Transmission DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1857 of 2895

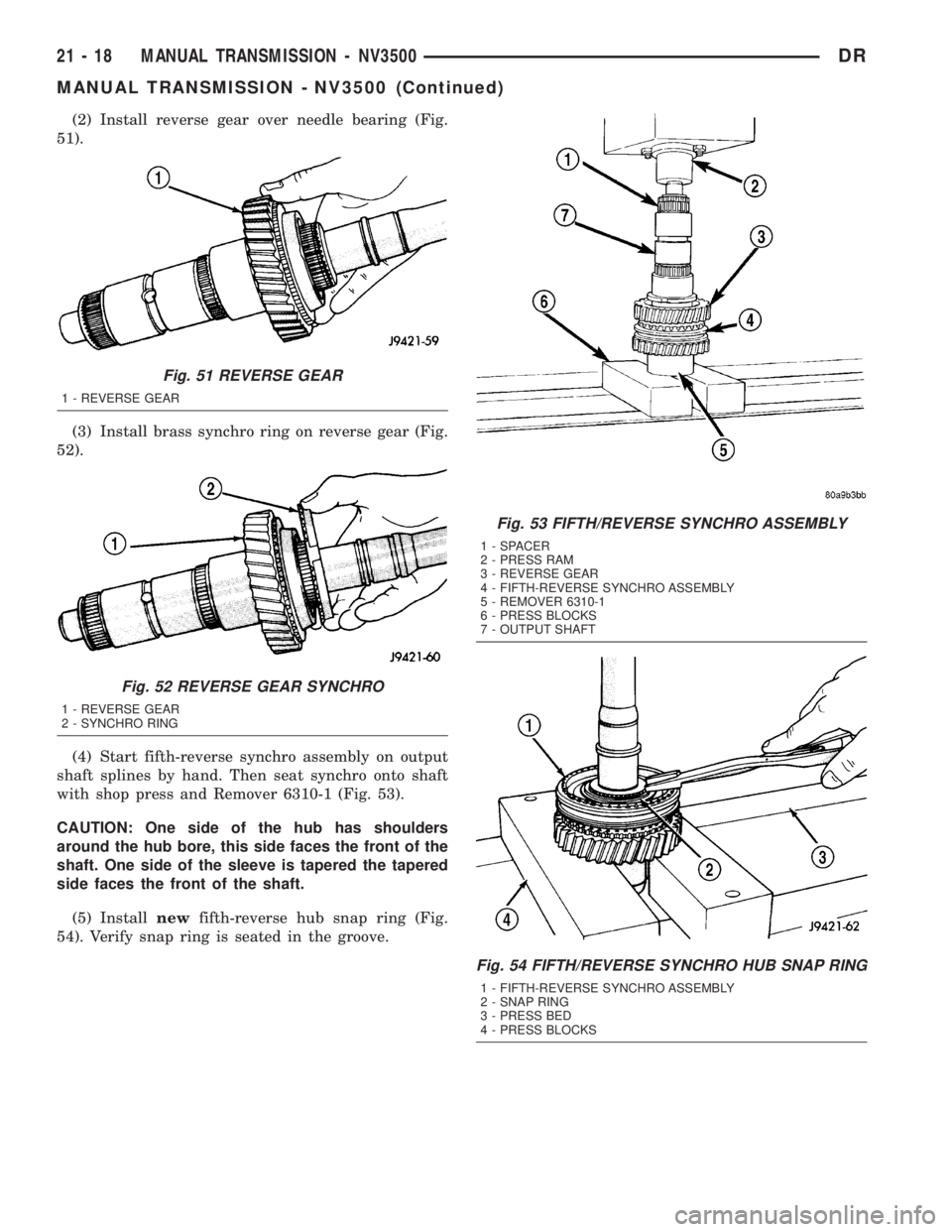

(2) Install reverse gear over needle bearing (Fig.

51).

(3) Install brass synchro ring on reverse gear (Fig.

52).

