hood release DODGE RAM 2003 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2637 of 2895

INSTALLATION

(1) Position the bracket onto the locating tabs and

slide down.

(2) Install the two screws.

(3) Install the diagnostic connector and install the

two screws.

(4) Install the hood release handle and tighten the

screws.

(5) Install the steering column opening cover.

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - INSTALLA-

TION)

STORAGE BIN

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Remove the center bezel. (Refer to 23 - BODY/

INSTRUMENT PANEL/INSTRUMENT PANEL

CENTER BEZEL - REMOVAL)

(2) Remove the floor console. (Refer to 23 - BODY/

INTERIOR/FLOOR CONSOLE - REMOVAL)

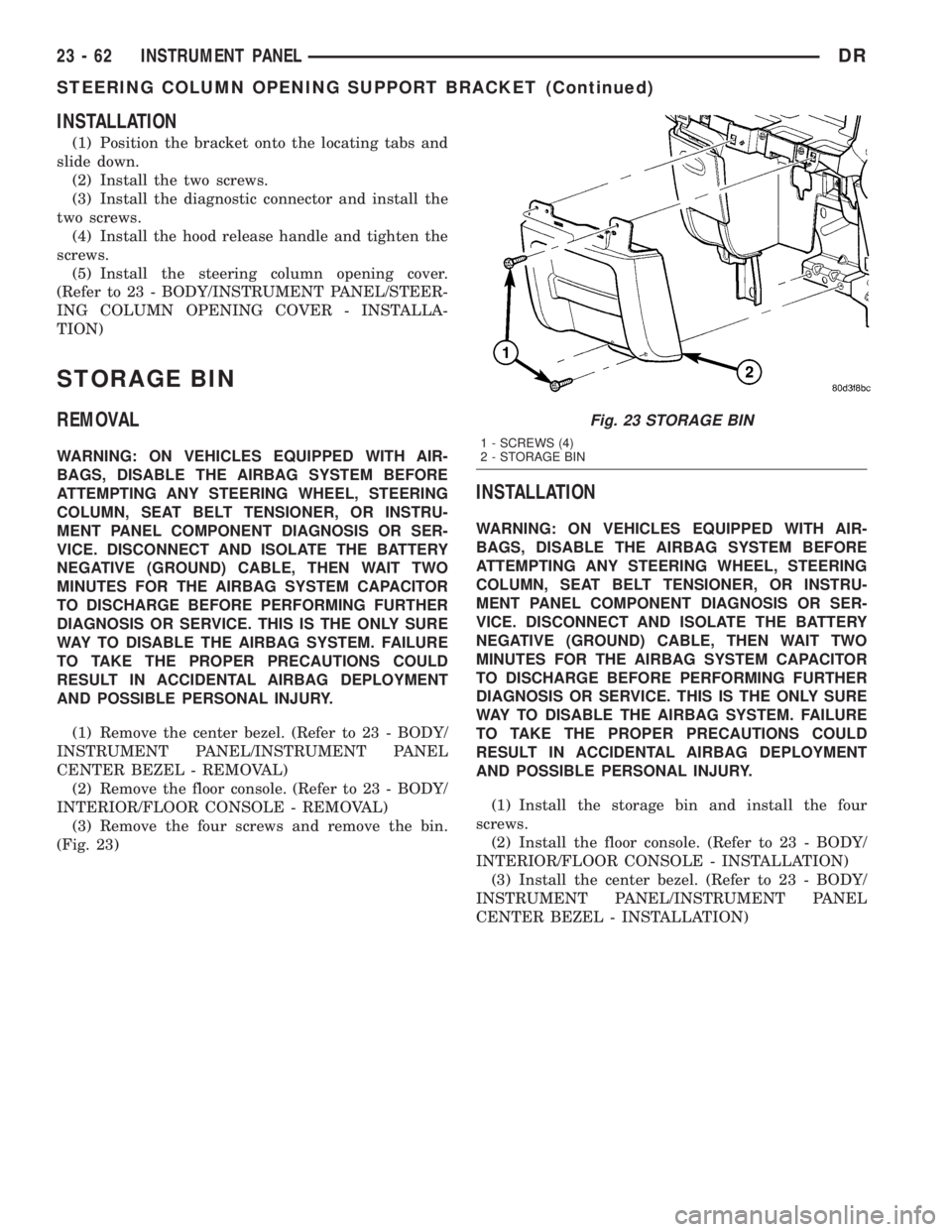

(3) Remove the four screws and remove the bin.

