sensor DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1256 of 2895

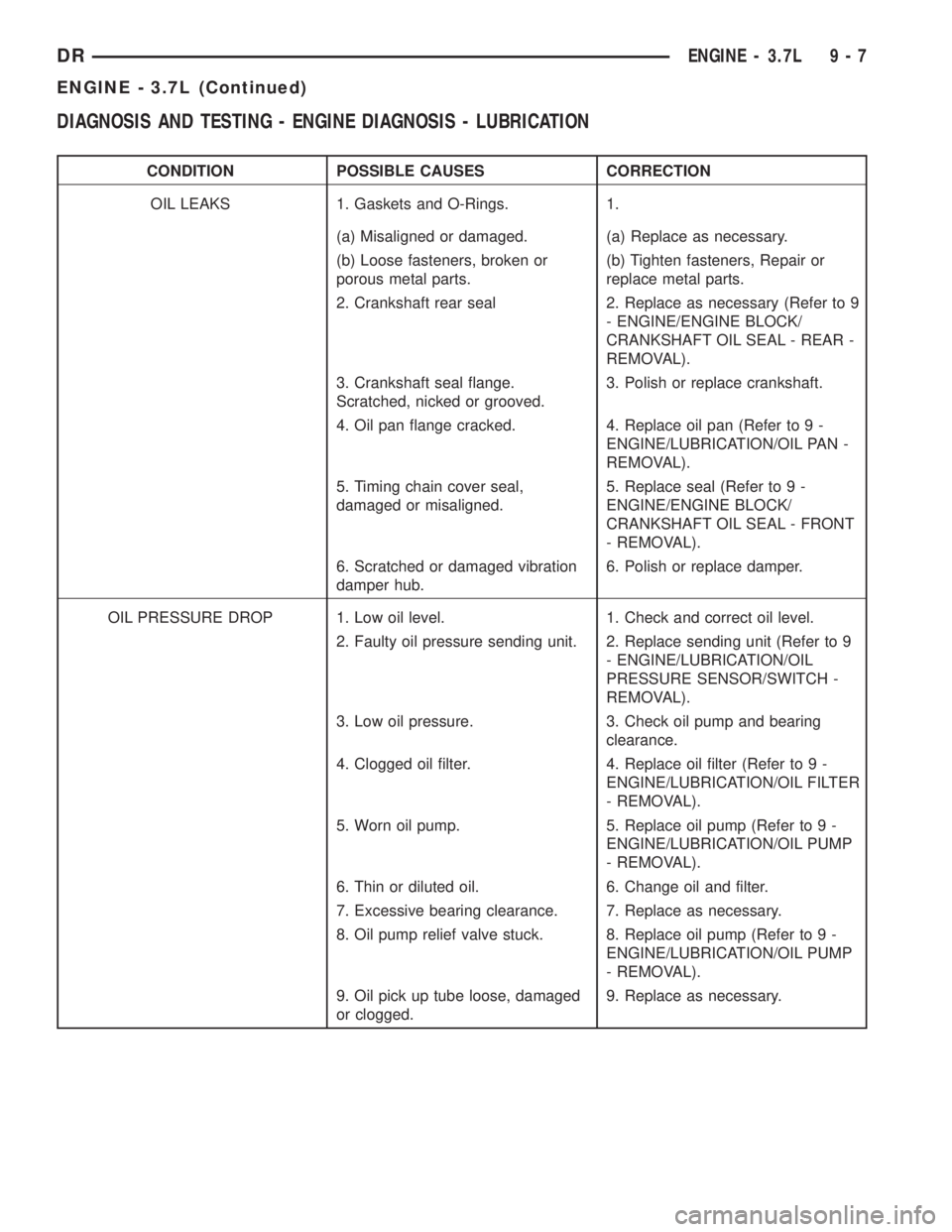

DIAGNOSIS AND TESTING - ENGINE DIAGNOSIS - LUBRICATION

CONDITION POSSIBLE CAUSES CORRECTION

OIL LEAKS 1. Gaskets and O-Rings. 1.

(a) Misaligned or damaged. (a) Replace as necessary.

(b) Loose fasteners, broken or

porous metal parts.(b) Tighten fasteners, Repair or

replace metal parts.

2. Crankshaft rear seal 2. Replace as necessary (Refer to 9

- ENGINE/ENGINE BLOCK/

CRANKSHAFT OIL SEAL - REAR -

REMOVAL).

3. Crankshaft seal flange.

Scratched, nicked or grooved.3. Polish or replace crankshaft.

4. Oil pan flange cracked. 4. Replace oil pan (Refer to 9 -

ENGINE/LUBRICATION/OIL PAN -

REMOVAL).

5. Timing chain cover seal,

damaged or misaligned.5. Replace seal (Refer to 9 -

ENGINE/ENGINE BLOCK/

CRANKSHAFT OIL SEAL - FRONT

- REMOVAL).

6. Scratched or damaged vibration

damper hub.6. Polish or replace damper.

OIL PRESSURE DROP 1. Low oil level. 1. Check and correct oil level.

2. Faulty oil pressure sending unit. 2. Replace sending unit (Refer to 9

- ENGINE/LUBRICATION/OIL

PRESSURE SENSOR/SWITCH -

REMOVAL).

3. Low oil pressure. 3. Check oil pump and bearing

clearance.

4. Clogged oil filter. 4. Replace oil filter (Refer to 9 -

ENGINE/LUBRICATION/OIL FILTER

- REMOVAL).

5. Worn oil pump. 5. Replace oil pump (Refer to 9 -

ENGINE/LUBRICATION/OIL PUMP

- REMOVAL).

6. Thin or diluted oil. 6. Change oil and filter.

7. Excessive bearing clearance. 7. Replace as necessary.

8. Oil pump relief valve stuck. 8. Replace oil pump (Refer to 9 -

ENGINE/LUBRICATION/OIL PUMP

- REMOVAL).

9. Oil pick up tube loose, damaged

or clogged.9. Replace as necessary.

DRENGINE - 3.7L 9 - 7

ENGINE - 3.7L (Continued)

Page 1260 of 2895

(12) Disconnect heater hoses from heater core and

remove hose assembly.

(13) Disconnect throttle and speed control cables.

(14) Remove upper radiator hose from engine.

(15) Remove lower radiator hose from engine.

(16) Remove radiator/cooling module assembly.

(17) Disconnect the engine to body ground straps

at the left side of cowl.

(18) Disconnect the engine wiring harness at the

following points:

²Intake air temperature (IAT) sensor

²Fuel Injectors

²Throttle Position (TPS) Switch

²Idle Air Control (IAC) Motor

²Engine Oil Pressure Switch

²Engine Coolant Temperature (ECT) Sensor

²Manifold Absolute Pressure MAP) Sensor

²Camshaft Position (CMP) Sensor

²Coil Over Plugs

²Crankshaft Position Sensor

(19) Remove coil over plugs.

(20) Release fuel rail pressure.

(21) Remove fuel rail and secure away from

engine.

NOTE: It is not necessary to release the quick con-

nect fitting from the fuel supply line for engine

removal.

(22) Remove the PCV hose.

(23) Remove the breather hoses.

(24) Remove the vacuum hose for the power brake

booster.

(25) Disconnect knock sensors.

(26) Remove engine oil dipstick tube.

(27) Remove intake manifold.

(28) Install engine lifting fixture,special tool#8247,

using original fasteners from the removed intake

manifold, and fuel rail. Torque to factory specifica-

tions.

NOTE: Recheck bolt torque for engine lift plate

before removing engine.

(29) Secure the left and right engine wiring har-

nesses away from engine.

(30) Raise vehicle.

(31) Disconnect oxygen sensor wiring.

(32) Disconnect crankshaft postion sensor.

(33) Disconnect the engine block heater power

cable, if equipped.

(34) Disconnect the front propshaft at the front

differential and secure out of way.

NOTE: It is necessary to disconnect the front prop-

shaft for access to the starter and left side exhaust

flange.(35) Remove the starter.

(36) Remove the ground straps from the left and

right side of the block.

(37) Disconnect the right and left exhaust pipes at

the manifolds and from the crossover, and remove

from the vehicle.

NOTE: The exhaust clamps at the manifolds cannot

be reused. New clamps must be used or leaks may

occur.

(38) Remove the structural cover.

(39) Remove torque convertor bolts, and mark

location for reassembly.