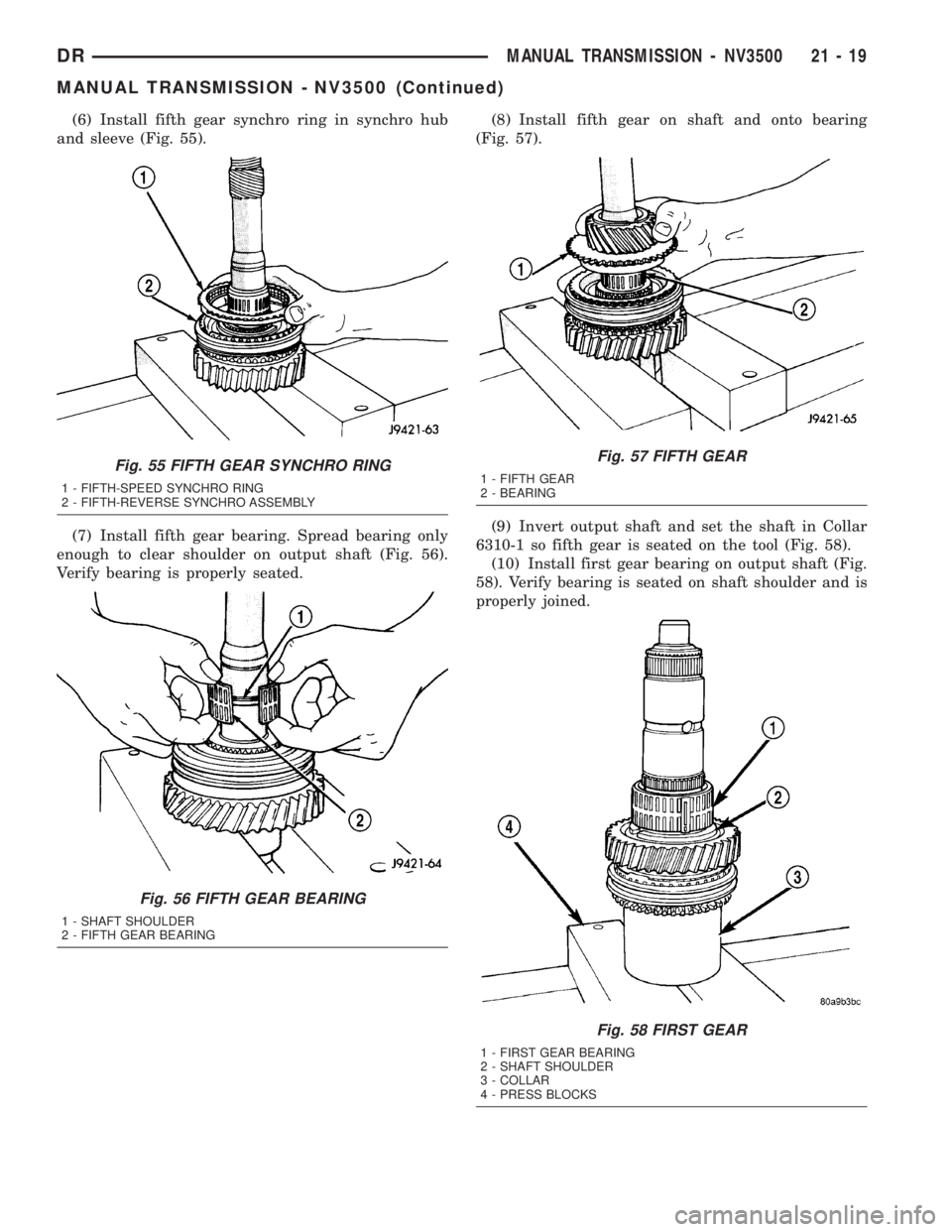

(4) Start fifth-reverse synchro assembly on output

shaft splines by hand. Then seat synchro onto shaft

with shop press and Remover 6310-1 (Fig. 53).

CAUTION: One side of the hub has shoulders

around the hub bore, this side faces the front of the

shaft. One side of the sleeve is tapered the tapered

side faces the front of the shaft.

(5) Installnewfifth-reverse hub snap ring (Fig.

54). Verify snap ring is seated in the groove.

Fig. 51 REVERSE GEAR

1 - REVERSE GEAR

Fig. 52 REVERSE GEAR SYNCHRO

1 - REVERSE GEAR

2 - SYNCHRO RING

Fig. 53 FIFTH/REVERSE SYNCHRO ASSEMBLY

1 - SPACER

2 - PRESS RAM

3 - REVERSE GEAR

4 - FIFTH-REVERSE SYNCHRO ASSEMBLY

5 - REMOVER 6310-1

6 - PRESS BLOCKS

7 - OUTPUT SHAFT

Fig. 54 FIFTH/REVERSE SYNCHRO HUB SNAP RING

1 - FIFTH-REVERSE SYNCHRO ASSEMBLY

2 - SNAP RING

3 - PRESS BED

4 - PRESS BLOCKS

21 - 18 MANUAL TRANSMISSION - NV3500DR

MANUAL TRANSMISSION - NV3500 (Continued)

Page 1858 of 2895

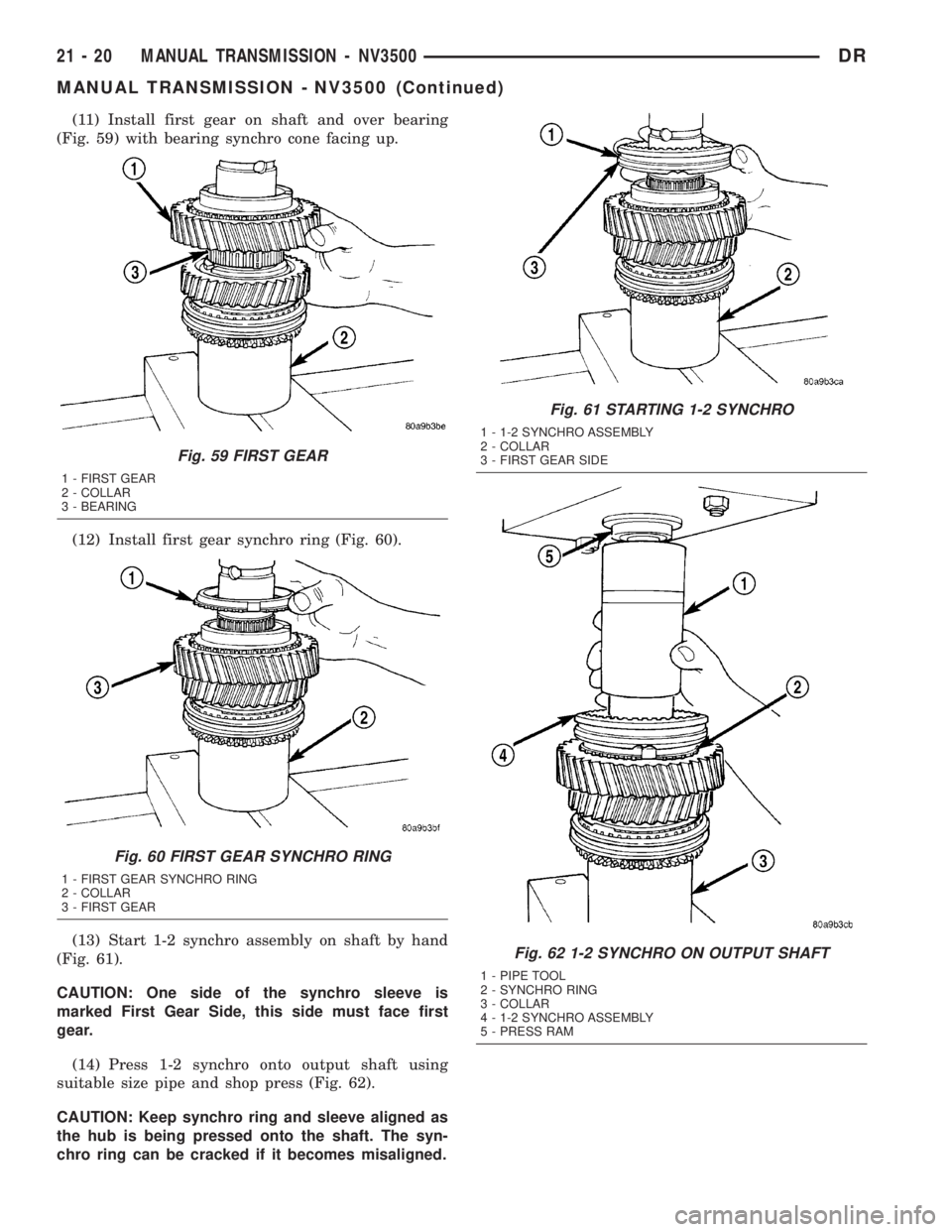

(6) Install fifth gear synchro ring in synchro hub

and sleeve (Fig. 55).

(7) Install fifth gear bearing. Spread bearing only

enough to clear shoulder on output shaft (Fig. 56).

Verify bearing is properly seated.(8) Install fifth gear on shaft and onto bearing

(Fig. 57).

(9) Invert output shaft and set the shaft in Collar

6310-1 so fifth gear is seated on the tool (Fig. 58).

