wheel bolt torque DODGE RAM 2003 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1576 of 2895

(11) Install the flywheel housing and bolts. Torque

bolts to 77 N´m (57 ft. lbs.).

(12) Install the flywheel or converter drive plate.

Tighten bolts to 137 N´m (101 ft. lbs.).

(13) Install the starter motor and torque to 43 N´m

(21 ft. lbs.)(Refer to 8 - ELECTRICAL/STARTING/

STARTER MOTOR - INSTALLATION).

(14) Install the transmission and transfer case (if

equipped).

(15) Lower vehicle.

(16) Fill the crankcase with new engine oil.

(17) Connect the battery negative cables.

(18) Start engine and check for oil leaks.

SOLID LIFTERS/TAPPETS

REMOVAL

NOTE: This procedure requires use of Miller Tool

8502 Tappet Replacement Kit.

(1) Remove camshaft (Refer to 9 - ENGINE/EN-

GINE BLOCK/CAMSHAFT & BEARINGS (IN

BLOCK) - REMOVAL).

(2) Insert the trough (provided with tool kit) the

full length of the camshaft bore (Fig. 79). Make sure

the cap end goes in first and the open side faces up

(towards tappets).

(3)Remove only one tappet at a time.Remove

rubber band from one cylinder pair and attach tappet

dowel not being removed to the next cylinder pair

(Fig. 80).

Fig. 79 Inserting the Trough - Typical

1 - TROUGH

Fig. 80 Secure Dowel/Tappet to Adjacent Cylinder -

typical

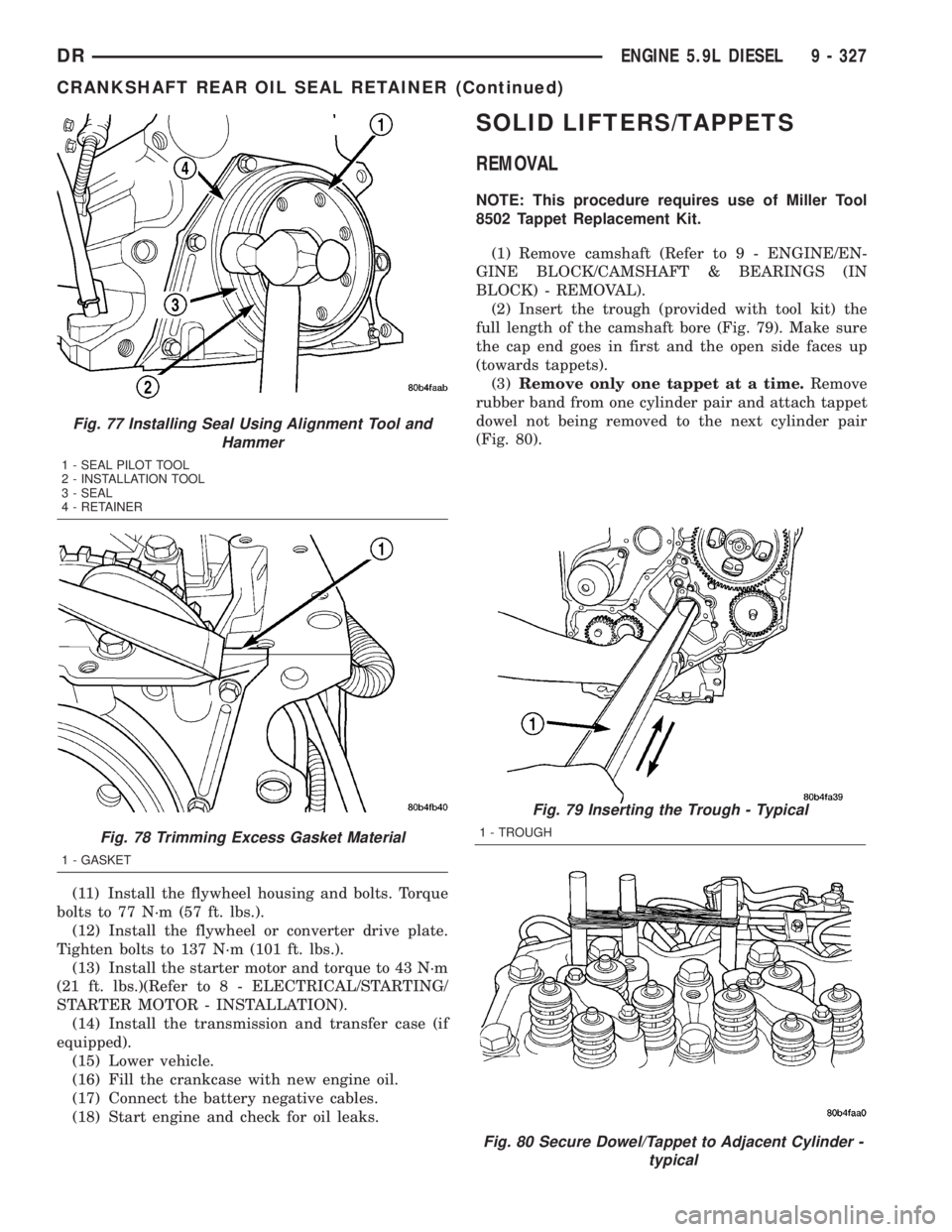

Fig. 77 Installing Seal Using Alignment Tool and

Hammer

1 - SEAL PILOT TOOL

2 - INSTALLATION TOOL

3 - SEAL

4 - RETAINER

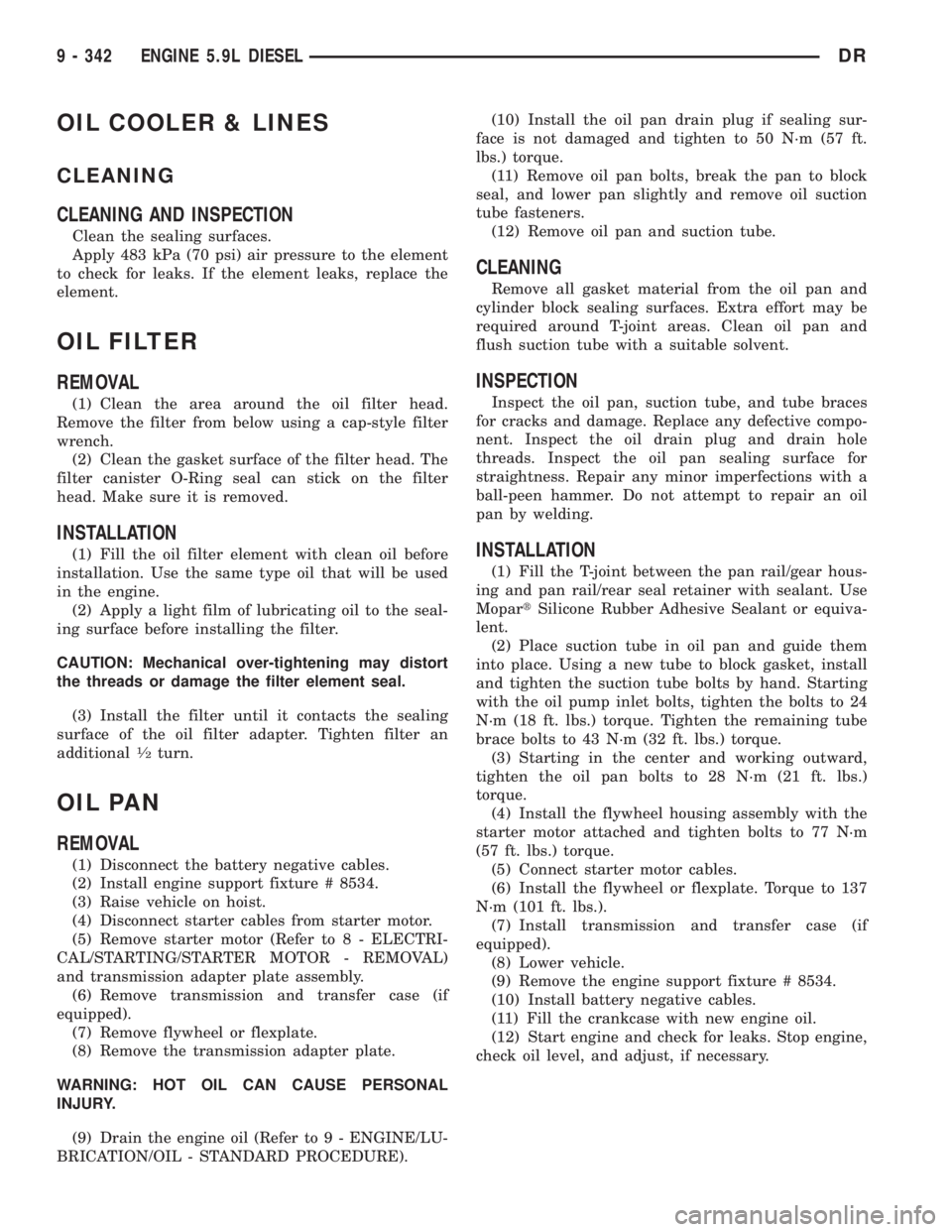

Fig. 78 Trimming Excess Gasket Material

1 - GASKET

DRENGINE 5.9L DIESEL 9 - 327

CRANKSHAFT REAR OIL SEAL RETAINER (Continued)

Page 1591 of 2895

OIL COOLER & LINES

CLEANING

CLEANING AND INSPECTION

Clean the sealing surfaces.