(Fig. 23)

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Install the storage bin and install the four

screws.

(2) Install the floor console. (Refer to 23 - BODY/

INTERIOR/FLOOR CONSOLE - INSTALLATION)

(3) Install the center bezel. (Refer to 23 - BODY/

INSTRUMENT PANEL/INSTRUMENT PANEL

CENTER BEZEL - INSTALLATION)

Fig. 23 STORAGE BIN

1 - SCREWS (4)

2 - STORAGE BIN

23 - 62 INSTRUMENT PANELDR

STEERING COLUMN OPENING SUPPORT BRACKET (Continued)

Page 2874 of 2895

JOINT - INSTALLATION, UPPER BALL.....2-33

JOINT - REMOVAL, LOWER BALL.....2-18,2-32

JOINT - REMOVAL, UPPER BALL.........2-33

JOINT-INNER - INSTALLATION, CV........3-16

JOINT-INNER - REMOVAL, CV............3-16

JOINT-OUTER - INSTALLATION, CV........3-13

JOINT-OUTER - REMOVAL, CV...........3-13

JOINTS - ASSEMBLY, SINGLE CARDAN

UNIVERSAL...........................3-9

JOINTS - DISASSEMBLY, SINGLE

CARDAN UNIVERSAL...................3-9

JOUNCE BUMPER - INSTALLATION.......2-40

JOUNCE BUMPER - REMOVAL...........2-40

JOURNAL CLEARANCE - STANDARD

PROCEDURE, CONNECTING ROD

BEARING AND CRANKSHAFT...........9-321

JUMP STARTING - STANDARD

PROCEDURE.........................0-13

JUNCTION BLOCK - INSTALLATION,

BRAKE..............................5-19

JUNCTION BLOCK - REMOVAL, BRAKE....5-19

KEY CYLINDER - INSTALLATION.........19-12

KEY CYLINDER - REMOVAL............19-12

KEY IMMOBILIZER MODULE -

DESCRIPTION, SENTRY................8E-13

KEY IMMOBILIZER MODULE -

INSTALLATION, SENTRY...............8E-15

KEY IMMOBILIZER MODULE -

OPERATION, SENTRY.................8E-13

KEY IMMOBILIZER MODULE - REMOVAL,

SENTRY............................8E-15

KEY IMMOBILIZER SYSTEM INDICATOR

LAMP - DESCRIPTION, SENTRY..........8Q-5

KEY IMMOBILIZER SYSTEM INDICATOR

LAMP - OPERATION, SENTRY...........8Q-5

KEY IMMOBILIZER SYSTEM

INITIALIZATION, STANDARD

PROCEDURE - SENTRY................8Q-3

KEY IMMOBILIZER SYSTEM (SKIS),

DESCRIPTION - SENTRY................8Q-1

KEY IMMOBILIZER SYSTEM

TRANSPONDER PROGRAMMING,

STANDARD PROCEDURE - SENTRY.......8Q-4

KEY LOCK CYLINDER - DIAGNOSIS AND

TESTING, IGNITION SWITCH............19-11

KEY-IN IGNITION SWITCH -

DESCRIPTION.......................19-11

KEYLESS ENTRY MODULE -

DESCRIPTION, REMOTE................8N-7

KEYLESS ENTRY MODULE - DIAGNOSIS

AND TESTING, REMOTE................8N-8

KEYLESS ENTRY MODULE -

INSTALLATION, REMOTE...............8N-8

KEYLESS ENTRY MODULE - OPERATION,

REMOTE............................8N-8

KEYLESS ENTRY MODULE - REMOVAL,

REMOTE............................8N-8

KEYLESS ENTRY TRANSMITTER -

DIAGNOSIS AND TESTING, REMOTE......8N-8

KEYLESS ENTRY TRANSMITTER -