(10) Install first gear bearing on output shaft (Fig.

58). Verify bearing is seated on shaft shoulder and is

properly joined.

Fig. 55 FIFTH GEAR SYNCHRO RING

1 - FIFTH-SPEED SYNCHRO RING

2 - FIFTH-REVERSE SYNCHRO ASSEMBLY

Fig. 56 FIFTH GEAR BEARING

1 - SHAFT SHOULDER

2 - FIFTH GEAR BEARING

Fig. 57 FIFTH GEAR

1 - FIFTH GEAR

2 - BEARING

Fig. 58 FIRST GEAR

1 - FIRST GEAR BEARING

2 - SHAFT SHOULDER

3 - COLLAR

4 - PRESS BLOCKS

DRMANUAL TRANSMISSION - NV3500 21 - 19

MANUAL TRANSMISSION - NV3500 (Continued)

Page 1859 of 2895

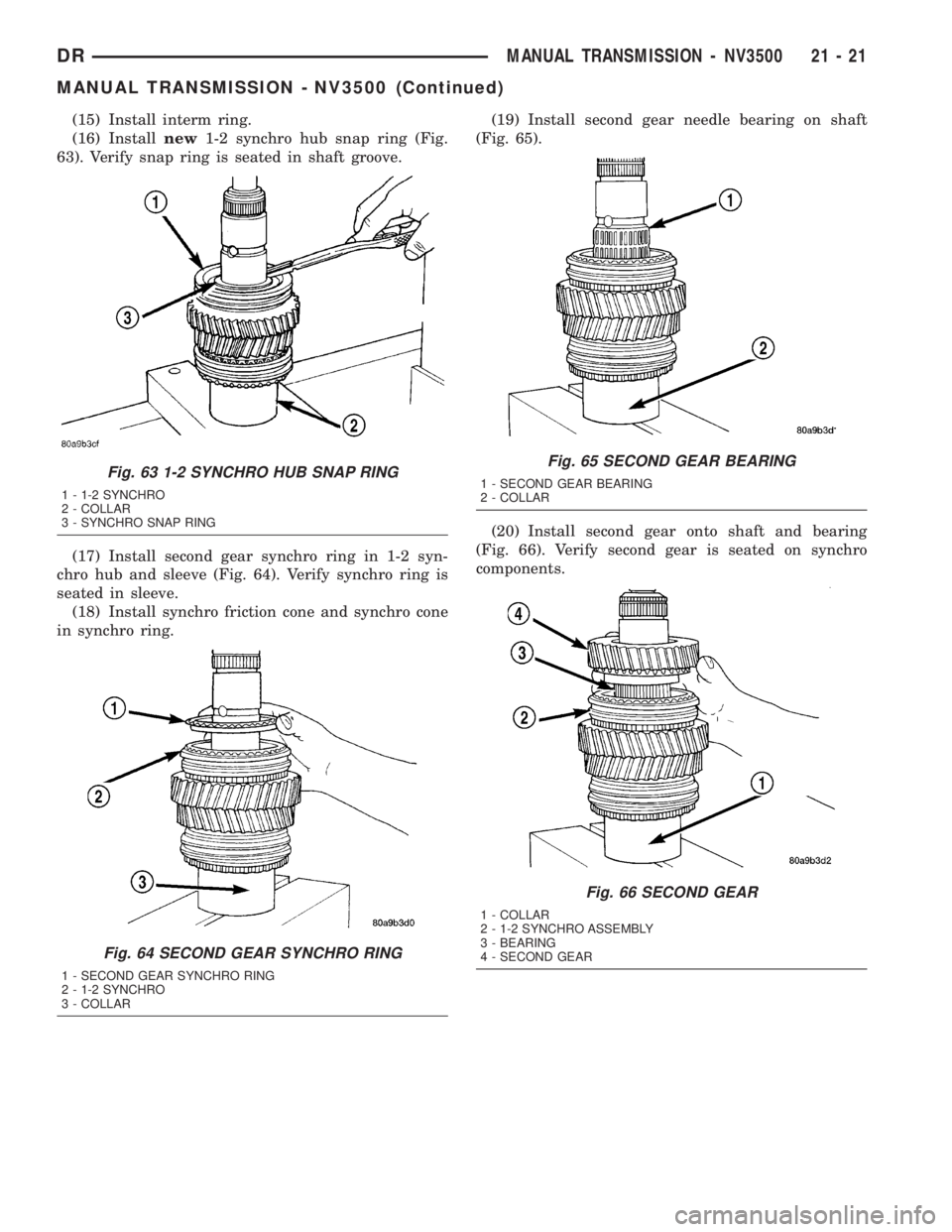

(11) Install first gear on shaft and over bearing

(Fig. 59) with bearing synchro cone facing up.

(12) Install first gear synchro ring (Fig. 60).

(13) Start 1-2 synchro assembly on shaft by hand

(Fig. 61).

CAUTION: One side of the synchro sleeve is

marked First Gear Side, this side must face first

gear.

(14) Press 1-2 synchro onto output shaft using

suitable size pipe and shop press (Fig. 62).

CAUTION: Keep synchro ring and sleeve aligned as

the hub is being pressed onto the shaft. The syn-

chro ring can be cracked if it becomes misaligned.

Fig. 59 FIRST GEAR

1 - FIRST GEAR

2 - COLLAR

3 - BEARING

Fig. 60 FIRST GEAR SYNCHRO RING

1 - FIRST GEAR SYNCHRO RING

2 - COLLAR

3 - FIRST GEAR

Fig. 61 STARTING 1-2 SYNCHRO

1 - 1-2 SYNCHRO ASSEMBLY

2 - COLLAR

3 - FIRST GEAR SIDE

Fig. 62 1-2 SYNCHRO ON OUTPUT SHAFT

1 - PIPE TOOL

2 - SYNCHRO RING

3 - COLLAR

4 - 1-2 SYNCHRO ASSEMBLY

5 - PRESS RAM

21 - 20 MANUAL TRANSMISSION - NV3500DR

MANUAL TRANSMISSION - NV3500 (Continued)

Page 1860 of 2895

(15) Install interm ring.

(16) Installnew1-2 synchro hub snap ring (Fig.

63). Verify snap ring is seated in shaft groove.

(17) Install second gear synchro ring in 1-2 syn-

chro hub and sleeve (Fig. 64). Verify synchro ring is

seated in sleeve.

(18) Install synchro friction cone and synchro cone

in synchro ring.(19) Install second gear needle bearing on shaft

(Fig. 65).

