Oil pump DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2278 of 2895

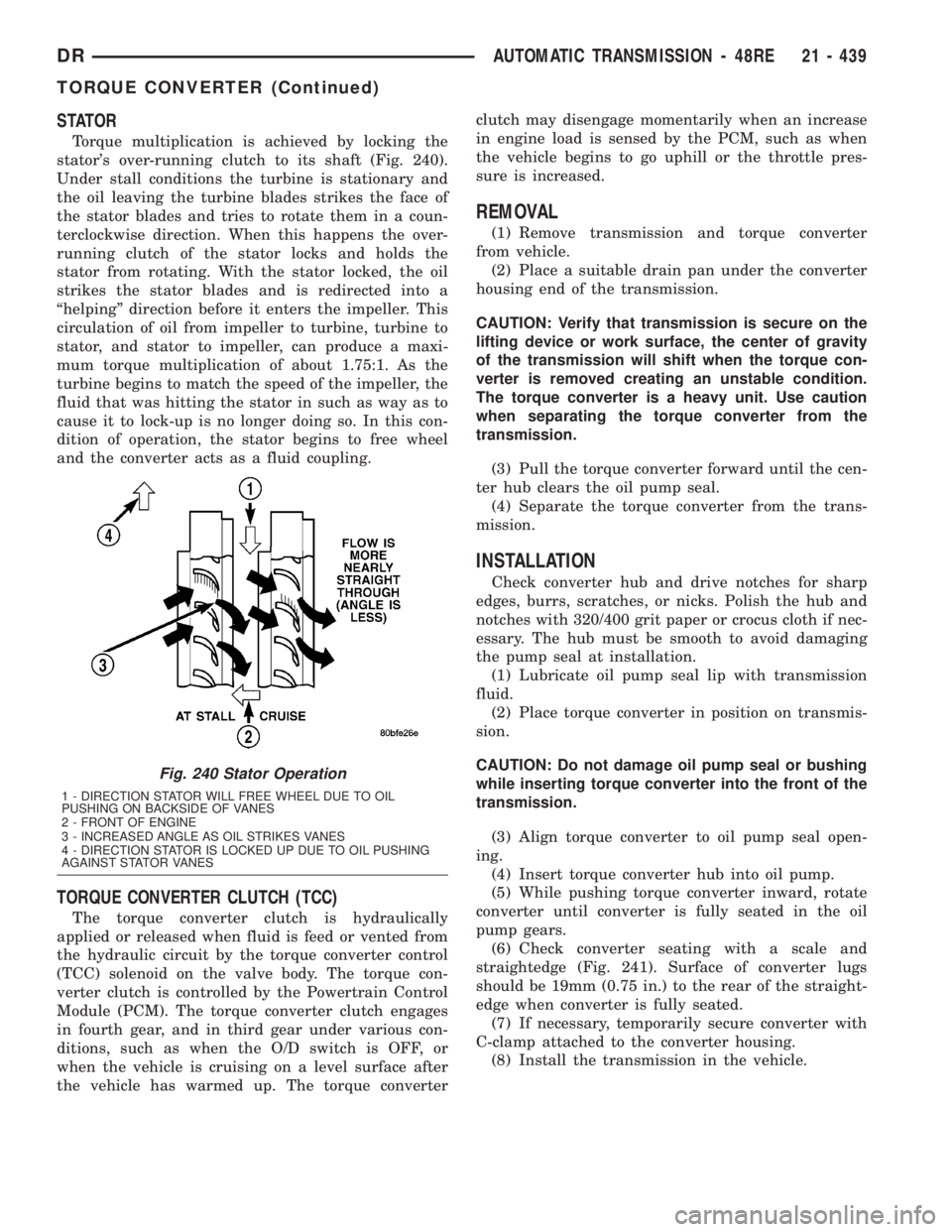

STATOR

Torque multiplication is achieved by locking the

stator's over-running clutch to its shaft (Fig. 240).

Under stall conditions the turbine is stationary and

the oil leaving the turbine blades strikes the face of

the stator blades and tries to rotate them in a coun-

terclockwise direction. When this happens the over-

running clutch of the stator locks and holds the

stator from rotating. With the stator locked, the oil

strikes the stator blades and is redirected into a

ªhelpingº direction before it enters the impeller. This

circulation of oil from impeller to turbine, turbine to

stator, and stator to impeller, can produce a maxi-

mum torque multiplication of about 1.75:1. As the

turbine begins to match the speed of the impeller, the

fluid that was hitting the stator in such as way as to

cause it to lock-up is no longer doing so. In this con-

dition of operation, the stator begins to free wheel

and the converter acts as a fluid coupling.

TORQUE CONVERTER CLUTCH (TCC)

The torque converter clutch is hydraulically

applied or released when fluid is feed or vented from

the hydraulic circuit by the torque converter control

(TCC) solenoid on the valve body. The torque con-

verter clutch is controlled by the Powertrain Control

Module (PCM). The torque converter clutch engages

in fourth gear, and in third gear under various con-

ditions, such as when the O/D switch is OFF, or

when the vehicle is cruising on a level surface after

the vehicle has warmed up. The torque converterclutch may disengage momentarily when an increase

in engine load is sensed by the PCM, such as when

the vehicle begins to go uphill or the throttle pres-

sure is increased.

REMOVAL

(1) Remove transmission and torque converter

from vehicle.

(2) Place a suitable drain pan under the converter

housing end of the transmission.

CAUTION: Verify that transmission is secure on the

lifting device or work surface, the center of gravity

of the transmission will shift when the torque con-

verter is removed creating an unstable condition.

The torque converter is a heavy unit. Use caution

when separating the torque converter from the

transmission.

(3) Pull the torque converter forward until the cen-

ter hub clears the oil pump seal.

(4) Separate the torque converter from the trans-

mission.

INSTALLATION

Check converter hub and drive notches for sharp

edges, burrs, scratches, or nicks. Polish the hub and

notches with 320/400 grit paper or crocus cloth if nec-

essary. The hub must be smooth to avoid damaging

the pump seal at installation.

(1) Lubricate oil pump seal lip with transmission

fluid.

(2) Place torque converter in position on transmis-

sion.

CAUTION: Do not damage oil pump seal or bushing

while inserting torque converter into the front of the

transmission.

(3) Align torque converter to oil pump seal open-

ing.

(4) Insert torque converter hub into oil pump.

(5) While pushing torque converter inward, rotate

converter until converter is fully seated in the oil

pump gears.

(6) Check converter seating with a scale and

straightedge (Fig. 241). Surface of converter lugs

should be 19mm (0.75 in.) to the rear of the straight-

edge when converter is fully seated.

(7) If necessary, temporarily secure converter with

C-clamp attached to the converter housing.