Apply 483 kPa (70 psi) air pressure to the element

to check for leaks. If the element leaks, replace the

element.

OIL FILTER

REMOVAL

(1) Clean the area around the oil filter head.

Remove the filter from below using a cap-style filter

wrench.

(2) Clean the gasket surface of the filter head. The

filter canister O-Ring seal can stick on the filter

head. Make sure it is removed.

INSTALLATION

(1) Fill the oil filter element with clean oil before

installation. Use the same type oil that will be used

in the engine.

(2) Apply a light film of lubricating oil to the seal-

ing surface before installing the filter.

CAUTION: Mechanical over-tightening may distort

the threads or damage the filter element seal.

(3) Install the filter until it contacts the sealing

surface of the oil filter adapter. Tighten filter an

additional

1¤2turn.

OIL PAN

REMOVAL

(1) Disconnect the battery negative cables.

(2) Install engine support fixture # 8534.

(3) Raise vehicle on hoist.

(4) Disconnect starter cables from starter motor.

(5) Remove starter motor (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - REMOVAL)

and transmission adapter plate assembly.

(6) Remove transmission and transfer case (if

equipped).

(7) Remove flywheel or flexplate.

(8) Remove the transmission adapter plate.

WARNING: HOT OIL CAN CAUSE PERSONAL

INJURY.

(9) Drain the engine oil (Refer to 9 - ENGINE/LU-

BRICATION/OIL - STANDARD PROCEDURE).(10) Install the oil pan drain plug if sealing sur-

face is not damaged and tighten to 50 N´m (57 ft.

lbs.) torque.

(11) Remove oil pan bolts, break the pan to block

seal, and lower pan slightly and remove oil suction

tube fasteners.

(12) Remove oil pan and suction tube.

CLEANING

Remove all gasket material from the oil pan and

cylinder block sealing surfaces. Extra effort may be

required around T-joint areas. Clean oil pan and

flush suction tube with a suitable solvent.

INSPECTION

Inspect the oil pan, suction tube, and tube braces

for cracks and damage. Replace any defective compo-

nent. Inspect the oil drain plug and drain hole

threads. Inspect the oil pan sealing surface for

straightness. Repair any minor imperfections with a

ball-peen hammer. Do not attempt to repair an oil

pan by welding.

INSTALLATION

(1) Fill the T-joint between the pan rail/gear hous-

ing and pan rail/rear seal retainer with sealant. Use

MopartSilicone Rubber Adhesive Sealant or equiva-

lent.

(2) Place suction tube in oil pan and guide them

into place. Using a new tube to block gasket, install

and tighten the suction tube bolts by hand. Starting

with the oil pump inlet bolts, tighten the bolts to 24

N´m (18 ft. lbs.) torque. Tighten the remaining tube

brace bolts to 43 N´m (32 ft. lbs.) torque.

(3) Starting in the center and working outward,

tighten the oil pan bolts to 28 N´m (21 ft. lbs.)

torque.

(4) Install the flywheel housing assembly with the

starter motor attached and tighten bolts to 77 N´m

(57 ft. lbs.) torque.

(5) Connect starter motor cables.

(6) Install the flywheel or flexplate. Torque to 137

N´m (101 ft. lbs.).

(7) Install transmission and transfer case (if

equipped).

(8) Lower vehicle.

(9) Remove the engine support fixture # 8534.

(10) Install battery negative cables.

(11) Fill the crankcase with new engine oil.

(12) Start engine and check for leaks. Stop engine,

check oil level, and adjust, if necessary.