(40) Remove transmission bellhousing to engine

bolts.

(41) Remove left and right engine mount thru

bolts.

(42) Lower the vehicle.

(43) Support the transmission with a suitable jack.

(44) Connect a suitable engine hoist to the engine

lift plate.

(45) Remove engine from vehicle.

INSTALLATION

(1) Position the engine in the vehicle.

(2) Install both left and right side engine mounts

onto engine.

(3) Raise the vehicle.

(4) Install the transmission bellhousing to engine

mounting bolts. Tighten the bolts to 41 N´m (30ft.

lbs.).

(5) Tighten the engine mount thru bolts.

(6) Install the torque convertor bolts.

(7) Connect the ground straps on the left and right

side of the engine.

(8) Install the starter.

(9) Connect the crankshaft position sensor.

(10) Install the engine block heater power cable, if

equipped.

CAUTION: The structural cover requires a specific

torque sequence. Failure to follow this sequence

may cause severe damage to the cover.

(11) Install the structural cover.

NOTE: New clamps must be used on exhaust man-

ifold flanges. Failure to use new clamps may result

in exhaust leaks.

(12) Install the left and right exhaust pipes.

(13) Connect the left and right oxygen sensors.

(14) Lower vehicle.

(15) Remove the engine lift plate.

(16) Connect the knock sensors.

DRENGINE - 3.7L 9 - 11

ENGINE - 3.7L (Continued)

Page 1261 of 2895

(17) Connect the engine to body ground straps at

the left side of the cowl.

(18) Install the intake manifold.

(19) Install the engine oil dipstick tube.

(20) Install the power brake booster vacuum hose.

(21) Install the breather hoses.

(22) Install the PCV hose.

(23) Install the fuel rail.

(24) Install the coil over plugs.

(25) Connect the engine wiring harness at the fol-

lowing points:

²Intake air temperature (IAT) sensor

²Fuel Injectors

²Throttle Position (TPS) Switch

²Idle Air Control (IAC) Motor

²Engine Oil Pressure Switch

²Engine Coolant Temperature (ECT) Sensor

²Manifold Absolute Pressure MAP) Sensor

²Camshaft Position (CMP) Sensor

²Coil Over Plugs

²Crankshaft Position Sensor

(26) Reinstall the radiator/cooling module assem-

bly.

(27) Connect lower radiator hose.

(28) Connect upper radiator hose.

(29) Connect throttle and speed control cables.

(30) Install the heater hose assembly.

(31) Install coolant recovery bottle.

(32) Install the power steering pump.

(33) Install the generator.

(34) Install the A/C compressor.

(35) Install the drive belt.

(36) Install the fan shroud with the viscous fan

assembly.

(37) Install the radiator core support bracket.

(38) Install the air cleaner assembly.

(39) Refill the engine cooling system.

(40) Recharge the air conditioning.

(41) Install the hood.

(42) Check and fill engine oil.

(43) Connect the battery negative cable.

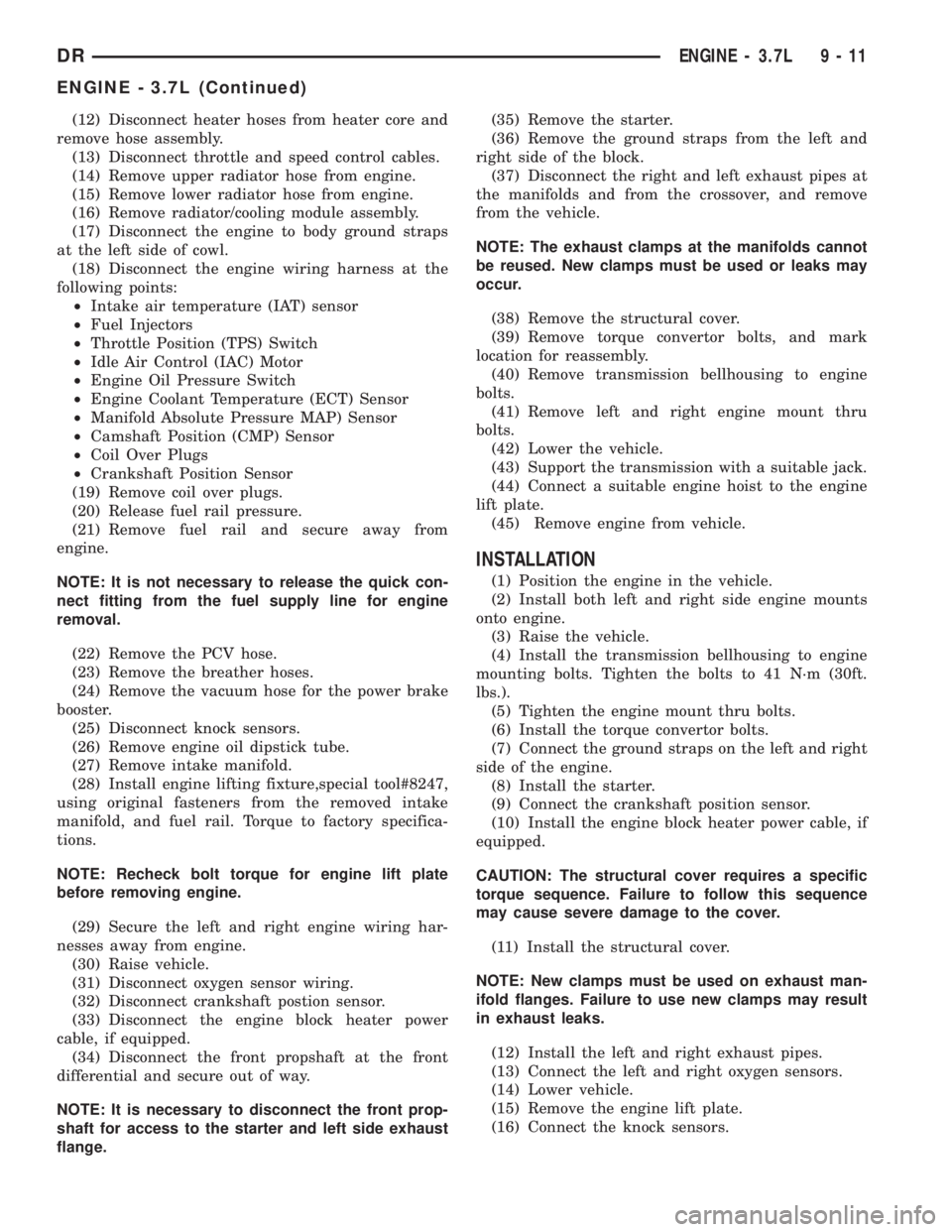

(44) Start the engine and check for leaks.SPECIFICATIONS

SPECIFICATIONS ± 3.7L ENGINE

DESCRIPTION SPECIFICATION

Engine Type 90É SOHC V-6 12-Valve

Displacement 3.7 Liters / 3700 cc

226 ( Cubic Inches)

Bore 93.0 mm (3.66 in.)

Stroke 90.8 mm (3.40 in.)

Compression Ratio 9.1:1

Horsepower 210 BHP @ 5200 RPM

Torque 225 LB-FT @ 4200 RPM

Lead Cylinder #1 Left Bank

Firing Order 1-6-5-4-3-2

CYLINDER BLOCK

Cylinder Block Cast Iron

Bore Diameter 93.0 .0075 mm

(3.6619 0.0003 in.)

Out of Round (MAX) 0.076 mm (0.003 in.)

Taper (MAX) 0.051 mm (0.002 in.)

PISTONS

Material Aluminum Alloy

Diameter 92.975 mm (3.6605 in.)

Weight 367.5 grams (12.96 oz)

Ring Groove Diameter

No. 1 83.73 - 83.13 mm

(3.296 - 3.273 in.)

No. 2 82.833 - 83.033 mm

(3.261 - 3.310 in.)

No. 3 83.88 - 84.08 mm

(3.302 - 3.310 in.)

PISTON PINS

Type Floating

Clearance In Piston 0.006 - 0.015 mm

(0.0002 - 0.0005 in.)

Diameter 24.017 - 24.020 mm

(0.9455 - 0.9456 in.)

PISTON RINGS

Ring Gap

Top Compression Ring 0.20 - 0.36 mm

(0.0079 - 0.0142 in.)

