airbag DODGE RAM 2003 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 454 of 2895

inoperative heated seat switch indicator lamps and

the heated seat elements do not heat, proceed. If the

problem being diagnosed involves inoperative heated

seat switch indicator lamps and the heated seat ele-

ments do heat, go to Step 6. If the problem being

diagnosed involves a heated seat switch indicator

lamp that remains illuminated after the heated seat

has been turned Off, (Refer to 8 - ELECTRICAL/

ELECTRONIC CONTROL MODULES/MEMORY

HEATED SEAT/MIRROR MODULE - DIAGNOSIS

AND TESTING).

(2) Disconnect and isolate the battery negative

cable. Remove the heated seat switch and bezel unit

from the instrument panel. Disconnect the heated

seat switch to be tested. Check for continuity

between the ground circuit cavity of the heated seat

switch and a good ground. There should be continu-

ity. If OK, go to Step 3. If not OK, repair the open

ground circuit to ground as required.

(3) Reconnect the battery negative cable. Turn the

park lamps on with the headlamp switch. Rotate the

panel lamps dimmer thumb wheel on the headlamp

switch upward to just before the interior lamps

detent. Check for battery voltage at the fused panel

lamps dimmer circuit cavity of the heated seat

switch. If OK, go to Step 4. If not OK, repair the

open fused panel lamps dimmer switch signal circuit

to the fuse in the Integrated Power Module as

required.

(4) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run) circuit cavity of the heated seat switch.

If OK, go to Step 5. If not OK, repair the open fused

ignition switch output (run) circuit as required.

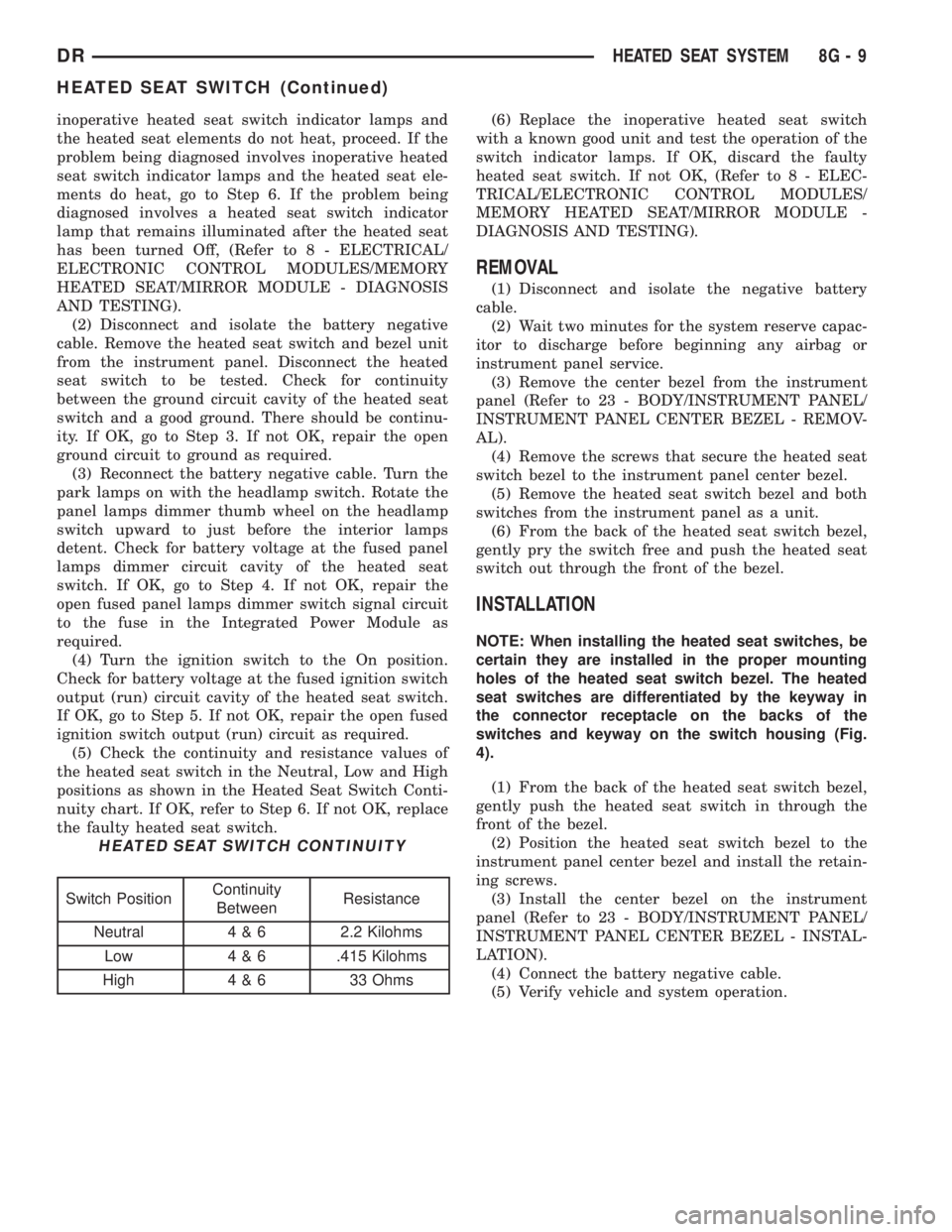

(5) Check the continuity and resistance values of

the heated seat switch in the Neutral, Low and High

positions as shown in the Heated Seat Switch Conti-

nuity chart. If OK, refer to Step 6. If not OK, replace

the faulty heated seat switch.

HEATED SEAT SWITCH CONTINUITY

Switch PositionContinuity

BetweenResistance

Neutral 4 & 6 2.2 Kilohms

Low 4 & 6 .415 Kilohms

High 4 & 6 33 Ohms(6) Replace the inoperative heated seat switch

with a known good unit and test the operation of the

switch indicator lamps. If OK, discard the faulty

heated seat switch. If not OK, (Refer to 8 - ELEC-

TRICAL/ELECTRONIC CONTROL MODULES/

MEMORY HEATED SEAT/MIRROR MODULE -

DIAGNOSIS AND TESTING).

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Wait two minutes for the system reserve capac-

itor to discharge before beginning any airbag or

instrument panel service.

(3) Remove the center bezel from the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL - REMOV-

AL).

(4) Remove the screws that secure the heated seat

switch bezel to the instrument panel center bezel.

(5) Remove the heated seat switch bezel and both

switches from the instrument panel as a unit.

(6) From the back of the heated seat switch bezel,

gently pry the switch free and push the heated seat

switch out through the front of the bezel.

INSTALLATION

NOTE: When installing the heated seat switches, be

certain they are installed in the proper mounting

holes of the heated seat switch bezel. The heated

seat switches are differentiated by the keyway in

the connector receptacle on the backs of the

switches and keyway on the switch housing (Fig.

4).

(1) From the back of the heated seat switch bezel,

gently push the heated seat switch in through the

front of the bezel.

(2) Position the heated seat switch bezel to the

instrument panel center bezel and install the retain-

ing screws.

(3) Install the center bezel on the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL - INSTAL-

LATION).

(4) Connect the battery negative cable.

(5) Verify vehicle and system operation.

DRHEATED SEAT SYSTEM 8G - 9

HEATED SEAT SWITCH (Continued)

Page 456 of 2895

HORN

TABLE OF CONTENTS

page page

HORN SYSTEM

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING - HORN SYSTEM . . . 1

HORN

DIAGNOSIS AND TESTING - HORN..........1REMOVAL.............................2

INSTALLATION..........................2

HORN SWITCH

DESCRIPTION..........................2

DIAGNOSIS AND TESTING - HORN SWITCH . . . 2

HORN SYSTEM

DESCRIPTION

The dual-note horn system features dual electro-

magnetic horn units. The horn system includes the

following major components:

²Horn- The two horns are located on the left

side of the engine compartment below the Integrated

Power Module (IPM).

