fuse is disconnected is to

reduce the normal IOD of the vehicle electrical sys-

tem during new vehicle transportation and pre-deliv-

ery storage to reduce battery depletion, while still

allowing vehicle operation so that the vehicle can be

loaded, unloaded and moved as needed by both vehi-

cle transportation company and dealer personnel.

The IOD fuse is disconnected from Integrated

Power Module fuse cavity # 51 when the vehicle is

shipped from the assembly plant. Dealer personnel

must reconnect the IOD fuse when the vehicle is

being prepared for delivery in order to restore full

electrical system operation. Once the vehicle is pre-

pared for delivery, the IOD function of this fuse

becomes transparent and the fuse that has been

assigned the IOD designation becomes only another

Fused B(+) circuit fuse.

The IOD fuse can be used by the vehicle owner as

a convenient means of reducing battery depletion

when a vehicle is to be stored for periods not to

exceed about thirty days. However, it must be

remembered that disconnecting the IOD fuse will not

eliminate IOD, but only reduce this normal condition.

If a vehicle will be stored for more than about thirty

days, the battery negative cable should be discon-

nected to eliminate normal IOD; and, the battery

should be tested and recharged at regular intervals

during the vehicle storage period to prevent the bat-

tery from becoming discharged or damaged.

REMOVAL

The Ignition-Off Draw (IOD) fuse is disconnected

from Integrated Power Module fuse cavity # 51 when

the vehicle is shipped from the assembly plant.

Dealer personnel must reconnect the IOD fuse when

the vehicle is being prepared for delivery in order to

restore full electrical system operation.

(1) Turn the ignition switch to the Off position.

(2) Remove the Integrated Power Module cover.

(3) Grasp the outer tabs of the IOD fuse holder

unit in fuse cavity # 51 between the thumb and fore-

finger and pull the unit firmly upward.

(4) Install the Integrated Power Module cover.

Fig. 6 IOD FUSE LOCATION

1 - IOD FUSE

8W - 97 - 6 8W-97 POWER DISTRIBUTIONDR

Page 1246 of 2895

INSTALLATION

(1) Turn the ignition switch to the Off position.

(2) Remove the Integrated Power Module cover.

(3) To install the IOD fuse, use a thumb to press

the IOD fuse holder unit in fuse cavity # 51 firmly

into the Integrated Power Module.

(4) Install the Integrated Power Module cover.

POWER OUTLET

DESCRIPTION

Two power outlets are utilized on this model. One

in the instrument panel center lower bezel and the

other in the center console. The power outlet bases

are secured by a snap fit within the instrument

panel or trim panel. A plastic protective cap snaps

into the power outlet base when the power outlet is

not being used, and hangs from the power outlet base

mount by an integral bail strap while the power out-

let is in use.

The power outlet receptacle unit and the accessory

power outlet protective cap are available for service.

The power outlet receptacle cannot be repaired and,

if faulty or damaged, it must be replaced.

OPERATION

The power outlet base or receptacle shell is con-

nected to ground, and an insulated contact in the

bottom of the shell is connected to battery current.

The power outlet receives battery voltage from a fuse

in the integrated power module at all times.

While the power outlet is very similar to a cigar

lighter base unit, it does not include the two small

spring-clip retainers inside the bottom of the recepta-

cle shell that are used to secure the cigar lighter

heating element to the insulated contact.

DIAGNOSIS AND TESTING - POWER OUTLET

For complete circuit diagrams, refer toWiring

Diagrams.

(1) Check the fused B(+) fuse in the integrated

power module. If OK, go to Step 2. If not OK, repair

the shorted circuit or component as required and

replace the faulty fuse.

(2) Check for battery voltage at the fused B(+) fuse

in the integrated power module. If OK, go to Step 3.

If not OK, repair the open fused B(+) circuit to the

battery as required.

(3) Remove the plastic protective cap from the

power outlet receptacle. Check for continuity between

the inside circumference of the power outlet recepta-

cle and a good ground. There should be continuity. If

OK, go to Step 4. If not OK, go to Step 5.(4) Check for battery voltage at the insulated con-

tact located at the back of the power outlet recepta-

cle. If not OK, go to Step 5.

(5) Disconnect and isolate the battery negative

cable. Remove the power outlet receptacle from the

instrument panel. Disconnect the wire harness con-

nector from the power outlet receptacle. Check for

continuity between the ground circuit cavity of the

power outlet wire harness connector and a good

ground. There should be continuity. If OK, go to Step

6. If not OK, repair the open ground circuit to ground

as required.

(6) Connect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

power outlet wire harness connector. If OK, replace

the faulty power outlet receptacle. If not OK, repair

the open fused B(+) circuit to the integrated power

module fuse as required.

