engine overheat DODGE RAM 2003 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 305 of 2895

CAUTION: Follow manufacturers instructions when

using these products.

STANDARD PROCEDUREÐDRAINING COOLING

SYSTEM 3.7L/4.7L/5.7L ENGINE

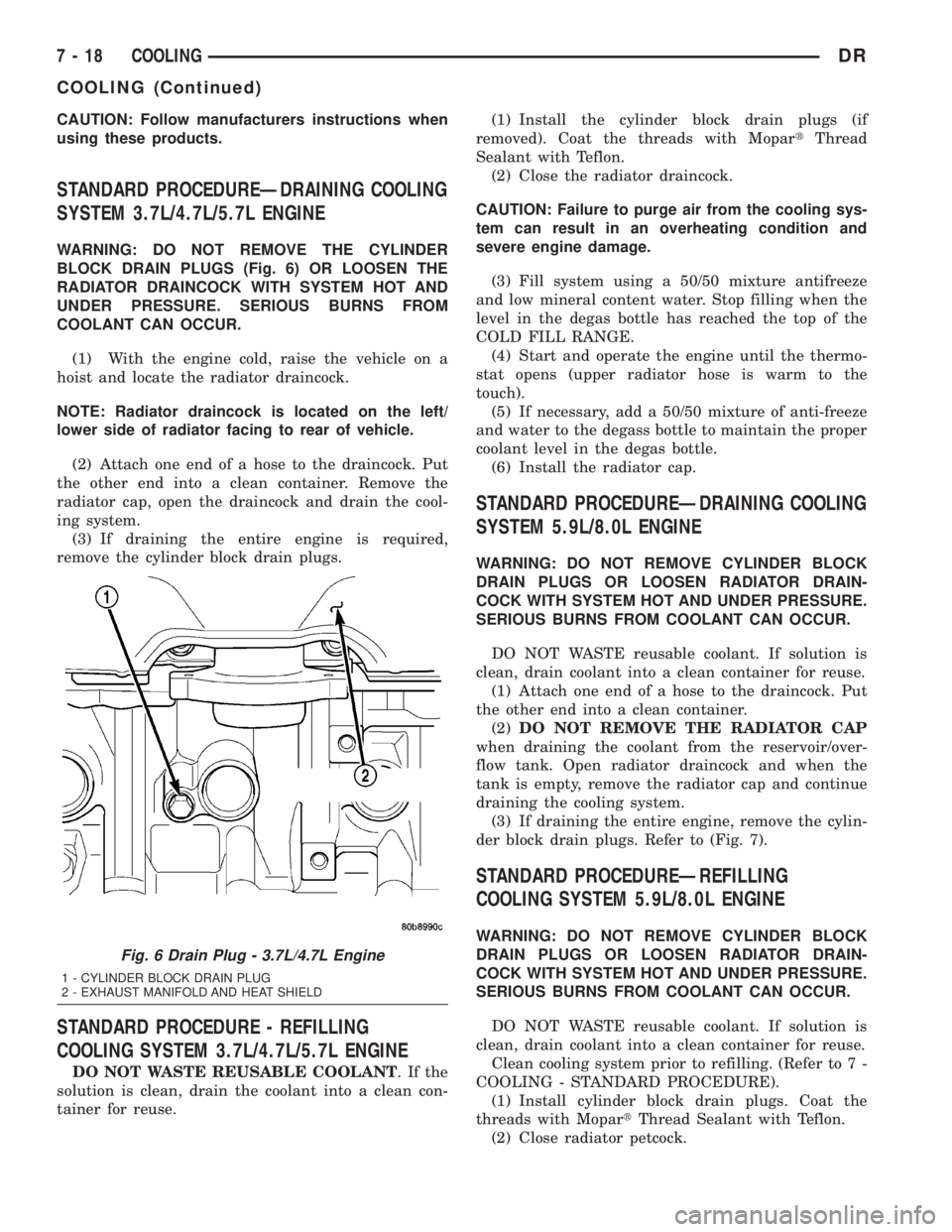

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS (Fig. 6) OR LOOSEN THE

RADIATOR DRAINCOCK WITH SYSTEM HOT AND

UNDER PRESSURE. SERIOUS BURNS FROM

COOLANT CAN OCCUR.

(1) With the engine cold, raise the vehicle on a

hoist and locate the radiator draincock.

NOTE: Radiator draincock is located on the left/

lower side of radiator facing to rear of vehicle.

(2) Attach one end of a hose to the draincock. Put

the other end into a clean container. Remove the

radiator cap, open the draincock and drain the cool-

ing system.

(3) If draining the entire engine is required,

remove the cylinder block drain plugs.

STANDARD PROCEDURE - REFILLING

COOLING SYSTEM 3.7L/4.7L/5.7L ENGINE

DO NOT WASTE REUSABLE COOLANT.Ifthe

solution is clean, drain the coolant into a clean con-

tainer for reuse.(1) Install the cylinder block drain plugs (if

removed). Coat the threads with MopartThread

Sealant with Teflon.

(2) Close the radiator draincock.

CAUTION: Failure to purge air from the cooling sys-

tem can result in an overheating condition and

severe engine damage.

(3) Fill system using a 50/50 mixture antifreeze

and low mineral content water. Stop filling when the

level in the degas bottle has reached the top of the

COLD FILL RANGE.

(4) Start and operate the engine until the thermo-

stat opens (upper radiator hose is warm to the

touch).

(5) If necessary, add a 50/50 mixture of anti-freeze

and water to the degass bottle to maintain the proper

coolant level in the degas bottle.

(6) Install the radiator cap.

STANDARD PROCEDUREÐDRAINING COOLING

SYSTEM 5.9L/8.0L ENGINE

WARNING: DO NOT REMOVE CYLINDER BLOCK

DRAIN PLUGS OR LOOSEN RADIATOR DRAIN-

COCK WITH SYSTEM HOT AND UNDER PRESSURE.

SERIOUS BURNS FROM COOLANT CAN OCCUR.

DO NOT WASTE reusable coolant. If solution is

clean, drain coolant into a clean container for reuse.

(1) Attach one end of a hose to the draincock. Put

the other end into a clean container.

(2)DO NOT REMOVE THE RADIATOR CAP

when draining the coolant from the reservoir/over-

flow tank. Open radiator draincock and when the

tank is empty, remove the radiator cap and continue

draining the cooling system.

(3) If draining the entire engine, remove the cylin-

der block drain plugs. Refer to (Fig. 7).

STANDARD PROCEDUREÐREFILLING

COOLING SYSTEM 5.9L/8.0L ENGINE

WARNING: DO NOT REMOVE CYLINDER BLOCK

DRAIN PLUGS OR LOOSEN RADIATOR DRAIN-

COCK WITH SYSTEM HOT AND UNDER PRESSURE.

SERIOUS BURNS FROM COOLANT CAN OCCUR.

DO NOT WASTE reusable coolant. If solution is

clean, drain coolant into a clean container for reuse.

Clean cooling system prior to refilling. (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(1) Install cylinder block drain plugs. Coat the

threads with MopartThread Sealant with Teflon.

(2) Close radiator petcock.

Fig. 6 Drain Plug - 3.7L/4.7L Engine

1 - CYLINDER BLOCK DRAIN PLUG

2 - EXHAUST MANIFOLD AND HEAT SHIELD

7 - 18 COOLINGDR

COOLING (Continued)

Page 309 of 2895

ACCESSORY DRIVE

TABLE OF CONTENTS

page page

BELT TENSIONERS - 3.7L / 4.7L

DESCRIPTION.........................22

OPERATION...........................22

REMOVAL.............................22

INSTALLATION.........................23

BELT TENSIONERS - 5.9L

DESCRIPTION.........................23

OPERATION...........................23

REMOVAL.............................23

INSTALLATION.........................24

BELT TENSIONERS - 5.9L DIESEL

DESCRIPTION.........................24

OPERATION...........................24

REMOVAL.............................25

INSTALLATION.........................25DRIVE BELTS - 3.7L / 4.7L

DIAGNOSIS AND TESTING - ACCESSORY

DRIVE BELT.........................25

REMOVAL.............................27

INSTALLATION.........................27

DRIVE BELTS - 5.9L

DIAGNOSIS AND TESTING - ACCESSORY

DRIVE BELT.........................28

REMOVAL.............................30

INSTALLATION.........................31

DRIVE BELTS - 5.9L DIESEL

DIAGNOSIS AND TESTINGÐACCESSORY

DRIVE BELT.........................31

REMOVAL.............................34

INSTALLATION.........................34

BELT TENSIONERS - 3.7L /

4.7L

DESCRIPTION

Correct drive belt tension is required to ensure

optimum performance of the belt driven engine acces-

sories. If specified tension is not maintained, belt

slippage may cause; engine overheating, lack of

power steering assist, loss of air conditioning capac-

ity, reduced generator output rate, and greatly

reduced belt life.

