wheel bolt torque DODGE RAM 2003 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 131 of 2895

ASSEMBLY

(1) Pack the bearing caps 1/3 full of wheel bearing

lubricant. Apply extreme pressure (EP), lithium-base

lubricant to aid in installation.

(2) Position the spider in the yoke. Insert the seals

and bearings. Tap the bearing caps into the yoke

bores far enough to hold the spider in position.

(3) Place the socket (driver) against one bearing

cap. Position the yoke with the socket in a vise.

(4) Tighten the vise to force the bearing caps into

the yoke. Force the caps enough to install the retain-

ing clips.

(5) Install the bearing cap retaining clips.

(6) Install axle shaft.

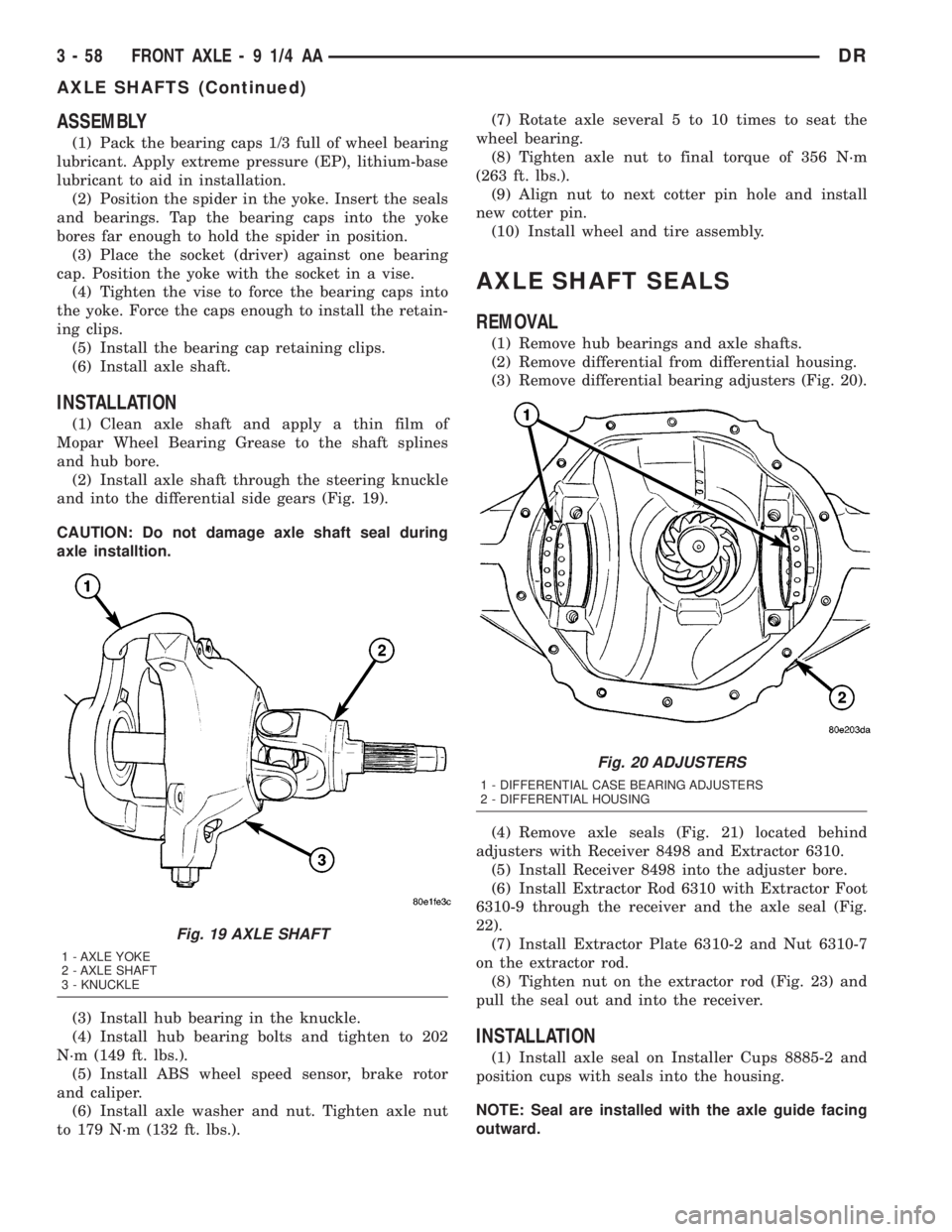

INSTALLATION

(1) Clean axle shaft and apply a thin film of

Mopar Wheel Bearing Grease to the shaft splines

and hub bore.

(2) Install axle shaft through the steering knuckle

and into the differential side gears (Fig. 19).

CAUTION: Do not damage axle shaft seal during

axle installtion.

(3) Install hub bearing in the knuckle.

(4) Install hub bearing bolts and tighten to 202

N´m (149 ft. lbs.).

(5) Install ABS wheel speed sensor, brake rotor

and caliper.

(6) Install axle washer and nut. Tighten axle nut

to 179 N´m (132 ft. lbs.).(7) Rotate axle several 5 to 10 times to seat the

wheel bearing.

(8) Tighten axle nut to final torque of 356 N´m

(263 ft. lbs.).

(9) Align nut to next cotter pin hole and install

new cotter pin.

(10) Install wheel and tire assembly.

AXLE SHAFT SEALS

REMOVAL

(1) Remove hub bearings and axle shafts.

(2) Remove differential from differential housing.

(3) Remove differential bearing adjusters (Fig. 20).

(4) Remove axle seals (Fig. 21) located behind

adjusters with Receiver 8498 and Extractor 6310.

(5) Install Receiver 8498 into the adjuster bore.

(6) Install Extractor Rod 6310 with Extractor Foot

6310-9 through the receiver and the axle seal (Fig.

22).

(7) Install Extractor Plate 6310-2 and Nut 6310-7

on the extractor rod.

(8) Tighten nut on the extractor rod (Fig. 23) and

pull the seal out and into the receiver.

INSTALLATION

(1) Install axle seal on Installer Cups 8885-2 and

position cups with seals into the housing.

NOTE: Seal are installed with the axle guide facing

outward.

Fig. 19 AXLE SHAFT

1 - AXLE YOKE

2 - AXLE SHAFT

3 - KNUCKLE

Fig. 20 ADJUSTERS

1 - DIFFERENTIAL CASE BEARING ADJUSTERS

2 - DIFFERENTIAL HOUSING

3 - 58 FRONT AXLE - 9 1/4 AADR

AXLE SHAFTS (Continued)

Page 134 of 2895

ments, until pinion rotating torque is 0.40-0.57 N´m

(3-5 in. lbs.) greater than recorded measurement.

(8) Rotate pinion several times then verify pinion

rotating torque again.

(9) Install axle shafts and hub bearings.

(10) Install propeller shaft with reference marks

aligned.

DIFFERENTIAL

DESCRIPTION

The differential case is a one-piece design. The dif-

ferential pinion shaft is retained with a snap ring.

Differential bearing preload and ring gear backlash

is adjusted by the use of adjusters. The adjuster are

between the differential bearings and the differential

housing. Pinion bearing preload is set and main-

tained by the use of a collapsible spacer. The

stamped steel cover provides a means for inspection

and servicing the differential.