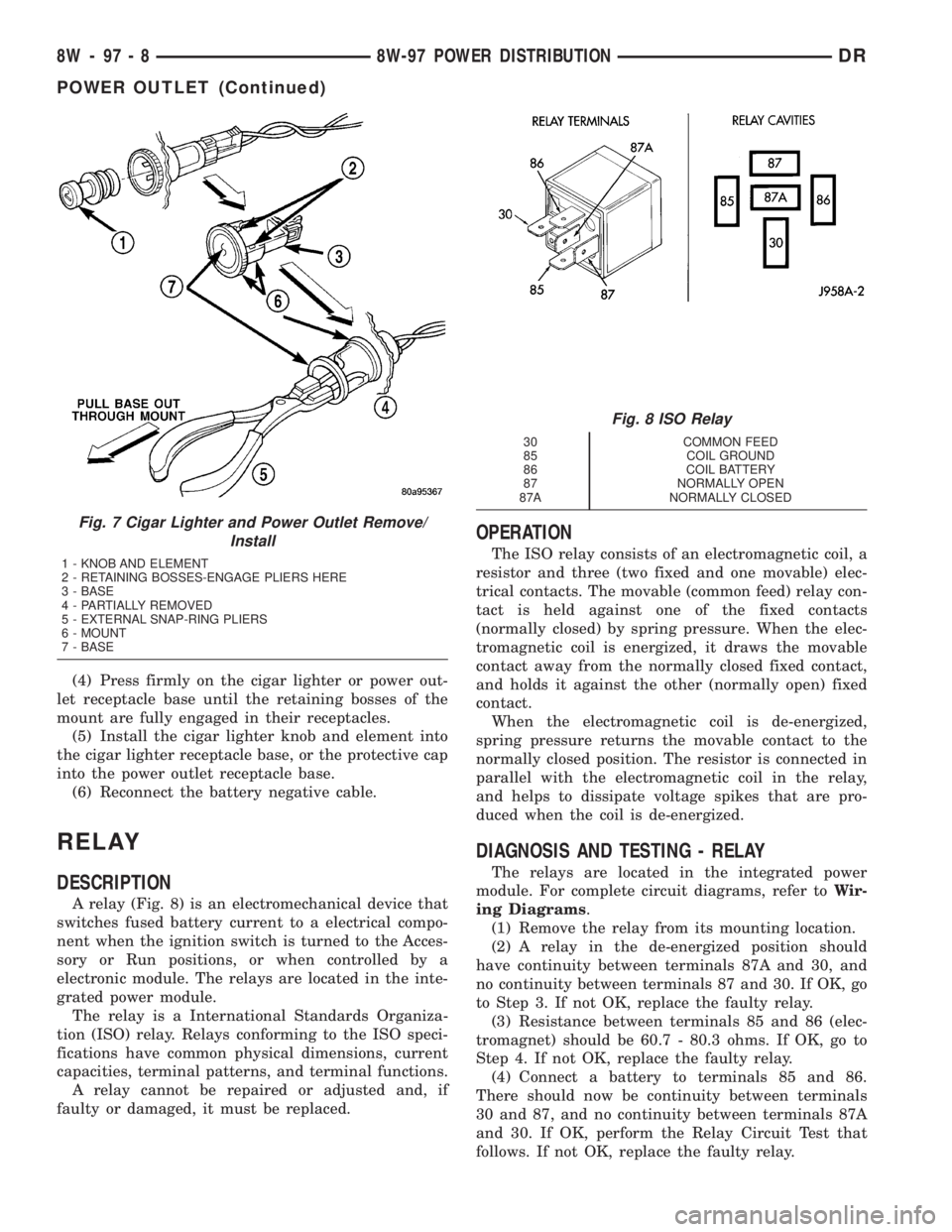

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Pull the cigar lighter knob and element out of

the cigar lighter receptacle base, or unsnap the pro-

tective cap from the power outlet receptacle base.

(3) Look inside the cigar lighter or power outlet

receptacle base and note the position of the rectangu-

lar retaining bosses of the mount that secures the

receptacle base to the panel (Fig. 7).

(4) Insert a pair of external snap ring pliers into

the cigar lighter or power outlet receptacle base and

engage the tips of the pliers with the retaining

bosses of the mount.

(5) Squeeze the pliers to disengage the mount

retaining bosses from the receptacle base and, using

a gentle rocking motion, pull the pliers and the

receptacle base out of the mount.

(6) Pull the receptacle base away from the instru-

ment panel far enough to access the instrument

panel wire harness connector.

(7) Disconnect the instrument panel wire harness

connector from the cigar lighter or power outlet

receptacle base connector receptacle.

(8) Remove the cigar lighter or power outlet mount

from the instrument panel.

INSTALLATION

(1) Reconnect the instrument panel wire harness

connector to the cigar lighter or power outlet recep-

tacle base connector receptacle.

(2) Install the cigar lighter or power outlet mount

into the instrument panel.

(3) Align the splines on the outside of the cigar

lighter or power outlet receptacle base connector

receptacle with the grooves on the inside of the

mount.

DR8W-97 POWER DISTRIBUTION 8W - 97 - 7

IOD FUSE (Continued)

Page 1247 of 2895

(4) Press firmly on the cigar lighter or power out-

let receptacle base until the retaining bosses of the

mount are fully engaged in their receptacles.

(5) Install the cigar lighter knob and element into

the cigar lighter receptacle base, or the protective cap

into the power outlet receptacle base.

(6) Reconnect the battery negative cable.