²Horn Switch- The horn switch is molded into

the driver airbag trim cover.

OPERATION

The horn system operates on battery current

received through a fuse in the Integrated Power

Module (IPM). The horn system circuit is designed so

that the system will remain operational, regardless

of the ignition switch position.

DIAGNOSIS AND TESTING - HORN SYSTEM

The most reliable, efficient, and accurate

means to diagnose the horn system requires the

use of a DRBIIItscan tool and the proper Diag-

nostic Procedures manual. The DRBIIItscan

tool can provide confirmation that the PCI data

bus is functional, that all of the electronic mod-

ules are sending and receiving the proper mes-

sages on the PCI data bus, and that the horns

are being sent the proper hard wired outputs

for them to perform their functions.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

In most cases, any problem involving continually

sounding horns can be quickly alleviated by removing

the horn fuse from the Integrated Power Module

(IPM).WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

HORN

DIAGNOSIS AND TESTING - HORN

The most reliable, efficient, and accurate

means to diagnose the horn system requires the

use of a DRBIIItscan tool and the proper Diag-

nostic Procedures manual. The DRBIIItscan

tool can provide confirmation that the PCI data

bus is functional, that all of the electronic mod-

ules are sending and receiving the proper mes-

sages on the PCI data bus, and that the horns

are being sent the proper hard wired outputs

for them to perform their functions.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

DRHORN 8H - 1

Page 457 of 2895

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

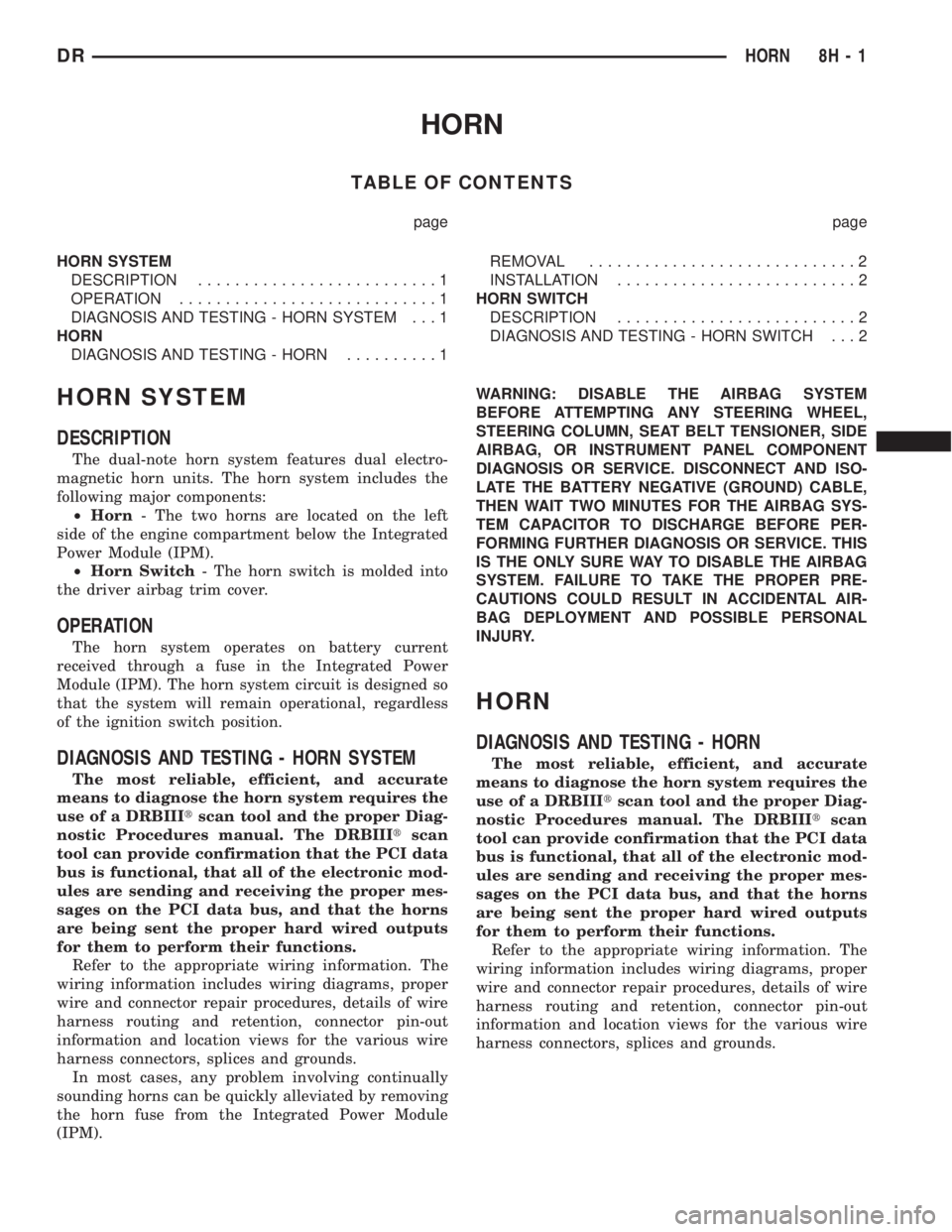

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Disconnect the wire harness connectors from

the horns (Fig. 1).

(3) Remove mounting bolt and remove horns.

INSTALLATION

(1) Position horns and install mounting bolt.

Tighten the bolt to 10 N´m (85 in. lbs.).

(2) Connect wire harness connectors.

(3) Connect battery negative cable.

HORN SWITCH

DESCRIPTION

The horn switch is molded into the driver airbag.

The horn switch can not be serviced separately. For

service procedures, (Refer to 8 - ELECTRICAL/RE-

STRAINTS/DRIVER AIRBAG - REMOVAL).

DIAGNOSIS AND TESTING - HORN SWITCH

The most reliable, efficient, and accurate

means to diagnose the horn system requires the

use of a DRBIIItscan tool and the proper Diag-

nostic Procedures manual. The DRBIIItscan

tool can provide confirmation that the PCI data

bus is functional, that all of the electronic mod-

ules are sending and receiving the proper mes-

sages on the PCI data bus, and that the horns

are being sent the proper hard wired outputs

for them to perform their functions.

For complete circuit diagrams, refer to the appro-

priate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

Fig. 1 HORN

1 - WIRE HARNESS CONNECTORS

2 - HORNS

3 - MOUNTING BOLT

8H - 2 HORNDR

HORN (Continued)

Page 494 of 2895

INSTRUMENT CLUSTER

TABLE OF CONTENTS

page page

INSTRUMENT CLUSTER

DESCRIPTION..........................2

OPERATION............................6

DIAGNOSIS AND TESTING - INSTRUMENT

CLUSTER...........................10

REMOVAL.............................14

DISASSEMBLY.........................14

ASSEMBLY............................15

INSTALLATION.........................16

ABS INDICATOR

DESCRIPTION.........................17

OPERATION...........................17

AIRBAG INDICATOR

DESCRIPTION.........................18

OPERATION...........................18

BRAKE/PARK BRAKE INDICATOR

DESCRIPTION.........................18

OPERATION...........................19

DIAGNOSIS AND TESTING - BRAKE

INDICATOR..........................19

CARGO LAMP INDICATOR

DESCRIPTION.........................20

OPERATION...........................20

CHECK GAUGES INDICATOR

DESCRIPTION.........................21

OPERATION...........................21

CRUISE INDICATOR

DESCRIPTION.........................22

OPERATION...........................22

DOOR AJAR INDICATOR

DESCRIPTION.........................23

OPERATION...........................23

ENGINE TEMPERATURE GAUGE

DESCRIPTION.........................23

OPERATION...........................23

ETC INDICATOR

DESCRIPTION.........................24

OPERATION...........................25

FUEL GAUGE

DESCRIPTION.........................25

OPERATION...........................26

GEAR SELECTOR INDICATOR

DESCRIPTION.........................26

OPERATION...........................27

HIGH BEAM INDICATOR

DESCRIPTION.........................27

OPERATION...........................28LAMP OUT INDICATOR

DESCRIPTION.........................28

OPERATION...........................28

LOW FUEL INDICATOR

DESCRIPTION.........................29

OPERATION...........................29

MALFUNCTION INDICATOR LAMP (MIL)

