fuses DODGE RAM 2003 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1240 of 2895

8W-97 POWER DISTRIBUTION

TABLE OF CONTENTS

page page

POWER DISTRIBUTION

DESCRIPTION..........................1

OPERATION............................1

SPECIAL TOOLS

POWER DISTRIBUTION SYSTEMS.........2

CIGAR LIGHTER OUTLET

DESCRIPTION..........................2

OPERATION............................2

DIAGNOSIS AND TESTING - CIGAR LIGHTER

OUTLET.............................2

INTEGRATED POWER MODULE

DESCRIPTION..........................3

OPERATION............................3

REMOVAL.............................3

INSTALLATION..........................4

FRONT CONTROL MODULE

DESCRIPTION..........................4

OPERATION............................5

DIAGNOSIS AND TESTING - FRONT

CONTROL MODULE....................5

REMOVAL.............................5

INSTALLATION..........................5

IOD FUSE

DESCRIPTION..........................6OPERATION............................6

REMOVAL.............................6

INSTALLATION..........................7

POWER OUTLET

DESCRIPTION..........................7

OPERATION............................7

DIAGNOSIS AND TESTING - POWER OUTLET . 7

REMOVAL.............................7

INSTALLATION..........................7

RELAY

DESCRIPTION..........................8

OPERATION............................8

DIAGNOSIS AND TESTING - RELAY.........8

REMOVAL.............................9

INSTALLATION..........................9

MICRO RELAY

DESCRIPTION..........................9

OPERATION............................9

DIAGNOSIS AND TESTING - MICRO-RELAY . . . 9

REMOVAL.............................10

INSTALLATION.........................10

POWER DISTRIBUTION

DESCRIPTION

This group covers the various standard and

optional power distribution components used on this

model. The power distribution system for this vehicle

consists of the following components:

²Integrated Power Module (IPM)

²Front Control Module (FCM)

²Power Distribution Center (PDC)

²Power Outlets

²Cigar Lighter Outlets

²Relays

Refer to Wiring Diagrams for complete circuit sche-

matics.

The power distribution system also incorporates

various types of circuit control and protection fea-

tures, including:

²Automatic resetting circuit breakers

²Blade-type fuses

²Cartridge fuses

²RelaysFollowing are general descriptions of the major

components in the power distribution system. See the

owner's manual in the vehicle glove box for more

information on the features and use of all of the

power distribution system components.

OPERATION

The power distribution system for this vehicle is

designed to provide safe, reliable, and centralized dis-

tribution points for the electrical current required to

operate all of the many standard and optional facto-

ry-installed electrical and electronic powertrain,

chassis, safety, security, comfort and convenience sys-

tems. At the same time, the power distribution sys-

tem was designed to provide ready access to these

electrical distribution points for the vehicle techni-

cian to use when conducting diagnosis and repair of

faulty circuits. The power distribution system can

also prove useful for the sourcing of additional elec-

trical circuits that may be required to provide the

electrical current needed to operate many accessories

that the vehicle owner may choose to have installed

in the aftermarket.

DR8W-97 POWER DISTRIBUTION 8W - 97 - 1

Page 1242 of 2895

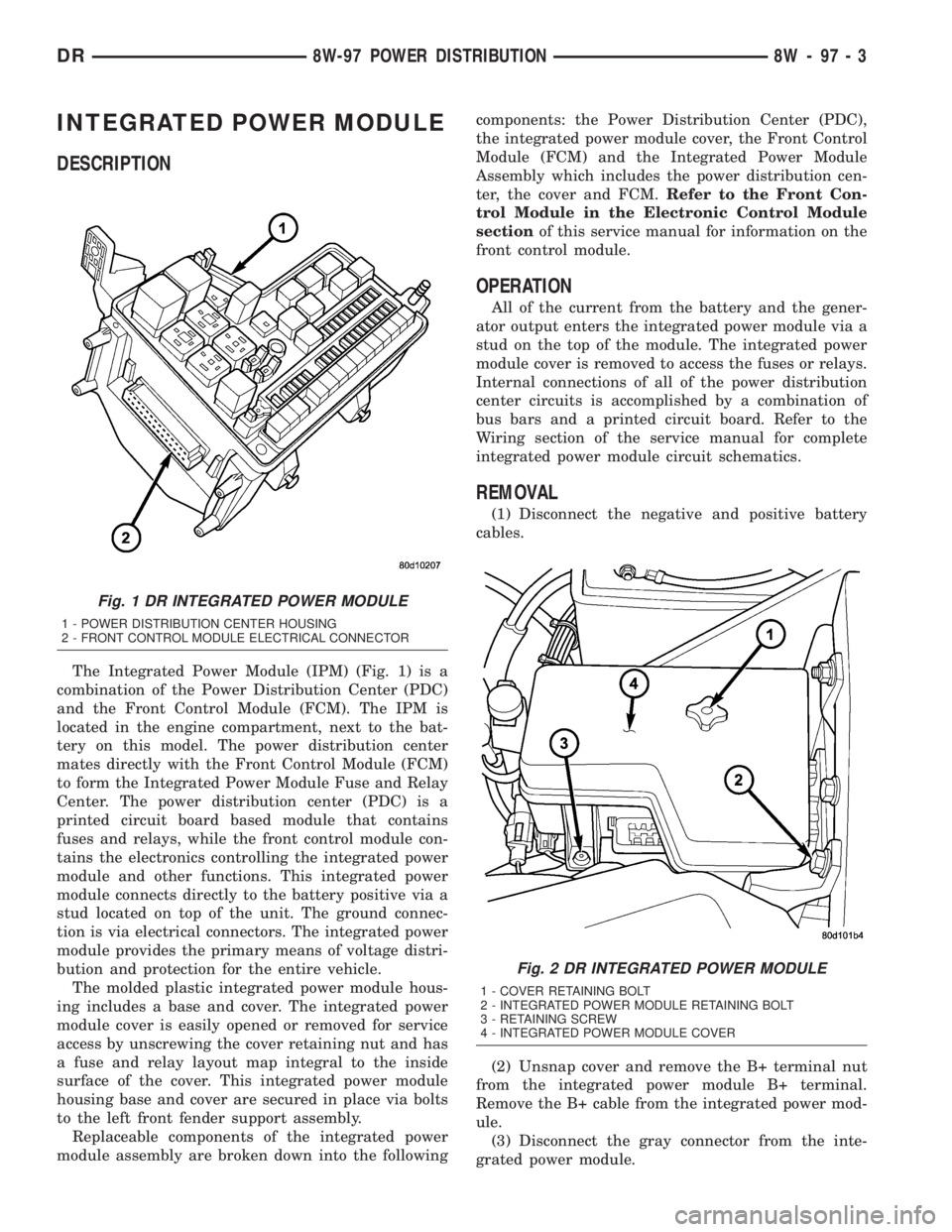

INTEGRATED POWER MODULE

DESCRIPTION

The Integrated Power Module (IPM) (Fig. 1) is a

combination of the Power Distribution Center (PDC)

and the Front Control Module (FCM). The IPM is

located in the engine compartment, next to the bat-

tery on this model. The power distribution center

mates directly with the Front Control Module (FCM)

to form the Integrated Power Module Fuse and Relay

Center. The power distribution center (PDC) is a

printed circuit board based module that contains

fuses and relays, while the front control module con-

tains the electronics controlling the integrated power

module and other functions. This integrated power

module connects directly to the battery positive via a

stud located on top of the unit. The ground connec-

tion is via electrical connectors. The integrated power

module provides the primary means of voltage distri-

bution and protection for the entire vehicle.

The molded plastic integrated power module hous-

ing includes a base and cover. The integrated power

module cover is easily opened or removed for service

access by unscrewing the cover retaining nut and has

a fuse and relay layout map integral to the inside

surface of the cover. This integrated power module

housing base and cover are secured in place via bolts

to the left front fender support assembly.

Replaceable components of the integrated power

module assembly are broken down into the followingcomponents: the Power Distribution Center (PDC),

the integrated power module cover, the Front Control

Module (FCM) and the Integrated Power Module

Assembly which includes the power distribution cen-

ter, the cover and FCM.Refer to the Front Con-

trol Module in the Electronic Control Module

sectionof this service manual for information on the

front control module.

OPERATION

All of the current from the battery and the gener-

ator output enters the integrated power module via a

stud on the top of the module. The integrated power

module cover is removed to access the fuses or relays.

Internal connections of all of the power distribution

center circuits is accomplished by a combination of

bus bars and a printed circuit board. Refer to the

Wiring section of the service manual for complete

integrated power module circuit schematics.

REMOVAL

(1) Disconnect the negative and positive battery

cables.

(2) Unsnap cover and remove the B+ terminal nut

from the integrated power module B+ terminal.

Remove the B+ cable from the integrated power mod-

ule.

(3) Disconnect the gray connector from the inte-

grated power module.

Fig. 1 DR INTEGRATED POWER MODULE

1 - POWER DISTRIBUTION CENTER HOUSING

2 - FRONT CONTROL MODULE ELECTRICAL CONNECTOR

Fig. 2 DR INTEGRATED POWER MODULE

1 - COVER RETAINING BOLT

2 - INTEGRATED POWER MODULE RETAINING BOLT

3 - RETAINING SCREW

4 - INTEGRATED POWER MODULE COVER

DR8W-97 POWER DISTRIBUTION 8W - 97 - 3

Page 2778 of 2895

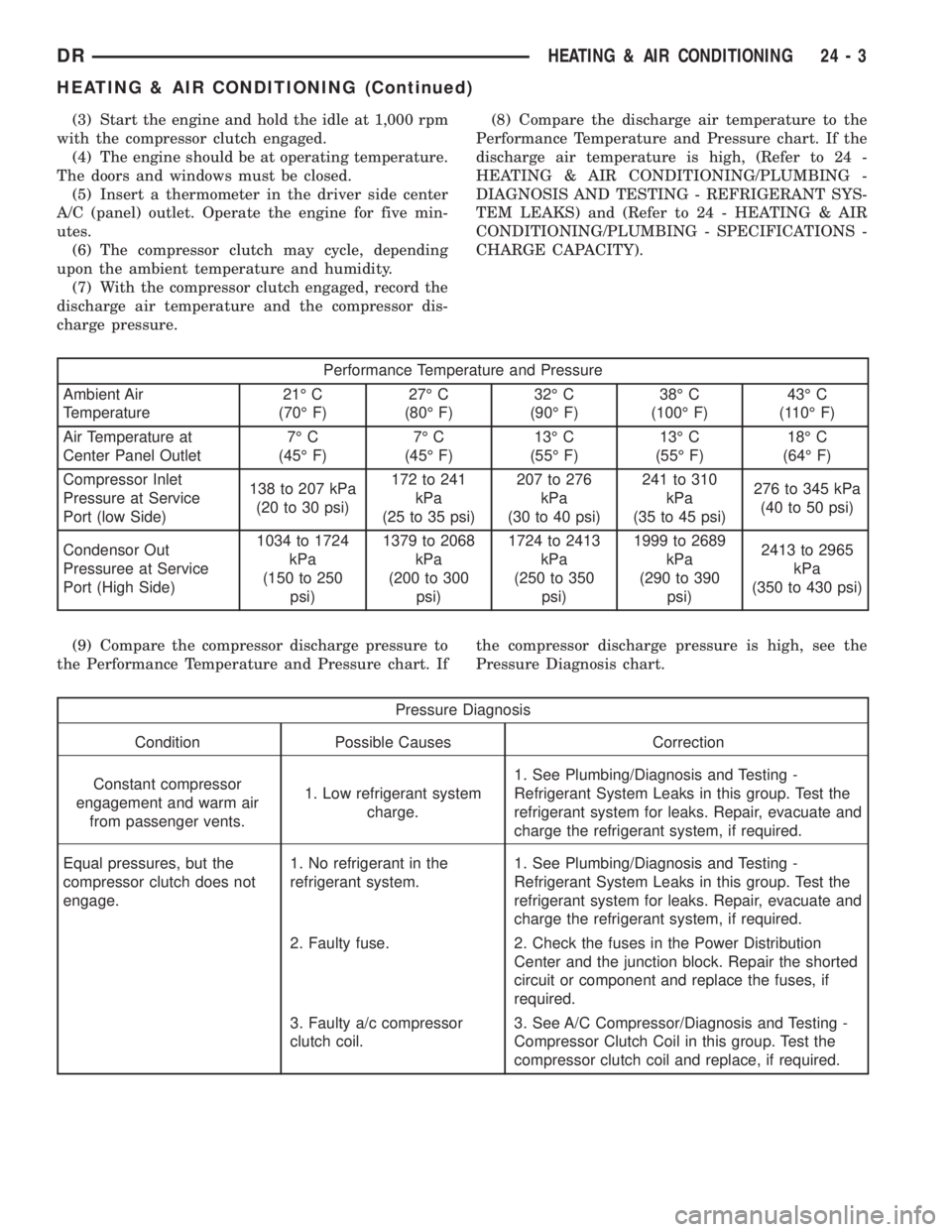

(3) Start the engine and hold the idle at 1,000 rpm

with the compressor clutch engaged.