9 - 342 ENGINE 5.9L DIESELDR

Page 1606 of 2895

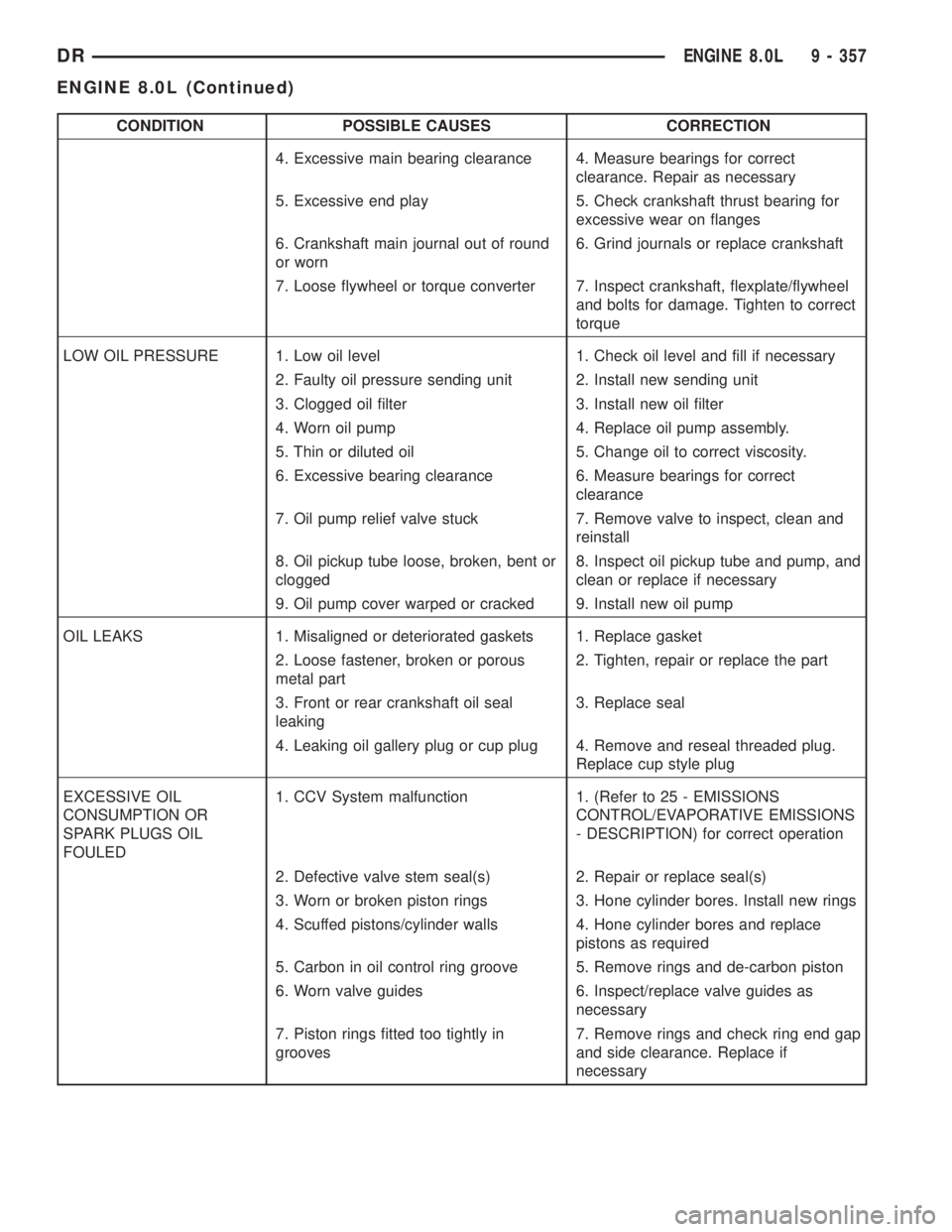

CONDITION POSSIBLE CAUSES CORRECTION

4. Excessive main bearing clearance 4. Measure bearings for correct

clearance. Repair as necessary

5. Excessive end play 5. Check crankshaft thrust bearing for

excessive wear on flanges

6. Crankshaft main journal out of round

or worn6. Grind journals or replace crankshaft

7. Loose flywheel or torque converter 7. Inspect crankshaft, flexplate/flywheel

and bolts for damage. Tighten to correct

torque

LOW OIL PRESSURE 1. Low oil level 1. Check oil level and fill if necessary

2. Faulty oil pressure sending unit 2. Install new sending unit

3. Clogged oil filter 3. Install new oil filter

4. Worn oil pump 4. Replace oil pump assembly.

5. Thin or diluted oil 5. Change oil to correct viscosity.

6. Excessive bearing clearance 6. Measure bearings for correct

clearance

7. Oil pump relief valve stuck 7. Remove valve to inspect, clean and

reinstall

8. Oil pickup tube loose, broken, bent or

clogged8. Inspect oil pickup tube and pump, and

clean or replace if necessary

9. Oil pump cover warped or cracked 9. Install new oil pump

OIL LEAKS 1. Misaligned or deteriorated gaskets 1. Replace gasket

2. Loose fastener, broken or porous

metal part2. Tighten, repair or replace the part

3. Front or rear crankshaft oil seal

leaking3. Replace seal

4. Leaking oil gallery plug or cup plug 4. Remove and reseal threaded plug.

Replace cup style plug

EXCESSIVE OIL

CONSUMPTION OR

SPARK PLUGS OIL

FOULED1. CCV System malfunction 1. (Refer to 25 - EMISSIONS

CONTROL/EVAPORATIVE EMISSIONS

- DESCRIPTION) for correct operation

2. Defective valve stem seal(s) 2. Repair or replace seal(s)

3. Worn or broken piston rings 3. Hone cylinder bores. Install new rings

4. Scuffed pistons/cylinder walls 4. Hone cylinder bores and replace

pistons as required

5. Carbon in oil control ring groove 5. Remove rings and de-carbon piston

6. Worn valve guides 6. Inspect/replace valve guides as

necessary

7. Piston rings fitted too tightly in

grooves7. Remove rings and check ring end gap

and side clearance. Replace if

necessary

DRENGINE 8.0L 9 - 357

ENGINE 8.0L (Continued)

Page 1669 of 2895

(9) If the turbocharger is not to be installed imme-

diately, cover the opening to prevent material from

entering into the manifold.

(10) If replacing the turbocharger, transfer the

compressor outlet and clamp to the new assembly.

(11) Clean and inspect the sealing surface.

CAUTION: The turbocharger is only serviced as an

assembly. Do not attempt to repair the turbocharger

as turbocharger and/or engine damage can result.

CLEANING

Clean the turbocharger and exhaust manifold

mounting surfaces with a suitable scraper.

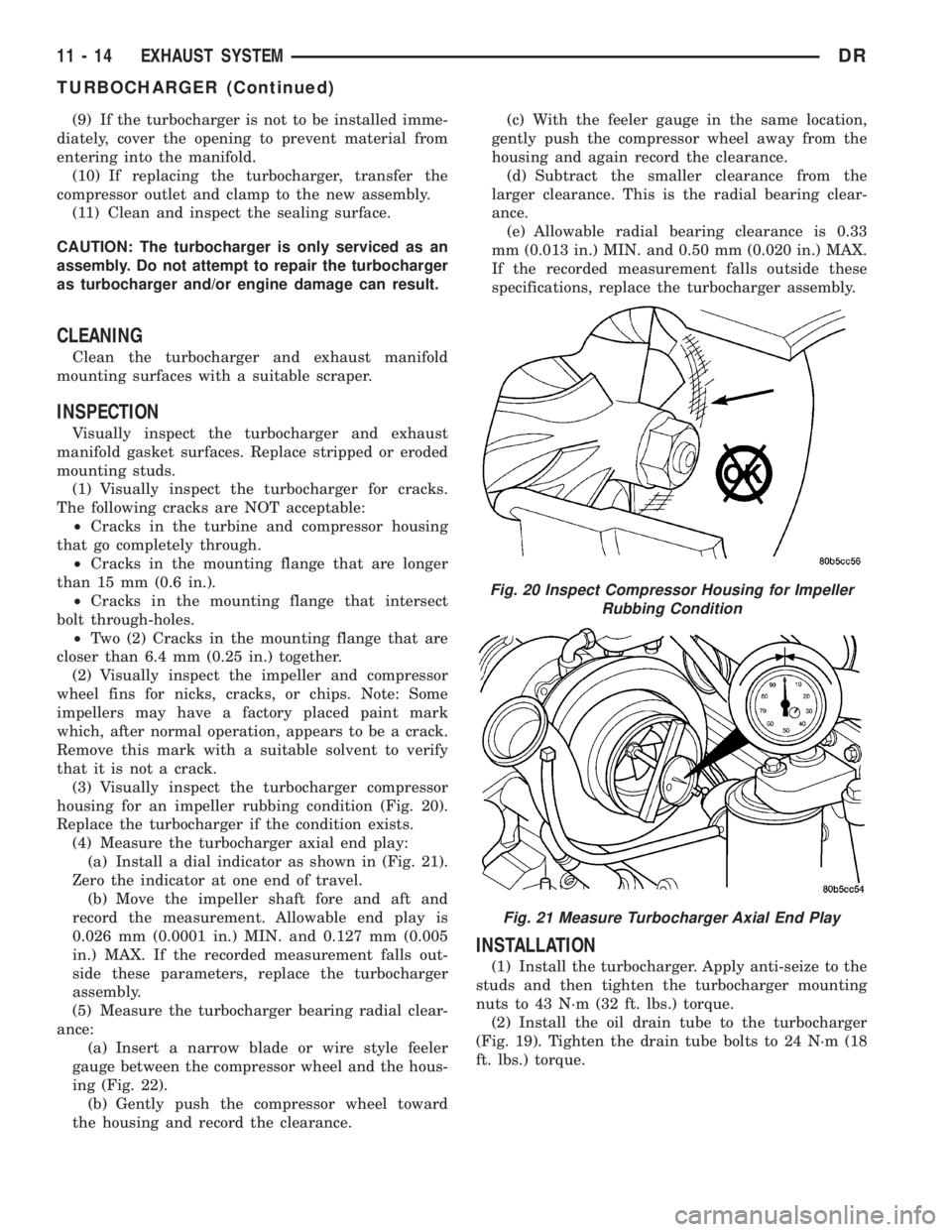

INSPECTION

Visually inspect the turbocharger and exhaust

manifold gasket surfaces. Replace stripped or eroded

mounting studs.

(1) Visually inspect the turbocharger for cracks.

The following cracks are NOT acceptable:

²Cracks in the turbine and compressor housing

that go completely through.

²Cracks in the mounting flange that are longer

than 15 mm (0.6 in.).

²Cracks in the mounting flange that intersect

bolt through-holes.

²Two (2) Cracks in the mounting flange that are

closer than 6.4 mm (0.25 in.) together.

(2) Visually inspect the impeller and compressor

wheel fins for nicks, cracks, or chips. Note: Some

impellers may have a factory placed paint mark

which, after normal operation, appears to be a crack.

Remove this mark with a suitable solvent to verify

that it is not a crack.

(3) Visually inspect the turbocharger compressor

housing for an impeller rubbing condition (Fig. 20).

Replace the turbocharger if the condition exists.

(4) Measure the turbocharger axial end play:

(a) Install a dial indicator as shown in (Fig. 21).

Zero the indicator at one end of travel.

(b) Move the impeller shaft fore and aft and

record the measurement. Allowable end play is

0.026 mm (0.0001 in.) MIN. and 0.127 mm (0.005

in.) MAX. If the recorded measurement falls out-

side these parameters, replace the turbocharger

assembly.