9 - 12 ENGINE - 3.7LDR

ENGINE - 3.7L (Continued)

Page 1281 of 2895

(6) Air ingested into oil due to broken or cracked

oil pump pick up.

(7) Worn valve guides.

(8) Rocker arm ears contacting valve spring

retainer.

(9) Rocker arm loose, adjuster stuck or at maxi-

mum extension and still leaves lash in the system.

(10) Oil leak or excessive cam bore wear in cylin-

der head.

(11) Faulty lash adjuster.

a. Check lash adjusters for sponginess while

installed in cylinder head and cam on camshaft at

base circle. Depress part of rocker arm over adjuster.

Normal adjusters should feel very firm. Spongy

adjusters can be bottomed out easily.

b. Remove suspected lash adjusters, and replace.

c. Before installation, make sure adjusters are at

least partially full of oil. This can be verified by little

or no plunger travel when lash adjuster is depressed.

REMOVAL

(1) Disconnect battery negative cable.

(2) Raise the vehicle on a hoist.

(3) Disconnect the exhaust pipe at the right side

exhaust manifold.

(4) Drain the engine coolant(Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

(5) Lower the vehicle.

(6) Remove the intake manifold(Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL).

(7) Remove the cylinder head cover(Refer to 9 -

ENGINE/CYLINDER HEAD - REMOVAL).

(8) Remove the fan shroud(Refer to 7 - COOLING/

ENGINE/RADIATOR FAN - REMOVAL).

(9) Remove oil fill housing from cylinder head.

(10) Remove accessory drive belt(Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(11) Rotate the crankshaft until the damper timing

mark is aligned with TDC indicator mark.

(12) Verify the V6 mark on the camshaft sprocket

is at the 12 o'clock position. Rotate the crankshaft

one turn if necessary.

(13) Remove the crankshaft damper(Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(14) Remove the timing chain cover(Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(15) Lock the secondary timing chains to the idler

sprocket using Special Tool 8429 Timing Chain Hold-

ing Fixture.

NOTE: Mark the secondary timing chain prior to

removal to aid in installation.(16) Mark the secondary timing chain, one link on

each side of the V6 mark on the camshaft drive gear.

(17) Remove the right side secondary chain ten-

sioner(Refer to 9 - ENGINE/VALVE TIMING/TIM-

ING BELT/CHAIN AND SPROCKETS - REMOVAL).

(18) Remove the cylinder head access plug.

(19) Remove the right side secondary chain

guide(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT/CHAIN AND SPROCKETS - REMOVAL).

CAUTION: The nut on the right side camshaft

sprocket should not be removed for any reason, as

the sprocket and camshaft sensor target wheel is

serviced as an assembly. If the nut was removed

retorque nut to 5 N´m (44 in. lbs.).

(20) Remove the retaining bolt and the camshaft

drive gear.

CAUTION: Do not allow the engine to rotate. severe

damage to the valve train can occur.

CAUTION: Do not overlook the four smaller bolts at

the front of the cylinder head. Do not attempt to

remove the cylinder head without removing these

four bolts.

CAUTION: Do not hold or pry on the camshaft tar-

get wheel for any reason. A damaged target wheel

can result in a vehicle no start condition.

NOTE: The cylinder head is attached to the cylinder

block with twelve bolts.

(21) Remove the cylinder head retaining bolts.

(22) Remove the cylinder head and gasket. Discard

the gasket.

CAUTION: Do not lay the cylinder head on its gas-

ket sealing surface, do to the design of the cylinder

head gasket any distortion to the cylinder head

sealing surface may prevent the gasket from prop-

erly sealing resulting in leaks.