(4) The engine should be at operating temperature.

The doors and windows must be closed.

(5) Insert a thermometer in the driver side center

A/C (panel) outlet. Operate the engine for five min-

utes.

(6) The compressor clutch may cycle, depending

upon the ambient temperature and humidity.

(7) With the compressor clutch engaged, record the

discharge air temperature and the compressor dis-

charge pressure.(8) Compare the discharge air temperature to the

Performance Temperature and Pressure chart. If the

discharge air temperature is high, (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

DIAGNOSIS AND TESTING - REFRIGERANT SYS-

TEM LEAKS) and (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - SPECIFICATIONS -

CHARGE CAPACITY).

Performance Temperature and Pressure

Ambient Air

Temperature21É C

(70É F)27É C

(80É F)32É C

(90É F)38É C

(100É F)43É C

(110É F)

Air Temperature at

Center Panel Outlet7É C

(45É F)7É C

(45É F)13É C

(55É F)13É C

(55É F)18É C

(64É F)

Compressor Inlet

Pressure at Service

Port (low Side)138 to 207 kPa

(20 to 30 psi)172 to 241

kPa

(25 to 35 psi)207 to 276

kPa

(30 to 40 psi)241 to 310

kPa

(35 to 45 psi)276 to 345 kPa

(40 to 50 psi)

Condensor Out

Pressuree at Service

Port (High Side)1034 to 1724

kPa

(150 to 250

psi)1379 to 2068

kPa

(200 to 300

psi)1724 to 2413

kPa

(250 to 350

psi)1999 to 2689

kPa

(290 to 390

psi)2413 to 2965

kPa

(350 to 430 psi)

(9) Compare the compressor discharge pressure to

the Performance Temperature and Pressure chart. Ifthe compressor discharge pressure is high, see the

Pressure Diagnosis chart.

Pressure Diagnosis

Condition Possible Causes Correction

Constant compressor

engagement and warm air

from passenger vents.1. Low refrigerant system

charge.1. See Plumbing/Diagnosis and Testing -

Refrigerant System Leaks in this group. Test the

refrigerant system for leaks. Repair, evacuate and

charge the refrigerant system, if required.

Equal pressures, but the

compressor clutch does not

engage.1. No refrigerant in the

refrigerant system.1. See Plumbing/Diagnosis and Testing -

Refrigerant System Leaks in this group. Test the

refrigerant system for leaks. Repair, evacuate and

charge the refrigerant system, if required.

2. Faulty fuse. 2. Check the fuses in the Power Distribution

Center and the junction block. Repair the shorted

circuit or component and replace the fuses, if

required.

3. Faulty a/c compressor

clutch coil.3. See A/C Compressor/Diagnosis and Testing -

Compressor Clutch Coil in this group. Test the

compressor clutch coil and replace, if required.

DRHEATING & AIR CONDITIONING 24 - 3

HEATING & AIR CONDITIONING (Continued)

Page 2785 of 2895

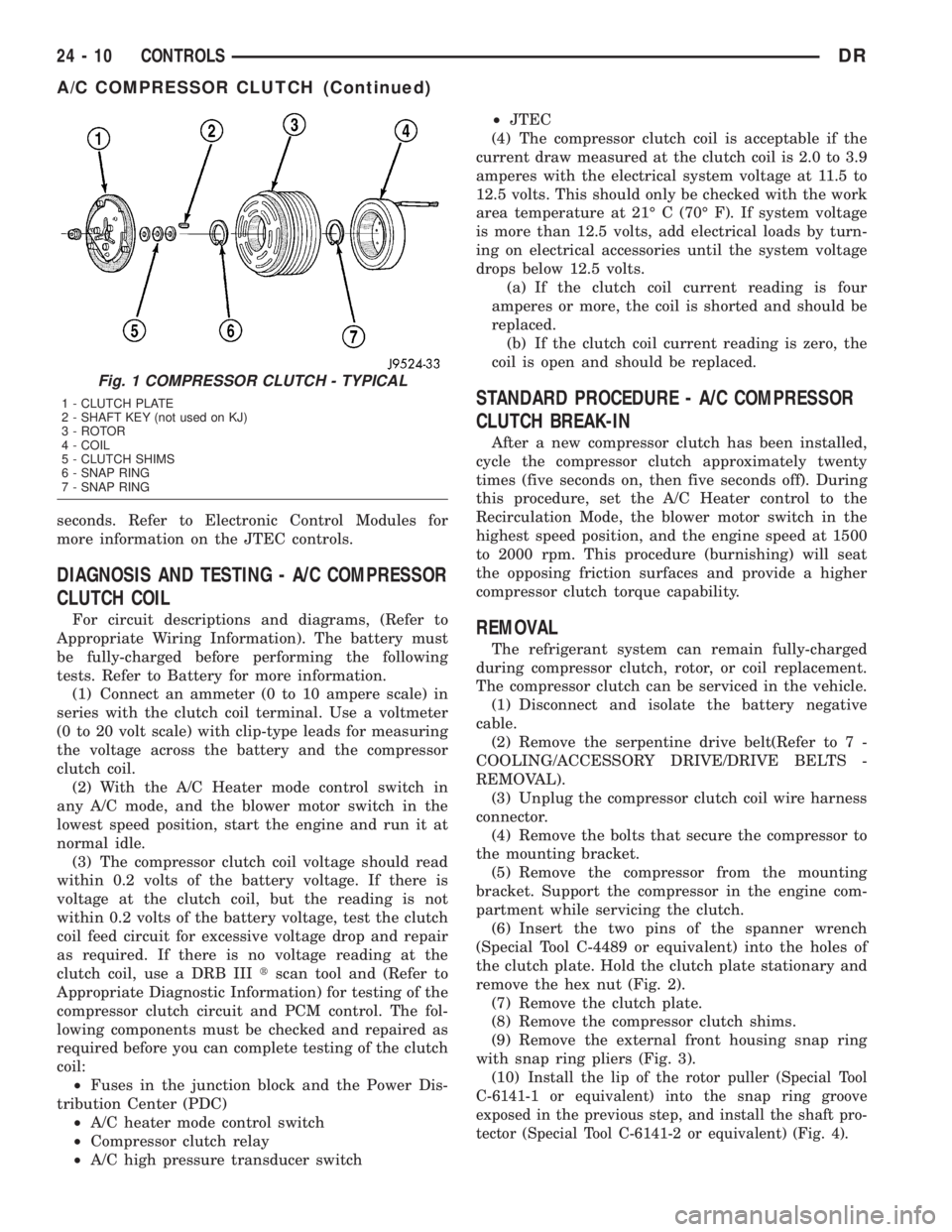

seconds. Refer to Electronic Control Modules for

more information on the JTEC controls.

DIAGNOSIS AND TESTING - A/C COMPRESSOR

CLUTCH COIL

For circuit descriptions and diagrams, (Refer to

Appropriate Wiring Information). The battery must

be fully-charged before performing the following

tests. Refer to Battery for more information.

(1) Connect an ammeter (0 to 10 ampere scale) in

series with the clutch coil terminal. Use a voltmeter

(0 to 20 volt scale) with clip-type leads for measuring

the voltage across the battery and the compressor

clutch coil.

(2) With the A/C Heater mode control switch in

any A/C mode, and the blower motor switch in the

lowest speed position, start the engine and run it at

normal idle.

(3) The compressor clutch coil voltage should read

within 0.2 volts of the battery voltage. If there is

voltage at the clutch coil, but the reading is not

within 0.2 volts of the battery voltage, test the clutch

coil feed circuit for excessive voltage drop and repair

as required. If there is no voltage reading at the

clutch coil, use a DRB IIItscan tool and (Refer to

Appropriate Diagnostic Information) for testing of the

compressor clutch circuit and PCM control. The fol-

lowing components must be checked and repaired as

required before you can complete testing of the clutch

coil:

²Fuses in the junction block and the Power Dis-

tribution Center (PDC)

²A/C heater mode control switch

²Compressor clutch relay

²A/C high pressure transducer switch²JTEC

(4) The compressor clutch coil is acceptable if the

current draw measured at the clutch coil is 2.0 to 3.9

amperes with the electrical system voltage at 11.5 to

12.5 volts. This should only be checked with the work

area temperature at 21É C (70É F). If system voltage

is more than 12.5 volts, add electrical loads by turn-

ing on electrical accessories until the system voltage

drops below 12.5 volts.

(a) If the clutch coil current reading is four

amperes or more, the coil is shorted and should be

replaced.

(b) If the clutch coil current reading is zero, the

coil is open and should be replaced.

STANDARD PROCEDURE - A/C COMPRESSOR

CLUTCH BREAK-IN

After a new compressor clutch has been installed,

cycle the compressor clutch approximately twenty

times (five seconds on, then five seconds off). During

this procedure, set the A/C Heater control to the

Recirculation Mode, the blower motor switch in the

highest speed position, and the engine speed at 1500

to 2000 rpm. This procedure (burnishing) will seat

the opposing friction surfaces and provide a higher

compressor clutch torque capability.

REMOVAL

The refrigerant system can remain fully-charged

during compressor clutch, rotor, or coil replacement.

The compressor clutch can be serviced in the vehicle.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the serpentine drive belt(Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(3) Unplug the compressor clutch coil wire harness

connector.

(4) Remove the bolts that secure the compressor to

the mounting bracket.

(5) Remove the compressor from the mounting

bracket. Support the compressor in the engine com-

partment while servicing the clutch.

(6) Insert the two pins of the spanner wrench

(Special Tool C-4489 or equivalent) into the holes of

the clutch plate. Hold the clutch plate stationary and

remove the hex nut (Fig. 2).

(7) Remove the clutch plate.

(8) Remove the compressor clutch shims.

(9) Remove the external front housing snap ring

with snap ring pliers (Fig. 3).

(10)

Install the lip of the rotor puller (Special Tool

C-6141-1 or equivalent) into the snap ring groove

exposed in the previous step, and install the shaft pro-

tector (Special Tool C-6141-2 or equivalent) (Fig. 4).

