torque DODGE RAM 2003 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 61 of 2895

(8) Align the bolt holes in the hub bearing flange

with the bolts installed in the knuckle. Then thread

the bolts into the bearing flange far enough to hold

the assembly in place.(9) Install the remaining bolts. Tighten the hub/

bearing bolts to 202 N´m (149 ft. lbs.

(10) Install the washer and axle nut and tighten a

beginning torque of 179 N´m (132 ft. lbs.).

(11) Rotate the axle 5 to 10 times to seat the hub

bearing.

(12) Tighten to a final torque of 356 N´m (263 ft.

lbs.).

(13) Align the axle nut to the next forward cotter

pin hole and install a new cotter pin in the axle nut.

(14) Install the brake caliper, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - INSTALLATION).

(15) Install the sensor wire to the steering knuckle

and frame and if equipped. Connect the wheel speed

sensor wire under the hood.

(16) Install the wheel and tire assemblies, (Refer

to 22 - TIRES/WHEELS/WHEELS - STANDARD

PROCEDURE).

(17) Remove the support and lower the vehicle.

(18) Apply the brakes several times to seat the

brake shoes and caliper piston. Do not move the vehi-

cle until a firm brake pedal is obtained.

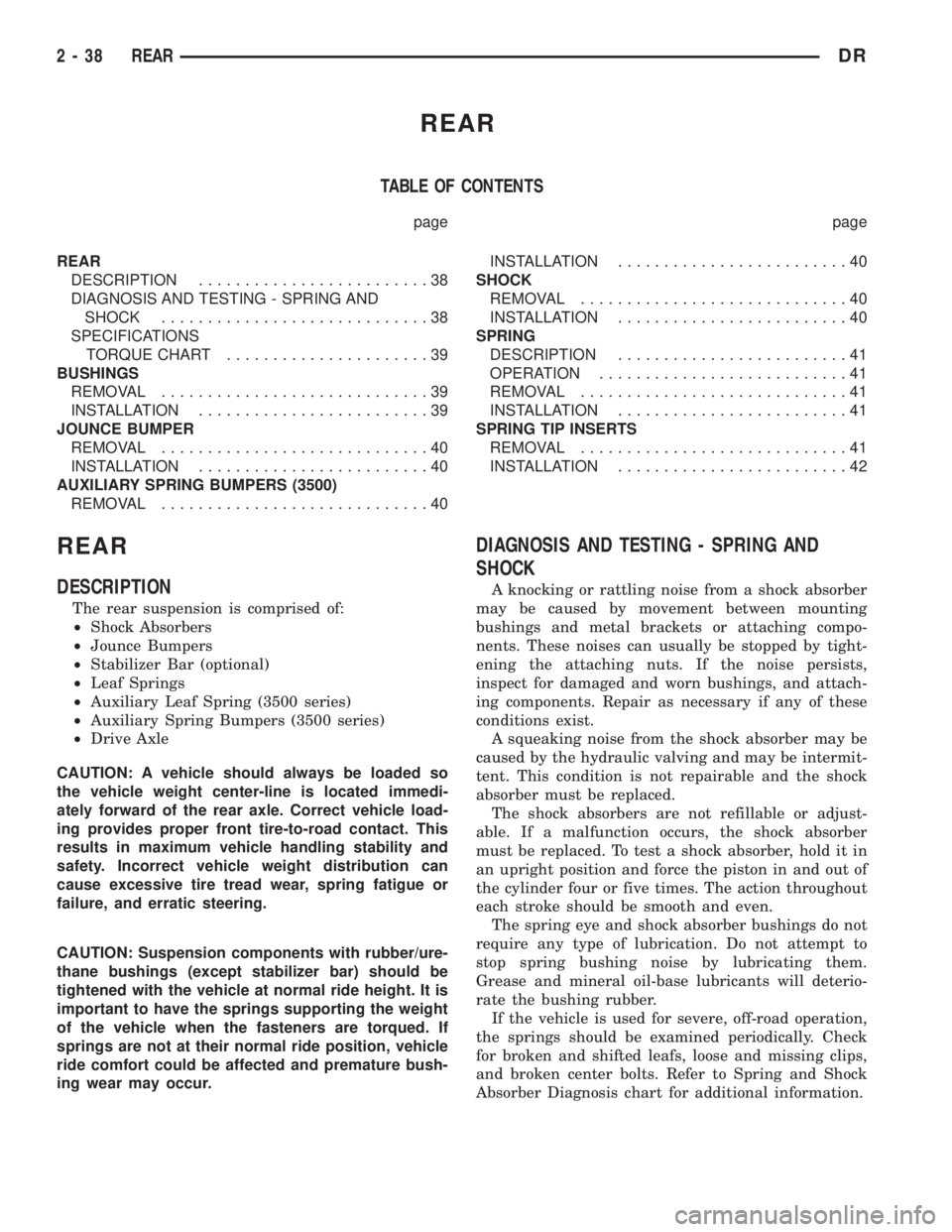

LOWER BALL JOINT

REMOVAL

(1) Remove lower snap ring from the lower ball

joint (Fig. 11).

(2) Position special tool 8975±2 (RECEIVER) and

8975±4 (DRIVER) with tool C4212±F as shown to

remove lower ball stud (Fig. 12).

