service DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1246 of 2895

INSTALLATION

(1) Turn the ignition switch to the Off position.

(2) Remove the Integrated Power Module cover.

(3) To install the IOD fuse, use a thumb to press

the IOD fuse holder unit in fuse cavity # 51 firmly

into the Integrated Power Module.

(4) Install the Integrated Power Module cover.

POWER OUTLET

DESCRIPTION

Two power outlets are utilized on this model. One

in the instrument panel center lower bezel and the

other in the center console. The power outlet bases

are secured by a snap fit within the instrument

panel or trim panel. A plastic protective cap snaps

into the power outlet base when the power outlet is

not being used, and hangs from the power outlet base

mount by an integral bail strap while the power out-

let is in use.

The power outlet receptacle unit and the accessory

power outlet protective cap are available for service.

The power outlet receptacle cannot be repaired and,

if faulty or damaged, it must be replaced.

OPERATION

The power outlet base or receptacle shell is con-

nected to ground, and an insulated contact in the

bottom of the shell is connected to battery current.

The power outlet receives battery voltage from a fuse

in the integrated power module at all times.

While the power outlet is very similar to a cigar

lighter base unit, it does not include the two small

spring-clip retainers inside the bottom of the recepta-

cle shell that are used to secure the cigar lighter

heating element to the insulated contact.

DIAGNOSIS AND TESTING - POWER OUTLET

For complete circuit diagrams, refer toWiring

Diagrams.

(1) Check the fused B(+) fuse in the integrated

power module. If OK, go to Step 2. If not OK, repair

the shorted circuit or component as required and

replace the faulty fuse.

(2) Check for battery voltage at the fused B(+) fuse

in the integrated power module. If OK, go to Step 3.

If not OK, repair the open fused B(+) circuit to the

battery as required.

(3) Remove the plastic protective cap from the

power outlet receptacle. Check for continuity between

the inside circumference of the power outlet recepta-

cle and a good ground. There should be continuity. If

OK, go to Step 4. If not OK, go to Step 5.(4) Check for battery voltage at the insulated con-

tact located at the back of the power outlet recepta-

cle. If not OK, go to Step 5.

(5) Disconnect and isolate the battery negative

cable. Remove the power outlet receptacle from the

instrument panel. Disconnect the wire harness con-

nector from the power outlet receptacle. Check for

continuity between the ground circuit cavity of the

power outlet wire harness connector and a good

ground. There should be continuity. If OK, go to Step

6. If not OK, repair the open ground circuit to ground

as required.

(6) Connect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

power outlet wire harness connector. If OK, replace

the faulty power outlet receptacle. If not OK, repair

the open fused B(+) circuit to the integrated power

module fuse as required.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Pull the cigar lighter knob and element out of

the cigar lighter receptacle base, or unsnap the pro-

tective cap from the power outlet receptacle base.

(3) Look inside the cigar lighter or power outlet

receptacle base and note the position of the rectangu-

lar retaining bosses of the mount that secures the

receptacle base to the panel (Fig. 7).

(4) Insert a pair of external snap ring pliers into

the cigar lighter or power outlet receptacle base and

engage the tips of the pliers with the retaining

bosses of the mount.

(5) Squeeze the pliers to disengage the mount

retaining bosses from the receptacle base and, using

a gentle rocking motion, pull the pliers and the

receptacle base out of the mount.

(6) Pull the receptacle base away from the instru-

ment panel far enough to access the instrument

panel wire harness connector.

(7) Disconnect the instrument panel wire harness

connector from the cigar lighter or power outlet

receptacle base connector receptacle.

(8) Remove the cigar lighter or power outlet mount

from the instrument panel.

INSTALLATION

(1) Reconnect the instrument panel wire harness

connector to the cigar lighter or power outlet recep-

tacle base connector receptacle.

(2) Install the cigar lighter or power outlet mount

into the instrument panel.

(3) Align the splines on the outside of the cigar

lighter or power outlet receptacle base connector

receptacle with the grooves on the inside of the

mount.

DR8W-97 POWER DISTRIBUTION 8W - 97 - 7

IOD FUSE (Continued)

Page 1251 of 2895

ROCKER ARM

DESCRIPTION.........................36

REMOVAL.............................36

VALVE GUIDE SEALS

DESCRIPTION.........................36

VALVE SPRINGS

DESCRIPTION.........................36

REMOVAL.............................37

INSTALLATION.........................37

ENGINE BLOCK

DESCRIPTION.........................37

STANDARD PROCEDUREÐCYLINDER BORE

HONING............................37

CLEANING............................38

INSPECTION..........................38

CRANKSHAFT

DESCRIPTION.........................39

REMOVAL.............................39

INSPECTION..........................40

INSTALLATION.........................41

CRANKSHAFT MAIN BEARINGS

STANDARD PROCEDURE

MAIN BEARING FITTING................43

CRANKSHAFT OIL SEAL - FRONT

REMOVAL.............................44

INSTALLATION.........................45

CRANKSHAFT OIL SEAL - REAR

REMOVAL.............................45

INSTALLATION.........................46

FLEX PLATE

REMOVAL.............................47

INSTALLATION.........................47

PISTON & CONNECTING ROD

DESCRIPTION.........................47

STANDARD PROCEDURE

CONNECTING ROD BEARING FITTING....48

STANDARD PROCEDUREÐPISTON

FITTING.............................50

REMOVAL.............................50

CLEANING............................51

INSPECTION..........................51

INSTALLATION.........................51

PISTON RINGS

STANDARD PROCEDURE - PISTON RING

FITTING.............................52

VIBRATION DAMPER

REMOVAL.............................54

INSTALLATION.........................55

STRUCTURAL COVER

DESCRIPTION.........................56

OPERATION...........................56

REMOVAL.............................56

INSTALLATION.........................56

FRONT MOUNT

REMOVAL.............................57

INSTALLATION.........................58REAR MOUNT

REMOVAL.............................60

INSTALLATION.........................60

LUBRICATION

DESCRIPTION.........................60

OPERATION...........................60

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTINGÐENGINE OIL

LEAK...............................63

DIAGNOSIS AND TESTING - CHECKING

ENGINE OIL PRESSURE................64

DIAGNOSIS AND TESTING - REAR SEAL

AREA LEAKS.........................64

OIL PAN

DESCRIPTION.........................65

REMOVAL.............................65

CLEANING............................65

INSPECTION..........................66

INSTALLATION.........................66

OIL PRESSURE SENSOR/SWITCH

DESCRIPTION.........................66

OPERATION...........................66

REMOVAL.............................67

INSTALLATION.........................67

OIL PUMP

REMOVAL.............................67

DISASSEMBLY.........................67

INSPECTION..........................67

ASSEMBLY............................68

INSTALLATION.........................68

OIL FILTER

REMOVAL.............................69

INSTALLATION.........................70

OIL

STANDARD PROCEDURE - ENGINE OIL

SERVICE............................70

INTAKE MANIFOLD

DESCRIPTION.........................71

DIAGNOSIS AND TESTING - INTAKE

MANIFOLD LEAKS.....................71

REMOVAL.............................72

INSTALLATION.........................72

EXHAUST MANIFOLD

DESCRIPTION.........................73

REMOVAL.............................73

INSTALLATION.........................74

VALVE TIMING

DESCRIPTION.........................75

OPERATION...........................75

STANDARD PROCEDURE

MEASURING TIMING CHAIN WEAR.......76

SERVICE PROCEDURE - TIMING

VERIFICATION........................76

BALANCE SHAFT

REMOVAL.............................79

INSTALLATION.........................79

9 - 2 ENGINE - 3.7LDR

Page 1253 of 2895

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - INTRODUCTION

Engine diagnosis is helpful in determining the

causes of malfunctions not detected and remedied by

routine maintenance.