Fig. 1 COMPRESSOR CLUTCH - TYPICAL

1 - CLUTCH PLATE

2 - SHAFT KEY (not used on KJ)

3 - ROTOR

4 - COIL

5 - CLUTCH SHIMS

6 - SNAP RING

7 - SNAP RING

24 - 10 CONTROLSDR

A/C COMPRESSOR CLUTCH (Continued)

Page 2870 of 2895

FUEL INJECTOR RAIL - DESCRIPTION....14-89

FUEL INJECTOR RAIL - INSTALLATION....14-90

FUEL INJECTOR RAIL - OPERATION......14-89

FUEL INJECTOR RAIL - REMOVAL.......14-89

FUEL LEVEL SENDING UNIT / SENSOR -

DESCRIPTION...................14-68,14-7

FUEL LEVEL SENDING UNIT / SENSOR -

INSTALLATION........................14-8

FUEL LEVEL SENDING UNIT / SENSOR -

OPERATION.....................14-68,14-7

FUEL LEVEL SENDING UNIT / SENSOR -

REMOVAL...........................14-7

FUEL LINE LEAKS - DIAGNOSIS AND

TESTING, HIGH-PRESSURE.............14-69

FUEL LINES - DESCRIPTION........14-69,14-8

FUEL LINES - INSTALLATION...........14-71

FUEL LINES - OPERATION..............14-69

FUEL LINES - REMOVAL...............14-69

FUEL PRESSURE LIMITING VALVE -

DESCRIPTION.......................14-72

FUEL PRESSURE LIMITING VALVE -

INSTALLATION.......................14-73

FUEL PRESSURE LIMITING VALVE -

OPERATION.........................14-72

FUEL PRESSURE LIMITING VALVE -

REMOVAL..........................14-72

FUEL PRESSURE SENSOR -

DESCRIPTION.......................14-72

FUEL PRESSURE SENSOR -

INSTALLATION.......................14-72

FUEL PRESSURE SENSOR - OPERATION....14-72

FUEL PRESSURE SENSOR - REMOVAL....14-72

FUEL PUMP - DESCRIPTION............14-12

FUEL PUMP - OPERATION.............14-12

FUEL PUMP MODULE - DESCRIPTION....14-12

FUEL PUMP MODULE - INSTALLATION . . . 14-13

FUEL PUMP MODULE - OPERATION......14-12

FUEL PUMP MODULE - REMOVAL.......14-12

FUEL PUMP RELAY - DESCRIPTION......14-33

FUEL PUMP RELAY - INSTALLATION.....14-33

FUEL PUMP RELAY - OPERATION........14-33

FUEL PUMP RELAY - REMOVAL.........14-33

FUEL PUMP RELAYS - DIAGNOSIS AND

TESTING, ASD........................8I-7

FUEL RAIL - DESCRIPTION.............14-13

FUEL RAIL - INSTALLATION............14-18

FUEL RAIL - OPERATION...............14-13

FUEL RAIL - REMOVAL................14-13

FUEL REQUIREMENTS - DIESEL ENGINE

- DESCRIPTION........................0-1

FUEL SENSOR - DESCRIPTION, WATER

IN ................................14-77

FUEL SENSOR - OPERATION, WATER IN . . 14-78

FUEL SENSOR - REMOVAL, WATER IN....14-78

FUEL SYSTEM - DESCRIPTION, DIESEL . . . 14-57

FUEL SYSTEM - TORQUE...............14-3

FUEL SYSTEM PARTS - STANDARD

PROCEDURES, CLEANING..............14-58

FUEL SYSTEM PRESSURE, DIESEL.......14-60

FUEL SYSTEM PRESSURE RELEASE -

STANDARD PROCEDURE................14-2

FUEL SYSTEM PRESSURE,

SPECIFICATIONS......................14-3

FUEL SYSTEM PRIMING - STANDARD

PROCEDURE........................14-59

FUEL SYSTEM, SPECIAL TOOLS..........14-5

FUEL SYSTEM, SPECIAL TOOLS -

DIESEL............................14-60

FUEL TANK - DESCRIPTION............14-20

FUEL TANK - OPERATION..............14-20

FUEL TANK MODULE - DESCRIPTION.....14-75

FUEL TANK MODULE - INSTALLATION....14-75

FUEL TANK MODULE - OPERATION......14-75

FUEL TANK MODULE - REMOVAL........14-75

FUEL TRANSFER PUMP - DESCRIPTION . . 14-75

FUEL TRANSFER PUMP - INSTALLATION . . 14-76

FUEL TRANSFER PUMP - OPERATION....14-76

FUEL TRANSFER PUMP - REMOVAL......14-76

FULL SIZE, SPARE WHEEL WITH

MATCHING TIRE - DESCRIPTION........22-15

FUNCTIONS - DESCRIPTION, CIRCUIT . . 8W-01-6

FUSE - DESCRIPTION, IOD

...........8W-97-6

FUSE - INSTALLATION, IOD

..........8W-97-7

FUSE - OPERATION, IOD

.............8W-97-6

FUSE - REMOVAL, IOD

..............8W-97-6

FUSES POWERING SEVERAL LOADS -

STANDARD PROCEDURE, TESTING

FOR A SHORT TO GROUND ON

......8W-01-10GAP AND FLUSH - SPECIFICATIONS......23-95

GAS - DESCRIPTION, FUEL DELIVERY.....14-1

GAS - INSTALLATION............19-30,19-41

GAS - OPERATION, FUEL DELIVERY.......14-2

GAS - REMOVAL................19-29,19-40

GAS ENGINE - DIAGNOSIS AND TESTING . . 11-2

GAS ENGINE - INSTALLATION...........19-24

GAS ENGINE - REMOVAL..............19-23

GASKET - DESCRIPTION, CYLINDER

HEAD COVER........................9-243

GASKET - DIAGNOSIS AND TESTING,

CYLINDER HEAD......................9-20

GASKET - OPERATION, CYLINDER HEAD

COVER.............................9-243

GASKET FAILURE - DIAGNOSIS AND

TESTING, CYLINDER HEAD . . . 9-194,9-243,9-370

GASKET SELECTION - STANDARD

PROCEDURE, HEAD...................9-330

GASKET SURFACE PREPARATION -

STANDARD PROCEDURE, ENGINE........9-10

GASKETS AND SEALERS - STANDARD

PROCEDURE, FORM-IN-PLACE....9-232,9-289,

9-360,9-9,9-93

GAUGE - DESCRIPTION, ENGINE

TEMPERATURE......................8J-23

GAUGE - DESCRIPTION, FUEL...........8J-25

GAUGE - DESCRIPTION, OIL PRESSURE . . 8J-32

GAUGE - DESCRIPTION, VOLTAGE.......8J-40

GAUGE - OPERATION, ENGINE

TEMPERATURE......................8J-23

GAUGE - OPERATION, FUEL............8J-26

GAUGE - OPERATION, OIL PRESSURE....8J-32

GAUGE - OPERATION, VOLTAGE.........8J-41

GAUGES - DIAGNOSIS AND TESTING,

PRESSURE..........................22-7

GAUGES INDICATOR - DESCRIPTION,

CHECK.............................8J-21

GAUGES INDICATOR - OPERATION,

CHECK.............................8J-21

GEAR - DESCRIPTION, CRANKSHAFT.....9-322

GEAR - INDEPENDENT FRONT

SUSPENSION - DESCRIPTION...........19-16

GEAR - INDEPENDENT FRONT

SUSPENSION - INSTALLATION..........19-17

GEAR - INDEPENDENT FRONT

SUSPENSION - REMOVAL..............19-16

GEAR - INSTALLATION................9-322

GEAR - INSTALLATION, PINION

GEAR/RING......................3-42,3-66

GEAR - LINK/COIL - DESCRIPTION.......19-19

GEAR - LINK/COIL - INSTALLATION......19-20

GEAR - LINK/COIL - OPERATION........19-19

GEAR - LINK/COIL - REMOVAL..........19-19

GEAR - REMOVAL....................9-322

GEAR - REMOVAL, PINION GEAR/RING....3-40,

3-65

GEAR HOUSING - INSTALLATION........9-349

GEAR HOUSING - REMOVAL............9-348

GEAR HOUSING COVER - INSTALLATION . . 9-350

GEAR HOUSING COVER - REMOVAL.....9-349

GEAR INPUT SHAFT SEAL -

INSTALLATION, STEERING.............19-28

GEAR INPUT SHAFT SEAL - REMOVAL,

STEERING..........................19-25

GEAR SELECTOR INDICATOR -

DESCRIPTION.......................8J-26

GEAR SELECTOR INDICATOR -

OPERATION.........................8J-27

GEAR SHIFT LEVER - INSTALLATION.....19-12

GEAR SHIFT LEVER - REMOVAL.........19-12

GEAR, SPECIAL TOOLS - POWER

STEERING..........................19-22

GEAR, SPECIFICATIONS - POWER

STEERING..........................19-21

GEAR TO COOLER - INSTALLATION,

RETURN HOSE.................19-43,19-44

GEAR TO COOLER - REMOVAL, RETURN

HOSE..............................19-43

GEAR/RING GEAR - INSTALLATION,

PINION

.........................3-42,3-66

GEAR/RING GEAR - REMOVAL, PINION

....3-40,

3-65

GEAR/RING GEAR/TONE RING -

INSTALLATION, PINION

.......3-123,3-150,3-96

GEAR/RING GEAR/TONE RING -

REMOVAL, PINION

..........3-122,3-149,3-94

GEARSHIFT CABLE - DIAGNOSIS AND

TESTING

..............21-209,21-389,21-544GEARSHIFT CABLE - INSTALLATION....21-210,

21-390,21-545

GEARSHIFT CABLE - REMOVAL . . 21-209,21-389,

21-544

GEARSHIFT CABLE, ADJUSTMENTS.....21-211,

21-391,21-546

GEAR/TONE RING - INSTALLATION,

PINION GEAR/RING..........3-123,3-150,3-96

GEAR/TONE RING - REMOVAL, PINION

GEAR/RING................3-122,3-149,3-94

GEARTRAIN - ASSEMBLY, PLANETARY . . . 21-573

GEARTRAIN - CLEANING, PLANETARY . . . 21-573

GEARTRAIN - DESCRIPTION,

PLANETARY........................21-571

GEARTRAIN - DISASSEMBLY,

PLANETARY........................21-573

GEARTRAIN - INSPECTION, PLANETARY . 21-573

GEARTRAIN - OPERATION, PLANETARY . . 21-571

GEARTRAIN/OUTPUT SHAFT -

ASSEMBLY, PLANETARY........21-245,21-423

GEARTRAIN/OUTPUT SHAFT -

DESCRIPTION, PLANETARY......21-242,21-420

GEARTRAIN/OUTPUT SHAFT -

DISASSEMBLY, PLANETARY.....21-243,21-421

GEARTRAIN/OUTPUT SHAFT -

INSPECTION, PLANETARY.......21-245,21-422

GEARTRAIN/OUTPUT SHAFT -

OPERATION, PLANETARY.......21-243,21-420

GENERAL - WARNINGS.............8W-01-7

GENERATOR / CHARGING SYSTEM -

SPECIFICATIONS, TORQUE.............8F-20

GENERATOR - DESCRIPTION.............8F-22

GENERATOR - INSTALLATION...........8F-25

GENERATOR - OPERATION.............8F-22

GENERATOR - REMOVAL...............8F-22

GENERATOR RATINGS, SPECIFICATIONS . . 8F-20

GENII - ASSEMBLY, TRANSFER CASE -

NV241............................21-604

GENII - CLEANING, TRANSFER CASE -

NV241............................21-602

GENII - DESCRIPTION, TRANSFER CASE

- NV241..............................0-4

GENII - DESCRIPTION, TRANSFER CASE

- NV241...........................21-591

GENII - DIAGNOSIS AND TESTING,

TRANSFER CASE - NV241.............21-592

GENII - DISASSEMBLY, TRANSFER CASE

- NV241...........................21-593

GENII - INSPECTION, TRANSFER CASE -

NV241............................21-602

GENII - INSTALLATION, TRANSFER CASE

- NV241...........................21-614

GENII - OPERATION, TRANSFER CASE -

NV241............................21-591

GENII - REMOVAL, TRANSFER CASE -

NV241............................21-593

GENII - TRANSFER CASE, NV241.......21-614

GLASS - INSTALLATION, BACKLITE VENT . 23-87

GLASS - INSTALLATION, DOOR....23-20,23-30

GLASS - INSTALLATION, SIDE VIEW

MIRROR...........................23-44

GLASS - REMOVAL, BACKLITE VENT.....23-87

GLASS - REMOVAL, DOOR........23-20,23-30