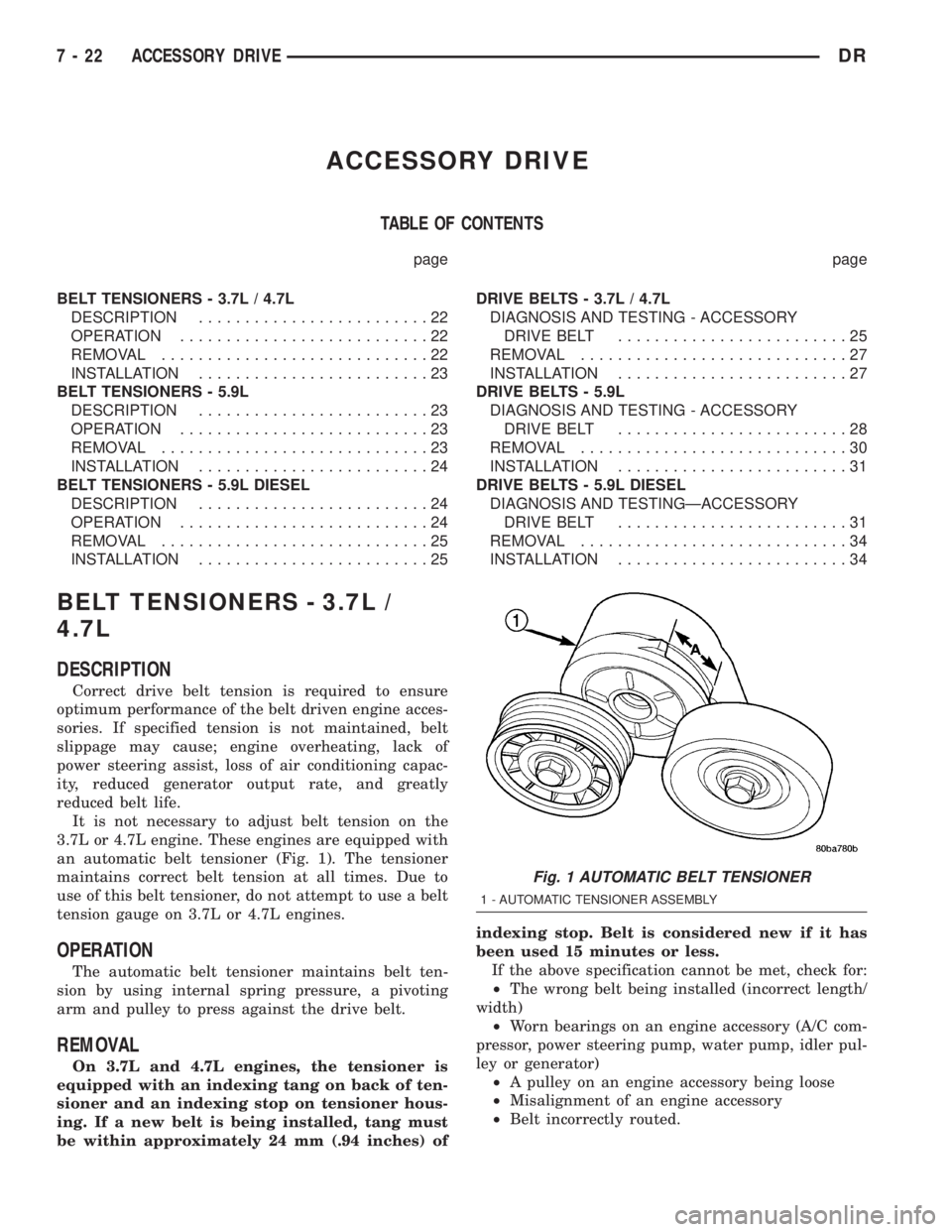

It is not necessary to adjust belt tension on the

3.7L or 4.7L engine. These engines are equipped with

an automatic belt tensioner (Fig. 1). The tensioner

maintains correct belt tension at all times. Due to

use of this belt tensioner, do not attempt to use a belt

tension gauge on 3.7L or 4.7L engines.

OPERATION

The automatic belt tensioner maintains belt ten-

sion by using internal spring pressure, a pivoting

arm and pulley to press against the drive belt.

REMOVAL

On 3.7L and 4.7L engines, the tensioner is

equipped with an indexing tang on back of ten-

sioner and an indexing stop on tensioner hous-

ing. If a new belt is being installed, tang must

be within approximately 24 mm (.94 inches) ofindexing stop. Belt is considered new if it has

been used 15 minutes or less.

If the above specification cannot be met, check for:

²The wrong belt being installed (incorrect length/

width)

²Worn bearings on an engine accessory (A/C com-

pressor, power steering pump, water pump, idler pul-

ley or generator)

²A pulley on an engine accessory being loose

²Misalignment of an engine accessory

²Belt incorrectly routed.

Fig. 1 AUTOMATIC BELT TENSIONER

1 - AUTOMATIC TENSIONER ASSEMBLY

7 - 22 ACCESSORY DRIVEDR

Page 310 of 2895

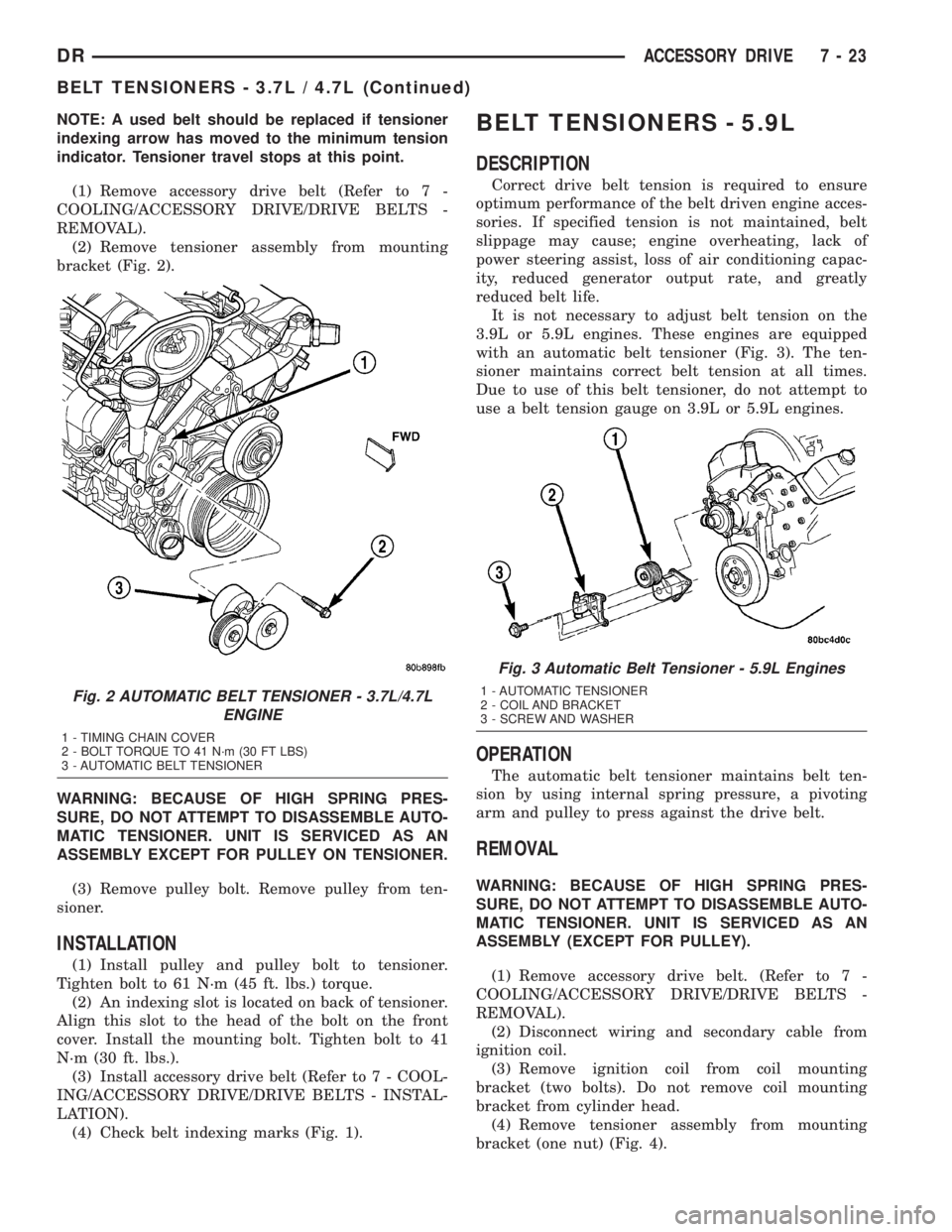

NOTE: A used belt should be replaced if tensioner

indexing arrow has moved to the minimum tension

indicator. Tensioner travel stops at this point.