These malfunctions may be classified as either per-

formance (e.g., engine idles rough and stalls) or

mechanical (e.g., a strange noise).

(Refer to 9 - ENGINE - DIAGNOSIS AND TEST-

ING)ÐPERFORMANCE and (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)ÐMECHANICAL for

possible causes and corrections of malfunctions.

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY -

DIAGNOSIS AND TESTING) and (Refer to 14 -

FUEL SYSTEM/FUEL INJECTION - DIAGNOSIS

AND TESTING) for the fuel system diagnosis.Additional tests and diagnostic procedures may be

necessary for specific engine malfunctions that can

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagno-

sis is provided within the following diagnosis:

²Cylinder Compression Pressure Test (Refer to 9 -

ENGINE - DIAGNOSIS AND TESTING).

²Cylinder Combustion Pressure Leakage Test

(Refer to 9 - ENGINE - DIAGNOSIS AND TEST-

ING).

²Engine Cylinder Head Gasket Failure Diagnosis

(Refer to 9 - ENGINE/CYLINDER HEAD - DIAGNO-

SIS AND TESTING).

²Intake Manifold Leakage Diagnosis (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

DIAGNOSIS AND TESTING).

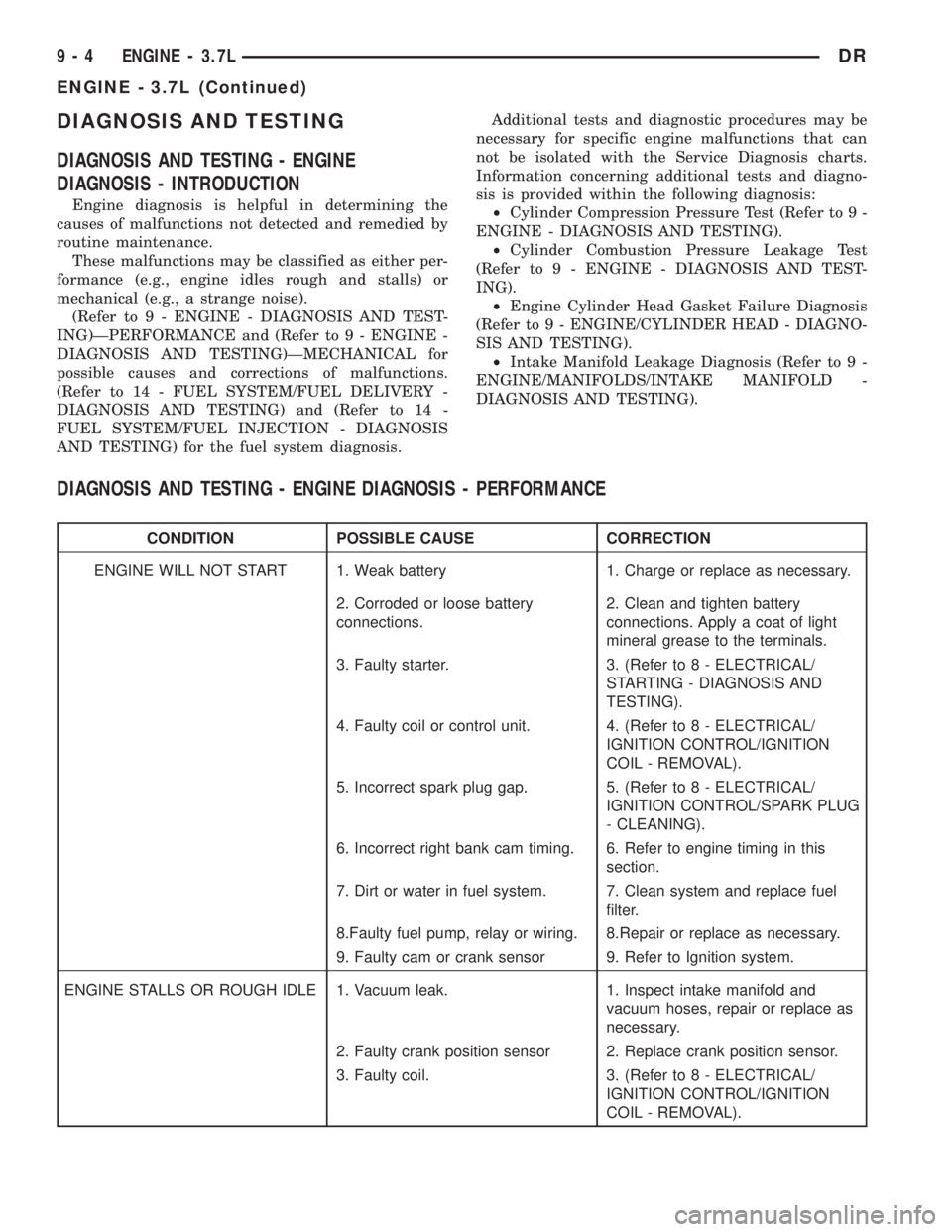

DIAGNOSIS AND TESTING - ENGINE DIAGNOSIS - PERFORMANCE

CONDITION POSSIBLE CAUSE CORRECTION

ENGINE WILL NOT START 1. Weak battery 1. Charge or replace as necessary.

2. Corroded or loose battery

connections.2. Clean and tighten battery

connections. Apply a coat of light

mineral grease to the terminals.

3. Faulty starter. 3. (Refer to 8 - ELECTRICAL/

STARTING - DIAGNOSIS AND

TESTING).

4. Faulty coil or control unit. 4. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/IGNITION

COIL - REMOVAL).

5. Incorrect spark plug gap. 5. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/SPARK PLUG

- CLEANING).

6. Incorrect right bank cam timing. 6. Refer to engine timing in this

section.

7. Dirt or water in fuel system. 7. Clean system and replace fuel

filter.

8.Faulty fuel pump, relay or wiring. 8.Repair or replace as necessary.

9. Faulty cam or crank sensor 9. Refer to Ignition system.

ENGINE STALLS OR ROUGH IDLE 1. Vacuum leak. 1. Inspect intake manifold and

vacuum hoses, repair or replace as

necessary.

2. Faulty crank position sensor 2. Replace crank position sensor.

3. Faulty coil. 3. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/IGNITION

COIL - REMOVAL).