(5) Measure the turbocharger bearing radial clear-

ance:

(a) Insert a narrow blade or wire style feeler

gauge between the compressor wheel and the hous-

ing (Fig. 22).

(b) Gently push the compressor wheel toward

the housing and record the clearance.(c) With the feeler gauge in the same location,

gently push the compressor wheel away from the

housing and again record the clearance.

(d) Subtract the smaller clearance from the

larger clearance. This is the radial bearing clear-

ance.

(e) Allowable radial bearing clearance is 0.33

mm (0.013 in.) MIN. and 0.50 mm (0.020 in.) MAX.

If the recorded measurement falls outside these

specifications, replace the turbocharger assembly.

INSTALLATION

(1) Install the turbocharger. Apply anti-seize to the

studs and then tighten the turbocharger mounting

nuts to 43 N´m (32 ft. lbs.) torque.

(2) Install the oil drain tube to the turbocharger

(Fig. 19). Tighten the drain tube bolts to 24 N´m (18

ft. lbs.) torque.

Fig. 20 Inspect Compressor Housing for Impeller

Rubbing Condition

Fig. 21 Measure Turbocharger Axial End Play

11 - 14 EXHAUST SYSTEMDR

TURBOCHARGER (Continued)

Page 1717 of 2895

(13) Start engine and check for leaks.

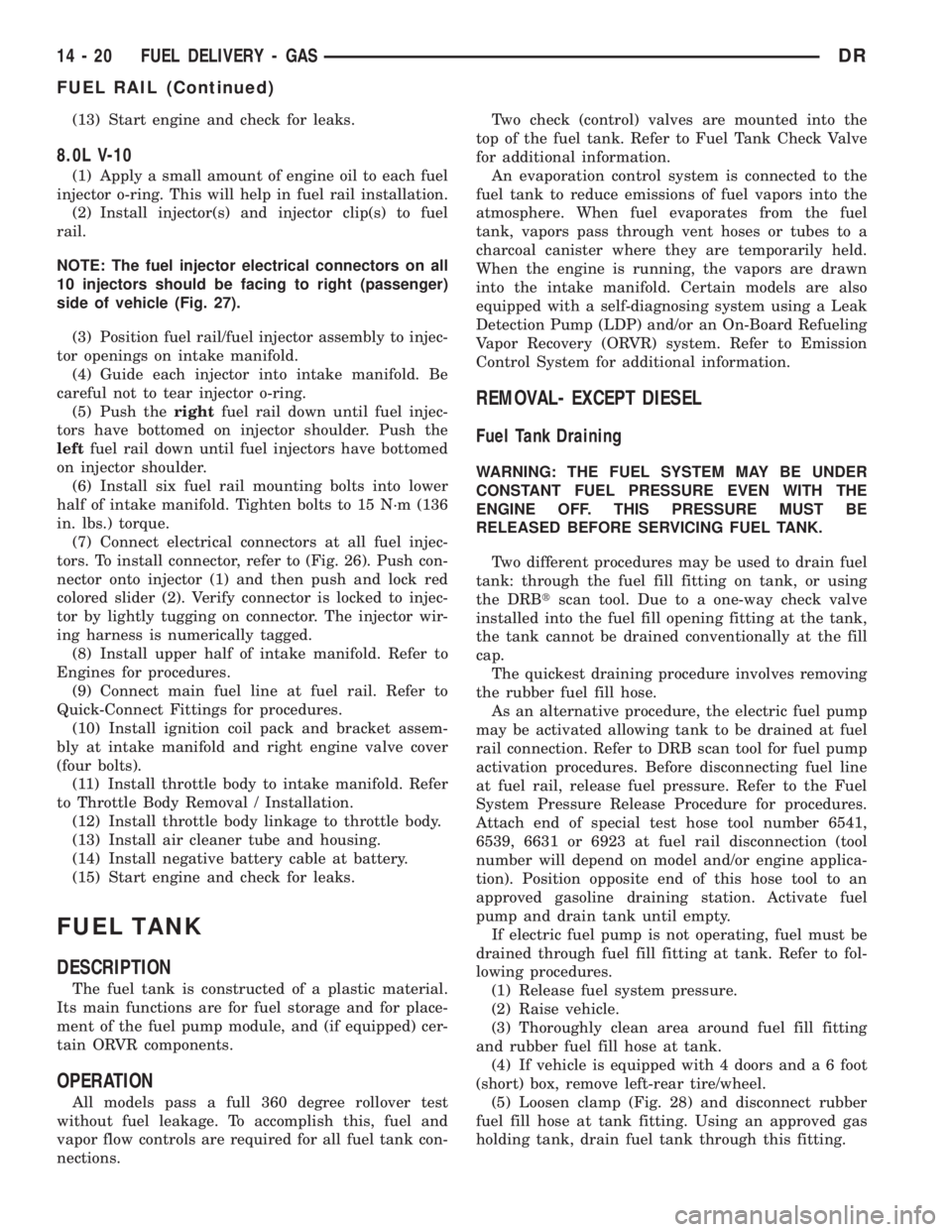

8.0L V-10

(1) Apply a small amount of engine oil to each fuel

injector o-ring. This will help in fuel rail installation.

(2) Install injector(s) and injector clip(s) to fuel

rail.

NOTE: The fuel injector electrical connectors on all

10 injectors should be facing to right (passenger)

side of vehicle (Fig. 27).

(3) Position fuel rail/fuel injector assembly to injec-

tor openings on intake manifold.

(4) Guide each injector into intake manifold. Be

careful not to tear injector o-ring.

(5) Push therightfuel rail down until fuel injec-

tors have bottomed on injector shoulder. Push the

leftfuel rail down until fuel injectors have bottomed

on injector shoulder.

(6) Install six fuel rail mounting bolts into lower

half of intake manifold. Tighten bolts to 15 N´m (136

in. lbs.) torque.

(7) Connect electrical connectors at all fuel injec-

tors. To install connector, refer to (Fig. 26). Push con-

nector onto injector (1) and then push and lock red

colored slider (2). Verify connector is locked to injec-

tor by lightly tugging on connector. The injector wir-

ing harness is numerically tagged.

(8) Install upper half of intake manifold. Refer to

Engines for procedures.

(9) Connect main fuel line at fuel rail. Refer to

Quick-Connect Fittings for procedures.

(10) Install ignition coil pack and bracket assem-

bly at intake manifold and right engine valve cover

(four bolts).

(11) Install throttle body to intake manifold. Refer

to Throttle Body Removal / Installation.

(12) Install throttle body linkage to throttle body.

(13) Install air cleaner tube and housing.

(14) Install negative battery cable at battery.

(15) Start engine and check for leaks.

FUEL TANK

DESCRIPTION

The fuel tank is constructed of a plastic material.

Its main functions are for fuel storage and for place-

ment of the fuel pump module, and (if equipped) cer-

tain ORVR components.

OPERATION

All models pass a full 360 degree rollover test

without fuel leakage. To accomplish this, fuel and

vapor flow controls are required for all fuel tank con-

nections.Two check (control) valves are mounted into the

top of the fuel tank. Refer to Fuel Tank Check Valve

for additional information.

An evaporation control system is connected to the

fuel tank to reduce emissions of fuel vapors into the

atmosphere. When fuel evaporates from the fuel

tank, vapors pass through vent hoses or tubes to a

charcoal canister where they are temporarily held.

When the engine is running, the vapors are drawn

into the intake manifold. Certain models are also

equipped with a self-diagnosing system using a Leak

Detection Pump (LDP) and/or an On-Board Refueling

Vapor Recovery (ORVR) system. Refer to Emission

Control System for additional information.

REMOVAL- EXCEPT DIESEL

Fuel Tank Draining

WARNING: THE FUEL SYSTEM MAY BE UNDER

CONSTANT FUEL PRESSURE EVEN WITH THE

ENGINE OFF. THIS PRESSURE MUST BE

RELEASED BEFORE SERVICING FUEL TANK.

Two different procedures may be used to drain fuel

tank: through the fuel fill fitting on tank, or using

the DRBtscan tool. Due to a one-way check valve

installed into the fuel fill opening fitting at the tank,

the tank cannot be drained conventionally at the fill

cap.

The quickest draining procedure involves removing

the rubber fuel fill hose.