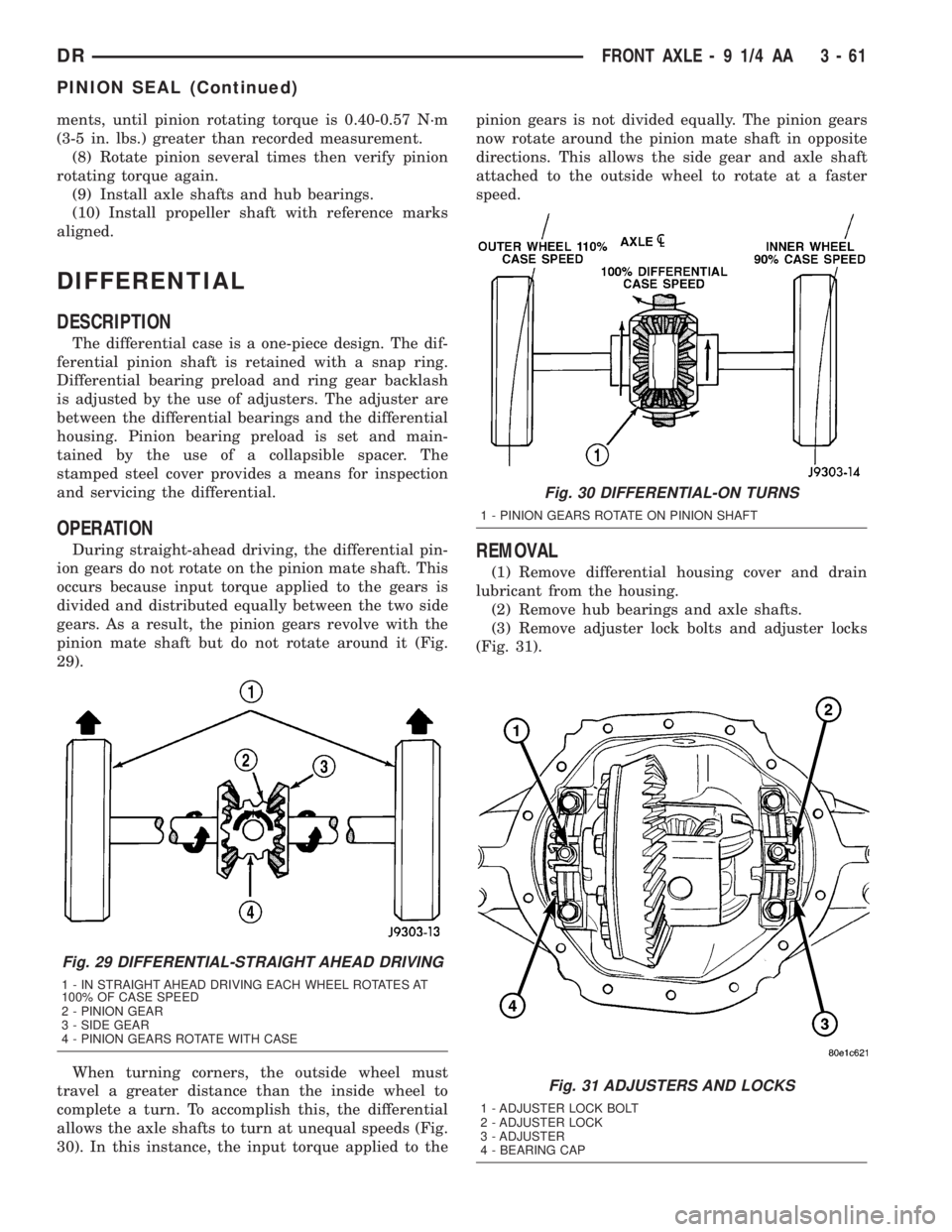

OPERATION

During straight-ahead driving, the differential pin-

ion gears do not rotate on the pinion mate shaft. This

occurs because input torque applied to the gears is

divided and distributed equally between the two side

gears. As a result, the pinion gears revolve with the

pinion mate shaft but do not rotate around it (Fig.

29).

When turning corners, the outside wheel must

travel a greater distance than the inside wheel to

complete a turn. To accomplish this, the differential

allows the axle shafts to turn at unequal speeds (Fig.

30). In this instance, the input torque applied to thepinion gears is not divided equally. The pinion gears

now rotate around the pinion mate shaft in opposite

directions. This allows the side gear and axle shaft

attached to the outside wheel to rotate at a faster

speed.REMOVAL

(1) Remove differential housing cover and drain

lubricant from the housing.

(2) Remove hub bearings and axle shafts.

(3) Remove adjuster lock bolts and adjuster locks

(Fig. 31).

Fig. 29 DIFFERENTIAL-STRAIGHT AHEAD DRIVING

1 - IN STRAIGHT AHEAD DRIVING EACH WHEEL ROTATES AT

100% OF CASE SPEED

2 - PINION GEAR

3 - SIDE GEAR

4 - PINION GEARS ROTATE WITH CASE

Fig. 30 DIFFERENTIAL-ON TURNS

1 - PINION GEARS ROTATE ON PINION SHAFT

Fig. 31 ADJUSTERS AND LOCKS

1 - ADJUSTER LOCK BOLT

2 - ADJUSTER LOCK

3 - ADJUSTER

4 - BEARING CAP

DRFRONT AXLE - 9 1/4 AA 3 - 61

PINION SEAL (Continued)

Page 159 of 2895

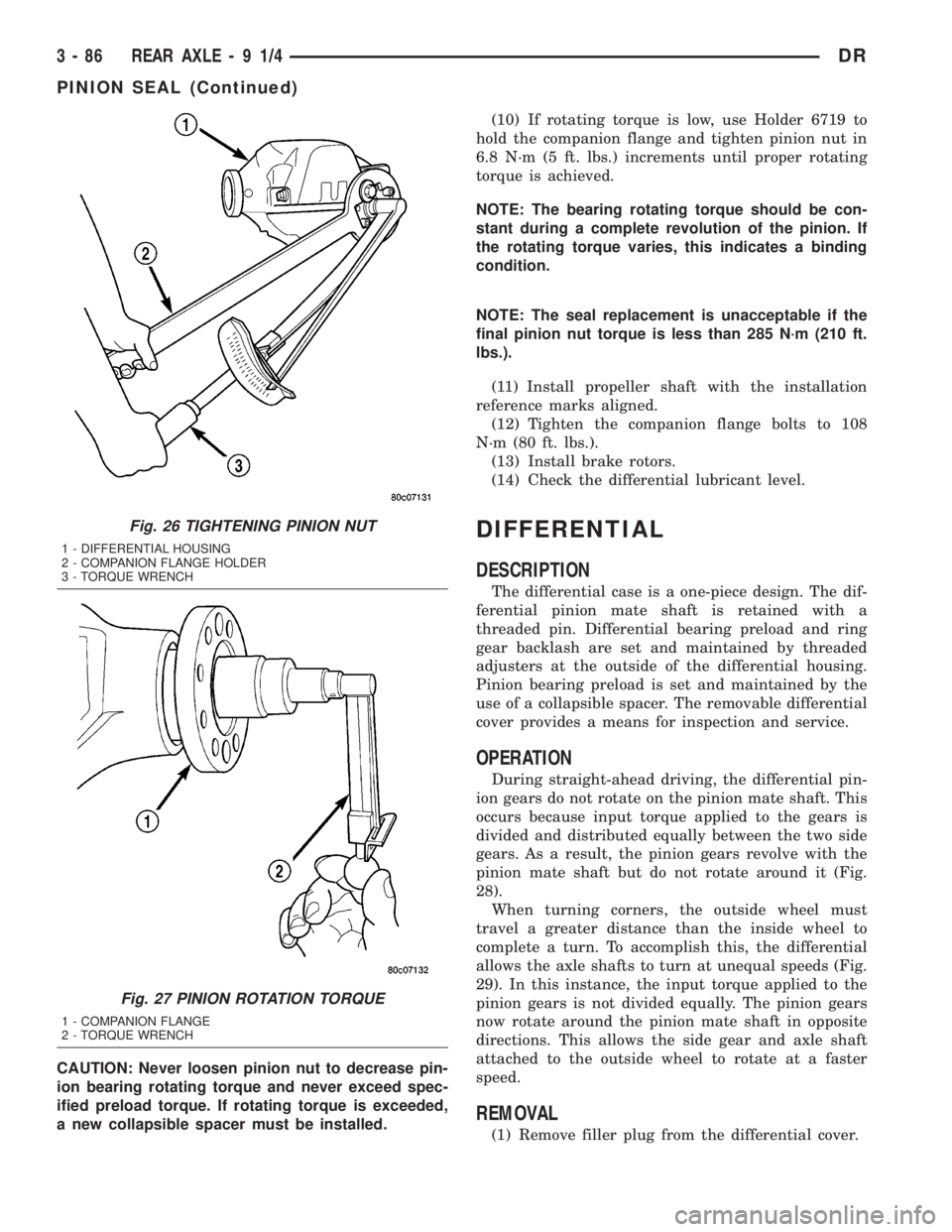

CAUTION: Never loosen pinion nut to decrease pin-

ion bearing rotating torque and never exceed spec-

ified preload torque. If rotating torque is exceeded,

a new collapsible spacer must be installed.(10) If rotating torque is low, use Holder 6719 to

hold the companion flange and tighten pinion nut in

6.8 N´m (5 ft. lbs.) increments until proper rotating

torque is achieved.

