torque DODGE RAM 2003 Service Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 176 of 2895

Condition Possible Causes Correction

Gear Teeth Broke 1. Overloading. 1. Replace gears. Examine other

gears and bearings for possible

damage.

2. Erratic clutch operation. 2. Replace gears and examine the

remaining parts for damage. Avoid

erratic clutch operation.

3. Ice-spotted pavement. 3. Replace gears and examine

remaining parts for damage.

4. Improper adjustments. 4. Replace gears and examine

remaining parts for damage. Ensure

ring gear backlash is correct.

Axle Noise 1. Insufficient lubricant. 1. Fill differential with the correct

fluid type and quantity.

2. Improper ring gear and pinion

adjustment.2. Check ring gear and pinion

contact pattern. Adjust backlash or

pinion depth.

3. Unmatched ring gear and pinion. 3. Replace gears with a matched

ring gear and pinion.

4. Worn teeth on ring gear and/or

pinion.4. Replace ring gear and pinion.

5. Loose pinion bearings. 5. Adjust pinion bearing pre-load.

6. Loose differential bearings. 6. Adjust differential bearing

pre-load.

7. Mis-aligned or sprung ring gear. 7. Measure ring gear run-out.

Replace components as necessary.

8. Loose differential bearing cap

bolts.8. Inspect differential components

and replace as necessary. Ensure

that the bearing caps are torqued

tot he proper specification.

9. Housing not machined properly. 9. Replace housing.

REMOVAL

(1) Raise and support the vehicle.

(2) Position a lifting device under the axle.

(3) Secure axle to device.

(4) Remove wheels and tires assemblies.

(5) Remove RWAL sensor from the differential

housing.

(6) Remove brake hose at the axle junction block

and axle vent hose.

(7) Disconnect parking brake cables and cable

brackets.

(8) Remove brake calipers and rotors.

(9) Mark propeller shaft and companion flange for

installation alignment reference.

(10) Remove propeller shaft.

(11) Remove shock absorbers from axle.

(12) Remove U-bolts from axle.

(13) Separate the axle from the vehicle.

INSTALLATION

(1) Raise axle with lifting device and align to the

leaf spring centering bolts.

(2) Install axle U-bolts and tighten to 149 N´m

(110 ft. lbs.).

(3) Install shock absorbers to axle and tighten to

specification.

(4) Install the RWAL sensor to the differential

housing.

(5) Connect the parking brake cables and cable

brackets.

(6) Install brake calipers.

(7) Connect brake hose to the axle junction block

and axle vent hose.

(8) Align propeller shaft and pinion companion

flange reference marks and tighten companion flange

bolts to 115 N´m (85 ft. lbs.).

(9) Install the wheels and tires.

DRREAR AXLE - 10 1/2 AA 3 - 103

REAR AXLE - 10 1/2 AA (Continued)

Page 177 of 2895

(10) Fill differential to specifications.

(11) Remove lifting device from axle and lower the

vehicle.

ADJUSTMENTS

Ring and pinion gears are supplied as matched

sets only. Compensation for pinion depth variance is

achieved with a select shim. The shim is located

between the rear pinion bearing and the pinion gear

head.

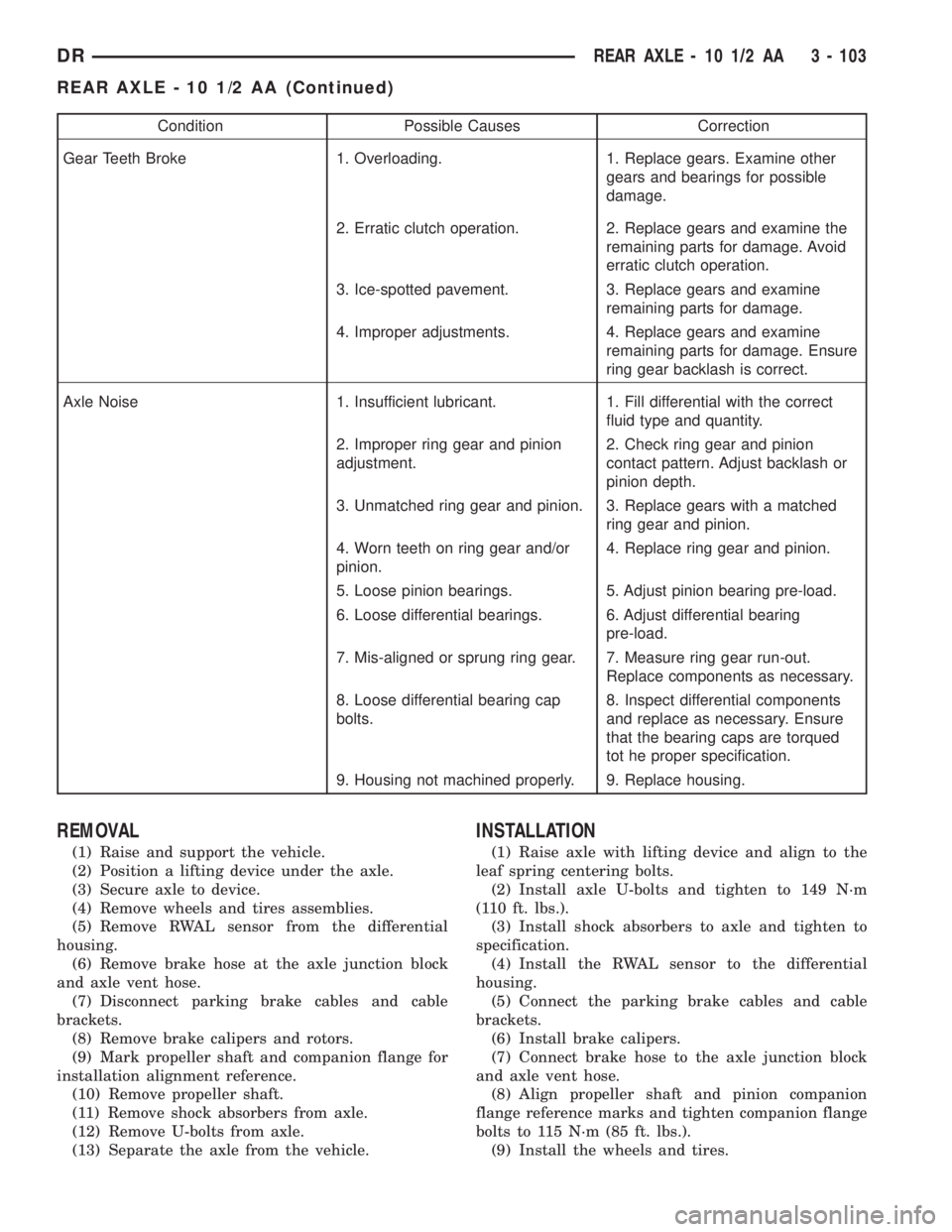

PINION DEPTH MEASUREMENT AND ADJUSTMENT

Measurements are taken with pinion bearing cups

and pinion bearings installed in the housing. Take

measurements with Pinion Gauge Set and Dial Indi-

cator C-3339 (Fig. 1).

(1) Assemble Pinion Height Block 6739, Pinion

Block 8899 and rear pinion bearing onto Screw 6741

(Fig. 1).