As an alternative procedure, the electric fuel pump

may be activated allowing tank to be drained at fuel

rail connection. Refer to DRB scan tool for fuel pump

activation procedures. Before disconnecting fuel line

at fuel rail, release fuel pressure. Refer to the Fuel

System Pressure Release Procedure for procedures.

Attach end of special test hose tool number 6541,

6539, 6631 or 6923 at fuel rail disconnection (tool

number will depend on model and/or engine applica-

tion). Position opposite end of this hose tool to an

approved gasoline draining station. Activate fuel

pump and drain tank until empty.

If electric fuel pump is not operating, fuel must be

drained through fuel fill fitting at tank. Refer to fol-

lowing procedures.

(1) Release fuel system pressure.

(2) Raise vehicle.

(3) Thoroughly clean area around fuel fill fitting

and rubber fuel fill hose at tank.

(4) If vehicle is equipped with 4 doors and a 6 foot

(short) box, remove left-rear tire/wheel.

(5) Loosen clamp (Fig. 28) and disconnect rubber

fuel fill hose at tank fitting. Using an approved gas

holding tank, drain fuel tank through this fitting.

14 - 20 FUEL DELIVERY - GASDR

FUEL RAIL (Continued)

Page 1723 of 2895

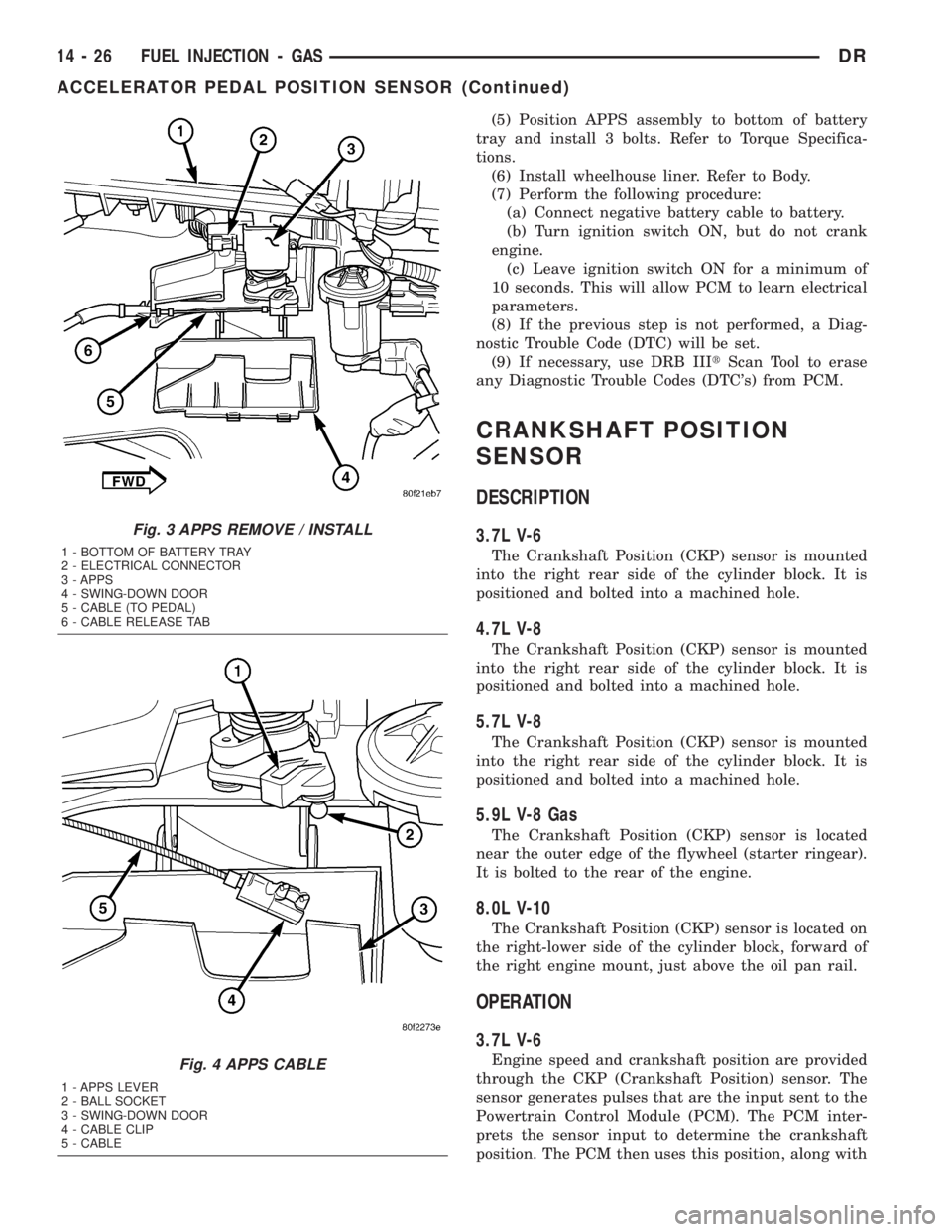

(5) Position APPS assembly to bottom of battery

tray and install 3 bolts. Refer to Torque Specifica-

tions.

(6) Install wheelhouse liner. Refer to Body.

(7) Perform the following procedure:

(a) Connect negative battery cable to battery.

(b) Turn ignition switch ON, but do not crank

engine.

(c) Leave ignition switch ON for a minimum of

10 seconds. This will allow PCM to learn electrical

parameters.

(8) If the previous step is not performed, a Diag-

nostic Trouble Code (DTC) will be set.

(9) If necessary, use DRB IIItScan Tool to erase

any Diagnostic Trouble Codes (DTC's) from PCM.

CRANKSHAFT POSITION

SENSOR

DESCRIPTION

3.7L V-6

The Crankshaft Position (CKP) sensor is mounted

into the right rear side of the cylinder block. It is

positioned and bolted into a machined hole.

4.7L V-8

The Crankshaft Position (CKP) sensor is mounted

into the right rear side of the cylinder block. It is

positioned and bolted into a machined hole.

5.7L V-8

The Crankshaft Position (CKP) sensor is mounted

into the right rear side of the cylinder block. It is

positioned and bolted into a machined hole.

5.9L V-8 Gas

The Crankshaft Position (CKP) sensor is located

near the outer edge of the flywheel (starter ringear).

It is bolted to the rear of the engine.

8.0L V-10

The Crankshaft Position (CKP) sensor is located on

the right-lower side of the cylinder block, forward of

the right engine mount, just above the oil pan rail.

OPERATION

3.7L V-6

Engine speed and crankshaft position are provided

through the CKP (Crankshaft Position) sensor. The

sensor generates pulses that are the input sent to the

Powertrain Control Module (PCM). The PCM inter-

prets the sensor input to determine the crankshaft

position. The PCM then uses this position, along with

Fig. 3 APPS REMOVE / INSTALL

1 - BOTTOM OF BATTERY TRAY

2 - ELECTRICAL CONNECTOR

3 - APPS

4 - SWING-DOWN DOOR

5 - CABLE (TO PEDAL)

6 - CABLE RELEASE TAB

Fig. 4 APPS CABLE

1 - APPS LEVER

2 - BALL SOCKET

3 - SWING-DOWN DOOR

4 - CABLE CLIP

5 - CABLE

14 - 26 FUEL INJECTION - GASDR

ACCELERATOR PEDAL POSITION SENSOR (Continued)