SPECIFICATIONS, REMOTE.............8N-10

KNOCK SENSOR - DESCRIPTION.........8I-25

KNOCK SENSOR - INSTALLATION........8I-26

KNOCK SENSOR - OPERATION..........8I-25

KNOCK SENSOR - REMOVAL............8I-25

KNUCKLE - DESCRIPTION...............2-17

KNUCKLE - INSTALLATION..........2-18,2-34

KNUCKLE - OPERATION................2-17

KNUCKLE - REMOVAL..............2-17,2-34

LABEL - DESCRIPTION, VEHICLE SAFETY

CERTIFICATION.....................Intro.-1

LAMP - DESCRIPTION, DOME...........8L-24

LAMP - DESCRIPTION, READING........8L-26

LAMP - DESCRIPTION, SENTRY KEY

IMMOBILIZER SYSTEM INDICATOR.......8Q-5

LAMP - INSTALLATION, BACKUP.........8L-7

LAMP - INSTALLATION, BRAKE..........8L-8

LAMP - INSTALLATION, CAB CLEARANCE . 8L-10

LAMP - INSTALLATION, CENTER HIGH

MOUNTED STOP.....................8L-10

LAMP - INSTALLATION, DOME..........8L-24

LAMP - INSTALLATION, FOG............8L-11

LAMP - INSTALLATION, LICENSE PLATE

. . 8L-16

LAMP - INSTALLATION, PARK/TURN

SIGNAL

............................8L-21

LAMP - INSTALLATION, READING

........8L-26

LAMP - INSTALLATION, TAIL

...........8L-21

LAMP - INSTALLATION, TURN

..........8L-22LAMP - INSTALLATION, UNDERHOOD....8L-22

LAMP - OPERATION, DOME............8L-24

LAMP - OPERATION, READING..........8L-26

LAMP - OPERATION, SENTRY KEY

IMMOBILIZER SYSTEM INDICATOR.......8Q-5

LAMP - REMOVAL, BACKUP.............8L-7

LAMP - REMOVAL, BRAKE..............8L-8

LAMP - REMOVAL, CAB CLEARANCE.....8L-10

LAMP - REMOVAL, CENTER HIGH

MOUNTED STOP.....................8L-10

LAMP - REMOVAL, DOME..............8L-24

LAMP - REMOVAL, FOG...............8L-11

LAMP - REMOVAL, LICENSE PLATE......8L-16

LAMP - REMOVAL, PARK/TURN SIGNAL . . 8L-21

LAMP - REMOVAL, READING...........8L-26

LAMP - REMOVAL, TAIL...............8L-21

LAMP - REMOVAL, TURN..............8L-22

LAMP - REMOVAL, UNDERHOOD........8L-22

LAMP INDICATOR - DESCRIPTION,

CARGO.............................8J-20

LAMP INDICATOR - OPERATION, CARGO . . 8J-20

LAMP (MIL) - DESCRIPTION,

MALFUNCTION INDICATOR.............8J-30

LAMP (MIL) - OPERATION,

MALFUNCTION INDICATOR.............8J-30

LAMP OUT INDICATOR - DESCRIPTION . . . 8J-28

LAMP OUT INDICATOR - OPERATION.....8J-28

LAMP RELAY - DESCRIPTION, FOG........8L-11

LAMP RELAY - DESCRIPTION, PARK.....8L-19

LAMP RELAY - DIAGNOSIS AND

TESTING, FRONT FOG.................8L-12

LAMP RELAY - DIAGNOSIS AND

TESTING, PARK......................8L-20

LAMP RELAY - INSTALLATION, FOG......8L-13

LAMP RELAY - INSTALLATION, PARK.....8L-21

LAMP RELAY - OPERATION, FOG........8L-12

LAMP RELAY - OPERATION, PARK.......8L-19