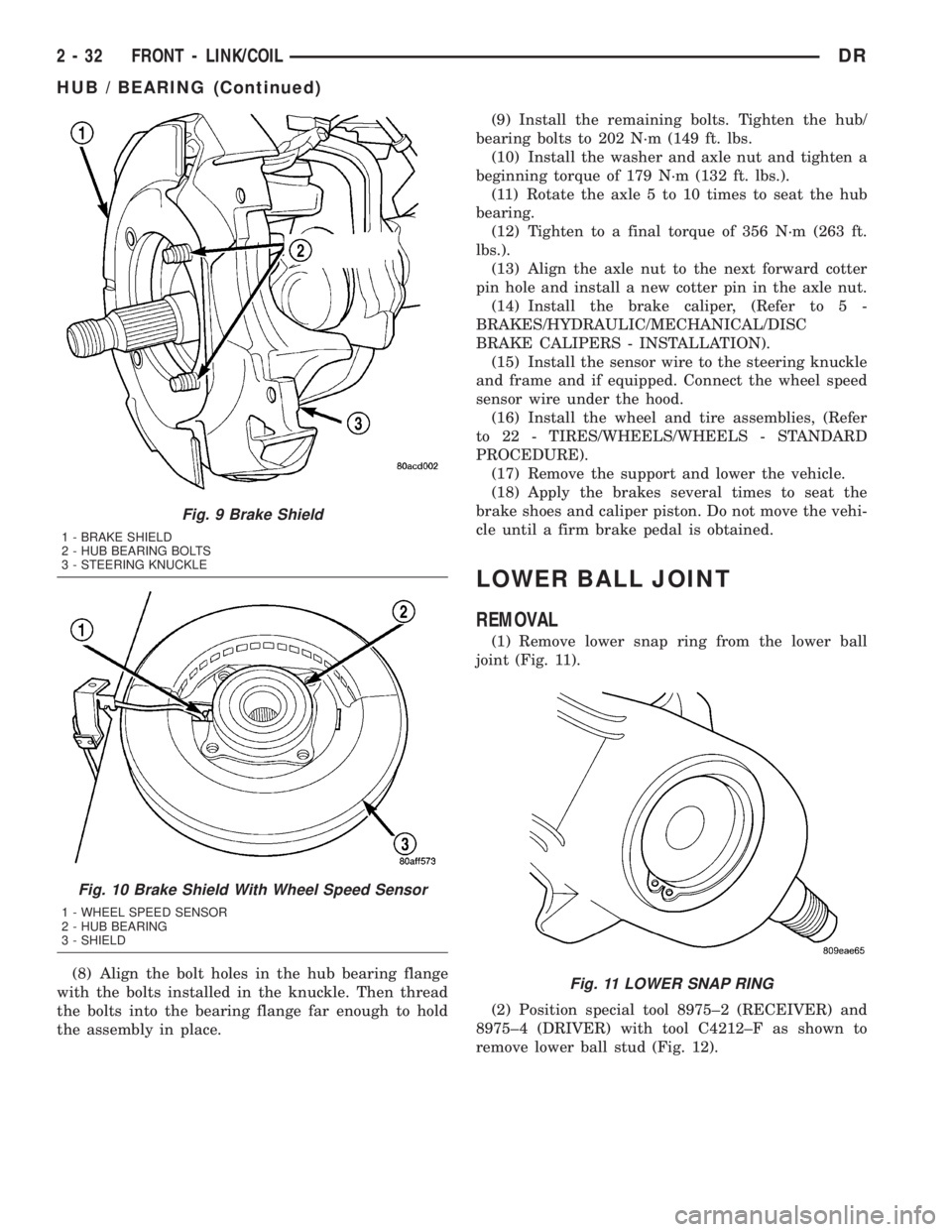

Fig. 9 Brake Shield

1 - BRAKE SHIELD

2 - HUB BEARING BOLTS

3 - STEERING KNUCKLE

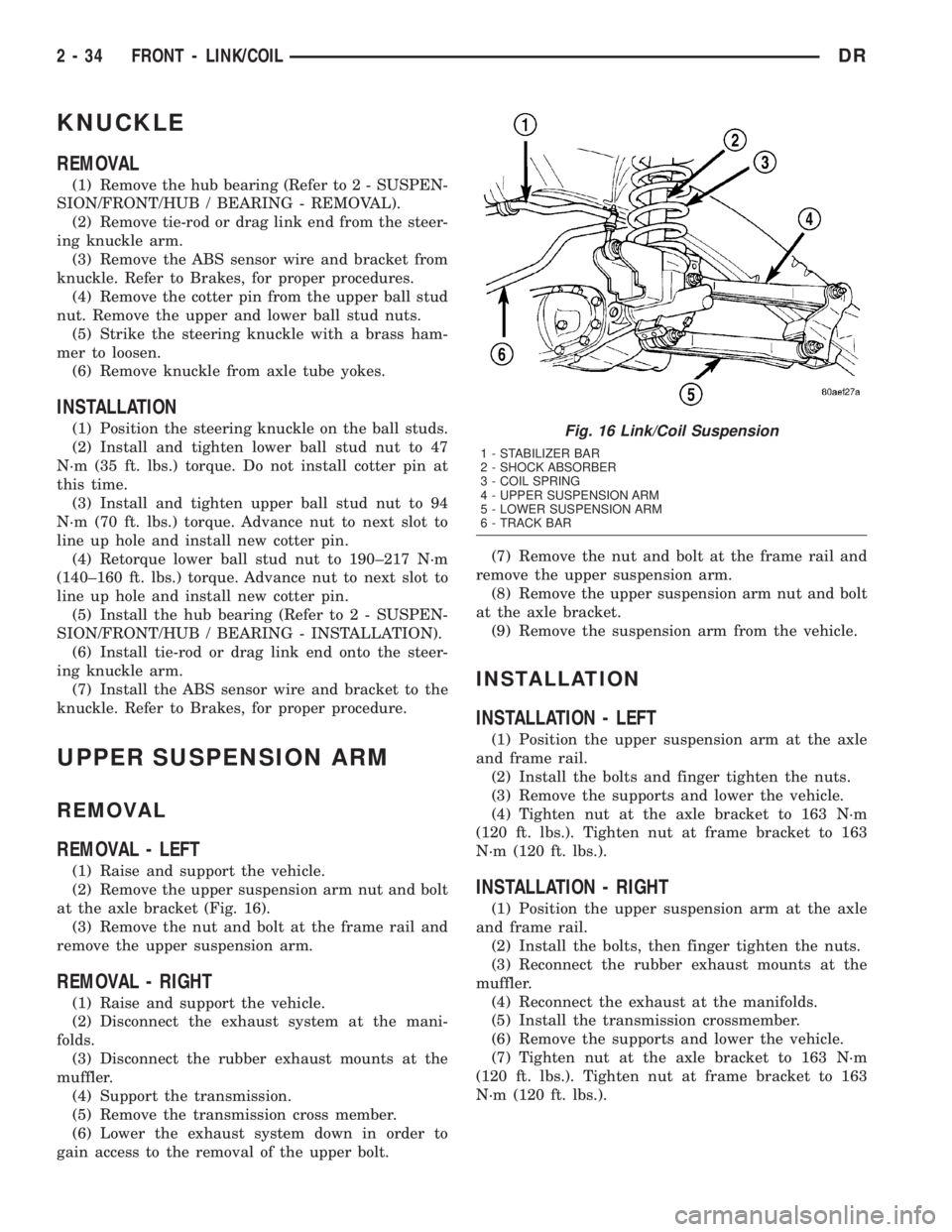

Fig. 10 Brake Shield With Wheel Speed Sensor

1 - WHEEL SPEED SENSOR

2 - HUB BEARING

3 - SHIELD

Fig. 11 LOWER SNAP RING

2 - 32 FRONT - LINK/COILDR

HUB / BEARING (Continued)

Page 63 of 2895

KNUCKLE

REMOVAL

(1) Remove the hub bearing (Refer to 2 - SUSPEN-

SION/FRONT/HUB / BEARING - REMOVAL).

(2) Remove tie-rod or drag link end from the steer-

ing knuckle arm.

(3) Remove the ABS sensor wire and bracket from

knuckle. Refer to Brakes, for proper procedures.

(4) Remove the cotter pin from the upper ball stud

nut. Remove the upper and lower ball stud nuts.

(5) Strike the steering knuckle with a brass ham-

mer to loosen.

(6) Remove knuckle from axle tube yokes.

INSTALLATION

(1) Position the steering knuckle on the ball studs.

(2) Install and tighten lower ball stud nut to 47

N´m (35 ft. lbs.) torque. Do not install cotter pin at

this time.

(3) Install and tighten upper ball stud nut to 94

N´m (70 ft. lbs.) torque. Advance nut to next slot to

line up hole and install new cotter pin.

(4) Retorque lower ball stud nut to 190±217 N´m

(140±160 ft. lbs.) torque. Advance nut to next slot to

line up hole and install new cotter pin.

(5) Install the hub bearing (Refer to 2 - SUSPEN-

SION/FRONT/HUB / BEARING - INSTALLATION).