(20) Install second gear onto shaft and bearing

(Fig. 66). Verify second gear is seated on synchro

components.

Fig. 63 1-2 SYNCHRO HUB SNAP RING

1 - 1-2 SYNCHRO

2 - COLLAR

3 - SYNCHRO SNAP RING

Fig. 64 SECOND GEAR SYNCHRO RING

1 - SECOND GEAR SYNCHRO RING

2 - 1-2 SYNCHRO

3 - COLLAR

Fig. 65 SECOND GEAR BEARING

1 - SECOND GEAR BEARING

2 - COLLAR

Fig. 66 SECOND GEAR

1 - COLLAR

2 - 1-2 SYNCHRO ASSEMBLY

3 - BEARING

4 - SECOND GEAR

DRMANUAL TRANSMISSION - NV3500 21 - 21

MANUAL TRANSMISSION - NV3500 (Continued)

Page 1861 of 2895

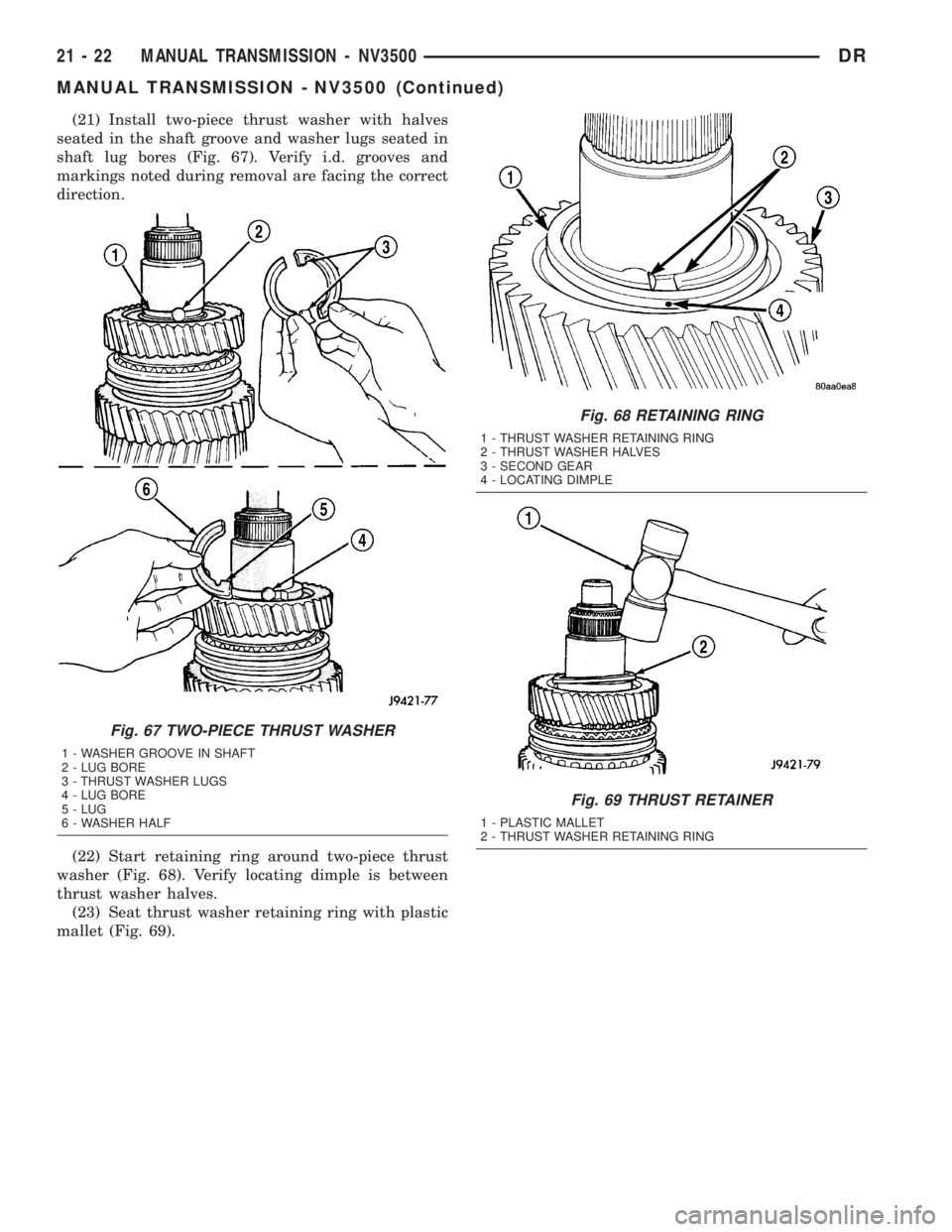

(21) Install two-piece thrust washer with halves

seated in the shaft groove and washer lugs seated in

shaft lug bores (Fig. 67). Verify i.d. grooves and

markings noted during removal are facing the correct

direction.

(22) Start retaining ring around two-piece thrust

washer (Fig. 68). Verify locating dimple is between

thrust washer halves.

(23) Seat thrust washer retaining ring with plastic

mallet (Fig. 69).

Fig. 67 TWO-PIECE THRUST WASHER

1 - WASHER GROOVE IN SHAFT

2 - LUG BORE

3 - THRUST WASHER LUGS

4 - LUG BORE

5 - LUG

6 - WASHER HALF

Fig. 68 RETAINING RING

1 - THRUST WASHER RETAINING RING

2 - THRUST WASHER HALVES

3 - SECOND GEAR

4 - LOCATING DIMPLE

Fig. 69 THRUST RETAINER

1 - PLASTIC MALLET

2 - THRUST WASHER RETAINING RING

21 - 22 MANUAL TRANSMISSION - NV3500DR

MANUAL TRANSMISSION - NV3500 (Continued)

