Oil pump DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2055 of 2895

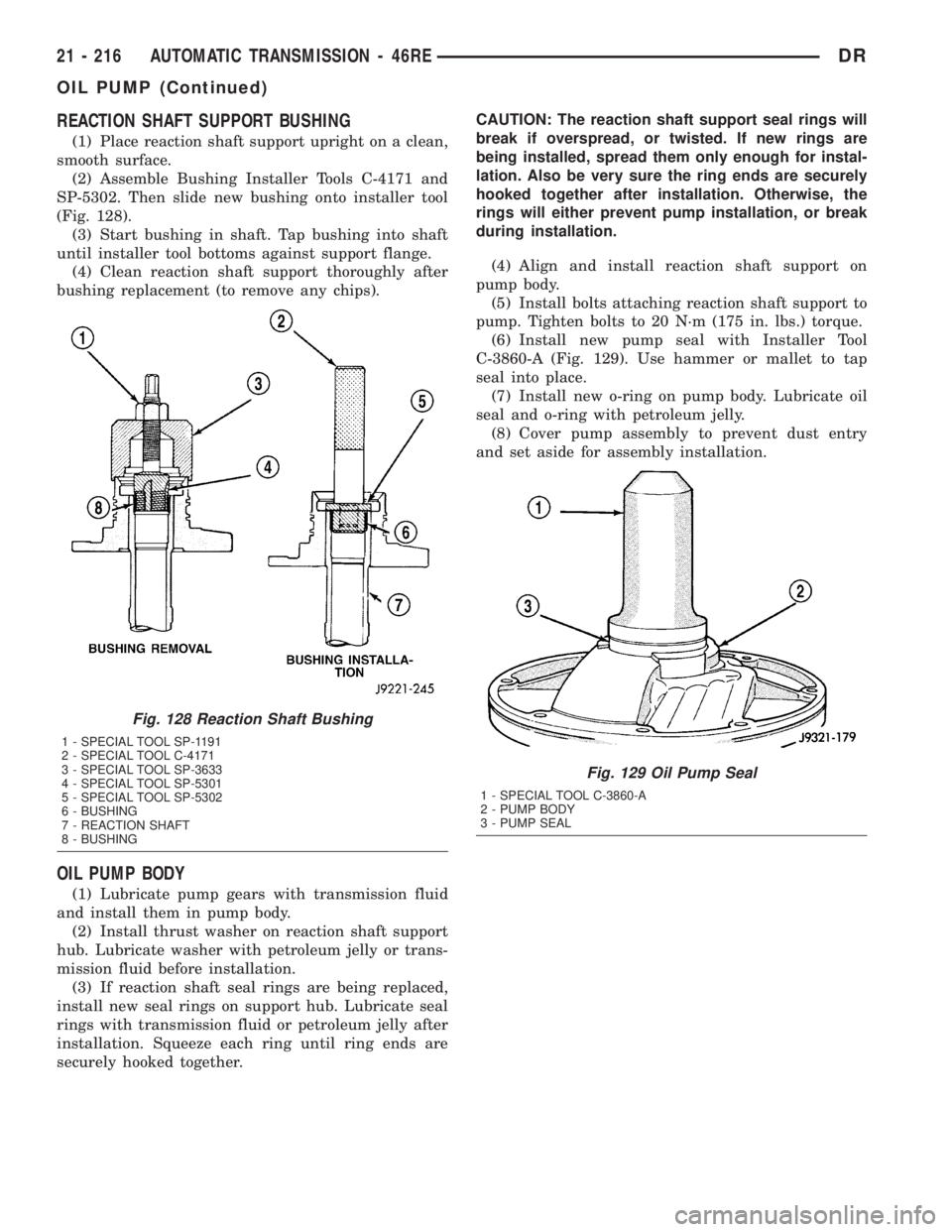

REACTION SHAFT SUPPORT BUSHING

(1) Place reaction shaft support upright on a clean,

smooth surface.

(2) Assemble Bushing Installer Tools C-4171 and

SP-5302. Then slide new bushing onto installer tool

(Fig. 128).

(3) Start bushing in shaft. Tap bushing into shaft

until installer tool bottoms against support flange.

(4) Clean reaction shaft support thoroughly after

bushing replacement (to remove any chips).

OIL PUMP BODY

(1) Lubricate pump gears with transmission fluid

and install them in pump body.

(2) Install thrust washer on reaction shaft support

hub. Lubricate washer with petroleum jelly or trans-

mission fluid before installation.

(3) If reaction shaft seal rings are being replaced,

install new seal rings on support hub. Lubricate seal

rings with transmission fluid or petroleum jelly after

installation. Squeeze each ring until ring ends are

securely hooked together.CAUTION: The reaction shaft support seal rings will

break if overspread, or twisted. If new rings are

being installed, spread them only enough for instal-

lation. Also be very sure the ring ends are securely

hooked together after installation. Otherwise, the

rings will either prevent pump installation, or break

during installation.

(4) Align and install reaction shaft support on

pump body.

(5) Install bolts attaching reaction shaft support to

pump. Tighten bolts to 20 N´m (175 in. lbs.) torque.

(6) Install new pump seal with Installer Tool

C-3860-A (Fig. 129). Use hammer or mallet to tap

seal into place.

(7) Install new o-ring on pump body. Lubricate oil

seal and o-ring with petroleum jelly.

(8) Cover pump assembly to prevent dust entry

and set aside for assembly installation.

Fig. 128 Reaction Shaft Bushing

1 - SPECIAL TOOL SP-1191

2 - SPECIAL TOOL C-4171

3 - SPECIAL TOOL SP-3633

4 - SPECIAL TOOL SP-5301

5 - SPECIAL TOOL SP-5302

6 - BUSHING

7 - REACTION SHAFT

8 - BUSHING

Fig. 129 Oil Pump Seal

1 - SPECIAL TOOL C-3860-A

2 - PUMP BODY

3 - PUMP SEAL

21 - 216 AUTOMATIC TRANSMISSION - 46REDR

OIL PUMP (Continued)