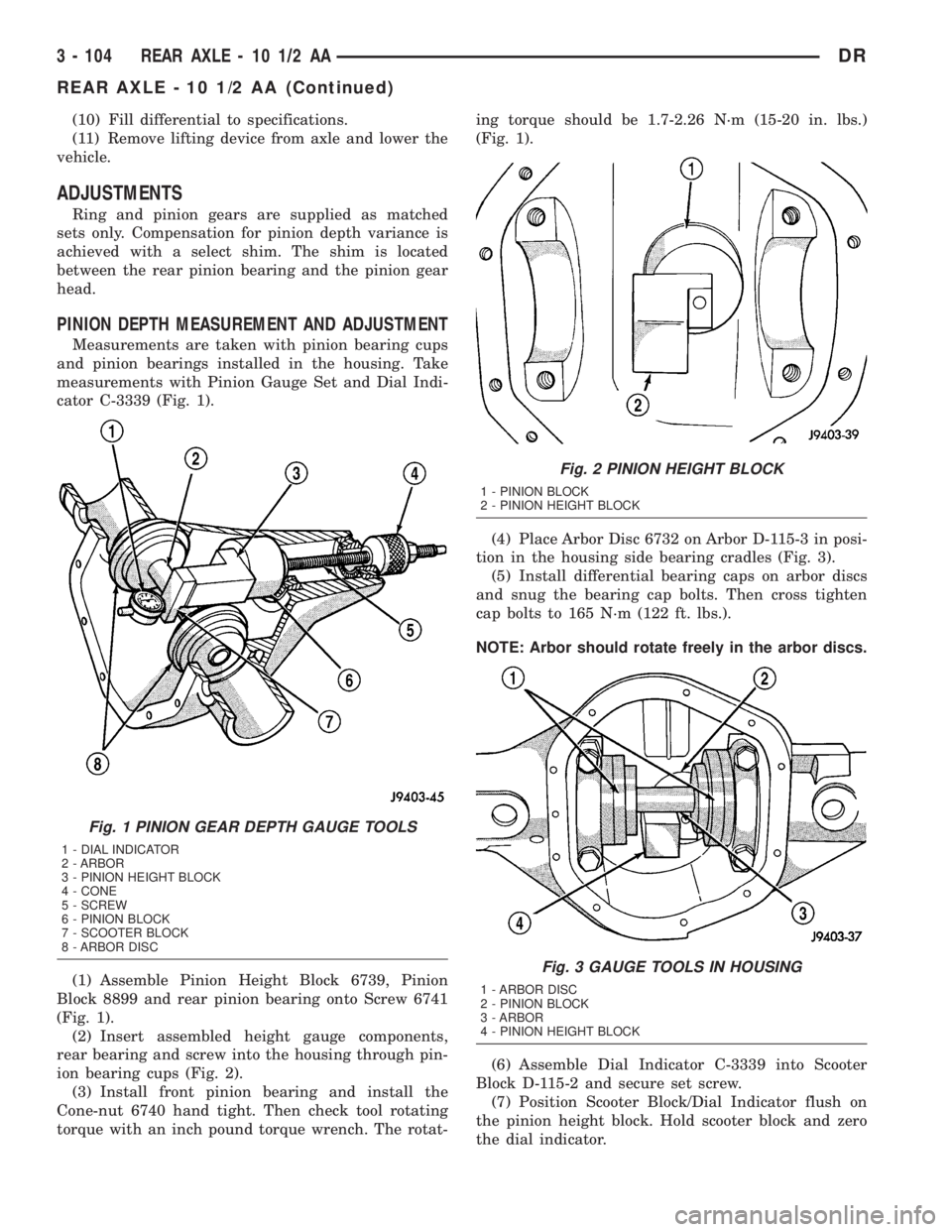

(2) Insert assembled height gauge components,

rear bearing and screw into the housing through pin-

ion bearing cups (Fig. 2).

(3) Install front pinion bearing and install the

Cone-nut 6740 hand tight. Then check tool rotating

torque with an inch pound torque wrench. The rotat-ing torque should be 1.7-2.26 N´m (15-20 in. lbs.)

(Fig. 1).

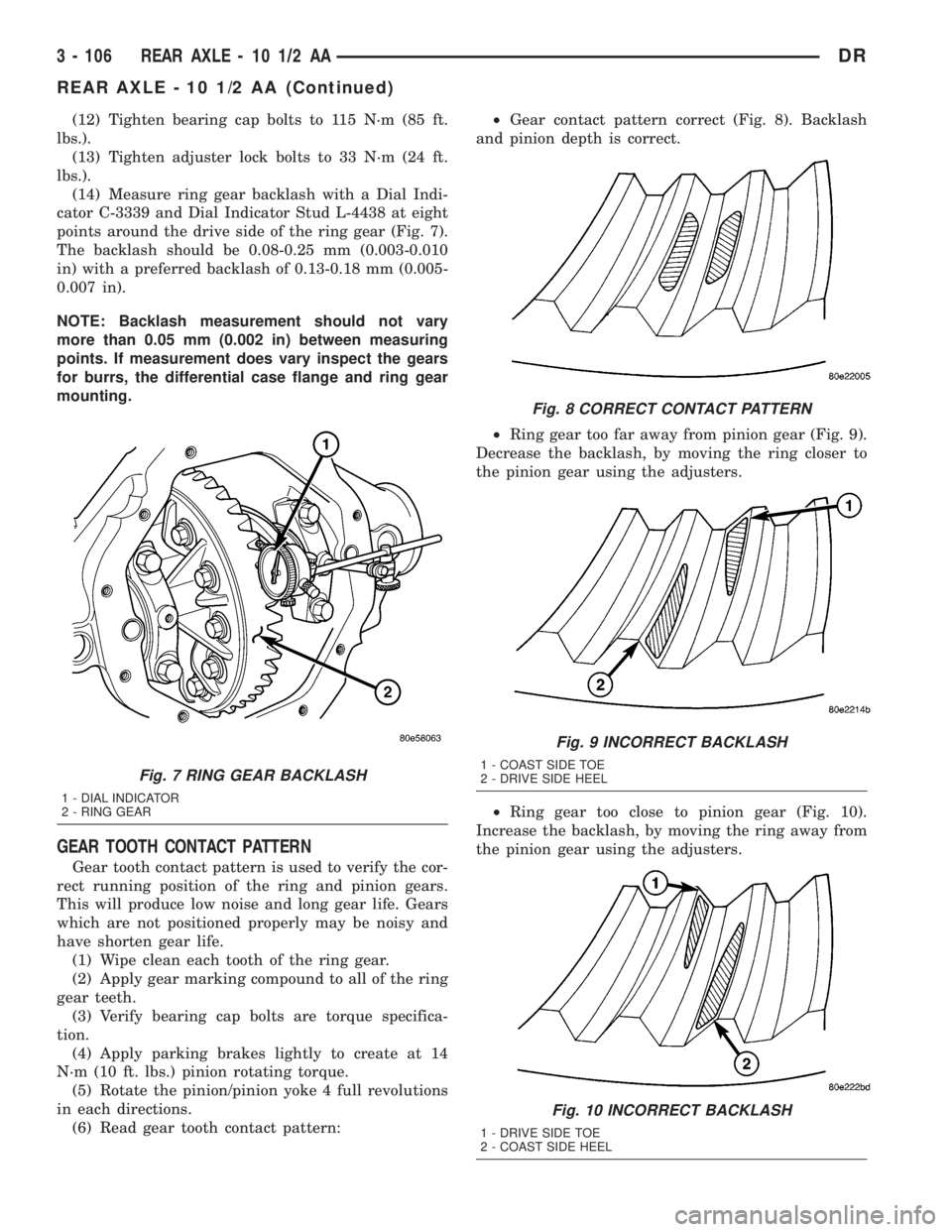

(4) Place Arbor Disc 6732 on Arbor D-115-3 in posi-

tion in the housing side bearing cradles (Fig. 3).