(6) Install tie-rod or drag link end onto the steer-

ing knuckle arm.

(7) Install the ABS sensor wire and bracket to the

knuckle. Refer to Brakes, for proper procedure.

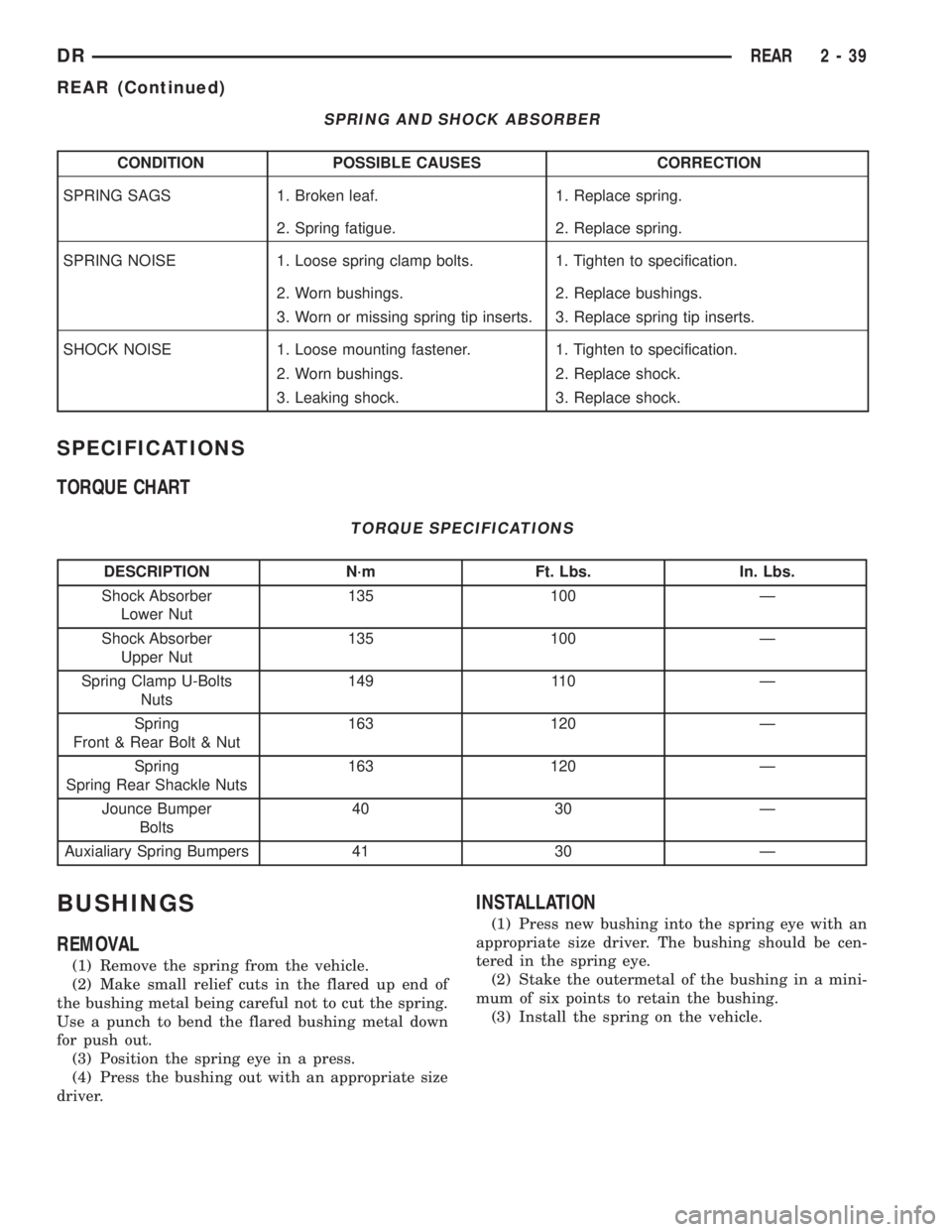

UPPER SUSPENSION ARM

REMOVAL

REMOVAL - LEFT

(1) Raise and support the vehicle.

(2) Remove the upper suspension arm nut and bolt

at the axle bracket (Fig. 16).

(3) Remove the nut and bolt at the frame rail and

remove the upper suspension arm.

REMOVAL - RIGHT

(1) Raise and support the vehicle.

(2) Disconnect the exhaust system at the mani-

folds.

(3) Disconnect the rubber exhaust mounts at the

muffler.

(4) Support the transmission.

(5) Remove the transmission cross member.

(6) Lower the exhaust system down in order to

gain access to the removal of the upper bolt.(7) Remove the nut and bolt at the frame rail and

remove the upper suspension arm.

(8) Remove the upper suspension arm nut and bolt

at the axle bracket.

(9) Remove the suspension arm from the vehicle.

INSTALLATION

INSTALLATION - LEFT

(1) Position the upper suspension arm at the axle

and frame rail.

(2) Install the bolts and finger tighten the nuts.

(3) Remove the supports and lower the vehicle.

(4) Tighten nut at the axle bracket to 163 N´m

(120 ft. lbs.). Tighten nut at frame bracket to 163

N´m (120 ft. lbs.).

INSTALLATION - RIGHT

(1) Position the upper suspension arm at the axle

and frame rail.

(2) Install the bolts, then finger tighten the nuts.

(3) Reconnect the rubber exhaust mounts at the

muffler.

(4) Reconnect the exhaust at the manifolds.

(5) Install the transmission crossmember.

(6) Remove the supports and lower the vehicle.

(7) Tighten nut at the axle bracket to 163 N´m

(120 ft. lbs.). Tighten nut at frame bracket to 163

N´m (120 ft. lbs.).

Fig. 16 Link/Coil Suspension

1 - STABILIZER BAR

2 - SHOCK ABSORBER

3 - COIL SPRING

4 - UPPER SUSPENSION ARM

5 - LOWER SUSPENSION ARM

6 - TRACK BAR

2 - 34 FRONT - LINK/COILDR

Page 67 of 2895

REAR

TABLE OF CONTENTS

page page

REAR

DESCRIPTION.........................38

DIAGNOSIS AND TESTING - SPRING AND

SHOCK.............................38

SPECIFICATIONS

TORQUE CHART......................39

BUSHINGS

REMOVAL.............................39

INSTALLATION.........................39

JOUNCE BUMPER

REMOVAL.............................40

INSTALLATION.........................40

AUXILIARY SPRING BUMPERS (3500)

REMOVAL.............................40INSTALLATION.........................40

SHOCK

REMOVAL.............................40

INSTALLATION.........................40

SPRING

DESCRIPTION.........................41

OPERATION...........................41

REMOVAL.............................41

INSTALLATION.........................41

SPRING TIP INSERTS

REMOVAL.............................41

INSTALLATION.........................42

REAR

DESCRIPTION

The rear suspension is comprised of:

²Shock Absorbers

²Jounce Bumpers

²Stabilizer Bar (optional)

²Leaf Springs

²Auxiliary Leaf Spring (3500 series)

²Auxiliary Spring Bumpers (3500 series)

²Drive Axle

CAUTION: A vehicle should always be loaded so

the vehicle weight center-line is located immedi-

ately forward of the rear axle. Correct vehicle load-

ing provides proper front tire-to-road contact. This

results in maximum vehicle handling stability and

safety. Incorrect vehicle weight distribution can

cause excessive tire tread wear, spring fatigue or

failure, and erratic steering.