DESCRIPTION.........................30

OPERATION...........................30

ODOMETER

DESCRIPTION.........................31

OPERATION...........................31

OIL PRESSURE GAUGE

DESCRIPTION.........................32

OPERATION...........................32

OVERDRIVE OFF INDICATOR

DESCRIPTION.........................33

OPERATION...........................33

SEATBELT INDICATOR

DESCRIPTION.........................34

OPERATION...........................34

SECURITY INDICATOR

DESCRIPTION.........................34

OPERATION...........................35

SERVICE 4WD INDICATOR

DESCRIPTION.........................35

OPERATION...........................36

SPEEDOMETER

DESCRIPTION.........................36

OPERATION...........................36

TACHOMETER

DESCRIPTION.........................37

OPERATION...........................37

TRANS TEMP INDICATOR

DESCRIPTION.........................38

OPERATION...........................38

TURN SIGNAL INDICATOR

DESCRIPTION.........................39

OPERATION...........................39

UPSHIFT INDICATOR

DESCRIPTION.........................40

OPERATION...........................40

VOLTAGE GAUGE

DESCRIPTION.........................40

OPERATION...........................41

WAIT-TO-START INDICATOR

DESCRIPTION.........................42

OPERATION...........................42

DRINSTRUMENT CLUSTER 8J - 1

Page 496 of 2895

molded plastic cluster housing serves as the carrier

for the cluster circuit board and circuitry, the cluster

connector receptacles, the RKE interface connector,

the gauges, a Light Emitting Diode (LED) for each

cluster indicator, two VFD units, an audible tone

generator, the cluster overlay, the gauge pointers, the

odometer/trip odometer switch and the switch button.

The cluster overlay is a laminated plastic unit. The

dark, visible, outer surface of the overlay is marked

with all of the gauge dial faces and graduations, but

this layer is also translucent. The darkness of this

outer layer prevents the cluster from appearing clut-

tered or busy by concealing the cluster indicators

that are not illuminated, while the translucence of

this layer allows those indicators and icons that are

illuminated to be readily visible. The underlying

layer of the overlay is opaque and allows light from

the LED for each of the various indicators and the

incandescent illumination lamps behind it to be visi-

ble through the outer layer of the overlay only

through predetermined stencil-like cutouts. A rectan-

gular opening in the overlay at the base of both the

speedometer and tachometer dial faces has a smoked

clear lens through which the illuminated VFD units

can be viewed.

Several versions of the EMIC module are offered

on this model. These versions accommodate all of the

variations of optional equipment and regulatory

requirements for the various markets in which the

vehicle will be offered. The microprocessor-based

EMIC utilizes integrated circuitry and information

carried on the Programmable Communications Inter-

face (PCI) data bus network along with several hard

wired analog and multiplexed inputs to monitor sen-

sors and switches throughout the vehicle. In response

to those inputs, the internal circuitry and program-

ming of the EMIC allow it to control and integrate

many electronic functions and features of the vehicle

through both hard wired outputs and the transmis-

sion of electronic message outputs to other electronic

modules in the vehicle over the PCI data bus. (Refer

to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/COMMUNICATION - DESCRIPTION -

PCI BUS).

Besides typical instrument cluster gauge and indi-

cator support, the electronic functions and features

that the EMIC supports or controls include the fol-

lowing:

²Audible Warnings- The EMIC electronic cir-

cuit board is equipped with an audible tone generator

and programming that allows it to provide various

audible alerts to the vehicle operator, including

chime tones and beep tones. An electromechanical

relay is also soldered onto the circuit board to pro-

duce audible clicks that emulate the sound of a con-

ventional turn signal or hazard warning flasher.(Refer to 8 - ELECTRICAL/CHIME/BUZZER -

DESCRIPTION).

²Brake Lamp Control- The EMIC provides

electronic brake lamp request messages to the Front

Control Module (FCM) located on the Integrated

Power Module (IPM) for brake lamp control, exclud-

ing control of the Center High Mounted Stop Lamp

(CHMSL), which remains controlled by a direct hard

wired output of the brake lamp switch.

²Brake Transmission Shift Interlock Control

- The EMIC monitors inputs from the brake lamp

switch, ignition switch, and the Transmission Range

Sensor (TRS), then controls a high-side driver output

to operate the Brake Transmission Shift Interlock

(BTSI) solenoid that locks and unlocks the automatic

transmission gearshift selector lever on the steering

column.

²Cargo Lamp Control- The EMIC provides

direct control of cargo lamp operation with a load

shedding (battery saver) feature which will automat-

ically turn off the cargo lamp if it remains on after a

timed interval.

²Central Locking- The EMIC provides support

for the central locking feature of the power lock sys-

tem. This feature will lock or unlock all doors based

upon the input from the door cylinder lock switch.

Door cylinder lock switches are used only on models

equipped with the optional Vehicle Theft Security

System (VTSS).

²Door Lock Inhibit- The EMIC inhibits locking

of the doors with the power lock switch when the key

is in the ignition switch and the driver side front

door is ajar. However, operation of the door locks is

not inhibited under the same conditions when the

Lock button of the optional RKE transmitter is

depressed.

²Enhanced Accident Response- The EMIC

monitors an input from the Airbag Control Module

(ACM) and, following an airbag deployment, will

immediately disable the power lock output, unlock all

doors by activating the power unlock output, then

enables the power lock output if the power lock

switch input remains inactive for two seconds. This

feature, like all other enhanced accident response

features, is dependent upon a functional vehicle elec-

trical system following the vehicle impact event.

²Exterior Lighting Control- The EMIC pro-

vides electronic head lamp and/or park lamp request

messages to the Front Control Module (FCM) located

on the Integrated Power Module (IPM) for the appro-

priate exterior lamp control of standard head and

park lamps, as well as optional front fog lamps. This

includes support for headlamp beam selection and

the optical horn feature, also known as flash-to-pass.

²Exterior Lighting Fail-safe- In the absence of

a headlamp switch input, the EMIC will turn on the

DRINSTRUMENT CLUSTER 8J - 3

INSTRUMENT CLUSTER (Continued)

Page 497 of 2895

cluster illumination lamps and provide electronic

headlamp low beam and park lamp request messages

to the Front Control Module (FCM) located on the

Integrated Power Module (IPM) for default exterior

lamp operation. The FCM will also provide default

park lamp and headlamp low beam operation and the

EMIC will turn on the cluster illumination lamps if

there is a failure of the electronic data bus commu-

nication between the EMIC and the FCM.

²Heated Seat Control- The EMIC monitors

inputs from the ignition switch and electronic engine

speed messages from the Powertrain Control Module

(PCM) to control a high side driver output to the

heated seat switch Light Emitting Diode (LED) indi-

cators. This input allows the heated seat switches to

wake up the heated seat module if the switch is actu-

ated. The EMIC will de-energize the heated seat

switch LED indicators, which deactivates the heated

seat system, if the ignition switch is turned to any

position except On or Start, or if the engine speed

message indicates zero. (Refer to 8 - ELECTRICAL/

HEATED SEATS - DESCRIPTION).