Page 2057 of 2895

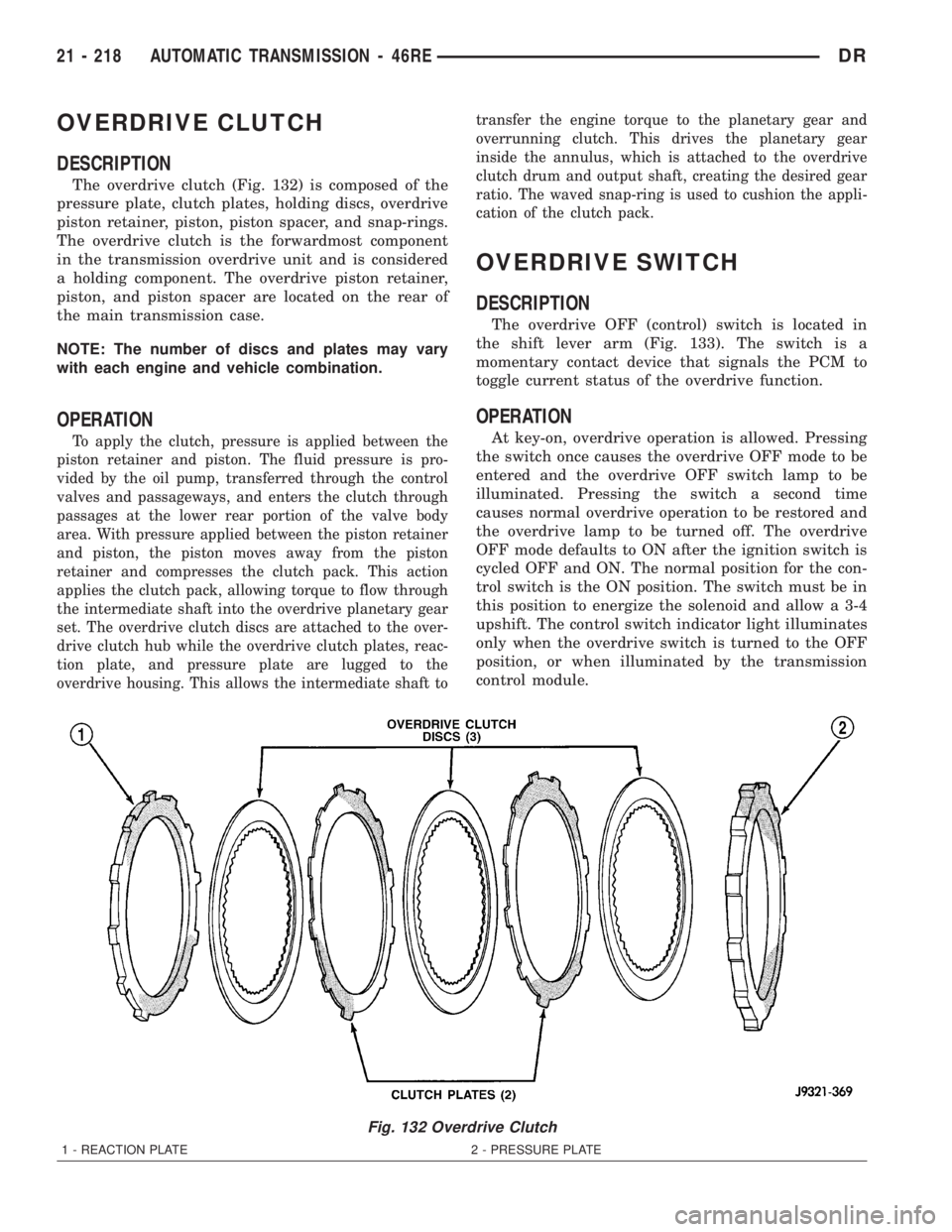

OVERDRIVE CLUTCH

DESCRIPTION

The overdrive clutch (Fig. 132) is composed of the

pressure plate, clutch plates, holding discs, overdrive

piston retainer, piston, piston spacer, and snap-rings.

The overdrive clutch is the forwardmost component

in the transmission overdrive unit and is considered

a holding component. The overdrive piston retainer,

piston, and piston spacer are located on the rear of

the main transmission case.

NOTE: The number of discs and plates may vary

with each engine and vehicle combination.

OPERATION

To apply the clutch, pressure is applied between the

piston retainer and piston. The fluid pressure is pro-

vided by the oil pump, transferred through the control

valves and passageways, and enters the clutch through

passages at the lower rear portion of the valve body

area. With pressure applied between the piston retainer

and piston, the piston moves away from the piston

retainer and compresses the clutch pack. This action

applies the clutch pack, allowing torque to flow through

the intermediate shaft into the overdrive planetary gear

set. The overdrive clutch discs are attached to the over-

drive clutch hub while the overdrive clutch plates, reac-

tion plate, and pressure plate are lugged to the

overdrive housing. This allows the intermediate shaft totransfer the engine torque to the planetary gear and

overrunning clutch. This drives the planetary gear

inside the annulus, which is attached to the overdrive

clutch drum and output shaft, creating the desired gear

ratio. The waved snap-ring is used to cushion the appli-

cation of the clutch pack.

OVERDRIVE SWITCH

DESCRIPTION

The overdrive OFF (control) switch is located in

the shift lever arm (Fig. 133). The switch is a

momentary contact device that signals the PCM to

toggle current status of the overdrive function.

OPERATION

At key-on, overdrive operation is allowed. Pressing

the switch once causes the overdrive OFF mode to be

entered and the overdrive OFF switch lamp to be

illuminated. Pressing the switch a second time

causes normal overdrive operation to be restored and

the overdrive lamp to be turned off. The overdrive

OFF mode defaults to ON after the ignition switch is

cycled OFF and ON. The normal position for the con-

trol switch is the ON position. The switch must be in

this position to energize the solenoid and allow a 3-4

upshift. The control switch indicator light illuminates

only when the overdrive switch is turned to the OFF

position, or when illuminated by the transmission

control module.