(1) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(2) Remove tensioner assembly from mounting

bracket (Fig. 2).

WARNING: BECAUSE OF HIGH SPRING PRES-

SURE, DO NOT ATTEMPT TO DISASSEMBLE AUTO-

MATIC TENSIONER. UNIT IS SERVICED AS AN

ASSEMBLY EXCEPT FOR PULLEY ON TENSIONER.

(3) Remove pulley bolt. Remove pulley from ten-

sioner.

INSTALLATION

(1) Install pulley and pulley bolt to tensioner.

Tighten bolt to 61 N´m (45 ft. lbs.) torque.

(2) An indexing slot is located on back of tensioner.

Align this slot to the head of the bolt on the front

cover. Install the mounting bolt. Tighten bolt to 41

N´m (30 ft. lbs.).

(3) Install accessory drive belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(4) Check belt indexing marks (Fig. 1).

BELT TENSIONERS - 5.9L

DESCRIPTION

Correct drive belt tension is required to ensure

optimum performance of the belt driven engine acces-

sories. If specified tension is not maintained, belt

slippage may cause; engine overheating, lack of

power steering assist, loss of air conditioning capac-

ity, reduced generator output rate, and greatly

reduced belt life.

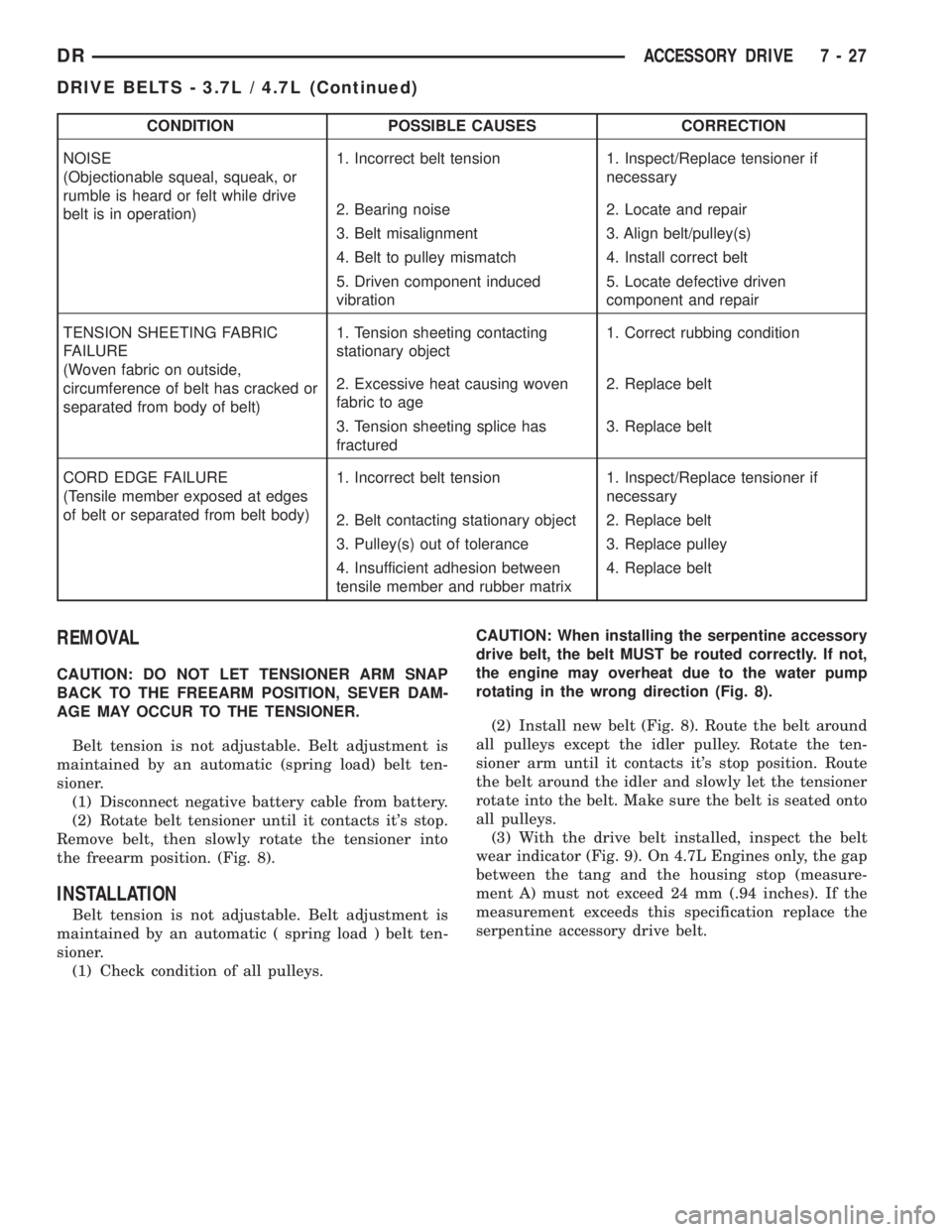

It is not necessary to adjust belt tension on the

3.9L or 5.9L engines. These engines are equipped

with an automatic belt tensioner (Fig. 3). The ten-

sioner maintains correct belt tension at all times.

Due to use of this belt tensioner, do not attempt to

use a belt tension gauge on 3.9L or 5.9L engines.

OPERATION

The automatic belt tensioner maintains belt ten-

sion by using internal spring pressure, a pivoting

arm and pulley to press against the drive belt.

REMOVAL

WARNING: BECAUSE OF HIGH SPRING PRES-

SURE, DO NOT ATTEMPT TO DISASSEMBLE AUTO-

MATIC TENSIONER. UNIT IS SERVICED AS AN

ASSEMBLY (EXCEPT FOR PULLEY).

(1) Remove accessory drive belt. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(2) Disconnect wiring and secondary cable from

ignition coil.

(3) Remove ignition coil from coil mounting

bracket (two bolts). Do not remove coil mounting

bracket from cylinder head.

(4) Remove tensioner assembly from mounting

bracket (one nut) (Fig. 4).

Fig. 2 AUTOMATIC BELT TENSIONER - 3.7L/4.7L

ENGINE

1 - TIMING CHAIN COVER

2 - BOLT TORQUE TO 41 N´m (30 FT LBS)

3 - AUTOMATIC BELT TENSIONER

Fig. 3 Automatic Belt Tensioner - 5.9L Engines

1 - AUTOMATIC TENSIONER

2 - COIL AND BRACKET

3 - SCREW AND WASHER

DRACCESSORY DRIVE 7 - 23

BELT TENSIONERS - 3.7L / 4.7L (Continued)

Page 314 of 2895

CONDITION POSSIBLE CAUSES CORRECTION

NOISE

(Objectionable squeal, squeak, or

rumble is heard or felt while drive

belt is in operation)1. Incorrect belt tension 1. Inspect/Replace tensioner if

necessary

2. Bearing noise 2. Locate and repair

3. Belt misalignment 3. Align belt/pulley(s)

4. Belt to pulley mismatch 4. Install correct belt

5. Driven component induced

vibration5. Locate defective driven

component and repair

TENSION SHEETING FABRIC

FAILURE

(Woven fabric on outside,

circumference of belt has cracked or

separated from body of belt)1. Tension sheeting contacting

stationary object1. Correct rubbing condition

2. Excessive heat causing woven

fabric to age2. Replace belt

3. Tension sheeting splice has

fractured3. Replace belt

CORD EDGE FAILURE

(Tensile member exposed at edges

of belt or separated from belt body)1. Incorrect belt tension 1. Inspect/Replace tensioner if

necessary

2. Belt contacting stationary object 2. Replace belt

3. Pulley(s) out of tolerance 3. Replace pulley

4. Insufficient adhesion between

tensile member and rubber matrix4. Replace belt

REMOVAL

CAUTION: DO NOT LET TENSIONER ARM SNAP

BACK TO THE FREEARM POSITION, SEVER DAM-

AGE MAY OCCUR TO THE TENSIONER.