(5) Install differential bearing caps on arbor discs

and snug the bearing cap bolts. Then cross tighten

cap bolts to 165 N´m (122 ft. lbs.).

NOTE: Arbor should rotate freely in the arbor discs.

(6) Assemble Dial Indicator C-3339 into Scooter

Block D-115-2 and secure set screw.

(7) Position Scooter Block/Dial Indicator flush on

the pinion height block. Hold scooter block and zero

the dial indicator.

Fig. 1 PINION GEAR DEPTH GAUGE TOOLS

1 - DIAL INDICATOR

2 - ARBOR

3 - PINION HEIGHT BLOCK

4 - CONE

5 - SCREW

6 - PINION BLOCK

7 - SCOOTER BLOCK

8 - ARBOR DISC

Fig. 2 PINION HEIGHT BLOCK

1 - PINION BLOCK

2 - PINION HEIGHT BLOCK

Fig. 3 GAUGE TOOLS IN HOUSING

1 - ARBOR DISC

2 - PINION BLOCK

3 - ARBOR

4 - PINION HEIGHT BLOCK

3 - 104 REAR AXLE - 10 1/2 AADR

REAR AXLE - 10 1/2 AA (Continued)

Page 179 of 2895

(12) Tighten bearing cap bolts to 115 N´m (85 ft.

lbs.).

(13) Tighten adjuster lock bolts to 33 N´m (24 ft.

lbs.).

(14) Measure ring gear backlash with a Dial Indi-

cator C-3339 and Dial Indicator Stud L-4438 at eight

points around the drive side of the ring gear (Fig. 7).

The backlash should be 0.08-0.25 mm (0.003-0.010

in) with a preferred backlash of 0.13-0.18 mm (0.005-

0.007 in).

NOTE: Backlash measurement should not vary

more than 0.05 mm (0.002 in) between measuring

points. If measurement does vary inspect the gears

for burrs, the differential case flange and ring gear

mounting.

GEAR TOOTH CONTACT PATTERN

Gear tooth contact pattern is used to verify the cor-

rect running position of the ring and pinion gears.

This will produce low noise and long gear life. Gears

which are not positioned properly may be noisy and

have shorten gear life.

(1) Wipe clean each tooth of the ring gear.

(2) Apply gear marking compound to all of the ring

gear teeth.

(3) Verify bearing cap bolts are torque specifica-

tion.

(4) Apply parking brakes lightly to create at 14

N´m (10 ft. lbs.) pinion rotating torque.

(5) Rotate the pinion/pinion yoke 4 full revolutions

in each directions.

(6) Read gear tooth contact pattern:²Gear contact pattern correct (Fig. 8). Backlash

and pinion depth is correct.

²Ring gear too far away from pinion gear (Fig. 9).

Decrease the backlash, by moving the ring closer to

the pinion gear using the adjusters.

²Ring gear too close to pinion gear (Fig. 10).

Increase the backlash, by moving the ring away from

the pinion gear using the adjusters.

Fig. 7 RING GEAR BACKLASH

1 - DIAL INDICATOR

2 - RING GEAR

Fig. 8 CORRECT CONTACT PATTERN

Fig. 9 INCORRECT BACKLASH

1 - COAST SIDE TOE

2 - DRIVE SIDE HEEL

Fig. 10 INCORRECT BACKLASH

1 - DRIVE SIDE TOE

2 - COAST SIDE HEEL

3 - 106 REAR AXLE - 10 1/2 AADR

REAR AXLE - 10 1/2 AA (Continued)

Page 181 of 2895

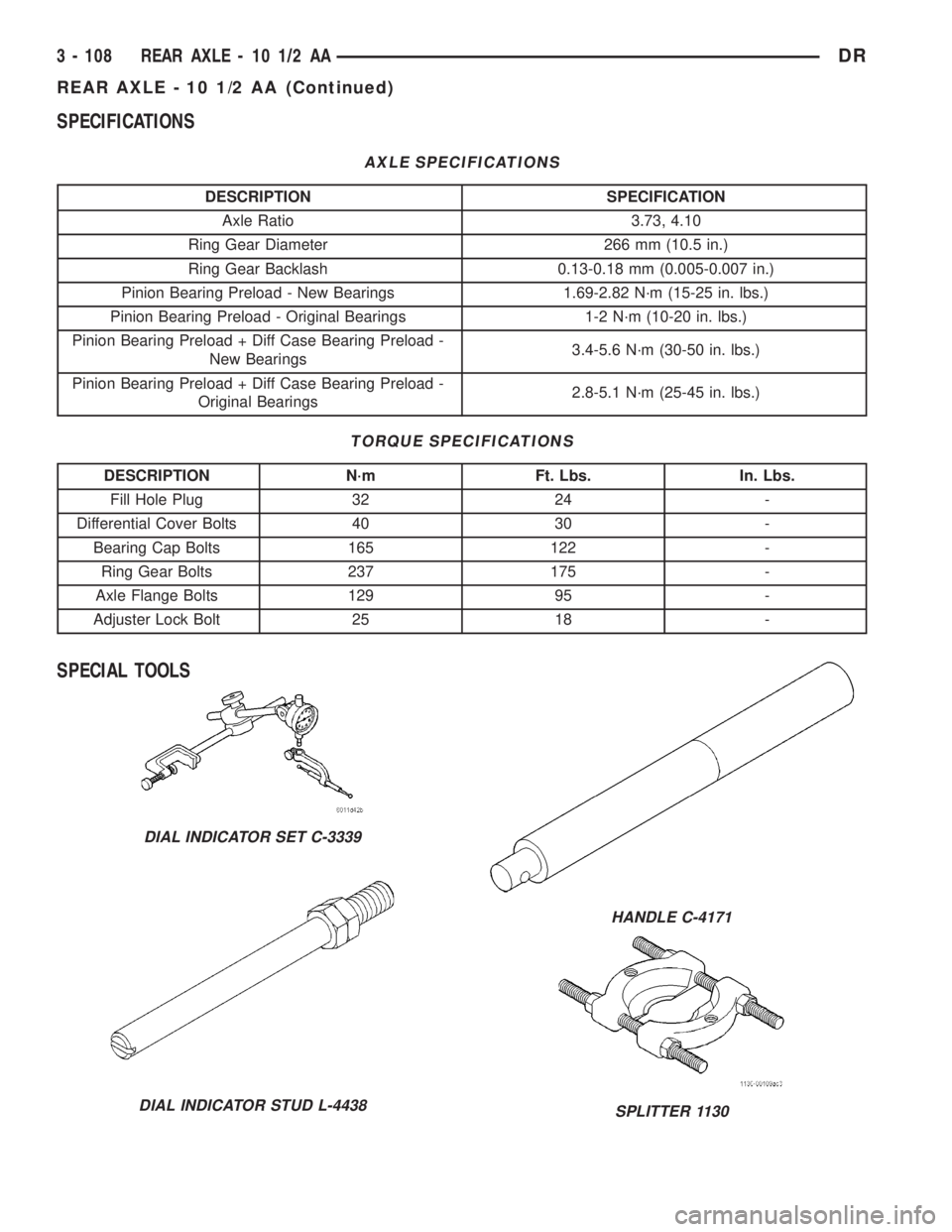

SPECIFICATIONS

AXLE SPECIFICATIONS

DESCRIPTION SPECIFICATION

Axle Ratio 3.73, 4.10

Ring Gear Diameter 266 mm (10.5 in.)