(8) Install the transmission in the vehicle.

Fig. 240 Stator Operation

1 - DIRECTION STATOR WILL FREE WHEEL DUE TO OIL

PUSHING ON BACKSIDE OF VANES

2 - FRONT OF ENGINE

3 - INCREASED ANGLE AS OIL STRIKES VANES

4 - DIRECTION STATOR IS LOCKED UP DUE TO OIL PUSHING

AGAINST STATOR VANES

DRAUTOMATIC TRANSMISSION - 48RE 21 - 439

TORQUE CONVERTER (Continued)

Page 2289 of 2895

OPERATION

NOTE: Refer to the Hydraulic Schematics for a

visual aid in determining valve location, operation

and design.

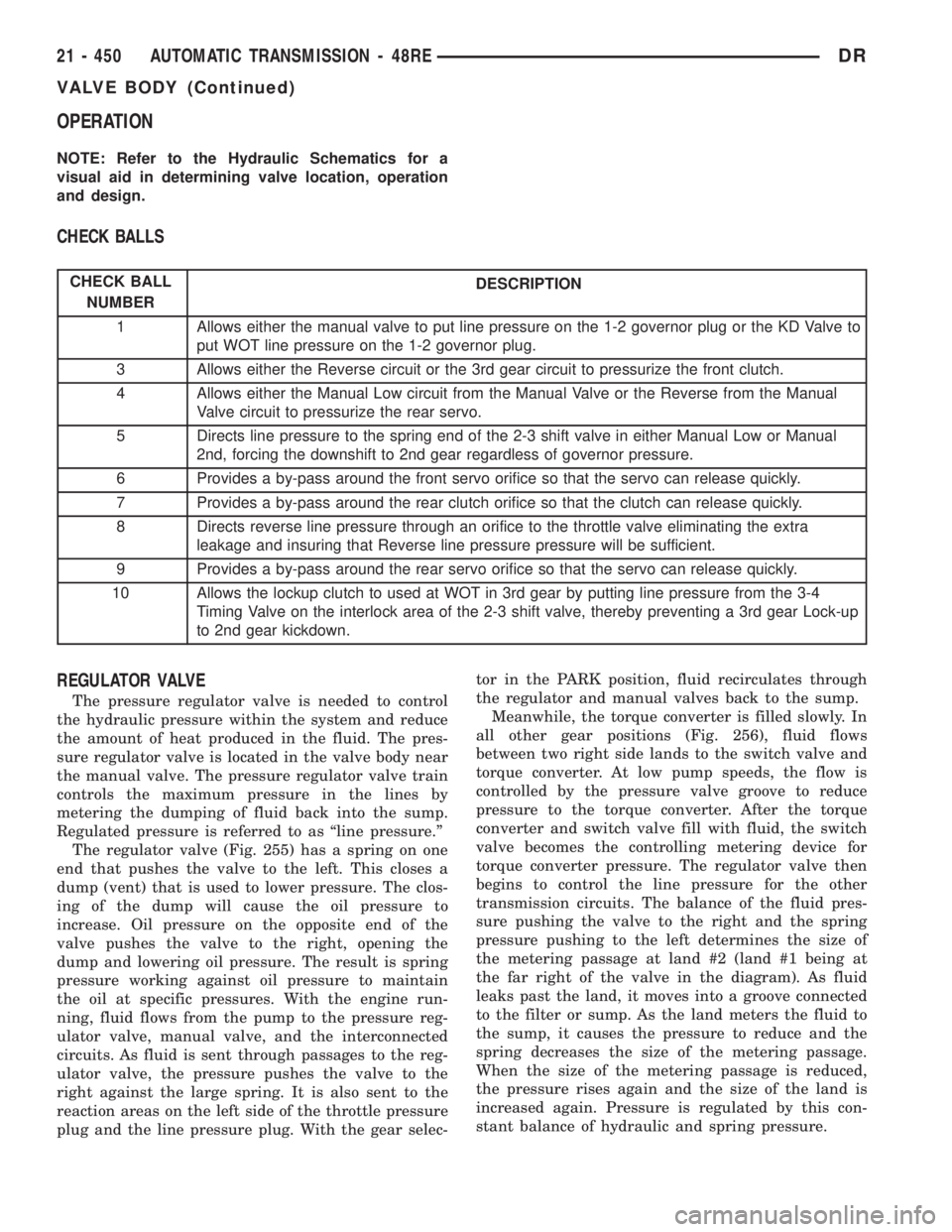

CHECK BALLS

CHECK BALL

NUMBERDESCRIPTION

1 Allows either the manual valve to put line pressure on the 1-2 governor plug or the KD Valve to

put WOT line pressure on the 1-2 governor plug.

3 Allows either the Reverse circuit or the 3rd gear circuit to pressurize the front clutch.

4 Allows either the Manual Low circuit from the Manual Valve or the Reverse from the Manual

Valve circuit to pressurize the rear servo.

5 Directs line pressure to the spring end of the 2-3 shift valve in either Manual Low or Manual

2nd, forcing the downshift to 2nd gear regardless of governor pressure.

6 Provides a by-pass around the front servo orifice so that the servo can release quickly.

7 Provides a by-pass around the rear clutch orifice so that the clutch can release quickly.

8 Directs reverse line pressure through an orifice to the throttle valve eliminating the extra

leakage and insuring that Reverse line pressure pressure will be sufficient.

9 Provides a by-pass around the rear servo orifice so that the servo can release quickly.

10 Allows the lockup clutch to used at WOT in 3rd gear by putting line pressure from the 3-4

Timing Valve on the interlock area of the 2-3 shift valve, thereby preventing a 3rd gear Lock-up

to 2nd gear kickdown.

REGULATOR VALVE

The pressure regulator valve is needed to control

the hydraulic pressure within the system and reduce

the amount of heat produced in the fluid. The pres-

sure regulator valve is located in the valve body near

the manual valve. The pressure regulator valve train

controls the maximum pressure in the lines by

metering the dumping of fluid back into the sump.

Regulated pressure is referred to as ªline pressure.º

The regulator valve (Fig. 255) has a spring on one

end that pushes the valve to the left. This closes a

dump (vent) that is used to lower pressure. The clos-

ing of the dump will cause the oil pressure to

increase. Oil pressure on the opposite end of the

valve pushes the valve to the right, opening the

dump and lowering oil pressure. The result is spring

pressure working against oil pressure to maintain

the oil at specific pressures. With the engine run-

ning, fluid flows from the pump to the pressure reg-

ulator valve, manual valve, and the interconnected

circuits. As fluid is sent through passages to the reg-

ulator valve, the pressure pushes the valve to the

right against the large spring. It is also sent to the

reaction areas on the left side of the throttle pressure

plug and the line pressure plug. With the gear selec-tor in the PARK position, fluid recirculates through

the regulator and manual valves back to the sump.