NOTE: The bearing rotating torque should be con-

stant during a complete revolution of the pinion. If

the rotating torque varies, this indicates a binding

condition.

NOTE: The seal replacement is unacceptable if the

final pinion nut torque is less than 285 N´m (210 ft.

lbs.).

(11) Install propeller shaft with the installation

reference marks aligned.

(12) Tighten the companion flange bolts to 108

N´m (80 ft. lbs.).

(13) Install brake rotors.

(14) Check the differential lubricant level.

DIFFERENTIAL

DESCRIPTION

The differential case is a one-piece design. The dif-

ferential pinion mate shaft is retained with a

threaded pin. Differential bearing preload and ring

gear backlash are set and maintained by threaded

adjusters at the outside of the differential housing.

Pinion bearing preload is set and maintained by the

use of a collapsible spacer. The removable differential

cover provides a means for inspection and service.

OPERATION

During straight-ahead driving, the differential pin-

ion gears do not rotate on the pinion mate shaft. This

occurs because input torque applied to the gears is

divided and distributed equally between the two side

gears. As a result, the pinion gears revolve with the

pinion mate shaft but do not rotate around it (Fig.

28).

When turning corners, the outside wheel must

travel a greater distance than the inside wheel to

complete a turn. To accomplish this, the differential

allows the axle shafts to turn at unequal speeds (Fig.

29). In this instance, the input torque applied to the

pinion gears is not divided equally. The pinion gears

now rotate around the pinion mate shaft in opposite

directions. This allows the side gear and axle shaft

attached to the outside wheel to rotate at a faster

speed.

REMOVAL

(1) Remove filler plug from the differential cover.

Fig. 26 TIGHTENING PINION NUT

1 - DIFFERENTIAL HOUSING

2 - COMPANION FLANGE HOLDER

3 - TORQUE WRENCH

Fig. 27 PINION ROTATION TORQUE

1 - COMPANION FLANGE

2 - TORQUE WRENCH

3 - 86 REAR AXLE-91/4DR

PINION SEAL (Continued)

Page 162 of 2895

CAUTION: If cover is not installed within 3 to 5 min-

utes, the cover must be cleaned and new RTV

applied or adhesion quality will be compromised.

(8) Install the cover and any identification tag and

tighten cover bolts to 41 N´m (30 ft. lbs.).

(9) Fill differential with lubricant to bottom of the

fill plug hole. Refer to the Lubricant Specifications

for the correct quantity and type.

NOTE: Trac-lokŸ differential equipped vehicles

should be road tested by making 10 to 12 slow fig-

ure-eight turns. This maneuver will pump the lubri-

cant through the clutch discs to eliminate a

possible chatter noise complaint.

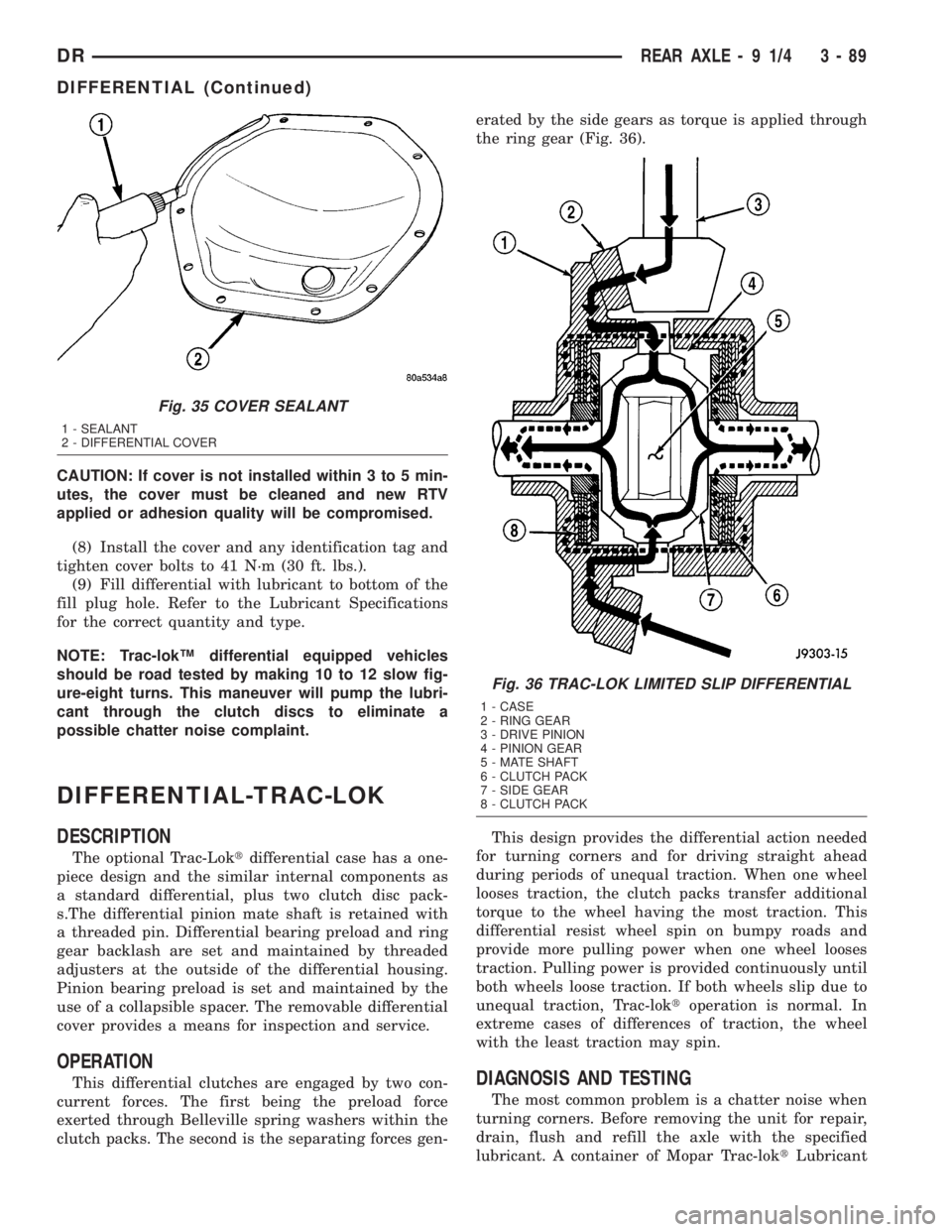

DIFFERENTIAL-TRAC-LOK

DESCRIPTION

The optional Trac-Loktdifferential case has a one-

piece design and the similar internal components as

a standard differential, plus two clutch disc pack-

s.The differential pinion mate shaft is retained with

a threaded pin. Differential bearing preload and ring

gear backlash are set and maintained by threaded

adjusters at the outside of the differential housing.

Pinion bearing preload is set and maintained by the

use of a collapsible spacer. The removable differential

cover provides a means for inspection and service.

OPERATION

This differential clutches are engaged by two con-

current forces. The first being the preload force

exerted through Belleville spring washers within the

clutch packs. The second is the separating forces gen-erated by the side gears as torque is applied through

the ring gear (Fig. 36).