Fig. 132 Overdrive Clutch

1 - REACTION PLATE 2 - PRESSURE PLATE

21 - 218 AUTOMATIC TRANSMISSION - 46REDR

Page 2088 of 2895

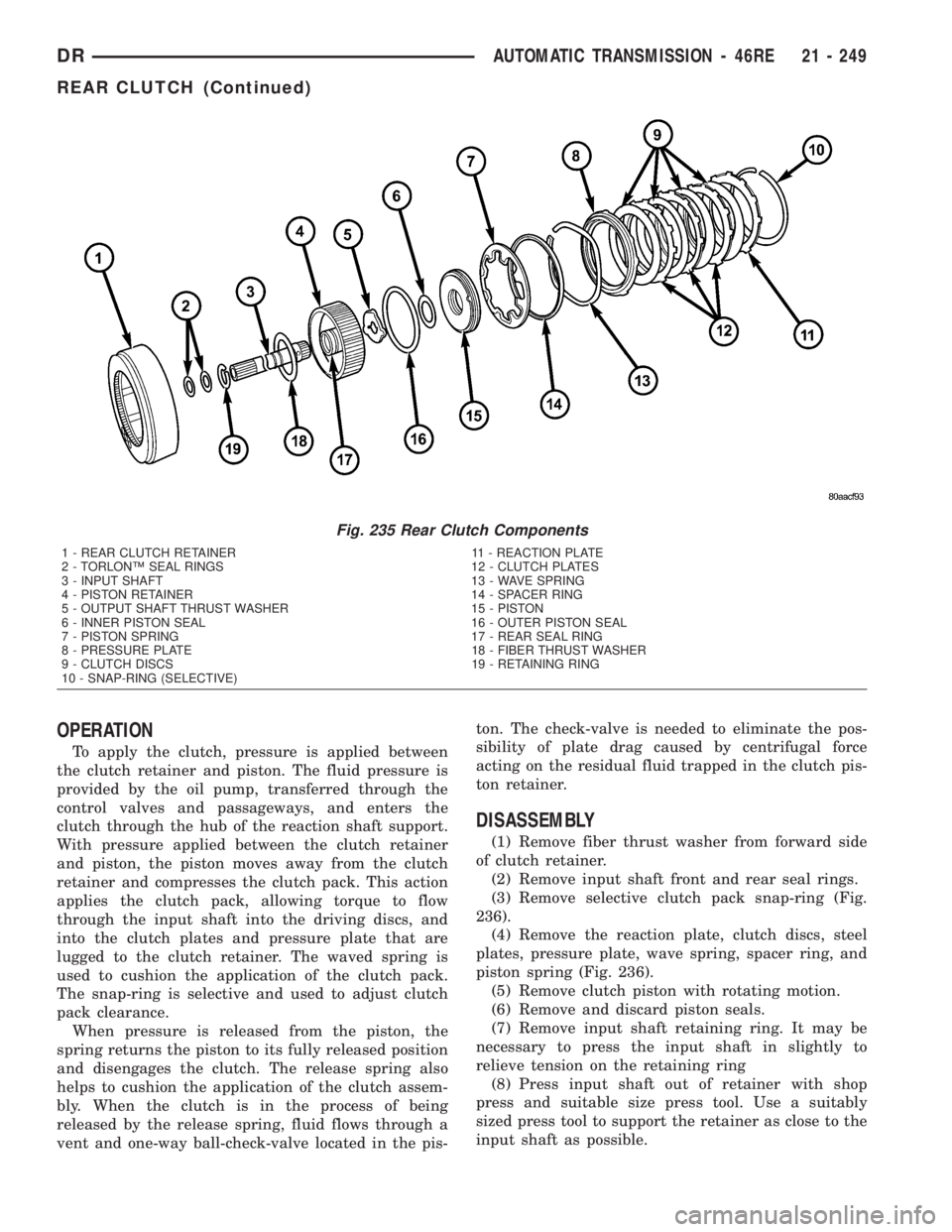

OPERATION

To apply the clutch, pressure is applied between

the clutch retainer and piston. The fluid pressure is

provided by the oil pump, transferred through the

control valves and passageways, and enters the

clutch through the hub of the reaction shaft support.

With pressure applied between the clutch retainer

and piston, the piston moves away from the clutch

retainer and compresses the clutch pack. This action

applies the clutch pack, allowing torque to flow

through the input shaft into the driving discs, and

into the clutch plates and pressure plate that are

lugged to the clutch retainer. The waved spring is

used to cushion the application of the clutch pack.

The snap-ring is selective and used to adjust clutch

pack clearance.

When pressure is released from the piston, the

spring returns the piston to its fully released position

and disengages the clutch. The release spring also

helps to cushion the application of the clutch assem-

bly. When the clutch is in the process of being

released by the release spring, fluid flows through a

vent and one-way ball-check-valve located in the pis-ton. The check-valve is needed to eliminate the pos-

sibility of plate drag caused by centrifugal force

acting on the residual fluid trapped in the clutch pis-

ton retainer.

DISASSEMBLY

(1) Remove fiber thrust washer from forward side

of clutch retainer.

(2) Remove input shaft front and rear seal rings.

(3) Remove selective clutch pack snap-ring (Fig.

236).

(4) Remove the reaction plate, clutch discs, steel

plates, pressure plate, wave spring, spacer ring, and

piston spring (Fig. 236).

(5) Remove clutch piston with rotating motion.

(6) Remove and discard piston seals.

(7) Remove input shaft retaining ring. It may be

necessary to press the input shaft in slightly to

relieve tension on the retaining ring

(8) Press input shaft out of retainer with shop

press and suitable size press tool. Use a suitably

sized press tool to support the retainer as close to the

input shaft as possible.

Fig. 235 Rear Clutch Components

1 - REAR CLUTCH RETAINER 11 - REACTION PLATE

2 - TORLONŸ SEAL RINGS 12 - CLUTCH PLATES

3 - INPUT SHAFT 13 - WAVE SPRING

4 - PISTON RETAINER 14 - SPACER RING

5 - OUTPUT SHAFT THRUST WASHER 15 - PISTON

6 - INNER PISTON SEAL 16 - OUTER PISTON SEAL

7 - PISTON SPRING 17 - REAR SEAL RING

8 - PRESSURE PLATE 18 - FIBER THRUST WASHER

9 - CLUTCH DISCS 19 - RETAINING RING

10 - SNAP-RING (SELECTIVE)

DRAUTOMATIC TRANSMISSION - 46RE 21 - 249

REAR CLUTCH (Continued)