²Interior Lamp Load Shedding- The EMIC

provides a battery saver feature which will automat-

ically turn off all interior lamps that remain on after

a timed interval of about fifteen minutes.

²Interior Lamps - Enhanced Accident

Response- The EMIC monitors inputs from the Air-

bag Control Module (ACM) and the Powertrain Con-

trol Module (PCM) to automatically turn on the

interior lighting after an airbag deployment event

ten seconds after the vehicle speed is zero. The inte-

rior lighting remains illuminated until the ignition

switch is turned to the Off position, at which time

the interior lighting returns to normal operation and

control. This feature, like all other enhanced accident

response features, is dependent upon a functional

vehicle electrical system following the vehicle impact

event.

²Interior Lighting Control- The EMIC moni-

tors inputs from the interior lighting switch, the door

ajar switches, the cargo lamp switch, the reading

lamp switches, and the Remote Keyless Entry (RKE)

module to provide courtesy lamp control. This

includes support for timed illuminated entry with

theater-style fade-to-off and courtesy illumination

defeat features.

²Lamp Out Indicator Control- The EMIC

monitors electronic lamp outage messages from the

Front Control Module (FCM) located on the Inte-

grated Power Module (IPM) in order to provide lamp

out indicator control for the headlamps (low and high

beams), turn signal lamps, and the brake lamps

(excluding CHMSL).

²Panel Lamps Dimming Control- The EMIC

provides a hard wired 12-volt Pulse-Width Modulated(PWM) output that synchronizes the dimming level

of all panel lamps dimmer controlled lamps with that

of the cluster illumination lamps.

²Parade Mode- The EMIC provides a parade

mode (also known as funeral mode) that allows all

Vacuum-Fluorescent Display (VFD) units in the vehi-

cle to be illuminated at full (daytime) intensity while

driving during daylight hours with the exterior

lamps turned on.

²Power Locks- The EMIC monitors inputs from

the power lock switches and the Remote Keyless

Entry (RKE) receiver module (optional) to provide

control of the power lock motors through high side

driver outputs to the power lock motors. This

includes support for rolling door locks (also known as

automatic door locks), automatic door unlock, a door

lock inhibit mode, and central locking (with the

optional Vehicle Theft Security System only). (Refer

to 8 - ELECTRICAL/POWER LOCKS - DESCRIP-

TION).

²Remote Keyless Entry- The EMIC supports

the optional Remote Keyless Entry (RKE) system fea-

tures, including support for the RKE Lock, Unlock

(with optional driver-door-only unlock, and unlock-

all-doors), Panic, audible chirp, optical chirp, illumi-

nated entry modes, an RKE programming mode, as

well as optional Vehicle Theft Security System

(VTSS) arming (when the proper VTSS arming con-

ditions are met) and disarming.

²Remote Radio Switch Interface- The EMIC

monitors inputs from the optional remote radio

switches and then provides the appropriate electronic

data bus messages to the radio to select the radio

operating mode, volume control, preset station scan

and station seek features.

²Rolling Door Locks- The EMIC provides sup-

port for the power lock system rolling door locks fea-

ture (also known as automatic door locks). This

feature will automatically lock all unlocked doors

each time the vehicle speed reaches twenty-four kilo-

meters-per-hour (fifteen miles-per-hour) and, follow-

ing an automatic lock event, will automatically

unlock all doors once the ignition is turned to the Off

position and the driver side front door is opened.

²Turn Signal & Hazard Warning Lamp Con-

trol- The EMIC provides electronic turn and hazard

lamp request messages to the Front Control Module

(FCM) located on the Integrated Power Module (IPM)

for turn and hazard lamp control. The EMIC also

provides an audible click at one of two rates to emu-

late normal and bulb out turn or hazard flasher oper-

ation based upon electronic lamp outage messages

from the FCM, and provides an audible turn signal

on chime warning if a turn is signalled continuously

for more than about 1.6 kilometers (one mile) and

8J - 4 INSTRUMENT CLUSTERDR

INSTRUMENT CLUSTER (Continued)

Page 498 of 2895

the vehicle speed remains greater than about twenty-

four kilometers-per-hour (fifteen miles-per-hour).

²Vacuum Fluorescent Display Synchroniza-

tion- The EMIC transmits electronic panel lamp

dimming level messages which allows all other elec-

tronic modules on the PCI data bus with Vacuum

Fluorescent Display (VFD) units to coordinate their

illumination intensity with that of the EMIC VFD

units.

²Vehicle Theft Security System- The EMIC

monitors inputs from the door cylinder lock switch-

(es), the door ajar switches, the ignition switch, and

the Remote Keyless Entry (RKE) receiver module,

then provides electronic horn and lighting request

messages to the Front Control Module (FCM) located

on the Integrated Power Module (IPM) for the appro-

priate VTSS alarm output features.

²Wiper/Washer System Control- The EMIC

provides electronic wiper and/or washer request mes-

sages to the Front Control Module (FCM) located on

the Integrated Power Module (IPM) for the appropri-

ate wiper and washer system features. (Refer to 8 -

ELECTRICAL/WIPERS/WASHERS - DESCRIP-

TION).