GLASS - REMOVAL, SIDE VIEW MIRROR . . 23-42

GLASS RUN CHANNEL - INSTALLATION . . 23-21,

23-31

GLASS RUN CHANNEL - REMOVAL . 23-21,23-30

GLASS RUN WEATHERSTRIP -

INSTALLATION, FRONT DOOR...........23-92

GLASS RUN WEATHERSTRIP -

INSTALLATION, REAR DOOR............23-93

GLASS RUN WEATHERSTRIP -

REMOVAL, FRONT DOOR..............23-92

GLASS RUN WEATHERSTRIP -

REMOVAL, REAR DOOR...............23-93

GLOVE BOX - INSTALLATION...........23-53

GLOVE BOX - REMOVAL...............23-53

GLOVE BOX LAMP/SWITCH -

INSTALLATION.......................8L-25

GLOVE BOX LAMP/SWITCH - REMOVAL . . . 8L-25

GLOVE BOX LATCH - INSTALLATION

.....23-53

GLOVE BOX LATCH - REMOVAL

.........23-53

GOVERNOR - DESCRIPTION,

ELECTRONIC

.................21-196,21-376

GOVERNOR - INSTALLATION,

ELECTRONIC

.................21-199,21-379

GOVERNOR - OPERATION, ELECTRONIC

. 21-196,

21-377

DRINDEX 15

Description Group-Page Description Group-Page Description Group-Page

Page 2871 of 2895

GOVERNOR - REMOVAL, ELECTRONIC . . 21-198,

21-378

GRAB HANDLE - INSTALLATION,

B-PILLAR...........................23-69

GRAB HANDLE - REMOVAL, B-PILLAR....23-69

GRILLE - INSTALLATION...............23-40

GRILLE - INSTALLATION, COWL.........23-38

GRILLE - REMOVAL..................23-39

GRILLE - REMOVAL, COWL............23-38

GRILLE FRAME - INSTALLATION.........23-40

GRILLE FRAME - REMOVAL............23-40

GROUND - STANDARD PROCEDURE,

TESTING FOR A SHORT TO..........8W-01-9

GROUND AND SPLICE INFORMATION -

DESCRIPTION, CONNECTOR..........8W-01-7

GROUND ON FUSES POWERING

SEVERAL LOADS - STANDARD

PROCEDURE, TESTING FOR A SHORT

TO.............................8W-01-10

GROUND STRAP - DESCRIPTION, RADIO

NOISE SUPPRESSION..................8A-8

GROUND STRAP - INSTALLATION,

RADIO NOISE SUPPRESSION...........8A-10

GROUND STRAP - OPERATION, RADIO

NOISE SUPPRESSION..................8A-8

GROUND STRAP - REMOVAL, RADIO

NOISE SUPPRESSION..................8A-9

GROUNDS - DESCRIPTION, POWER......8E-10

GUIDE SEALS - DESCRIPTION, VALVE . 9-31,9-36

GUIDES - DESCRIPTION, VALVE....9-106,9-197

GUIDES AND SPRINGS - STANDARD

PROCEDURE, VALVES............9-246,9-305

HALF SHAFT - CAUTION................3-11

HALF SHAFT - DIAGNOSIS AND TESTING . . 3-11

HALF SHAFT - INSTALLATION............3-12

HALF SHAFT - REMOVAL...............3-11

HALF SHAFT - SPECIAL TOOLS..........3-12

HALF SHAFT - SPECIFICATIONS..........3-12

HANDLE - INSTALLATION, A-PILLAR

TRIM/GRAB.........................23-64

HANDLE - INSTALLATION, B-PILLAR

GRAB..............................23-69

HANDLE - INSTALLATION, EXTERIOR....23-20,

23-30

HANDLE - INSTALLATION, RELEASE.......5-38

HANDLE - REMOVAL, A-PILLAR

TRIM/GRAB.........................23-64

HANDLE - REMOVAL, B-PILLAR GRAB....23-69

HANDLE - REMOVAL, EXTERIOR . . . 23-20,23-30

HANDLE - REMOVAL, RELEASE..........5-38

HANDLE ACTUATOR - INSTALLATION,

INSIDE........................23-22,23-32

HANDLE ACTUATOR - REMOVAL, INSIDE . 23-22,

23-31

HANDLE/LATCH REMOTE -

INSTALLATION, RELEASE..............23-17

HANDLE/LATCH REMOTE - REMOVAL,

RELEASE...........................23-17

HANDLING NON-DEPLOYED

SUPPLEMENTAL RESTRAINTS -

STANDARD PROCEDURE...............8O-6

HARNESS - DIAGNOSIS AND TESTING,

WIRING..........................8W-01-7

HAT BRAKE - CLEANING, REAR DRUM

IN .................................5-33

HAT BRAKE - INSPECTION, REAR DRUM

IN .................................5-33

HAZARD SWITCH - DESCRIPTION.......8L-13

HAZARD SWITCH - OPERATION.........8L-13

HCU (HYDRAULIC CONTROL UNIT) -

DESCRIPTION........................5-43

HCU (HYDRAULIC CONTROL UNIT) -

INSTALLATION........................5-44

HCU (HYDRAULIC CONTROL UNIT) -

OPERATION..........................5-43

HCU (HYDRAULIC CONTROL UNIT) -

REMOVAL...........................5-44

HD - INSTALLATION, 4X4..............19-15

HD - INSTALLATION, ALL LD & HD

EXCEPT 4X4........................19-15

HD - REMOVAL, 4X4

..................19-14

HD - REMOVAL, ALL LD & HD EXCEPT

4X4

...............................19-14

HD EXCEPT 4X4 HD - INSTALLATION,

ALL LD

............................19-15

HD EXCEPT 4X4 HD - REMOVAL, ALL LD

. 19-14

HEAD - CLEANING, CYLINDER

.....9-195,9-300,

9-372HEAD - DESCRIPTION, CYLINDER . . 9-106,9-243,

9-298,9-370

HEAD - INSPECTION, CYLINDER . . . 9-195,9-301,

9-372

HEAD - INSTALLATION, CYLINDER . . 9-195,9-372

HEAD - INSTALLATION, LEFT CYLINDER . . 9-110

HEAD - INSTALLATION, RIGHT

CYLINDER..........................9-111

HEAD - LEFT - INSTALLATION,

CYLINDER...........................9-23

HEAD - LEFT - REMOVAL, CYLINDER......9-21

HEAD - OPERATION, CYLINDER....9-194,9-243

HEAD - REMOVAL, CYLINDER.....9-195,9-298,

9-371

HEAD - REMOVAL, LEFT CYLINDER......9-106

HEAD - REMOVAL, RIGHT CYLINDER.....9-108

HEAD - RIGHT - INSTALLATION,

CYLINDER...........................9-32

HEAD - RIGHT - REMOVAL, CYLINDER....9-32

HEAD COVER - INSTALLATION,

CYLINDER..........................9-304

HEAD COVER - REMOVAL, CYLINDER....9-304

HEAD COVER GASKET - DESCRIPTION,

CYLINDER..........................9-243

HEAD COVER GASKET - OPERATION,

CYLINDER..........................9-243

HEAD COVER(S) - CLEANING, CYLINDER . 9-245,

9-374

HEAD COVER(S) - DESCRIPTION,

CYLINDER.................9-121,9-26,9-373

HEAD COVER(S) - INSPECTION,

CYLINDER.....................9-245,9-374

HEAD COVER(S) - INSTALLATION,

CYLINDER........9-196,9-245,9-27,9-36,9-374

HEAD COVER(S) - REMOVAL, CYLINDER . 9-196,

9-245,9-26,9-35,9-373

HEAD GASKET - DIAGNOSIS AND

TESTING, CYLINDER...................9-20

HEAD GASKET FAILURE - DIAGNOSIS

AND TESTING, CYLINDER....9-194,9-243,9-370

HEAD GASKET SELECTION - STANDARD

PROCEDURE........................9-330

HEADLAMP - INSTALLATION............8L-13

HEADLAMP - REMOVAL...............8L-13

HEADLAMP ALIGNMENT - SPECIAL

TOOLS..............................8L-7

HEADLAMP SWITCH - DESCRIPTION.....8L-14

HEADLAMP SWITCH - INSTALLATION....8L-14

HEADLAMP SWITCH - OPERATION.......8L-14

HEADLAMP SWITCH - REMOVAL........8L-14

HEADLAMP SWITCH BEZEL -

INSTALLATION, INSTRUMENT PANEL.....23-57

HEADLAMP SWITCH BEZEL - REMOVAL,

INSTRUMENT PANEL..................23-57

HEADLAMP UNIT - ADJUSTMENTS......8L-15

HEADLAMP UNIT - INSTALLATION.......8L-15

HEADLAMP UNIT - REMOVAL...........8L-15

HEADLINER - INSTALLATION...........23-69

HEADLINER - REMOVAL...............23-69

HEADREST - INSTALLATION............23-82

HEADREST - REMOVAL................23-82

HEADREST SLEEVE - INSTALLATION.....23-82

HEADREST SLEEVE - REMOVAL.........23-82

HEAT SHIELDS - DESCRIPTION..........11-7

HEAT SHIELDS - INSTALLATION..........11-8

HEAT SHIELDS - REMOVAL.............11-7

HEAT STAKING - STANDARD

PROCEDURE.........................23-3

HEATED MIRROR SYSTEM -

DESCRIPTION........................8G-1

HEATED MIRROR SYSTEM - DIAGNOSIS

AND TESTING........................8G-2

HEATED MIRROR SYSTEM - OPERATION . . . 8G-1

HEATED SEAT ELEMENT - DESCRIPTION . . . 8G-5

HEATED SEAT ELEMENT - DIAGNOSIS

AND TESTING........................8G-6

HEATED SEAT ELEMENT - INSTALLATION . . 8G-6

HEATED SEAT ELEMENT - OPERATION.....8G-6

HEATED SEAT ELEMENT - REMOVAL......8G-6

HEATED SEAT MODULE - DESCRIPTION....8E-6

HEATED SEAT MODULE - DIAGNOSIS

AND TESTING........................8E-7

HEATED SEAT MODULE - INSTALLATION

. . . 8E-7

HEATED SEAT MODULE - OPERATION

.....8E-6

HEATED SEAT MODULE - REMOVAL

.......8E-7

HEATED SEAT SENSOR - DESCRIPTION

....8G-7

HEATED SEAT SENSOR - DIAGNOSIS

AND TESTING

........................8G-7HEATED SEAT SENSOR - OPERATION.....8G-7

HEATED SEAT SENSOR - REMOVAL.......8G-7

HEATED SEAT SWITCH - DESCRIPTION....8G-7

HEATED SEAT SWITCH - DIAGNOSIS

AND TESTING........................8G-8

HEATED SEAT SWITCH - INSTALLATION . . . 8G-9

HEATED SEAT SWITCH - OPERATION......8G-8

HEATED SEAT SWITCH - REMOVAL.......8G-9

HEATED SEAT SYSTEM - DESCRIPTION....8G-3

HEATED SEAT SYSTEM - DIAGNOSIS

AND TESTING........................8G-4

HEATED SEAT SYSTEM - OPERATION.....8G-4

HEATER - 5.9L DIESEL - DESCRIPTION,

ENGINE BLOCK.......................7-43

HEATER - 5.9L DIESEL - INSTALLATION,

ENGINE BLOCK.......................7-44

HEATER - 5.9L DIESEL - OPERATION,

ENGINE BLOCK.......................7-43

HEATER - 5.9L DIESEL - REMOVAL,

ENGINE BLOCK.......................7-43

HEATER - DESCRIPTION, ENGINE BLOCK . . . 7-42

HEATER - DESCRIPTION, FUEL..........14-63

HEATER - DESCRIPTION, INTAKE AIR.....14-91

HEATER - DIAGNOSIS AND TESTING,

ENGINE BLOCK.......................7-42

HEATER - DIAGNOSIS AND TESTING,

FUEL..............................14-63

HEATER - INSTALLATION, ENGINE

BLOCK..............................7-43

HEATER - INSTALLATION, INTAKE AIR......14-91

HEATER - OPERATION, ENGINE BLOCK....7-42

HEATER - OPERATION, FUEL............14-63

HEATER - OPERATION, INTAKE AIR......14-91

HEATER - REMOVAL, ENGINE BLOCK......7-43

HEATER - REMOVAL, INTAKE AIR........14-91

HEATER AND AIR CONDITIONER -

DESCRIPTION........................24-1

HEATER AND AIR CONDITIONER -

OPERATION..........................24-1

HEATER CONTROL - DESCRIPTION, A/C . . . 24-14

HEATER CONTROL - INSTALLATION, A/C . . 24-15

HEATER CONTROL - REMOVAL, A/C......24-14

HEATER CORE - DESCRIPTION..........24-50

HEATER CORE - INSTALLATION.........24-50

HEATER CORE - OPERATION............24-50

HEATER CORE - REMOVAL.............24-50