Page 2096 of 2895

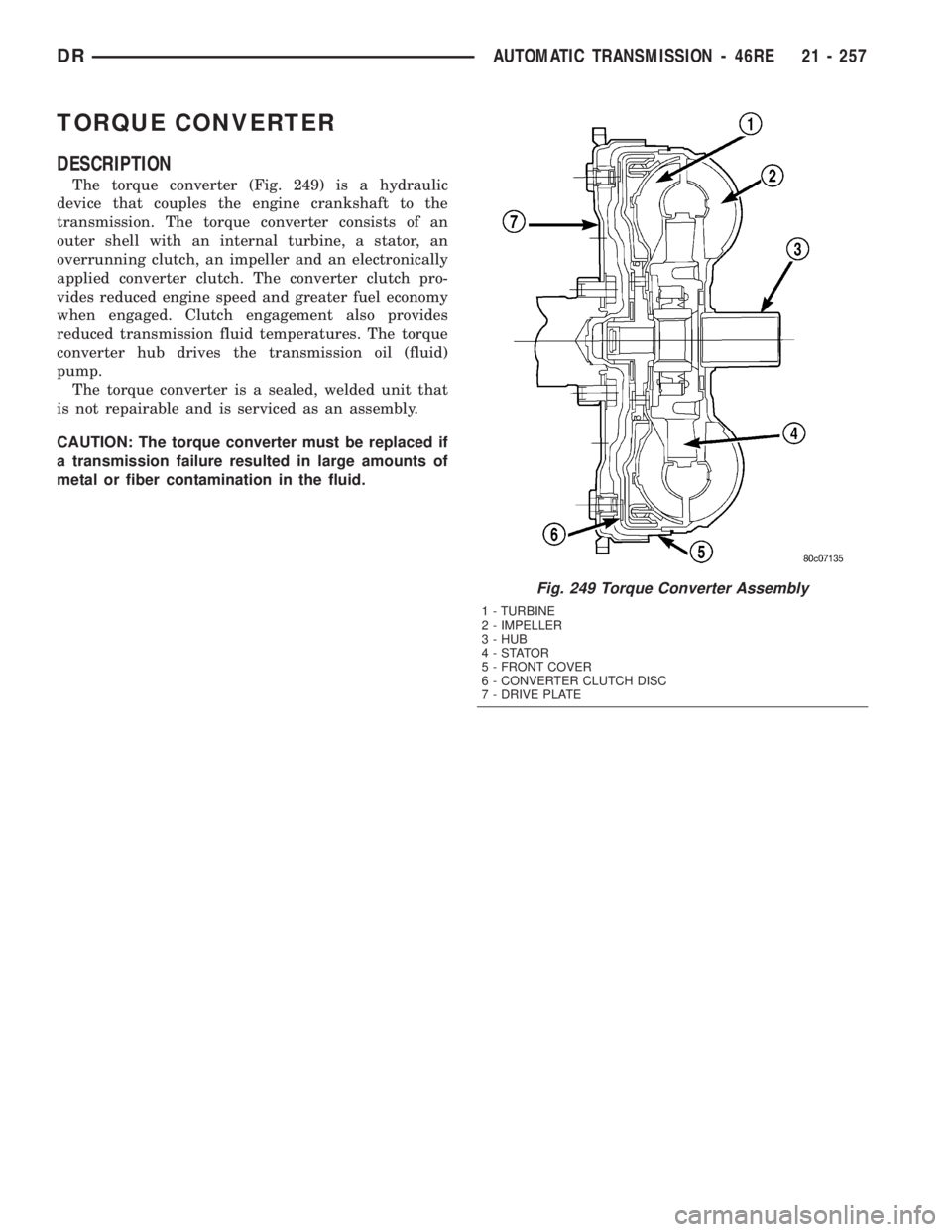

TORQUE CONVERTER

DESCRIPTION

The torque converter (Fig. 249) is a hydraulic

device that couples the engine crankshaft to the

transmission. The torque converter consists of an

outer shell with an internal turbine, a stator, an

overrunning clutch, an impeller and an electronically

applied converter clutch. The converter clutch pro-

vides reduced engine speed and greater fuel economy

when engaged. Clutch engagement also provides

reduced transmission fluid temperatures. The torque

converter hub drives the transmission oil (fluid)

pump.

The torque converter is a sealed, welded unit that

is not repairable and is serviced as an assembly.

CAUTION: The torque converter must be replaced if

a transmission failure resulted in large amounts of

metal or fiber contamination in the fluid.

Fig. 249 Torque Converter Assembly

1 - TURBINE

2 - IMPELLER

3 - HUB

4-STATOR

5 - FRONT COVER

6 - CONVERTER CLUTCH DISC

7 - DRIVE PLATE

DRAUTOMATIC TRANSMISSION - 46RE 21 - 257

Page 2099 of 2895

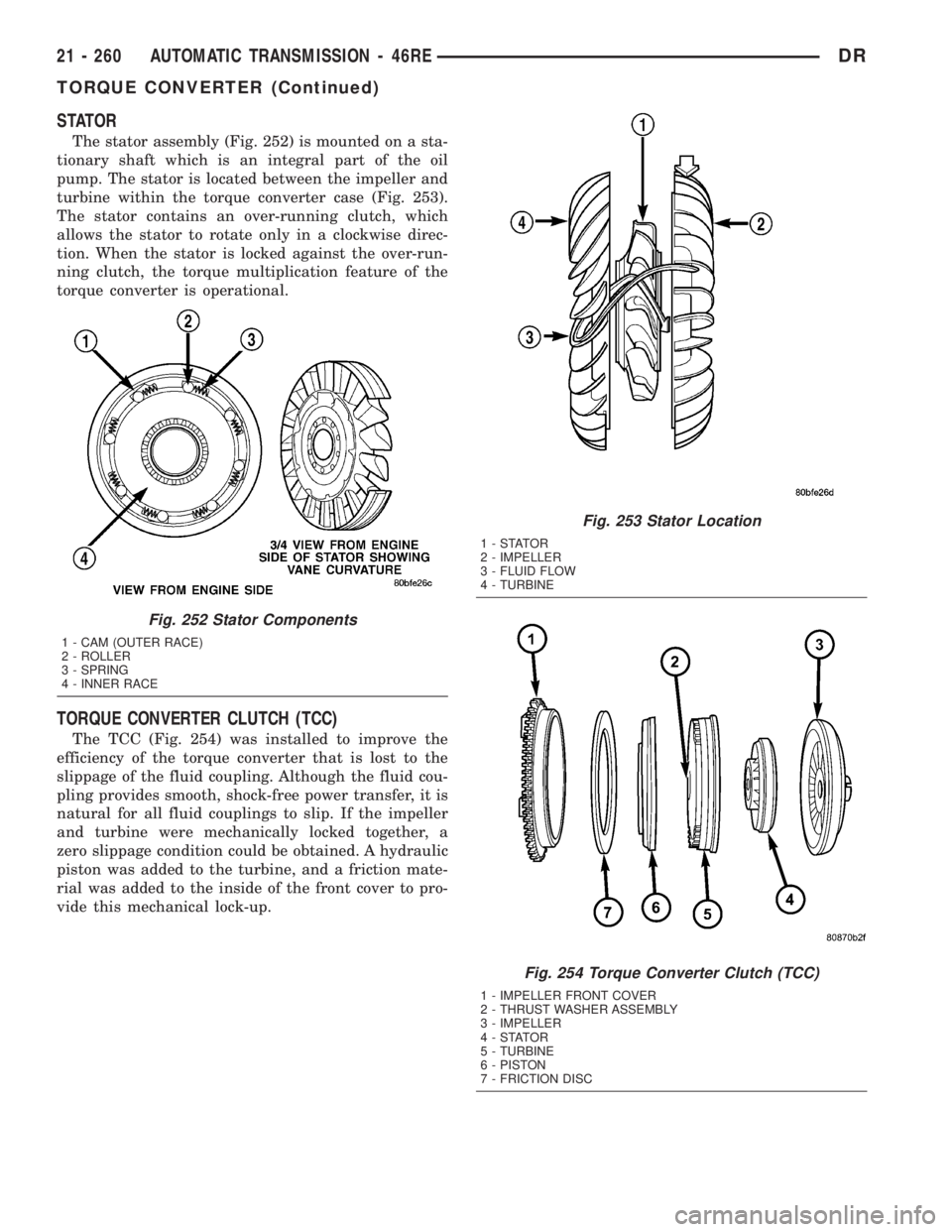

STATOR

The stator assembly (Fig. 252) is mounted on a sta-

tionary shaft which is an integral part of the oil

pump. The stator is located between the impeller and

turbine within the torque converter case (Fig. 253).

The stator contains an over-running clutch, which

allows the stator to rotate only in a clockwise direc-

tion. When the stator is locked against the over-run-

ning clutch, the torque multiplication feature of the

torque converter is operational.

