bolt pattern DODGE RAM 2003 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 203 of 2895

Condition Possible Causes Correction

Gear Teeth Broke 1. Overloading. 1. Replace gears. Examine other

gears and bearings for possible

damage.

2. Erratic clutch operation. 2. Replace gears and examine the

remaining parts for damage. Avoid

erratic clutch operation.

3. Ice-spotted pavement. 3. Replace gears and examine

remaining parts for damage.

4. Improper adjustments. 4. Replace gears and examine

remaining parts for damage. Ensure

ring gear backlash is correct.

Axle Noise 1. Insufficient lubricant. 1. Fill differential with the correct

fluid type and quantity.

2. Improper ring gear and pinion

adjustment.2. Check ring gear and pinion

contact pattern. Adjust backlash or

pinion depth.

3. Unmatched ring gear and pinion. 3. Replace gears with a matched

ring gear and pinion.

4. Worn teeth on ring gear and/or

pinion.4. Replace ring gear and pinion.

5. Loose pinion bearings. 5. Adjust pinion bearing pre-load.

6. Loose differential bearings. 6. Adjust differential bearing

pre-load.

7. Mis-aligned or sprung ring gear. 7. Measure ring gear run-out.

Replace components as necessary.

8. Loose differential bearing cap

bolts.8. Inspect differential components

and replace as necessary. Ensure

that the bearing caps are torqued

tot he proper specification.

9. Housing not machined properly. 9. Replace housing.

REMOVAL

(1) Raise and support the vehicle.

(2) Position a lifting device under the axle.

(3) Secure axle to device.

(4) Remove wheels and tires assemblies.

(5) Remove RWAL sensor from the differential

housing.

(6) Remove brake hose at the axle junction block

and axle vent hose.

(7) Disconnect parking brake cables and cable

brackets.

(8) Remove brake calipers.

(9) Mark propeller shaft and companion flange for

installation alignment reference.

(10) Remove propeller shaft.

(11) Remove shock absorbers from axle.

(12) Remove U-bolets from axle.

(13) Separate the axle from the vehicle.

INSTALLATION

(1) Raise axle with lifting device and align to the

leaf spring centering bolts.

(2) Install axle U-bolts and tighten to 149 N´m

(110 ft. lbs.).

(3) Install shock absorbers to axle and tighten to

specification.

(4) Install the RWAL sensor to the differential

housing.

(5) Connect the parking brake cables and cable

brackets.

(6) Connect brake hose to the axle junction block

and axle vent hose.

(7) Align propeller shaft and pinion companion

flange reference marks and tighten companion flange

bolts to 115 N´m (85 ft. lbs.).

(8) Install the wheels and tires.

(9) Fill differential to specifications.

3 - 130 REAR AXLE - 11 1/2 AADR

REAR AXLE - 11 1/2 AA (Continued)