Meanwhile, the torque converter is filled slowly. In

all other gear positions (Fig. 256), fluid flows

between two right side lands to the switch valve and

torque converter. At low pump speeds, the flow is

controlled by the pressure valve groove to reduce

pressure to the torque converter. After the torque

converter and switch valve fill with fluid, the switch

valve becomes the controlling metering device for

torque converter pressure. The regulator valve then

begins to control the line pressure for the other

transmission circuits. The balance of the fluid pres-

sure pushing the valve to the right and the spring

pressure pushing to the left determines the size of

the metering passage at land #2 (land #1 being at

the far right of the valve in the diagram). As fluid

leaks past the land, it moves into a groove connected

to the filter or sump. As the land meters the fluid to

the sump, it causes the pressure to reduce and the

spring decreases the size of the metering passage.

When the size of the metering passage is reduced,

the pressure rises again and the size of the land is

increased again. Pressure is regulated by this con-

stant balance of hydraulic and spring pressure.

21 - 450 AUTOMATIC TRANSMISSION - 48REDR

VALVE BODY (Continued)

Page 2327 of 2895

AUTOMATIC TRANSMISSION - 45RFE/545RFE

TABLE OF CONTENTS

page page

AUTOMATIC TRANSMISSION - 45RFE/545RFE

DESCRIPTION........................489

OPERATION..........................490

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AUTOMATIC

TRANSMISSION.....................491

DIAGNOSIS AND TESTING - PRELIMINARY. . 491

DIAGNOSIS AND TESTING - ROAD

TESTING...........................491

DIAGNOSIS AND TESTING - HYDRAULIC

PRESSURE TEST....................493

DIAGNOSIS AND TESTING - AIR CHECKING

TRANSMISSION CLUTCH OPERATION....494

DIAGNOSIS AND TESTING - CONVERTER

HOUSING FLUID LEAK................495

STANDARD PROCEDURE - ALUMINUM

THREAD REPAIR.....................495

REMOVAL............................495

DISASSEMBLY........................497

CLEANING...........................502

INSPECTION.........................503

ASSEMBLY...........................503

INSTALLATION........................510

SCHEMATICS AND DIAGRAMS

HYDRAULIC SCHEMATICS.............513

SPECIFICATIONS

TRANSMISSION.....................534

SPECIAL TOOLS

RFE TRANSMISSION.................535

4C RETAINER/BULKHEAD

DISASSEMBLY........................538

ASSEMBLY...........................538

ADAPTER HOUSING SEAL

REMOVAL............................539

INSTALLATION........................539

BRAKE TRANSMISSION SHIFT INTERLOCK

SYSTEM

DESCRIPTION........................540

OPERATION..........................540

DIAGNOSIS AND TESTING - BRAKE

TRANSMISSION SHIFT INTERLOCK......540

ADJUSTMENTS - BRAKE TRANSMISSION

SHIFT INTERLOCK...................540

FLUID AND FILTER

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - EFFECTS OF

INCORRECT FLUID LEVEL.............541

DIAGNOSIS AND TESTING - CAUSES OF

BURNT FLUID.......................541DIAGNOSIS AND TESTING - FLUID

CONTAMINATION....................541

STANDARD PROCEDURE

STANDARD PROCEDURE - FLUID LEVEL

CHECK............................542

STANDARD PROCEDURE - FLUID AND

FILTER REPLACEMENT...............542

STANDARD PROCEDURE - TRANSMISSION

FILL...............................544

GEARSHIFT CABLE

DIAGNOSIS AND TESTING - GEARSHIFT

CABLE.............................544

REMOVAL............................544

INSTALLATION........................545

ADJUSTMENTS

GEARSHIFT CABLE..................546

HOLDING CLUTCHES

DESCRIPTION........................546

OPERATION..........................546

INPUT CLUTCH ASSEMBLY

DESCRIPTION........................549

OPERATION..........................549

DISASSEMBLY........................550

ASSEMBLY...........................552

INPUT SPEED SENSOR

DESCRIPTION........................558

OPERATION..........................558

REMOVAL............................559

INSTALLATION........................559

LINE PRESSURE (LP) SENSOR

DESCRIPTION........................559

OPERATION..........................559

REMOVAL............................559

INSTALLATION........................560

LOW/REVERSE CLUTCH

DISASSEMBLY........................560

CLEANING...........................561

INSPECTION.........................561

ASSEMBLY...........................561

OIL PUMP

DESCRIPTION........................562

OPERATION..........................562

STANDARD PROCEDURE - OIL PUMP

VOLUME CHECK.....................563

DISASSEMBLY........................564

CLEANING...........................566

INSPECTION.........................566

ASSEMBLY...........................566

21 - 488 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

Page 2328 of 2895

OIL PUMP FRONT SEAL

REMOVAL............................567

INSTALLATION........................567

OUTPUT SPEED SENSOR

DESCRIPTION........................567

OPERATION..........................567

REMOVAL............................567

INSTALLATION........................567

OVERDRIVE SWITCH

DESCRIPTION........................568

OPERATION..........................568

REMOVAL............................568

INSTALLATION........................569

PISTONS

DESCRIPTION........................569

OPERATION..........................569

PLANETARY GEARTRAIN

DESCRIPTION........................571

OPERATION..........................571

DISASSEMBLY........................573

CLEANING...........................573

INSPECTION.........................573

ASSEMBLY...........................573

SHIFT MECHANISM

DESCRIPTION........................574

OPERATION..........................574

SOLENOID SWITCH VALVE

DESCRIPTION........................574

OPERATION..........................574

SOLENOIDS

DESCRIPTION........................574OPERATION..........................575

TORQUE CONVERTER

DESCRIPTION........................575

OPERATION..........................579

REMOVAL............................580

INSTALLATION........................580

TRANSMISSION CONTROL RELAY

DESCRIPTION........................581

OPERATION..........................581

TRANSMISSION RANGE SENSOR

DESCRIPTION........................581

OPERATION..........................581

TRANSMISSION SOLENOID/TRS ASSEMBLY

DESCRIPTION........................582

OPERATION..........................582

REMOVAL............................583

INSTALLATION........................583

TRANSMISSION TEMPERATURE SENSOR

DESCRIPTION........................583

OPERATION..........................583

VALVE BODY

DESCRIPTION........................584

OPERATION..........................585

REMOVAL............................585

DISASSEMBLY........................586

CLEANING...........................588

INSPECTION.........................588

ASSEMBLY...........................590

INSTALLATION........................590

AUTOMATIC TRANSMISSION -

45RFE/545RFE

DESCRIPTION

The 45RFE/545RFE automatic transmissions is a

sophisticated, multi-range, electronically controlled

transmission which combines optimized gear ratios

for responsive performance, state of the art efficiency

features and low NVH. Other features include driver

adaptive shifting and three planetary gear sets to

provide wide ratio capability with precise ratio steps

for optimum driveability. The three planetary gear

sets also make available a unique alternate second

gear ratio. The primary 2nd gear ratio fits between

1st and 3rd gears for normal through-gear accelera-

tions. The alternate second gear ratio (2prime) allows

smoother 4-2 kickdowns at high speeds to provide

2nd gear passing performance over a wider highway

cruising range.