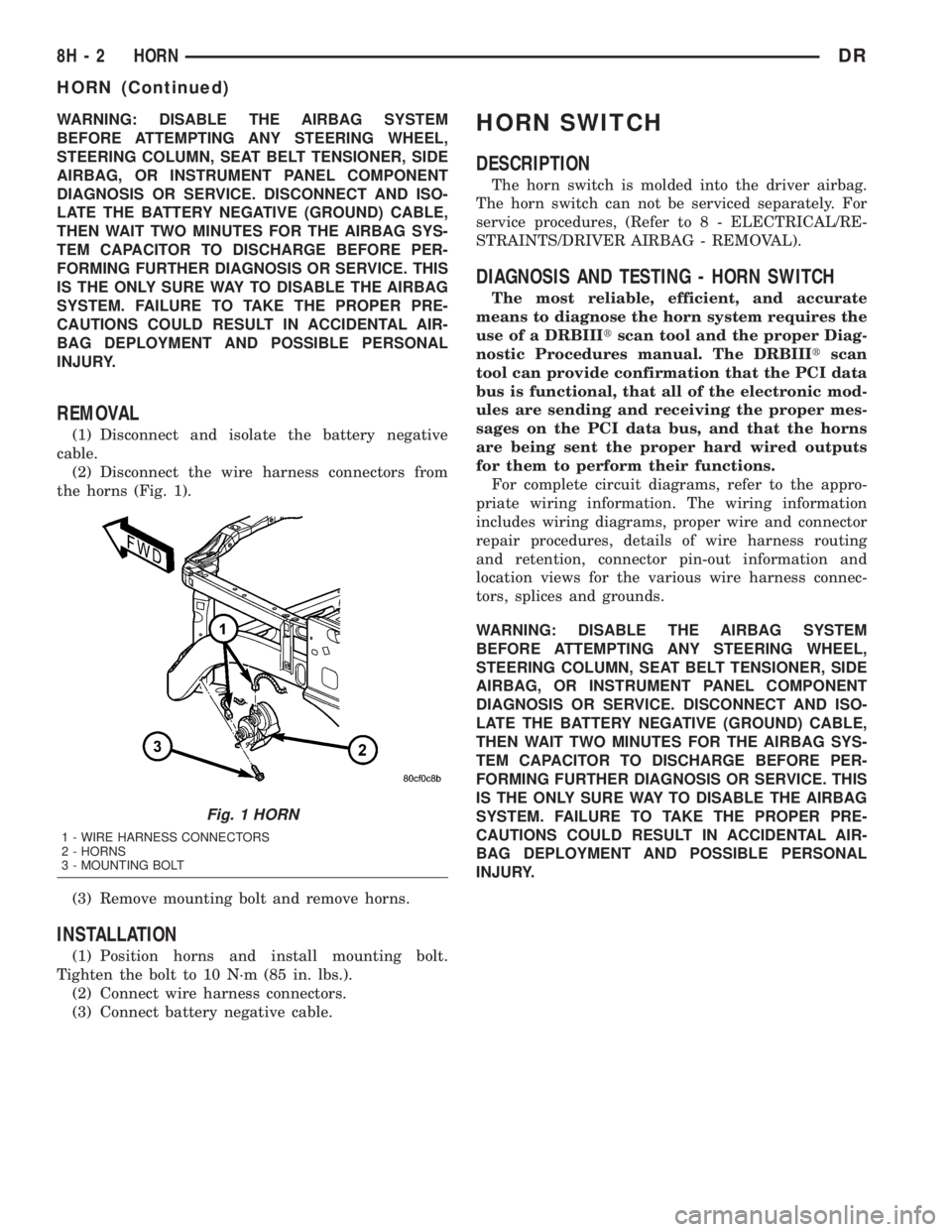

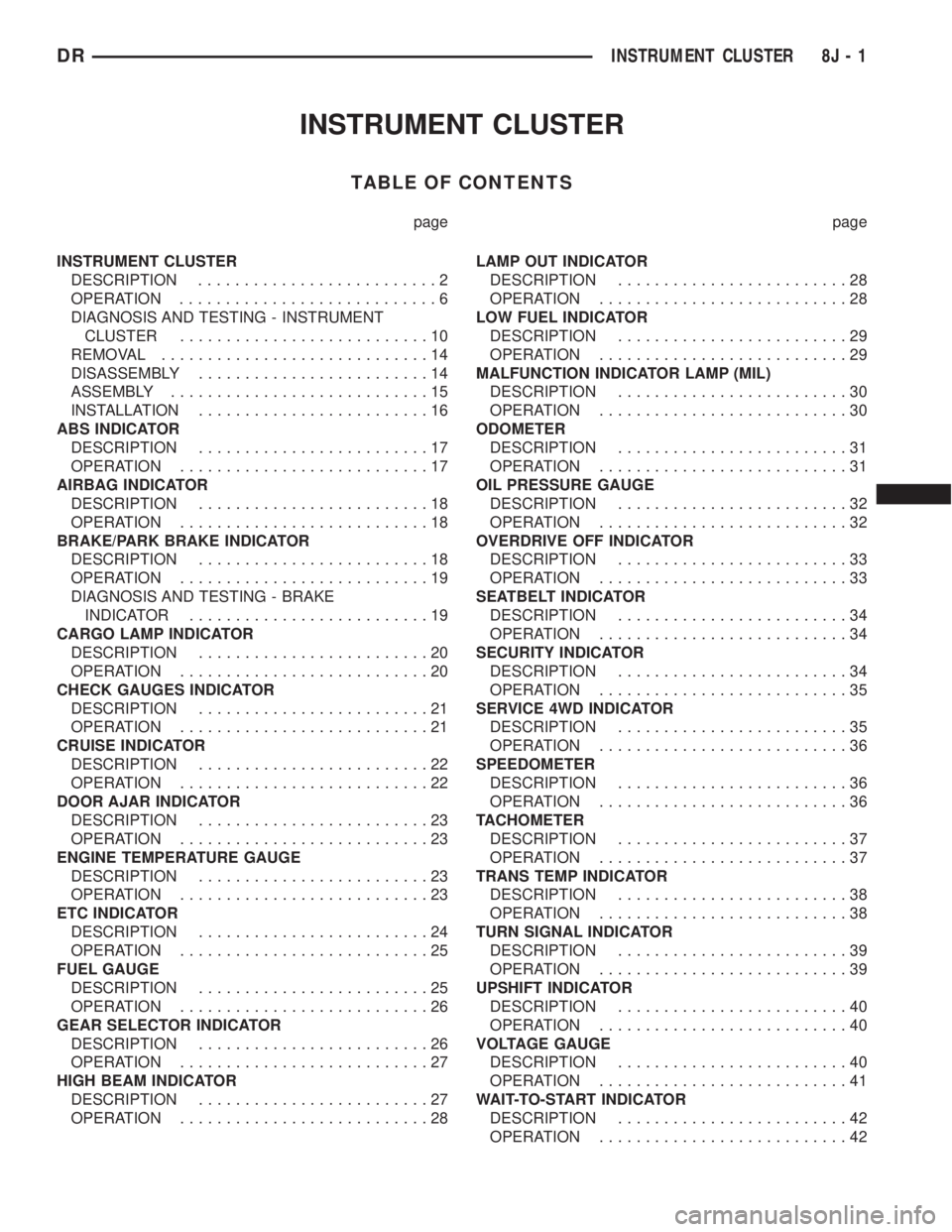

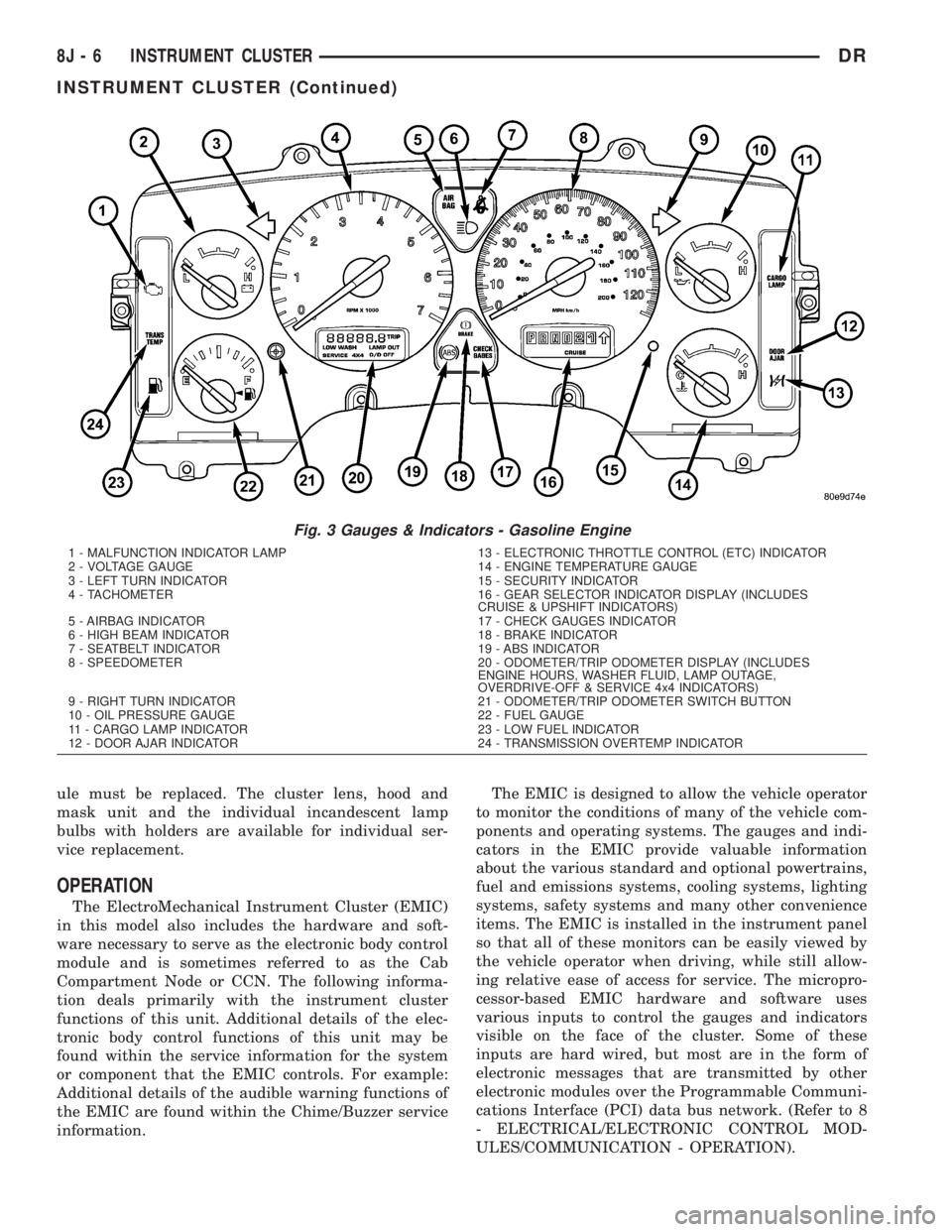

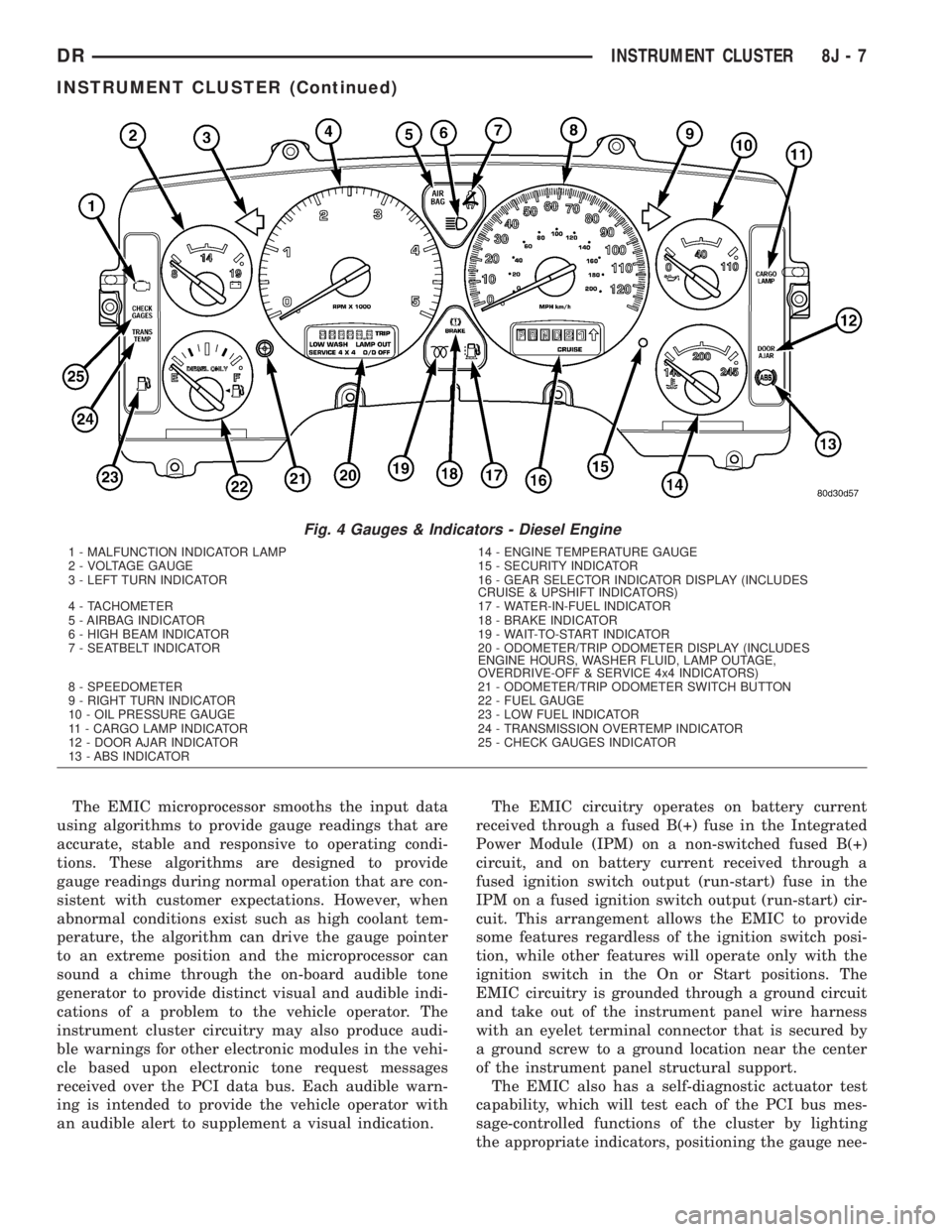

The EMIC houses six analog gauges and has pro-

visions for up to twenty-three indicators (Fig. 3) or

(Fig. 4). The EMIC includes the following analog

gauges:

²Coolant Temperature Gauge

²Fuel Gauge

²Oil Pressure Gauge

²Speedometer

²Tachometer

²Voltage Gauge

Some of the EMIC indicators are automatically

configured when the EMIC is connected to the vehi-

cle electrical system for compatibility with certain

optional equipment or equipment required for regula-

tory purposes in certain markets. While each EMIC

may have provisions for indicators to support every

available option, the configurable indicators will not

be functional in a vehicle that does not have the

equipment that an indicator supports. The EMIC

includes provisions for the following indicators (Fig.

3) or (Fig. 4):

²Airbag Indicator (with Airbag System only)

²Antilock Brake System (ABS) Indicator

(with ABS or Rear Wheel Anti-Lock [RWAL]

brakes only)

²Brake Indicator

²Cargo Lamp Indicator

²Check Gauges Indicator

²Cruise Indicator (with Speed Control only)

²Door Ajar Indicator

²Electronic Throttle Control (ETC) Indicator

(with 5.7L Gasoline Engine only)²Gear Selector Indicator (with Automatic

Transmission only)

²High Beam Indicator

²Lamp Out Indicator

²Low Fuel Indicator

²Malfunction Indicator Lamp (MIL)

²Overdrive-Off Indicator (with Automatic

Transmission only)

²Seatbelt Indicator

²Security Indicator (with Sentry Key Immo-

bilizer & Vehicle Theft Security Systems only)

²Service Four-Wheel Drive Indicator (with