INSTALLATION

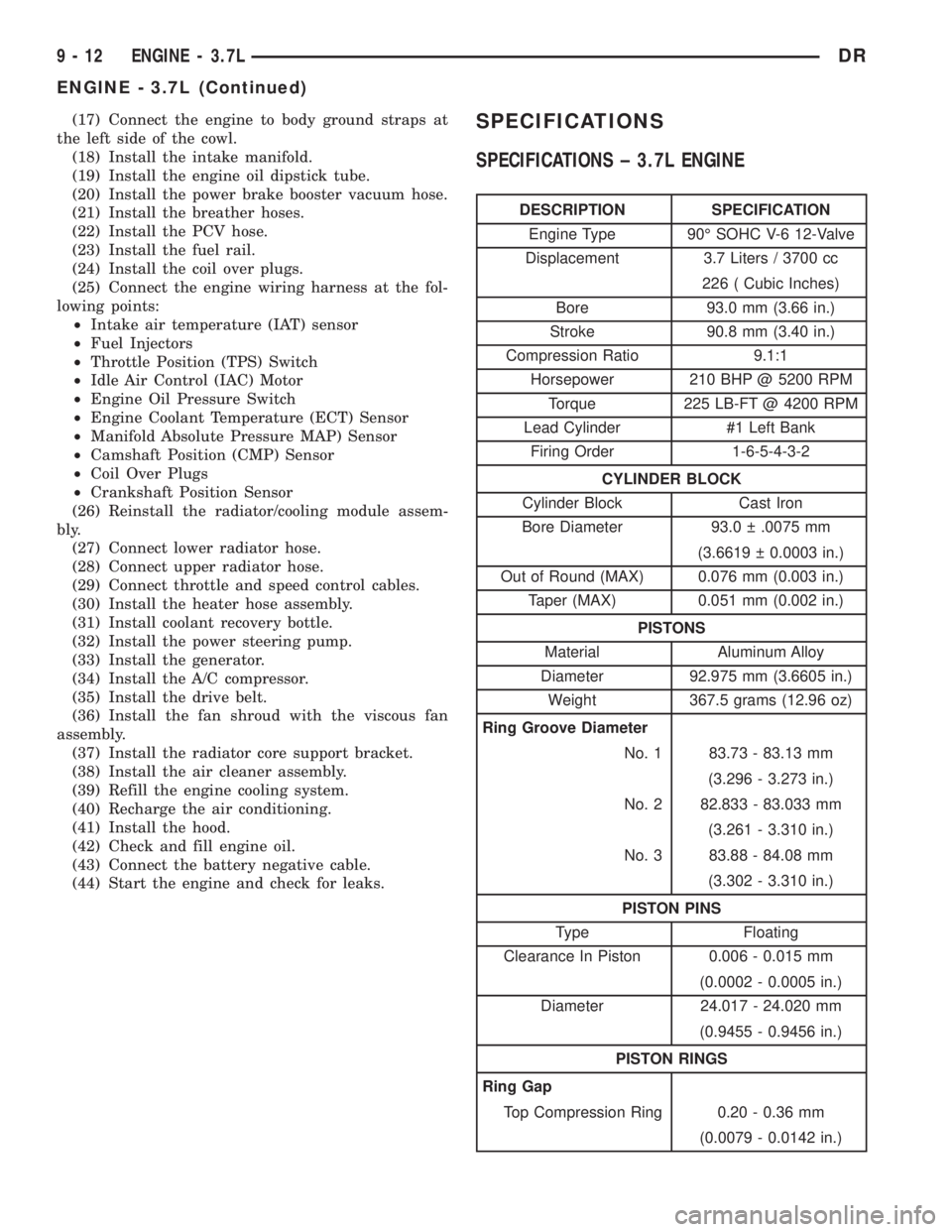

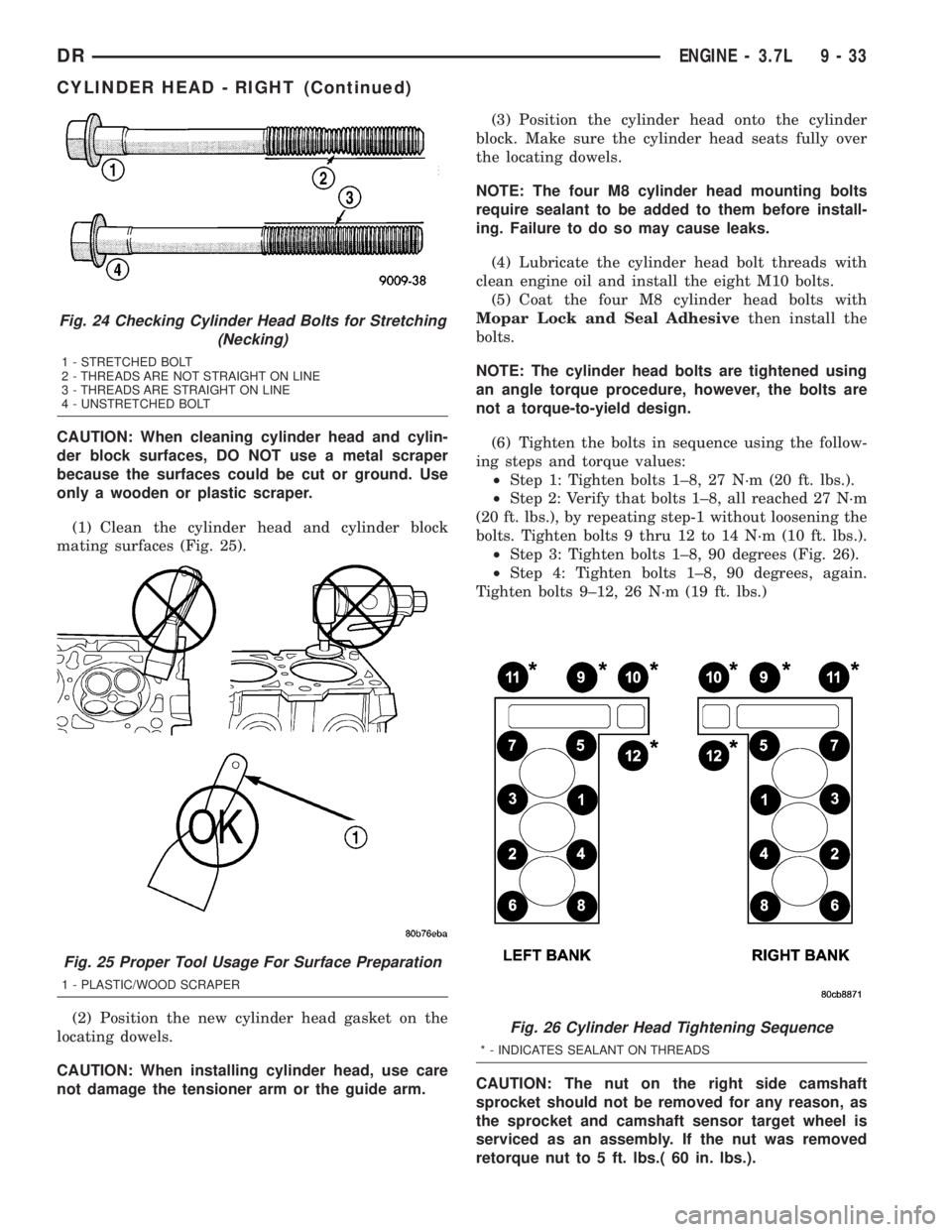

NOTE: The cylinder head bolts are tightened using

a torque plus angle procedure. The bolts must be

examined BEFORE reuse. If the threads are necked

down the bolts should be replaced.

Necking can be checked by holding a straight edge

against the threads (Fig. 24). If all the threads do not

contact the scale, the bolt should be replaced.

9 - 32 ENGINE - 3.7LDR

CYLINDER HEAD - RIGHT (Continued)

Page 1282 of 2895

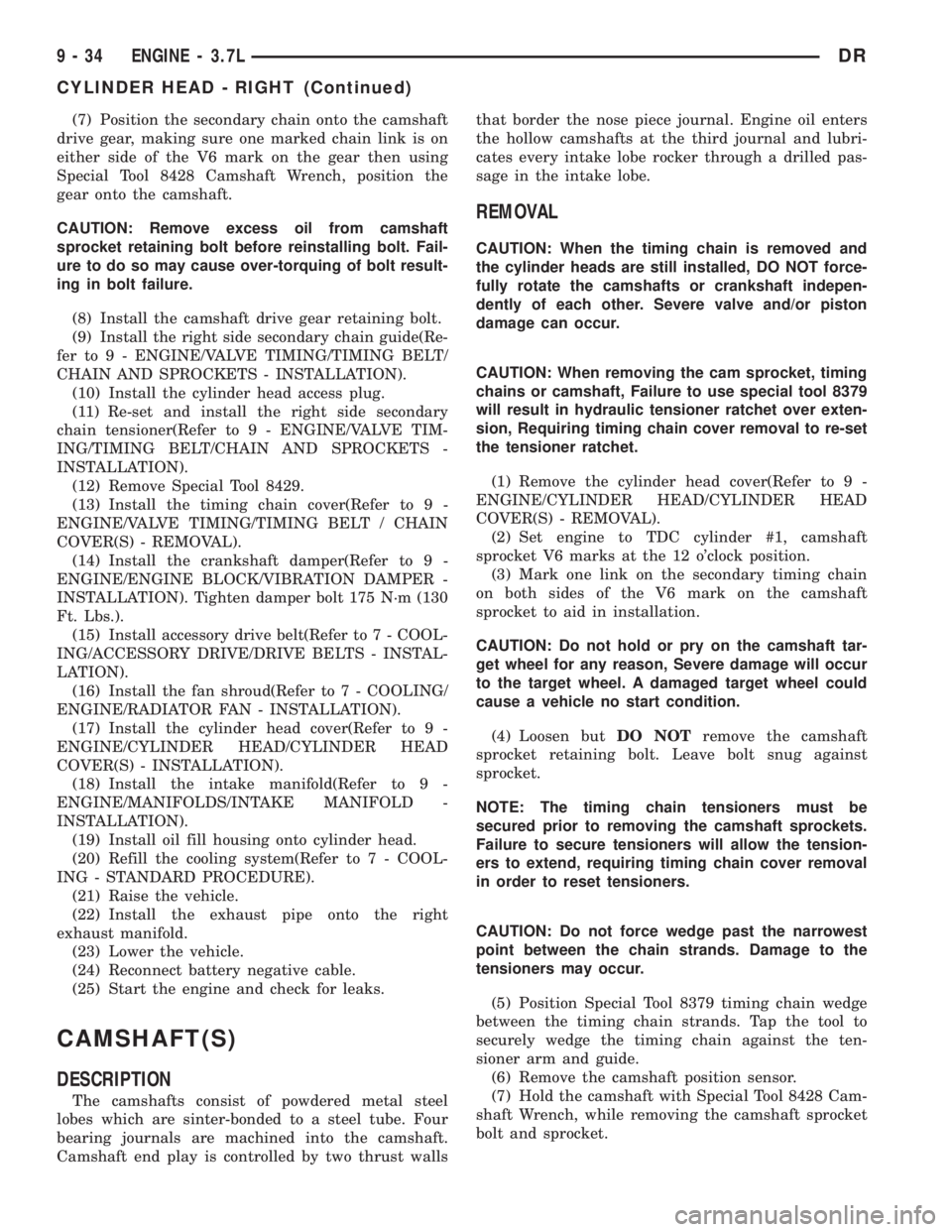

CAUTION: When cleaning cylinder head and cylin-

der block surfaces, DO NOT use a metal scraper

because the surfaces could be cut or ground. Use

only a wooden or plastic scraper.

(1) Clean the cylinder head and cylinder block

mating surfaces (Fig. 25).

(2) Position the new cylinder head gasket on the

locating dowels.

CAUTION: When installing cylinder head, use care

not damage the tensioner arm or the guide arm.(3) Position the cylinder head onto the cylinder

block. Make sure the cylinder head seats fully over

the locating dowels.

NOTE: The four M8 cylinder head mounting bolts

require sealant to be added to them before install-

ing. Failure to do so may cause leaks.

(4) Lubricate the cylinder head bolt threads with

clean engine oil and install the eight M10 bolts.

(5) Coat the four M8 cylinder head bolts with

Mopar Lock and Seal Adhesivethen install the

bolts.