Page 205 of 2895

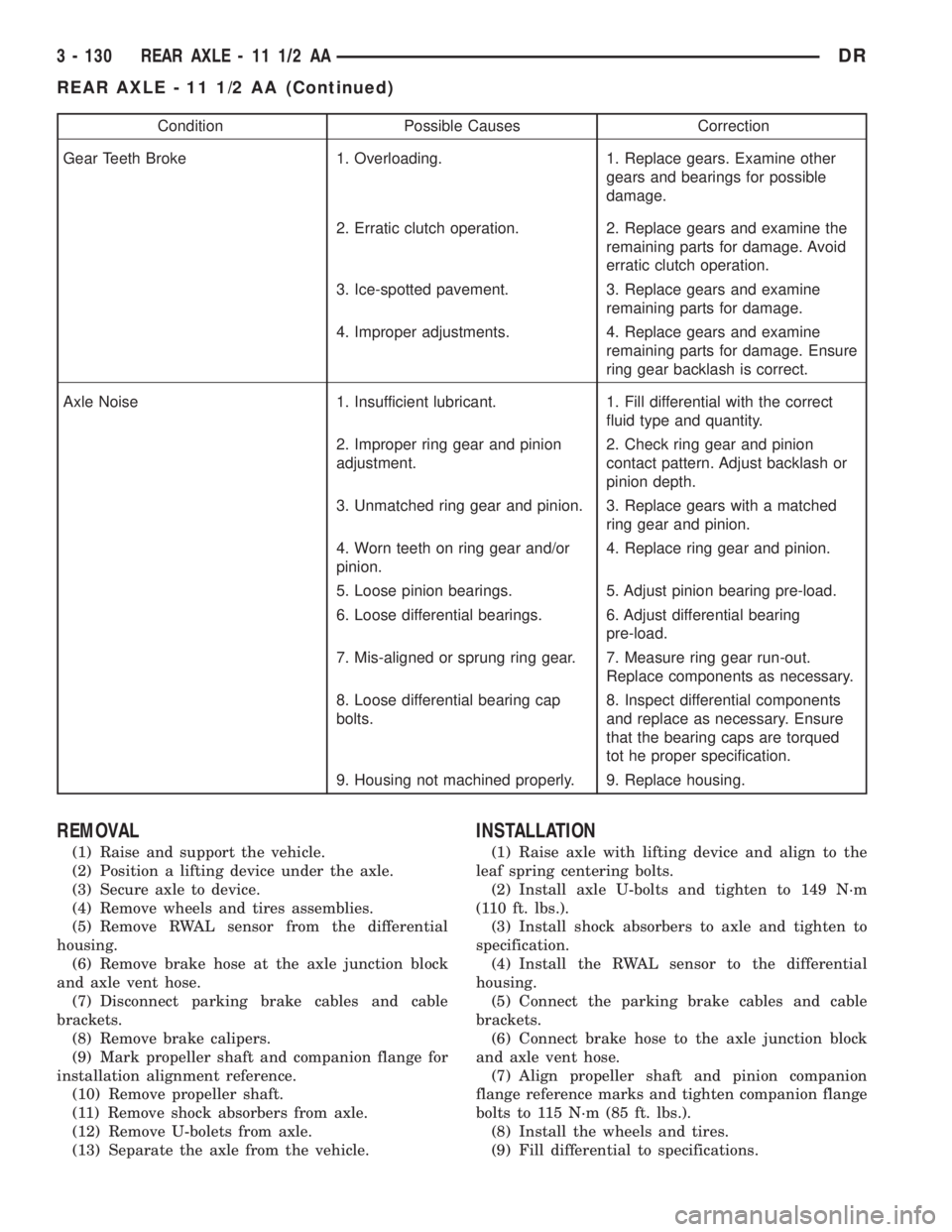

(8) Slowly slide the scooter block across the pinion

height block over to the arbor (Fig. 4). Move the

scooter block till dial indicator crests the arbor, then

record the highest reading.

(9) Select a shim equal to the dial indicator read-

ing.

(10) Install the select shim between the rear pin-

ion bearing and the pinion gear head.

DIFFERENTIAL CASE BEARING PRELOAD AND

GEAR BACKLASH

Backlash is adjusted by moving the adjusters in

and out or both. By moving the adjusters the case/

ring gear will move closer or further away from the

pinion. In most cases this adjustment can be used to

achieve the correct gear tooth pattern and set the

case bearing preload.