Belt tension is not adjustable. Belt adjustment is

maintained by an automatic (spring load) belt ten-

sioner.

(1) Disconnect negative battery cable from battery.

(2) Rotate belt tensioner until it contacts it's stop.

Remove belt, then slowly rotate the tensioner into

the freearm position. (Fig. 8).

INSTALLATION

Belt tension is not adjustable. Belt adjustment is

maintained by an automatic ( spring load ) belt ten-

sioner.

(1) Check condition of all pulleys.CAUTION: When installing the serpentine accessory

drive belt, the belt MUST be routed correctly. If not,

the engine may overheat due to the water pump

rotating in the wrong direction (Fig. 8).

(2) Install new belt (Fig. 8). Route the belt around

all pulleys except the idler pulley. Rotate the ten-

sioner arm until it contacts it's stop position. Route

the belt around the idler and slowly let the tensioner

rotate into the belt. Make sure the belt is seated onto

all pulleys.

(3) With the drive belt installed, inspect the belt

wear indicator (Fig. 9). On 4.7L Engines only, the gap

between the tang and the housing stop (measure-

ment A) must not exceed 24 mm (.94 inches). If the

measurement exceeds this specification replace the

serpentine accessory drive belt.

DRACCESSORY DRIVE 7 - 27

DRIVE BELTS - 3.7L / 4.7L (Continued)

Page 318 of 2895

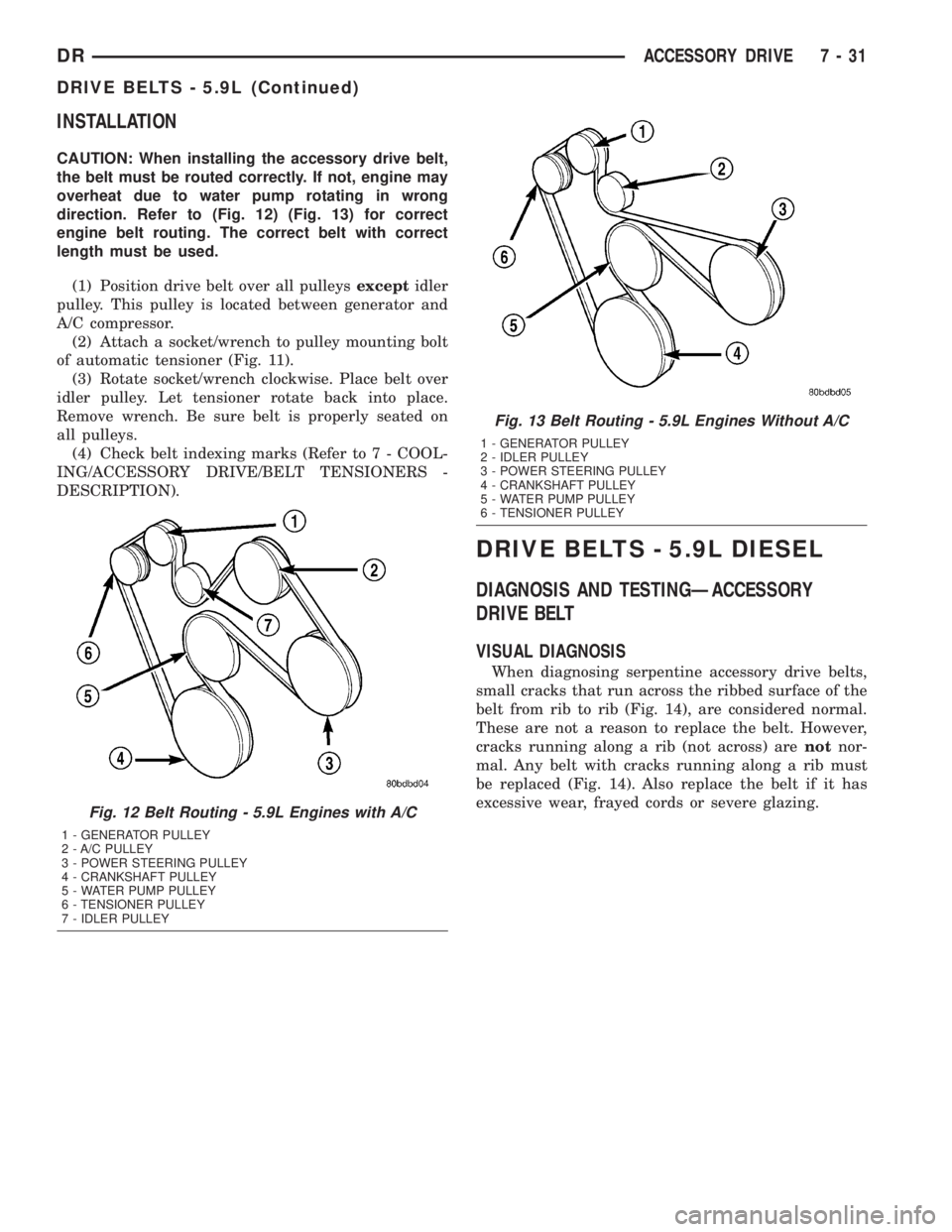

INSTALLATION

CAUTION: When installing the accessory drive belt,

the belt must be routed correctly. If not, engine may

overheat due to water pump rotating in wrong

direction. Refer to (Fig. 12) (Fig. 13) for correct

engine belt routing. The correct belt with correct

length must be used.

(1) Position drive belt over all pulleysexceptidler

pulley. This pulley is located between generator and

A/C compressor.

(2) Attach a socket/wrench to pulley mounting bolt

of automatic tensioner (Fig. 11).

(3) Rotate socket/wrench clockwise. Place belt over

idler pulley. Let tensioner rotate back into place.

Remove wrench. Be sure belt is properly seated on

all pulleys.

(4) Check belt indexing marks (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/BELT TENSIONERS -

DESCRIPTION).