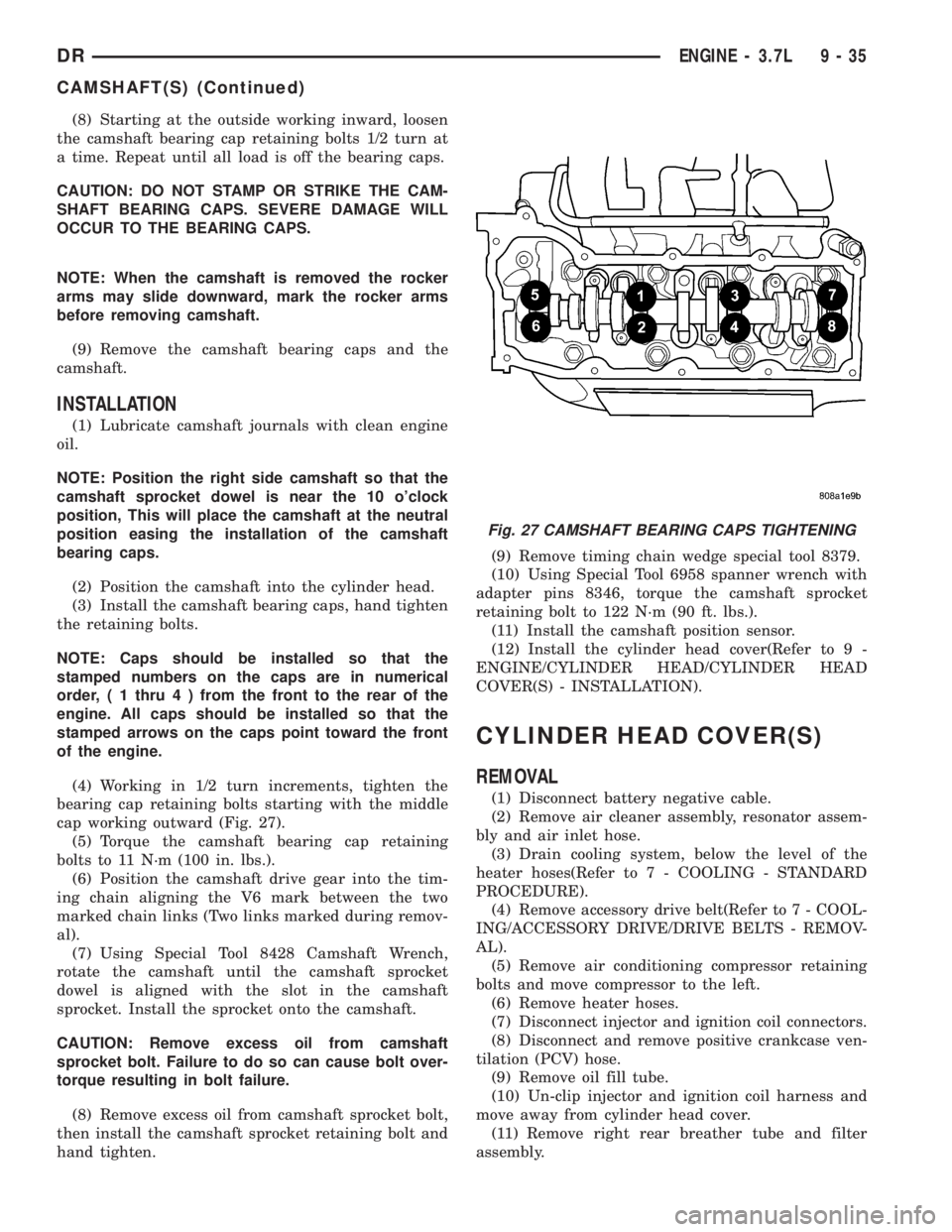

NOTE: The cylinder head bolts are tightened using

an angle torque procedure, however, the bolts are

not a torque-to-yield design.

(6) Tighten the bolts in sequence using the follow-

ing steps and torque values:

²Step 1: Tighten bolts 1±8, 27 N´m (20 ft. lbs.).

²Step 2: Verify that bolts 1±8, all reached 27 N´m

(20 ft. lbs.), by repeating step-1 without loosening the

bolts. Tighten bolts 9 thru 12 to 14 N´m (10 ft. lbs.).

²Step 3: Tighten bolts 1±8, 90 degrees (Fig. 26).

²Step 4: Tighten bolts 1±8, 90 degrees, again.

Tighten bolts 9±12, 26 N´m (19 ft. lbs.)

CAUTION: The nut on the right side camshaft

sprocket should not be removed for any reason, as

the sprocket and camshaft sensor target wheel is

serviced as an assembly. If the nut was removed

retorque nut to 5 ft. lbs.( 60 in. lbs.).

Fig. 24 Checking Cylinder Head Bolts for Stretching

(Necking)

1 - STRETCHED BOLT

2 - THREADS ARE NOT STRAIGHT ON LINE

3 - THREADS ARE STRAIGHT ON LINE

4 - UNSTRETCHED BOLT

Fig. 25 Proper Tool Usage For Surface Preparation

1 - PLASTIC/WOOD SCRAPER

Fig. 26 Cylinder Head Tightening Sequence

* - INDICATES SEALANT ON THREADS

DRENGINE - 3.7L 9 - 33

CYLINDER HEAD - RIGHT (Continued)

Page 1283 of 2895

(7) Position the secondary chain onto the camshaft

drive gear, making sure one marked chain link is on

either side of the V6 mark on the gear then using

Special Tool 8428 Camshaft Wrench, position the

gear onto the camshaft.

CAUTION: Remove excess oil from camshaft

sprocket retaining bolt before reinstalling bolt. Fail-

ure to do so may cause over-torquing of bolt result-

ing in bolt failure.

(8) Install the camshaft drive gear retaining bolt.

(9) Install the right side secondary chain guide(Re-

fer to 9 - ENGINE/VALVE TIMING/TIMING BELT/

CHAIN AND SPROCKETS - INSTALLATION).

(10) Install the cylinder head access plug.

(11) Re-set and install the right side secondary

chain tensioner(Refer to 9 - ENGINE/VALVE TIM-

ING/TIMING BELT/CHAIN AND SPROCKETS -

INSTALLATION).

(12) Remove Special Tool 8429.

(13) Install the timing chain cover(Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(14) Install the crankshaft damper(Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION). Tighten damper bolt 175 N´m (130

Ft. Lbs.).

(15) Install accessory drive belt(Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(16) Install the fan shroud(Refer to 7 - COOLING/

ENGINE/RADIATOR FAN - INSTALLATION).

(17) Install the cylinder head cover(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(18) Install the intake manifold(Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION).

(19) Install oil fill housing onto cylinder head.

(20) Refill the cooling system(Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

(21) Raise the vehicle.

(22) Install the exhaust pipe onto the right

exhaust manifold.

(23) Lower the vehicle.

(24) Reconnect battery negative cable.

(25) Start the engine and check for leaks.

CAMSHAFT(S)

DESCRIPTION

The camshafts consist of powdered metal steel

lobes which are sinter-bonded to a steel tube. Four

bearing journals are machined into the camshaft.

Camshaft end play is controlled by two thrust wallsthat border the nose piece journal. Engine oil enters

the hollow camshafts at the third journal and lubri-

cates every intake lobe rocker through a drilled pas-

sage in the intake lobe.

REMOVAL

CAUTION: When the timing chain is removed and

the cylinder heads are still installed, DO NOT force-

fully rotate the camshafts or crankshaft indepen-

dently of each other. Severe valve and/or piston

damage can occur.

CAUTION: When removing the cam sprocket, timing

chains or camshaft, Failure to use special tool 8379

will result in hydraulic tensioner ratchet over exten-

sion, Requiring timing chain cover removal to re-set

the tensioner ratchet.

(1) Remove the cylinder head cover(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(2) Set engine to TDC cylinder #1, camshaft

sprocket V6 marks at the 12 o'clock position.

(3) Mark one link on the secondary timing chain

on both sides of the V6 mark on the camshaft

sprocket to aid in installation.

CAUTION: Do not hold or pry on the camshaft tar-

get wheel for any reason, Severe damage will occur

to the target wheel. A damaged target wheel could

cause a vehicle no start condition.

(4) Loosen butDO NOTremove the camshaft

sprocket retaining bolt. Leave bolt snug against

sprocket.

NOTE: The timing chain tensioners must be

secured prior to removing the camshaft sprockets.

Failure to secure tensioners will allow the tension-

ers to extend, requiring timing chain cover removal

in order to reset tensioners.

CAUTION: Do not force wedge past the narrowest

point between the chain strands. Damage to the

tensioners may occur.

(5) Position Special Tool 8379 timing chain wedge

between the timing chain strands. Tap the tool to

securely wedge the timing chain against the ten-

sioner arm and guide.

(6) Remove the camshaft position sensor.

(7) Hold the camshaft with Special Tool 8428 Cam-

shaft Wrench, while removing the camshaft sprocket

bolt and sprocket.