9 - 4 ENGINE - 3.7LDR

ENGINE - 3.7L (Continued)

Page 1255 of 2895

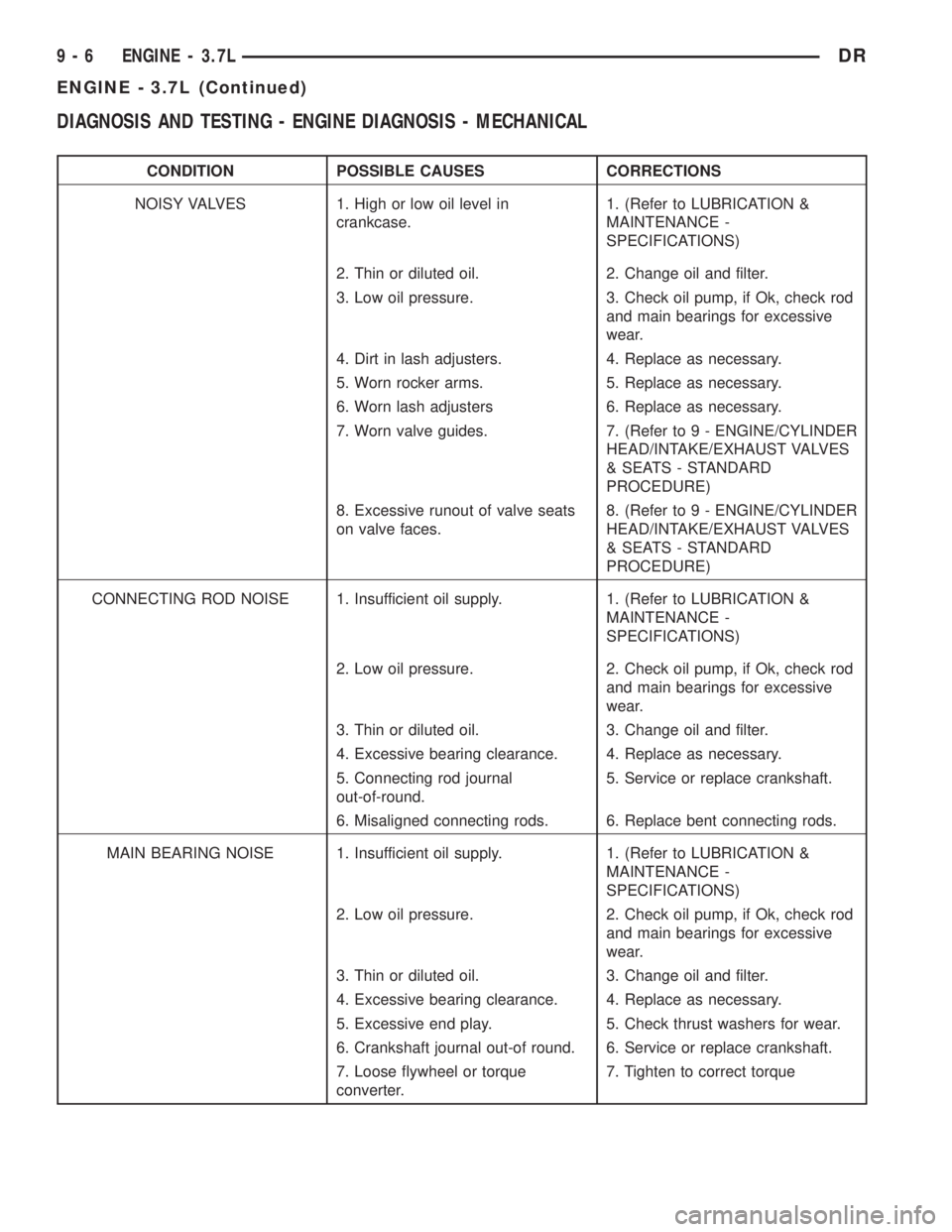

DIAGNOSIS AND TESTING - ENGINE DIAGNOSIS - MECHANICAL

CONDITION POSSIBLE CAUSES CORRECTIONS

NOISY VALVES 1. High or low oil level in

crankcase.1. (Refer to LUBRICATION &

MAINTENANCE -

SPECIFICATIONS)

2. Thin or diluted oil. 2. Change oil and filter.

3. Low oil pressure. 3. Check oil pump, if Ok, check rod

and main bearings for excessive

wear.

4. Dirt in lash adjusters. 4. Replace as necessary.

5. Worn rocker arms. 5. Replace as necessary.

6. Worn lash adjusters 6. Replace as necessary.

7. Worn valve guides. 7. (Refer to 9 - ENGINE/CYLINDER

HEAD/INTAKE/EXHAUST VALVES

& SEATS - STANDARD

PROCEDURE)

8. Excessive runout of valve seats

on valve faces.8. (Refer to 9 - ENGINE/CYLINDER

HEAD/INTAKE/EXHAUST VALVES

& SEATS - STANDARD

PROCEDURE)

CONNECTING ROD NOISE 1. Insufficient oil supply. 1. (Refer to LUBRICATION &

MAINTENANCE -

SPECIFICATIONS)

2. Low oil pressure. 2. Check oil pump, if Ok, check rod

and main bearings for excessive

wear.

3. Thin or diluted oil. 3. Change oil and filter.

4. Excessive bearing clearance. 4. Replace as necessary.

5. Connecting rod journal

out-of-round.5. Service or replace crankshaft.

6. Misaligned connecting rods. 6. Replace bent connecting rods.

MAIN BEARING NOISE 1. Insufficient oil supply. 1. (Refer to LUBRICATION &

MAINTENANCE -

SPECIFICATIONS)

2. Low oil pressure. 2. Check oil pump, if Ok, check rod

and main bearings for excessive

wear.

3. Thin or diluted oil. 3. Change oil and filter.

4. Excessive bearing clearance. 4. Replace as necessary.

5. Excessive end play. 5. Check thrust washers for wear.

6. Crankshaft journal out-of round. 6. Service or replace crankshaft.

7. Loose flywheel or torque

converter.7. Tighten to correct torque

9 - 6 ENGINE - 3.7LDR

ENGINE - 3.7L (Continued)

Page 1281 of 2895

(6) Air ingested into oil due to broken or cracked

oil pump pick up.

(7) Worn valve guides.

(8) Rocker arm ears contacting valve spring

retainer.

(9) Rocker arm loose, adjuster stuck or at maxi-

mum extension and still leaves lash in the system.

(10) Oil leak or excessive cam bore wear in cylin-

der head.

(11) Faulty lash adjuster.

a. Check lash adjusters for sponginess while

installed in cylinder head and cam on camshaft at

base circle. Depress part of rocker arm over adjuster.

Normal adjusters should feel very firm. Spongy

adjusters can be bottomed out easily.

b. Remove suspected lash adjusters, and replace.

c. Before installation, make sure adjusters are at

least partially full of oil. This can be verified by little

or no plunger travel when lash adjuster is depressed.

REMOVAL

(1) Disconnect battery negative cable.

(2) Raise the vehicle on a hoist.

(3) Disconnect the exhaust pipe at the right side

exhaust manifold.

(4) Drain the engine coolant(Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

(5) Lower the vehicle.

(6) Remove the intake manifold(Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL).

(7) Remove the cylinder head cover(Refer to 9 -

ENGINE/CYLINDER HEAD - REMOVAL).

(8) Remove the fan shroud(Refer to 7 - COOLING/

ENGINE/RADIATOR FAN - REMOVAL).

(9) Remove oil fill housing from cylinder head.

(10) Remove accessory drive belt(Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(11) Rotate the crankshaft until the damper timing

mark is aligned with TDC indicator mark.