The hydraulic portion of the transmission consists

of the transmission fluid, fluid passages, hydraulic

valves, and various line pressure control components.The primary mechanical components of the trans-

mission consist of the following:

²Three multiple disc input clutches

²Three multiple disc holding clutches

²Five hydraulic accumulators

²Three planetary gear sets

²Dual Stage Hydraulic oil pump

²Valve body

²Solenoid pack

The TCM is the ªheartº or ªbrainº of the electronic

control system and relies on information from vari-

ous direct and indirect inputs (sensors, switches, etc.)

to determine driver demand and vehicle operating

conditions. With this information, the TCM can cal-

culate and perform timely and quality shifts through

various output or control devices (solenoid pack,

transmission control relay, etc.).

TRANSMISSION IDENTIFICATION

Transmission identification numbers are stamped

on the left side of the case just above the oil pan

sealing surface (Fig. 1). Refer to this information

when ordering replacement parts. A label is attached

to the transmission case above the stamped numbers.

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 489

Page 2330 of 2895

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AUTOMATIC

TRANSMISSION

CAUTION: Before attempting any repair on a RFE

automatic transmission, check for Diagnostic Trou-

ble Codes with the DRBTscan tool.

Transmission malfunctions may be caused by these

general conditions:

²Poor engine performance

²Improper adjustments

²Hydraulic malfunctions

²Mechanical malfunctions

²Electronic malfunctions

Diagnosis of these problems should always begin

by checking the easily accessible variables: fluid level

and condition, gearshift cable adjustment. Then per-

form a road test to determine if the problem has been

corrected or if more diagnosis is necessary. If the

problem persists after the preliminary tests and cor-

rections are completed, hydraulic pressure checks

should be performed.

DIAGNOSIS AND TESTING - PRELIMINARY

Two basic procedures are required. One procedure

for vehicles that are drivable and an alternate proce-

dure for disabled vehicles (will not back up or move

forward).

VEHICLE IS DRIVABLE

(1) Check for transmission fault codes using DRBt

scan tool.

(2) Check fluid level and condition.

(3) Adjust gearshift cable if complaint was based

on delayed, erratic, or harsh shifts.

(4) Road test and note how transmission upshifts,

downshifts, and engages.

(5) Perform hydraulic pressure test if shift prob-

lems were noted during road test.

(6) Perform air-pressure test to check clutch oper-

ation.

VEHICLE IS DISABLED

(1) Check fluid level and condition.

(2) Check for broken or disconnected gearshift

cable.

(3) Check for cracked, leaking cooler lines, or loose

or missing pressure-port plugs.

(4) Raise and support vehicle on safety stands,

start engine, shift transmission into gear, and note

following:

(a) If propeller shaft turns but wheels do not,

problem is with differential or axle shafts.

(b) If propeller shaft does not turn and transmis-

sion is noisy, stop engine. Remove oil pan, and

check for debris. If pan is clear, remove transmis-

sion and check for damaged driveplate, converter,

oil pump, or input shaft.

(c) If propeller shaft does not turn and transmis-

sion is not noisy, perform hydraulic-pressure test to

determine if problem is hydraulic or mechanical.

DIAGNOSIS AND TESTING - ROAD TESTING

Before road testing, be sure the fluid level and con-

trol cable adjustments have been checked and

adjusted if necessary. Verify that all diagnostic trou-

ble codes have been resolved.

Observe engine performance during the road test.

A poorly tuned engine will not allow accurate analy-

sis of transmission operation.

Operate the transmission in all gear ranges. Check

for shift variations and engine flare which indicates

slippage. Note if shifts are harsh, spongy, delayed,

early, or if part throttle downshifts are sensitive.

Slippage indicated by engine flare, usually means

clutch, overrunning clutch, or line pressure problems.

A slipping clutch can often be determined by com-

paring which internal units are applied in the vari-

ous gear ranges. The Clutch Application charts

provide a basis for analyzing road test results.

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 491

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)

Page 2333 of 2895

NOTE: The 45RFE/545RFE utilizes closed loop con-

trol of pump line pressure. The pressure readings

may therefore vary greatly but should always follow

line pressure.

Some common pressures that can be measured to

evaluate pump and clutch performance are the

upshift/downshift pressures, garage shift pressures,

and TCC pressure. The upshift/downshift pressure

for all shifts are shown in UPSHIFT PRESSURES

and DOWNSHIFT PRESSURES. In-gear maximum

pressure for each gear position is shown in IN-GEAR

PRESSURES. The garage shift pressure when per-

forming a N-R shift is 220 psi for 3.7L/4.7L equipped

vehicles and 250 psi for 5.7L equipped vehicles. The

garage shift pressure for the R-N shift is 120 psi. The

garage shift pressure for the N-1 shift is 135 psi for

3.7L/4.7L equipped vehicles and 165 psi for 5.7L

equipped vehicles. Torque converter lock-up pressure

is 120 psi for 3.7L/4.7L equipped vehicles and 125 psi

for 5.7L equipped vehicles.