LAMP RELAY - REMOVAL, FOG.........8L-13

LAMP RELAY - REMOVAL, PARK........8L-20

LAMP REPLACEMENT - STANDARD

PROCEDURE, MODULE................8M-3

LAMP REPLACEMENT - STANDARD

PROCEDURE, READING/COURTESY.......8M-3

LAMP SWITCH - DESCRIPTION, BACKUP . . . 8L-7

LAMP SWITCH - DESCRIPTION, BRAKE....8L-8

LAMP SWITCH - DIAGNOSIS AND

TESTING, BACKUP.....................8L-8

LAMP SWITCH - DIAGNOSIS AND

TESTING, BRAKE......................8L-9

LAMP SWITCH - INSTALLATION, BRAKE . . 8L-10

LAMP SWITCH - OPERATION, BACKUP....8L-8

LAMP SWITCH - OPERATION, BRAKE......8L-8

LAMP SWITCH - REMOVAL, BRAKE.......8L-9

LAMP UNIT - INSTALLATION, CENTER

HIGH MOUNTED STOP................8L-10

LAMP UNIT - INSTALLATION, LICENSE

PLATE .............................8L-16

LAMP UNIT - INSTALLATION, TAIL.......8L-21

LAMP UNIT - INSTALLATION,

UNDERHOOD........................8L-23

LAMP UNIT - REMOVAL, CENTER HIGH

MOUNTED STOP.....................8L-10

LAMP UNIT - REMOVAL, LICENSE PLATE . . 8L-16

LAMP UNIT - REMOVAL, TAIL...........8L-21

LAMP UNIT - REMOVAL, UNDERHOOD . . . 8L-22

LAMPS, SPECIFICATIONS - EXTERIOR.....8L-7

LAMPS/LIGHTING - EXTERIOR -

DESCRIPTION........................8L-2

LAMPS/LIGHTING - EXTERIOR -

DIAGNOSIS AND TESTING..............8L-3

LAMPS/LIGHTING - EXTERIOR -

OPERATION..........................8L-2

LAMP/SWITCH - INSTALLATION, GLOVE

BOX ...............................8L-25

LAMP/SWITCH - REMOVAL, GLOVE BOX . . 8L-25

LASH ADJUSTER - DIAGNOSIS AND

TESTING, HYDRAULIC.............9-124,9-31

LASH ADJUSTMENT AND VERIFICATION

- STANDARD PROCEDURE, VALVE.......9-308

LATCH - INSTALLATION.....23-16,23-23,23-32,

23-47

LATCH - INSTALLATION, GLOVE BOX

.....23-53

LATCH - INSTALLATION, UNDER SEAT

STORAGE BIN

.......................23-81

LATCH - REMOVAL

....23-16,23-23,23-32,23-47

LATCH - REMOVAL, GLOVE BOX

.........23-53

LATCH - REMOVAL, UNDER SEAT

STORAGE BIN

.......................23-81LATCH RELEASE CABLE/HANDLE

ASSEMBLY - INSTALLATION............23-47

LATCH RELEASE CABLE/HANDLE

ASSEMBLY - REMOVAL................23-47

LATCH STRIKER - INSTALLATION . . 23-17,23-24,

23-33

LATCH STRIKER - REMOVAL . 23-17,23-24,23-33

LATCH STRIKER / SECONDARY CATCH -

INSTALLATION.......................23-48

LATCH STRIKER / SECONDARY CATCH -

REMOVAL..........................23-48

LD & HD EXCEPT 4X4 HD -

INSTALLATION, ALL..................19-15

LD & HD EXCEPT 4X4 HD - REMOVAL,

ALL ...............................19-14

LEAD - DIAGNOSIS AND TESTING,

TIRE/VEHICLE........................22-8

LEAK - DIAGNOSIS AND TESTING,

CONVERTER HOUSING FLUID . . . 21-143,21-324,

21-495

LEAK - DIAGNOSIS AND TESTING,