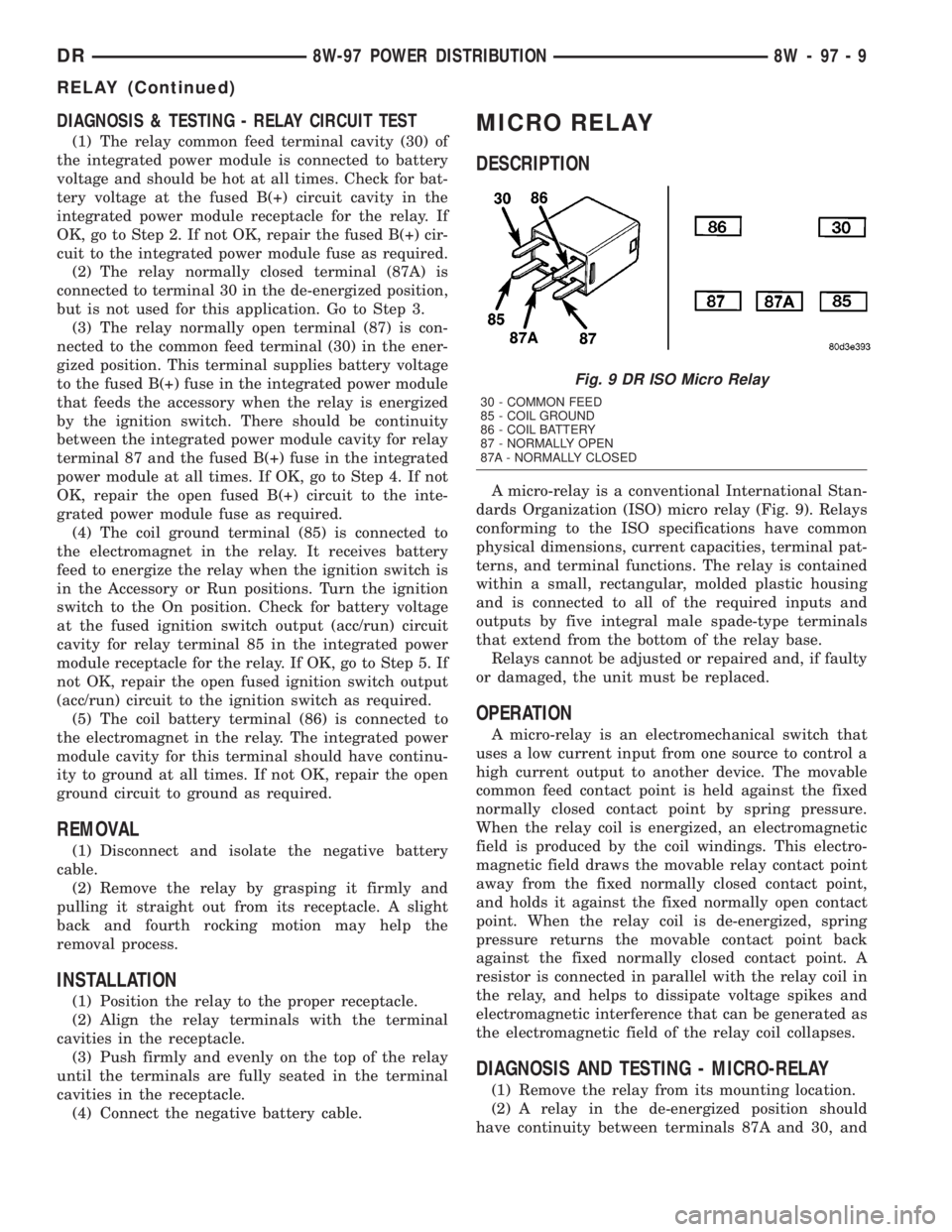

RELAY

DESCRIPTION

A relay (Fig. 8) is an electromechanical device that

switches fused battery current to a electrical compo-

nent when the ignition switch is turned to the Acces-

sory or Run positions, or when controlled by a

electronic module. The relays are located in the inte-

grated power module.

The relay is a International Standards Organiza-

tion (ISO) relay. Relays conforming to the ISO speci-

fications have common physical dimensions, current

capacities, terminal patterns, and terminal functions.

A relay cannot be repaired or adjusted and, if

faulty or damaged, it must be replaced.

OPERATION

The ISO relay consists of an electromagnetic coil, a

resistor and three (two fixed and one movable) elec-

trical contacts. The movable (common feed) relay con-

tact is held against one of the fixed contacts

(normally closed) by spring pressure. When the elec-

tromagnetic coil is energized, it draws the movable

contact away from the normally closed fixed contact,

and holds it against the other (normally open) fixed

contact.

When the electromagnetic coil is de-energized,

spring pressure returns the movable contact to the

normally closed position. The resistor is connected in

parallel with the electromagnetic coil in the relay,

and helps to dissipate voltage spikes that are pro-

duced when the coil is de-energized.

DIAGNOSIS AND TESTING - RELAY

The relays are located in the integrated power

module. For complete circuit diagrams, refer toWir-

ing Diagrams.

(1) Remove the relay from its mounting location.

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 3. If not OK, replace the faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 60.7 - 80.3 ohms. If OK, go to

Step 4. If not OK, replace the faulty relay.

(4) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, perform the Relay Circuit Test that

follows. If not OK, replace the faulty relay.

Fig. 7 Cigar Lighter and Power Outlet Remove/

Install

1 - KNOB AND ELEMENT

2 - RETAINING BOSSES-ENGAGE PLIERS HERE

3 - BASE

4 - PARTIALLY REMOVED

5 - EXTERNAL SNAP-RING PLIERS

6 - MOUNT

7 - BASE

Fig. 8 ISO Relay

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

8W - 97 - 8 8W-97 POWER DISTRIBUTIONDR

POWER OUTLET (Continued)

Page 1248 of 2895

DIAGNOSIS & TESTING - RELAY CIRCUIT TEST

(1) The relay common feed terminal cavity (30) of

the integrated power module is connected to battery

voltage and should be hot at all times. Check for bat-

tery voltage at the fused B(+) circuit cavity in the

integrated power module receptacle for the relay. If

OK, go to Step 2. If not OK, repair the fused B(+) cir-

cuit to the integrated power module fuse as required.

(2) The relay normally closed terminal (87A) is

connected to terminal 30 in the de-energized position,

but is not used for this application. Go to Step 3.