UPSHIFT PRESSURES

ENGINE 1-2 2-3 2prime-3 3-4 2prime-4 2-5 3-5 4-5

5.7L150 125 125 135 135 135 135 135

3.7L/

4.7L120 120 120 120 120 120 120 130

DOWNSHIFT PRESSURES

ENG-

INE5-4 5-3 5-2 4-34-2

prime3-23-2

prime2

prime

-12-1 3-1

5.7L135 135 135 135 135 135 135 135 135 135

3.7L/

4.7L120 120 120 120 120 120 120 120 120 120

IN-GEAR PRESSURES

ENGINE 1 22

prime345NEUT-

RALREV-

ERSE

5.7L160 135 135 135 135 135 120 250

3.7L/

4.7L135 120 120 120 120 120 120 220

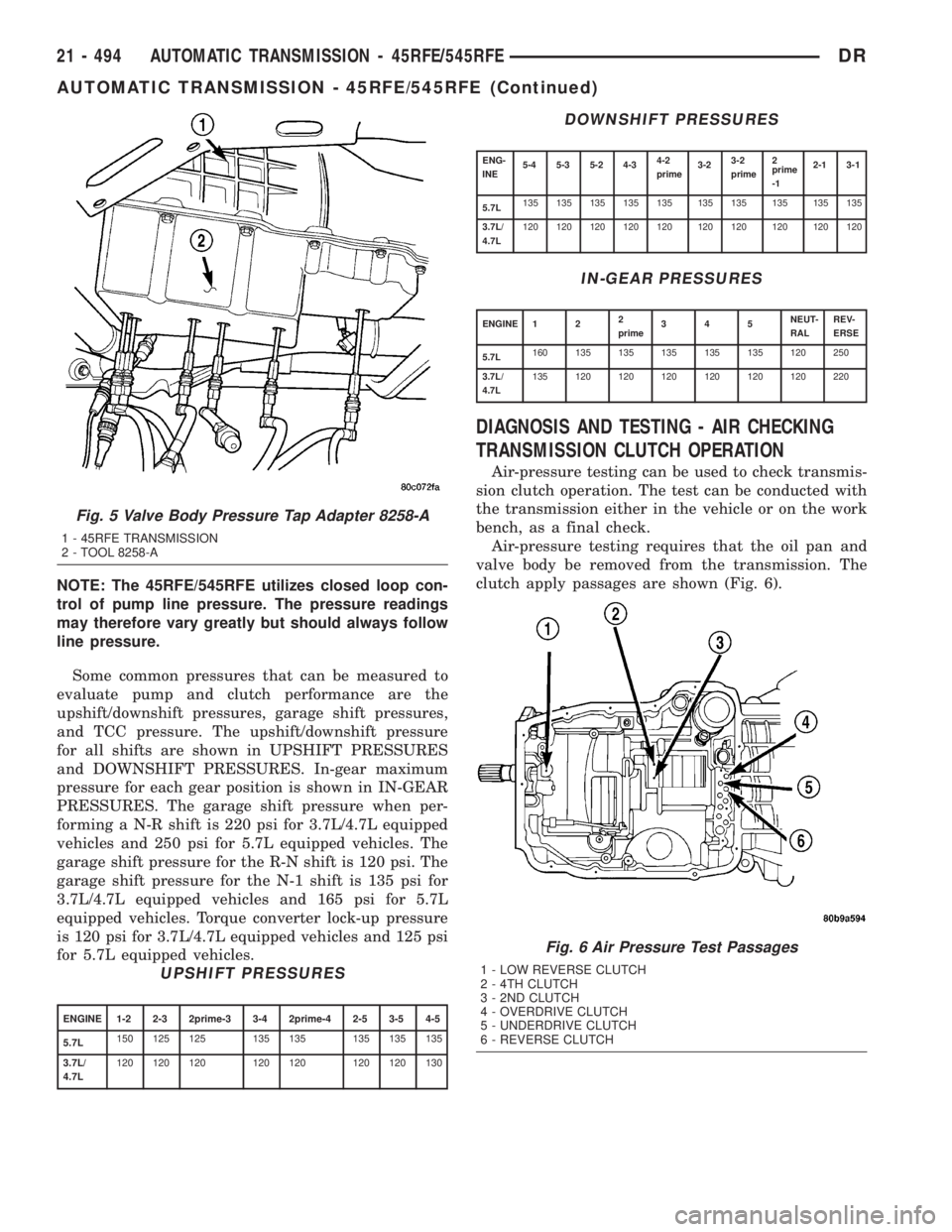

DIAGNOSIS AND TESTING - AIR CHECKING

TRANSMISSION CLUTCH OPERATION

Air-pressure testing can be used to check transmis-

sion clutch operation. The test can be conducted with

the transmission either in the vehicle or on the work

bench, as a final check.

Air-pressure testing requires that the oil pan and

valve body be removed from the transmission. The

clutch apply passages are shown (Fig. 6).