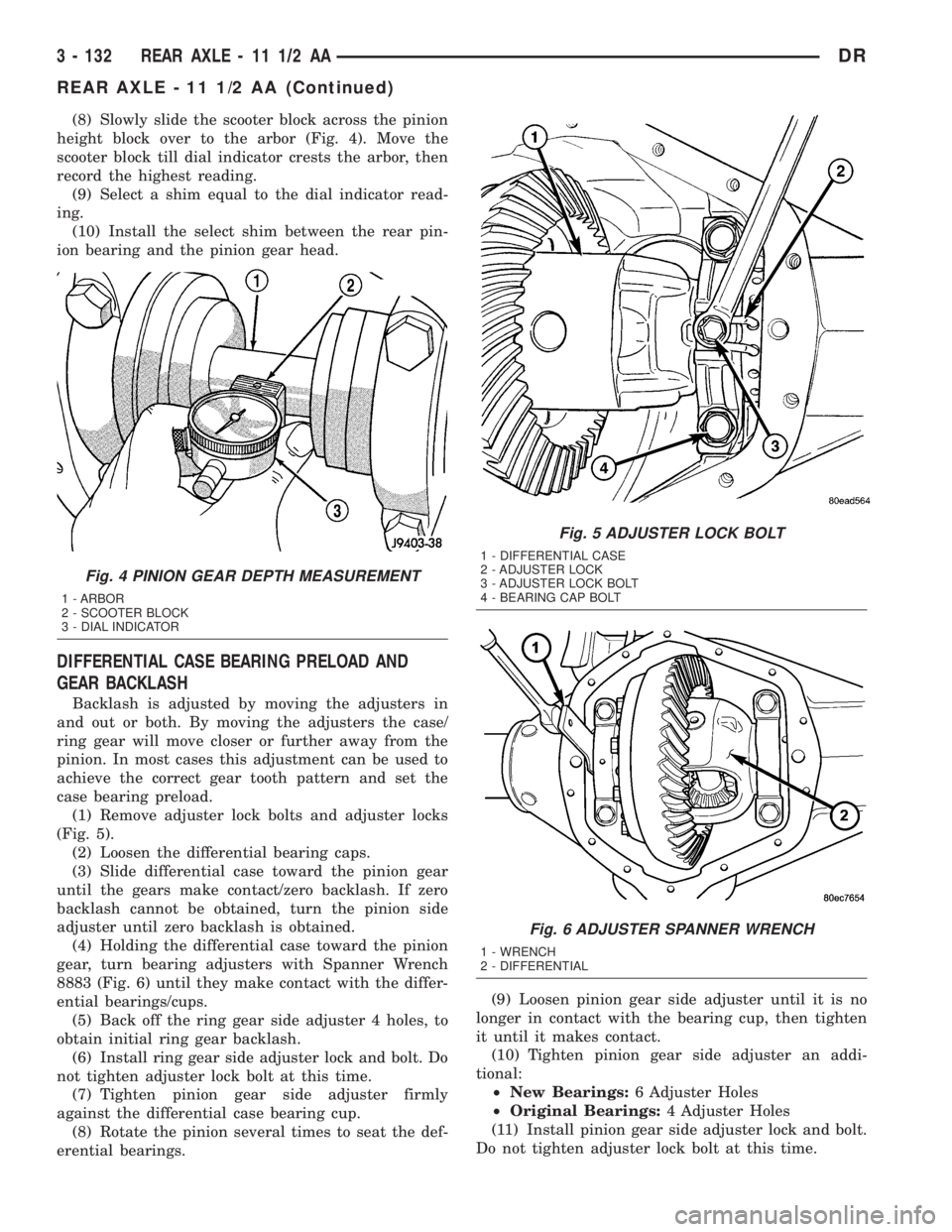

(1) Remove adjuster lock bolts and adjuster locks

(Fig. 5).

(2) Loosen the differential bearing caps.

(3) Slide differential case toward the pinion gear

until the gears make contact/zero backlash. If zero

backlash cannot be obtained, turn the pinion side

adjuster until zero backlash is obtained.