Page 1862 of 2895

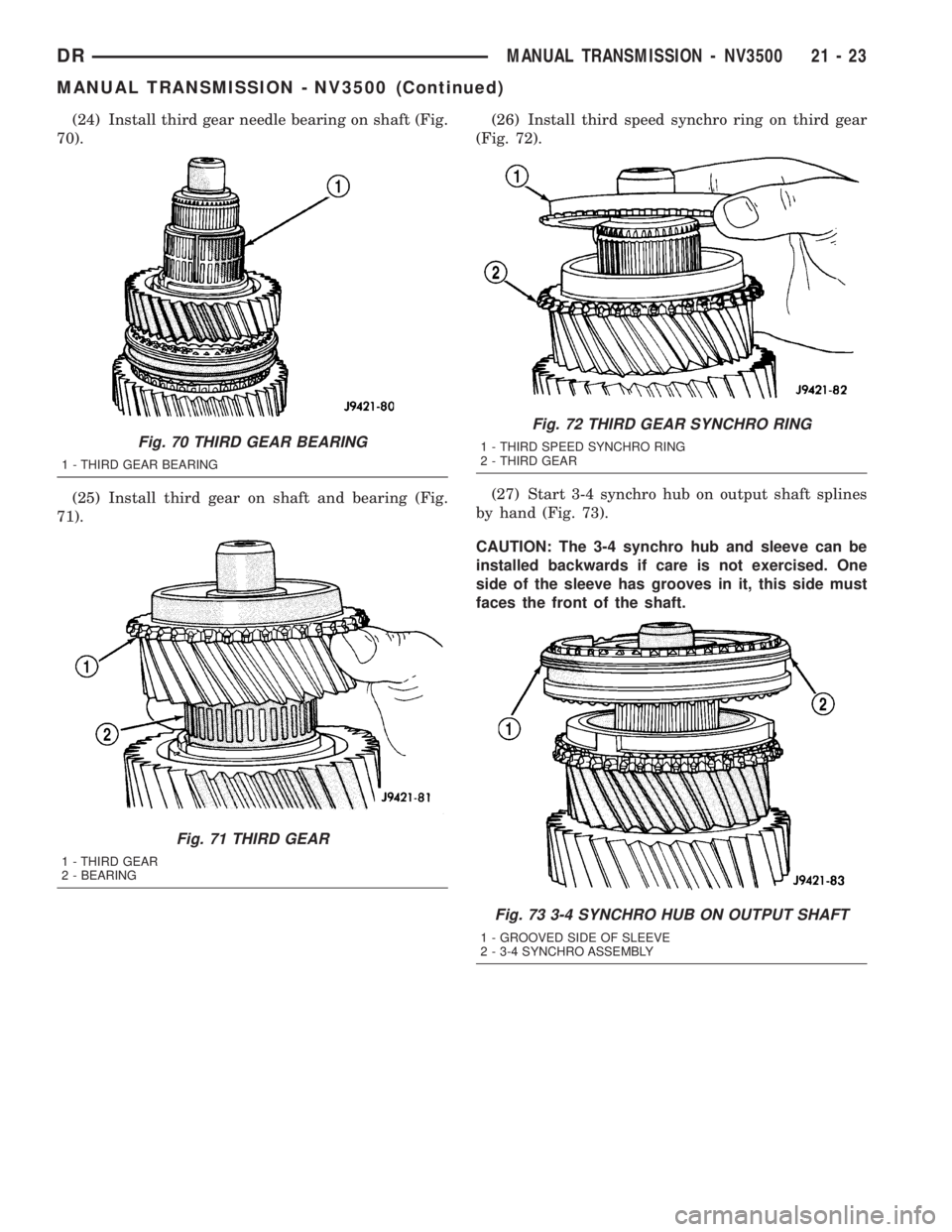

(24) Install third gear needle bearing on shaft (Fig.

70).

(25) Install third gear on shaft and bearing (Fig.

71).(26) Install third speed synchro ring on third gear

(Fig. 72).

(27) Start 3-4 synchro hub on output shaft splines

by hand (Fig. 73).

CAUTION: The 3-4 synchro hub and sleeve can be

installed backwards if care is not exercised. One

side of the sleeve has grooves in it, this side must

faces the front of the shaft.

Fig. 70 THIRD GEAR BEARING

1 - THIRD GEAR BEARING

Fig. 71 THIRD GEAR

1 - THIRD GEAR

2 - BEARING

Fig. 72 THIRD GEAR SYNCHRO RING

1 - THIRD SPEED SYNCHRO RING

2 - THIRD GEAR

Fig. 73 3-4 SYNCHRO HUB ON OUTPUT SHAFT

1 - GROOVED SIDE OF SLEEVE

2 - 3-4 SYNCHRO ASSEMBLY

DRMANUAL TRANSMISSION - NV3500 21 - 23

MANUAL TRANSMISSION - NV3500 (Continued)