HEATER PERFORMANCE - DIAGNOSIS

AND TESTING........................24-5

HEATER RELAY - DESCRIPTION, FUEL....14-64

HEATER RELAY - DESCRIPTION, INTAKE

AIR ...............................14-92

HEATER RELAY - INSTALLATION, FUEL . . . 14-64

HEATER RELAY - INSTALLATION, INTAKE

AIR ...............................14-93

HEATER RELAY - OPERATION, FUEL......14-64

HEATER RELAY - OPERATION, INTAKE

AIR ...............................14-92

HEATER RELAY - REMOVAL, FUEL.......14-64

HEATER RELAY - REMOVAL, INTAKE AIR . . 14-93

HEIGHT ADJUSTMENT - 4WD (LD) -

STANDARD PROCEDURE.................2-3

HEIGHT MEASUREMENT - 4WD (LD) -

STANDARD PROCEDURE.................2-3

HIGH BEAM INDICATOR - DESCRIPTION . . 8J-27

HIGH BEAM INDICATOR - OPERATION

....8J-28

HIGH MOUNTED STOP LAMP -

INSTALLATION, CENTER

...............8L-10

HIGH MOUNTED STOP LAMP -

REMOVAL, CENTER

...................8L-10

HIGH MOUNTED STOP LAMP UNIT -

INSTALLATION, CENTER

...............8L-10

HIGH MOUNTED STOP LAMP UNIT -

REMOVAL, CENTER

...................8L-10

HIGH PRESSURE RELIEF VALVE -

DESCRIPTION

.......................24-35

HIGH PRESSURE RELIEF VALVE -

OPERATION

.........................24-36

HIGH SPEEDS - DESCRIPTION, TIRE

PRESSURE

..........................22-6

HIGH/LOW RELAY - DESCRIPTION,

WIPER

.............................8R-20

HIGH/LOW RELAY - DIAGNOSIS AND

TESTING, WIPER

.....................8R-21

HIGH/LOW RELAY - INSTALLATION,

WIPER

.............................8R-21

HIGH/LOW RELAY - OPERATION, WIPER

. . 8R-20

HIGH/LOW RELAY - REMOVAL, WIPER

. . . 8R-21

16 INDEXDR

Description Group-Page Description Group-Page Description Group-Page

Page 2875 of 2895

LEVEL - STANDARD PROCEDURE,

REFRIGERANT OIL...................24-54

LEVEL CHECK - STANDARD

PROCEDURE, COOLANT................7-17

LEVEL CHECK - STANDARD

PROCEDURE, FLUID.....21-201,21-381,21-542

LEVEL CHECKING - STANDARD

PROCEDURE, POWER STEERING FLUID . . . 19-42

LEVEL SENDING UNIT / SENSOR -

DESCRIPTION, FUEL..............14-68,14-7

LEVEL SENDING UNIT / SENSOR -

INSTALLATION, FUEL..................14-8

LEVEL SENDING UNIT / SENSOR -

OPERATION, FUEL................14-68,14-7

LEVEL SENDING UNIT / SENSOR -

REMOVAL, FUEL......................14-7

LEVEL SWITCH - DESCRIPTION,

WASHER FLUID......................8R-9

LEVEL SWITCH - INSTALLATION,

WASHER FLUID.....................8R-11

LEVEL SWITCH - OPERATION, WASHER

FLUID..............................8R-9

LEVEL SWITCH - REMOVAL, WASHER

FLUID.............................8R-10

LEVER - ADJUSTMENT, SHIFT . . . 21-622,21-657

LEVER - INSTALLATION, GEAR SHIFT.....19-12

LEVER - INSTALLATION, SHIFT . . . 21-621,21-656

LEVER - REMOVAL, GEAR SHIFT........19-12

LEVER - REMOVAL, SHIFT......21-620,21-655

LICENSE PLATE LAMP - INSTALLATION . . . 8L-16

LICENSE PLATE LAMP - REMOVAL.......8L-16

LICENSE PLATE LAMP UNIT -

INSTALLATION.......................8L-16

LICENSE PLATE LAMP UNIT - REMOVAL . . 8L-16

LID - INSTALLATION, CENTER SEAT

BACK..............................23-80

LID - REMOVAL, CENTER SEAT BACK....23-80

LIFTERS - CLEANING, HYDRAULIC . . 9-260,9-388

LIFTERS - INSTALLATION, HYDRAULIC . . . 9-260,

9-388

LIFTERS - REMOVAL, HYDRAULIC . . 9-259,9-387

LIFTERS/TAPPETS - CLEANING, SOLID....9-328

LIFTERS/TAPPETS - INSPECTION, SOLID . . 9-328

LIFTERS/TAPPETS - INSTALLATION,

SOLID.............................9-328

LIFTERS/TAPPETS - REMOVAL, SOLID....9-327

LIGHT DUTY FRONT FRAME RAIL TIP

REPLACEMENT - STANDARD

PROCEDURE.........................13-4

LIGHTER OUTLET - DESCRIPTION,

CIGAR...........................8W-97-2

LIGHTER OUTLET - DIAGNOSIS AND

TESTING, CIGAR...................8W-97-2

LIGHTER OUTLET - OPERATION, CIGAR . 8W-97-2

LIMITING VALVE - DESCRIPTION, FUEL

PRESSURE.........................14-72

LIMITING VALVE - INSTALLATION, FUEL

PRESSURE.........................14-73

LIMITING VALVE - OPERATION, FUEL

PRESSURE.........................14-72

LIMITING VALVE - REMOVAL, FUEL

PRESSURE.........................14-72

LINE - DESCRIPTION, REFRIGERANT.....24-32

LINE - INSTALLATION, LIQUID..........24-45

LINE - REMOVAL, LIQUID..............24-45

LINE COUPLER - DESCRIPTION,

REFRIGERANT.......................24-52

LINE COUPLER - INSTALLATION,

REFRIGERANT.......................24-53

LINE COUPLER - OPERATION,

REFRIGERANT.......................24-52

LINE COUPLER - REMOVAL,

REFRIGERANT.......................24-52

LINE LEAKS - DIAGNOSIS AND TESTING,

HIGH-PRESSURE FUEL................14-69

LINE PRESSURE (LP) SENSOR -

DESCRIPTION......................21-559

LINE PRESSURE (LP) SENSOR -

INSTALLATION......................21-560

LINE PRESSURE (LP) SENSOR -

OPERATION........................21-559

LINE PRESSURE (LP) SENSOR -

REMOVAL.........................21-559

LINES - DESCRIPTION, FUEL

.......14-69,14-8

LINES - DESCRIPTION, VACUUM

........25-22

LINES - INSTALLATION, FUEL

...........14-71

LINES - OPERATION, FUEL

.............14-69

LINES - OPERATION, REFRIGERANT

......24-32LINES - REMOVAL, FUEL..............14-69

LINK - INSTALLATION, DRAG...........19-35

LINK - REMOVAL, DRAG...............19-35

LINK CONNECTOR - DESCRIPTION, DATA . . 8E-3

LINK CONNECTOR - OPERATION, DATA....8E-3

LINKAGE - INSTALLATION...............6-13

LINKAGE - LINK/COIL - DESCRIPTION....19-33

LINKAGE - REMOVAL..................6-13

LINKAGE, SPECIAL TOOLS - STEERING . . . 19-35

LINK/COIL - DESCRIPTION, GEAR........19-19

LINK/COIL - DESCRIPTION, LINKAGE.....19-33

LINK/COIL - INSTALLATION, GEAR.......19-20

LINK/COIL - OPERATION, GEAR.........19-19

LINK/COIL - REMOVAL, GEAR...........19-19

LINK/COIL SUSPENSION - STANDARD

PROCEDURE, ALIGNMENT...............2-5

LIQUID LINE - INSTALLATION...........24-45

LIQUID LINE - REMOVAL..............24-45

LOAD FLOOR - INSTALLATION..........23-73

LOAD FLOOR - REMOVAL..............23-73

LOAD FLOOR SUPPORT CYLINDER -

INSTALLATION.......................23-73

LOAD FLOOR SUPPORT CYLINDER -

REMOVAL..........................23-73

LOADS - STANDARD PROCEDURE,

TESTING FOR A SHORT TO GROUND

ON FUSES POWERING SEVERAL.....8W-01-10

LOCATION - DESCRIPTION, CONNECTOR/

GROUND/SPLICE...................8W-91-1

LOCATIONS - SPECIFICATIONS, SEALER . 23-103

LOCATIONS - SPECIFICATIONS,

STRUCTURAL ADHESIVE..............23-113

LOCATIONS - SPECIFICATIONS, WELD . . . 23-122

LOCK - STANDARD PROCEDURE,

HYDROSTATIC........9-186,9-232,9-290,9-361

LOCK CYLINDER - DIAGNOSIS AND

TESTING, IGNITION SWITCH AND KEY....19-11

LOCK CYLINDER - INSTALLATION.......23-24

LOCK CYLINDER - REMOVAL...........23-24

LOCK MOTOR - DESCRIPTION, DOOR.....8N-5

LOCK MOTOR - DIAGNOSIS AND

TESTING, DOOR......................8N-5

LOCK MOTOR - OPERATION, DOOR.......8N-5

LOCK SWITCH - DIAGNOSIS AND

TESTING, POWER.....................8N-4

LOCK SWITCH - INSTALLATION, POWER . . . 8N-4

LOCK SWITCH - REMOVAL, POWER......8N-4

LOCKING RETRACTOR - DESCRIPTION,

AUTOMATIC........................8O-13

LOCKING RETRACTOR - OPERATION,

AUTOMATIC........................8O-14

LOCKS - DESCRIPTION, POWER.........8N-1

LOCKS - DIAGNOSIS AND TESTING,

POWER.............................8N-3

LOCKS - OPERATION, POWER...........8N-2

LOOP ADJUSTER - INSTALLATION, SEAT

BELT TURNING......................8O-50

LOOP ADJUSTER - REMOVAL, SEAT

BELT TURNING......................8O-50

LOOP BRACKETS - INSTALLATION, SEAT

BACK REAR - FOOTMANS..............23-85

LOOP BRACKETS - REMOVAL, SEAT

BACK REAR - FOOTMANS..............23-85

LOW FUEL INDICATOR - DESCRIPTION . . . 8J-29

LOW FUEL INDICATOR - OPERATION.....8J-29

LOWER BALL JOINT - DIAGNOSIS AND

TESTING............................2-18

LOWER BALL JOINT - INSTALLATION . 2-19,2-33

LOWER BALL JOINT - REMOVAL.....2-18,2-32

LOWER CONTROL ARM BUSHINGS -

2WD (LD) - INSTALLATION..............2-14

LOWER CONTROL ARM BUSHINGS -

2WD (LD) - REMOVAL.................2-12

LOWER CONTROL ARM BUSHINGS -

4WD (LD) - INSTALLATION..............2-13

LOWER CONTROL ARM BUSHINGS -

4WD (LD) - REMOVAL.................2-12

LOWER SURROUND - INSTALLATION,

INSTRUMENT PANEL..................23-60

LOWER SURROUND - REMOVAL,

INSTRUMENT PANEL

..................23-60

LOWER SUSPENSION ARM -

INSTALLATION

........................2-35

LOWER SUSPENSION ARM - REMOVAL

....2-35

LOWER TRIM - INSTALLATION,

B-PILLAR

...........................23-65

LOWER TRIM - INSTALLATION,

C-PILLAR

...........................23-68LOWER TRIM - REMOVAL, B-PILLAR.....23-64

LOWER TRIM - REMOVAL, C-PILLAR.....23-67

LOW/REVERSE CLUTCH - ASSEMBLY....21-561

LOW/REVERSE CLUTCH - CLEANING....21-561

LOW/REVERSE CLUTCH - DISASSEMBLY . 21-560

LOW/REVERSE CLUTCH - INSPECTION . . 21-561

LUBRICANTS - DESCRIPTION, ENGINE

OIL .................................0-2

LUBRICATION - DESCRIPTION.....9-148,9-214,

9-267,9-337,9-393,9-60

LUBRICATION - DIAGNOSIS AND

TESTING, ENGINE DIAGNOSIS.....9-183,9-230,

9-358,9-7

LUBRICATION - OPERATION . 9-148,9-267,9-337,

9-393,9-60

LUBRICATION - STANDARD PROCEDURE . . 19-34

LUBRICATION - STANDARD PROCEDURE,

BODY...............................23-3

LUMBAR CONTROL SWITCH -

DESCRIPTION.......................8N-19

LUMBAR CONTROL SWITCH -

OPERATION.........................8N-19

LUMBAR CONTROL SWITCH - REMOVAL . 8N-19

LUMBAR MOTOR - DESCRIPTION.......8N-19

LUMBAR MOTOR - DIAGNOSIS AND

TESTING...........................8N-20