9 - 34 ENGINE - 3.7LDR

CYLINDER HEAD - RIGHT (Continued)

Page 1284 of 2895

(8) Starting at the outside working inward, loosen

the camshaft bearing cap retaining bolts 1/2 turn at

a time. Repeat until all load is off the bearing caps.

CAUTION: DO NOT STAMP OR STRIKE THE CAM-

SHAFT BEARING CAPS. SEVERE DAMAGE WILL

OCCUR TO THE BEARING CAPS.

NOTE: When the camshaft is removed the rocker

arms may slide downward, mark the rocker arms

before removing camshaft.

(9) Remove the camshaft bearing caps and the

camshaft.

INSTALLATION

(1) Lubricate camshaft journals with clean engine

oil.

NOTE: Position the right side camshaft so that the

camshaft sprocket dowel is near the 10 o'clock

position, This will place the camshaft at the neutral

position easing the installation of the camshaft

bearing caps.

(2) Position the camshaft into the cylinder head.

(3) Install the camshaft bearing caps, hand tighten

the retaining bolts.

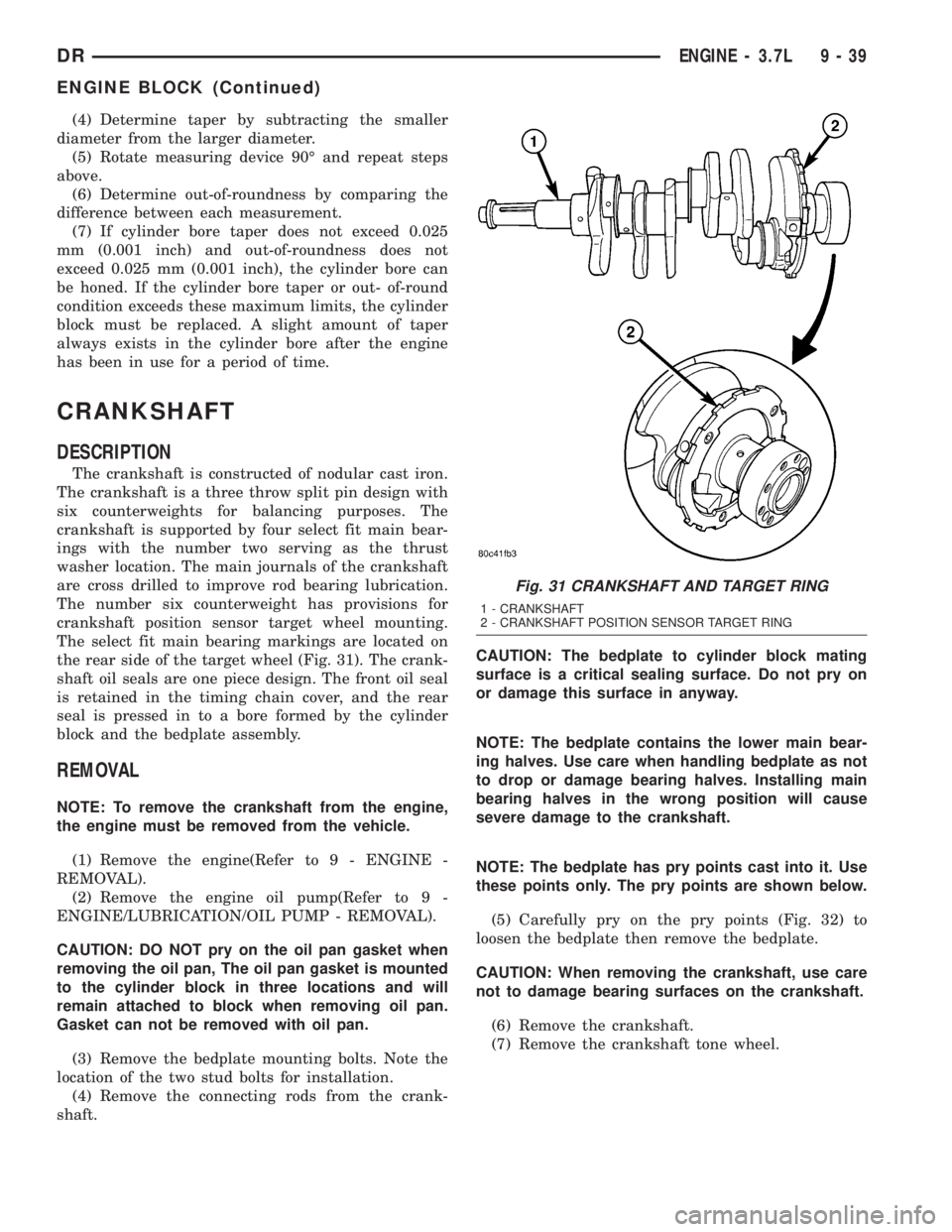

NOTE: Caps should be installed so that the

stamped numbers on the caps are in numerical

order, ( 1 thru 4 ) from the front to the rear of the

engine. All caps should be installed so that the

stamped arrows on the caps point toward the front

of the engine.

(4) Working in 1/2 turn increments, tighten the

bearing cap retaining bolts starting with the middle

cap working outward (Fig. 27).

(5) Torque the camshaft bearing cap retaining

bolts to 11 N´m (100 in. lbs.).

(6) Position the camshaft drive gear into the tim-

ing chain aligning the V6 mark between the two

marked chain links (Two links marked during remov-

al).

(7) Using Special Tool 8428 Camshaft Wrench,

rotate the camshaft until the camshaft sprocket

dowel is aligned with the slot in the camshaft

sprocket. Install the sprocket onto the camshaft.

CAUTION: Remove excess oil from camshaft

sprocket bolt. Failure to do so can cause bolt over-

torque resulting in bolt failure.

(8) Remove excess oil from camshaft sprocket bolt,

then install the camshaft sprocket retaining bolt and

hand tighten.(9) Remove timing chain wedge special tool 8379.

(10) Using Special Tool 6958 spanner wrench with

adapter pins 8346, torque the camshaft sprocket

retaining bolt to 122 N´m (90 ft. lbs.).

(11) Install the camshaft position sensor.

(12) Install the cylinder head cover(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

CYLINDER HEAD COVER(S)

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove air cleaner assembly, resonator assem-

bly and air inlet hose.

(3) Drain cooling system, below the level of the

heater hoses(Refer to 7 - COOLING - STANDARD

PROCEDURE).

(4) Remove accessory drive belt(Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - REMOV-

AL).

(5) Remove air conditioning compressor retaining

bolts and move compressor to the left.

(6) Remove heater hoses.

(7) Disconnect injector and ignition coil connectors.

(8) Disconnect and remove positive crankcase ven-

tilation (PCV) hose.

(9) Remove oil fill tube.

(10) Un-clip injector and ignition coil harness and

move away from cylinder head cover.

(11) Remove right rear breather tube and filter

assembly.

Fig. 27 CAMSHAFT BEARING CAPS TIGHTENING

DRENGINE - 3.7L 9 - 35

CAMSHAFT(S) (Continued)

Page 1288 of 2895

(4) Determine taper by subtracting the smaller

diameter from the larger diameter.

(5) Rotate measuring device 90É and repeat steps

above.

(6) Determine out-of-roundness by comparing the

difference between each measurement.

(7) If cylinder bore taper does not exceed 0.025

mm (0.001 inch) and out-of-roundness does not

exceed 0.025 mm (0.001 inch), the cylinder bore can

be honed. If the cylinder bore taper or out- of-round

condition exceeds these maximum limits, the cylinder

block must be replaced. A slight amount of taper

always exists in the cylinder bore after the engine

has been in use for a period of time.

CRANKSHAFT

DESCRIPTION

The crankshaft is constructed of nodular cast iron.

The crankshaft is a three throw split pin design with

six counterweights for balancing purposes. The

crankshaft is supported by four select fit main bear-

ings with the number two serving as the thrust

washer location. The main journals of the crankshaft

are cross drilled to improve rod bearing lubrication.

The number six counterweight has provisions for

crankshaft position sensor target wheel mounting.

The select fit main bearing markings are located on

the rear side of the target wheel (Fig. 31). The crank-

shaft oil seals are one piece design. The front oil seal

is retained in the timing chain cover, and the rear

seal is pressed in to a bore formed by the cylinder

block and the bedplate assembly.