Page 1770 of 2895

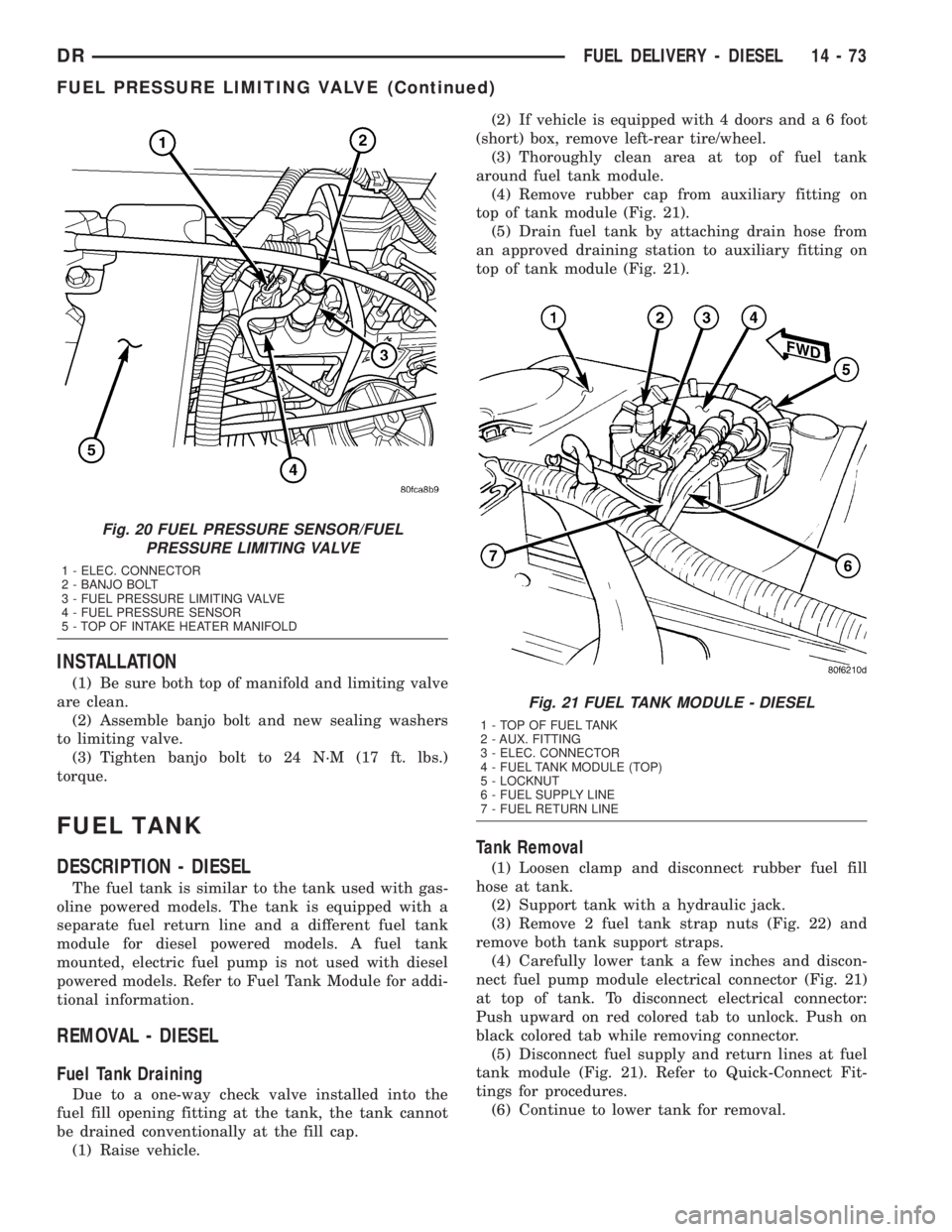

INSTALLATION

(1) Be sure both top of manifold and limiting valve

are clean.

(2) Assemble banjo bolt and new sealing washers

to limiting valve.

(3) Tighten banjo bolt to 24 N´M (17 ft. lbs.)

torque.

FUEL TANK

DESCRIPTION - DIESEL

The fuel tank is similar to the tank used with gas-

oline powered models. The tank is equipped with a

separate fuel return line and a different fuel tank

module for diesel powered models. A fuel tank

mounted, electric fuel pump is not used with diesel

powered models. Refer to Fuel Tank Module for addi-

tional information.

REMOVAL - DIESEL

Fuel Tank Draining

Due to a one-way check valve installed into the

fuel fill opening fitting at the tank, the tank cannot

be drained conventionally at the fill cap.

(1) Raise vehicle.(2) If vehicle is equipped with 4 doors and a 6 foot

(short) box, remove left-rear tire/wheel.

(3) Thoroughly clean area at top of fuel tank

around fuel tank module.

(4) Remove rubber cap from auxiliary fitting on

top of tank module (Fig. 21).

(5) Drain fuel tank by attaching drain hose from

an approved draining station to auxiliary fitting on

top of tank module (Fig. 21).

Tank Removal

(1) Loosen clamp and disconnect rubber fuel fill

hose at tank.

(2) Support tank with a hydraulic jack.

(3) Remove 2 fuel tank strap nuts (Fig. 22) and

remove both tank support straps.

(4) Carefully lower tank a few inches and discon-

nect fuel pump module electrical connector (Fig. 21)

at top of tank. To disconnect electrical connector:

Push upward on red colored tab to unlock. Push on

black colored tab while removing connector.

(5) Disconnect fuel supply and return lines at fuel

tank module (Fig. 21). Refer to Quick-Connect Fit-

tings for procedures.

(6) Continue to lower tank for removal.

Fig. 20 FUEL PRESSURE SENSOR/FUEL

PRESSURE LIMITING VALVE

1 - ELEC. CONNECTOR

2 - BANJO BOLT

3 - FUEL PRESSURE LIMITING VALVE

4 - FUEL PRESSURE SENSOR

5 - TOP OF INTAKE HEATER MANIFOLD

Fig. 21 FUEL TANK MODULE - DIESEL

1 - TOP OF FUEL TANK

2 - AUX. FITTING

3 - ELEC. CONNECTOR

4 - FUEL TANK MODULE (TOP)

5 - LOCKNUT

6 - FUEL SUPPLY LINE

7 - FUEL RETURN LINE

DRFUEL DELIVERY - DIESEL 14 - 73

FUEL PRESSURE LIMITING VALVE (Continued)

Page 1779 of 2895

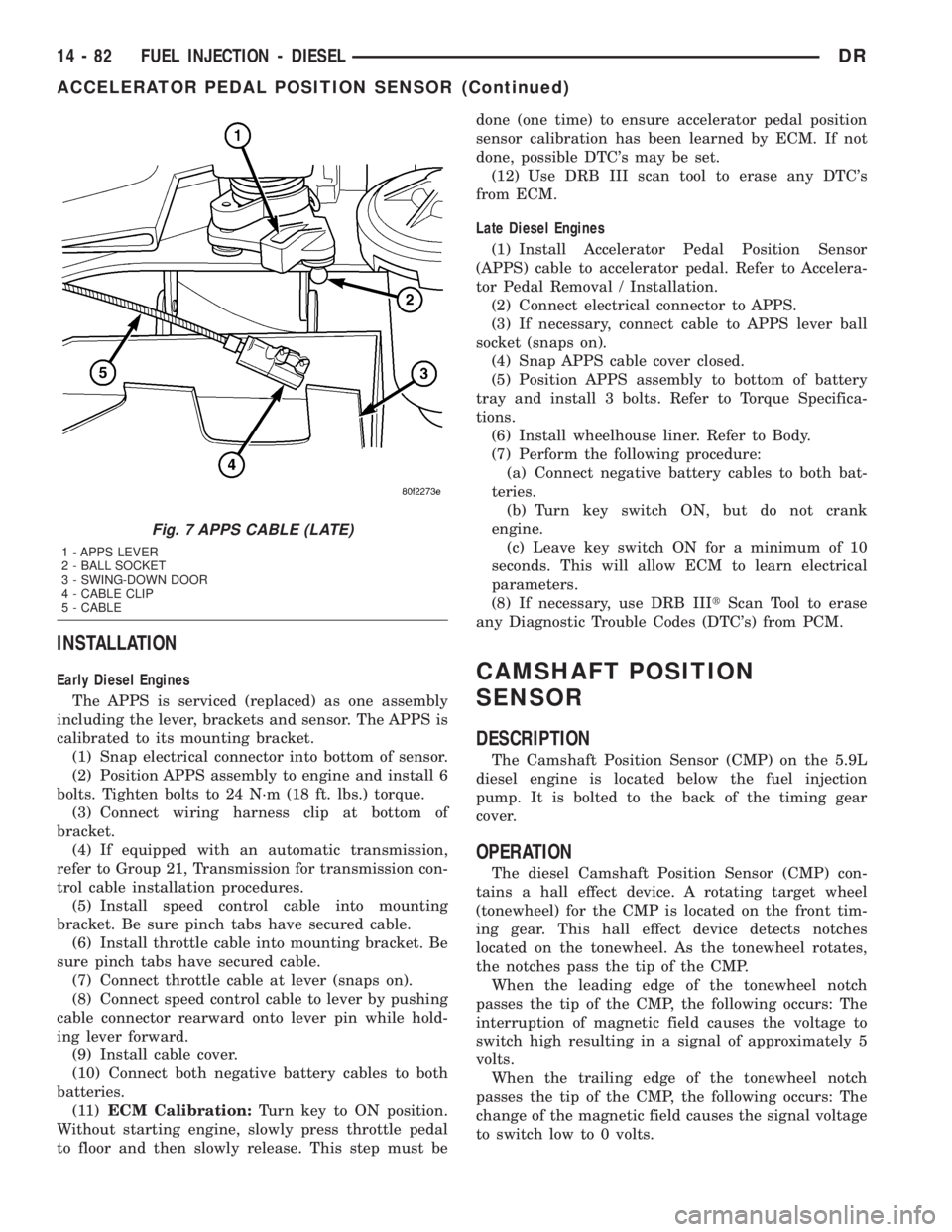

INSTALLATION

Early Diesel Engines

The APPS is serviced (replaced) as one assembly

including the lever, brackets and sensor. The APPS is

calibrated to its mounting bracket.