CAUTION: Suspension components with rubber/ure-

thane bushings (except stabilizer bar) should be

tightened with the vehicle at normal ride height. It is

important to have the springs supporting the weight

of the vehicle when the fasteners are torqued. If

springs are not at their normal ride position, vehicle

ride comfort could be affected and premature bush-

ing wear may occur.

DIAGNOSIS AND TESTING - SPRING AND

SHOCK

A knocking or rattling noise from a shock absorber

may be caused by movement between mounting

bushings and metal brackets or attaching compo-

nents. These noises can usually be stopped by tight-

ening the attaching nuts. If the noise persists,

inspect for damaged and worn bushings, and attach-

ing components. Repair as necessary if any of these

conditions exist.

A squeaking noise from the shock absorber may be

caused by the hydraulic valving and may be intermit-

tent. This condition is not repairable and the shock

absorber must be replaced.

The shock absorbers are not refillable or adjust-

able. If a malfunction occurs, the shock absorber

must be replaced. To test a shock absorber, hold it in

an upright position and force the piston in and out of

the cylinder four or five times. The action throughout

each stroke should be smooth and even.

The spring eye and shock absorber bushings do not

require any type of lubrication. Do not attempt to

stop spring bushing noise by lubricating them.

Grease and mineral oil-base lubricants will deterio-

rate the bushing rubber.

If the vehicle is used for severe, off-road operation,

the springs should be examined periodically. Check

for broken and shifted leafs, loose and missing clips,

and broken center bolts. Refer to Spring and Shock

Absorber Diagnosis chart for additional information.

2 - 38 REARDR

Page 68 of 2895

SPRING AND SHOCK ABSORBER

CONDITION POSSIBLE CAUSES CORRECTION

SPRING SAGS 1. Broken leaf. 1. Replace spring.

2. Spring fatigue. 2. Replace spring.

SPRING NOISE 1. Loose spring clamp bolts. 1. Tighten to specification.

2. Worn bushings. 2. Replace bushings.

3. Worn or missing spring tip inserts. 3. Replace spring tip inserts.

SHOCK NOISE 1. Loose mounting fastener. 1. Tighten to specification.

2. Worn bushings. 2. Replace shock.

3. Leaking shock. 3. Replace shock.

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Shock Absorber

Lower Nut135 100 Ð

Shock Absorber

Upper Nut135 100 Ð

Spring Clamp U-Bolts

Nuts149 110 Ð

Spring

Front & Rear Bolt & Nut163 120 Ð

Spring

Spring Rear Shackle Nuts163 120 Ð

Jounce Bumper

Bolts40 30 Ð

Auxialiary Spring Bumpers 41 30 Ð

BUSHINGS

REMOVAL

(1) Remove the spring from the vehicle.

(2) Make small relief cuts in the flared up end of

the bushing metal being careful not to cut the spring.

Use a punch to bend the flared bushing metal down

for push out.

(3) Position the spring eye in a press.

(4) Press the bushing out with an appropriate size

driver.

INSTALLATION

(1) Press new bushing into the spring eye with an

appropriate size driver. The bushing should be cen-

tered in the spring eye.

(2) Stake the outermetal of the bushing in a mini-

mum of six points to retain the bushing.

(3) Install the spring on the vehicle.

DRREAR 2 - 39

REAR (Continued)

Page 70 of 2895

SPRING

DESCRIPTION

The rear suspension system uses a multi-leaf

springs and a solid drive axle. The forward end of the

springs are mounted to the body rail hangers

through rubber bushings. The rearward end of the

springs are attached to the body by the use of shack-

les. The spring and shackles use rubber bushings.

OPERATION

The springs control ride quality and maintain vehi-

cle ride height. The shackles allow the springs to

change their length as the vehicle moves over various

road conditions.

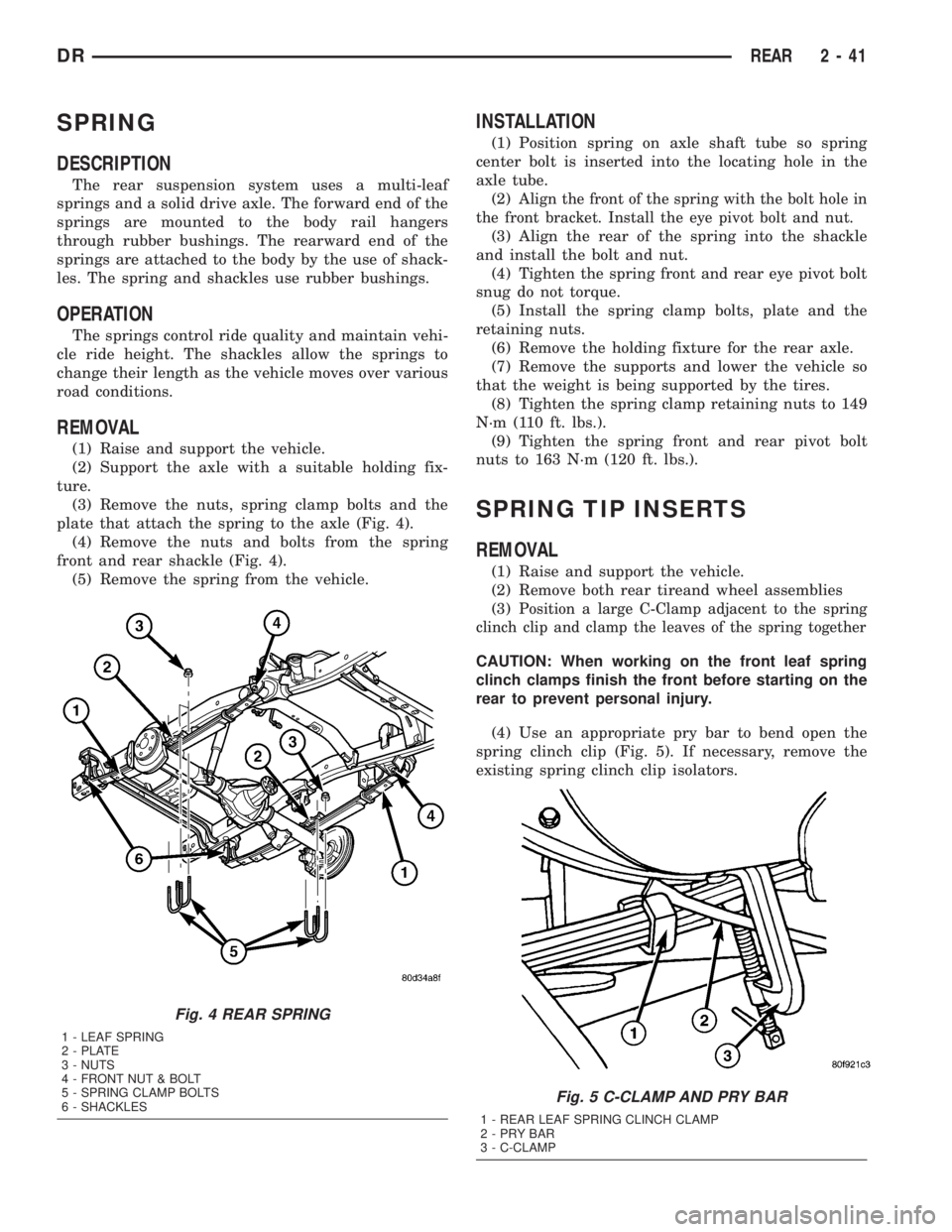

REMOVAL

(1) Raise and support the vehicle.