REMOVAL

NOTE: To remove the crankshaft from the engine,

the engine must be removed from the vehicle.

(1) Remove the engine(Refer to 9 - ENGINE -

REMOVAL).

(2) Remove the engine oil pump(Refer to 9 -

ENGINE/LUBRICATION/OIL PUMP - REMOVAL).

CAUTION: DO NOT pry on the oil pan gasket when

removing the oil pan, The oil pan gasket is mounted

to the cylinder block in three locations and will

remain attached to block when removing oil pan.

Gasket can not be removed with oil pan.

(3) Remove the bedplate mounting bolts. Note the

location of the two stud bolts for installation.

(4) Remove the connecting rods from the crank-

shaft.CAUTION: The bedplate to cylinder block mating

surface is a critical sealing surface. Do not pry on

or damage this surface in anyway.

NOTE: The bedplate contains the lower main bear-

ing halves. Use care when handling bedplate as not

to drop or damage bearing halves. Installing main

bearing halves in the wrong position will cause

severe damage to the crankshaft.

NOTE: The bedplate has pry points cast into it. Use

these points only. The pry points are shown below.

(5) Carefully pry on the pry points (Fig. 32) to

loosen the bedplate then remove the bedplate.

CAUTION: When removing the crankshaft, use care

not to damage bearing surfaces on the crankshaft.

(6) Remove the crankshaft.

(7) Remove the crankshaft tone wheel.

Fig. 31 CRANKSHAFT AND TARGET RING

1 - CRANKSHAFT

2 - CRANKSHAFT POSITION SENSOR TARGET RING

DRENGINE - 3.7L 9 - 39

ENGINE BLOCK (Continued)

Page 1292 of 2895

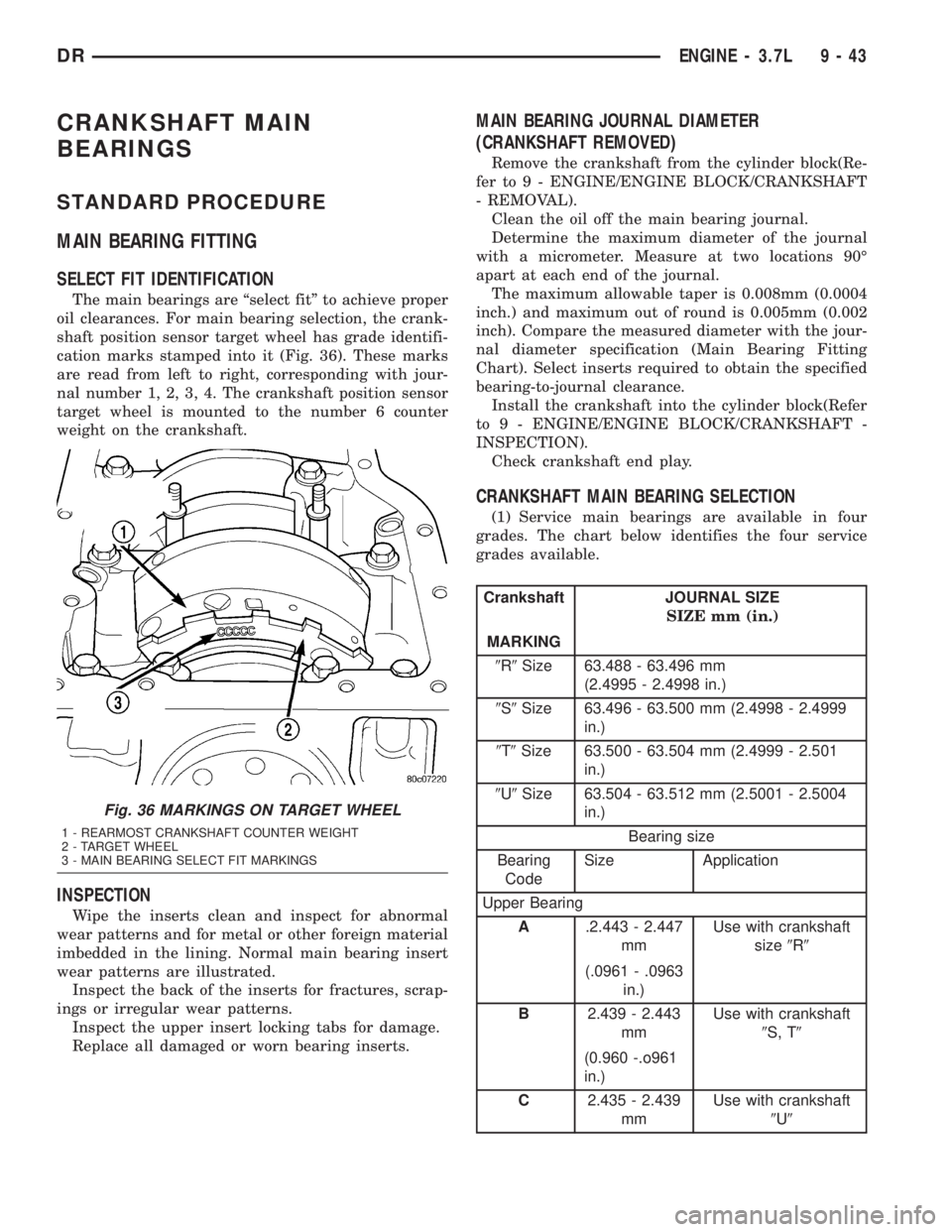

CRANKSHAFT MAIN

BEARINGS

STANDARD PROCEDURE

MAIN BEARING FITTING

SELECT FIT IDENTIFICATION

The main bearings are ªselect fitº to achieve proper

oil clearances. For main bearing selection, the crank-

shaft position sensor target wheel has grade identifi-

cation marks stamped into it (Fig. 36). These marks

are read from left to right, corresponding with jour-

nal number 1, 2, 3, 4. The crankshaft position sensor

target wheel is mounted to the number 6 counter

weight on the crankshaft.

INSPECTION

Wipe the inserts clean and inspect for abnormal

wear patterns and for metal or other foreign material

imbedded in the lining. Normal main bearing insert

wear patterns are illustrated.

Inspect the back of the inserts for fractures, scrap-

ings or irregular wear patterns.

Inspect the upper insert locking tabs for damage.

Replace all damaged or worn bearing inserts.

MAIN BEARING JOURNAL DIAMETER

(CRANKSHAFT REMOVED)

Remove the crankshaft from the cylinder block(Re-

fer to 9 - ENGINE/ENGINE BLOCK/CRANKSHAFT

- REMOVAL).

Clean the oil off the main bearing journal.

Determine the maximum diameter of the journal

with a micrometer. Measure at two locations 90É

apart at each end of the journal.

The maximum allowable taper is 0.008mm (0.0004

inch.) and maximum out of round is 0.005mm (0.002

inch). Compare the measured diameter with the jour-

nal diameter specification (Main Bearing Fitting

Chart). Select inserts required to obtain the specified

bearing-to-journal clearance.

Install the crankshaft into the cylinder block(Refer

to 9 - ENGINE/ENGINE BLOCK/CRANKSHAFT -

INSPECTION).

Check crankshaft end play.

CRANKSHAFT MAIN BEARING SELECTION

(1) Service main bearings are available in four

grades. The chart below identifies the four service

grades available.

Crankshaft JOURNAL SIZE

SIZE mm (in.)

MARKING

9R9Size 63.488 - 63.496 mm

(2.4995 - 2.4998 in.)

9S9Size 63.496 - 63.500 mm (2.4998 - 2.4999

in.)

9T9Size 63.500 - 63.504 mm (2.4999 - 2.501

in.)

9U9Size 63.504 - 63.512 mm (2.5001 - 2.5004

in.)

Bearing size

Bearing

CodeSize Application

Upper Bearing

A.2.443 - 2.447

mmUse with crankshaft

size9R9

(.0961 - .0963

in.)

B2.439 - 2.443

mmUse with crankshaft

9S, T9

(0.960 -.o961

in.)