This design provides the differential action needed

for turning corners and for driving straight ahead

during periods of unequal traction. When one wheel

looses traction, the clutch packs transfer additional

torque to the wheel having the most traction. This

differential resist wheel spin on bumpy roads and

provide more pulling power when one wheel looses

traction. Pulling power is provided continuously until

both wheels loose traction. If both wheels slip due to

unequal traction, Trac-loktoperation is normal. In

extreme cases of differences of traction, the wheel

with the least traction may spin.DIAGNOSIS AND TESTING

The most common problem is a chatter noise when

turning corners. Before removing the unit for repair,

drain, flush and refill the axle with the specified

lubricant. A container of Mopar Trac-loktLubricant

Fig. 35 COVER SEALANT

1 - SEALANT

2 - DIFFERENTIAL COVER

Fig. 36 TRAC-LOK LIMITED SLIP DIFFERENTIAL

1 - CASE

2 - RING GEAR

3 - DRIVE PINION

4 - PINION GEAR

5 - MATE SHAFT

6 - CLUTCH PACK

7 - SIDE GEAR

8 - CLUTCH PACK

DRREAR AXLE - 9 1/4 3 - 89

DIFFERENTIAL (Continued)

Page 163 of 2895

(friction modifier) should be added after repair ser-

vice or during a lubricant change.

After changing the lubricant, drive the vehicle and

make 10 to 12 slow, figure-eight turns. This maneu-

ver will pump lubricant through the clutches. This

will correct the condition in most instances. If the

chatter persists, clutch damage could have occurred.

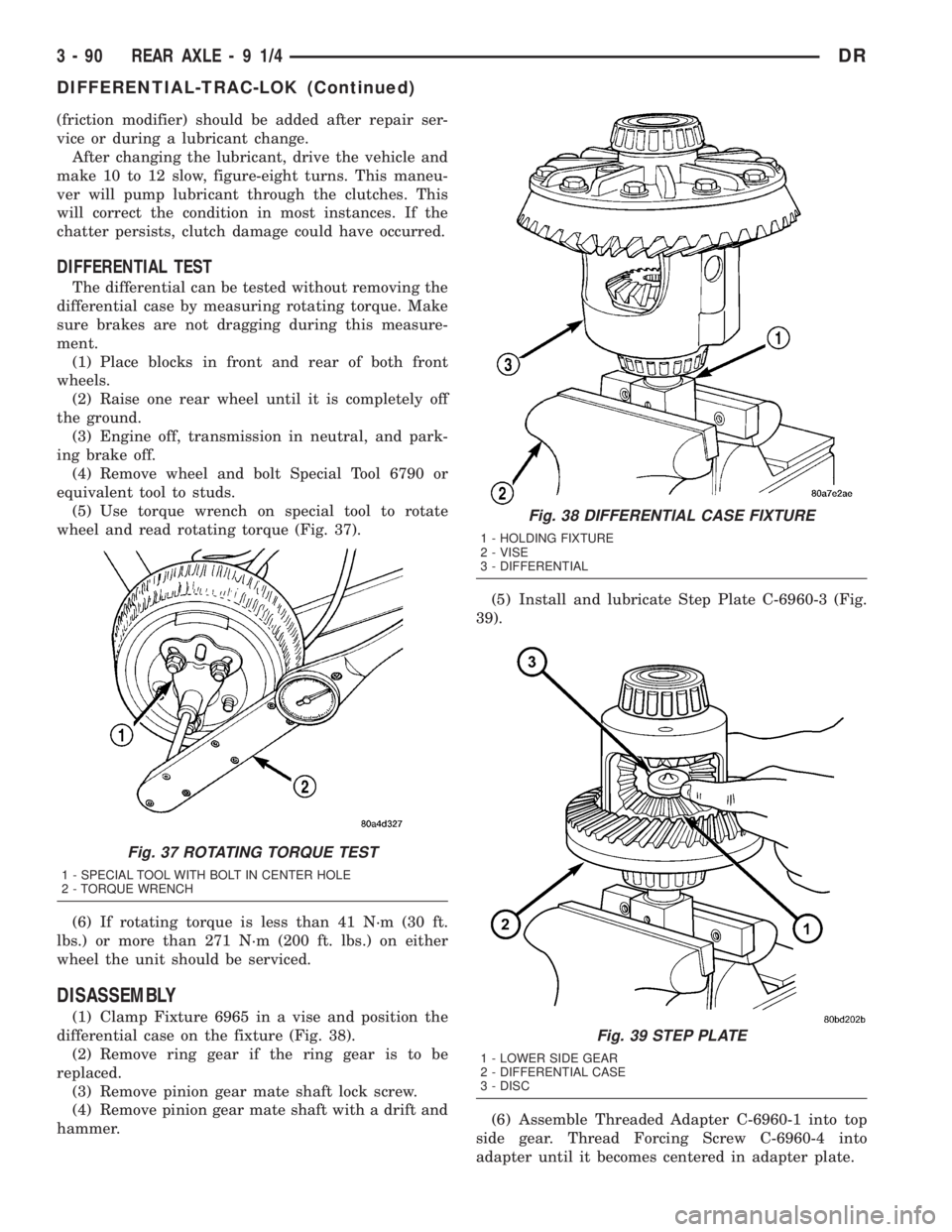

DIFFERENTIAL TEST

The differential can be tested without removing the

differential case by measuring rotating torque. Make

sure brakes are not dragging during this measure-

ment.

(1) Place blocks in front and rear of both front

wheels.

(2) Raise one rear wheel until it is completely off

the ground.

(3) Engine off, transmission in neutral, and park-

ing brake off.

(4) Remove wheel and bolt Special Tool 6790 or

equivalent tool to studs.

(5) Use torque wrench on special tool to rotate

wheel and read rotating torque (Fig. 37).

(6) If rotating torque is less than 41 N´m (30 ft.

lbs.) or more than 271 N´m (200 ft. lbs.) on either

wheel the unit should be serviced.