LUMBAR MOTOR - OPERATION.........8N-20

MAIN BEARING - FITTING - STANDARD

PROCEDURE, CRANKSHAFT.......9-133,9-202

MAIN BEARING CLEARANCE -

STANDARD PROCEDURE................9-322

MAIN BEARING FITTING - STANDARD

PROCEDURE, CRANKSHAFT............9-253

MAIN BEARING FITTING, STANDARD

PROCEDURE.........................9-43

MAIN BEARINGS - DESCRIPTION,

CRANKSHAFT.......................9-253

MAIN BEARINGS - INSPECTION,

CRANKSHAFT..................9-133,9-203

MAIN BEARINGS - INSTALLATION,

CRANKSHAFT..................9-254,9-383

MAIN BEARINGS - OPERATION,

CRANKSHAFT.......................9-253

MAIN BEARINGS - REMOVAL,

CRANKSHAFT..................9-254,9-383

MAIN BEARINGS - STANDARD

PROCEDURE, FITTING CRANKSHAFT.....9-383

MAINTENANCE SCHEDULES -

DESCRIPTION.........................0-6

MALFUNCTION INDICATOR LAMP (MIL) -

DESCRIPTION.......................8J-30

MALFUNCTION INDICATOR LAMP (MIL) -

OPERATION.........................8J-30

MANAGER - DESCRIPTION, TASK.........25-1

MANAGER - OPERATION, TASK..........25-5

MANIFOLD - CLEANING, EXHAUST . 9-161,9-220,

9-277,9-347,9-404

MANIFOLD - CLEANING, INTAKE . . . 9-158,9-219,

9-275,9-346,9-402

MANIFOLD - DESCRIPTION, EXHAUST . . . 9-159,

9-220,9-277,9-403,9-73

MANIFOLD - DESCRIPTION, INTAKE.....9-157,

9-219,9-274,9-401,9-71

MANIFOLD - INSPECTION, EXHAUST.....9-161,

9-220,9-277,9-347,9-404

MANIFOLD - INSPECTION, INTAKE . 9-158,9-219,

9-275,9-346,9-402

MANIFOLD - INSTALLATION, EXHAUST . . . 9-162,

9-220,9-277,9-347,9-404,9-74

MANIFOLD - INSTALLATION, INTAKE.....9-158,

9-219,9-275,9-346,9-402,9-72

MANIFOLD - OPERATION, EXHAUST.....9-220,

9-277,9-403

MANIFOLD - OPERATION, INTAKE........9-274

MANIFOLD - REMOVAL, EXHAUST . . 9-159,9-220,

9-277,9-347,9-404,9-73

MANIFOLD - REMOVAL, INTAKE . . . 9-157,9-219,

9-275,9-345,9-401,9-72

MANIFOLD LEAKAGE - DIAGNOSIS AND

TESTING, INTAKE

.....9-157,9-219,9-274,9-401

MANIFOLD LEAKS - DIAGNOSIS AND

TESTING, INTAKE

.....................9-71

MANUAL - INSTALLATION, WINDOW

REGULATOR

...................23-26,23-35

MANUAL - REMOVAL, WINDOW

REGULATOR

...................23-26,23-35

MANUAL BLEEDING - STANDARD

PROCEDURE

..........................5-5

20 INDEXDR

Description Group-Page Description Group-Page Description Group-Page

Page 2880 of 2895

PLANETARY GEARTRAIN/OUTPUT SHAFT

- INSPECTION................21-245,21-422

PLANETARY GEARTRAIN/OUTPUT SHAFT

- OPERATION.................21-243,21-420

PLASTIC BODY PANEL REPAIR -

STANDARD PROCEDURE................23-3

PLATE - DESCRIPTION, BODY CODE....Intro.-4

PLATE - DESCRIPTION, ENGINE DATA....9-297

PLATE - INSTALLATION, FLEX . . 9-137,9-205,9-47

PLATE - INSTALLATION, FRONT SKID.....13-24

PLATE - INSTALLATION, SUPPORT........5-29

PLATE - INSTALLATION, TRANSFER

CASE SKID.........................13-26

PLATE - REMOVAL, FLEX.....9-137,9-205,9-47

PLATE - REMOVAL, FRONT SKID........13-24

PLATE - REMOVAL, SUPPORT...........5-29

PLATE - REMOVAL, TRANSFER CASE

SKID..............................13-26

PLATE LAMP - INSTALLATION, LICENSE . . 8L-16

PLATE LAMP - REMOVAL, LICENSE......8L-16

PLATE LAMP UNIT - INSTALLATION,

LICENSE...........................8L-16

PLATE LAMP UNIT - REMOVAL, LICENSE . . 8L-16

PLATES - INSTALLATION, EXTERIOR

NAME.............................23-38

PLATES - REMOVAL, EXTERIOR NAME....23-38

PLUG - DESCRIPTION, SPARK...........8I-27

PLUG - INSTALLATION, CAMSHAFT

CORE HOLE.........................9-201

PLUG - REMOVAL, CAMSHAFT CORE

HOLE..............................9-200

PLUG - REMOVAL, SPARK..............8I-30

PLUG CABLE - DESCRIPTION, SPARK.....8I-33

PLUG CABLE - INSTALLATION, SPARK....8I-35

PLUG CABLE - OPERATION, SPARK.......8I-33

PLUG CABLE - REMOVAL, SPARK........8I-34

PLUG CABLE ORDER, 8.0L V-10 ENGINE

- SPARK .............................8I-5

PLUG CABLE RESISTANCE,

SPECIFICATIONS - SPARK...............8I-5

PLUG CABLES - DIAGNOSIS AND

TESTING, SPARK.....................8I-33

PLUG CONDITIONS - DIAGNOSIS AND

TESTING, SPARK.....................8I-27

PLUGS - INSTALLATION, CORE..........9-130

PLUGS - REMOVAL, CORE.............9-129

PLUGS, SPECIFICATIONS - SPARK........8I-5

PLUMBING - CLEANING, CHARGE AIR

COOLER............................11-16

PLUMBING - DESCRIPTION, CHARGE

AIR COOLER........................11-15

PLUMBING - INSPECTION, CHARGE AIR

COOLER............................11-16

PLUMBING - INSTALLATION, CHARGE

AIR COOLER........................11-16

PLUMBING - OPERATION, CHARGE AIR

COOLER............................11-15

PLUMBING - REMOVAL, CHARGE AIR

COOLER............................11-15

PLY TIRES - DESCRIPTION, RADIAL.......22-6

POLISHING - DESCRIPTION, FINESSE

SANDING/BUFFING...................23-75

PORT - DESCRIPTION, REFRIGERANT

SYSTEM SERVICE.....................24-1

PORT - OPERATION, REFRIGERANT

SYSTEM SERVICE.....................24-2

POSITION SENSOR - DESCRIPTION.....21-618,

21-654

POSITION SENSOR - DESCRIPTION,

ACCELERATOR PEDAL.................14-25

POSITION SENSOR - DESCRIPTION,

CAMSHAFT.........................14-82

POSITION SENSOR - DESCRIPTION,

CAMSHAFT...........................8I-8

POSITION SENSOR - DESCRIPTION,

CRANKSHAFT..................14-26,14-83

POSITION SENSOR - DESCRIPTION,

THROTTLE..........................14-52

POSITION SENSOR - INSTALLATION

....21-619,

21-654

POSITION SENSOR - INSTALLATION,

ACCELERATOR PEDAL

.................14-25

POSITION SENSOR - INSTALLATION,

CAMSHAFT

.........................14-83

POSITION SENSOR - INSTALLATION,

CAMSHAFT

..........................8I-14

POSITION SENSOR - INSTALLATION,

CRANKSHAFT

..................14-30,14-84POSITION SENSOR - INSTALLATION,

THROTTLE..........................14-54

POSITION SENSOR - OPERATION . 21-619,21-654

POSITION SENSOR - OPERATION,

ACCELERATOR PEDAL.................14-25

POSITION SENSOR - OPERATION,

CAMSHAFT.........................14-82

POSITION SENSOR - OPERATION,

CAMSHAFT...........................8I-8

POSITION SENSOR - OPERATION,

CRANKSHAFT..................14-26,14-83

POSITION SENSOR - OPERATION,

THROTTLE..........................14-52

POSITION SENSOR - REMOVAL . . 21-619,21-654

POSITION SENSOR - REMOVAL,

ACCELERATOR PEDAL.................14-25

POSITION SENSOR - REMOVAL,

CAMSHAFT.........................14-83

POSITION SENSOR - REMOVAL,

CAMSHAFT..........................8I-11

POSITION SENSOR - REMOVAL,

CRANKSHAFT..................14-29,14-84

POSITION SENSOR - REMOVAL,

THROTTLE..........................14-53

POSITION SWITCH - DESCRIPTION,

CLUTCH PEDAL.......................6-14

POSITION SWITCH - DIAGNOSIS AND

TESTING, CLUTCH PEDAL...............6-14

POSITION SWITCH - OPERATION,

CLUTCH PEDAL.......................6-14

POTENTIAL - STANDARD PROCEDURE,

TESTING OF VOLTAGE..............8W-01-9

POWER - INSTALLATION, WINDOW

REGULATOR...................23-25,23-34

POWER - REMOVAL, WINDOW

REGULATOR...................23-25,23-34

POWER BRAKE BOOSTER -

DESCRIPTION........................5-25

POWER BRAKE BOOSTER -

INSTALLATION........................5-25

POWER BRAKE BOOSTER - OPERATION . . . 5-25

POWER BRAKE BOOSTER - REMOVAL.....5-25

POWER DISTRIBUTION - DESCRIPTION . 8W-97-1

POWER DISTRIBUTION - OPERATION . . 8W-97-1

POWER DISTRIBUTION SYSTEMS,

SPECIAL TOOLS...................8W-97-2

POWER GROUNDS - DESCRIPTION......8E-10

POWER LOCK SWITCH - DIAGNOSIS

AND TESTING........................8N-4

POWER LOCK SWITCH - INSTALLATION . . . 8N-4

POWER LOCK SWITCH - REMOVAL.......8N-4

POWER LOCKS - DESCRIPTION..........8N-1

POWER LOCKS - DIAGNOSIS AND

TESTING............................8N-3

POWER LOCKS - OPERATION............8N-2

POWER MIRROR SWITCH - DIAGNOSIS

AND TESTING.......................8N-13

POWER MIRROR SWITCH - REMOVAL

. . . 8N-13

POWER MIRRORS - DESCRIPTION

......8N-11

POWER MIRRORS - DIAGNOSIS AND

TESTING

...........................8N-11

POWER MIRRORS - OPERATION

........8N-11

POWER MODULE - DESCRIPTION,

INTEGRATED

......................8W-97-3

POWER MODULE - INSTALLATION,

INTEGRATED

......................8W-97-4

POWER MODULE - OPERATION,

INTEGRATED

......................8W-97-3

POWER MODULE - REMOVAL,

INTEGRATED

......................8W-97-3

POWER OUTLET - DESCRIPTION

......8W-97-7

POWER OUTLET - DIAGNOSIS AND

TESTING

.........................8W-97-7

POWER OUTLET - INSTALLATION

.....8W-97-7

POWER OUTLET - OPERATION

........8W-97-7

POWER OUTLET - REMOVAL

.........8W-97-7

POWER SEAT SYSTEM - DIAGNOSIS

AND TESTING

.......................8N-14

POWER SEAT TRACK - DESCRIPTION

....8N-18

POWER SEAT TRACK - DIAGNOSIS AND

TESTING

...........................8N-18

POWER SEAT TRACK - INSTALLATION

....8N-19

POWER SEAT TRACK - OPERATION

......8N-18

POWER SEAT TRACK - REMOVAL

.......8N-19

POWER SEATS - DESCRIPTION

.........8N-14

POWER SEATS - OPERATION

...........8N-14POWER STEERING FLOW AND

PRESSURE - DIAGNOSIS AND

TESTING............................19-4

POWER STEERING FLUID -

DESCRIPTION.........................0-3

POWER STEERING FLUID LEVEL

CHECKING - STANDARD PROCEDURE....19-42

POWER STEERING GEAR, SPECIAL

TOOLS.............................19-22

POWER STEERING GEAR,

SPECIFICATIONS.....................19-21

POWER STEERING PRESSURE SWITCH -

DESCRIPTION.......................19-45

POWER STEERING PRESSURE SWITCH -

OPERATION.........................19-45