(3) The relay normally open terminal (87) is con-

nected to the common feed terminal (30) in the ener-

gized position. This terminal supplies battery voltage

to the fused B(+) fuse in the integrated power module

that feeds the accessory when the relay is energized

by the ignition switch. There should be continuity

between the integrated power module cavity for relay

terminal 87 and the fused B(+) fuse in the integrated

power module at all times. If OK, go to Step 4. If not

OK, repair the open fused B(+) circuit to the inte-

grated power module fuse as required.

(4) The coil ground terminal (85) is connected to

the electromagnet in the relay. It receives battery

feed to energize the relay when the ignition switch is

in the Accessory or Run positions. Turn the ignition

switch to the On position. Check for battery voltage

at the fused ignition switch output (acc/run) circuit

cavity for relay terminal 85 in the integrated power

module receptacle for the relay. If OK, go to Step 5. If

not OK, repair the open fused ignition switch output

(acc/run) circuit to the ignition switch as required.

(5) The coil battery terminal (86) is connected to

the electromagnet in the relay. The integrated power

module cavity for this terminal should have continu-

ity to ground at all times. If not OK, repair the open

ground circuit to ground as required.

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the relay by grasping it firmly and

pulling it straight out from its receptacle. A slight

back and fourth rocking motion may help the

removal process.

INSTALLATION

(1) Position the relay to the proper receptacle.

(2) Align the relay terminals with the terminal

cavities in the receptacle.

(3) Push firmly and evenly on the top of the relay

until the terminals are fully seated in the terminal

cavities in the receptacle.

(4) Connect the negative battery cable.

MICRO RELAY

DESCRIPTION

A micro-relay is a conventional International Stan-

dards Organization (ISO) micro relay (Fig. 9). Relays

conforming to the ISO specifications have common

physical dimensions, current capacities, terminal pat-

terns, and terminal functions. The relay is contained

within a small, rectangular, molded plastic housing

and is connected to all of the required inputs and

outputs by five integral male spade-type terminals

that extend from the bottom of the relay base.

Relays cannot be adjusted or repaired and, if faulty

or damaged, the unit must be replaced.

OPERATION

A micro-relay is an electromechanical switch that

uses a low current input from one source to control a

high current output to another device. The movable

common feed contact point is held against the fixed

normally closed contact point by spring pressure.

When the relay coil is energized, an electromagnetic

field is produced by the coil windings. This electro-

magnetic field draws the movable relay contact point

away from the fixed normally closed contact point,

and holds it against the fixed normally open contact

point. When the relay coil is de-energized, spring

pressure returns the movable contact point back

against the fixed normally closed contact point. A

resistor is connected in parallel with the relay coil in

the relay, and helps to dissipate voltage spikes and

electromagnetic interference that can be generated as

the electromagnetic field of the relay coil collapses.

DIAGNOSIS AND TESTING - MICRO-RELAY

(1) Remove the relay from its mounting location.

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

Fig. 9 DR ISO Micro Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

DR8W-97 POWER DISTRIBUTION 8W - 97 - 9

RELAY (Continued)