Fig. 5 Valve Body Pressure Tap Adapter 8258-A

1 - 45RFE TRANSMISSION

2 - TOOL 8258-A

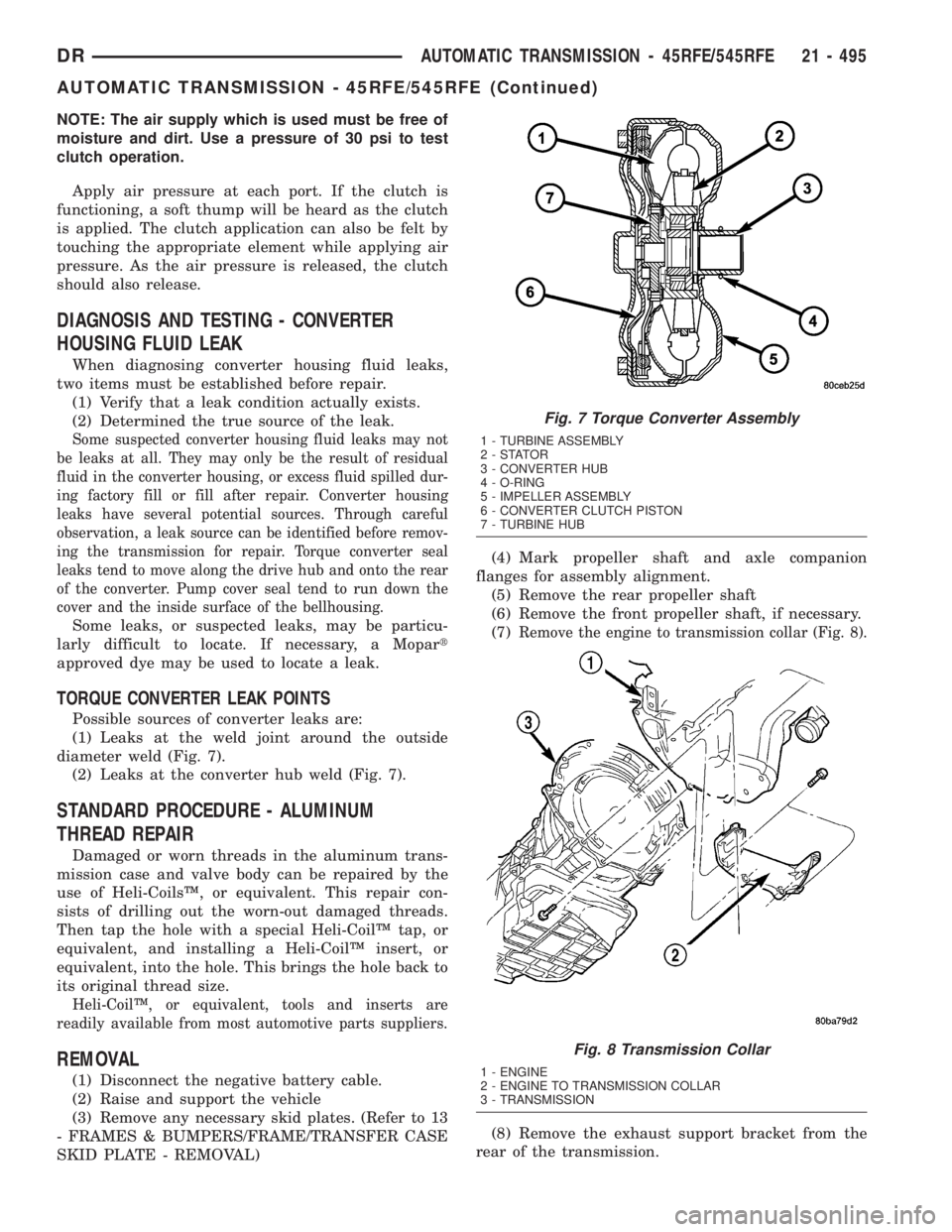

Fig. 6 Air Pressure Test Passages

1 - LOW REVERSE CLUTCH

2 - 4TH CLUTCH

3 - 2ND CLUTCH

4 - OVERDRIVE CLUTCH

5 - UNDERDRIVE CLUTCH

6 - REVERSE CLUTCH

21 - 494 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)

Page 2334 of 2895

NOTE: The air supply which is used must be free of

moisture and dirt. Use a pressure of 30 psi to test

clutch operation.

Apply air pressure at each port. If the clutch is

functioning, a soft thump will be heard as the clutch

is applied. The clutch application can also be felt by

touching the appropriate element while applying air

pressure. As the air pressure is released, the clutch

should also release.

DIAGNOSIS AND TESTING - CONVERTER

HOUSING FLUID LEAK

When diagnosing converter housing fluid leaks,

two items must be established before repair.

(1) Verify that a leak condition actually exists.

(2) Determined the true source of the leak.

Some suspected converter housing fluid leaks may not

be leaks at all. They may only be the result of residual

fluid in the converter housing, or excess fluid spilled dur-

ing factory fill or fill after repair. Converter housing

leaks have several potential sources. Through careful

observation, a leak source can be identified before remov-

ing the transmission for repair. Torque converter seal

leaks tend to move along the drive hub and onto the rear

of the converter. Pump cover seal tend to run down the

cover and the inside surface of the bellhousing.

Some leaks, or suspected leaks, may be particu-

larly difficult to locate. If necessary, a Mopart

approved dye may be used to locate a leak.

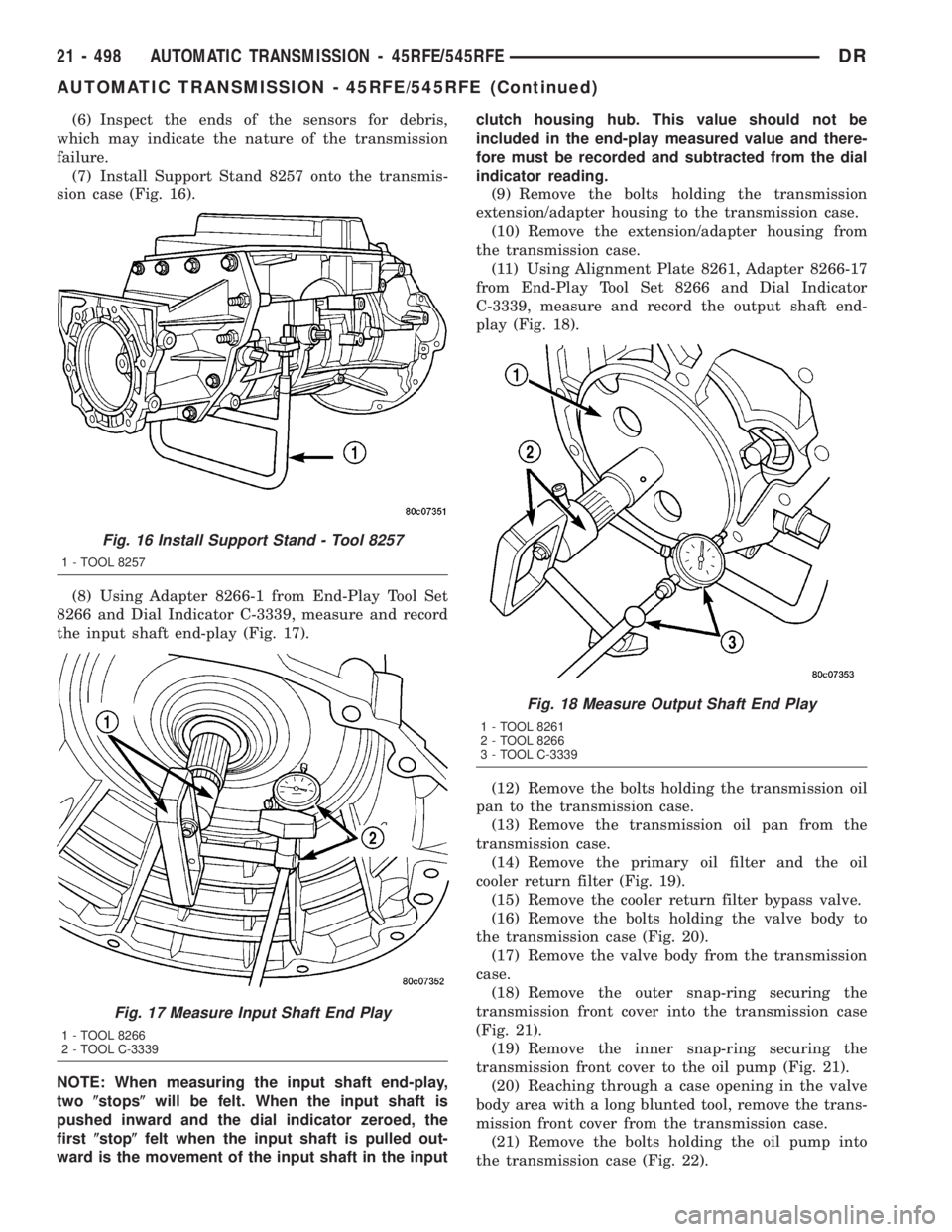

TORQUE CONVERTER LEAK POINTS

Possible sources of converter leaks are:

(1) Leaks at the weld joint around the outside

diameter weld (Fig. 7).

(2) Leaks at the converter hub weld (Fig. 7).

STANDARD PROCEDURE - ALUMINUM

THREAD REPAIR

Damaged or worn threads in the aluminum trans-

mission case and valve body can be repaired by the

use of Heli-CoilsŸ, or equivalent. This repair con-

sists of drilling out the worn-out damaged threads.

Then tap the hole with a special Heli-CoilŸ tap, or

equivalent, and installing a Heli-CoilŸ insert, or

equivalent, into the hole. This brings the hole back to

its original thread size.