POWER STEERING PUMP - INITIAL

OPERATION - STANDARD PROCEDURE . . . 19-39

POWER STEERING SYSTEM -

DIAGNOSIS AND TESTING..............19-2

POWER STEERING SYSTEM -

STANDARD PROCEDURE, FLUSHING.....19-39

POWER WINDOWS - DESCRIPTION......8N-21

POWER WINDOWS - DIAGNOSIS AND

TESTING...........................8N-21

POWER WINDOWS - OPERATION........8N-21

POWERING SEVERAL LOADS -

STANDARD PROCEDURE, TESTING

FOR A SHORT TO GROUND ON FUSES . 8W-01-10

PRE-ALIGNMENT INSPECTION -

DIAGNOSIS AND TESTING...............2-2

PRECAUTIONS - CAUTION,

REFRIGERANT HOSES/LINES/TUBES......24-33

PRECAUTIONS AND WARNINGS,

WARNING - SAFETY.....................23-1

PRECAUTIONS, STANDARD PROCEDURE

- SAFETY............................8L-7

PRECAUTIONS, WARNING -

WINDSHIELD SAFETY.................23-88

PREFERENCES - STANDARD

PROCEDURE, RKE TRANSMITTER

CUSTOMER..........................8N-9

PRELIMINARY - DIAGNOSIS AND

TESTING..............21-139,21-320,21-491

PRELIMINARY CHECKS - DIAGNOSIS

AND TESTING........................7-10

PREPARATION - STANDARD

PROCEDURE, ENGINE GASKET

SURFACE............................9-10

PRESSURE - DIAGNOSIS AND TESTING,

CHECKING ENGINE OIL.......9-150,9-214,9-64

PRESSURE - DIAGNOSIS AND TESTING,

CYLINDER COMPRESSION . . . 9-182,9-231,9-359,

9-8,9-92

PRESSURE - DIAGNOSIS AND TESTING,

ENGINE OIL...............9-269,9-338,9-396

PRESSURE - DIAGNOSIS AND TESTING,

POWER STEERING FLOW...............19-4

PRESSURE - DIAGNOSIS AND TESTING,

TURBOCHARGER BOOST...............11-10

PRESSURE BLEEDING - STANDARD

PROCEDURE..........................5-5

PRESSURE CAP - DESCRIPTION,

RADIATOR...........................7-60

PRESSURE CAP - OPERATION,

RADIATOR...........................7-61

PRESSURE, DIESEL - FUEL SYSTEM

.....14-60

PRESSURE FOR HIGH SPEEDS -

DESCRIPTION, TIRE

...................22-6

PRESSURE GAUGE - DESCRIPTION, OIL

. . 8J-32

PRESSURE GAUGE - OPERATION, OIL

....8J-32

PRESSURE GAUGES - DIAGNOSIS AND

TESTING

............................22-7

PRESSURE HOSE - INSTALLATION

. . 19-43,19-44

PRESSURE HOSE - REMOVAL

.....19-43,19-44

PRESSURE LEAKAGE - DIAGNOSIS AND

TESTING, CYLINDER COMBUSTION

. 9-182,9-231,

9-359,9-8,9-92

PRESSURE LIMITING VALVE -

DESCRIPTION, FUEL

..................14-72

PRESSURE LIMITING VALVE -

INSTALLATION, FUEL

.................14-73

PRESSURE LIMITING VALVE -

OPERATION, FUEL

....................14-72

PRESSURE LIMITING VALVE - REMOVAL,

FUEL

..............................14-72

PRESSURE (LP) SENSOR -

DESCRIPTION, LINE

.................21-559

DRINDEX 25

Description Group-Page Description Group-Page Description Group-Page

Page 2886 of 2895

SENSOR - OPERATION, FUEL LEVEL

SENDING UNIT..................14-68,14-7

SENSOR - OPERATION, FUEL PRESSURE . . 14-72

SENSOR - OPERATION, HEATED SEAT.....8G-7

SENSOR - OPERATION, INLET AIR

TEMPERATURE SENSOR/PRESSURE......14-90

SENSOR - OPERATION, INPUT SPEED . . . 21-558

SENSOR - OPERATION, INTAKE AIR

TEMPERATURE......................14-36

SENSOR - OPERATION, INTAKE AIR

TEMPERATURE SENSOR/MAP...........14-93

SENSOR - OPERATION, KNOCK..........8I-25

SENSOR - OPERATION, LINE PRESSURE

(LP)..............................21-559

SENSOR - OPERATION, MAP...........14-39

SENSOR - OPERATION, MODE . . . 21-684,21-718

SENSOR - OPERATION, OUTPUT SPEED . . 21-567

SENSOR - OPERATION, OXYGEN........14-43

SENSOR - OPERATION, POSITION......21-619,

21-654

SENSOR - OPERATION, SPEED . . . 21-254,21-431

SENSOR - OPERATION, THROTTLE

POSITION..........................14-52

SENSOR - OPERATION, TRANSMISSION

RANGE................21-263,21-441,21-581

SENSOR - OPERATION, TRANSMISSION

TEMPERATURE.........21-267,21-445,21-583

SENSOR - OPERATION, WATER IN FUEL . . 14-78

SENSOR - REMOVAL, ACCELERATOR

PEDAL POSITION....................14-25

SENSOR - REMOVAL, BATTERY

TEMPERATURE......................8F-21

SENSOR - REMOVAL, CAMSHAFT

POSITION..........................14-83

SENSOR - REMOVAL, CAMSHAFT

POSITION...........................8I-11

SENSOR - REMOVAL, CRANKSHAFT

POSITION.....................14-29,14-84

SENSOR - REMOVAL, ENGINE COOLANT

TEMPERATURE.......................7-44

SENSOR - REMOVAL, FRONT WHEEL

SPEED..............................5-41

SENSOR - REMOVAL, FUEL LEVEL

SENDING UNIT.......................14-7

SENSOR - REMOVAL, FUEL PRESSURE . . . 14-72

SENSOR - REMOVAL, HEATED SEAT......8G-7

SENSOR - REMOVAL, INLET AIR

TEMPERATURE SENSOR/PRESSURE......14-90

SENSOR - REMOVAL, INPUT SPEED.....21-559

SENSOR - REMOVAL, INTAKE AIR

TEMPERATURE......................14-36

SENSOR - REMOVAL, INTAKE AIR

TEMPERATURE SENSOR/MAP...........14-93

SENSOR - REMOVAL, KNOCK...........8I-25

SENSOR - REMOVAL, LINE PRESSURE

(LP)..............................21-559

SENSOR - REMOVAL, MAP.............14-40

SENSOR - REMOVAL, OUTPUT SPEED . . . 21-567

SENSOR - REMOVAL, OXYGEN..........14-44

SENSOR - REMOVAL, POSITION . . 21-619,21-654

SENSOR - REMOVAL, REAR WHEEL

SPEED

..............................5-42

SENSOR - REMOVAL, THROTTLE

POSITION

..........................14-53

SENSOR - REMOVAL, TRANSMISSION

RANGE

......................21-265,21-443

SENSOR - REMOVAL, WATER IN FUEL

....14-78

SENSOR CIRCUIT - DIAGNOSIS AND

TESTING, AMBIENT TEMPERATURE

......8M-11

SENSOR RETURN - DESCRIPTION

.......8E-10

SENSOR (TRS) - DIAGNOSIS AND

TESTING, TRANSMISSION RANGE

......21-264,

21-442

SENSOR/MAP SENSOR - DESCRIPTION,

INTAKE AIR TEMPERATURE

............14-93

SENSOR/MAP SENSOR - INSTALLATION,

INTAKE AIR TEMPERATURE

............14-94

SENSOR/MAP SENSOR - OPERATION,

INTAKE AIR TEMPERATURE

............14-93

SENSOR/MAP SENSOR - REMOVAL,

INTAKE AIR TEMPERATURE

............14-93

SENSOR/PRESSURE SENSOR -

DESCRIPTION, INLET AIR

TEMPERATURE

......................14-90

SENSOR/PRESSURE SENSOR -

INSTALLATION, INLET AIR

TEMPERATURE

......................14-90SENSOR/PRESSURE SENSOR -

OPERATION, INLET AIR TEMPERATURE . . . 14-90

SENSOR/PRESSURE SENSOR -

REMOVAL, INLET AIR TEMPERATURE....14-90

SENSOR/SWITCH - DESCRIPTION, OIL

PRESSURE..........................9-66

SENSOR/SWITCH - INSTALLATION, OIL

PRESSURE.....................9-343,9-67

SENSOR/SWITCH - OPERATION, OIL

PRESSURE..........................9-66

SENSOR/SWITCH - REMOVAL, OIL

PRESSURE.....................9-343,9-67

SENTRY KEY IMMOBILIZER MODULE -

DESCRIPTION.......................8E-13

SENTRY KEY IMMOBILIZER MODULE -

INSTALLATION.......................8E-15

SENTRY KEY IMMOBILIZER MODULE -

OPERATION.........................8E-13

SENTRY KEY IMMOBILIZER MODULE -

REMOVAL..........................8E-15

SENTRY KEY IMMOBILIZER SYSTEM

INDICATOR LAMP - DESCRIPTION........8Q-5

SENTRY KEY IMMOBILIZER SYSTEM

INDICATOR LAMP - OPERATION..........8Q-5

SENTRY KEY IMMOBILIZER SYSTEM

INITIALIZATION, STANDARD

PROCEDURE.........................8Q-3

SENTRY KEY IMMOBILIZER SYSTEM

(SKIS), DESCRIPTION..................8Q-1

SENTRY KEY IMMOBILIZER SYSTEM

TRANSPONDER PROGRAMMING,

STANDARD PROCEDURE...............8Q-4

SEPARATOR - DESCRIPTION, FUEL

FILTER / WATER .....................14-61

SEPARATOR - INSTALLATION, FUEL

FILTER / WATER .....................14-62

SEPARATOR - OPERATION, FUEL FILTER

/ WATER ...........................14-61

SEPARATOR - REMOVAL, FUEL FILTER /

WATER.............................14-61

SERVO - ASSEMBLY, FRONT.....21-209,21-388

SERVO - ASSEMBLY, REAR......21-253,21-430

SERVO - CLEANING, FRONT.....21-208,21-388

SERVO - CLEANING, REAR......21-252,21-430

SERVO - DESCRIPTION.................8P-6

SERVO - DESCRIPTION, FRONT . . 21-207,21-387

SERVO - DESCRIPTION, REAR . . . 21-252,21-429

SERVO - DISASSEMBLY, FRONT . . 21-208,21-388

SERVO - DISASSEMBLY, REAR . . . 21-252,21-430

SERVO - INSPECTION, FRONT . . . 21-208,21-388

SERVO - INSTALLATION................8P-7

SERVO - OPERATION..................8P-7

SERVO - OPERATION, FRONT....21-208,21-387

SERVO - OPERATION, REAR.....21-252,21-429

SERVO - REMOVAL....................8P-7

SETTING TRANSMITTER CODES -

STANDARD PROCEDURE..............8M-12

SEVERAL LOADS - STANDARD

PROCEDURE, TESTING FOR A SHORT

TO GROUND ON FUSES POWERING . . . 8W-01-10

SHAFT - ASSEMBLY, PLANETARY

GEARTRAIN/OUTPUT...........21-245,21-423

SHAFT - CAUTION, HALF................3-11

SHAFT - DESCRIPTION, PLANETARY

GEARTRAIN/OUTPUT...........21-242,21-420

SHAFT - DIAGNOSIS AND TESTING,

HALF...............................3-11

SHAFT - DIAGNOSIS AND TESTING,

PROPELLER...........................3-1

SHAFT - DISASSEMBLY, PLANETARY

GEARTRAIN/OUTPUT...........21-243,21-421

SHAFT - INSPECTION, PLANETARY

GEARTRAIN/OUTPUT...........21-245,21-422

SHAFT - INSTALLATION, BALANCE........9-79

SHAFT - INSTALLATION, FRONT

PROPELLER...........................3-7

SHAFT - INSTALLATION, HALF...........3-12

SHAFT - INSTALLATION, IDLER.....9-175,9-80

SHAFT - INSTALLATION, REAR

PROPELLER...........................3-8

SHAFT - OPERATION, PLANETARY

GEARTRAIN/OUTPUT...........21-243,21-420

SHAFT - REMOVAL, BALANCE...........9-79

SHAFT - REMOVAL, FRONT PROPELLER

....3-6

SHAFT - REMOVAL, HALF

...............3-11

SHAFT - REMOVAL, IDLER

.........9-175,9-79

SHAFT - REMOVAL, REAR PROPELLER

.....3-7

SHAFT - SPECIAL TOOLS, HALF

..........3-12SHAFT - SPECIAL TOOLS, PROPELLER.....3-6

SHAFT - SPECIFICATIONS, HALF..........3-12

SHAFT - SPECIFICATIONS, PROPELLER.....3-6