Four-Wheel Drive only)

²Transmission Overtemp Indicator (with

Automatic Transmission only)

²Turn Signal (Right and Left) Indicators

²Upshift Indicator (with Manual Transmis-

sion only)

²Washer Fluid Indicator

²Wait-To-Start Indicator (with Diesel Engine

only)

²Water-In-Fuel Indicator (with Diesel Engine

only)

Each indicator in the EMIC, except those located

within one of the VFD units, is illuminated by a ded-

icated LED that is soldered onto the EMIC electronic

circuit board. The LED units are not available for

service replacement and, if damaged or faulty, the

entire EMIC must be replaced. Cluster illumination

is accomplished by dimmable incandescent back

lighting, which illuminates the gauges for visibility

when the exterior lighting is turned on. Each of the

incandescent bulbs is secured by an integral bulb

holder to the electronic circuit board from the back of

the cluster housing.

Hard wired circuitry connects the EMIC to the

electrical system of the vehicle. These hard wired cir-

cuits are integral to several wire harnesses, which

are routed throughout the vehicle and retained by

many different methods. These circuits may be con-

nected to each other, to the vehicle electrical system

and to the EMIC through the use of a combination of

soldered splices, splice block connectors, and many

different types of wire harness terminal connectors

and insulators. Refer to the appropriate wiring infor-

mation. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

further details on wire harness routing and reten-

tion, as well as pin-out and location views for the

various wire harness connectors, splices and grounds.