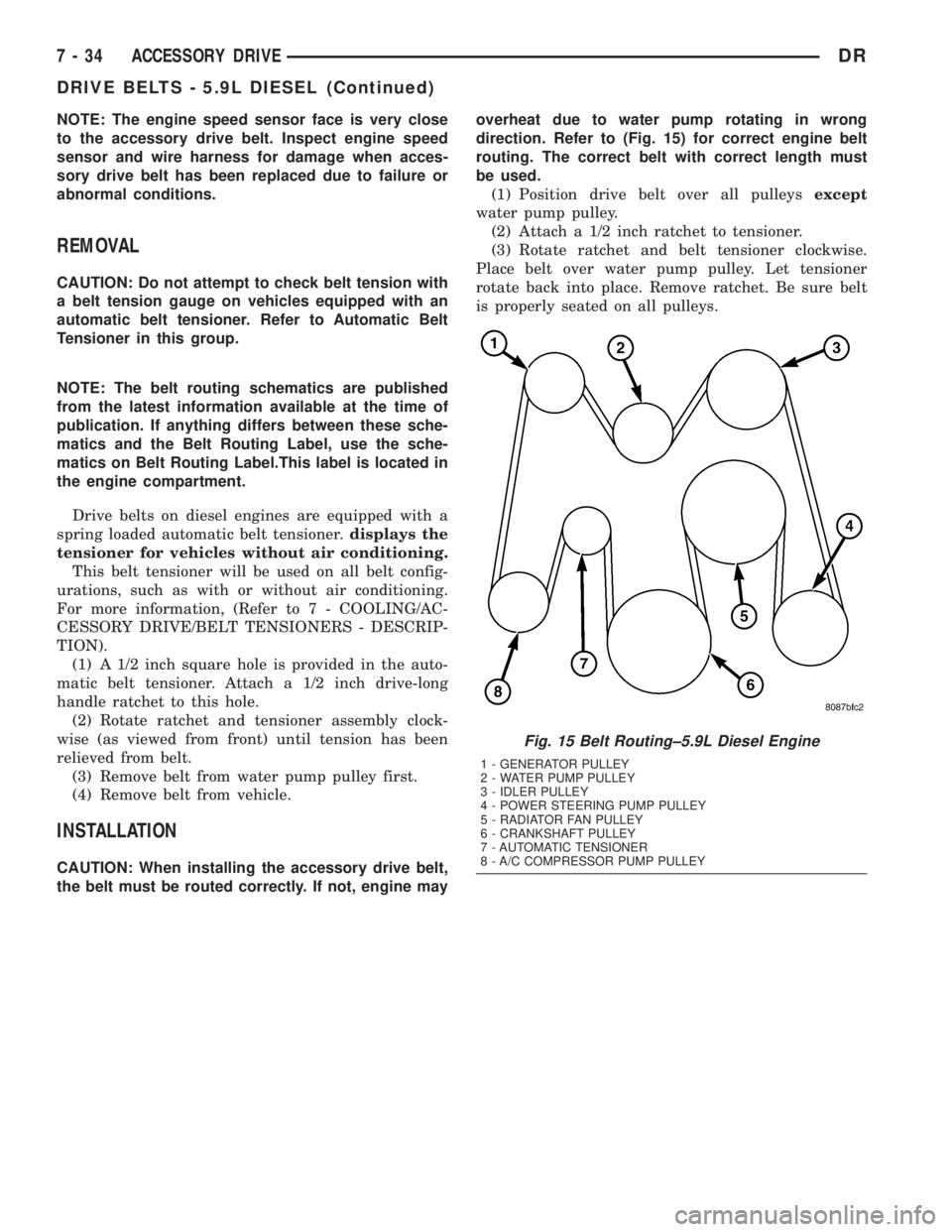

DRIVE BELTS - 5.9L DIESEL

DIAGNOSIS AND TESTINGÐACCESSORY

DRIVE BELT

VISUAL DIAGNOSIS

When diagnosing serpentine accessory drive belts,

small cracks that run across the ribbed surface of the

belt from rib to rib (Fig. 14), are considered normal.

These are not a reason to replace the belt. However,

cracks running along a rib (not across) arenotnor-

mal. Any belt with cracks running along a rib must

be replaced (Fig. 14). Also replace the belt if it has

excessive wear, frayed cords or severe glazing.

Fig. 12 Belt Routing - 5.9L Engines with A/C

1 - GENERATOR PULLEY

2 - A/C PULLEY

3 - POWER STEERING PULLEY

4 - CRANKSHAFT PULLEY

5 - WATER PUMP PULLEY

6 - TENSIONER PULLEY

7 - IDLER PULLEY

Fig. 13 Belt Routing - 5.9L Engines Without A/C

1 - GENERATOR PULLEY

2 - IDLER PULLEY

3 - POWER STEERING PULLEY

4 - CRANKSHAFT PULLEY

5 - WATER PUMP PULLEY

6 - TENSIONER PULLEY

DRACCESSORY DRIVE 7 - 31

DRIVE BELTS - 5.9L (Continued)

Page 321 of 2895

NOTE: The engine speed sensor face is very close

to the accessory drive belt. Inspect engine speed

sensor and wire harness for damage when acces-

sory drive belt has been replaced due to failure or

abnormal conditions.

REMOVAL

CAUTION: Do not attempt to check belt tension with

a belt tension gauge on vehicles equipped with an

automatic belt tensioner. Refer to Automatic Belt

Tensioner in this group.

NOTE: The belt routing schematics are published

from the latest information available at the time of

publication. If anything differs between these sche-

matics and the Belt Routing Label, use the sche-

matics on Belt Routing Label.This label is located in

the engine compartment.

Drive belts on diesel engines are equipped with a

spring loaded automatic belt tensioner.displays the

tensioner for vehicles without air conditioning.

This belt tensioner will be used on all belt config-

urations, such as with or without air conditioning.

For more information, (Refer to 7 - COOLING/AC-

CESSORY DRIVE/BELT TENSIONERS - DESCRIP-

TION).

(1) A 1/2 inch square hole is provided in the auto-

matic belt tensioner. Attach a 1/2 inch drive-long

handle ratchet to this hole.

(2) Rotate ratchet and tensioner assembly clock-

wise (as viewed from front) until tension has been

relieved from belt.

(3) Remove belt from water pump pulley first.

(4) Remove belt from vehicle.

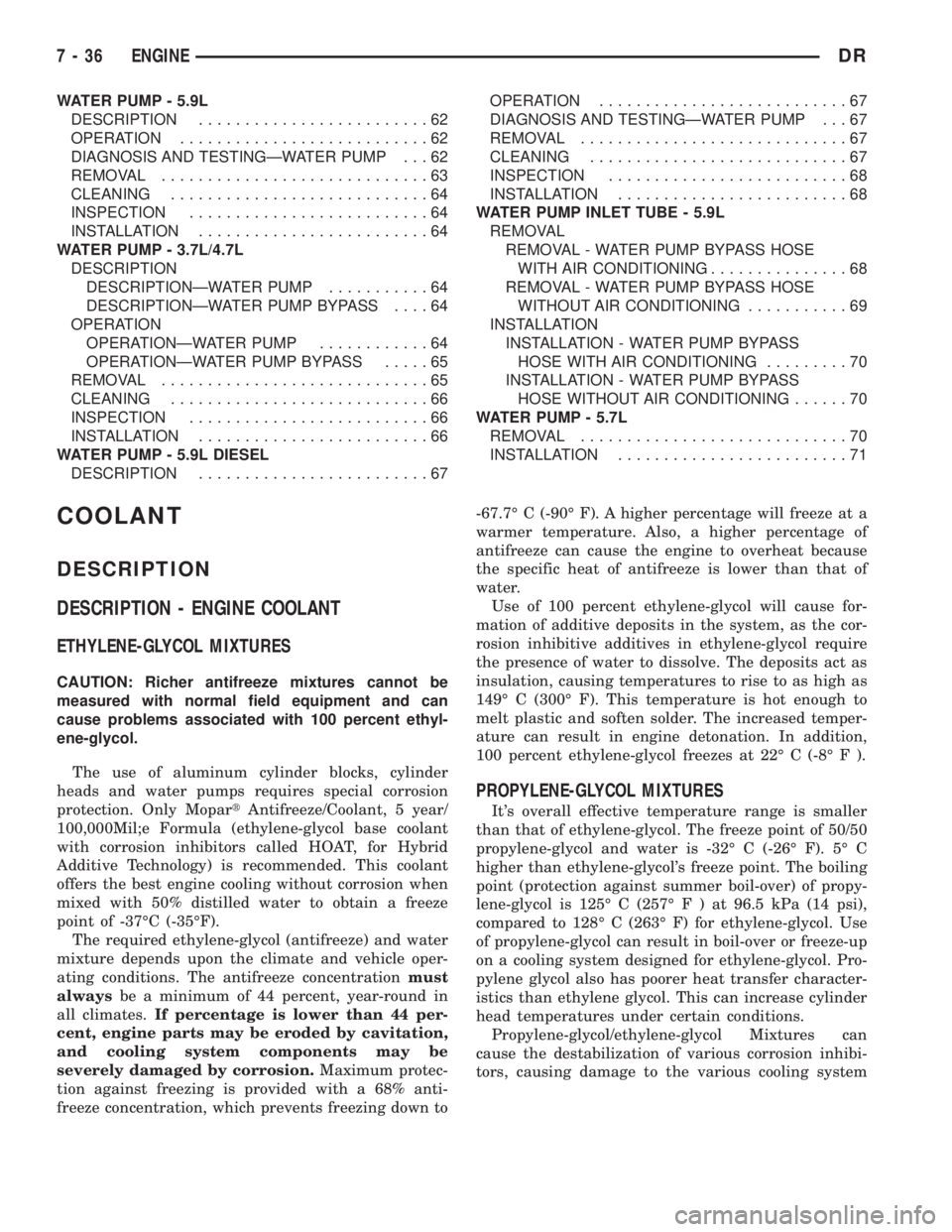

INSTALLATION

CAUTION: When installing the accessory drive belt,

the belt must be routed correctly. If not, engine mayoverheat due to water pump rotating in wrong

direction. Refer to (Fig. 15) for correct engine belt

routing. The correct belt with correct length must

be used.