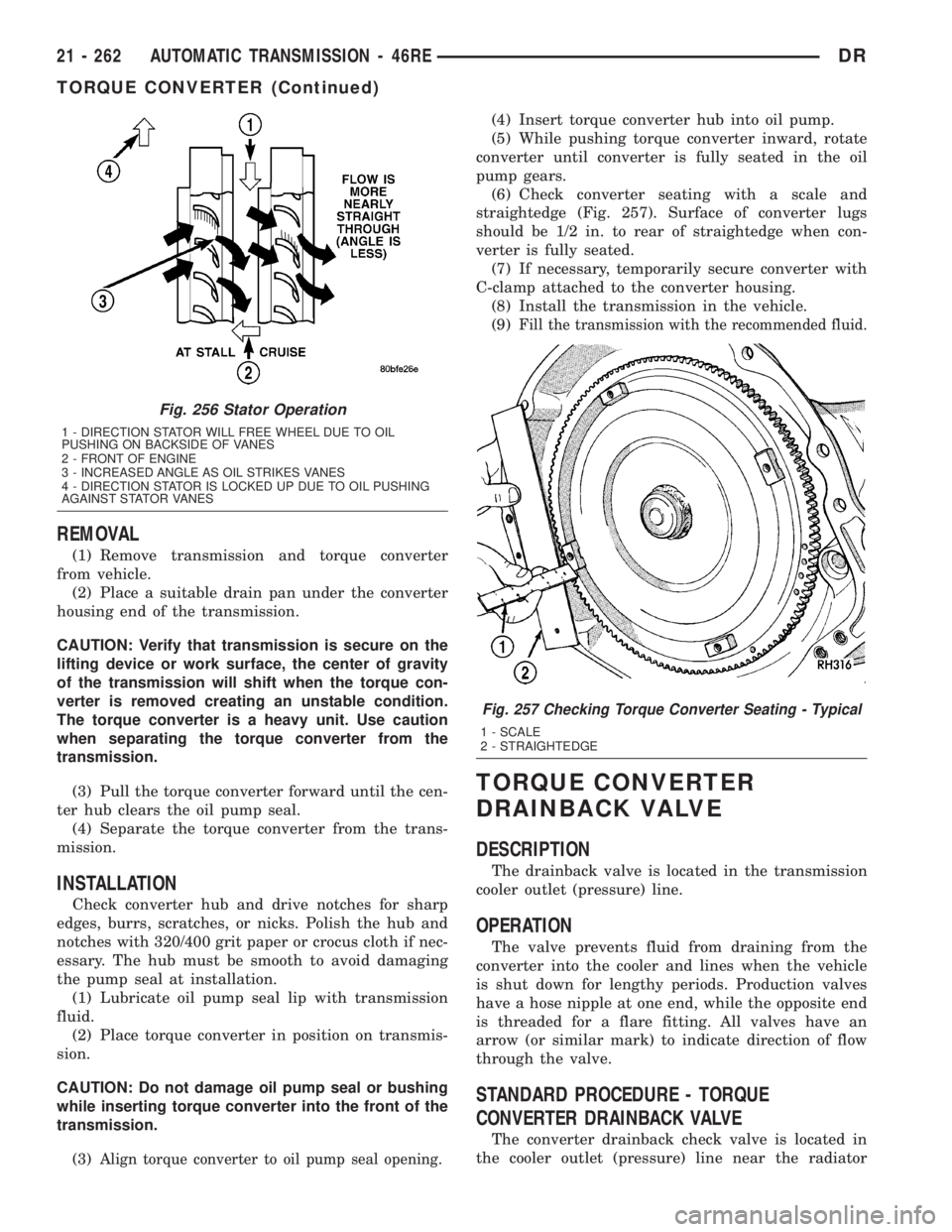

TORQUE CONVERTER CLUTCH (TCC)

The TCC (Fig. 254) was installed to improve the

efficiency of the torque converter that is lost to the

slippage of the fluid coupling. Although the fluid cou-

pling provides smooth, shock-free power transfer, it is

natural for all fluid couplings to slip. If the impeller

and turbine were mechanically locked together, a

zero slippage condition could be obtained. A hydraulic

piston was added to the turbine, and a friction mate-

rial was added to the inside of the front cover to pro-

vide this mechanical lock-up.

Fig. 252 Stator Components

1 - CAM (OUTER RACE)

2 - ROLLER

3 - SPRING

4 - INNER RACE

Fig. 253 Stator Location

1-STATOR

2 - IMPELLER

3 - FLUID FLOW

4 - TURBINE

Fig. 254 Torque Converter Clutch (TCC)

1 - IMPELLER FRONT COVER

2 - THRUST WASHER ASSEMBLY

3 - IMPELLER

4-STATOR

5 - TURBINE

6 - PISTON

7 - FRICTION DISC

21 - 260 AUTOMATIC TRANSMISSION - 46REDR

TORQUE CONVERTER (Continued)

Page 2101 of 2895

REMOVAL

(1) Remove transmission and torque converter

from vehicle.

(2) Place a suitable drain pan under the converter

housing end of the transmission.

CAUTION: Verify that transmission is secure on the

lifting device or work surface, the center of gravity

of the transmission will shift when the torque con-

verter is removed creating an unstable condition.

The torque converter is a heavy unit. Use caution

when separating the torque converter from the

transmission.

(3) Pull the torque converter forward until the cen-

ter hub clears the oil pump seal.

(4) Separate the torque converter from the trans-

mission.

INSTALLATION

Check converter hub and drive notches for sharp

edges, burrs, scratches, or nicks. Polish the hub and

notches with 320/400 grit paper or crocus cloth if nec-

essary. The hub must be smooth to avoid damaging

the pump seal at installation.

(1) Lubricate oil pump seal lip with transmission

fluid.

(2) Place torque converter in position on transmis-

sion.

CAUTION: Do not damage oil pump seal or bushing

while inserting torque converter into the front of the

transmission.

(3)

Align torque converter to oil pump seal opening.

(4) Insert torque converter hub into oil pump.

(5) While pushing torque converter inward, rotate

converter until converter is fully seated in the oil

pump gears.

(6) Check converter seating with a scale and

straightedge (Fig. 257). Surface of converter lugs

should be 1/2 in. to rear of straightedge when con-

verter is fully seated.

(7) If necessary, temporarily secure converter with

C-clamp attached to the converter housing.

(8) Install the transmission in the vehicle.

(9)

Fill the transmission with the recommended fluid.

TORQUE CONVERTER

DRAINBACK VALVE

DESCRIPTION

The drainback valve is located in the transmission

cooler outlet (pressure) line.

OPERATION

The valve prevents fluid from draining from the

converter into the cooler and lines when the vehicle

is shut down for lengthy periods. Production valves

have a hose nipple at one end, while the opposite end

is threaded for a flare fitting. All valves have an

arrow (or similar mark) to indicate direction of flow

through the valve.