Ring Gear Backlash 0.13-0.18 mm (0.005-0.007 in.)

Pinion Bearing Preload - New Bearings 1.69-2.82 N´m (15-25 in. lbs.)

Pinion Bearing Preload - Original Bearings 1-2 N´m (10-20 in. lbs.)

Pinion Bearing Preload + Diff Case Bearing Preload -

New Bearings3.4-5.6 N´m (30-50 in. lbs.)

Pinion Bearing Preload + Diff Case Bearing Preload -

Original Bearings2.8-5.1 N´m (25-45 in. lbs.)

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Fill Hole Plug 32 24 -

Differential Cover Bolts 40 30 -

Bearing Cap Bolts 165 122 -

Ring Gear Bolts 237 175 -

Axle Flange Bolts 129 95 -

Adjuster Lock Bolt 25 18 -

SPECIAL TOOLS

DIAL INDICATOR SET C-3339

DIAL INDICATOR STUD L-4438

HANDLE C-4171

SPLITTER 1130

3 - 108 REAR AXLE - 10 1/2 AADR

REAR AXLE - 10 1/2 AA (Continued)

Page 186 of 2895

PINION SEAL

REMOVAL

(1) Remove axle shafts.

(2) Mark propeller shaft and pinion flange for

installation reference and remove shaft.

(3) Rotate pinion gear three or four times.

(4) Measure and record the amount of torque nec-

essary to rotate the pinion gear with an inch pound

torque wrench (Fig. 20).

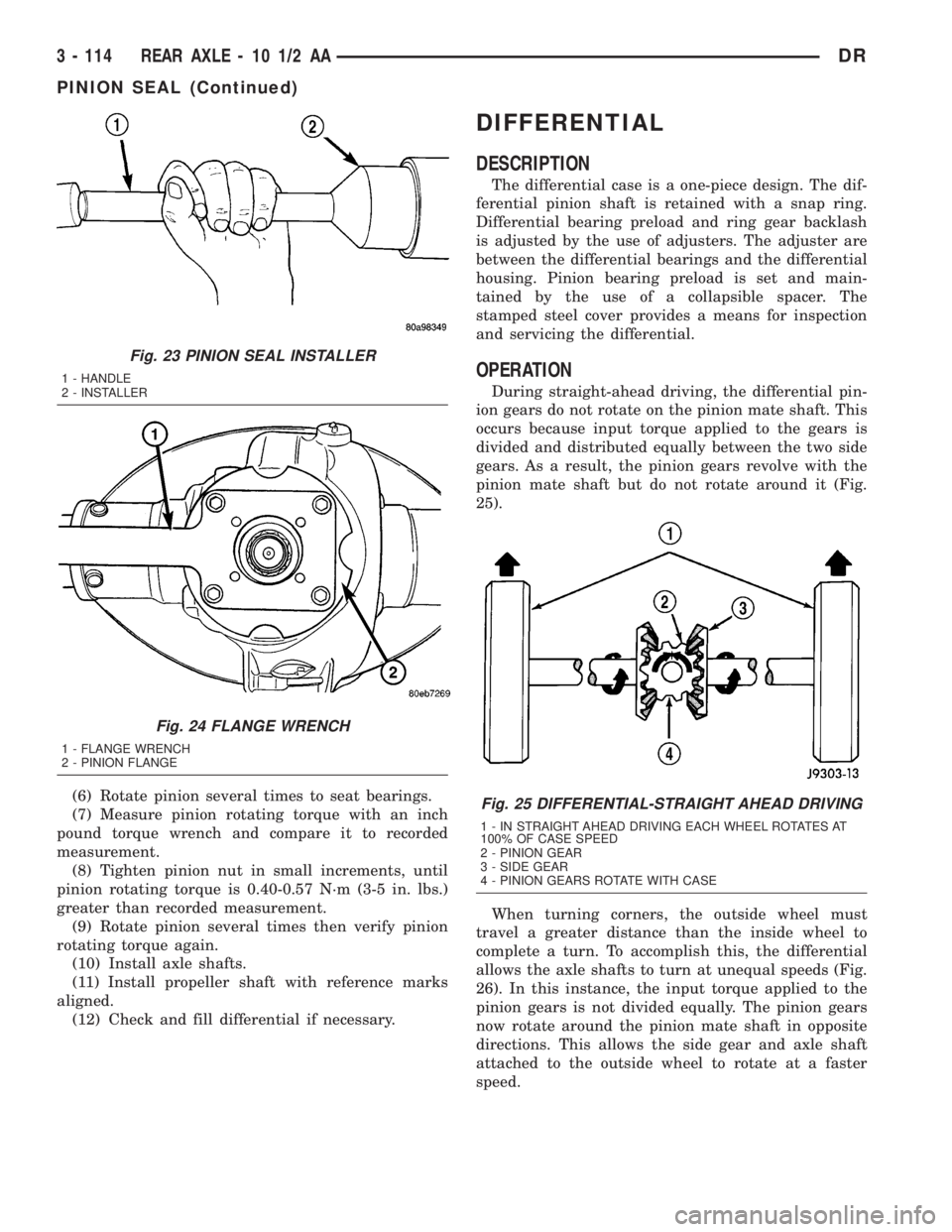

(5) Hold pinion flange with Flange Wrench 8979

(Fig. 21) and remove pinion flange nut and washer.(6) Remove pinion flange with Pinion Flange

Puller 8992 (Fig. 22).

(7) Remove pinion shaft seal with a pry tool or

slide hammer mounted screw.