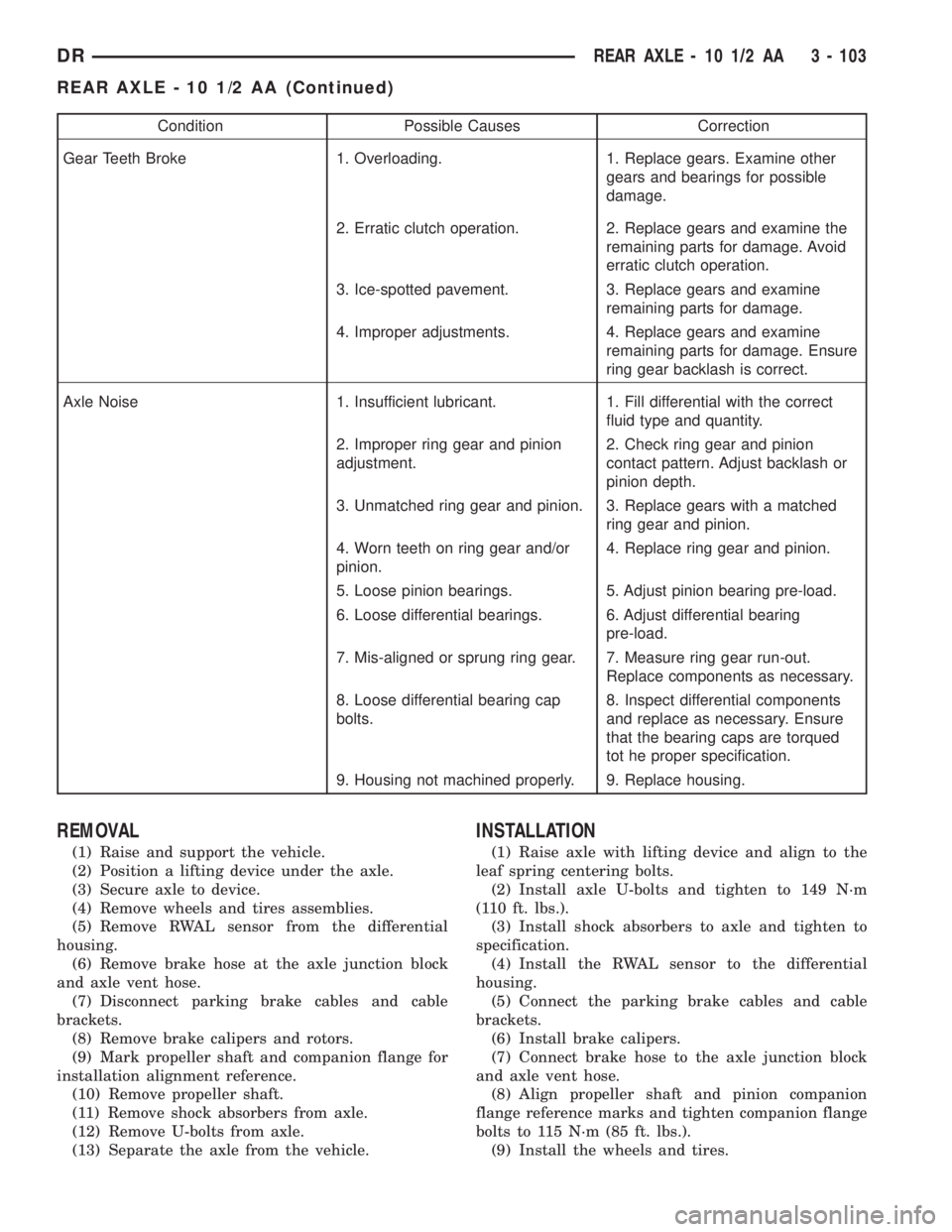

DISASSEMBLY

(1) Clamp Fixture 6965 in a vise and position the

differential case on the fixture (Fig. 38).

(2) Remove ring gear if the ring gear is to be

replaced.

(3) Remove pinion gear mate shaft lock screw.

(4) Remove pinion gear mate shaft with a drift and

hammer.(5) Install and lubricate Step Plate C-6960-3 (Fig.

39).

(6) Assemble Threaded Adapter C-6960-1 into top

side gear. Thread Forcing Screw C-6960-4 into

adapter until it becomes centered in adapter plate.

Fig. 37 ROTATING TORQUE TEST

1 - SPECIAL TOOL WITH BOLT IN CENTER HOLE

2 - TORQUE WRENCH

Fig. 38 DIFFERENTIAL CASE FIXTURE

1 - HOLDING FIXTURE

2 - VISE

3 - DIFFERENTIAL

Fig. 39 STEP PLATE

1 - LOWER SIDE GEAR

2 - DIFFERENTIAL CASE

3 - DISC

3 - 90 REAR AXLE-91/4DR

DIFFERENTIAL-TRAC-LOK (Continued)

Page 176 of 2895

Condition Possible Causes Correction

Gear Teeth Broke 1. Overloading. 1. Replace gears. Examine other

gears and bearings for possible

damage.

2. Erratic clutch operation. 2. Replace gears and examine the

remaining parts for damage. Avoid

erratic clutch operation.

3. Ice-spotted pavement. 3. Replace gears and examine

remaining parts for damage.

4. Improper adjustments. 4. Replace gears and examine

remaining parts for damage. Ensure

ring gear backlash is correct.

Axle Noise 1. Insufficient lubricant. 1. Fill differential with the correct

fluid type and quantity.

2. Improper ring gear and pinion

adjustment.2. Check ring gear and pinion

contact pattern. Adjust backlash or

pinion depth.

3. Unmatched ring gear and pinion. 3. Replace gears with a matched

ring gear and pinion.

4. Worn teeth on ring gear and/or

pinion.4. Replace ring gear and pinion.

5. Loose pinion bearings. 5. Adjust pinion bearing pre-load.

6. Loose differential bearings. 6. Adjust differential bearing

pre-load.

7. Mis-aligned or sprung ring gear. 7. Measure ring gear run-out.

Replace components as necessary.

8. Loose differential bearing cap

bolts.8. Inspect differential components

and replace as necessary. Ensure

that the bearing caps are torqued

tot he proper specification.

9. Housing not machined properly. 9. Replace housing.

REMOVAL

(1) Raise and support the vehicle.

(2) Position a lifting device under the axle.

(3) Secure axle to device.

(4) Remove wheels and tires assemblies.

(5) Remove RWAL sensor from the differential

housing.

(6) Remove brake hose at the axle junction block

and axle vent hose.

(7) Disconnect parking brake cables and cable

brackets.

(8) Remove brake calipers and rotors.

(9) Mark propeller shaft and companion flange for

installation alignment reference.

(10) Remove propeller shaft.

(11) Remove shock absorbers from axle.

(12) Remove U-bolts from axle.

(13) Separate the axle from the vehicle.

INSTALLATION

(1) Raise axle with lifting device and align to the

leaf spring centering bolts.

(2) Install axle U-bolts and tighten to 149 N´m

(110 ft. lbs.).

(3) Install shock absorbers to axle and tighten to

specification.

(4) Install the RWAL sensor to the differential

housing.

(5) Connect the parking brake cables and cable

brackets.

(6) Install brake calipers.

(7) Connect brake hose to the axle junction block

and axle vent hose.

(8) Align propeller shaft and pinion companion

flange reference marks and tighten companion flange

bolts to 115 N´m (85 ft. lbs.).

(9) Install the wheels and tires.

DRREAR AXLE - 10 1/2 AA 3 - 103

REAR AXLE - 10 1/2 AA (Continued)