STANDARD PROCEDURE - TORQUE

CONVERTER DRAINBACK VALVE

The converter drainback check valve is located in

the cooler outlet (pressure) line near the radiator

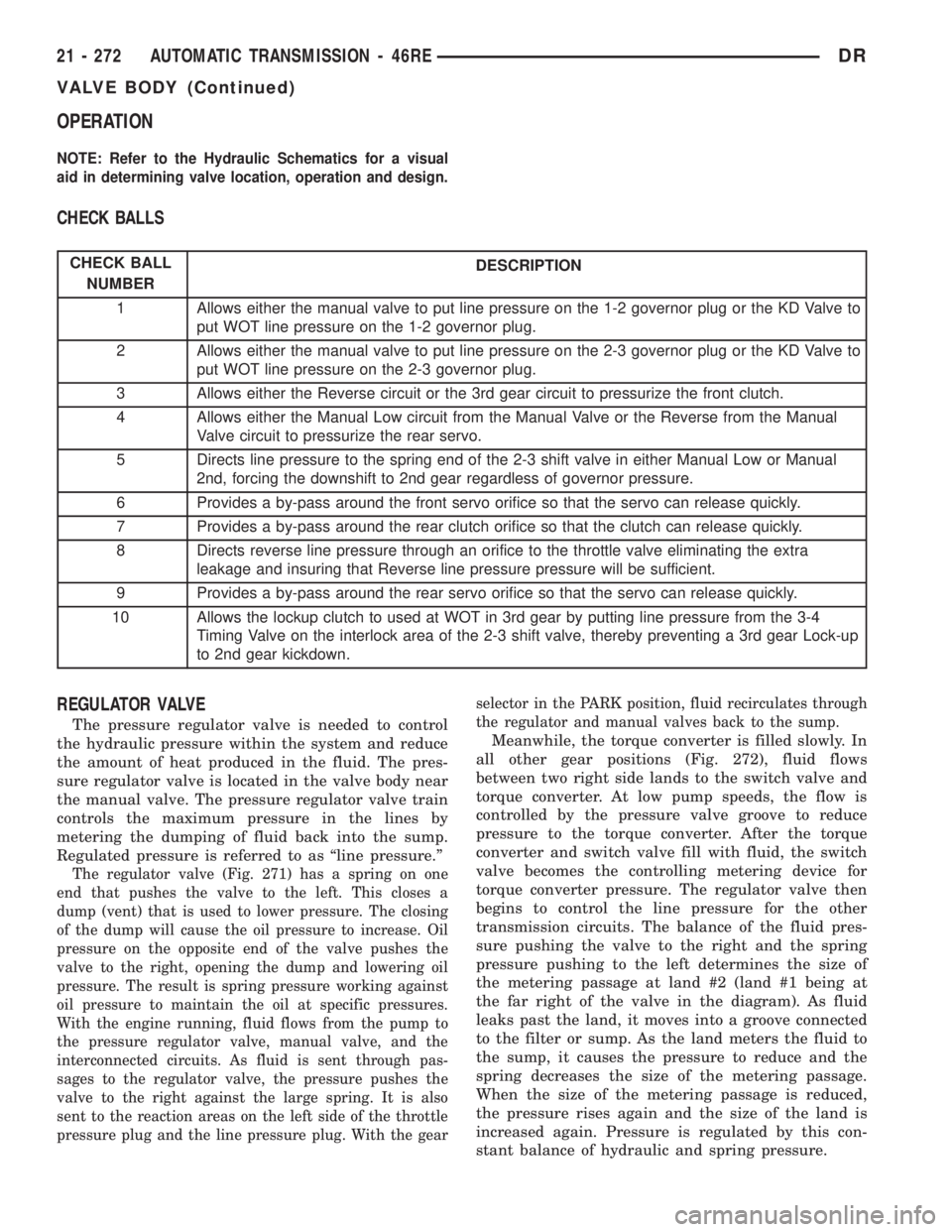

Fig. 256 Stator Operation

1 - DIRECTION STATOR WILL FREE WHEEL DUE TO OIL

PUSHING ON BACKSIDE OF VANES

2 - FRONT OF ENGINE

3 - INCREASED ANGLE AS OIL STRIKES VANES

4 - DIRECTION STATOR IS LOCKED UP DUE TO OIL PUSHING

AGAINST STATOR VANES

Fig. 257 Checking Torque Converter Seating - Typical

1 - SCALE

2 - STRAIGHTEDGE

21 - 262 AUTOMATIC TRANSMISSION - 46REDR

TORQUE CONVERTER (Continued)

Page 2111 of 2895

OPERATION

NOTE: Refer to the Hydraulic Schematics for a visual

aid in determining valve location, operation and design.

CHECK BALLS

CHECK BALL

NUMBERDESCRIPTION

1 Allows either the manual valve to put line pressure on the 1-2 governor plug or the KD Valve to

put WOT line pressure on the 1-2 governor plug.

2 Allows either the manual valve to put line pressure on the 2-3 governor plug or the KD Valve to

put WOT line pressure on the 2-3 governor plug.

3 Allows either the Reverse circuit or the 3rd gear circuit to pressurize the front clutch.

4 Allows either the Manual Low circuit from the Manual Valve or the Reverse from the Manual

Valve circuit to pressurize the rear servo.

5 Directs line pressure to the spring end of the 2-3 shift valve in either Manual Low or Manual

2nd, forcing the downshift to 2nd gear regardless of governor pressure.

6 Provides a by-pass around the front servo orifice so that the servo can release quickly.

7 Provides a by-pass around the rear clutch orifice so that the clutch can release quickly.

8 Directs reverse line pressure through an orifice to the throttle valve eliminating the extra

leakage and insuring that Reverse line pressure pressure will be sufficient.

9 Provides a by-pass around the rear servo orifice so that the servo can release quickly.

10 Allows the lockup clutch to used at WOT in 3rd gear by putting line pressure from the 3-4

Timing Valve on the interlock area of the 2-3 shift valve, thereby preventing a 3rd gear Lock-up

to 2nd gear kickdown.

REGULATOR VALVE

The pressure regulator valve is needed to control

the hydraulic pressure within the system and reduce

the amount of heat produced in the fluid. The pres-

sure regulator valve is located in the valve body near

the manual valve. The pressure regulator valve train

controls the maximum pressure in the lines by

metering the dumping of fluid back into the sump.

Regulated pressure is referred to as ªline pressure.º

The regulator valve (Fig. 271) has a spring on one

end that pushes the valve to the left. This closes a

dump (vent) that is used to lower pressure. The closing

of the dump will cause the oil pressure to increase. Oil

pressure on the opposite end of the valve pushes the

valve to the right, opening the dump and lowering oil

pressure. The result is spring pressure working against

oil pressure to maintain the oil at specific pressures.

With the engine running, fluid flows from the pump to

the pressure regulator valve, manual valve, and the

interconnected circuits. As fluid is sent through pas-

sages to the regulator valve, the pressure pushes the

valve to the right against the large spring. It is also

sent to the reaction areas on the left side of the throttle

pressure plug and the line pressure plug. With the gearselector in the PARK position, fluid recirculates through

the regulator and manual valves back to the sump.

Meanwhile, the torque converter is filled slowly. In

all other gear positions (Fig. 272), fluid flows

between two right side lands to the switch valve and

torque converter. At low pump speeds, the flow is

controlled by the pressure valve groove to reduce

pressure to the torque converter. After the torque

converter and switch valve fill with fluid, the switch

valve becomes the controlling metering device for

torque converter pressure. The regulator valve then

begins to control the line pressure for the other

transmission circuits. The balance of the fluid pres-

sure pushing the valve to the right and the spring

pressure pushing to the left determines the size of

the metering passage at land #2 (land #1 being at

the far right of the valve in the diagram). As fluid

leaks past the land, it moves into a groove connected

to the filter or sump. As the land meters the fluid to

the sump, it causes the pressure to reduce and the

spring decreases the size of the metering passage.

When the size of the metering passage is reduced,

the pressure rises again and the size of the land is

increased again. Pressure is regulated by this con-

stant balance of hydraulic and spring pressure.