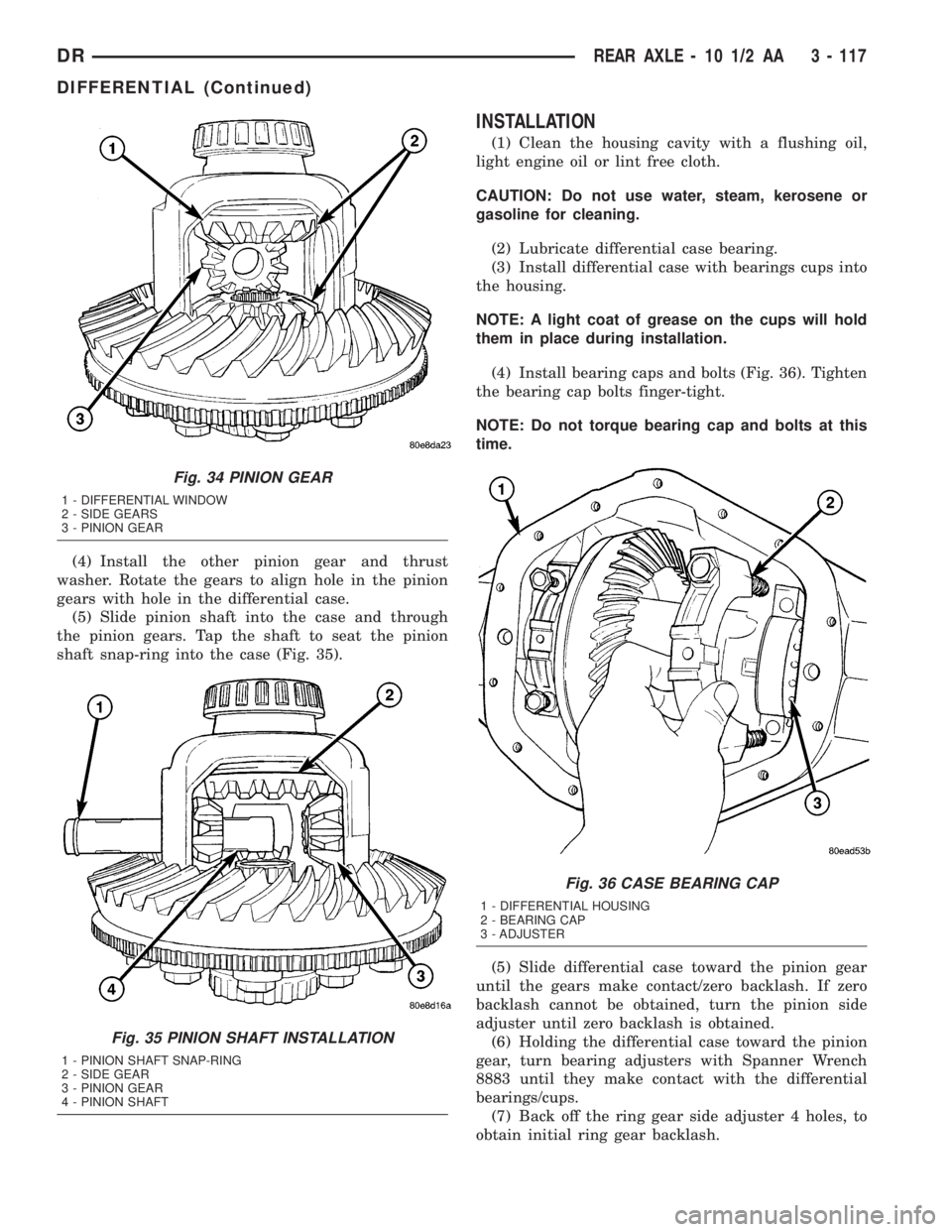

INSTALLATION

(1) Installnewpinion seal with Installer 8896 and

Handle C-4171 (Fig. 23).

(2) Apply a light coat of teflon sealant to the pin-

ion flange splines.

(3) Lightly tap the pinion flange onto the pinion

until a few threads are showing.

(4) Install flange washer andnewpinion nut.

(5) Hold flange with Flange Wrench 8979 (Fig. 24)

and tighten pinion nut until pinion end play is taken

up.

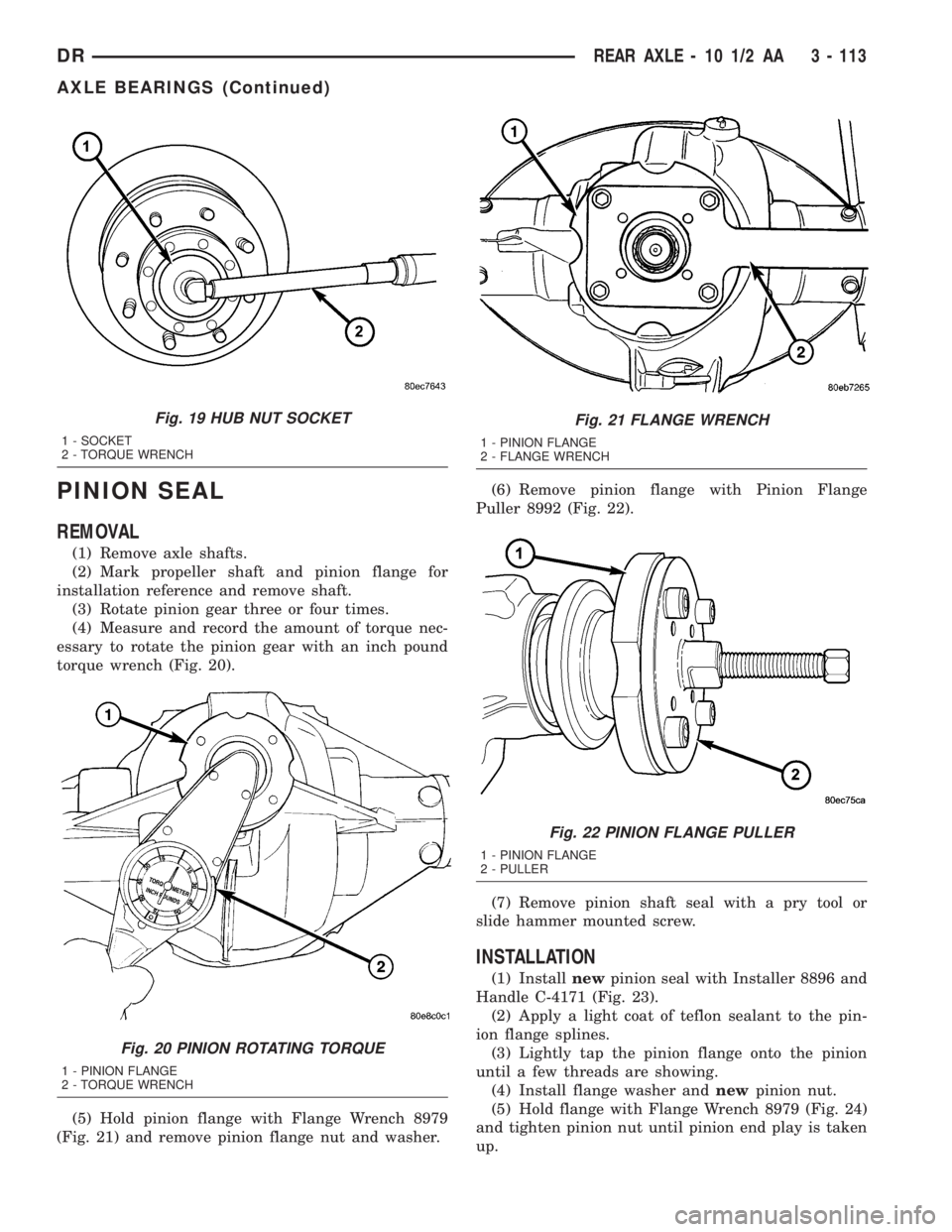

Fig. 19 HUB NUT SOCKET

1 - SOCKET

2 - TORQUE WRENCH

Fig. 20 PINION ROTATING TORQUE

1 - PINION FLANGE

2 - TORQUE WRENCH

Fig. 21 FLANGE WRENCH

1 - PINION FLANGE

2 - FLANGE WRENCH

Fig. 22 PINION FLANGE PULLER

1 - PINION FLANGE

2 - PULLER

DRREAR AXLE - 10 1/2 AA 3 - 113

AXLE BEARINGS (Continued)

Page 187 of 2895

(6) Rotate pinion several times to seat bearings.