SHAFT - STANDARD PROCEDURE,

PROPELLER...........................3-3

SHAFT FRONT BEARING -

INSTALLATION, OUTPUT........21-217,21-395

SHAFT FRONT BEARING - REMOVAL,

OUTPUT.....................21-217,21-395

SHAFT REAR BEARING - INSTALLATION,

OUTPUT.....................21-217,21-396

SHAFT REAR BEARING - REMOVAL,

OUTPUT.....................21-217,21-395

SHAFT SEAL - INSTALLATION, FRONT

OUTPUT.........21-618,21-653,21-683,21-717

SHAFT SEAL - INSTALLATION, STEERING

GEAR INPUT........................19-28

SHAFT SEAL - REMOVAL, FRONT

OUTPUT.........21-617,21-653,21-683,21-717

SHAFT SEAL - REMOVAL, STEERING

GEAR INPUT........................19-25

SHAFT SEALS - INSTALLATION, AXLE . 3-33,3-58,

3-84

SHAFT SEALS - REMOVAL, AXLE . 3-33,3-58,3-84

SHAFTS - ASSEMBLY, AXLE.............3-58

SHAFTS - DISASSEMBLY, AXLE..........3-56

SHAFTS - INSTALLATION, AXLE....3-111,3-138,

3-33,3-58,3-83

SHAFTS - REMOVAL, AXLE . . . 3-111,3-138,3-33,

3-56,3-83

SHIELD - INSTALLATION, FRONT

WHEELHOUSE SPLASH.................23-41

SHIELD - INSTALLATION, REAR

WHEELHOUSE SPLASH................23-41

SHIELD - REMOVAL, FRONT

WHEELHOUSE SPLASH................23-40

SHIELD - REMOVAL, REAR

WHEELHOUSE SPLASH................23-41

SHIELDS - DESCRIPTION, HEAT..........11-7

SHIELDS - INSTALLATION, HEAT.........11-8

SHIELDS - REMOVAL, HEAT.............11-7

SHIFT BOOT - INSTALLATION, 4WD

FLOOR.............................23-64

SHIFT BOOT - REMOVAL, 4WD FLOOR....23-63

SHIFT COVER - INSTALLATION....21-128,21-86

SHIFT COVER - REMOVAL.......21-128,21-86

SHIFT INTERLOCK - ADJUSTMENTS,

BRAKE TRANSMISSION . . 21-195,21-376,21-540

SHIFT INTERLOCK - DIAGNOSIS AND

TESTING, BRAKE TRANSMISSION......21-195,

21-375,21-540

SHIFT INTERLOCK SYSTEM -

DESCRIPTION, BRAKE TRANSMISSION . . 21-194,

21-375,21-540

SHIFT INTERLOCK SYSTEM -

OPERATION, BRAKE TRANSMISSION....21-194,

21-375,21-540

SHIFT LEVER - ADJUSTMENT....21-622,21-657

SHIFT LEVER - INSTALLATION . . . 21-621,21-656

SHIFT LEVER - INSTALLATION, GEAR.....19-12

SHIFT LEVER - REMOVAL.......21-620,21-655

SHIFT LEVER - REMOVAL, GEAR........19-12

SHIFT MECHANISM - DESCRIPTION....21-253,

21-430,21-574

SHIFT MECHANISM - INSTALLATION.....21-85

SHIFT MECHANISM - OPERATION......21-253,

21-430,21-574

SHIFT MECHANISM - REMOVAL.........21-84

SHIFT MOTOR - DESCRIPTION . . . 21-686,21-720

SHIFT MOTOR - INSTALLATION . . 21-686,21-720

SHIFT MOTOR - OPERATION.....21-686,21-720

SHIFT MOTOR - REMOVAL......21-686,21-720

SHOCK - DIAGNOSIS AND TESTING . . . 2-23,2-35

SHOCK - DIAGNOSIS AND TESTING,

SPRING.............................2-38

SHOCK - INSTALLATION............2-35,2-40

SHOCK - REMOVAL................2-35,2-40

SHOES - ADJUSTMENT, PARKING BRAKE . . 5-34

SHOES - INSTALLATION................5-34

SHOES - REMOVAL

....................5-33

SHORT TO GROUND - STANDARD

PROCEDURE, TESTING FOR A

........8W-01-9

SHORT TO GROUND ON FUSES

POWERING SEVERAL LOADS -

STANDARD PROCEDURE, TESTING

FOR A

..........................8W-01-10

SIDE - INSTALLATION, LEFT

............9-122

SIDE - INSTALLATION, RIGHT

...........9-121

DRINDEX 31

Description Group-Page Description Group-Page Description Group-Page

Page 2890 of 2895

TIRE REVOLUTIONS PER MILE,

SPECIFICATIONS.....................22-10

TIRE ROTATION - STANDARD

PROCEDURE.........................22-2

TIRE WEAR PATTERNS - DIAGNOSIS

AND TESTING........................22-8

TIRES - DESCRIPTION.................22-5

TIRES - DESCRIPTION, RADIAL - PLY.....22-6

TIRES - DESCRIPTION, REPLACEMENT....22-6

TIRE/VEHICLE LEAD - DIAGNOSIS AND

TESTING............................22-8

TO COOLER - INSTALLATION, RETURN

HOSE - GEAR..................19-43,19-44

TO COOLER - INSTALLATION, RETURN

HOSE - RESERVOIR.............19-43,19-44

TO COOLER - REMOVAL, RETURN HOSE

- GEAR............................19-43

TO COOLER - REMOVAL, RETURN HOSE

- RESERVOIR..................19-43,19-44

TO GROUND - STANDARD PROCEDURE,

TESTING FOR A SHORT.............8W-01-9

TO GROUND ON FUSES POWERING

SEVERAL LOADS - STANDARD

PROCEDURE, TESTING FOR A SHORT . 8W-01-10

TO OIL COOLER - INSTALLATION, AIR.....7-75

TO OIL COOLER - REMOVAL, AIR.........7-74

TO OIL COOLER - REMOVAL, WATER......7-74

TO USE WIRING DIAGRAMS -

DESCRIPTION, HOW................8W-01-1

TOE ADJUSTMENT - STANDARD

PROCEDURE..........................2-4

TOE ADJUSTMENT - STANDARD

PROCEDURE, CAMBER, CASTER..........2-4

TOOL - ADJUSTMENT, WITH ADJUSTING . . . 5-36

TOOLS - 4.7L ENGINE, SPECIAL.........9-102

TOOLS - 5.7L ENGINE, SPECIAL.........9-192

TOOLS - 5.9L DIESEL ENGINE, SPECIAL . . 9-294

TOOLS - 5.9L ENGINE, SPECIAL.........9-240

TOOLS - 8.0L ENGINE, SPECIAL.........9-367

TOOLS - 9 1/4 AA, SPECIAL.............2-29

TOOLS - BASE BRAKES, SPECIAL.........5-5

TOOLS - BATTERY SYSTEM SPECIAL

TOOLS, SPECIAL......................8F-7

TOOLS - BODY, SPECIAL...............23-14

TOOLS - COOLING, SPECIAL.............7-20

TOOLS - DIESEL FUEL SYSTEM,

SPECIAL...........................14-60

TOOLS - FRONT SUSPENSION, SPECIAL . . . 2-11

TOOLS - FUEL SYSTEM, SPECIAL........14-5

TOOLS - OVERHEAD CONSOLE, SPECIAL . . 8M-6

TOOLS - POWER DISTRIBUTION

SYSTEMS, SPECIAL................8W-97-2

TOOLS - POWER STEERING GEAR,

SPECIAL...........................19-22

TOOLS - RE TRANSMISSION, SPECIAL . . 21-189,

21-370

TOOLS - RFE TRANSMISSION, SPECIAL . . 21-535

TOOLS - STEERING LINKAGE, SPECIAL . . . 19-35

TOOLS - STEERING, SPECIAL............19-5

TOOLS - TRANSFER CASE NV271/NV273,

SPECIAL....................21-650,21-714

TOOLS - WHEEL ALIGNMENT, SPECIAL.....2-7

TOOLS - WIRING/TERMINAL, SPECIAL . 8W-01-10

TOOLS, DIAGNOSIS AND TESTING -

SPECIAL............................11-4

TOOLS, FRONT AXLE - 9 1/4 AA -

SPECIAL............................3-53

TOOLS, FRONT AXLE - C205F - SPECIAL . . . 3-30

TOOLS, HALF SHAFT - SPECIAL..........3-12

TOOLS, HEADLAMP ALIGNMENT -

SPECIAL............................8L-7

TOOLS, MANUAL TRANSMISSION -

NV3500 - SPECIAL...................21-40

TOOLS, MANUAL TRANSMISSION -

NV4500 - SPECIAL...................21-79

TOOLS, MANUAL TRANSMISSION -

NV5600 - SPECIAL..................21-122

TOOLS, PROPELLER SHAFT - SPECIAL.....3-6

TOOLS, REAR AXLE - 10 1/2 AA -

SPECIAL...........................3-108

TOOLS, REAR AXLE - 11 1/2 AA -

SPECIAL

...........................3-135

TOOLS, REAR AXLE - 9 1/4 - SPECIAL

.....3-80

TOOLS, SPECIAL TOOLS - BATTERY

SYSTEM SPECIAL

.....................8F-7

TOOLS, SPECIFICATIONS - SPECIAL

.......9-16

TOP COVER - INSTALLATION,

INSTRUMENT PANEL

..................23-60TOP COVER - REMOVAL, INSTRUMENT

PANEL.............................23-59

TORSION BAR - DESCRIPTION...........2-25

TORSION BAR - INSTALLATION..........2-26

TORSION BAR - OPERATION.............2-25

TORSION BAR - REMOVAL..............2-25

TORSION BAR CROSS MEMBER

BUSHING - INSTALLATION..............2-14

TORSION BAR CROSSMEMBER

BUSHING - REMOVAL..................2-12

TOUCH-UP - DESCRIPTION, PAINT.......23-75

TOUCH-UP - STANDARD PROCEDURE,

PAINT.............................23-75

TOW HOOK ASSEMBLY - INSTALLATION,

FRONT.............................13-26

TOW HOOK ASSEMBLY - REMOVAL,

FRONT.............................13-26

TOW WIRING - DESCRIPTION, TRAILER . . 8L-22

TOWING - STANDARD PROCEDURE.......0-15

TRACK - DESCRIPTION, POWER SEAT....8N-18

TRACK - DIAGNOSIS AND TESTING,

POWER SEAT.......................8N-18

TRACK - INSTALLATION, POWER SEAT . . . 8N-19

TRACK - INSTALLATION, SEAT..........23-83

TRACK - OPERATION, POWER SEAT.....8N-18

TRACK - REMOVAL, POWER SEAT.......8N-19

TRACK - REMOVAL, SEAT..............23-83

TRACK BAR - INSTALLATION...........19-37

TRACK BAR - REMOVAL................19-37

TRAC-RITE - ASSEMBLY, DIFFERENTIAL . . 3-120,

3-147

TRAC-RITE - CLEANING, DIFFERENTIAL . . 3-119,

3-146

TRAC-RITE - DESCRIPTION,

DIFFERENTIAL..................3-118,3-145

TRAC-RITE - DISASSEMBLY,

DIFFERENTIAL..................3-118,3-145

TRAC-RITE - INSPECTION, DIFFERENTIAL . 3-119,

3-146

TRAC-RITE - OPERATION, DIFFERENTIAL . 3-118,

3-145

TRAILER HITCH - INSTALLATION........13-25

TRAILER HITCH - REMOVAL............13-25

TRAILER TOW WIRING - DESCRIPTION . . . 8L-22

TRANS COOLER - 5.9L DIESEL -

DESCRIPTION........................7-73

TRANS COOLER - 5.9L DIESEL -

OPERATION..........................7-74

TRANS TEMP INDICATOR -

DESCRIPTION.......................8J-38

TRANS TEMP INDICATOR - OPERATION . . . 8J-38

TRANSDUCER - DESCRIPTION, A/C

PRESSURE.........................24-15

TRANSDUCER - DIAGNOSIS AND

TESTING, A/C PRESSURE..............24-15

TRANSDUCER - INSTALLATION, A/C

PRESSURE.........................24-16

TRANSDUCER - OPERATION, A/C

PRESSURE.........................24-15

TRANSDUCER - REMOVAL, A/C

PRESSURE.........................24-16

TRANSFER CASE - NV241 GENII -

ASSEMBLY.........................21-604

TRANSFER CASE - NV241 GENII -

CLEANING

.........................21-602

TRANSFER CASE - NV241 GENII -

DESCRIPTION

.........................0-4

TRANSFER CASE - NV241 GENII -

DESCRIPTION

......................21-591

TRANSFER CASE - NV241 GENII -

DIAGNOSIS AND TESTING

............21-592

TRANSFER CASE - NV241 GENII -

DISASSEMBLY

......................21-593

TRANSFER CASE - NV241 GENII -

INSPECTION

.......................21-602

TRANSFER CASE - NV241 GENII -