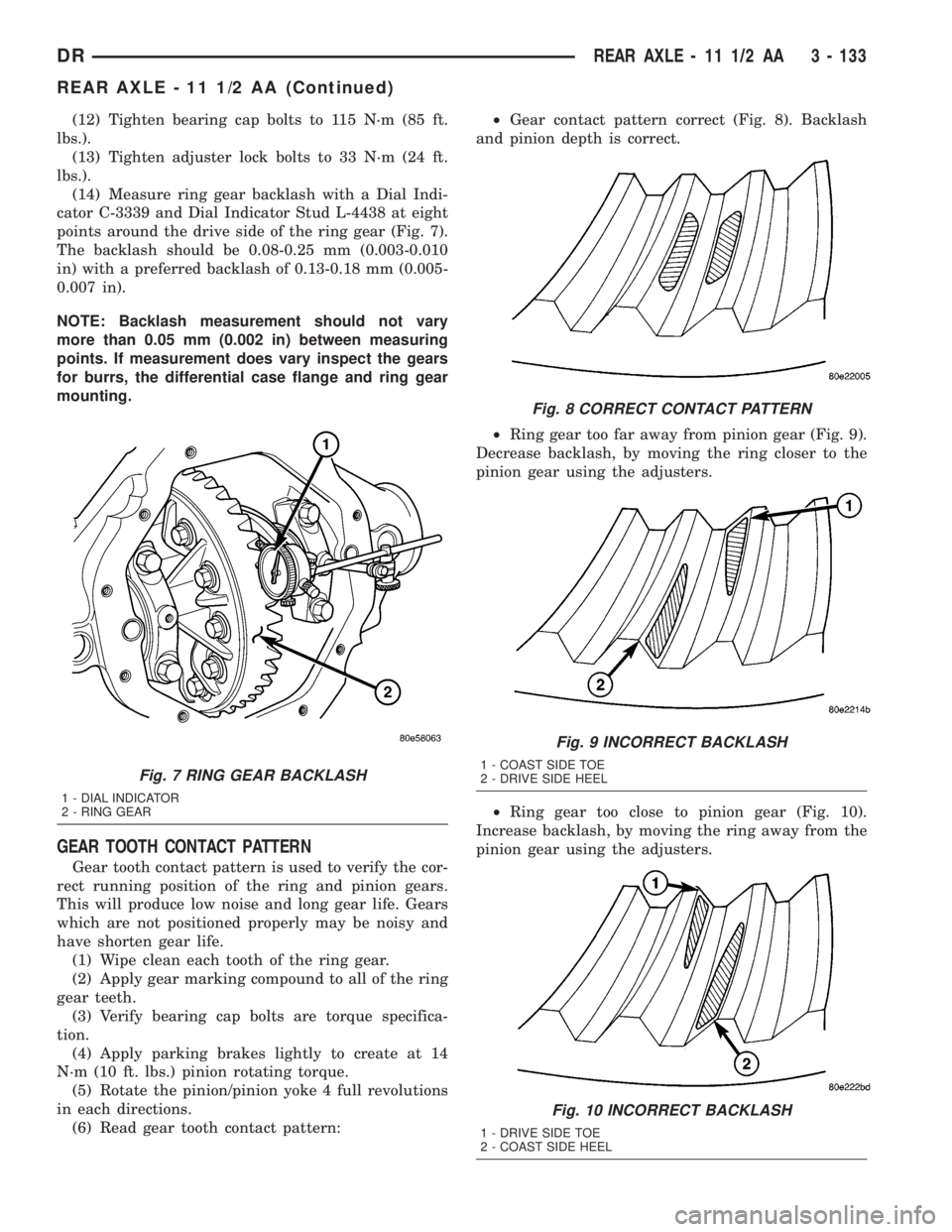

(4) Holding the differential case toward the pinion

gear, turn bearing adjusters with Spanner Wrench

8883 (Fig. 6) until they make contact with the differ-

ential bearings/cups.

(5) Back off the ring gear side adjuster 4 holes, to

obtain initial ring gear backlash.

(6) Install ring gear side adjuster lock and bolt. Do

not tighten adjuster lock bolt at this time.

(7) Tighten pinion gear side adjuster firmly

against the differential case bearing cup.

(8) Rotate the pinion several times to seat the def-

erential bearings.(9) Loosen pinion gear side adjuster until it is no

longer in contact with the bearing cup, then tighten

it until it makes contact.

(10) Tighten pinion gear side adjuster an addi-

tional:

²New Bearings:6 Adjuster Holes

²Original Bearings:4 Adjuster Holes

(11) Install pinion gear side adjuster lock and bolt.

Do not tighten adjuster lock bolt at this time.

Fig. 4 PINION GEAR DEPTH MEASUREMENT

1 - ARBOR

2 - SCOOTER BLOCK

3 - DIAL INDICATOR

Fig. 5 ADJUSTER LOCK BOLT

1 - DIFFERENTIAL CASE

2 - ADJUSTER LOCK

3 - ADJUSTER LOCK BOLT

4 - BEARING CAP BOLT

Fig. 6 ADJUSTER SPANNER WRENCH

1 - WRENCH

2 - DIFFERENTIAL

3 - 132 REAR AXLE - 11 1/2 AADR

REAR AXLE - 11 1/2 AA (Continued)

Page 206 of 2895

(12) Tighten bearing cap bolts to 115 N´m (85 ft.

lbs.).