(12) Verify the V6 mark on the camshaft sprocket

is at the 12 o'clock position. Rotate the crankshaft

one turn if necessary.

(13) Remove the crankshaft damper(Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(14) Remove the timing chain cover(Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(15) Lock the secondary timing chains to the idler

sprocket using Special Tool 8429 Timing Chain Hold-

ing Fixture.

NOTE: Mark the secondary timing chain prior to

removal to aid in installation.(16) Mark the secondary timing chain, one link on

each side of the V6 mark on the camshaft drive gear.

(17) Remove the right side secondary chain ten-

sioner(Refer to 9 - ENGINE/VALVE TIMING/TIM-

ING BELT/CHAIN AND SPROCKETS - REMOVAL).

(18) Remove the cylinder head access plug.

(19) Remove the right side secondary chain

guide(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT/CHAIN AND SPROCKETS - REMOVAL).

CAUTION: The nut on the right side camshaft

sprocket should not be removed for any reason, as

the sprocket and camshaft sensor target wheel is

serviced as an assembly. If the nut was removed

retorque nut to 5 N´m (44 in. lbs.).

(20) Remove the retaining bolt and the camshaft

drive gear.

CAUTION: Do not allow the engine to rotate. severe

damage to the valve train can occur.

CAUTION: Do not overlook the four smaller bolts at

the front of the cylinder head. Do not attempt to

remove the cylinder head without removing these

four bolts.

CAUTION: Do not hold or pry on the camshaft tar-

get wheel for any reason. A damaged target wheel

can result in a vehicle no start condition.

NOTE: The cylinder head is attached to the cylinder

block with twelve bolts.

(21) Remove the cylinder head retaining bolts.

(22) Remove the cylinder head and gasket. Discard

the gasket.

CAUTION: Do not lay the cylinder head on its gas-

ket sealing surface, do to the design of the cylinder

head gasket any distortion to the cylinder head

sealing surface may prevent the gasket from prop-

erly sealing resulting in leaks.

INSTALLATION

NOTE: The cylinder head bolts are tightened using

a torque plus angle procedure. The bolts must be

examined BEFORE reuse. If the threads are necked

down the bolts should be replaced.

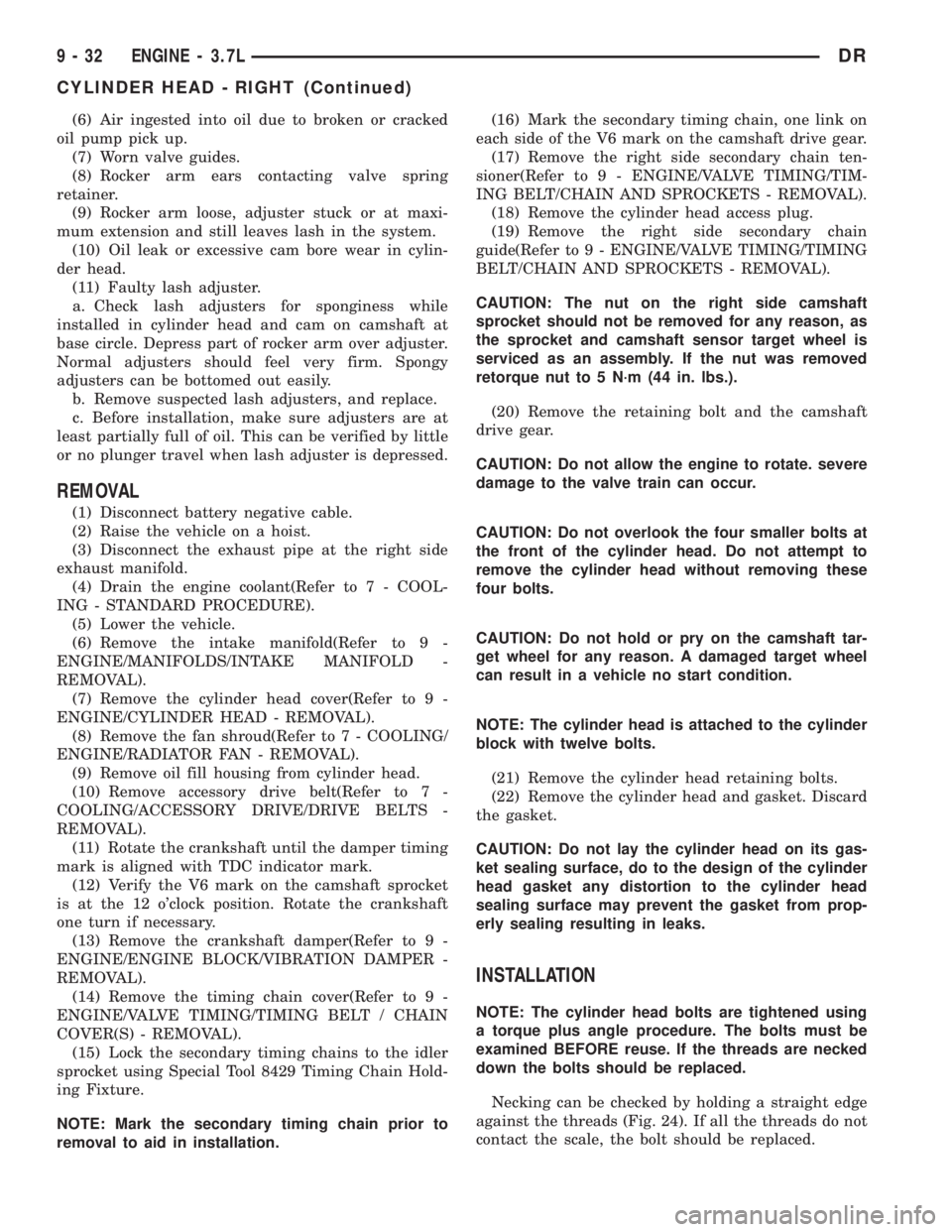

Necking can be checked by holding a straight edge

against the threads (Fig. 24). If all the threads do not

contact the scale, the bolt should be replaced.

9 - 32 ENGINE - 3.7LDR

CYLINDER HEAD - RIGHT (Continued)