(1) Snap electrical connector into bottom of sensor.

(2) Position APPS assembly to engine and install 6

bolts. Tighten bolts to 24 N´m (18 ft. lbs.) torque.

(3) Connect wiring harness clip at bottom of

bracket.

(4) If equipped with an automatic transmission,

refer to Group 21, Transmission for transmission con-

trol cable installation procedures.

(5) Install speed control cable into mounting

bracket. Be sure pinch tabs have secured cable.

(6) Install throttle cable into mounting bracket. Be

sure pinch tabs have secured cable.

(7) Connect throttle cable at lever (snaps on).

(8) Connect speed control cable to lever by pushing

cable connector rearward onto lever pin while hold-

ing lever forward.

(9) Install cable cover.

(10) Connect both negative battery cables to both

batteries.

(11)ECM Calibration:Turn key to ON position.

Without starting engine, slowly press throttle pedal

to floor and then slowly release. This step must bedone (one time) to ensure accelerator pedal position

sensor calibration has been learned by ECM. If not

done, possible DTC's may be set.

(12) Use DRB III scan tool to erase any DTC's

from ECM.

Late Diesel Engines

(1) Install Accelerator Pedal Position Sensor

(APPS) cable to accelerator pedal. Refer to Accelera-

tor Pedal Removal / Installation.

(2) Connect electrical connector to APPS.

(3) If necessary, connect cable to APPS lever ball

socket (snaps on).

(4) Snap APPS cable cover closed.

(5) Position APPS assembly to bottom of battery

tray and install 3 bolts. Refer to Torque Specifica-

tions.

(6) Install wheelhouse liner. Refer to Body.

(7) Perform the following procedure:

(a) Connect negative battery cables to both bat-

teries.

(b) Turn key switch ON, but do not crank

engine.

(c) Leave key switch ON for a minimum of 10

seconds. This will allow ECM to learn electrical

parameters.

(8) If necessary, use DRB IIItScan Tool to erase

any Diagnostic Trouble Codes (DTC's) from PCM.CAMSHAFT POSITION

SENSOR

DESCRIPTION

The Camshaft Position Sensor (CMP) on the 5.9L

diesel engine is located below the fuel injection

pump. It is bolted to the back of the timing gear

cover.

OPERATION

The diesel Camshaft Position Sensor (CMP) con-

tains a hall effect device. A rotating target wheel

(tonewheel) for the CMP is located on the front tim-

ing gear. This hall effect device detects notches

located on the tonewheel. As the tonewheel rotates,

the notches pass the tip of the CMP.

When the leading edge of the tonewheel notch

passes the tip of the CMP, the following occurs: The

interruption of magnetic field causes the voltage to

switch high resulting in a signal of approximately 5

volts.

When the trailing edge of the tonewheel notch

passes the tip of the CMP, the following occurs: The

change of the magnetic field causes the signal voltage

to switch low to 0 volts.

Fig. 7 APPS CABLE (LATE)

1 - APPS LEVER

2 - BALL SOCKET

3 - SWING-DOWN DOOR

4 - CABLE CLIP

5 - CABLE

14 - 82 FUEL INJECTION - DIESELDR

ACCELERATOR PEDAL POSITION SENSOR (Continued)

Page 1780 of 2895

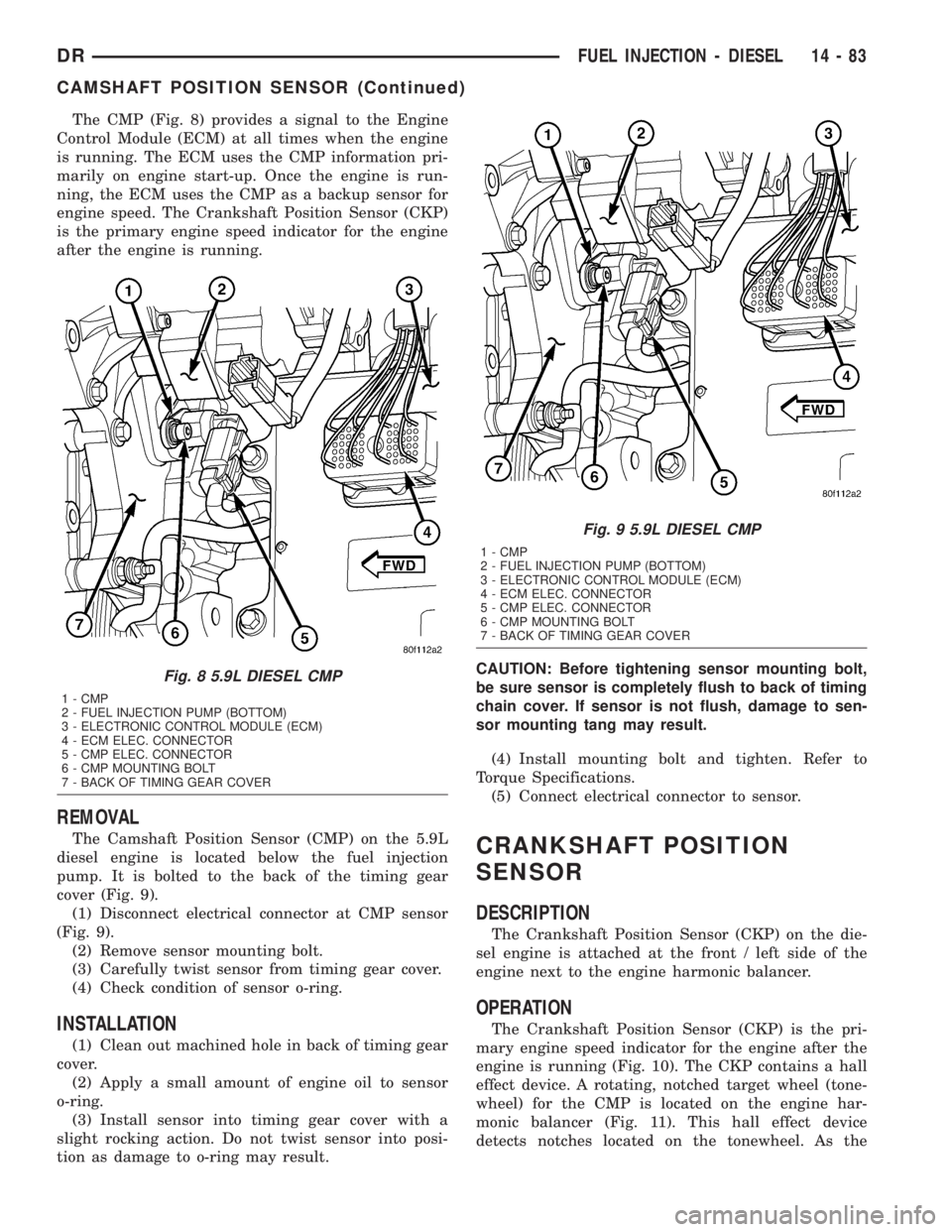

The CMP (Fig. 8) provides a signal to the Engine

Control Module (ECM) at all times when the engine

is running. The ECM uses the CMP information pri-

marily on engine start-up. Once the engine is run-

ning, the ECM uses the CMP as a backup sensor for

engine speed. The Crankshaft Position Sensor (CKP)

is the primary engine speed indicator for the engine

after the engine is running.