(13) Tighten adjuster lock bolts to 33 N´m (24 ft.

lbs.).

(14) Measure ring gear backlash with a Dial Indi-

cator C-3339 and Dial Indicator Stud L-4438 at eight

points around the drive side of the ring gear (Fig. 7).

The backlash should be 0.08-0.25 mm (0.003-0.010

in) with a preferred backlash of 0.13-0.18 mm (0.005-

0.007 in).

NOTE: Backlash measurement should not vary

more than 0.05 mm (0.002 in) between measuring

points. If measurement does vary inspect the gears

for burrs, the differential case flange and ring gear

mounting.

GEAR TOOTH CONTACT PATTERN

Gear tooth contact pattern is used to verify the cor-

rect running position of the ring and pinion gears.

This will produce low noise and long gear life. Gears

which are not positioned properly may be noisy and

have shorten gear life.

(1) Wipe clean each tooth of the ring gear.

(2) Apply gear marking compound to all of the ring

gear teeth.

(3) Verify bearing cap bolts are torque specifica-

tion.

(4) Apply parking brakes lightly to create at 14

N´m (10 ft. lbs.) pinion rotating torque.

(5) Rotate the pinion/pinion yoke 4 full revolutions

in each directions.

(6) Read gear tooth contact pattern:²Gear contact pattern correct (Fig. 8). Backlash

and pinion depth is correct.

²Ring gear too far away from pinion gear (Fig. 9).

Decrease backlash, by moving the ring closer to the

pinion gear using the adjusters.

²Ring gear too close to pinion gear (Fig. 10).

Increase backlash, by moving the ring away from the

pinion gear using the adjusters.

Fig. 7 RING GEAR BACKLASH

1 - DIAL INDICATOR

2 - RING GEAR

Fig. 8 CORRECT CONTACT PATTERN

Fig. 9 INCORRECT BACKLASH

1 - COAST SIDE TOE

2 - DRIVE SIDE HEEL

Fig. 10 INCORRECT BACKLASH

1 - DRIVE SIDE TOE

2 - COAST SIDE HEEL

DRREAR AXLE - 11 1/2 AA 3 - 133

REAR AXLE - 11 1/2 AA (Continued)