(7) Measure pinion rotating torque with an inch

pound torque wrench and compare it to recorded

measurement.

(8) Tighten pinion nut in small increments, until

pinion rotating torque is 0.40-0.57 N´m (3-5 in. lbs.)

greater than recorded measurement.

(9) Rotate pinion several times then verify pinion

rotating torque again.

(10) Install axle shafts.

(11) Install propeller shaft with reference marks

aligned.

(12) Check and fill differential if necessary.

DIFFERENTIAL

DESCRIPTION

The differential case is a one-piece design. The dif-

ferential pinion shaft is retained with a snap ring.

Differential bearing preload and ring gear backlash

is adjusted by the use of adjusters. The adjuster are

between the differential bearings and the differential

housing. Pinion bearing preload is set and main-

tained by the use of a collapsible spacer. The

stamped steel cover provides a means for inspection

and servicing the differential.

OPERATION

During straight-ahead driving, the differential pin-

ion gears do not rotate on the pinion mate shaft. This

occurs because input torque applied to the gears is

divided and distributed equally between the two side

gears. As a result, the pinion gears revolve with the

pinion mate shaft but do not rotate around it (Fig.

25).

When turning corners, the outside wheel must

travel a greater distance than the inside wheel to

complete a turn. To accomplish this, the differential

allows the axle shafts to turn at unequal speeds (Fig.

26). In this instance, the input torque applied to the

pinion gears is not divided equally. The pinion gears

now rotate around the pinion mate shaft in opposite

directions. This allows the side gear and axle shaft

attached to the outside wheel to rotate at a faster

speed.

Fig. 23 PINION SEAL INSTALLER

1 - HANDLE

2 - INSTALLER

Fig. 24 FLANGE WRENCH

1 - FLANGE WRENCH

2 - PINION FLANGE

Fig. 25 DIFFERENTIAL-STRAIGHT AHEAD DRIVING

1 - IN STRAIGHT AHEAD DRIVING EACH WHEEL ROTATES AT

100% OF CASE SPEED

2 - PINION GEAR

3 - SIDE GEAR

4 - PINION GEARS ROTATE WITH CASE

3 - 114 REAR AXLE - 10 1/2 AADR

PINION SEAL (Continued)

Page 190 of 2895

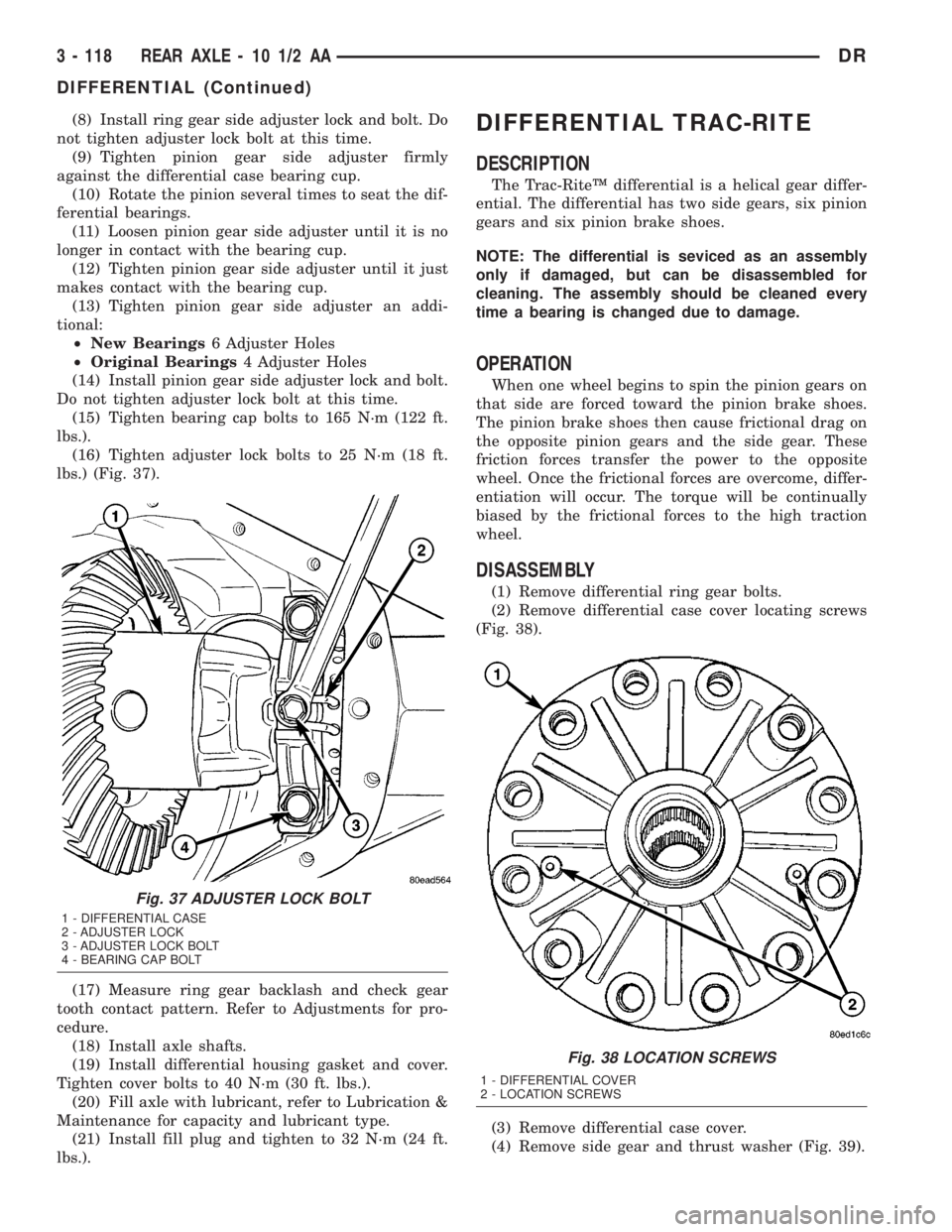

(4) Install the other pinion gear and thrust

washer. Rotate the gears to align hole in the pinion

gears with hole in the differential case.

(5) Slide pinion shaft into the case and through

the pinion gears. Tap the shaft to seat the pinion

shaft snap-ring into the case (Fig. 35).

INSTALLATION

(1) Clean the housing cavity with a flushing oil,

light engine oil or lint free cloth.

CAUTION: Do not use water, steam, kerosene or

gasoline for cleaning.

(2) Lubricate differential case bearing.

(3) Install differential case with bearings cups into

the housing.

NOTE: A light coat of grease on the cups will hold

them in place during installation.

(4) Install bearing caps and bolts (Fig. 36). Tighten

the bearing cap bolts finger-tight.

NOTE: Do not torque bearing cap and bolts at this

time.

(5) Slide differential case toward the pinion gear

until the gears make contact/zero backlash. If zero

backlash cannot be obtained, turn the pinion side

adjuster until zero backlash is obtained.