21 - 272 AUTOMATIC TRANSMISSION - 46REDR

VALVE BODY (Continued)

Page 2149 of 2895

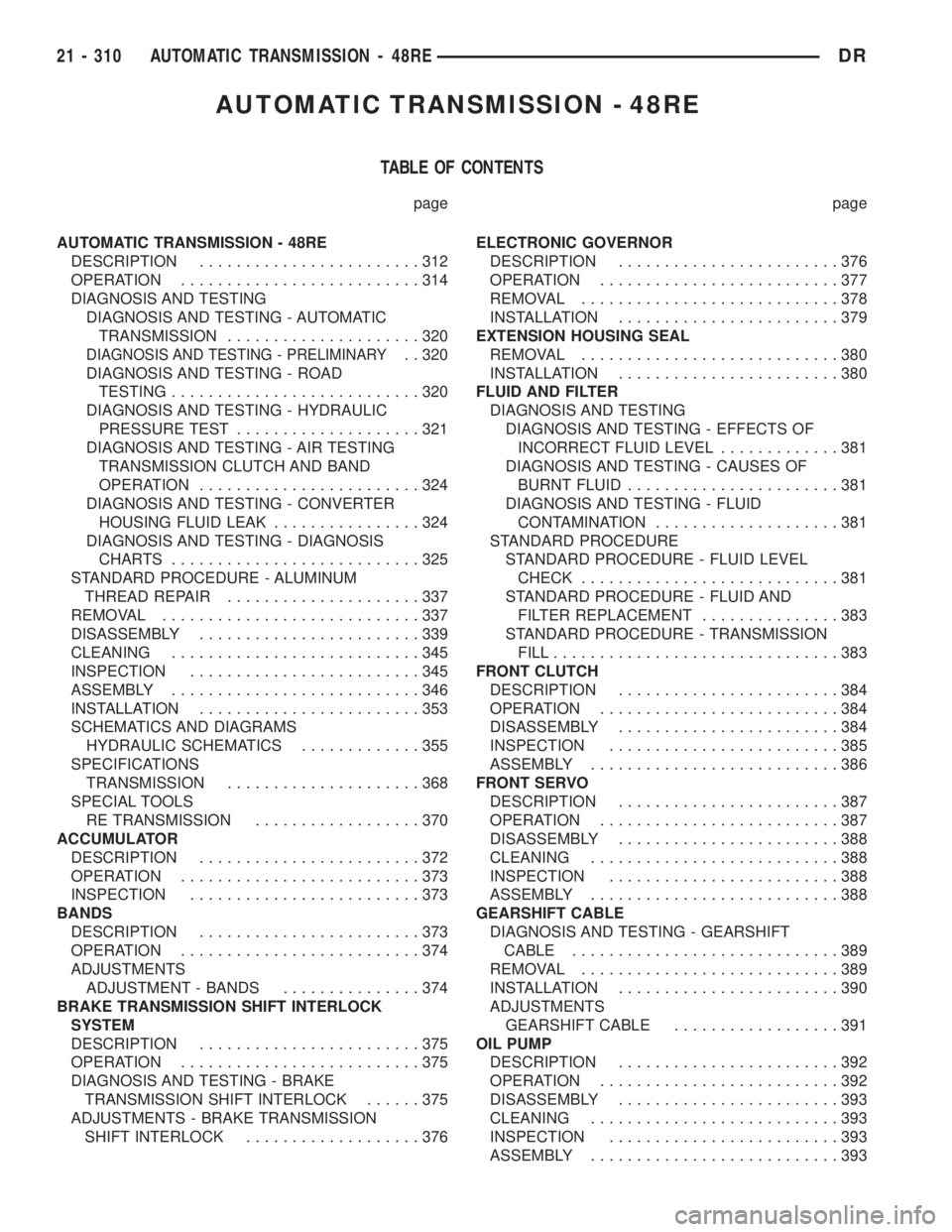

AUTOMATIC TRANSMISSION - 48RE

TABLE OF CONTENTS

page page

AUTOMATIC TRANSMISSION - 48RE

DESCRIPTION........................312

OPERATION..........................314

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AUTOMATIC

TRANSMISSION.....................320

DIAGNOSIS AND TESTING - PRELIMINARY. . 320

DIAGNOSIS AND TESTING - ROAD

TESTING...........................320

DIAGNOSIS AND TESTING - HYDRAULIC

PRESSURE TEST....................321

DIAGNOSIS AND TESTING - AIR TESTING

TRANSMISSION CLUTCH AND BAND

OPERATION........................324

DIAGNOSIS AND TESTING - CONVERTER

HOUSING FLUID LEAK................324

DIAGNOSIS AND TESTING - DIAGNOSIS

CHARTS...........................325

STANDARD PROCEDURE - ALUMINUM

THREAD REPAIR.....................337

REMOVAL............................337

DISASSEMBLY........................339

CLEANING...........................345

INSPECTION.........................345

ASSEMBLY...........................346

INSTALLATION........................353

SCHEMATICS AND DIAGRAMS

HYDRAULIC SCHEMATICS.............355

SPECIFICATIONS

TRANSMISSION.....................368

SPECIAL TOOLS

RE TRANSMISSION..................370

ACCUMULATOR

DESCRIPTION........................372

OPERATION..........................373

INSPECTION.........................373

BANDS

DESCRIPTION........................373

OPERATION..........................374

ADJUSTMENTS

ADJUSTMENT - BANDS...............374

BRAKE TRANSMISSION SHIFT INTERLOCK

SYSTEM

DESCRIPTION........................375

OPERATION..........................375

DIAGNOSIS AND TESTING - BRAKE

TRANSMISSION SHIFT INTERLOCK......375

ADJUSTMENTS - BRAKE TRANSMISSION

SHIFT INTERLOCK...................376ELECTRONIC GOVERNOR

DESCRIPTION........................376

OPERATION..........................377

REMOVAL............................378

INSTALLATION........................379

EXTENSION HOUSING SEAL

REMOVAL............................380

INSTALLATION........................380

FLUID AND FILTER

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - EFFECTS OF

INCORRECT FLUID LEVEL.............381

DIAGNOSIS AND TESTING - CAUSES OF

BURNT FLUID.......................381

DIAGNOSIS AND TESTING - FLUID

CONTAMINATION....................381

STANDARD PROCEDURE

STANDARD PROCEDURE - FLUID LEVEL

CHECK............................381

STANDARD PROCEDURE - FLUID AND

FILTER REPLACEMENT...............383

STANDARD PROCEDURE - TRANSMISSION

FILL...............................383

FRONT CLUTCH

DESCRIPTION........................384

OPERATION..........................384

DISASSEMBLY........................384

INSPECTION.........................385

ASSEMBLY...........................386

FRONT SERVO

DESCRIPTION........................387

OPERATION..........................387

DISASSEMBLY........................388

CLEANING...........................388

INSPECTION.........................388

ASSEMBLY...........................388

GEARSHIFT CABLE

DIAGNOSIS AND TESTING - GEARSHIFT

CABLE.............................389

REMOVAL............................389

INSTALLATION........................390

ADJUSTMENTS

GEARSHIFT CABLE..................391

OIL PUMP

DESCRIPTION........................392

OPERATION..........................392

DISASSEMBLY........................393

CLEANING...........................393

INSPECTION.........................393

ASSEMBLY...........................393

21 - 310 AUTOMATIC TRANSMISSION - 48REDR

Page 2151 of 2895

AUTOMATIC TRANSMISSION -

48RE

DESCRIPTION

The 48RE (Fig. 1) is a four speed fully automatic

transmission with an electronic governor. The 48RE

is equipped with a lock-up clutch in the torque con-

verter. First through third gear ranges are provided

by the clutches, bands, overrunning clutch, and plan-

etary gear sets in the transmission. Fourth gear

range is provided by the overdrive unit that contains

an overdrive clutch, direct clutch, planetary gear set,

and overrunning clutch.