(2) Support the axle with a suitable holding fix-

ture.

(3) Remove the nuts, spring clamp bolts and the

plate that attach the spring to the axle (Fig. 4).

(4) Remove the nuts and bolts from the spring

front and rear shackle (Fig. 4).

(5) Remove the spring from the vehicle.

INSTALLATION

(1) Position spring on axle shaft tube so spring

center bolt is inserted into the locating hole in the

axle tube.

(2)

Align the front of the spring with the bolt hole in

the front bracket. Install the eye pivot bolt and nut.

(3) Align the rear of the spring into the shackle

and install the bolt and nut.

(4) Tighten the spring front and rear eye pivot bolt

snug do not torque.

(5) Install the spring clamp bolts, plate and the

retaining nuts.

(6) Remove the holding fixture for the rear axle.

(7) Remove the supports and lower the vehicle so

that the weight is being supported by the tires.

(8) Tighten the spring clamp retaining nuts to 149

N´m (110 ft. lbs.).

(9) Tighten the spring front and rear pivot bolt

nuts to 163 N´m (120 ft. lbs.).

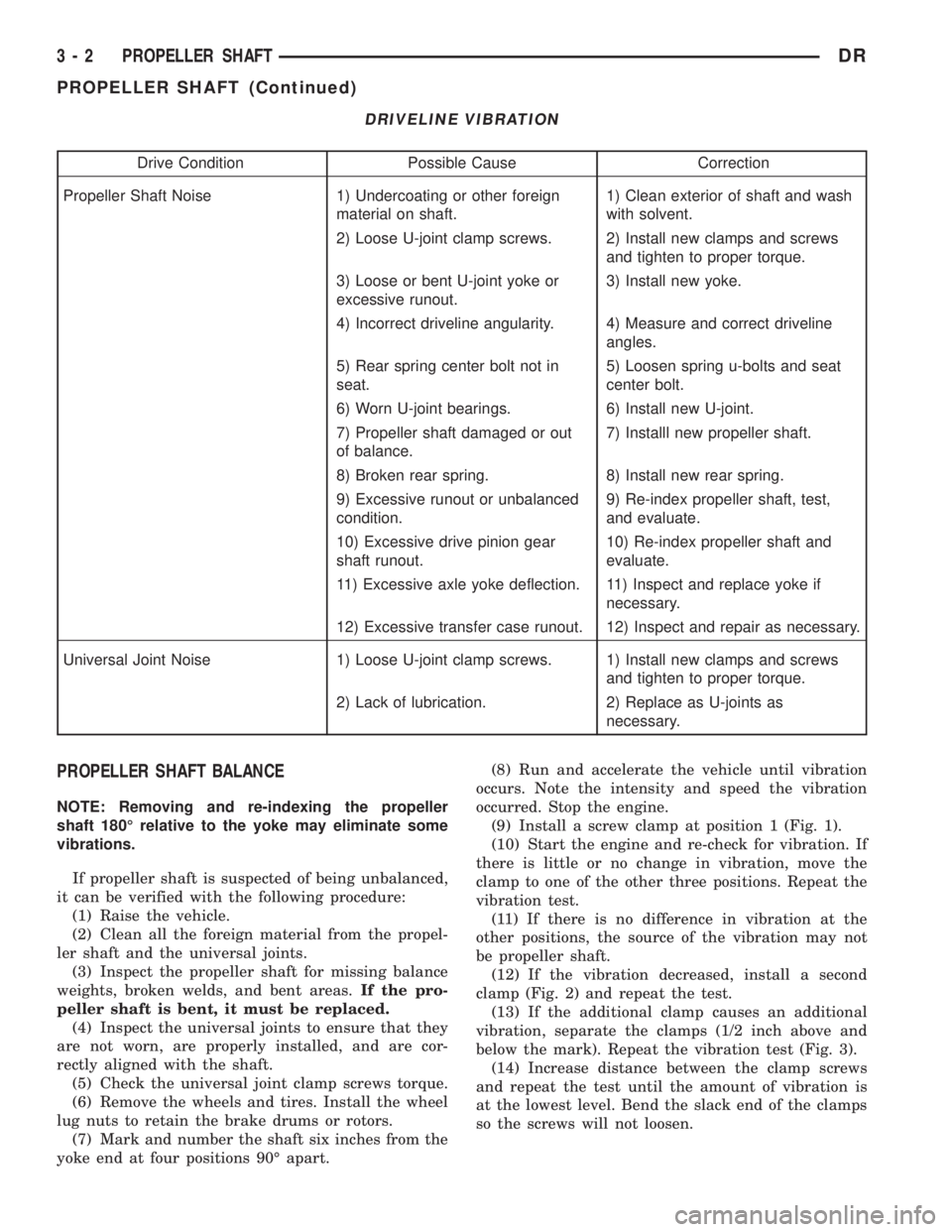

SPRING TIP INSERTS

REMOVAL

(1) Raise and support the vehicle.

(2) Remove both rear tireand wheel assemblies

(3)

Position a large C-Clamp adjacent to the spring

clinch clip and clamp the leaves of the spring together

CAUTION: When working on the front leaf spring

clinch clamps finish the front before starting on the

rear to prevent personal injury.

(4) Use an appropriate pry bar to bend open the

spring clinch clip (Fig. 5). If necessary, remove the

existing spring clinch clip isolators.