(1) Position drive belt over all pulleysexcept

water pump pulley.

(2) Attach a 1/2 inch ratchet to tensioner.

(3) Rotate ratchet and belt tensioner clockwise.

Place belt over water pump pulley. Let tensioner

rotate back into place. Remove ratchet. Be sure belt

is properly seated on all pulleys.

Fig. 15 Belt Routing±5.9L Diesel Engine

1 - GENERATOR PULLEY

2 - WATER PUMP PULLEY

3 - IDLER PULLEY

4 - POWER STEERING PUMP PULLEY

5 - RADIATOR FAN PULLEY

6 - CRANKSHAFT PULLEY

7 - AUTOMATIC TENSIONER

8 - A/C COMPRESSOR PUMP PULLEY

7 - 34 ACCESSORY DRIVEDR

DRIVE BELTS - 5.9L DIESEL (Continued)

Page 323 of 2895

WATER PUMP - 5.9L

DESCRIPTION.........................62

OPERATION...........................62

DIAGNOSIS AND TESTINGÐWATER PUMP . . . 62

REMOVAL.............................63

CLEANING............................64

INSPECTION..........................64

INSTALLATION.........................64

WATER PUMP - 3.7L/4.7L

DESCRIPTION

DESCRIPTIONÐWATER PUMP...........64

DESCRIPTIONÐWATER PUMP BYPASS....64

OPERATION

OPERATIONÐWATER PUMP............64

OPERATIONÐWATER PUMP BYPASS.....65

REMOVAL.............................65

CLEANING............................66

INSPECTION..........................66

INSTALLATION.........................66

WATER PUMP - 5.9L DIESEL

DESCRIPTION.........................67OPERATION...........................67

DIAGNOSIS AND TESTINGÐWATER PUMP . . . 67

REMOVAL.............................67

CLEANING............................67

INSPECTION..........................68

INSTALLATION.........................68

WATER PUMP INLET TUBE - 5.9L

REMOVAL

REMOVAL - WATER PUMP BYPASS HOSE

WITH AIR CONDITIONING...............68

REMOVAL - WATER PUMP BYPASS HOSE

WITHOUT AIR CONDITIONING...........69

INSTALLATION

INSTALLATION - WATER PUMP BYPASS

HOSE WITH AIR CONDITIONING.........70

INSTALLATION - WATER PUMP BYPASS

HOSE WITHOUT AIR CONDITIONING......70

WATER PUMP - 5.7L

REMOVAL.............................70

INSTALLATION.........................71

COOLANT

DESCRIPTION

DESCRIPTION - ENGINE COOLANT

ETHYLENE-GLYCOL MIXTURES

CAUTION: Richer antifreeze mixtures cannot be

measured with normal field equipment and can

cause problems associated with 100 percent ethyl-

ene-glycol.

The use of aluminum cylinder blocks, cylinder

heads and water pumps requires special corrosion

protection. Only MopartAntifreeze/Coolant, 5 year/

100,000Mil;e Formula (ethylene-glycol base coolant

with corrosion inhibitors called HOAT, for Hybrid

Additive Technology) is recommended. This coolant

offers the best engine cooling without corrosion when

mixed with 50% distilled water to obtain a freeze

point of -37ÉC (-35ÉF).

The required ethylene-glycol (antifreeze) and water

mixture depends upon the climate and vehicle oper-

ating conditions. The antifreeze concentrationmust

alwaysbe a minimum of 44 percent, year-round in

all climates.If percentage is lower than 44 per-

cent, engine parts may be eroded by cavitation,

and cooling system components may be

severely damaged by corrosion.Maximum protec-

tion against freezing is provided with a 68% anti-

freeze concentration, which prevents freezing down to-67.7É C (-90É F). A higher percentage will freeze at a

warmer temperature. Also, a higher percentage of

antifreeze can cause the engine to overheat because

the specific heat of antifreeze is lower than that of

water.

Use of 100 percent ethylene-glycol will cause for-

mation of additive deposits in the system, as the cor-

rosion inhibitive additives in ethylene-glycol require

the presence of water to dissolve. The deposits act as

insulation, causing temperatures to rise to as high as

149É C (300É F). This temperature is hot enough to

melt plastic and soften solder. The increased temper-

ature can result in engine detonation. In addition,

100 percent ethylene-glycol freezes at 22É C (-8É F ).

PROPYLENE-GLYCOL MIXTURES

It's overall effective temperature range is smaller

than that of ethylene-glycol. The freeze point of 50/50

propylene-glycol and water is -32É C (-26É F). 5É C

higher than ethylene-glycol's freeze point. The boiling

point (protection against summer boil-over) of propy-

lene-glycol is 125É C (257ÉF)at96.5 kPa (14 psi),

compared to 128É C (263É F) for ethylene-glycol. Use

of propylene-glycol can result in boil-over or freeze-up

on a cooling system designed for ethylene-glycol. Pro-

pylene glycol also has poorer heat transfer character-

istics than ethylene glycol. This can increase cylinder

head temperatures under certain conditions.

Propylene-glycol/ethylene-glycol Mixtures can

cause the destabilization of various corrosion inhibi-

tors, causing damage to the various cooling system

7 - 36 ENGINEDR

Page 327 of 2895

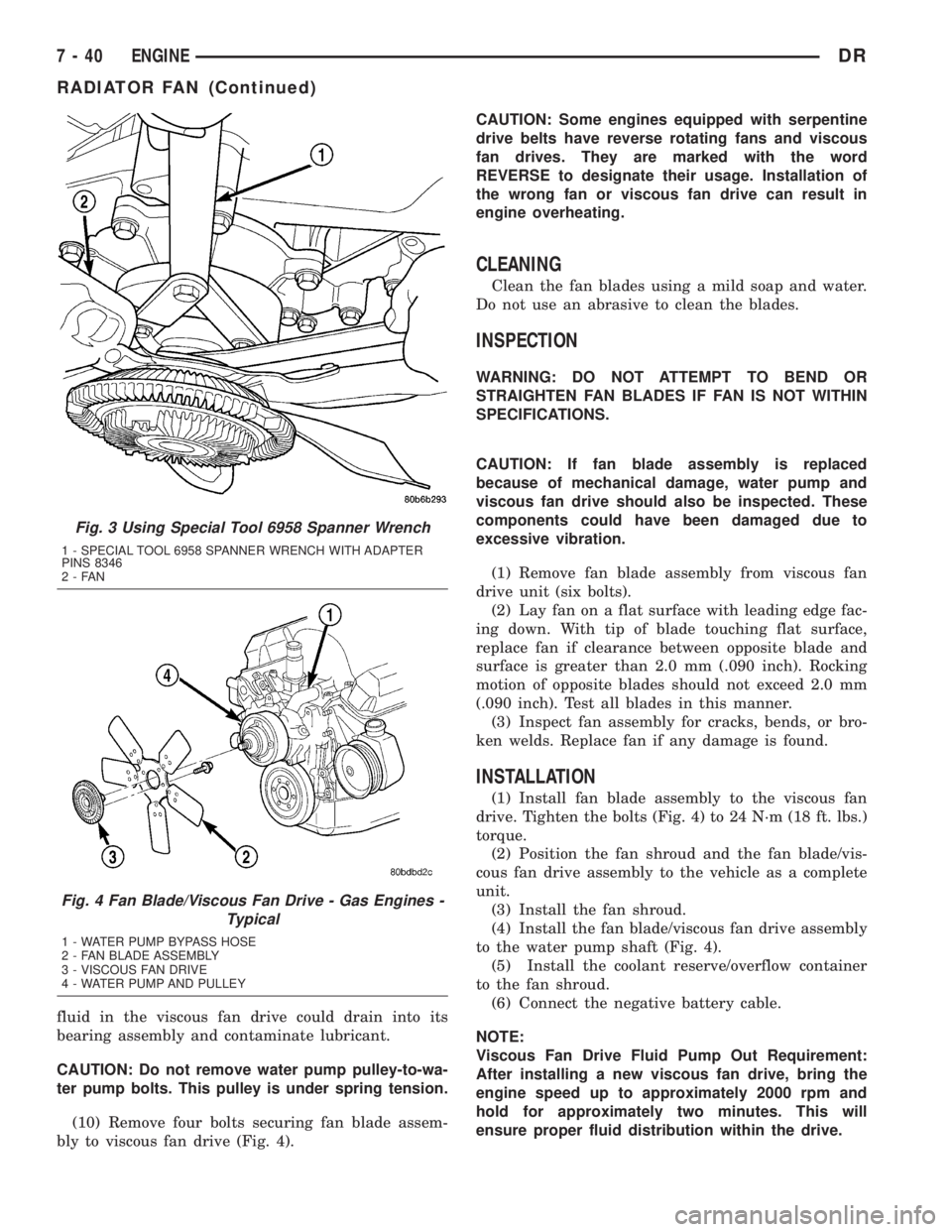

fluid in the viscous fan drive could drain into its

bearing assembly and contaminate lubricant.