Page 1282 of 2895

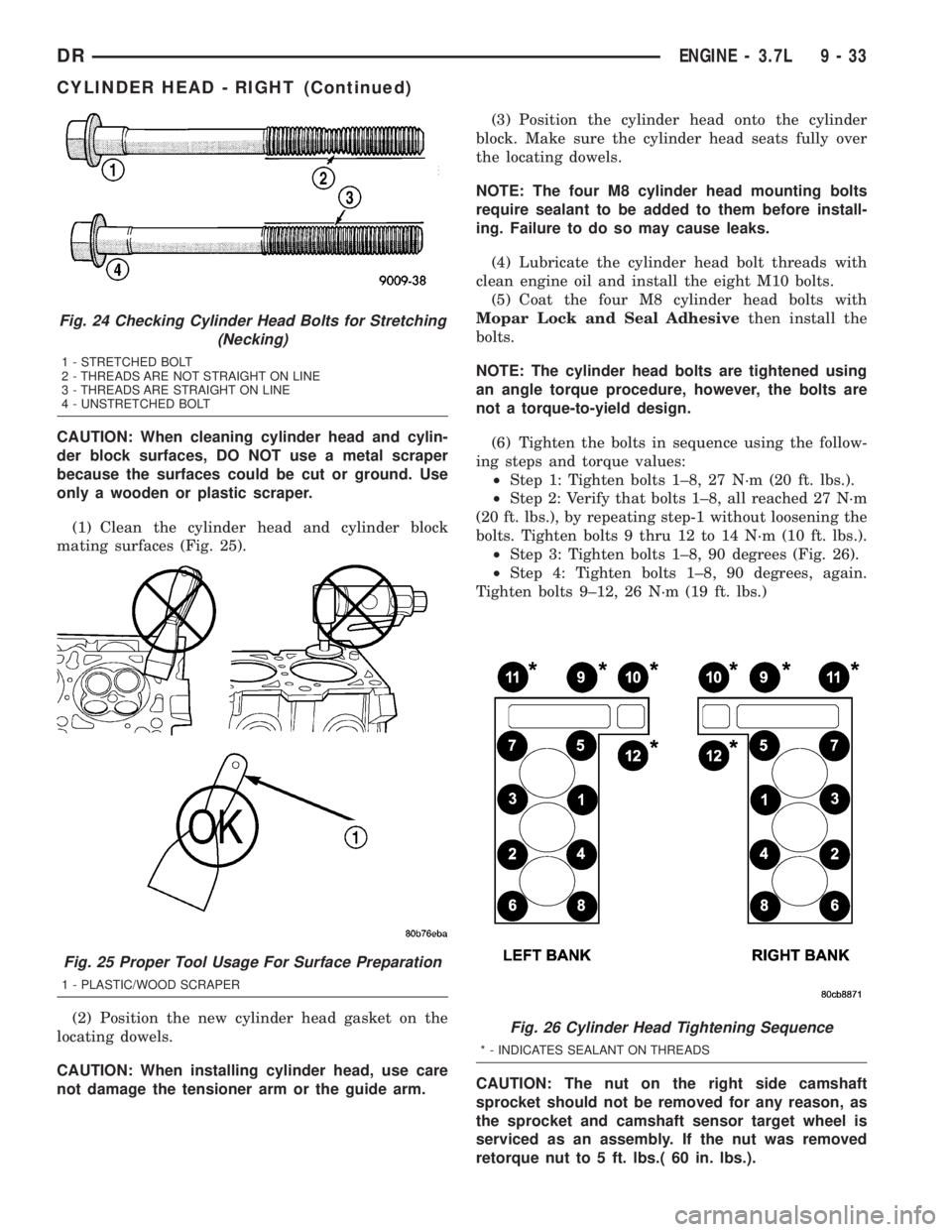

CAUTION: When cleaning cylinder head and cylin-

der block surfaces, DO NOT use a metal scraper

because the surfaces could be cut or ground. Use

only a wooden or plastic scraper.

(1) Clean the cylinder head and cylinder block

mating surfaces (Fig. 25).

(2) Position the new cylinder head gasket on the

locating dowels.

CAUTION: When installing cylinder head, use care

not damage the tensioner arm or the guide arm.(3) Position the cylinder head onto the cylinder

block. Make sure the cylinder head seats fully over

the locating dowels.

NOTE: The four M8 cylinder head mounting bolts

require sealant to be added to them before install-

ing. Failure to do so may cause leaks.

(4) Lubricate the cylinder head bolt threads with

clean engine oil and install the eight M10 bolts.

(5) Coat the four M8 cylinder head bolts with

Mopar Lock and Seal Adhesivethen install the

bolts.

NOTE: The cylinder head bolts are tightened using

an angle torque procedure, however, the bolts are

not a torque-to-yield design.

(6) Tighten the bolts in sequence using the follow-

ing steps and torque values:

²Step 1: Tighten bolts 1±8, 27 N´m (20 ft. lbs.).

²Step 2: Verify that bolts 1±8, all reached 27 N´m

(20 ft. lbs.), by repeating step-1 without loosening the

bolts. Tighten bolts 9 thru 12 to 14 N´m (10 ft. lbs.).

²Step 3: Tighten bolts 1±8, 90 degrees (Fig. 26).

²Step 4: Tighten bolts 1±8, 90 degrees, again.

Tighten bolts 9±12, 26 N´m (19 ft. lbs.)

CAUTION: The nut on the right side camshaft

sprocket should not be removed for any reason, as

the sprocket and camshaft sensor target wheel is

serviced as an assembly. If the nut was removed

retorque nut to 5 ft. lbs.( 60 in. lbs.).

Fig. 24 Checking Cylinder Head Bolts for Stretching

(Necking)

1 - STRETCHED BOLT

2 - THREADS ARE NOT STRAIGHT ON LINE

3 - THREADS ARE STRAIGHT ON LINE

4 - UNSTRETCHED BOLT

Fig. 25 Proper Tool Usage For Surface Preparation

1 - PLASTIC/WOOD SCRAPER

Fig. 26 Cylinder Head Tightening Sequence

* - INDICATES SEALANT ON THREADS

DRENGINE - 3.7L 9 - 33

CYLINDER HEAD - RIGHT (Continued)