(6) Holding the differential case toward the pinion

gear, turn bearing adjusters with Spanner Wrench

8883 until they make contact with the differential

bearings/cups.

(7) Back off the ring gear side adjuster 4 holes, to

obtain initial ring gear backlash.

Fig. 34 PINION GEAR

1 - DIFFERENTIAL WINDOW

2 - SIDE GEARS

3 - PINION GEAR

Fig. 35 PINION SHAFT INSTALLATION

1 - PINION SHAFT SNAP-RING

2 - SIDE GEAR

3 - PINION GEAR

4 - PINION SHAFT

Fig. 36 CASE BEARING CAP

1 - DIFFERENTIAL HOUSING

2 - BEARING CAP

3 - ADJUSTER

DRREAR AXLE - 10 1/2 AA 3 - 117

DIFFERENTIAL (Continued)

Page 191 of 2895

(8) Install ring gear side adjuster lock and bolt. Do

not tighten adjuster lock bolt at this time.

(9) Tighten pinion gear side adjuster firmly

against the differential case bearing cup.

(10) Rotate the pinion several times to seat the dif-

ferential bearings.

(11) Loosen pinion gear side adjuster until it is no

longer in contact with the bearing cup.

(12) Tighten pinion gear side adjuster until it just

makes contact with the bearing cup.

(13) Tighten pinion gear side adjuster an addi-

tional:

²New Bearings6 Adjuster Holes

²Original Bearings4 Adjuster Holes

(14) Install pinion gear side adjuster lock and bolt.

Do not tighten adjuster lock bolt at this time.

(15) Tighten bearing cap bolts to 165 N´m (122 ft.

lbs.).

(16) Tighten adjuster lock bolts to 25 N´m (18 ft.

lbs.) (Fig. 37).

(17) Measure ring gear backlash and check gear

tooth contact pattern. Refer to Adjustments for pro-

cedure.

(18) Install axle shafts.

(19) Install differential housing gasket and cover.

Tighten cover bolts to 40 N´m (30 ft. lbs.).

(20) Fill axle with lubricant, refer to Lubrication &

Maintenance for capacity and lubricant type.

(21) Install fill plug and tighten to 32 N´m (24 ft.

lbs.).DIFFERENTIAL TRAC-RITE

DESCRIPTION

The Trac-RiteŸ differential is a helical gear differ-

ential. The differential has two side gears, six pinion

gears and six pinion brake shoes.

NOTE: The differential is seviced as an assembly

only if damaged, but can be disassembled for

cleaning. The assembly should be cleaned every

time a bearing is changed due to damage.

OPERATION

When one wheel begins to spin the pinion gears on

that side are forced toward the pinion brake shoes.

The pinion brake shoes then cause frictional drag on

the opposite pinion gears and the side gear. These

friction forces transfer the power to the opposite

wheel. Once the frictional forces are overcome, differ-

entiation will occur. The torque will be continually

biased by the frictional forces to the high traction

wheel.

DISASSEMBLY

(1) Remove differential ring gear bolts.

(2) Remove differential case cover locating screws

(Fig. 38).

(3) Remove differential case cover.

(4) Remove side gear and thrust washer (Fig. 39).

Fig. 37 ADJUSTER LOCK BOLT

1 - DIFFERENTIAL CASE

2 - ADJUSTER LOCK

3 - ADJUSTER LOCK BOLT

4 - BEARING CAP BOLT

Fig. 38 LOCATION SCREWS

1 - DIFFERENTIAL COVER

2 - LOCATION SCREWS

3 - 118 REAR AXLE - 10 1/2 AADR

DIFFERENTIAL (Continued)

Page 198 of 2895

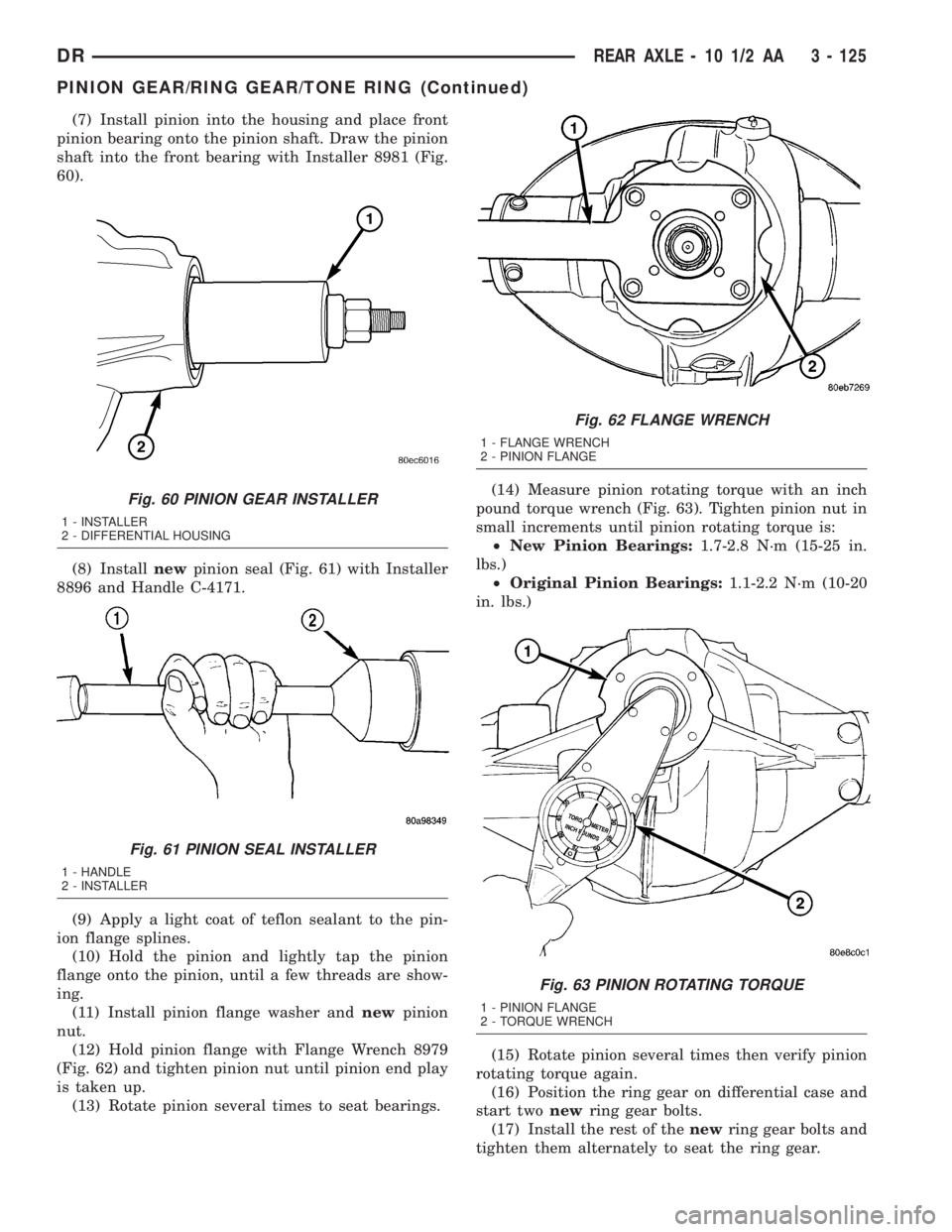

(7) Install pinion into the housing and place front

pinion bearing onto the pinion shaft. Draw the pinion

shaft into the front bearing with Installer 8981 (Fig.