CAUTION: Do not remove water pump pulley-to-wa-

ter pump bolts. This pulley is under spring tension.

(10) Remove four bolts securing fan blade assem-

bly to viscous fan drive (Fig. 4).CAUTION: Some engines equipped with serpentine

drive belts have reverse rotating fans and viscous

fan drives. They are marked with the word

REVERSE to designate their usage. Installation of

the wrong fan or viscous fan drive can result in

engine overheating.

CLEANING

Clean the fan blades using a mild soap and water.

Do not use an abrasive to clean the blades.

INSPECTION

WARNING: DO NOT ATTEMPT TO BEND OR

STRAIGHTEN FAN BLADES IF FAN IS NOT WITHIN

SPECIFICATIONS.

CAUTION: If fan blade assembly is replaced

because of mechanical damage, water pump and

viscous fan drive should also be inspected. These

components could have been damaged due to

excessive vibration.

(1) Remove fan blade assembly from viscous fan

drive unit (six bolts).

(2) Lay fan on a flat surface with leading edge fac-

ing down. With tip of blade touching flat surface,

replace fan if clearance between opposite blade and

surface is greater than 2.0 mm (.090 inch). Rocking

motion of opposite blades should not exceed 2.0 mm

(.090 inch). Test all blades in this manner.

(3) Inspect fan assembly for cracks, bends, or bro-

ken welds. Replace fan if any damage is found.

INSTALLATION

(1) Install fan blade assembly to the viscous fan

drive. Tighten the bolts (Fig. 4) to 24 N´m (18 ft. lbs.)

torque.

(2) Position the fan shroud and the fan blade/vis-

cous fan drive assembly to the vehicle as a complete

unit.

(3) Install the fan shroud.

(4) Install the fan blade/viscous fan drive assembly

to the water pump shaft (Fig. 4).

(5) Install the coolant reserve/overflow container

to the fan shroud.

(6) Connect the negative battery cable.

NOTE:

Viscous Fan Drive Fluid Pump Out Requirement:

After installing a new viscous fan drive, bring the

engine speed up to approximately 2000 rpm and

hold for approximately two minutes. This will

ensure proper fluid distribution within the drive.

Fig. 3 Using Special Tool 6958 Spanner Wrench

1 - SPECIAL TOOL 6958 SPANNER WRENCH WITH ADAPTER

PINS 8346

2-FAN

Fig. 4 Fan Blade/Viscous Fan Drive - Gas Engines -

Typical

1 - WATER PUMP BYPASS HOSE

2 - FAN BLADE ASSEMBLY

3 - VISCOUS FAN DRIVE

4 - WATER PUMP AND PULLEY

7 - 40 ENGINEDR

RADIATOR FAN (Continued)

Page 328 of 2895

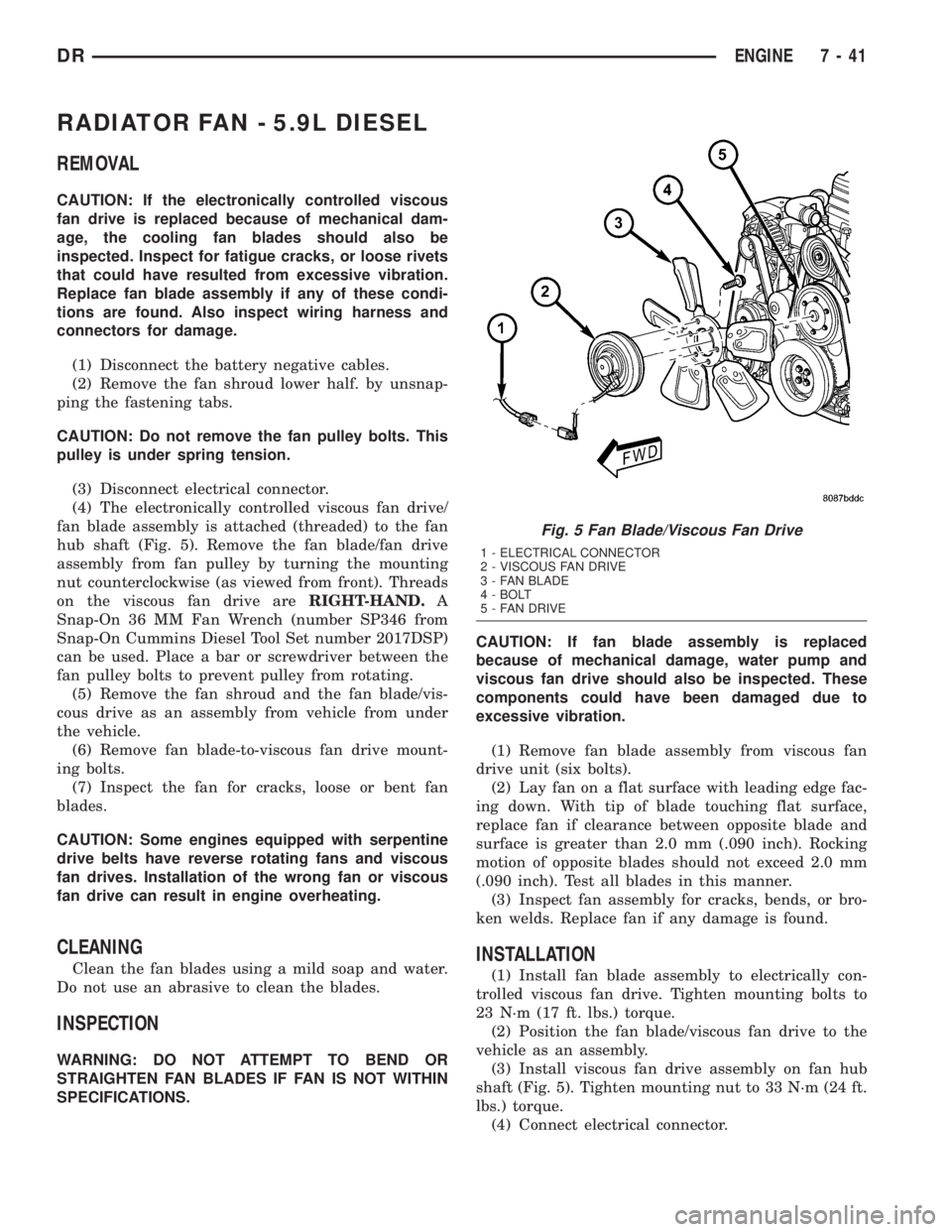

RADIATOR FAN - 5.9L DIESEL

REMOVAL

CAUTION: If the electronically controlled viscous

fan drive is replaced because of mechanical dam-

age, the cooling fan blades should also be

inspected. Inspect for fatigue cracks, or loose rivets

that could have resulted from excessive vibration.

Replace fan blade assembly if any of these condi-

tions are found. Also inspect wiring harness and

connectors for damage.

(1) Disconnect the battery negative cables.

(2) Remove the fan shroud lower half. by unsnap-

ping the fastening tabs.

CAUTION: Do not remove the fan pulley bolts. This

pulley is under spring tension.

(3) Disconnect electrical connector.

(4) The electronically controlled viscous fan drive/

fan blade assembly is attached (threaded) to the fan

hub shaft (Fig. 5). Remove the fan blade/fan drive

assembly from fan pulley by turning the mounting

nut counterclockwise (as viewed from front). Threads

on the viscous fan drive areRIGHT-HAND.A

Snap-On 36 MM Fan Wrench (number SP346 from

Snap-On Cummins Diesel Tool Set number 2017DSP)

can be used. Place a bar or screwdriver between the

fan pulley bolts to prevent pulley from rotating.