Page 1289 of 2895

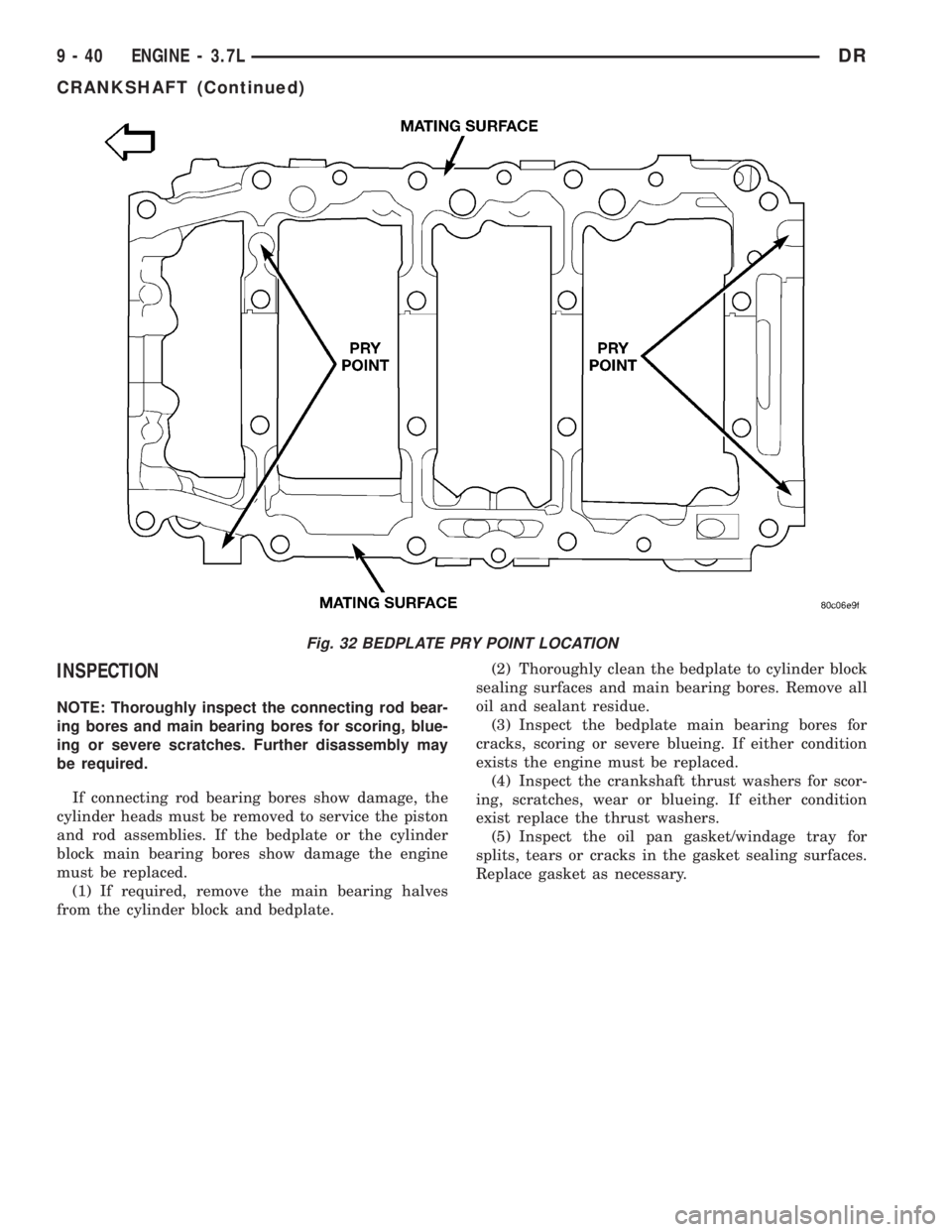

INSPECTION

NOTE: Thoroughly inspect the connecting rod bear-

ing bores and main bearing bores for scoring, blue-

ing or severe scratches. Further disassembly may

be required.

If connecting rod bearing bores show damage, the

cylinder heads must be removed to service the piston

and rod assemblies. If the bedplate or the cylinder

block main bearing bores show damage the engine

must be replaced.

(1) If required, remove the main bearing halves

from the cylinder block and bedplate.(2) Thoroughly clean the bedplate to cylinder block

sealing surfaces and main bearing bores. Remove all

oil and sealant residue.

(3) Inspect the bedplate main bearing bores for

cracks, scoring or severe blueing. If either condition

exists the engine must be replaced.

(4) Inspect the crankshaft thrust washers for scor-

ing, scratches, wear or blueing. If either condition

exist replace the thrust washers.

(5) Inspect the oil pan gasket/windage tray for

splits, tears or cracks in the gasket sealing surfaces.

Replace gasket as necessary.

Fig. 32 BEDPLATE PRY POINT LOCATION

9 - 40 ENGINE - 3.7LDR

CRANKSHAFT (Continued)

Page 1292 of 2895

CRANKSHAFT MAIN

BEARINGS

STANDARD PROCEDURE

MAIN BEARING FITTING

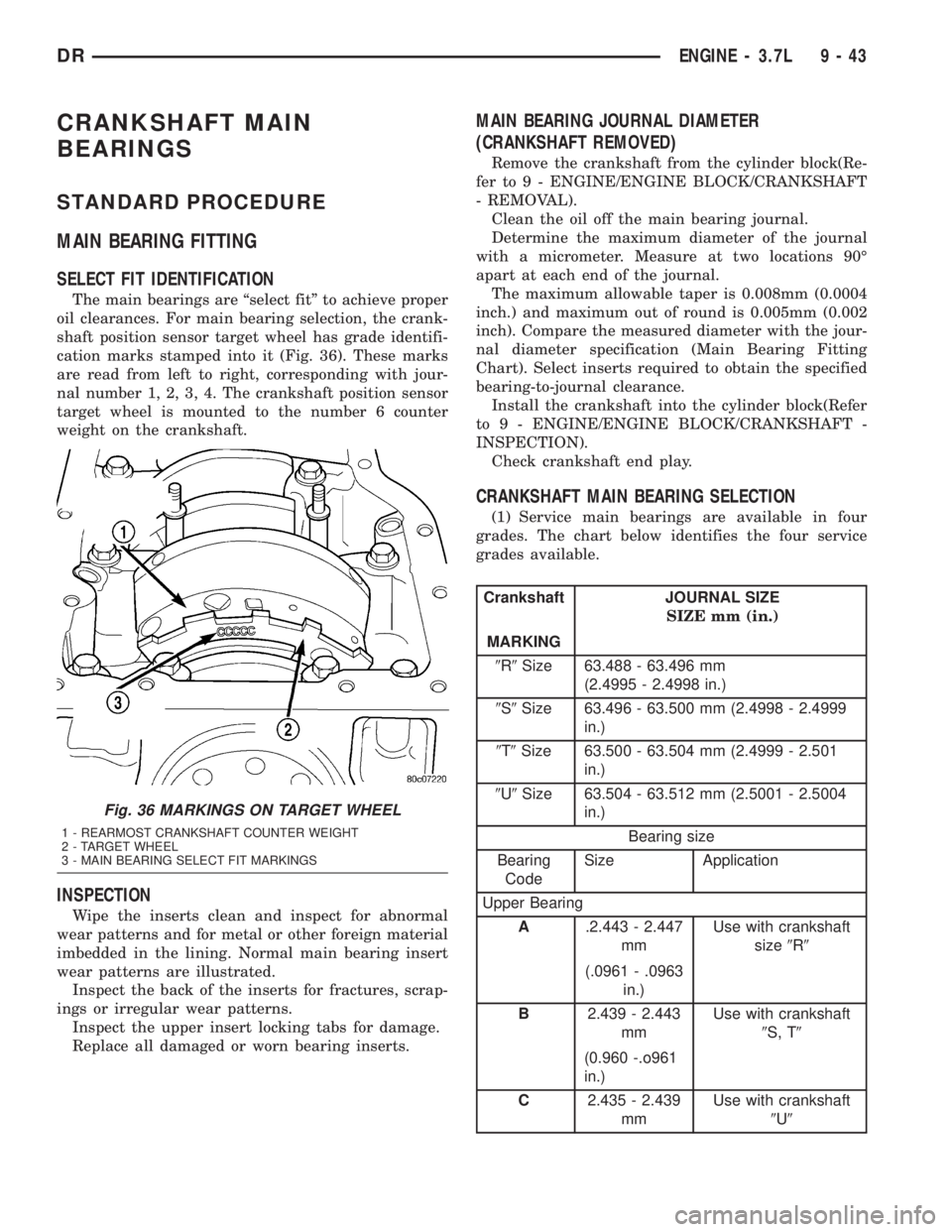

SELECT FIT IDENTIFICATION

The main bearings are ªselect fitº to achieve proper

oil clearances. For main bearing selection, the crank-

shaft position sensor target wheel has grade identifi-

cation marks stamped into it (Fig. 36). These marks

are read from left to right, corresponding with jour-

nal number 1, 2, 3, 4. The crankshaft position sensor

target wheel is mounted to the number 6 counter

weight on the crankshaft.

INSPECTION

Wipe the inserts clean and inspect for abnormal

wear patterns and for metal or other foreign material

imbedded in the lining. Normal main bearing insert

wear patterns are illustrated.