Page 191 of 2895

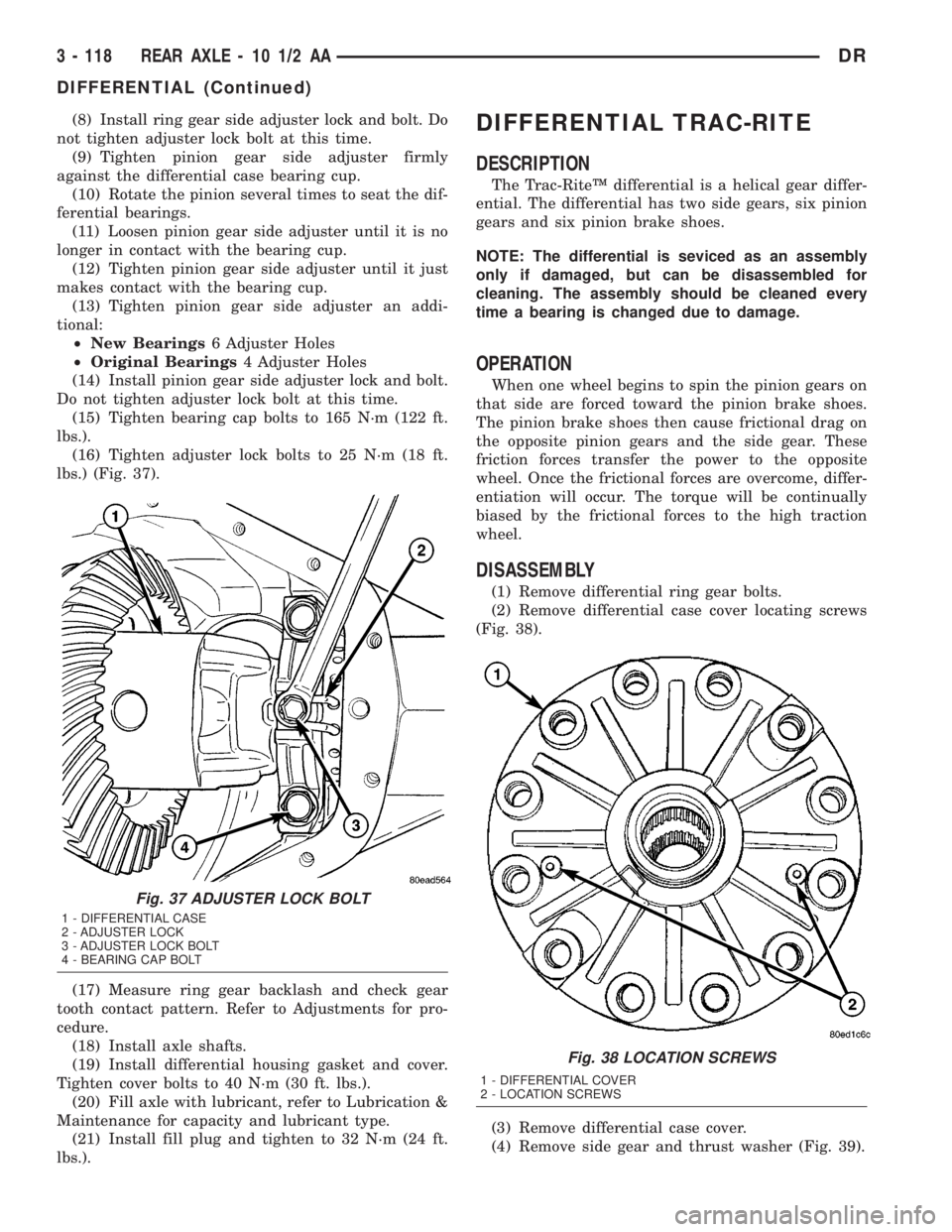

(8) Install ring gear side adjuster lock and bolt. Do

not tighten adjuster lock bolt at this time.

(9) Tighten pinion gear side adjuster firmly

against the differential case bearing cup.

(10) Rotate the pinion several times to seat the dif-

ferential bearings.

(11) Loosen pinion gear side adjuster until it is no

longer in contact with the bearing cup.

(12) Tighten pinion gear side adjuster until it just

makes contact with the bearing cup.

(13) Tighten pinion gear side adjuster an addi-

tional:

²New Bearings6 Adjuster Holes

²Original Bearings4 Adjuster Holes

(14) Install pinion gear side adjuster lock and bolt.

Do not tighten adjuster lock bolt at this time.

(15) Tighten bearing cap bolts to 165 N´m (122 ft.

lbs.).

(16) Tighten adjuster lock bolts to 25 N´m (18 ft.

lbs.) (Fig. 37).

(17) Measure ring gear backlash and check gear

tooth contact pattern. Refer to Adjustments for pro-

cedure.

(18) Install axle shafts.

(19) Install differential housing gasket and cover.

Tighten cover bolts to 40 N´m (30 ft. lbs.).

(20) Fill axle with lubricant, refer to Lubrication &

Maintenance for capacity and lubricant type.

(21) Install fill plug and tighten to 32 N´m (24 ft.

lbs.).DIFFERENTIAL TRAC-RITE

DESCRIPTION

The Trac-RiteŸ differential is a helical gear differ-

ential. The differential has two side gears, six pinion

gears and six pinion brake shoes.

NOTE: The differential is seviced as an assembly

only if damaged, but can be disassembled for

cleaning. The assembly should be cleaned every

time a bearing is changed due to damage.

OPERATION

When one wheel begins to spin the pinion gears on

that side are forced toward the pinion brake shoes.

The pinion brake shoes then cause frictional drag on

the opposite pinion gears and the side gear. These

friction forces transfer the power to the opposite

wheel. Once the frictional forces are overcome, differ-

entiation will occur. The torque will be continually

biased by the frictional forces to the high traction

wheel.

DISASSEMBLY

(1) Remove differential ring gear bolts.

(2) Remove differential case cover locating screws

(Fig. 38).

(3) Remove differential case cover.

(4) Remove side gear and thrust washer (Fig. 39).

Fig. 37 ADJUSTER LOCK BOLT

1 - DIFFERENTIAL CASE

2 - ADJUSTER LOCK

3 - ADJUSTER LOCK BOLT

4 - BEARING CAP BOLT

Fig. 38 LOCATION SCREWS

1 - DIFFERENTIAL COVER

2 - LOCATION SCREWS

3 - 118 REAR AXLE - 10 1/2 AADR

DIFFERENTIAL (Continued)

Page 203 of 2895

Condition Possible Causes Correction

Gear Teeth Broke 1. Overloading. 1. Replace gears. Examine other

gears and bearings for possible

damage.

2. Erratic clutch operation. 2. Replace gears and examine the

remaining parts for damage. Avoid

erratic clutch operation.

3. Ice-spotted pavement. 3. Replace gears and examine

remaining parts for damage.

4. Improper adjustments. 4. Replace gears and examine

remaining parts for damage. Ensure

ring gear backlash is correct.

Axle Noise 1. Insufficient lubricant. 1. Fill differential with the correct

fluid type and quantity.

2. Improper ring gear and pinion

adjustment.2. Check ring gear and pinion

contact pattern. Adjust backlash or

pinion depth.

3. Unmatched ring gear and pinion. 3. Replace gears with a matched

ring gear and pinion.

4. Worn teeth on ring gear and/or

pinion.4. Replace ring gear and pinion.

5. Loose pinion bearings. 5. Adjust pinion bearing pre-load.

6. Loose differential bearings. 6. Adjust differential bearing

pre-load.

7. Mis-aligned or sprung ring gear. 7. Measure ring gear run-out.

Replace components as necessary.

8. Loose differential bearing cap

bolts.8. Inspect differential components

and replace as necessary. Ensure

that the bearing caps are torqued

tot he proper specification.

9. Housing not machined properly. 9. Replace housing.

REMOVAL

(1) Raise and support the vehicle.

(2) Position a lifting device under the axle.

(3) Secure axle to device.

(4) Remove wheels and tires assemblies.

(5) Remove RWAL sensor from the differential

housing.

(6) Remove brake hose at the axle junction block

and axle vent hose.

(7) Disconnect parking brake cables and cable

brackets.

(8) Remove brake calipers.

(9) Mark propeller shaft and companion flange for

installation alignment reference.

(10) Remove propeller shaft.

(11) Remove shock absorbers from axle.

(12) Remove U-bolets from axle.

(13) Separate the axle from the vehicle.

INSTALLATION

(1) Raise axle with lifting device and align to the

leaf spring centering bolts.

(2) Install axle U-bolts and tighten to 149 N´m

(110 ft. lbs.).

(3) Install shock absorbers to axle and tighten to

specification.

(4) Install the RWAL sensor to the differential

housing.

(5) Connect the parking brake cables and cable

brackets.

(6) Connect brake hose to the axle junction block

and axle vent hose.

(7) Align propeller shaft and pinion companion

flange reference marks and tighten companion flange

bolts to 115 N´m (85 ft. lbs.).

(8) Install the wheels and tires.

(9) Fill differential to specifications.