The EMIC modules for this model are serviced only

as complete units. The EMIC module cannot be

adjusted or repaired. If a gauge, an LED indicator, a

VFD unit, the electronic circuit board, the circuit

board hardware, the cluster overlay, or the EMIC

housing are damaged or faulty, the entire EMIC mod-

DRINSTRUMENT CLUSTER 8J - 5

INSTRUMENT CLUSTER (Continued)

Page 499 of 2895

ule must be replaced. The cluster lens, hood and

mask unit and the individual incandescent lamp

bulbs with holders are available for individual ser-

vice replacement.

OPERATION

The ElectroMechanical Instrument Cluster (EMIC)

in this model also includes the hardware and soft-

ware necessary to serve as the electronic body control

module and is sometimes referred to as the Cab

Compartment Node or CCN. The following informa-

tion deals primarily with the instrument cluster

functions of this unit. Additional details of the elec-

tronic body control functions of this unit may be

found within the service information for the system

or component that the EMIC controls. For example:

Additional details of the audible warning functions of

the EMIC are found within the Chime/Buzzer service

information.The EMIC is designed to allow the vehicle operator

to monitor the conditions of many of the vehicle com-

ponents and operating systems. The gauges and indi-

cators in the EMIC provide valuable information

about the various standard and optional powertrains,

fuel and emissions systems, cooling systems, lighting

systems, safety systems and many other convenience

items. The EMIC is installed in the instrument panel

so that all of these monitors can be easily viewed by

the vehicle operator when driving, while still allow-

ing relative ease of access for service. The micropro-

cessor-based EMIC hardware and software uses

various inputs to control the gauges and indicators

visible on the face of the cluster. Some of these

inputs are hard wired, but most are in the form of

electronic messages that are transmitted by other

electronic modules over the Programmable Communi-

cations Interface (PCI) data bus network. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/COMMUNICATION - OPERATION).

Fig. 3 Gauges & Indicators - Gasoline Engine

1 - MALFUNCTION INDICATOR LAMP 13 - ELECTRONIC THROTTLE CONTROL (ETC) INDICATOR

2 - VOLTAGE GAUGE 14 - ENGINE TEMPERATURE GAUGE

3 - LEFT TURN INDICATOR 15 - SECURITY INDICATOR

4 - TACHOMETER 16 - GEAR SELECTOR INDICATOR DISPLAY (INCLUDES

CRUISE & UPSHIFT INDICATORS)

5 - AIRBAG INDICATOR 17 - CHECK GAUGES INDICATOR

6 - HIGH BEAM INDICATOR 18 - BRAKE INDICATOR

7 - SEATBELT INDICATOR 19 - ABS INDICATOR

8 - SPEEDOMETER 20 - ODOMETER/TRIP ODOMETER DISPLAY (INCLUDES

ENGINE HOURS, WASHER FLUID, LAMP OUTAGE,

OVERDRIVE-OFF & SERVICE 4x4 INDICATORS)

9 - RIGHT TURN INDICATOR 21 - ODOMETER/TRIP ODOMETER SWITCH BUTTON

10 - OIL PRESSURE GAUGE 22 - FUEL GAUGE

11 - CARGO LAMP INDICATOR 23 - LOW FUEL INDICATOR

12 - DOOR AJAR INDICATOR 24 - TRANSMISSION OVERTEMP INDICATOR

8J - 6 INSTRUMENT CLUSTERDR

INSTRUMENT CLUSTER (Continued)

Page 500 of 2895

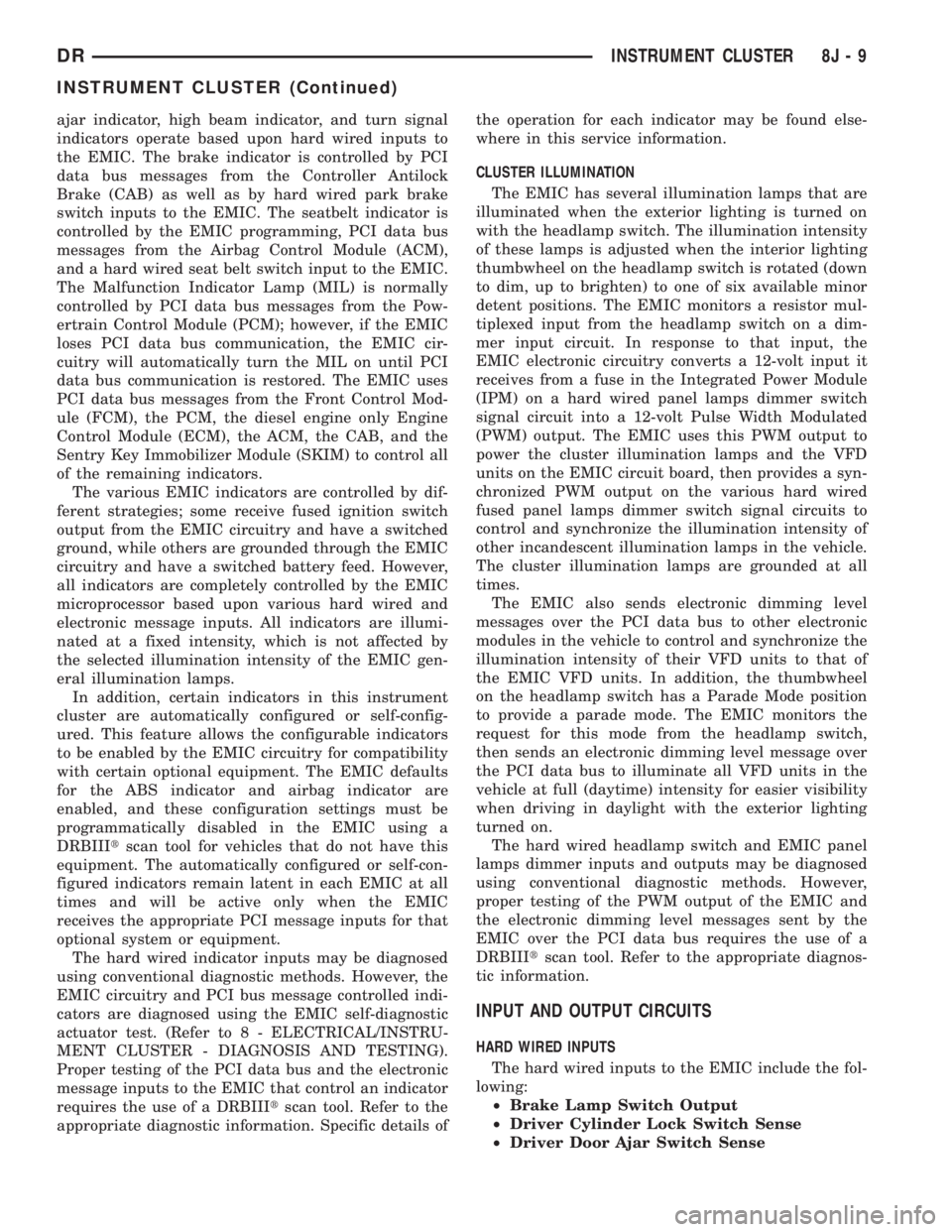

The EMIC microprocessor smooths the input data

using algorithms to provide gauge readings that are

accurate, stable and responsive to operating condi-

tions. These algorithms are designed to provide

gauge readings during normal operation that are con-

sistent with customer expectations. However, when

abnormal conditions exist such as high coolant tem-

perature, the algorithm can drive the gauge pointer

to an extreme position and the microprocessor can

sound a chime through the on-board audible tone

generator to provide distinct visual and audible indi-

cations of a problem to the vehicle operator. The

instrument cluster circuitry may also produce audi-

ble warnings for other electronic modules in the vehi-

cle based upon electronic tone request messages

received over the PCI data bus. Each audible warn-

ing is intended to provide the vehicle operator with

an audible alert to supplement a visual indication.The EMIC circuitry operates on battery current

received through a fused B(+) fuse in the Integrated

Power Module (IPM) on a non-switched fused B(+)

circuit, and on battery current received through a

fused ignition switch output (run-start) fuse in the

IPM on a fused ignition switch output (run-start) cir-

cuit. This arrangement allows the EMIC to provide

some features regardless of the ignition switch posi-

tion, while other features will operate only with the

ignition switch in the On or Start positions. The

EMIC circuitry is grounded through a ground circuit

and take out of the instrument panel wire harness

with an eyelet terminal connector that is secured by

a ground screw to a ground location near the center

of the instrument panel structural support.