Fig. 4 REAR SPRING

1 - LEAF SPRING

2 - PLATE

3 - NUTS

4 - FRONT NUT & BOLT

5 - SPRING CLAMP BOLTS

6 - SHACKLES

Fig. 5 C-CLAMP AND PRY BAR

1 - REAR LEAF SPRING CLINCH CLAMP

2-PRYBAR

3 - C-CLAMP

DRREAR 2 - 41

Page 75 of 2895

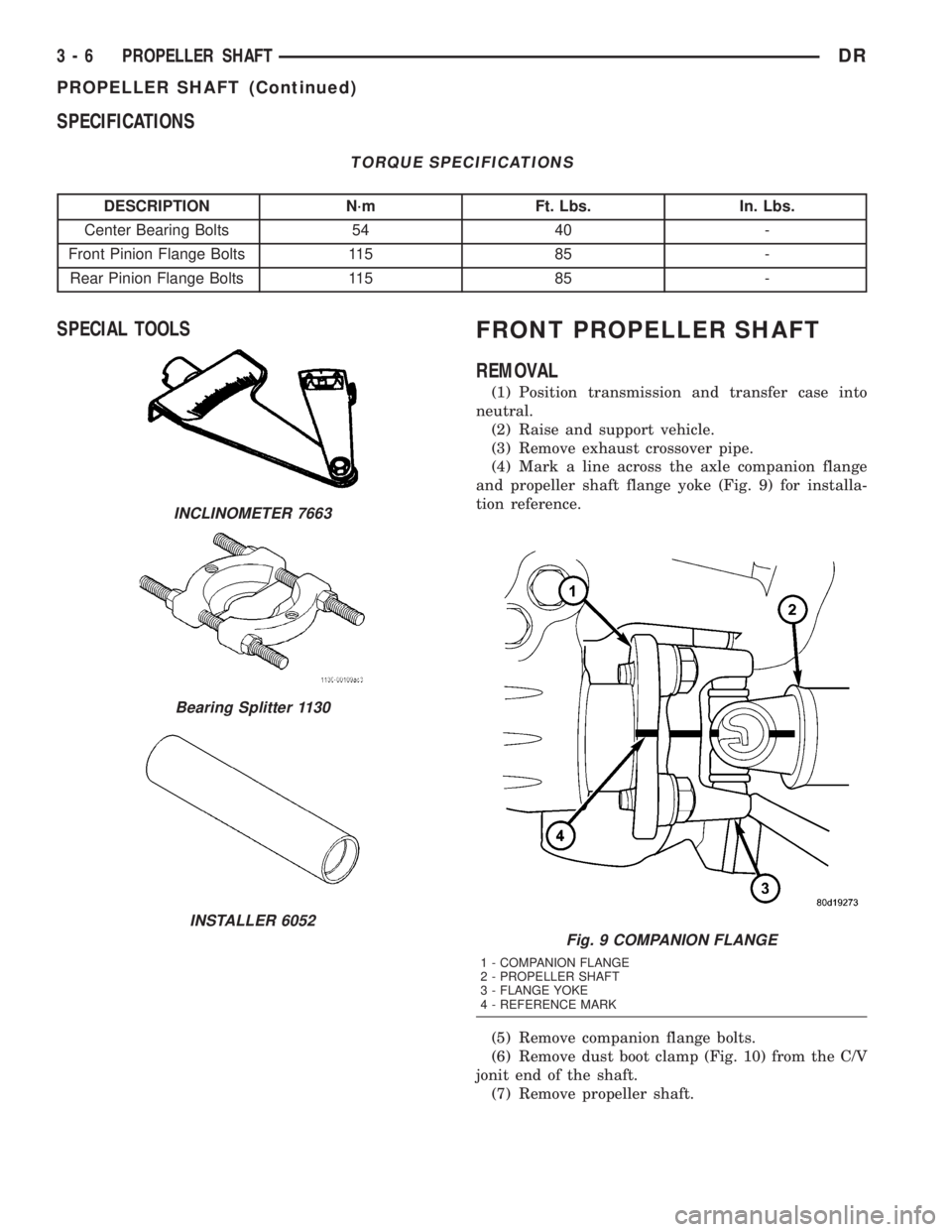

DRIVELINE VIBRATION

Drive Condition Possible Cause Correction

Propeller Shaft Noise 1) Undercoating or other foreign

material on shaft.1) Clean exterior of shaft and wash

with solvent.

2) Loose U-joint clamp screws. 2) Install new clamps and screws

and tighten to proper torque.

3) Loose or bent U-joint yoke or

excessive runout.3) Install new yoke.

4) Incorrect driveline angularity. 4) Measure and correct driveline

angles.

5) Rear spring center bolt not in

seat.5) Loosen spring u-bolts and seat

center bolt.

6) Worn U-joint bearings. 6) Install new U-joint.

7) Propeller shaft damaged or out

of balance.7) Installl new propeller shaft.

8) Broken rear spring. 8) Install new rear spring.

9) Excessive runout or unbalanced

condition.9) Re-index propeller shaft, test,

and evaluate.

10) Excessive drive pinion gear

shaft runout.10) Re-index propeller shaft and

evaluate.

11) Excessive axle yoke deflection. 11) Inspect and replace yoke if

necessary.

12) Excessive transfer case runout. 12) Inspect and repair as necessary.

Universal Joint Noise 1) Loose U-joint clamp screws. 1) Install new clamps and screws

and tighten to proper torque.

2) Lack of lubrication. 2) Replace as U-joints as

necessary.

PROPELLER SHAFT BALANCE

NOTE: Removing and re-indexing the propeller

shaft 180É relative to the yoke may eliminate some

vibrations.

If propeller shaft is suspected of being unbalanced,

it can be verified with the following procedure:

(1) Raise the vehicle.

(2) Clean all the foreign material from the propel-

ler shaft and the universal joints.

(3) Inspect the propeller shaft for missing balance

weights, broken welds, and bent areas.If the pro-

peller shaft is bent, it must be replaced.

(4) Inspect the universal joints to ensure that they

are not worn, are properly installed, and are cor-

rectly aligned with the shaft.

(5) Check the universal joint clamp screws torque.

(6) Remove the wheels and tires. Install the wheel

lug nuts to retain the brake drums or rotors.

(7) Mark and number the shaft six inches from the

yoke end at four positions 90É apart.(8) Run and accelerate the vehicle until vibration

occurs. Note the intensity and speed the vibration

occurred. Stop the engine.

(9) Install a screw clamp at position 1 (Fig. 1).

(10) Start the engine and re-check for vibration. If

there is little or no change in vibration, move the

clamp to one of the other three positions. Repeat the

vibration test.

(11) If there is no difference in vibration at the

other positions, the source of the vibration may not

be propeller shaft.

(12) If the vibration decreased, install a second

clamp (Fig. 2) and repeat the test.

(13) If the additional clamp causes an additional

vibration, separate the clamps (1/2 inch above and

below the mark). Repeat the vibration test (Fig. 3).

(14) Increase distance between the clamp screws

and repeat the test until the amount of vibration is

at the lowest level. Bend the slack end of the clamps

so the screws will not loosen.

3 - 2 PROPELLER SHAFTDR

PROPELLER SHAFT (Continued)

Page 79 of 2895

SPECIFICATIONS

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Center Bearing Bolts 54 40 -

Front Pinion Flange Bolts 115 85 -

Rear Pinion Flange Bolts 115 85 -

SPECIAL TOOLSFRONT PROPELLER SHAFT

REMOVAL

(1) Position transmission and transfer case into

neutral.

(2) Raise and support vehicle.

(3) Remove exhaust crossover pipe.

(4) Mark a line across the axle companion flange

and propeller shaft flange yoke (Fig. 9) for installa-

tion reference.

(5) Remove companion flange bolts.

(6) Remove dust boot clamp (Fig. 10) from the C/V

jonit end of the shaft.

(7) Remove propeller shaft.

INCLINOMETER 7663

Bearing Splitter 1130

INSTALLER 6052

Fig. 9 COMPANION FLANGE

1 - COMPANION FLANGE

2 - PROPELLER SHAFT

3 - FLANGE YOKE

4 - REFERENCE MARK

3 - 6 PROPELLER SHAFTDR

PROPELLER SHAFT (Continued)

Page 81 of 2895

INSTALLATION

(1) Slide the slip yoke onto the transmission/trans-

fer case output shaft.