Page 1723 of 2895

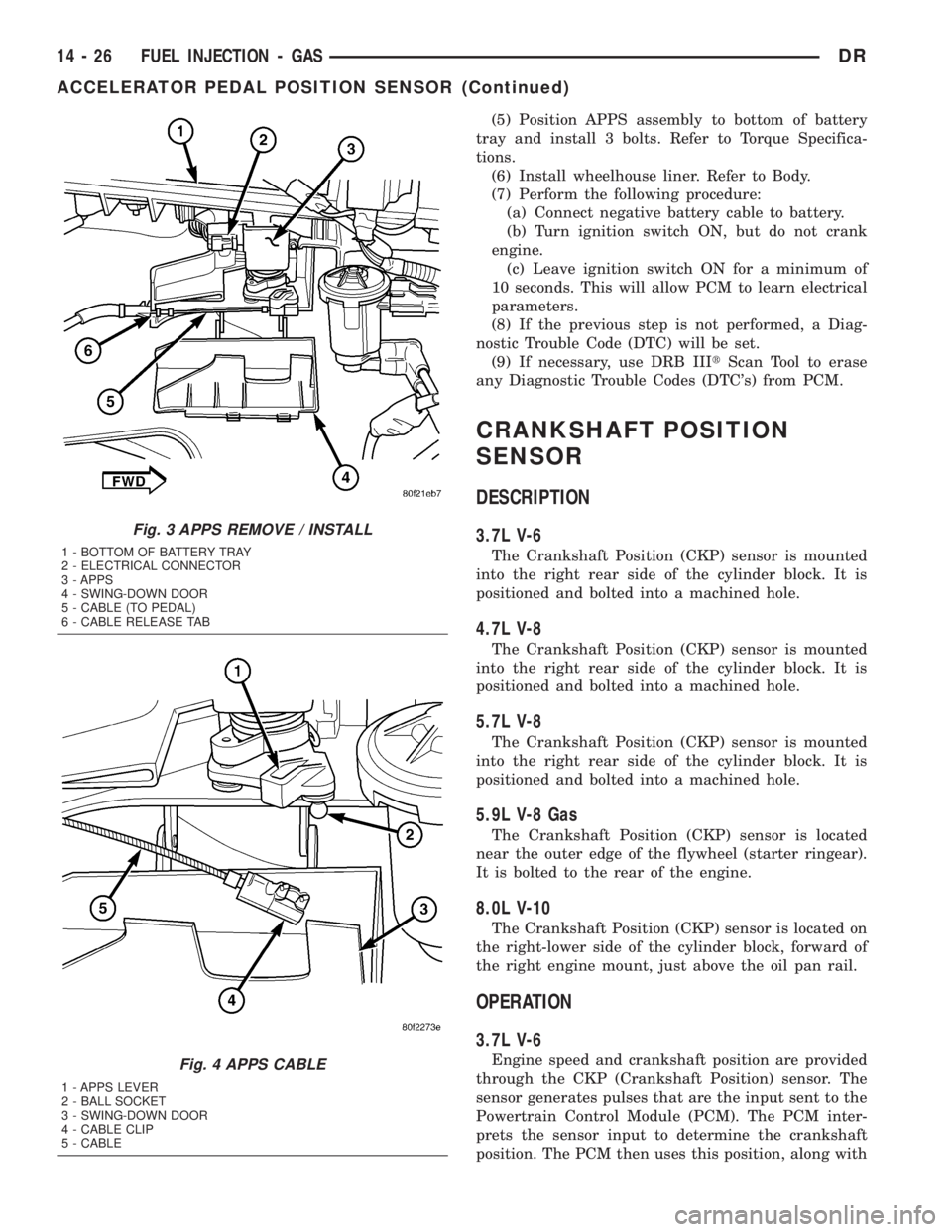

(5) Position APPS assembly to bottom of battery

tray and install 3 bolts. Refer to Torque Specifica-

tions.

(6) Install wheelhouse liner. Refer to Body.

(7) Perform the following procedure:

(a) Connect negative battery cable to battery.

(b) Turn ignition switch ON, but do not crank

engine.

(c) Leave ignition switch ON for a minimum of

10 seconds. This will allow PCM to learn electrical

parameters.

(8) If the previous step is not performed, a Diag-

nostic Trouble Code (DTC) will be set.

(9) If necessary, use DRB IIItScan Tool to erase

any Diagnostic Trouble Codes (DTC's) from PCM.

CRANKSHAFT POSITION

SENSOR

DESCRIPTION

3.7L V-6

The Crankshaft Position (CKP) sensor is mounted

into the right rear side of the cylinder block. It is

positioned and bolted into a machined hole.

4.7L V-8

The Crankshaft Position (CKP) sensor is mounted

into the right rear side of the cylinder block. It is

positioned and bolted into a machined hole.

5.7L V-8

The Crankshaft Position (CKP) sensor is mounted

into the right rear side of the cylinder block. It is

positioned and bolted into a machined hole.

5.9L V-8 Gas

The Crankshaft Position (CKP) sensor is located

near the outer edge of the flywheel (starter ringear).

It is bolted to the rear of the engine.

8.0L V-10

The Crankshaft Position (CKP) sensor is located on

the right-lower side of the cylinder block, forward of

the right engine mount, just above the oil pan rail.

OPERATION

3.7L V-6

Engine speed and crankshaft position are provided

through the CKP (Crankshaft Position) sensor. The

sensor generates pulses that are the input sent to the

Powertrain Control Module (PCM). The PCM inter-

prets the sensor input to determine the crankshaft

position. The PCM then uses this position, along with

Fig. 3 APPS REMOVE / INSTALL

1 - BOTTOM OF BATTERY TRAY

2 - ELECTRICAL CONNECTOR

3 - APPS

4 - SWING-DOWN DOOR

5 - CABLE (TO PEDAL)

6 - CABLE RELEASE TAB

Fig. 4 APPS CABLE

1 - APPS LEVER

2 - BALL SOCKET

3 - SWING-DOWN DOOR

4 - CABLE CLIP

5 - CABLE

14 - 26 FUEL INJECTION - GASDR

ACCELERATOR PEDAL POSITION SENSOR (Continued)