The EMIC also has a self-diagnostic actuator test

capability, which will test each of the PCI bus mes-

sage-controlled functions of the cluster by lighting

the appropriate indicators, positioning the gauge nee-

Fig. 4 Gauges & Indicators - Diesel Engine

1 - MALFUNCTION INDICATOR LAMP 14 - ENGINE TEMPERATURE GAUGE

2 - VOLTAGE GAUGE 15 - SECURITY INDICATOR

3 - LEFT TURN INDICATOR 16 - GEAR SELECTOR INDICATOR DISPLAY (INCLUDES

CRUISE & UPSHIFT INDICATORS)

4 - TACHOMETER 17 - WATER-IN-FUEL INDICATOR

5 - AIRBAG INDICATOR 18 - BRAKE INDICATOR

6 - HIGH BEAM INDICATOR 19 - WAIT-TO-START INDICATOR

7 - SEATBELT INDICATOR 20 - ODOMETER/TRIP ODOMETER DISPLAY (INCLUDES

ENGINE HOURS, WASHER FLUID, LAMP OUTAGE,

OVERDRIVE-OFF & SERVICE 4x4 INDICATORS)

8 - SPEEDOMETER 21 - ODOMETER/TRIP ODOMETER SWITCH BUTTON

9 - RIGHT TURN INDICATOR 22 - FUEL GAUGE

10 - OIL PRESSURE GAUGE 23 - LOW FUEL INDICATOR

11 - CARGO LAMP INDICATOR 24 - TRANSMISSION OVERTEMP INDICATOR

12 - DOOR AJAR INDICATOR 25 - CHECK GAUGES INDICATOR

13 - ABS INDICATOR

DRINSTRUMENT CLUSTER 8J - 7

INSTRUMENT CLUSTER (Continued)

Page 502 of 2895

ajar indicator, high beam indicator, and turn signal

indicators operate based upon hard wired inputs to

the EMIC. The brake indicator is controlled by PCI

data bus messages from the Controller Antilock

Brake (CAB) as well as by hard wired park brake

switch inputs to the EMIC. The seatbelt indicator is

controlled by the EMIC programming, PCI data bus

messages from the Airbag Control Module (ACM),

and a hard wired seat belt switch input to the EMIC.

The Malfunction Indicator Lamp (MIL) is normally

controlled by PCI data bus messages from the Pow-

ertrain Control Module (PCM); however, if the EMIC

loses PCI data bus communication, the EMIC cir-

cuitry will automatically turn the MIL on until PCI

data bus communication is restored. The EMIC uses

PCI data bus messages from the Front Control Mod-

ule (FCM), the PCM, the diesel engine only Engine

Control Module (ECM), the ACM, the CAB, and the

Sentry Key Immobilizer Module (SKIM) to control all

of the remaining indicators.

The various EMIC indicators are controlled by dif-

ferent strategies; some receive fused ignition switch

output from the EMIC circuitry and have a switched

ground, while others are grounded through the EMIC

circuitry and have a switched battery feed. However,

all indicators are completely controlled by the EMIC

microprocessor based upon various hard wired and

electronic message inputs. All indicators are illumi-

nated at a fixed intensity, which is not affected by

the selected illumination intensity of the EMIC gen-

eral illumination lamps.

In addition, certain indicators in this instrument

cluster are automatically configured or self-config-

ured. This feature allows the configurable indicators

to be enabled by the EMIC circuitry for compatibility

with certain optional equipment. The EMIC defaults

for the ABS indicator and airbag indicator are

enabled, and these configuration settings must be

programmatically disabled in the EMIC using a

DRBIIItscan tool for vehicles that do not have this

equipment. The automatically configured or self-con-

figured indicators remain latent in each EMIC at all

times and will be active only when the EMIC

receives the appropriate PCI message inputs for that

optional system or equipment.

The hard wired indicator inputs may be diagnosed

using conventional diagnostic methods. However, the

EMIC circuitry and PCI bus message controlled indi-

cators are diagnosed using the EMIC self-diagnostic

actuator test. (Refer to 8 - ELECTRICAL/INSTRU-

MENT CLUSTER - DIAGNOSIS AND TESTING).

Proper testing of the PCI data bus and the electronic

message inputs to the EMIC that control an indicator

requires the use of a DRBIIItscan tool. Refer to the

appropriate diagnostic information. Specific details ofthe operation for each indicator may be found else-

where in this service information.

CLUSTER ILLUMINATION

The EMIC has several illumination lamps that are

illuminated when the exterior lighting is turned on

with the headlamp switch. The illumination intensity

of these lamps is adjusted when the interior lighting

thumbwheel on the headlamp switch is rotated (down

to dim, up to brighten) to one of six available minor

detent positions. The EMIC monitors a resistor mul-

tiplexed input from the headlamp switch on a dim-

mer input circuit. In response to that input, the

EMIC electronic circuitry converts a 12-volt input it

receives from a fuse in the Integrated Power Module

(IPM) on a hard wired panel lamps dimmer switch

signal circuit into a 12-volt Pulse Width Modulated

(PWM) output. The EMIC uses this PWM output to

power the cluster illumination lamps and the VFD

units on the EMIC circuit board, then provides a syn-

chronized PWM output on the various hard wired

fused panel lamps dimmer switch signal circuits to

control and synchronize the illumination intensity of

other incandescent illumination lamps in the vehicle.

The cluster illumination lamps are grounded at all

times.

The EMIC also sends electronic dimming level

messages over the PCI data bus to other electronic

modules in the vehicle to control and synchronize the

illumination intensity of their VFD units to that of

the EMIC VFD units. In addition, the thumbwheel

on the headlamp switch has a Parade Mode position

to provide a parade mode. The EMIC monitors the

request for this mode from the headlamp switch,

then sends an electronic dimming level message over

the PCI data bus to illuminate all VFD units in the

vehicle at full (daytime) intensity for easier visibility

when driving in daylight with the exterior lighting

turned on.

The hard wired headlamp switch and EMIC panel

lamps dimmer inputs and outputs may be diagnosed

using conventional diagnostic methods. However,

proper testing of the PWM output of the EMIC and

the electronic dimming level messages sent by the

EMIC over the PCI data bus requires the use of a

DRBIIItscan tool. Refer to the appropriate diagnos-

tic information.

INPUT AND OUTPUT CIRCUITS

HARD WIRED INPUTS

The hard wired inputs to the EMIC include the fol-

lowing:

²Brake Lamp Switch Output

²Driver Cylinder Lock Switch Sense

²Driver Door Ajar Switch Sense

DRINSTRUMENT CLUSTER 8J - 9

INSTRUMENT CLUSTER (Continued)