(2) Align and install center bearing on crossmem-

ber, if necessary and tighten nutts to 54 N´m (40 ft.

lbs.).

(3) Align reference marks on the propeller shaft

yoke and pinion companion flange (Fig. 13).

(4) Tighten pinion companion flange bolts to 115

N´m (85 ft. lbs.).

(5) Lower the vehicle.

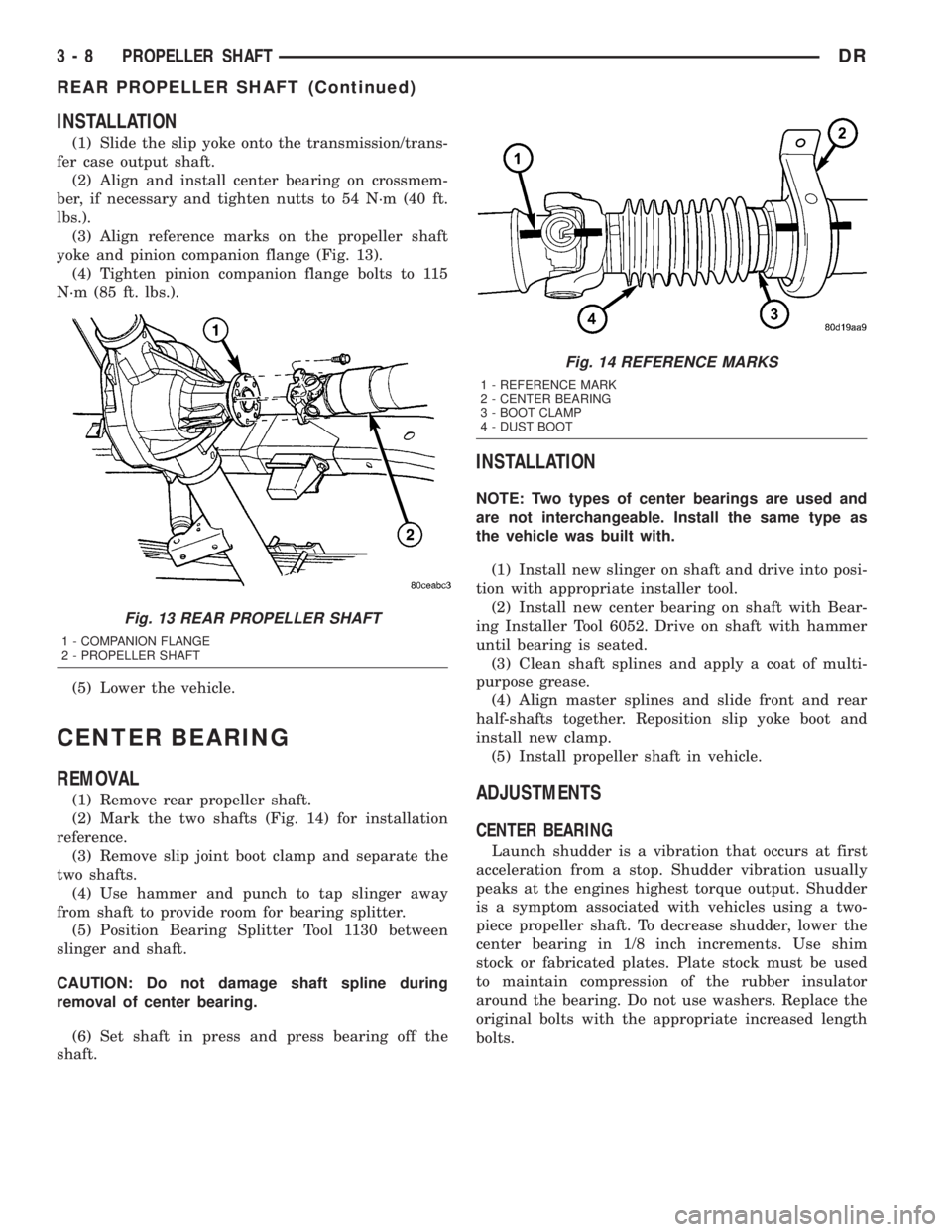

CENTER BEARING

REMOVAL

(1) Remove rear propeller shaft.

(2) Mark the two shafts (Fig. 14) for installation

reference.

(3) Remove slip joint boot clamp and separate the

two shafts.

(4) Use hammer and punch to tap slinger away

from shaft to provide room for bearing splitter.

(5) Position Bearing Splitter Tool 1130 between

slinger and shaft.

CAUTION: Do not damage shaft spline during

removal of center bearing.

(6) Set shaft in press and press bearing off the

shaft.

INSTALLATION

NOTE: Two types of center bearings are used and

are not interchangeable. Install the same type as

the vehicle was built with.

(1) Install new slinger on shaft and drive into posi-

tion with appropriate installer tool.

(2) Install new center bearing on shaft with Bear-

ing Installer Tool 6052. Drive on shaft with hammer

until bearing is seated.

(3) Clean shaft splines and apply a coat of multi-

purpose grease.

(4) Align master splines and slide front and rear

half-shafts together. Reposition slip yoke boot and

install new clamp.

(5) Install propeller shaft in vehicle.

ADJUSTMENTS

CENTER BEARING

Launch shudder is a vibration that occurs at first

acceleration from a stop. Shudder vibration usually

peaks at the engines highest torque output. Shudder

is a symptom associated with vehicles using a two-

piece propeller shaft. To decrease shudder, lower the

center bearing in 1/8 inch increments. Use shim

stock or fabricated plates. Plate stock must be used

to maintain compression of the rubber insulator

around the bearing. Do not use washers. Replace the

original bolts with the appropriate increased length

bolts.

Fig. 13 REAR PROPELLER SHAFT

1 - COMPANION FLANGE

2 - PROPELLER SHAFT

Fig. 14 REFERENCE MARKS

1 - REFERENCE MARK

2 - CENTER BEARING

3 - BOOT CLAMP

4 - DUST BOOT

3 - 8 PROPELLER SHAFTDR

REAR PROPELLER SHAFT (Continued)