Page 1729 of 2895

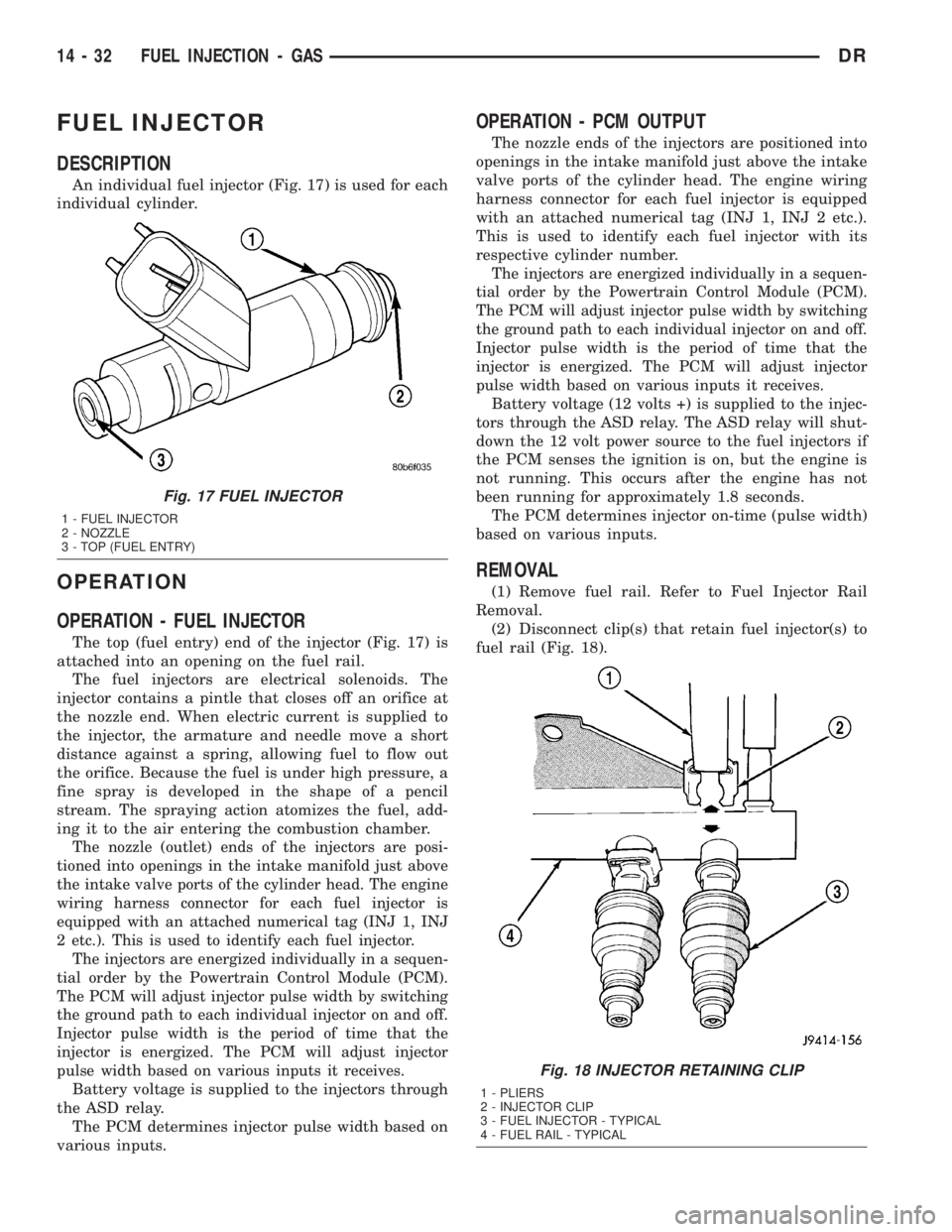

FUEL INJECTOR

DESCRIPTION

An individual fuel injector (Fig. 17) is used for each

individual cylinder.

OPERATION

OPERATION - FUEL INJECTOR

The top (fuel entry) end of the injector (Fig. 17) is

attached into an opening on the fuel rail.

The fuel injectors are electrical solenoids. The

injector contains a pintle that closes off an orifice at

the nozzle end. When electric current is supplied to

the injector, the armature and needle move a short

distance against a spring, allowing fuel to flow out

the orifice. Because the fuel is under high pressure, a

fine spray is developed in the shape of a pencil

stream. The spraying action atomizes the fuel, add-

ing it to the air entering the combustion chamber.

The nozzle (outlet) ends of the injectors are posi-

tioned into openings in the intake manifold just above

the intake valve ports of the cylinder head. The engine

wiring harness connector for each fuel injector is

equipped with an attached numerical tag (INJ 1, INJ

2 etc.). This is used to identify each fuel injector.

The injectors are energized individually in a sequen-

tial order by the Powertrain Control Module (PCM).

The PCM will adjust injector pulse width by switching

the ground path to each individual injector on and off.

Injector pulse width is the period of time that the

injector is energized. The PCM will adjust injector

pulse width based on various inputs it receives.

Battery voltage is supplied to the injectors through

the ASD relay.

The PCM determines injector pulse width based on

various inputs.

OPERATION - PCM OUTPUT

The nozzle ends of the injectors are positioned into

openings in the intake manifold just above the intake

valve ports of the cylinder head. The engine wiring

harness connector for each fuel injector is equipped

with an attached numerical tag (INJ 1, INJ 2 etc.).

This is used to identify each fuel injector with its

respective cylinder number.

The injectors are energized individually in a sequen-

tial order by the Powertrain Control Module (PCM).

The PCM will adjust injector pulse width by switching

the ground path to each individual injector on and off.

Injector pulse width is the period of time that the

injector is energized. The PCM will adjust injector

pulse width based on various inputs it receives.

Battery voltage (12 volts +) is supplied to the injec-

tors through the ASD relay. The ASD relay will shut-

down the 12 volt power source to the fuel injectors if

the PCM senses the ignition is on, but the engine is

not running. This occurs after the engine has not

been running for approximately 1.8 seconds.

The PCM determines injector on-time (pulse width)

based on various inputs.

REMOVAL

(1) Remove fuel rail. Refer to Fuel Injector Rail

Removal.

(2) Disconnect clip(s) that retain fuel injector(s) to

fuel rail (Fig. 18).

Fig. 17 FUEL INJECTOR

1 - FUEL INJECTOR

2 - NOZZLE

3 - TOP (FUEL ENTRY)