The transmission contains a front, rear, and direct

clutch which function as the input driving compo-

nents. It also contains the kickdown (front) and thelow/reverse (rear) bands which, along with the over-

running clutch and overdrive clutch, serve as the

holding components. The driving and holding compo-

nents combine to select the necessary planetary gear

components, in the front, rear, or overdrive planetary

gear set, transfer the engine power from the input

shaft through to the output shaft.

The valve body is mounted to the lower side of the

transmission and contains the valves to control pres-

sure regulation, fluid flow control, and clutch/band

application. The oil pump is mounted at the front of

the transmission and is driven by the torque con-

verter hub. The pump supplies the oil pressure nec-

essary for clutch/band actuation and transmission

lubrication.

21 - 312 AUTOMATIC TRANSMISSION - 48REDR

Page 2153 of 2895

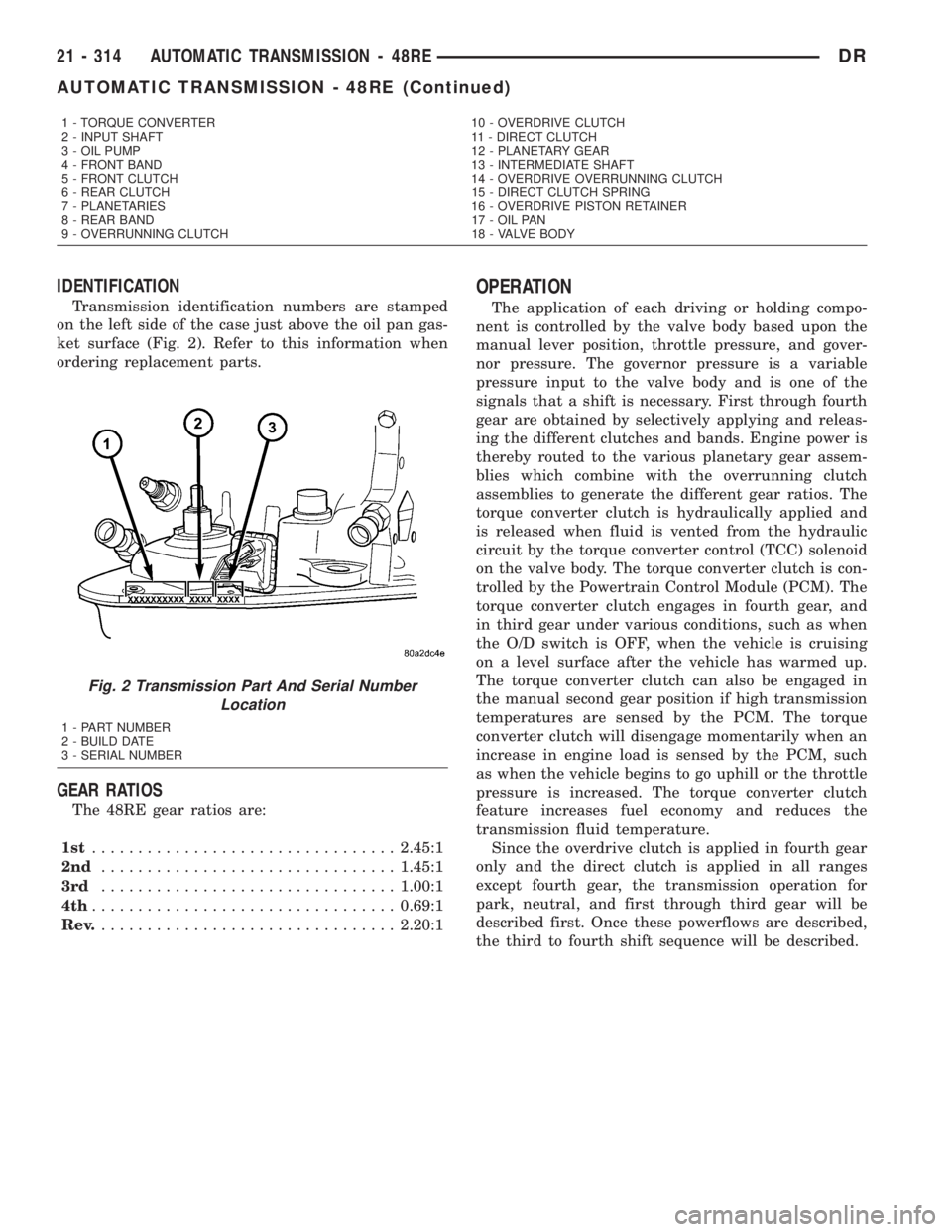

IDENTIFICATION

Transmission identification numbers are stamped

on the left side of the case just above the oil pan gas-

ket surface (Fig. 2). Refer to this information when

ordering replacement parts.

GEAR RATIOS

The 48RE gear ratios are:

1st.................................2.45:1

2nd................................1.45:1

3rd................................1.00:1

4th.................................0.69:1

Rev.................................2.20:1

OPERATION

The application of each driving or holding compo-

nent is controlled by the valve body based upon the

manual lever position, throttle pressure, and gover-

nor pressure. The governor pressure is a variable

pressure input to the valve body and is one of the

signals that a shift is necessary. First through fourth

gear are obtained by selectively applying and releas-

ing the different clutches and bands. Engine power is

thereby routed to the various planetary gear assem-

blies which combine with the overrunning clutch

assemblies to generate the different gear ratios. The

torque converter clutch is hydraulically applied and

is released when fluid is vented from the hydraulic

circuit by the torque converter control (TCC) solenoid

on the valve body. The torque converter clutch is con-

trolled by the Powertrain Control Module (PCM). The

torque converter clutch engages in fourth gear, and

in third gear under various conditions, such as when

the O/D switch is OFF, when the vehicle is cruising

on a level surface after the vehicle has warmed up.

The torque converter clutch can also be engaged in

the manual second gear position if high transmission

temperatures are sensed by the PCM. The torque

converter clutch will disengage momentarily when an

increase in engine load is sensed by the PCM, such

as when the vehicle begins to go uphill or the throttle

pressure is increased. The torque converter clutch

feature increases fuel economy and reduces the

transmission fluid temperature.

Since the overdrive clutch is applied in fourth gear

only and the direct clutch is applied in all ranges

except fourth gear, the transmission operation for

park, neutral, and first through third gear will be

described first. Once these powerflows are described,

the third to fourth shift sequence will be described.

1 - TORQUE CONVERTER 10 - OVERDRIVE CLUTCH

2 - INPUT SHAFT 11 - DIRECT CLUTCH

3 - OIL PUMP 12 - PLANETARY GEAR

4 - FRONT BAND 13 - INTERMEDIATE SHAFT

5 - FRONT CLUTCH 14 - OVERDRIVE OVERRUNNING CLUTCH

6 - REAR CLUTCH 15 - DIRECT CLUTCH SPRING

7 - PLANETARIES 16 - OVERDRIVE PISTON RETAINER

8 - REAR BAND 17 - OIL PAN

9 - OVERRUNNING CLUTCH 18 - VALVE BODY

Fig. 2 Transmission Part And Serial Number

Location

1 - PART NUMBER

2 - BUILD DATE

3 - SERIAL NUMBER

21 - 314 AUTOMATIC TRANSMISSION - 48REDR

AUTOMATIC TRANSMISSION - 48RE (Continued)