(5) Remove the fan shroud and the fan blade/vis-

cous drive as an assembly from vehicle from under

the vehicle.

(6) Remove fan blade-to-viscous fan drive mount-

ing bolts.

(7) Inspect the fan for cracks, loose or bent fan

blades.

CAUTION: Some engines equipped with serpentine

drive belts have reverse rotating fans and viscous

fan drives. Installation of the wrong fan or viscous

fan drive can result in engine overheating.

CLEANING

Clean the fan blades using a mild soap and water.

Do not use an abrasive to clean the blades.

INSPECTION

WARNING: DO NOT ATTEMPT TO BEND OR

STRAIGHTEN FAN BLADES IF FAN IS NOT WITHIN

SPECIFICATIONS.CAUTION: If fan blade assembly is replaced

because of mechanical damage, water pump and

viscous fan drive should also be inspected. These

components could have been damaged due to

excessive vibration.

(1) Remove fan blade assembly from viscous fan

drive unit (six bolts).

(2) Lay fan on a flat surface with leading edge fac-

ing down. With tip of blade touching flat surface,

replace fan if clearance between opposite blade and

surface is greater than 2.0 mm (.090 inch). Rocking

motion of opposite blades should not exceed 2.0 mm

(.090 inch). Test all blades in this manner.

(3) Inspect fan assembly for cracks, bends, or bro-

ken welds. Replace fan if any damage is found.

INSTALLATION

(1) Install fan blade assembly to electrically con-

trolled viscous fan drive. Tighten mounting bolts to

23 N´m (17 ft. lbs.) torque.

(2) Position the fan blade/viscous fan drive to the

vehicle as an assembly.

(3) Install viscous fan drive assembly on fan hub

shaft (Fig. 5). Tighten mounting nut to 33 N´m (24 ft.

lbs.) torque.

(4) Connect electrical connector.

Fig. 5 Fan Blade/Viscous Fan Drive

1 - ELECTRICAL CONNECTOR

2 - VISCOUS FAN DRIVE

3 - FAN BLADE

4 - BOLT

5 - FAN DRIVE

DRENGINE 7 - 41

Page 337 of 2895

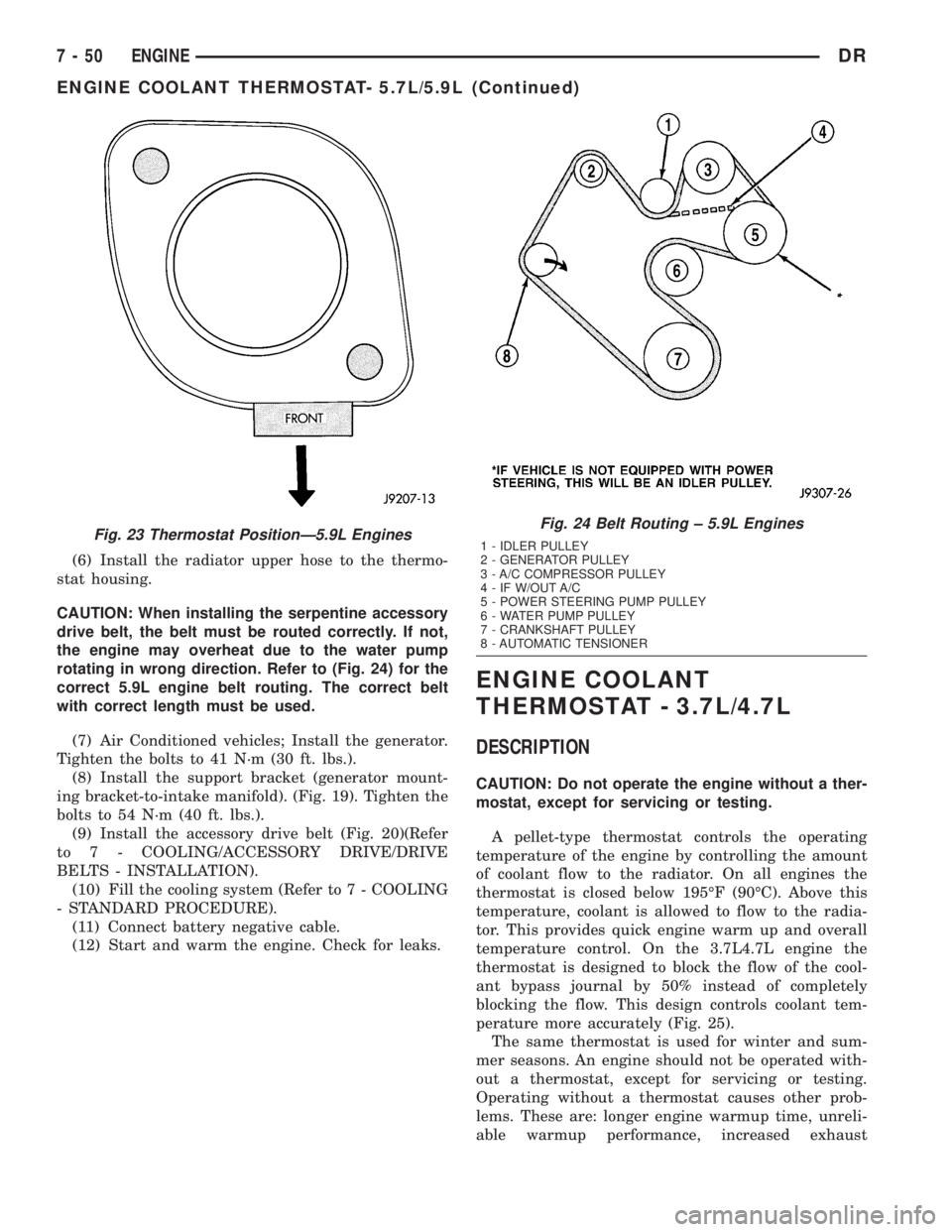

(6) Install the radiator upper hose to the thermo-

stat housing.

CAUTION: When installing the serpentine accessory

drive belt, the belt must be routed correctly. If not,

the engine may overheat due to the water pump

rotating in wrong direction. Refer to (Fig. 24) for the

correct 5.9L engine belt routing. The correct belt

with correct length must be used.

(7) Air Conditioned vehicles; Install the generator.

Tighten the bolts to 41 N´m (30 ft. lbs.).

(8) Install the support bracket (generator mount-

ing bracket-to-intake manifold). (Fig. 19). Tighten the

bolts to 54 N´m (40 ft. lbs.).

(9) Install the accessory drive belt (Fig. 20)(Refer

to 7 - COOLING/ACCESSORY DRIVE/DRIVE

BELTS - INSTALLATION).

(10) Fill the cooling system (Refer to 7 - COOLING

- STANDARD PROCEDURE).

(11) Connect battery negative cable.

(12) Start and warm the engine. Check for leaks.

ENGINE COOLANT

THERMOSTAT - 3.7L/4.7L

DESCRIPTION

CAUTION: Do not operate the engine without a ther-

mostat, except for servicing or testing.

A pellet-type thermostat controls the operating

temperature of the engine by controlling the amount

of coolant flow to the radiator. On all engines the

thermostat is closed below 195ÉF (90ÉC). Above this

temperature, coolant is allowed to flow to the radia-

tor. This provides quick engine warm up and overall

temperature control. On the 3.7L4.7L engine the

thermostat is designed to block the flow of the cool-

ant bypass journal by 50% instead of completely

blocking the flow. This design controls coolant tem-

perature more accurately (Fig. 25).

The same thermostat is used for winter and sum-

mer seasons. An engine should not be operated with-

out a thermostat, except for servicing or testing.

Operating without a thermostat causes other prob-

lems. These are: longer engine warmup time, unreli-

able warmup performance, increased exhaust

Fig. 23 Thermostat PositionÐ5.9L EnginesFig. 24 Belt Routing ± 5.9L Engines

1 - IDLER PULLEY

2 - GENERATOR PULLEY

3 - A/C COMPRESSOR PULLEY

4 - IF W/OUT A/C

5 - POWER STEERING PUMP PULLEY

6 - WATER PUMP PULLEY

7 - CRANKSHAFT PULLEY

8 - AUTOMATIC TENSIONER

7 - 50 ENGINEDR

ENGINE COOLANT THERMOSTAT- 5.7L/5.9L (Continued)