Page 1863 of 2895

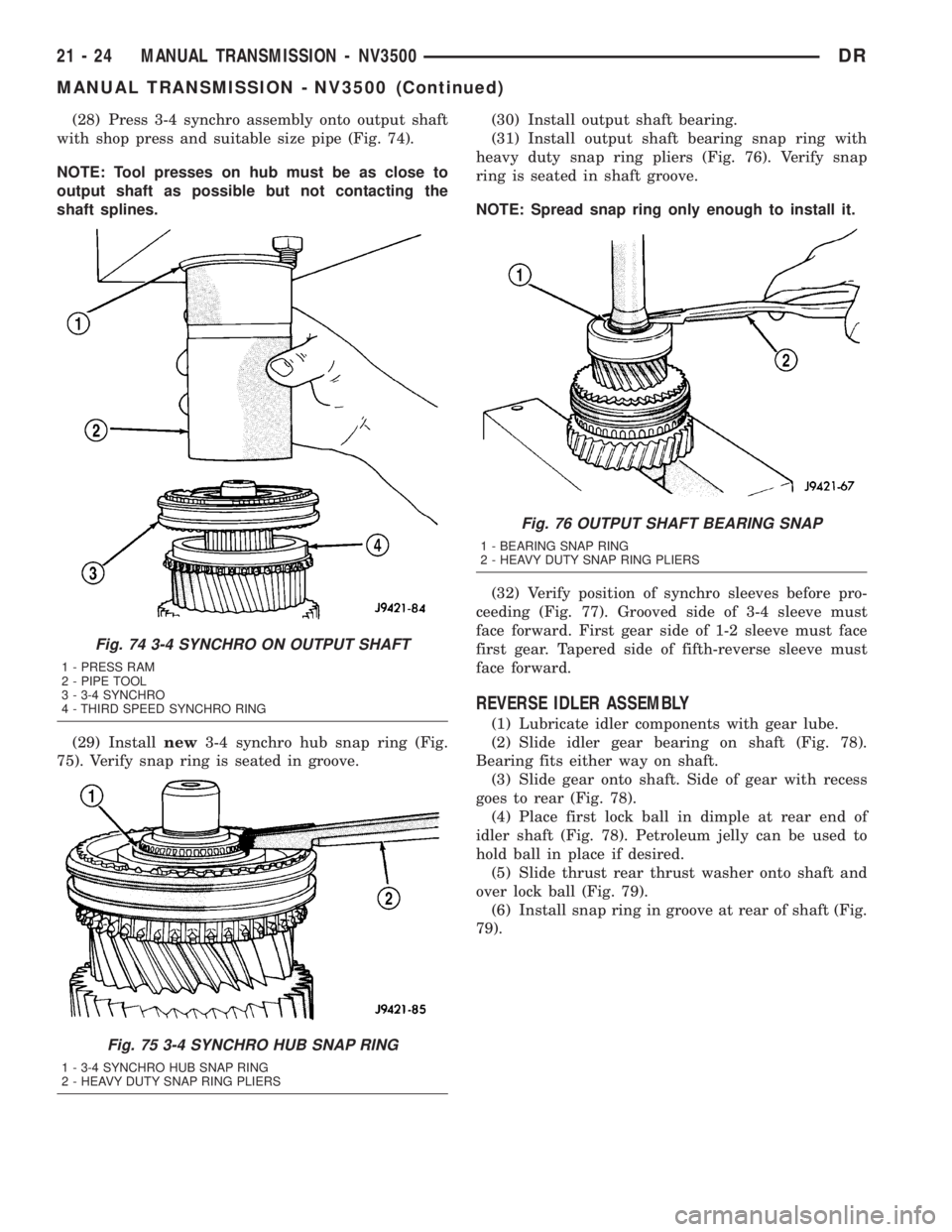

(28) Press 3-4 synchro assembly onto output shaft

with shop press and suitable size pipe (Fig. 74).

NOTE: Tool presses on hub must be as close to

output shaft as possible but not contacting the

shaft splines.

(29) Installnew3-4 synchro hub snap ring (Fig.

75). Verify snap ring is seated in groove.(30) Install output shaft bearing.

(31) Install output shaft bearing snap ring with

heavy duty snap ring pliers (Fig. 76). Verify snap

ring is seated in shaft groove.

NOTE: Spread snap ring only enough to install it.

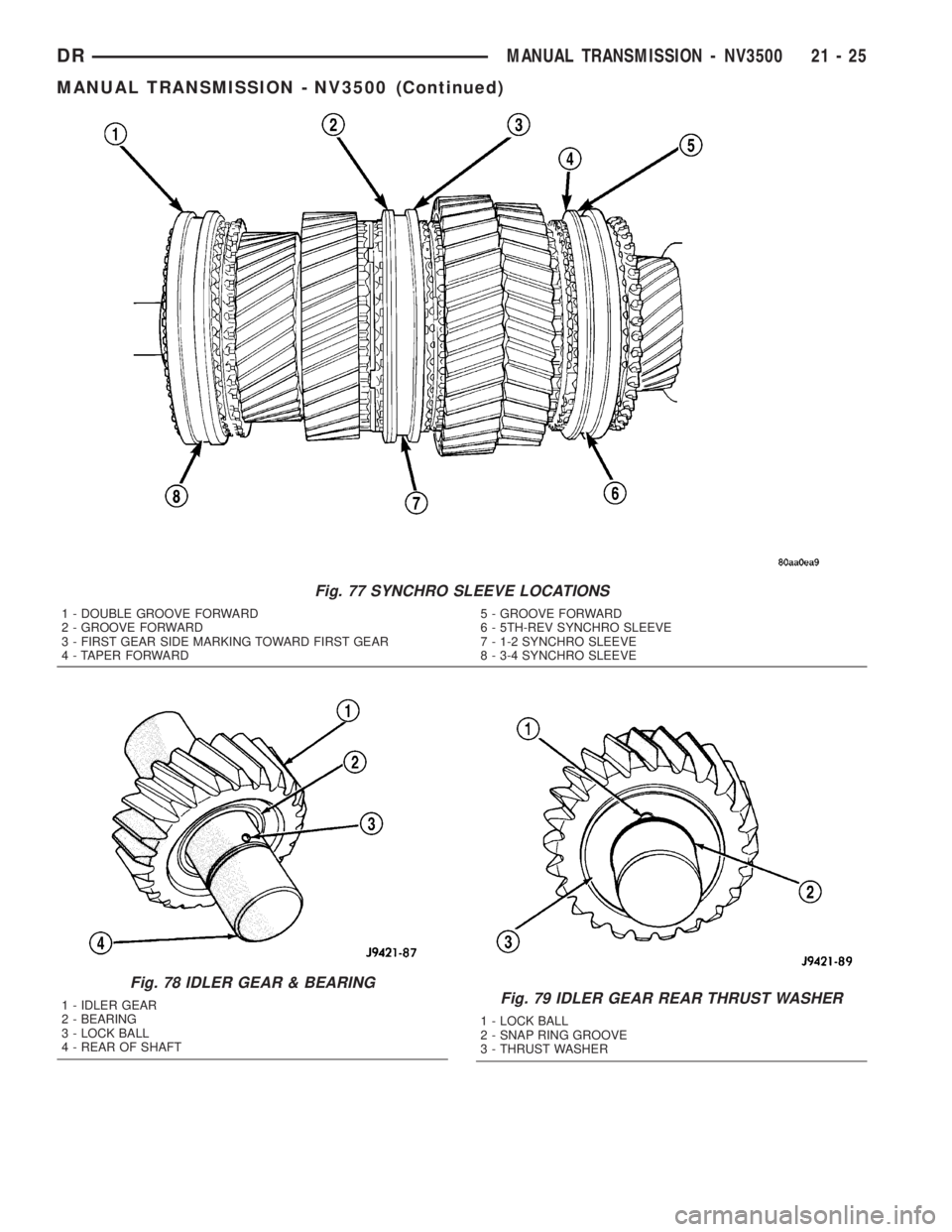

(32) Verify position of synchro sleeves before pro-

ceeding (Fig. 77). Grooved side of 3-4 sleeve must

face forward. First gear side of 1-2 sleeve must face

first gear. Tapered side of fifth-reverse sleeve must

face forward.

REVERSE IDLER ASSEMBLY

(1) Lubricate idler components with gear lube.

(2) Slide idler gear bearing on shaft (Fig. 78).

Bearing fits either way on shaft.

(3) Slide gear onto shaft. Side of gear with recess

goes to rear (Fig. 78).

(4) Place first lock ball in dimple at rear end of

idler shaft (Fig. 78). Petroleum jelly can be used to

hold ball in place if desired.

(5) Slide thrust rear thrust washer onto shaft and

over lock ball (Fig. 79).

(6) Install snap ring in groove at rear of shaft (Fig.

79).