Heli-CoilŸ, or equivalent, tools and inserts are

readily available from most automotive parts suppliers.

REMOVAL

(1) Disconnect the negative battery cable.

(2) Raise and support the vehicle

(3) Remove any necessary skid plates. (Refer to 13

- FRAMES & BUMPERS/FRAME/TRANSFER CASE

SKID PLATE - REMOVAL)(4) Mark propeller shaft and axle companion

flanges for assembly alignment.

(5) Remove the rear propeller shaft

(6) Remove the front propeller shaft, if necessary.

(7)

Remove the engine to transmission collar (Fig. 8).

(8) Remove the exhaust support bracket from the

rear of the transmission.

Fig. 7 Torque Converter Assembly

1 - TURBINE ASSEMBLY

2-STATOR

3 - CONVERTER HUB

4 - O-RING

5 - IMPELLER ASSEMBLY

6 - CONVERTER CLUTCH PISTON

7 - TURBINE HUB

Fig. 8 Transmission Collar

1 - ENGINE

2 - ENGINE TO TRANSMISSION COLLAR

3 - TRANSMISSION

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 495

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)

Page 2337 of 2895

(6) Inspect the ends of the sensors for debris,

which may indicate the nature of the transmission

failure.

(7) Install Support Stand 8257 onto the transmis-

sion case (Fig. 16).

(8) Using Adapter 8266-1 from End-Play Tool Set

8266 and Dial Indicator C-3339, measure and record

the input shaft end-play (Fig. 17).

NOTE: When measuring the input shaft end-play,

two(stops(will be felt. When the input shaft is

pushed inward and the dial indicator zeroed, the

first(stop(felt when the input shaft is pulled out-

ward is the movement of the input shaft in the inputclutch housing hub. This value should not be

included in the end-play measured value and there-

fore must be recorded and subtracted from the dial

indicator reading.

(9) Remove the bolts holding the transmission

extension/adapter housing to the transmission case.

(10) Remove the extension/adapter housing from

the transmission case.

(11) Using Alignment Plate 8261, Adapter 8266-17

from End-Play Tool Set 8266 and Dial Indicator

C-3339, measure and record the output shaft end-

play (Fig. 18).

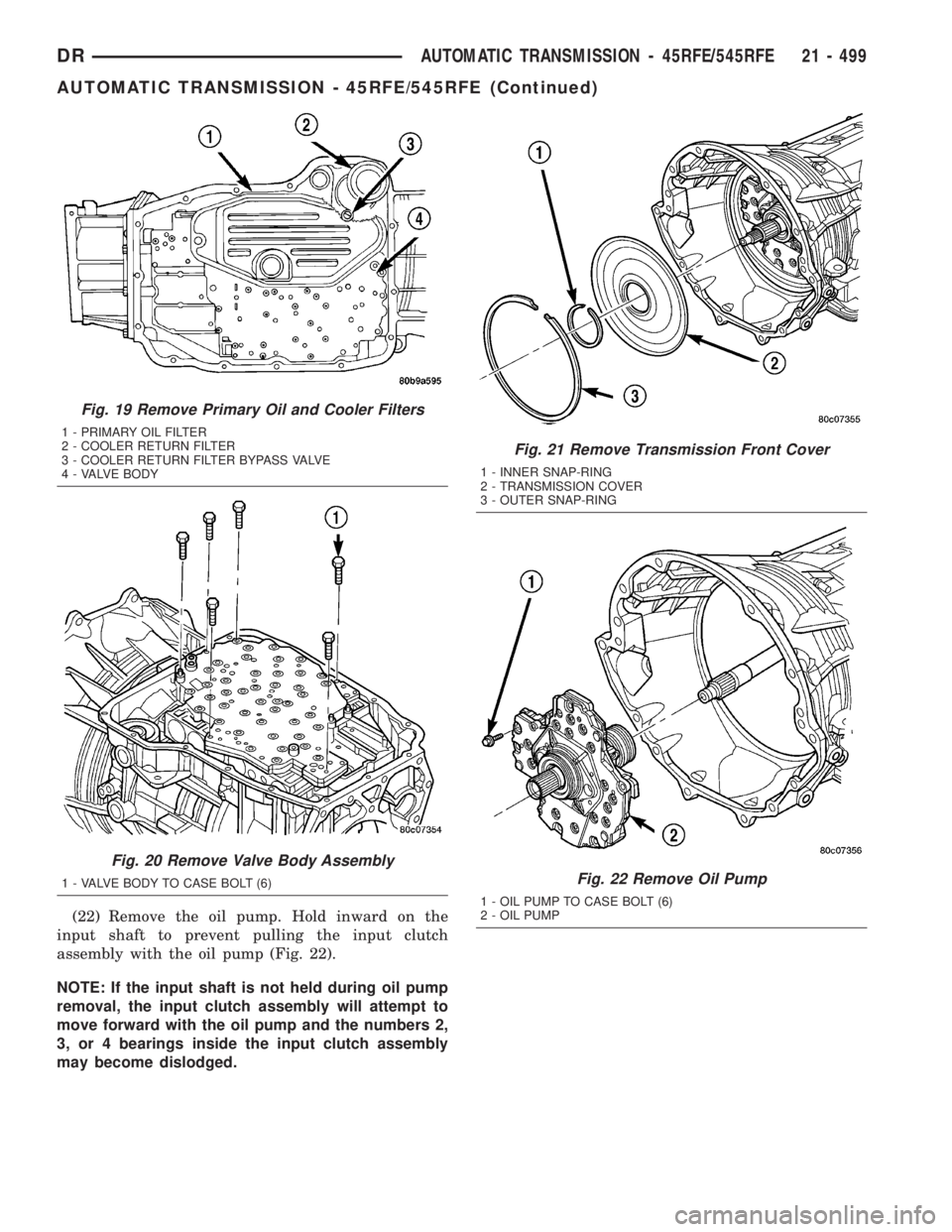

(12) Remove the bolts holding the transmission oil

pan to the transmission case.

(13) Remove the transmission oil pan from the

transmission case.

(14) Remove the primary oil filter and the oil

cooler return filter (Fig. 19).

(15) Remove the cooler return filter bypass valve.

(16) Remove the bolts holding the valve body to

the transmission case (Fig. 20).

(17) Remove the valve body from the transmission

case.

(18) Remove the outer snap-ring securing the

transmission front cover into the transmission case

(Fig. 21).

(19) Remove the inner snap-ring securing the

transmission front cover to the oil pump (Fig. 21).

(20) Reaching through a case opening in the valve

body area with a long blunted tool, remove the trans-

mission front cover from the transmission case.

(21) Remove the bolts holding the oil pump into

the transmission case (Fig. 22).