REMOVAL

The Camshaft Position Sensor (CMP) on the 5.9L

diesel engine is located below the fuel injection

pump. It is bolted to the back of the timing gear

cover (Fig. 9).

(1) Disconnect electrical connector at CMP sensor

(Fig. 9).

(2) Remove sensor mounting bolt.

(3) Carefully twist sensor from timing gear cover.

(4) Check condition of sensor o-ring.

INSTALLATION

(1) Clean out machined hole in back of timing gear

cover.

(2) Apply a small amount of engine oil to sensor

o-ring.

(3) Install sensor into timing gear cover with a

slight rocking action. Do not twist sensor into posi-

tion as damage to o-ring may result.CAUTION: Before tightening sensor mounting bolt,

be sure sensor is completely flush to back of timing

chain cover. If sensor is not flush, damage to sen-

sor mounting tang may result.

(4) Install mounting bolt and tighten. Refer to

Torque Specifications.

(5) Connect electrical connector to sensor.

CRANKSHAFT POSITION

SENSOR

DESCRIPTION

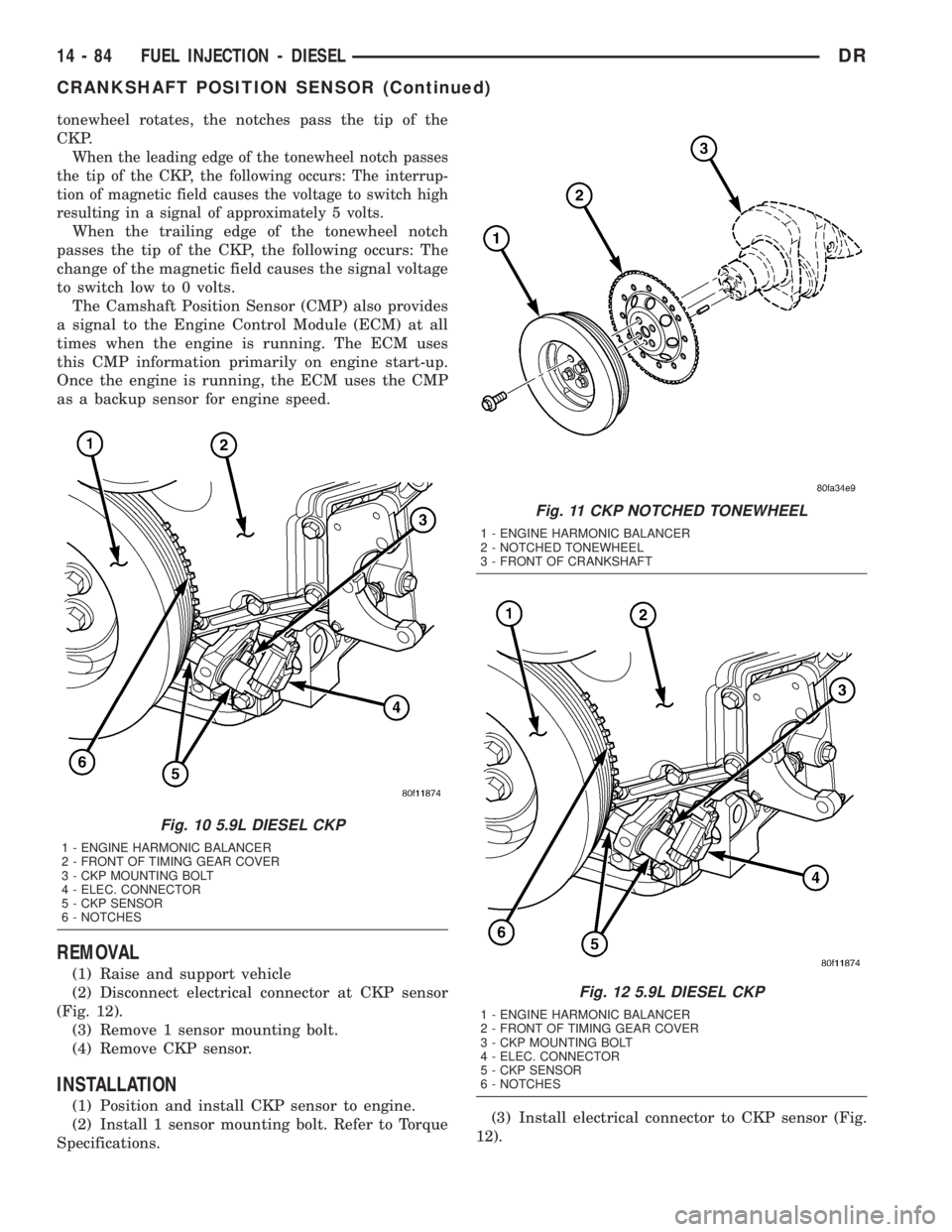

The Crankshaft Position Sensor (CKP) on the die-

sel engine is attached at the front / left side of the

engine next to the engine harmonic balancer.

OPERATION

The Crankshaft Position Sensor (CKP) is the pri-

mary engine speed indicator for the engine after the

engine is running (Fig. 10). The CKP contains a hall

effect device. A rotating, notched target wheel (tone-

wheel) for the CMP is located on the engine har-

monic balancer (Fig. 11). This hall effect device

detects notches located on the tonewheel. As the

Fig. 8 5.9L DIESEL CMP

1 - CMP

2 - FUEL INJECTION PUMP (BOTTOM)

3 - ELECTRONIC CONTROL MODULE (ECM)

4 - ECM ELEC. CONNECTOR

5 - CMP ELEC. CONNECTOR

6 - CMP MOUNTING BOLT

7 - BACK OF TIMING GEAR COVER

Fig. 9 5.9L DIESEL CMP

1 - CMP

2 - FUEL INJECTION PUMP (BOTTOM)

3 - ELECTRONIC CONTROL MODULE (ECM)

4 - ECM ELEC. CONNECTOR

5 - CMP ELEC. CONNECTOR

6 - CMP MOUNTING BOLT

7 - BACK OF TIMING GEAR COVER

DRFUEL INJECTION - DIESEL 14 - 83

CAMSHAFT POSITION SENSOR (Continued)

Page 1781 of 2895

tonewheel rotates, the notches pass the tip of the

CKP.

When the leading edge of the tonewheel notch passes

the tip of the CKP, the following occurs: The interrup-

tion of magnetic field causes the voltage to switch high

resulting in a signal of approximately 5 volts.

When the trailing edge of the tonewheel notch

passes the tip of the CKP, the following occurs: The

change of the magnetic field causes the signal voltage

to switch low to 0 volts.

The Camshaft Position Sensor (CMP) also provides

a signal to the Engine Control Module (ECM) at all

times when the engine is running. The ECM uses

this CMP information primarily on engine start-up.

Once the engine is running, the ECM uses the CMP

as a backup sensor for engine speed.

REMOVAL

(1) Raise and support vehicle

(2) Disconnect electrical connector at CKP sensor

(Fig. 12).

(3) Remove 1 sensor mounting bolt.

(4) Remove CKP sensor.

INSTALLATION

(1) Position and install CKP sensor to engine.

(2) Install 1 sensor mounting bolt. Refer to Torque

Specifications.(3) Install electrical connector to CKP sensor (Fig.

12).

Fig. 10 5.9L DIESEL CKP

1 - ENGINE HARMONIC BALANCER

2 - FRONT OF TIMING GEAR COVER

3 - CKP MOUNTING BOLT

4 - ELEC. CONNECTOR

5 - CKP SENSOR

6 - NOTCHES

Fig. 11 CKP NOTCHED TONEWHEEL

1 - ENGINE HARMONIC BALANCER

2 - NOTCHED TONEWHEEL

3 - FRONT OF CRANKSHAFT

Fig. 12 5.9L DIESEL CKP

1 - ENGINE HARMONIC BALANCER

2 - FRONT OF TIMING GEAR COVER

3 - CKP MOUNTING BOLT

4 - ELEC. CONNECTOR

5 - CKP SENSOR

6 - NOTCHES

14 - 84 FUEL INJECTION - DIESELDR

CRANKSHAFT POSITION SENSOR (Continued)