Page 85 of 2895

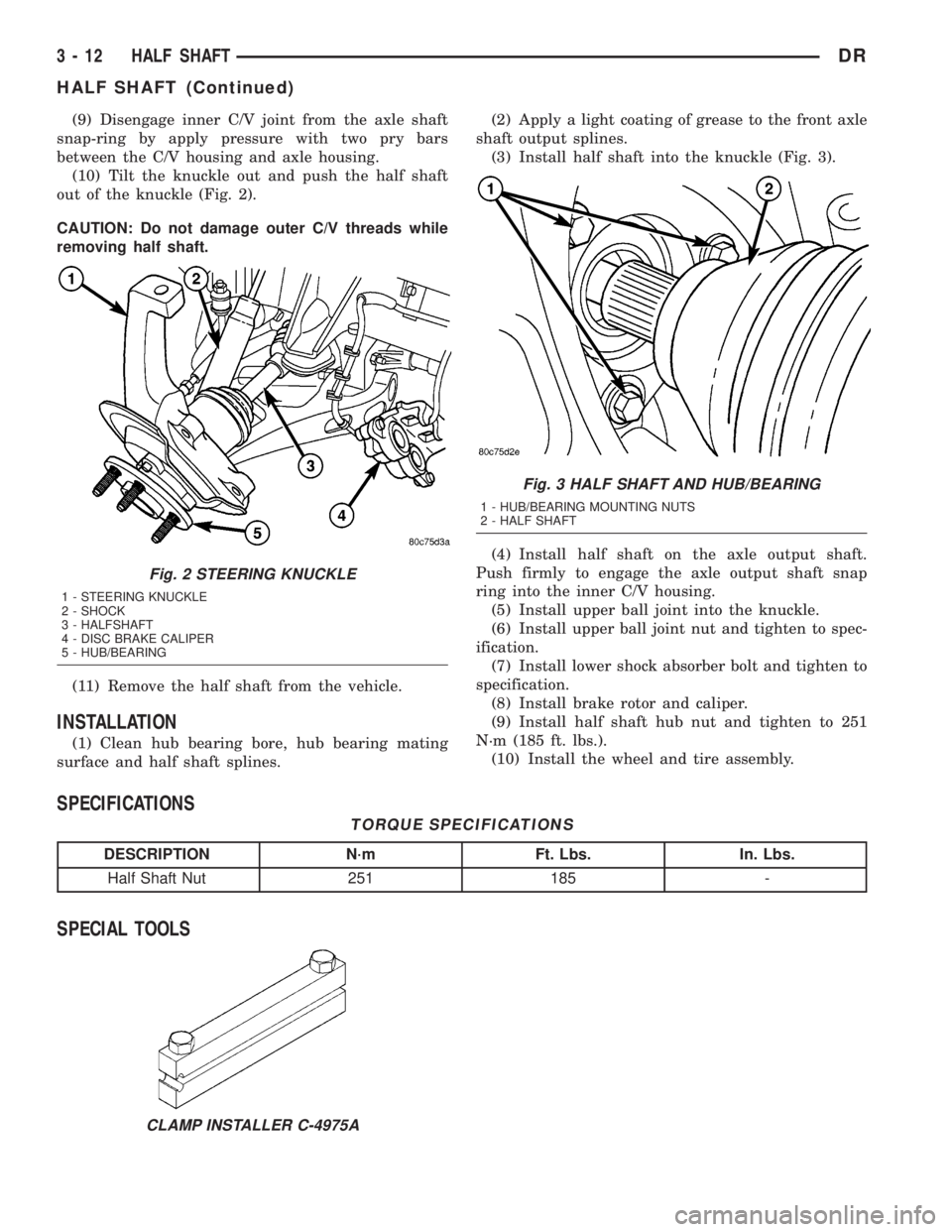

(9) Disengage inner C/V joint from the axle shaft

snap-ring by apply pressure with two pry bars

between the C/V housing and axle housing.

(10) Tilt the knuckle out and push the half shaft

out of the knuckle (Fig. 2).

CAUTION: Do not damage outer C/V threads while

removing half shaft.

(11) Remove the half shaft from the vehicle.

INSTALLATION

(1) Clean hub bearing bore, hub bearing mating

surface and half shaft splines.(2) Apply a light coating of grease to the front axle

shaft output splines.

(3) Install half shaft into the knuckle (Fig. 3).

(4) Install half shaft on the axle output shaft.

Push firmly to engage the axle output shaft snap

ring into the inner C/V housing.

(5) Install upper ball joint into the knuckle.

(6) Install upper ball joint nut and tighten to spec-

ification.

(7) Install lower shock absorber bolt and tighten to

specification.

(8) Install brake rotor and caliper.

(9) Install half shaft hub nut and tighten to 251

N´m (185 ft. lbs.).

(10) Install the wheel and tire assembly.

SPECIFICATIONS

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Half Shaft Nut 251 185 -

SPECIAL TOOLS

Fig. 2 STEERING KNUCKLE

1 - STEERING KNUCKLE

2 - SHOCK

3 - HALFSHAFT

4 - DISC BRAKE CALIPER

5 - HUB/BEARING

Fig. 3 HALF SHAFT AND HUB/BEARING

1 - HUB/BEARING MOUNTING NUTS

2 - HALF SHAFT

CLAMP INSTALLER C-4975A

3 - 12 HALF SHAFTDR

HALF SHAFT (Continued)

Page 94 of 2895

Condition Possible Causes Correction

Gear Teeth Broke 1. Overloading. 1. Replace gears. Examine other

gears and bearings for possible

damage.

2. Erratic clutch operation. 2. Replace gears and examine the

remaining parts for damage. Avoid

erratic clutch operation.

3. Ice-spotted pavement. 3. Replace gears and examine

remaining parts for damage.

4. Improper adjustments. 4. Replace gears and examine

remaining parts for damage. Ensure

ring gear backlash is correct.

Axle Noise 1. Insufficient lubricant. 1. Fill differential with the correct

fluid type and quantity.

2. Improper ring gear and pinion

adjustment.2. Check ring gear and pinion

contact pattern.

3. Unmatched ring gear and pinion. 3. Replace gears with a matched

ring gear and pinion.

4. Worn teeth on ring gear and/or

pinion.4. Replace ring gear and pinion.

5. Loose pinion bearings. 5. Adjust pinion bearing pre-load.

6. Loose differential bearings. 6. Adjust differential bearing

pre-load.

7. Mis-aligned or sprung ring gear. 7. Measure ring gear run-out.

Replace components as necessary.

8. Loose differential bearing cap

bolts.8. Inspect differential components

and replace as necessary. Ensure

that the bearing caps are torqued

tot he proper specification.

9. Housing not machined properly. 9. Replace housing.

REMOVAL

(1) Place transmission in netural.

(2) Raise and support the vehicle.

(3) Remove tire and wheel assemblies.

(4) Remove axle half shafts.

(5) Remove exhaust crossover.

(6) Mark front propeller shaft and remove shaft.

(7) Remove suspension crossmember mounting

bolts (Fig. 1) and remove crossmember.

(8) Support axle with hydraulic jack.

(9) Remove axle housing pinion mounting bolts

(Fig. 2).

(10) Remove axle shaft tube mounting bolts (Fig.

3).

(11) Remove differential housing mounting bolts

(Fig. 4).

(12) Lower axle from the vehicle.

INSTALLATION

(1) Raise axle into position.

(2) Install axle mounting bolts and tighten nuts to

95 N´m (70 ft. lbs.).

(3) Install suspension crossmember and bolts.

Tighten crossmember nuts to 102 N´m (75 ft. lbs.).

(4) Install front propeller shaft with reference

marks aligned (Fig. 5) and tighten bolts to 115 N´m

(85 ft. lbs.).

(5) Install exhaust crossover.

(6) Install axle half shafts.

(7) Check the differential fluid level and add fluid

if necessary.

(8) Install tire and wheel assemblies.

(9) Remove support lower the vehicle.

ADJUSTMENTS

Ring gear and pinion are supplied as matched sets

only. The identifying numbers for the ring gear and

DRFRONT AXLE - C205F 3 - 21

FRONT AXLE - C205F (Continued)