Fig. 16 Install Support Stand - Tool 8257

1 - TOOL 8257

Fig. 17 Measure Input Shaft End Play

1 - TOOL 8266

2 - TOOL C-3339

Fig. 18 Measure Output Shaft End Play

1 - TOOL 8261

2 - TOOL 8266

3 - TOOL C-3339

21 - 498 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)

Page 2338 of 2895

(22) Remove the oil pump. Hold inward on the

input shaft to prevent pulling the input clutch

assembly with the oil pump (Fig. 22).

NOTE: If the input shaft is not held during oil pump

removal, the input clutch assembly will attempt to

move forward with the oil pump and the numbers 2,

3, or 4 bearings inside the input clutch assembly

may become dislodged.

Fig. 19 Remove Primary Oil and Cooler Filters

1 - PRIMARY OIL FILTER

2 - COOLER RETURN FILTER

3 - COOLER RETURN FILTER BYPASS VALVE

4 - VALVE BODY

Fig. 20 Remove Valve Body Assembly

1 - VALVE BODY TO CASE BOLT (6)

Fig. 21 Remove Transmission Front Cover

1 - INNER SNAP-RING

2 - TRANSMISSION COVER

3 - OUTER SNAP-RING

Fig. 22 Remove Oil Pump

1 - OIL PUMP TO CASE BOLT (6)

2 - OIL PUMP

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 499

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)

Page 2347 of 2895

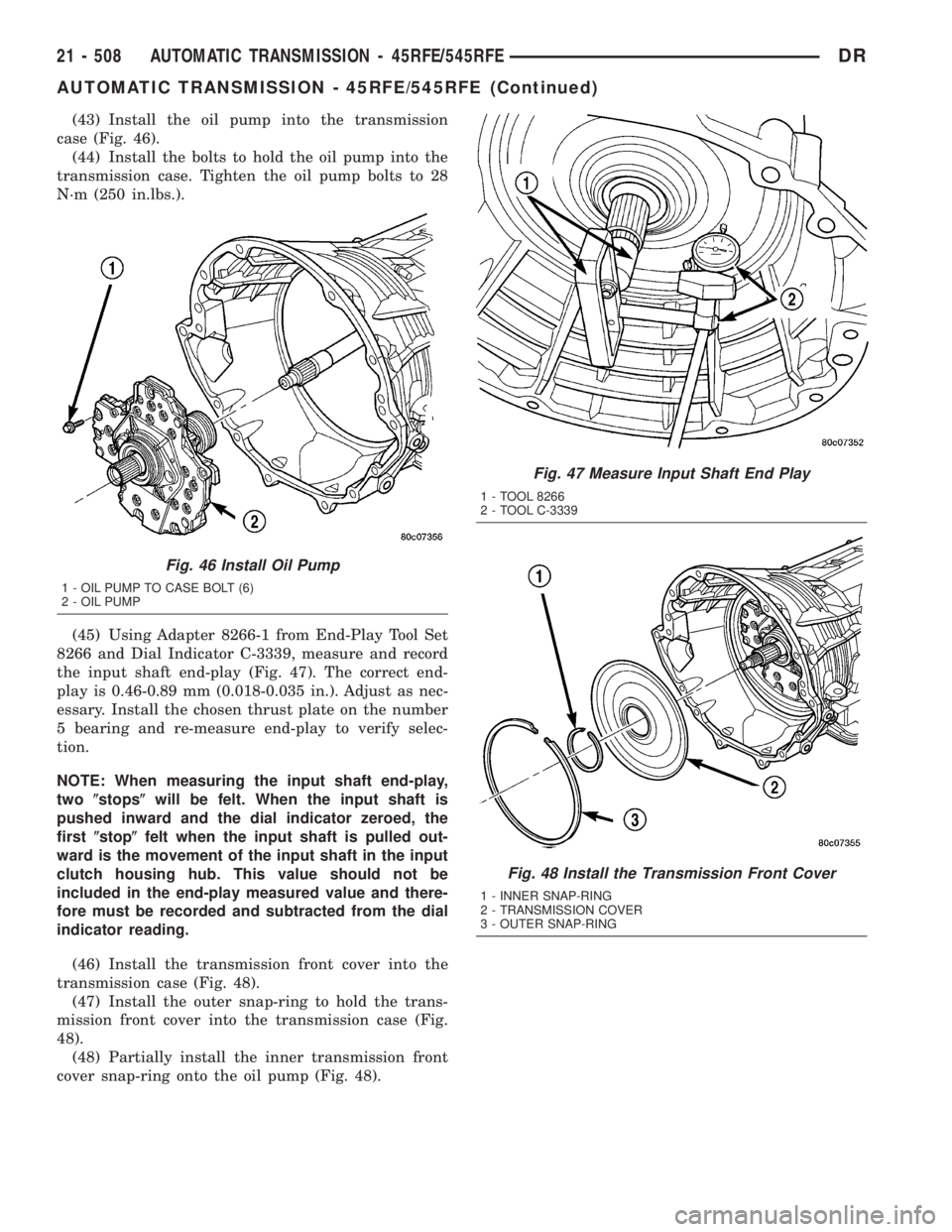

(43) Install the oil pump into the transmission

case (Fig. 46).

(44) Install the bolts to hold the oil pump into the

transmission case. Tighten the oil pump bolts to 28

N´m (250 in.lbs.).

(45) Using Adapter 8266-1 from End-Play Tool Set

8266 and Dial Indicator C-3339, measure and record

the input shaft end-play (Fig. 47). The correct end-

play is 0.46-0.89 mm (0.018-0.035 in.). Adjust as nec-

essary. Install the chosen thrust plate on the number

5 bearing and re-measure end-play to verify selec-

tion.

NOTE: When measuring the input shaft end-play,

two(stops(will be felt. When the input shaft is

pushed inward and the dial indicator zeroed, the

first(stop(felt when the input shaft is pulled out-

ward is the movement of the input shaft in the input

clutch housing hub. This value should not be

included in the end-play measured value and there-

fore must be recorded and subtracted from the dial

indicator reading.

(46) Install the transmission front cover into the

transmission case (Fig. 48).

(47) Install the outer snap-ring to hold the trans-

mission front cover into the transmission case (Fig.

48).

(48) Partially install the inner transmission front

cover snap-ring onto the oil pump (Fig. 48).

Fig. 46 Install Oil Pump

1 - OIL PUMP TO CASE BOLT (6)

2 - OIL PUMP

Fig. 47 Measure Input Shaft End Play

1 - TOOL 8266

2 - TOOL C-3339

Fig. 48 Install the Transmission Front Cover

1 - INNER SNAP-RING

2 - TRANSMISSION COVER

3 - OUTER SNAP-RING

21 - 508 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)