Fig. 74 3-4 SYNCHRO ON OUTPUT SHAFT

1 - PRESS RAM

2 - PIPE TOOL

3 - 3-4 SYNCHRO

4 - THIRD SPEED SYNCHRO RING

Fig. 75 3-4 SYNCHRO HUB SNAP RING

1 - 3-4 SYNCHRO HUB SNAP RING

2 - HEAVY DUTY SNAP RING PLIERS

Fig. 76 OUTPUT SHAFT BEARING SNAP

1 - BEARING SNAP RING

2 - HEAVY DUTY SNAP RING PLIERS

21 - 24 MANUAL TRANSMISSION - NV3500DR

MANUAL TRANSMISSION - NV3500 (Continued)

Page 1864 of 2895

Fig. 77 SYNCHRO SLEEVE LOCATIONS

1 - DOUBLE GROOVE FORWARD

2 - GROOVE FORWARD

3 - FIRST GEAR SIDE MARKING TOWARD FIRST GEAR

4 - TAPER FORWARD5 - GROOVE FORWARD

6 - 5TH-REV SYNCHRO SLEEVE

7 - 1-2 SYNCHRO SLEEVE

8 - 3-4 SYNCHRO SLEEVE

Fig. 78 IDLER GEAR & BEARING

1 - IDLER GEAR

2 - BEARING

3 - LOCK BALL

4 - REAR OF SHAFTFig. 79 IDLER GEAR REAR THRUST WASHER

1 - LOCK BALL

2 - SNAP RING GROOVE

3 - THRUST WASHER

DRMANUAL TRANSMISSION - NV3500 21 - 25

MANUAL TRANSMISSION - NV3500 (Continued)

Page 1865 of 2895

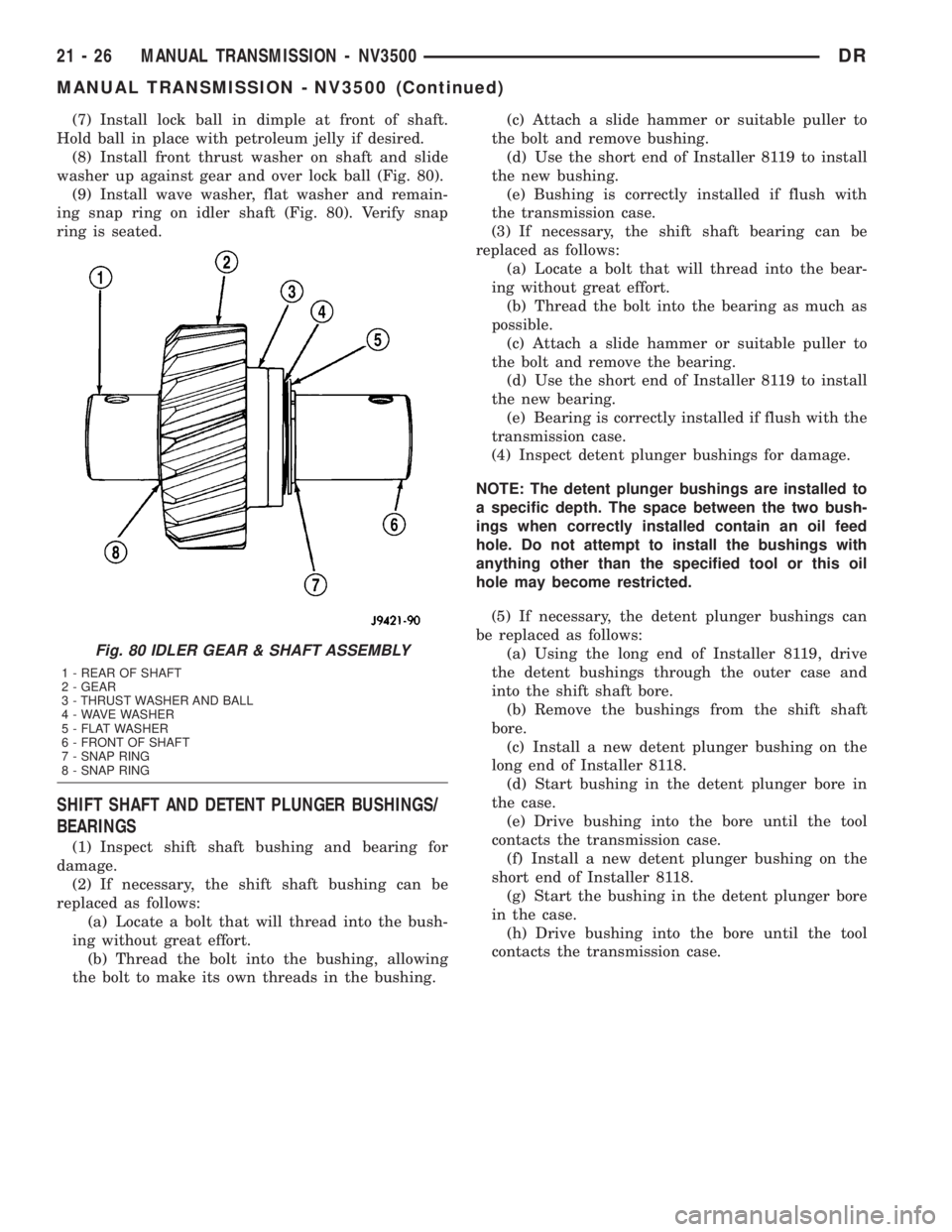

(7) Install lock ball in dimple at front of shaft.

Hold ball in place with petroleum jelly if desired.

(8) Install front thrust washer on shaft and slide

washer up against gear and over lock ball (Fig. 80).

(9) Install wave washer, flat washer and remain-

ing snap ring on idler shaft (Fig. 80). Verify snap

ring is seated.

SHIFT SHAFT AND DETENT PLUNGER BUSHINGS/

BEARINGS

(1) Inspect shift shaft bushing and bearing for

damage.

(2) If necessary, the shift shaft bushing can be

replaced as follows:

(a) Locate a bolt that will thread into the bush-

ing without great effort.

(b) Thread the bolt into the bushing, allowing

the bolt to make its own threads in the bushing.(c) Attach a slide hammer or suitable puller to

the bolt and remove bushing.

(d) Use the short end of Installer 8119 to install

the new bushing.

(e) Bushing is correctly installed if flush with

the transmission case.

(3) If necessary, the shift shaft bearing can be

replaced as follows:

(a) Locate a bolt that will thread into the bear-

ing without great effort.

(b) Thread the bolt into the bearing as much as

possible.

(c) Attach a slide hammer or suitable puller to

the bolt and remove the bearing.

(d) Use the short end of Installer 8119 to install

the new bearing.

(e) Bearing is correctly installed if flush with the

transmission case.

(4) Inspect detent plunger bushings for damage.