3 - 130 REAR AXLE - 11 1/2 AADR

REAR AXLE - 11 1/2 AA (Continued)

Page 218 of 2895

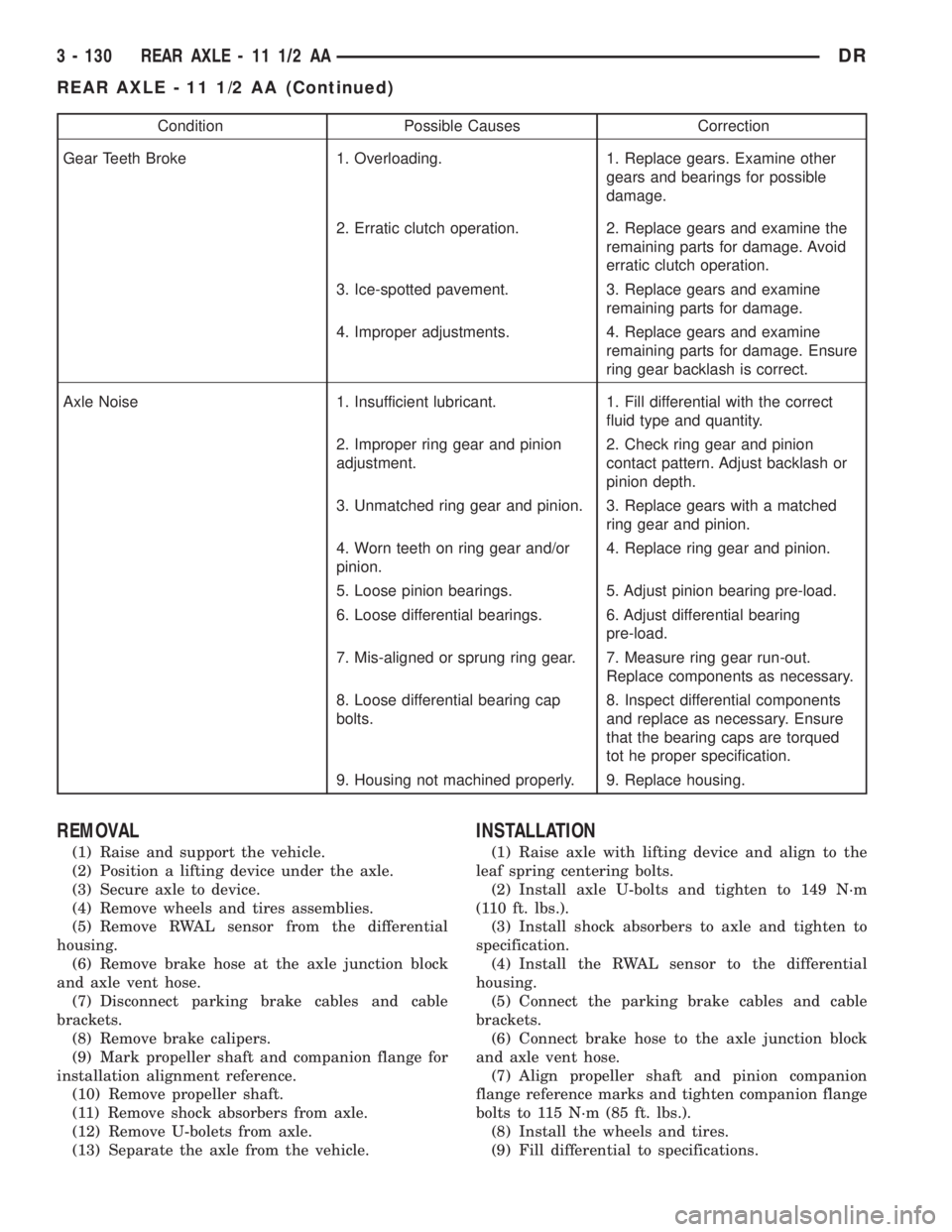

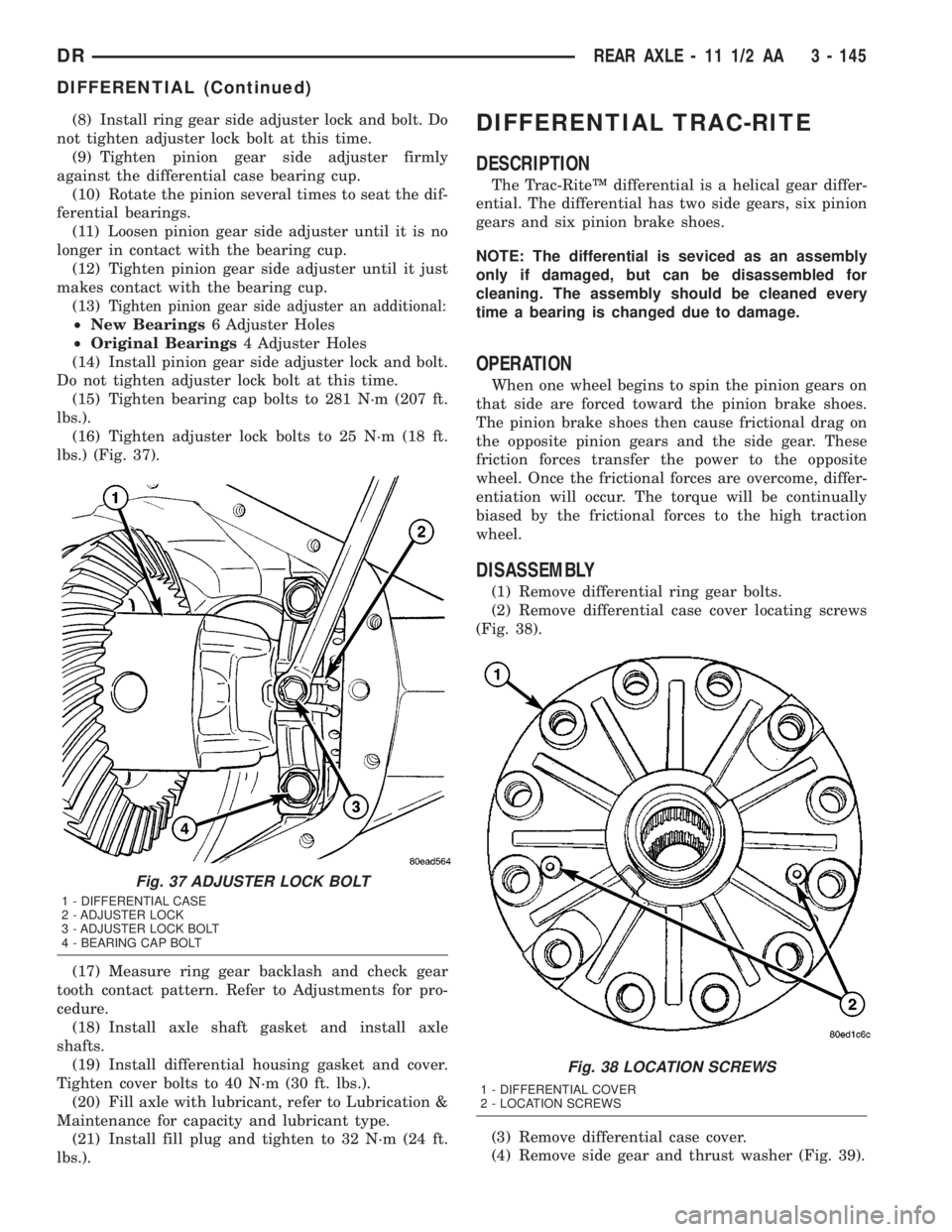

(8) Install ring gear side adjuster lock and bolt. Do

not tighten adjuster lock bolt at this time.

(9) Tighten pinion gear side adjuster firmly

against the differential case bearing cup.

(10) Rotate the pinion several times to seat the dif-

ferential bearings.

(11) Loosen pinion gear side adjuster until it is no

longer in contact with the bearing cup.

(12) Tighten pinion gear side adjuster until it just

makes contact with the bearing cup.

(13)

Tighten pinion gear side adjuster an additional:

²New Bearings6 Adjuster Holes

²Original Bearings4 Adjuster Holes

(14) Install pinion gear side adjuster lock and bolt.

Do not tighten adjuster lock bolt at this time.

(15) Tighten bearing cap bolts to 281 N´m (207 ft.

lbs.).

(16) Tighten adjuster lock bolts to 25 N´m (18 ft.

lbs.) (Fig. 37).

(17) Measure ring gear backlash and check gear

tooth contact pattern. Refer to Adjustments for pro-

cedure.

(18) Install axle shaft gasket and install axle

shafts.

(19) Install differential housing gasket and cover.

Tighten cover bolts to 40 N´m (30 ft. lbs.).

(20) Fill axle with lubricant, refer to Lubrication &

Maintenance for capacity and lubricant type.

(21) Install fill plug and tighten to 32 N´m (24 ft.

lbs.).

DIFFERENTIAL TRAC-RITE

DESCRIPTION

The Trac-RiteŸ differential is a helical gear differ-

ential. The differential has two side gears, six pinion

gears and six pinion brake shoes.