C2.435 - 2.439

mmUse with crankshaft

9U9

Fig. 36 MARKINGS ON TARGET WHEEL

1 - REARMOST CRANKSHAFT COUNTER WEIGHT

2 - TARGET WHEEL

3 - MAIN BEARING SELECT FIT MARKINGS

DRENGINE - 3.7L 9 - 43

Page 1311 of 2895

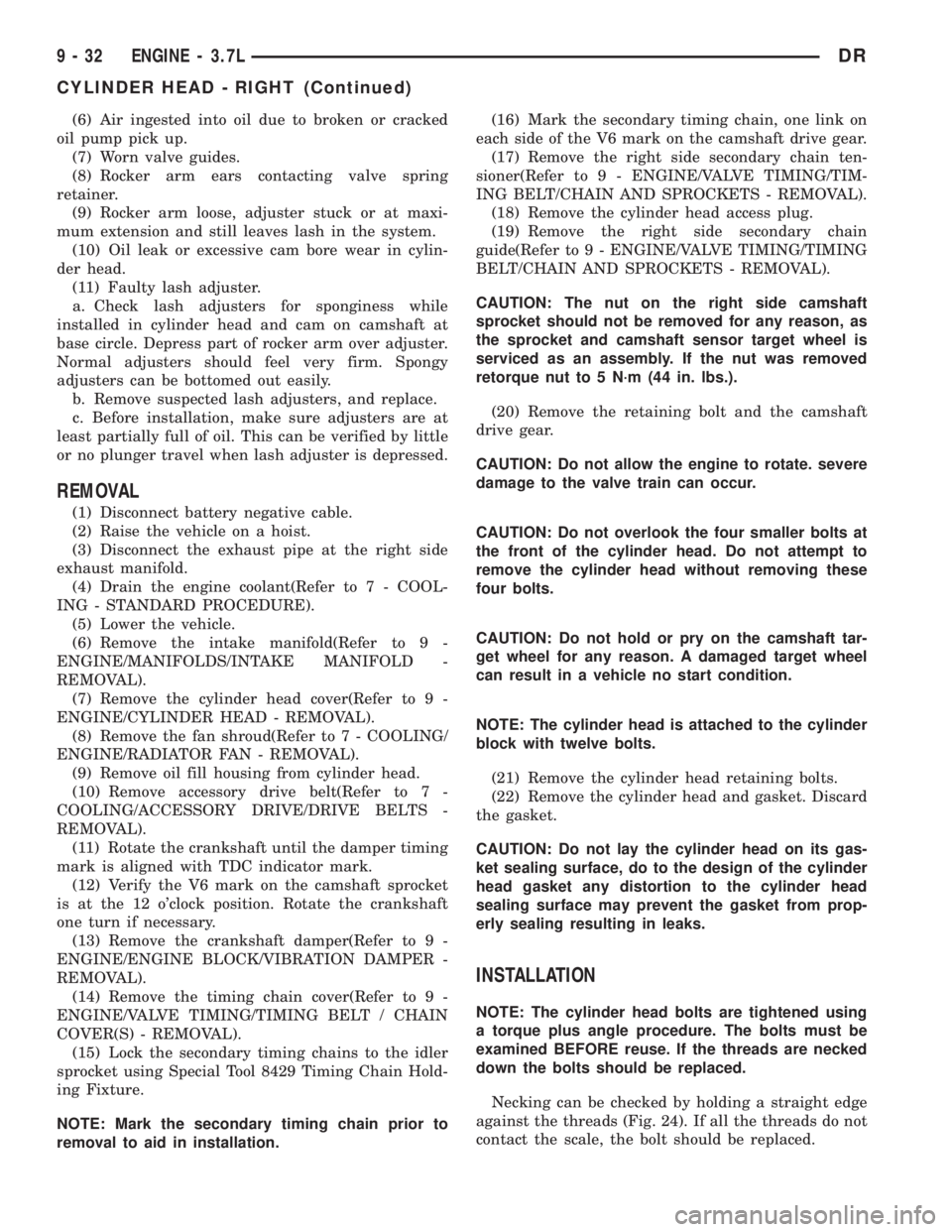

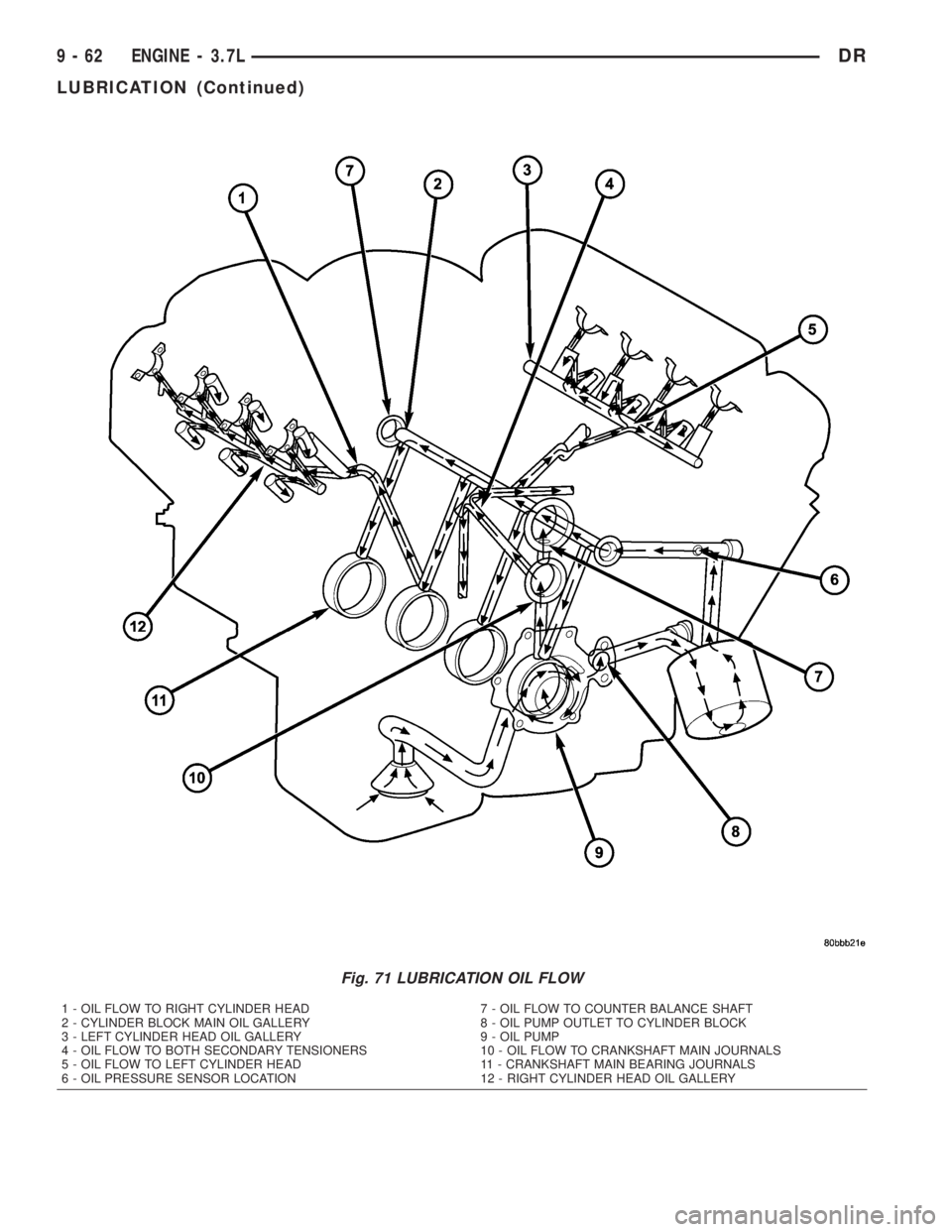

Fig. 71 LUBRICATION OIL FLOW

1 - OIL FLOW TO RIGHT CYLINDER HEAD

2 - CYLINDER BLOCK MAIN OIL GALLERY

3 - LEFT CYLINDER HEAD OIL GALLERY

4 - OIL FLOW TO BOTH SECONDARY TENSIONERS

5 - OIL FLOW TO LEFT CYLINDER HEAD

6 - OIL PRESSURE SENSOR LOCATION7 - OIL FLOW TO COUNTER BALANCE SHAFT

8 - OIL PUMP OUTLET TO CYLINDER BLOCK

9 - OIL PUMP

10 - OIL FLOW TO CRANKSHAFT MAIN JOURNALS

11 - CRANKSHAFT MAIN BEARING JOURNALS

12 - RIGHT CYLINDER HEAD OIL GALLERY

9 - 62 ENGINE - 3.7LDR

LUBRICATION (Continued)