Inspect the back of the inserts for fractures, scrap-

ings or irregular wear patterns.

Inspect the upper insert locking tabs for damage.

Replace all damaged or worn bearing inserts.

MAIN BEARING JOURNAL DIAMETER

(CRANKSHAFT REMOVED)

Remove the crankshaft from the cylinder block(Re-

fer to 9 - ENGINE/ENGINE BLOCK/CRANKSHAFT

- REMOVAL).

Clean the oil off the main bearing journal.

Determine the maximum diameter of the journal

with a micrometer. Measure at two locations 90É

apart at each end of the journal.

The maximum allowable taper is 0.008mm (0.0004

inch.) and maximum out of round is 0.005mm (0.002

inch). Compare the measured diameter with the jour-

nal diameter specification (Main Bearing Fitting

Chart). Select inserts required to obtain the specified

bearing-to-journal clearance.

Install the crankshaft into the cylinder block(Refer

to 9 - ENGINE/ENGINE BLOCK/CRANKSHAFT -

INSPECTION).

Check crankshaft end play.

CRANKSHAFT MAIN BEARING SELECTION

(1) Service main bearings are available in four

grades. The chart below identifies the four service

grades available.

Crankshaft JOURNAL SIZE

SIZE mm (in.)

MARKING

9R9Size 63.488 - 63.496 mm

(2.4995 - 2.4998 in.)

9S9Size 63.496 - 63.500 mm (2.4998 - 2.4999

in.)

9T9Size 63.500 - 63.504 mm (2.4999 - 2.501

in.)

9U9Size 63.504 - 63.512 mm (2.5001 - 2.5004

in.)

Bearing size

Bearing

CodeSize Application

Upper Bearing

A.2.443 - 2.447

mmUse with crankshaft

size9R9

(.0961 - .0963

in.)

B2.439 - 2.443

mmUse with crankshaft

9S, T9

(0.960 -.o961

in.)

C2.435 - 2.439

mmUse with crankshaft

9U9

Fig. 36 MARKINGS ON TARGET WHEEL

1 - REARMOST CRANKSHAFT COUNTER WEIGHT

2 - TARGET WHEEL

3 - MAIN BEARING SELECT FIT MARKINGS

DRENGINE - 3.7L 9 - 43

Page 1298 of 2895

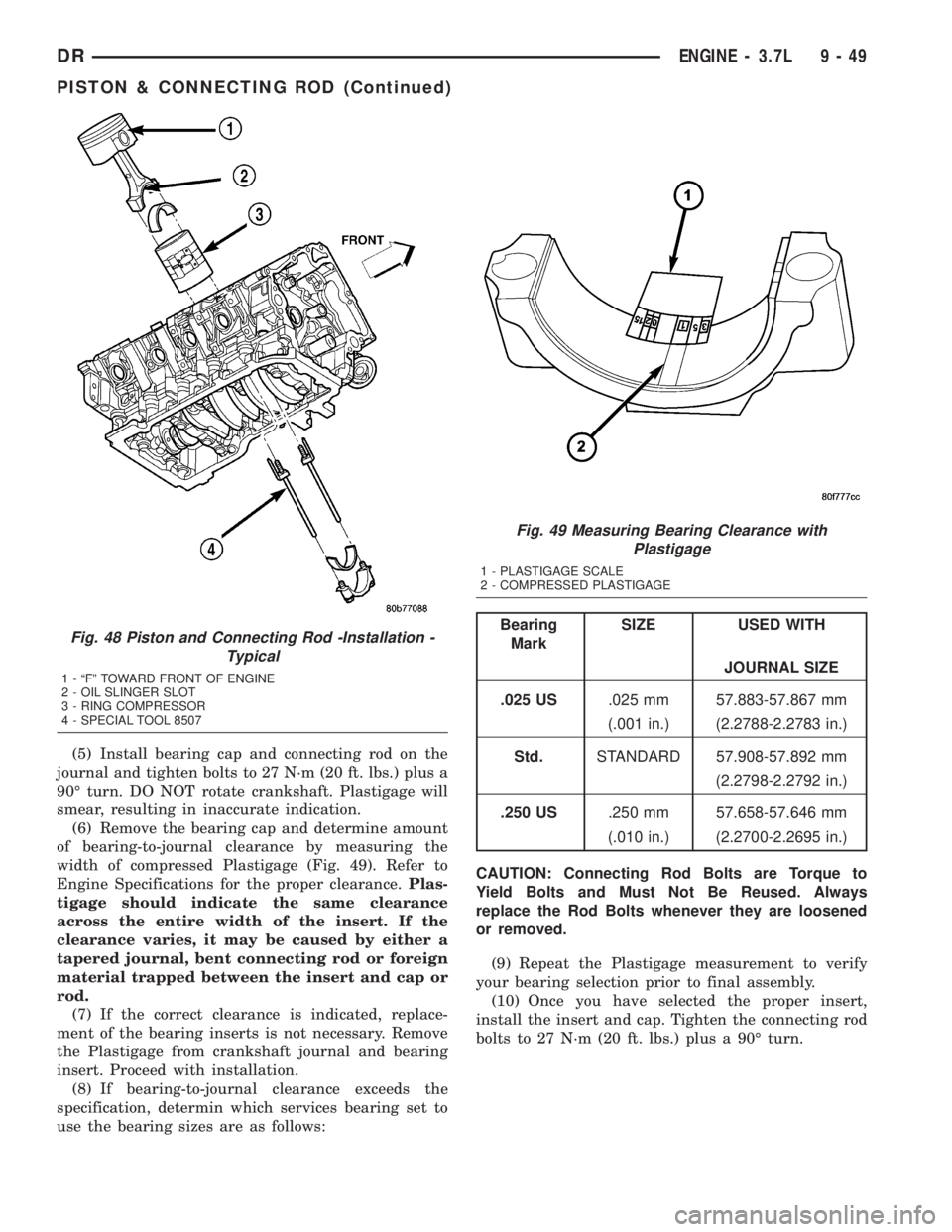

(5) Install bearing cap and connecting rod on the

journal and tighten bolts to 27 N´m (20 ft. lbs.) plus a

90É turn. DO NOT rotate crankshaft. Plastigage will

smear, resulting in inaccurate indication.

(6) Remove the bearing cap and determine amount

of bearing-to-journal clearance by measuring the

width of compressed Plastigage (Fig. 49). Refer to

Engine Specifications for the proper clearance.Plas-

tigage should indicate the same clearance

across the entire width of the insert. If the

clearance varies, it may be caused by either a

tapered journal, bent connecting rod or foreign

material trapped between the insert and cap or

rod.

(7) If the correct clearance is indicated, replace-

ment of the bearing inserts is not necessary. Remove

the Plastigage from crankshaft journal and bearing

insert. Proceed with installation.

(8) If bearing-to-journal clearance exceeds the

specification, determin which services bearing set to

use the bearing sizes are as follows:

Bearing

MarkSIZE USED WITH

JOURNAL SIZE

.025 US.025 mm 57.883-57.867 mm

(.001 in.) (2.2788-2.2783 in.)

Std.STANDARD 57.908-57.892 mm

(2.2798-2.2792 in.)

.250 US.250 mm 57.658-57.646 mm

(.010 in.) (2.2700-2.2695 in.)