NOTE: The differential is seviced as an assembly

only if damaged, but can be disassembled for

cleaning. The assembly should be cleaned every

time a bearing is changed due to damage.

OPERATION

When one wheel begins to spin the pinion gears on

that side are forced toward the pinion brake shoes.

The pinion brake shoes then cause frictional drag on

the opposite pinion gears and the side gear. These

friction forces transfer the power to the opposite

wheel. Once the frictional forces are overcome, differ-

entiation will occur. The torque will be continually

biased by the frictional forces to the high traction

wheel.

DISASSEMBLY

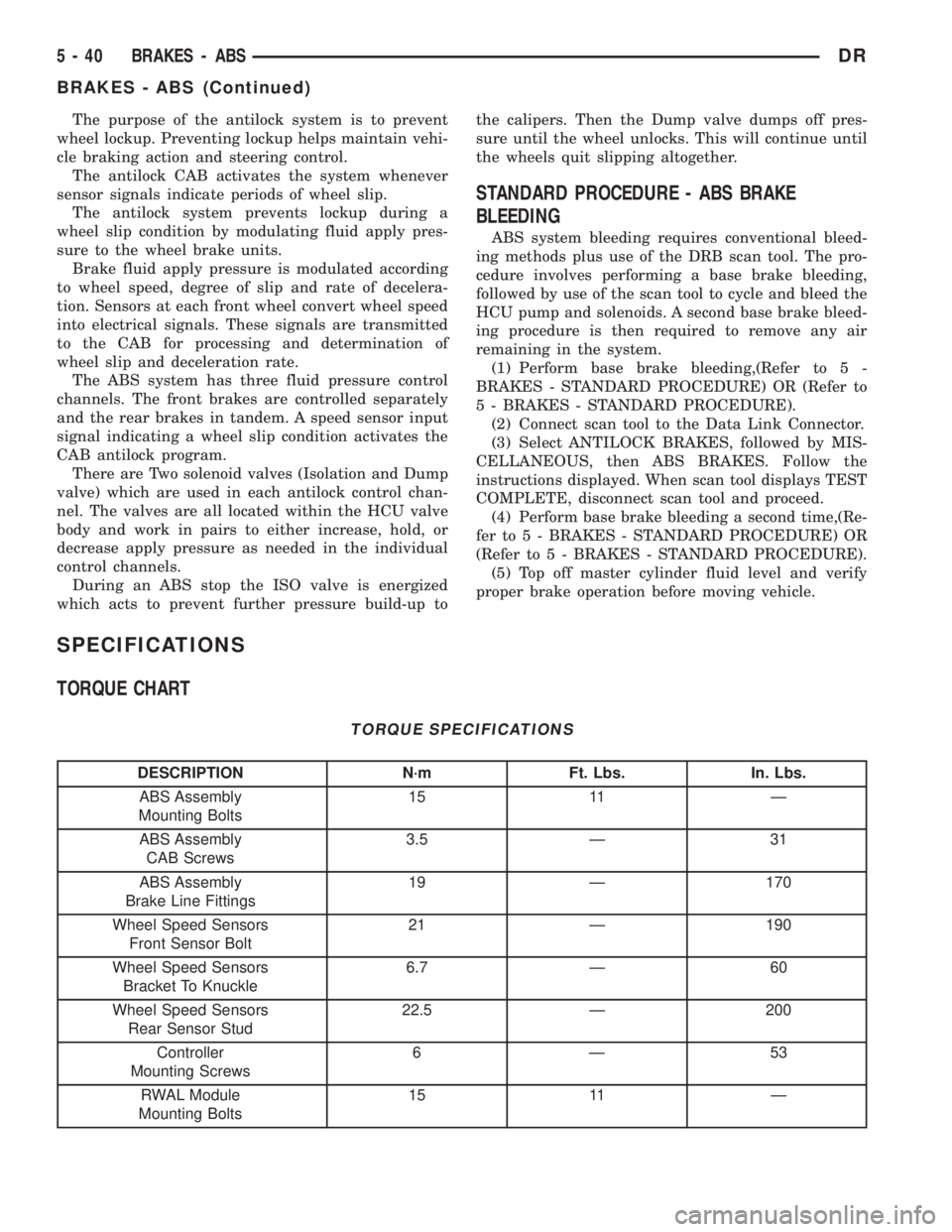

(1) Remove differential ring gear bolts.

(2) Remove differential case cover locating screws

(Fig. 38).

(3) Remove differential case cover.

(4) Remove side gear and thrust washer (Fig. 39).

Fig. 37 ADJUSTER LOCK BOLT

1 - DIFFERENTIAL CASE

2 - ADJUSTER LOCK

3 - ADJUSTER LOCK BOLT

4 - BEARING CAP BOLT

Fig. 38 LOCATION SCREWS

1 - DIFFERENTIAL COVER

2 - LOCATION SCREWS

DRREAR AXLE - 11 1/2 AA 3 - 145

DIFFERENTIAL (Continued)

Page 267 of 2895

The purpose of the antilock system is to prevent

wheel lockup. Preventing lockup helps maintain vehi-

cle braking action and steering control.

The antilock CAB activates the system whenever

sensor signals indicate periods of wheel slip.

The antilock system prevents lockup during a

wheel slip condition by modulating fluid apply pres-

sure to the wheel brake units.

Brake fluid apply pressure is modulated according

to wheel speed, degree of slip and rate of decelera-

tion. Sensors at each front wheel convert wheel speed

into electrical signals. These signals are transmitted

to the CAB for processing and determination of

wheel slip and deceleration rate.

The ABS system has three fluid pressure control

channels. The front brakes are controlled separately

and the rear brakes in tandem. A speed sensor input

signal indicating a wheel slip condition activates the

CAB antilock program.

There are Two solenoid valves (Isolation and Dump

valve) which are used in each antilock control chan-

nel. The valves are all located within the HCU valve

body and work in pairs to either increase, hold, or

decrease apply pressure as needed in the individual

control channels.

During an ABS stop the ISO valve is energized

which acts to prevent further pressure build-up tothe calipers. Then the Dump valve dumps off pres-

sure until the wheel unlocks. This will continue until

the wheels quit slipping altogether.

STANDARD PROCEDURE - ABS BRAKE

BLEEDING

ABS system bleeding requires conventional bleed-

ing methods plus use of the DRB scan tool. The pro-

cedure involves performing a base brake bleeding,

followed by use of the scan tool to cycle and bleed the

HCU pump and solenoids. A second base brake bleed-

ing procedure is then required to remove any air

remaining in the system.

(1) Perform base brake bleeding,(Refer to 5 -

BRAKES - STANDARD PROCEDURE) OR (Refer to

5 - BRAKES - STANDARD PROCEDURE).

(2) Connect scan tool to the Data Link Connector.

(3) Select ANTILOCK BRAKES, followed by MIS-

CELLANEOUS, then ABS BRAKES. Follow the

instructions displayed. When scan tool displays TEST

COMPLETE, disconnect scan tool and proceed.

(4) Perform base brake bleeding a second time,(Re-

fer to 5 - BRAKES - STANDARD PROCEDURE) OR

(Refer to 5 - BRAKES - STANDARD PROCEDURE).

(5) Top off master cylinder fluid level and verify

proper brake operation before moving vehicle.

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

ABS Assembly

Mounting Bolts15 11 Ð

ABS Assembly

CAB Screws3.5 Ð 31

ABS Assembly

Brake Line Fittings19 Ð 170

Wheel Speed Sensors

Front Sensor Bolt21 Ð 190

Wheel Speed Sensors

Bracket To Knuckle6.7 Ð 60

Wheel Speed Sensors

Rear Sensor Stud22.5 Ð 200

Controller

Mounting Screws6Ð53

RWAL Module

Mounting Bolts15 11 Ð

5 - 40 BRAKES - ABSDR

BRAKES - ABS (Continued)