ENGINE OIL................9-150,9-214,9-63

LEAK DETECTION ASSY - DESCRIPTION,

NATURAL VAC.......................25-23

LEAK DETECTION ASSY - INSTALLATION,

NATURAL VAC.......................25-24

LEAK DETECTION ASSY - OPERATION,

NATURAL VAC.......................25-23

LEAK DETECTION ASSY - REMOVAL,

NATURAL VAC.......................25-24

LEAK DETECTION PUMP - DESCRIPTION . . 25-13

LEAK DETECTION PUMP - INSTALLATION . 25-16

LEAK DETECTION PUMP - OPERATION.....25-14

LEAK DETECTION PUMP - REMOVAL.....25-16

LEAKAGE - DIAGNOSIS AND TESTING,

CYLINDER COMBUSTION PRESSURE....9-182,

9-231,9-359,9-8,9-92

LEAKAGE - DIAGNOSIS AND TESTING,

INTAKE MANIFOLD....9-157,9-219,9-274,9-401

LEAKAGE - DIAGNOSIS AND TESTING,

PUMP.............................19-39

LEAKS - DIAGNOSIS AND TESTING,

CHARGE AIR COOLER SYSTEM.........11-15

LEAKS - DIAGNOSIS AND TESTING,

COOLING SYSTEM - TESTING.............7-5

LEAKS - DIAGNOSIS AND TESTING,

ENGINE OIL....................9-269,9-394

LEAKS - DIAGNOSIS AND TESTING,

HIGH-PRESSURE FUEL LINE............14-69

LEAKS - DIAGNOSIS AND TESTING,

INTAKE MANIFOLD....................9-71

LEAKS - DIAGNOSIS AND TESTING,

REAR SEAL AREA...........9-135,9-204,9-64

LEAKS - DIAGNOSIS AND TESTING,

REFRIGERANT SYSTEM...............24-51

LEAKS - DIAGNOSIS AND TESTING,

WATER .............................23-1

LEAKS - STANDARD PROCEDURE,

REPAIRING.........................22-10

LEARN - STANDARD PROCEDURE,

DRIVE.............................8E-21

LEARN - STANDARD PROCEDURE, TCM

QUICK.............................8E-21

LEFT - DESCRIPTION, CAMSHAFT(S).....9-113

LEFT - INSTALLATION..................2-34

LEFT - INSTALLATION, CAMSHAFT(S)....9-114

LEFT - INSTALLATION, CYLINDER HEAD . . . 9-23

LEFT - REMOVAL......................2-34

LEFT - REMOVAL, CAMSHAFT(S)........9-113

LEFT - REMOVAL, CYLINDER HEAD.......9-21

LEFT CYLINDER HEAD - INSTALLATION . . . 9-110

LEFT CYLINDER HEAD - REMOVAL.......9-106

LEFT OUTBOARD - INSTALLATION,

CENTER............................8O-45

LEFT OUTBOARD - REMOVAL, CENTER . . . 8O-43

LEFT REAR CABLE - INSTALLATION.......5-33

LEFT REAR CABLE - REMOVAL...........5-32

LEFT SIDE - INSTALLATION............9-122

LEFT SIDE - REMOVAL

................9-121

LENS REPLACEMENT - STANDARD

PROCEDURE, MODULE

................8M-3

LEVEL - DIAGNOSIS AND TESTING,

EFFECTS OF INCORRECT FLUID

. . 21-201,21-381,

21-541

LEVEL - STANDARD PROCEDURE,

BRAKE FLUID

........................5-18

LEVEL - STANDARD PROCEDURE,

ENGINE OIL

.........................9-341

DRINDEX 19

Description Group-Page Description Group-Page Description Group-Page