60).

(8) Installnewpinion seal (Fig. 61) with Installer

8896 and Handle C-4171.

(9) Apply a light coat of teflon sealant to the pin-

ion flange splines.

(10) Hold the pinion and lightly tap the pinion

flange onto the pinion, until a few threads are show-

ing.

(11) Install pinion flange washer andnewpinion

nut.

(12) Hold pinion flange with Flange Wrench 8979

(Fig. 62) and tighten pinion nut until pinion end play

is taken up.

(13) Rotate pinion several times to seat bearings.(14) Measure pinion rotating torque with an inch

pound torque wrench (Fig. 63). Tighten pinion nut in

small increments until pinion rotating torque is:

²New Pinion Bearings:1.7-2.8 N´m (15-25 in.

lbs.)

²Original Pinion Bearings:1.1-2.2 N´m (10-20

in. lbs.)

(15) Rotate pinion several times then verify pinion

rotating torque again.

(16) Position the ring gear on differential case and

start twonewring gear bolts.

(17) Install the rest of thenewring gear bolts and

tighten them alternately to seat the ring gear.

Fig. 60 PINION GEAR INSTALLER

1 - INSTALLER

2 - DIFFERENTIAL HOUSING

Fig. 61 PINION SEAL INSTALLER

1 - HANDLE

2 - INSTALLER

Fig. 62 FLANGE WRENCH

1 - FLANGE WRENCH

2 - PINION FLANGE

Fig. 63 PINION ROTATING TORQUE

1 - PINION FLANGE

2 - TORQUE WRENCH

DRREAR AXLE - 10 1/2 AA 3 - 125

PINION GEAR/RING GEAR/TONE RING (Continued)

Page 199 of 2895

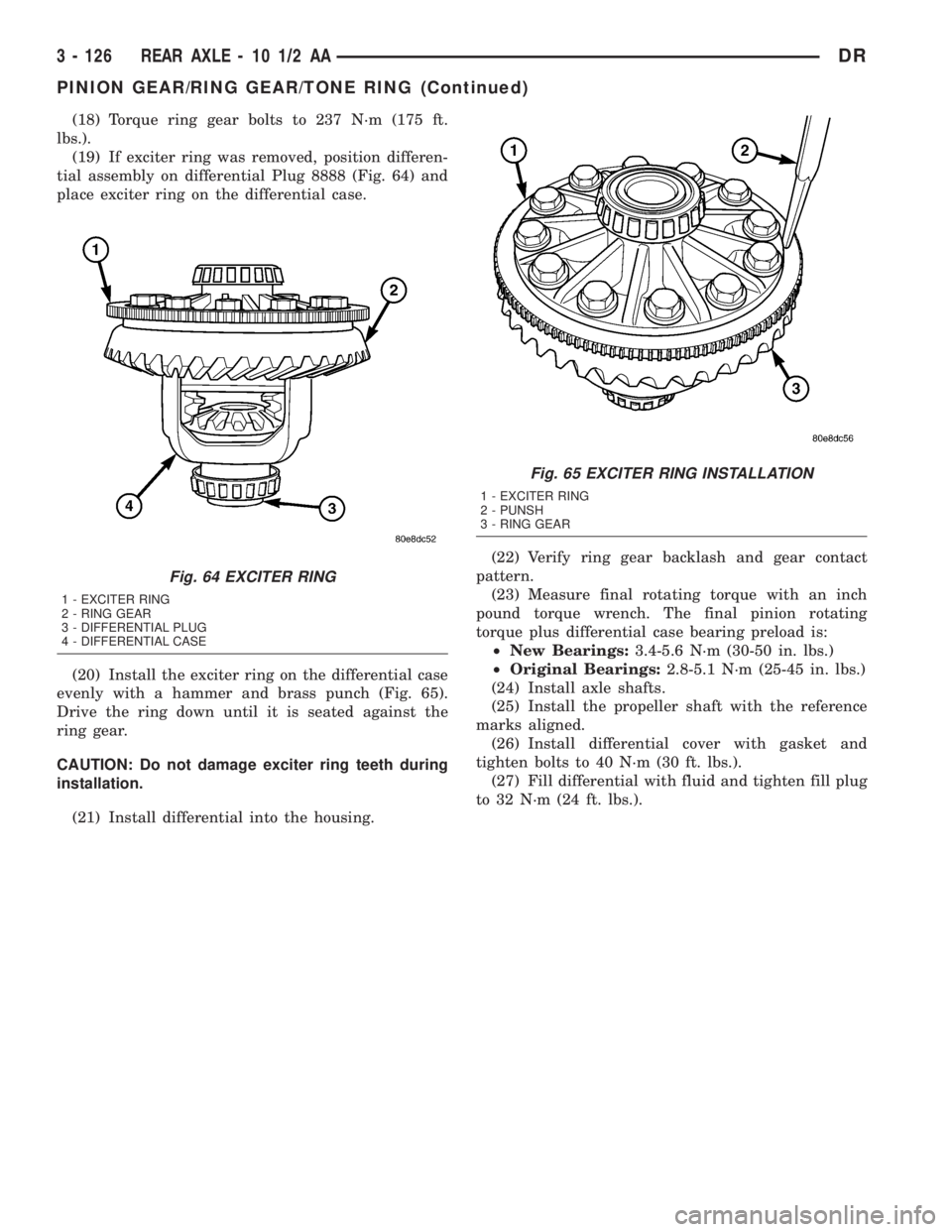

(18) Torque ring gear bolts to 237 N´m (175 ft.

lbs.).

(19) If exciter ring was removed, position differen-

tial assembly on differential Plug 8888 (Fig. 64) and

place exciter ring on the differential case.

(20) Install the exciter ring on the differential case

evenly with a hammer and brass punch (Fig. 65).

Drive the ring down until it is seated against the

ring gear.

CAUTION: Do not damage exciter ring teeth during

installation.

(21) Install differential into the housing.(22) Verify ring gear backlash and gear contact

pattern.

(23) Measure final rotating torque with an inch

pound torque wrench. The final pinion rotating

torque plus differential case bearing preload is:

²New Bearings:3.4-5.6 N´m (30-50 in. lbs.)

²Original Bearings:2.8-5.1 N´m (25-45 in. lbs.)

(24) Install axle shafts.

(25) Install the propeller shaft with the reference

marks aligned.

(26) Install differential cover with gasket and

tighten bolts to 40 N´m (30 ft. lbs.).

(27) Fill differential with fluid and tighten fill plug

to 32 N´m (24 ft. lbs.).

Fig. 64 EXCITER RING

1 - EXCITER RING

2 - RING GEAR

3 - DIFFERENTIAL PLUG

4 - DIFFERENTIAL CASE

Fig. 65 EXCITER RING INSTALLATION

1 - EXCITER RING

2 - PUNSH

3 - RING GEAR

3 - 126 REAR AXLE - 10 1/2 AADR

PINION GEAR/RING GEAR/TONE RING (Continued)