Fig. 18 INJECTOR RETAINING CLIP

1 - PLIERS

2 - INJECTOR CLIP

3 - FUEL INJECTOR - TYPICAL

4 - FUEL RAIL - TYPICAL

14 - 32 FUEL INJECTION - GASDR

Page 1743 of 2895

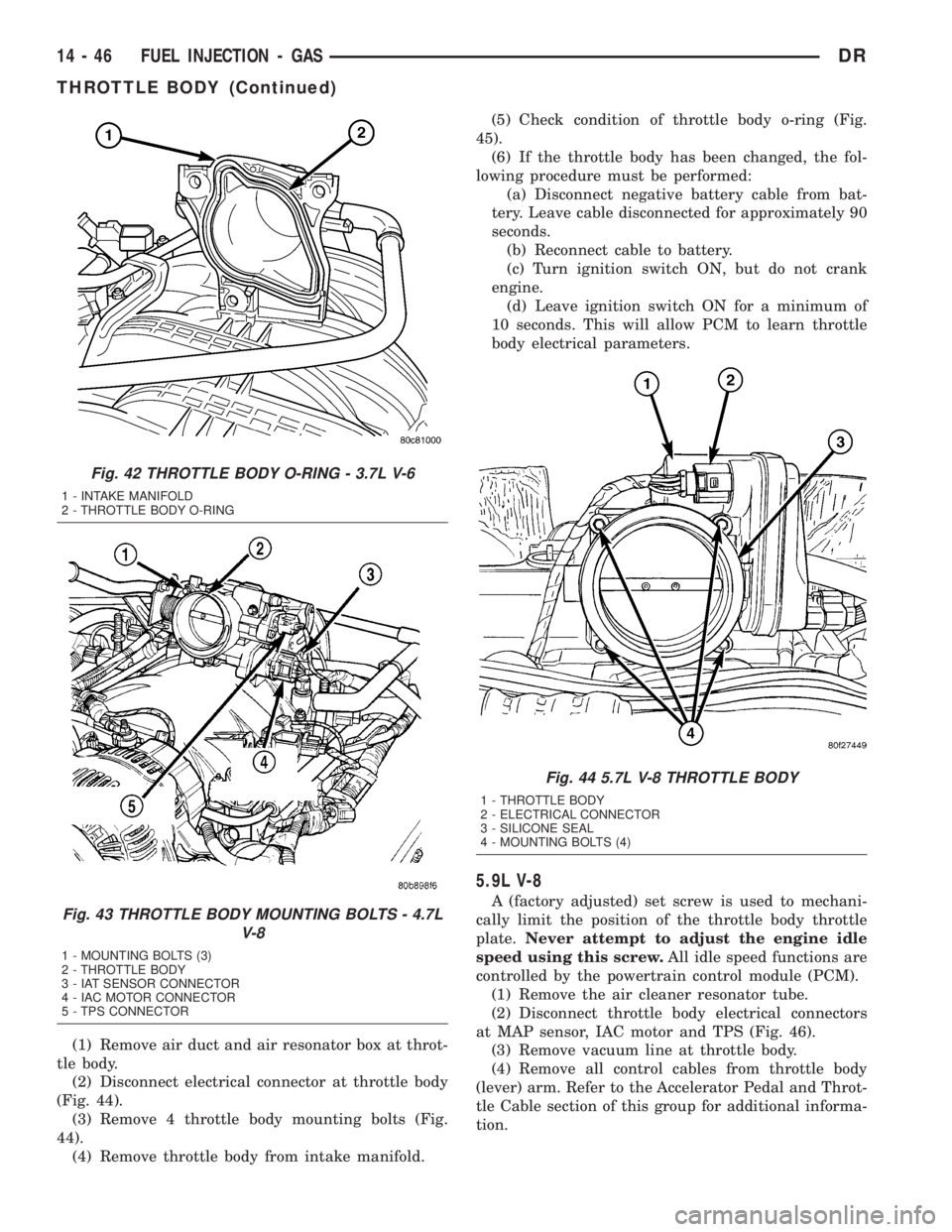

(1) Remove air duct and air resonator box at throt-

tle body.

(2) Disconnect electrical connector at throttle body

(Fig. 44).

(3) Remove 4 throttle body mounting bolts (Fig.

44).

(4) Remove throttle body from intake manifold.(5) Check condition of throttle body o-ring (Fig.

45).

(6) If the throttle body has been changed, the fol-

lowing procedure must be performed:

(a) Disconnect negative battery cable from bat-

tery. Leave cable disconnected for approximately 90

seconds.

(b) Reconnect cable to battery.

(c) Turn ignition switch ON, but do not crank

engine.

(d) Leave ignition switch ON for a minimum of

10 seconds. This will allow PCM to learn throttle

body electrical parameters.

5.9L V-8

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the powertrain control module (PCM).

(1) Remove the air cleaner resonator tube.

(2) Disconnect throttle body electrical connectors

at MAP sensor, IAC motor and TPS (Fig. 46).

(3) Remove vacuum line at throttle body.

(4) Remove all control cables from throttle body

(lever) arm. Refer to the Accelerator Pedal and Throt-

tle Cable section of this group for additional informa-

tion.

Fig. 42 THROTTLE BODY O-RING - 3.7L V-6

1 - INTAKE MANIFOLD

2 - THROTTLE BODY O-RING

Fig. 43 THROTTLE BODY MOUNTING BOLTS - 4.7L

V-8

1 - MOUNTING BOLTS (3)

2 - THROTTLE BODY

3 - IAT SENSOR CONNECTOR

4 - IAC MOTOR CONNECTOR

5 - TPS CONNECTOR

Fig. 44 5.7L V-8 THROTTLE BODY

1 - THROTTLE BODY

2 - ELECTRICAL CONNECTOR

3 - SILICONE SEAL

4 - MOUNTING BOLTS (4)

14 - 46 FUEL INJECTION - GASDR

THROTTLE BODY (Continued)

Page 1745 of 2895

(6) Install control cables.

(7) Install electrical connectors.

(8) Install necessary vacuum lines.

(9) Install air plenum.

4.7L V-8

(1) Clean throttle body-to-intake manifold o-ring.

(2) Clean mating surfaces of throttle body and

intake manifold.

(3) Install throttle body to intake manifold by posi-

tioning throttle body to manifold alignment pins.

(4) Install three mounting bolts. Tighten bolts to

12 N´m (105 in. lbs.) torque.

(5) Install control cables.

(6) Install vacuum line to throttle body.

(7) Install electrical connectors.

(8) Install air plenum.

5.7L V-8

CAUTION: Do not use spray (carb) cleaners on any

part of the throttle body. Do not apply silicone lubri-

cants to any part of the throttle body.

(1) Clean and check condition of throttle body-to-

intake manifold o-ring.