CAUTION: Connecting Rod Bolts are Torque to

Yield Bolts and Must Not Be Reused. Always

replace the Rod Bolts whenever they are loosened

or removed.

(9) Repeat the Plastigage measurement to verify

your bearing selection prior to final assembly.

(10) Once you have selected the proper insert,

install the insert and cap. Tighten the connecting rod

bolts to 27 N´m (20 ft. lbs.) plus a 90É turn.Fig. 48 Piston and Connecting Rod -Installation -

Typical

1 - ªFº TOWARD FRONT OF ENGINE

2 - OIL SLINGER SLOT

3 - RING COMPRESSOR

4 - SPECIAL TOOL 8507

Fig. 49 Measuring Bearing Clearance with

Plastigage

1 - PLASTIGAGE SCALE

2 - COMPRESSED PLASTIGAGE

DRENGINE - 3.7L 9 - 49

PISTON & CONNECTING ROD (Continued)

Page 1299 of 2895

Slide snug-fitting feeler gauge between the con-

necting rod and crankshaft journal flange (Fig. 50).

Refer to Engine Specifications for the proper clear-

ance. Replace the connecting rod if the side clearance

is not within specification.

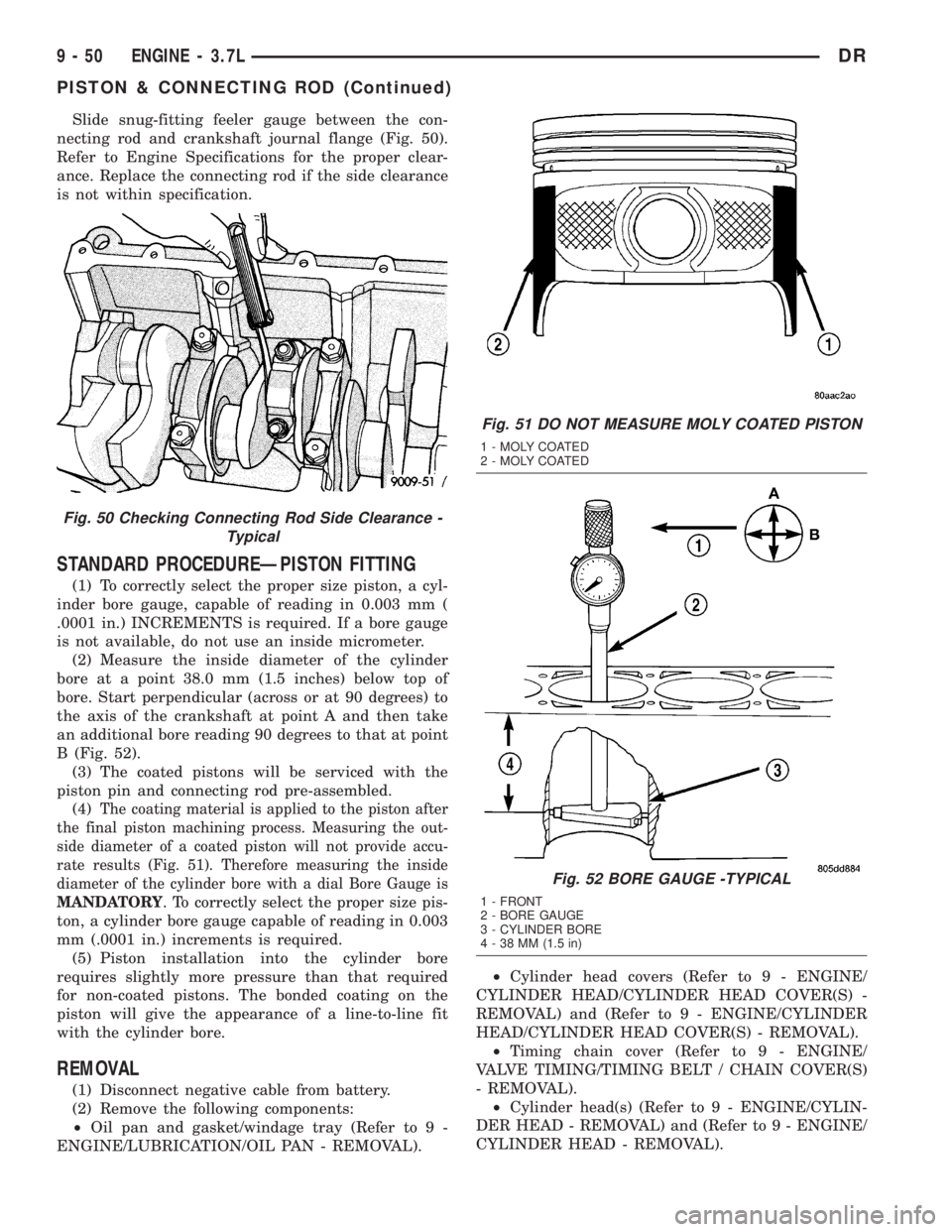

STANDARD PROCEDUREÐPISTON FITTING

(1) To correctly select the proper size piston, a cyl-

inder bore gauge, capable of reading in 0.003 mm (

.0001 in.) INCREMENTS is required. If a bore gauge

is not available, do not use an inside micrometer.

(2) Measure the inside diameter of the cylinder

bore at a point 38.0 mm (1.5 inches) below top of

bore. Start perpendicular (across or at 90 degrees) to

the axis of the crankshaft at point A and then take

an additional bore reading 90 degrees to that at point

B (Fig. 52).

(3) The coated pistons will be serviced with the

piston pin and connecting rod pre-assembled.

(4)

The coating material is applied to the piston after

the final piston machining process. Measuring the out-

side diameter of a coated piston will not provide accu-

rate results (Fig. 51). Therefore measuring the inside

diameter of the cylinder bore with a dial Bore Gauge is

MANDATORY

. To correctly select the proper size pis-

ton, a cylinder bore gauge capable of reading in 0.003

mm (.0001 in.) increments is required.

(5) Piston installation into the cylinder bore

requires slightly more pressure than that required

for non-coated pistons. The bonded coating on the

piston will give the appearance of a line-to-line fit

with the cylinder bore.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the following components:

²Oil pan and gasket/windage tray (Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - REMOVAL).²Cylinder head covers (Refer to 9 - ENGINE/

CYLINDER HEAD/CYLINDER HEAD COVER(S) -

REMOVAL) and (Refer to 9 - ENGINE/CYLINDER

HEAD/CYLINDER HEAD COVER(S) - REMOVAL).

²Timing chain cover (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT / CHAIN COVER(S)

- REMOVAL).

²Cylinder head(s) (Refer to 9 - ENGINE/CYLIN-

DER HEAD - REMOVAL) and (Refer to 9 - ENGINE/

CYLINDER HEAD - REMOVAL).

Fig. 50 Checking Connecting Rod Side Clearance -

Typical

Fig. 51 DO NOT MEASURE MOLY COATED PISTON

1 - MOLY COATED

2 - MOLY COATED

Fig. 52 BORE GAUGE -TYPICAL

1 - FRONT

2 - BORE GAUGE

3 - CYLINDER BORE

4 - 38 MM (1.5 in)

9 - 50 ENGINE - 3.7LDR

PISTON & CONNECTING ROD (Continued)