NOTE: The detent plunger bushings are installed to

a specific depth. The space between the two bush-

ings when correctly installed contain an oil feed

hole. Do not attempt to install the bushings with

anything other than the specified tool or this oil

hole may become restricted.

(5) If necessary, the detent plunger bushings can

be replaced as follows:

(a) Using the long end of Installer 8119, drive

the detent bushings through the outer case and

into the shift shaft bore.

(b) Remove the bushings from the shift shaft

bore.

(c) Install a new detent plunger bushing on the

long end of Installer 8118.

(d) Start bushing in the detent plunger bore in

the case.

(e) Drive bushing into the bore until the tool

contacts the transmission case.

(f) Install a new detent plunger bushing on the

short end of Installer 8118.

(g) Start the bushing in the detent plunger bore

in the case.

(h) Drive bushing into the bore until the tool

contacts the transmission case.

Fig. 80 IDLER GEAR & SHAFT ASSEMBLY

1 - REAR OF SHAFT

2 - GEAR

3 - THRUST WASHER AND BALL

4 - WAVE WASHER

5 - FLAT WASHER

6 - FRONT OF SHAFT

7 - SNAP RING

8 - SNAP RING

21 - 26 MANUAL TRANSMISSION - NV3500DR

MANUAL TRANSMISSION - NV3500 (Continued)

Page 1866 of 2895

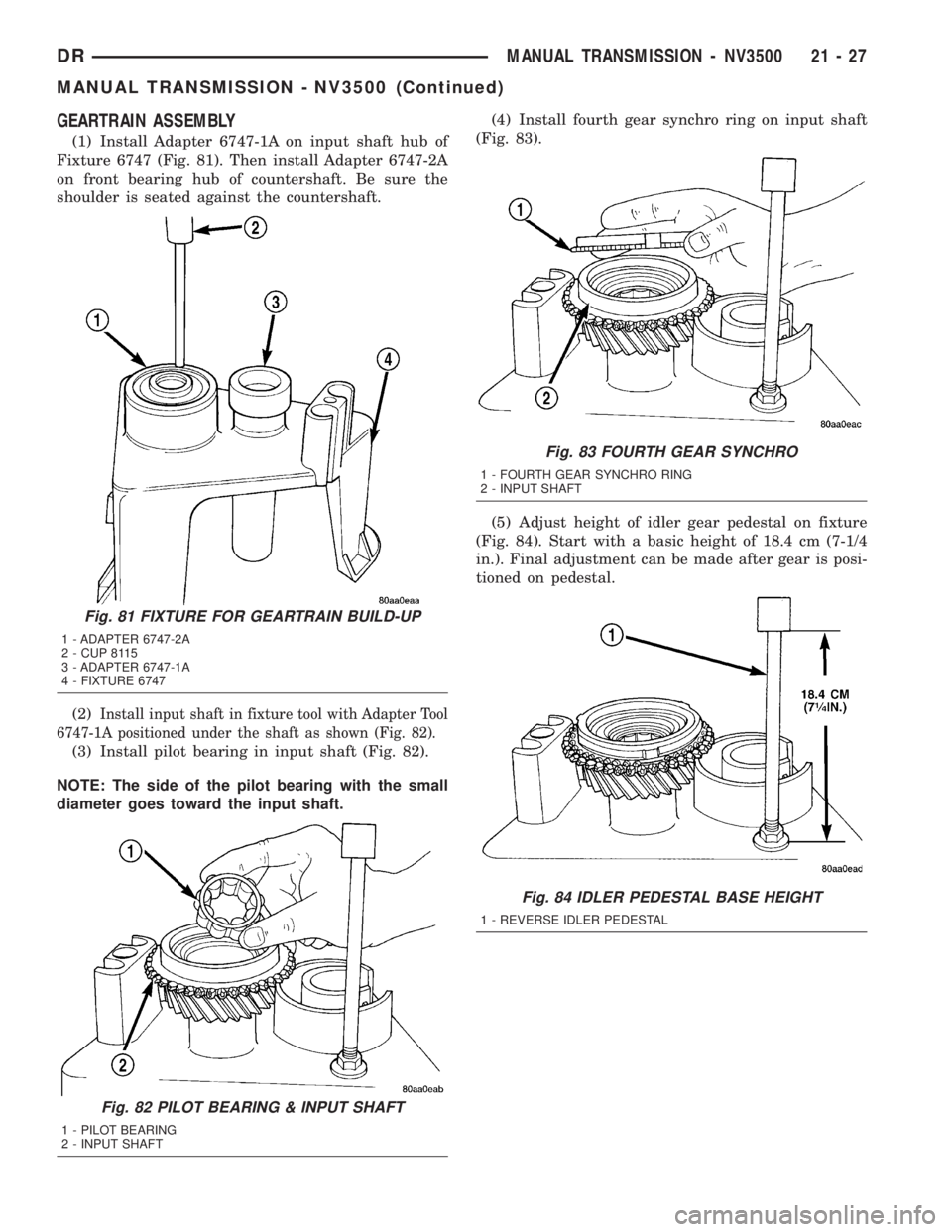

GEARTRAIN ASSEMBLY

(1) Install Adapter 6747-1A on input shaft hub of

Fixture 6747 (Fig. 81). Then install Adapter 6747-2A

on front bearing hub of countershaft. Be sure the

shoulder is seated against the countershaft.

(2)

Install input shaft in fixture tool with Adapter Tool

6747-1A positioned under the shaft as shown (Fig. 82).

(3) Install pilot bearing in input shaft (Fig. 82).

NOTE: The side of the pilot bearing with the small

diameter goes toward the input shaft.(4) Install fourth gear synchro ring on input shaft

(Fig. 83).

(5) Adjust height of idler gear pedestal on fixture

(Fig. 84). Start with a basic height of 18.4 cm (7-1/4

in.). Final adjustment can be made after gear is posi-

tioned on pedestal.

Fig. 81 FIXTURE FOR GEARTRAIN BUILD-UP

1 - ADAPTER 6747-2A

2 - CUP 8115

3 - ADAPTER 6747-1A

4 - FIXTURE 6747

Fig. 82 PILOT BEARING & INPUT SHAFT

1 - PILOT BEARING

2 - INPUT SHAFT

Fig. 83 FOURTH GEAR SYNCHRO

1 - FOURTH GEAR SYNCHRO RING

2 - INPUT SHAFT

Fig. 84 IDLER PEDESTAL BASE HEIGHT

1 - REVERSE IDLER PEDESTAL

DRMANUAL TRANSMISSION - NV3500 21 - 27

MANUAL TRANSMISSION - NV3500 (Continued)