(2) Clean mating surfaces of throttle body and

intake manifold.(3) Install throttle body to intake manifold by posi-

tioning throttle body to manifold alignment pins.

(4) Install 4 mounting bolts. Refer to Torque Spec-

ifications.

(5) Install electrical connector.

(6) Install air plenum.

(7)If the throttle body has been changed, the

following procedure must be performed:

(a) Disconnect negative battery cable from bat-

tery. Leave cable disconnected for approximately 90

seconds.

(b) Reconnect cable to battery.

(c) Turn ignition switch ON, but do not crank

engine.

(d) Leave ignition switch ON for a minimum of

10 seconds. This will allow PCM to learn throttle

body electrical parameters.

5.9L V-8

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the powertrain control module (PCM).

(1) Clean the mating surfaces of the throttle body

and the intake manifold.

(2) Install new throttle body-to-intake manifold

gasket.

(3) Install throttle body to intake manifold.

(4) Install four mounting bolts. Tighten bolts to 23

N´m (200 in. lbs.) torque.

(5) Install control cables.

(6) Install vacuum line to throttle body.

(7) Install electrical connectors.

(8) Install air plenum.

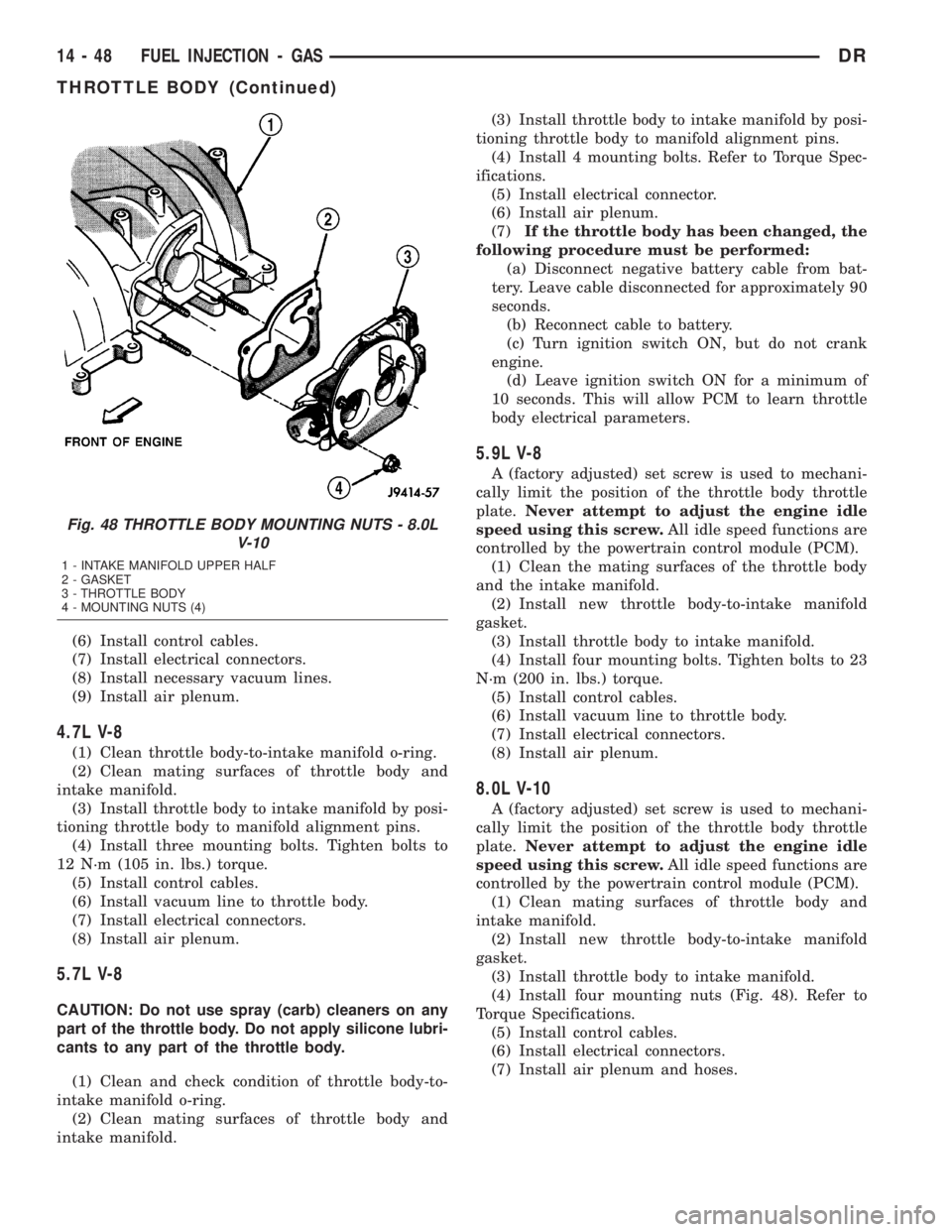

8.0L V-10

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the powertrain control module (PCM).

(1) Clean mating surfaces of throttle body and

intake manifold.

(2) Install new throttle body-to-intake manifold

gasket.

(3) Install throttle body to intake manifold.

(4) Install four mounting nuts (Fig. 48). Refer to

Torque Specifications.

(5) Install control cables.

(6) Install electrical connectors.

(7) Install air plenum and hoses.

Fig. 48 THROTTLE BODY MOUNTING NUTS - 8.0L

V-10

1 - INTAKE MANIFOLD UPPER HALF

2 - GASKET

3 - THROTTLE BODY

4 - MOUNTING NUTS (4)

14 - 48 FUEL INJECTION - GASDR

THROTTLE BODY (Continued)