Page 218 of 2895

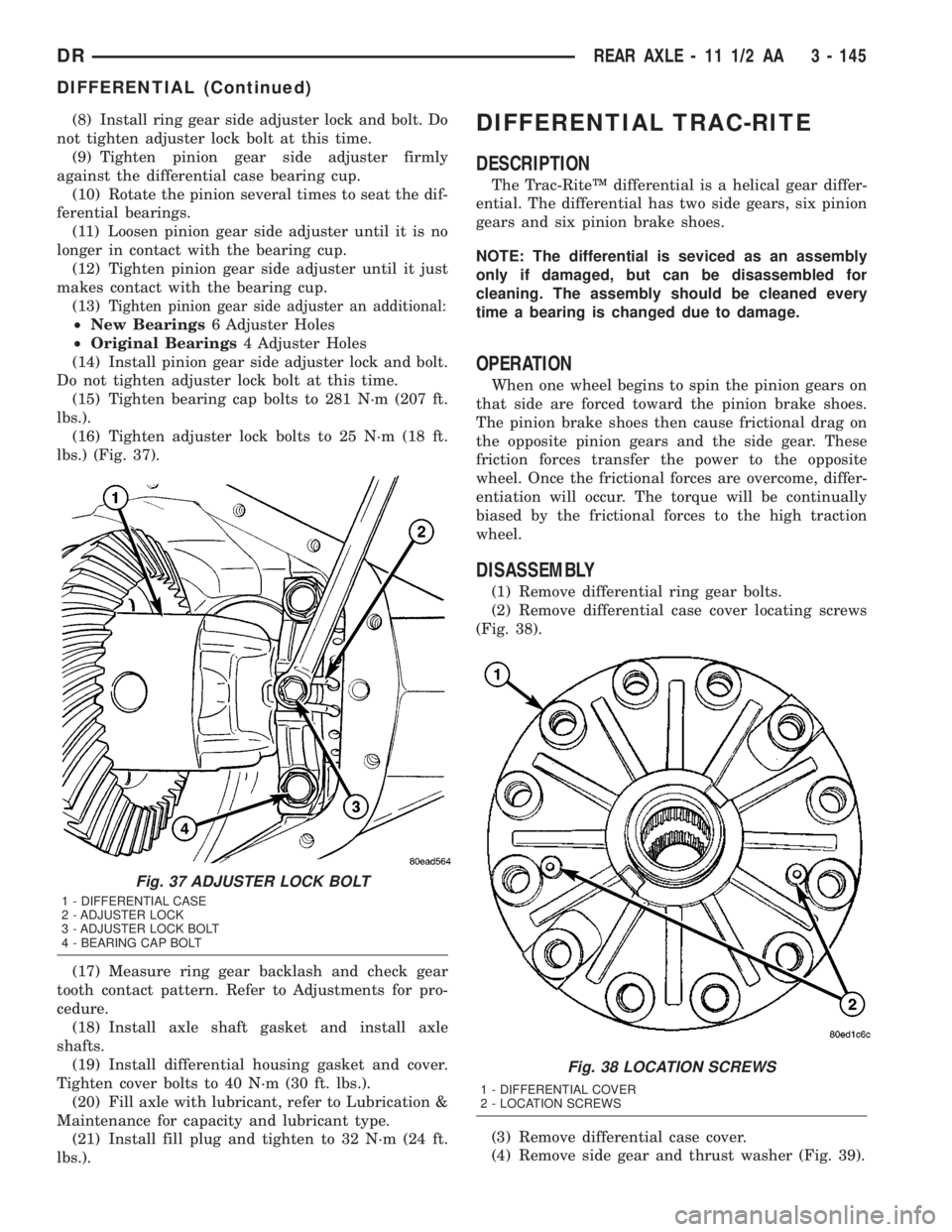

(8) Install ring gear side adjuster lock and bolt. Do

not tighten adjuster lock bolt at this time.

(9) Tighten pinion gear side adjuster firmly

against the differential case bearing cup.

(10) Rotate the pinion several times to seat the dif-

ferential bearings.

(11) Loosen pinion gear side adjuster until it is no

longer in contact with the bearing cup.

(12) Tighten pinion gear side adjuster until it just

makes contact with the bearing cup.

(13)

Tighten pinion gear side adjuster an additional:

²New Bearings6 Adjuster Holes

²Original Bearings4 Adjuster Holes

(14) Install pinion gear side adjuster lock and bolt.

Do not tighten adjuster lock bolt at this time.

(15) Tighten bearing cap bolts to 281 N´m (207 ft.

lbs.).

(16) Tighten adjuster lock bolts to 25 N´m (18 ft.

lbs.) (Fig. 37).

(17) Measure ring gear backlash and check gear

tooth contact pattern. Refer to Adjustments for pro-

cedure.

(18) Install axle shaft gasket and install axle

shafts.

(19) Install differential housing gasket and cover.

Tighten cover bolts to 40 N´m (30 ft. lbs.).

(20) Fill axle with lubricant, refer to Lubrication &

Maintenance for capacity and lubricant type.

(21) Install fill plug and tighten to 32 N´m (24 ft.

lbs.).

DIFFERENTIAL TRAC-RITE

DESCRIPTION

The Trac-RiteŸ differential is a helical gear differ-

ential. The differential has two side gears, six pinion

gears and six pinion brake shoes.

NOTE: The differential is seviced as an assembly

only if damaged, but can be disassembled for

cleaning. The assembly should be cleaned every

time a bearing is changed due to damage.

OPERATION

When one wheel begins to spin the pinion gears on

that side are forced toward the pinion brake shoes.

The pinion brake shoes then cause frictional drag on

the opposite pinion gears and the side gear. These

friction forces transfer the power to the opposite

wheel. Once the frictional forces are overcome, differ-

entiation will occur. The torque will be continually

biased by the frictional forces to the high traction

wheel.

DISASSEMBLY

(1) Remove differential ring gear bolts.

(2) Remove differential case cover locating screws

(Fig. 38).

(3) Remove differential case cover.

(4) Remove side gear and thrust washer (Fig. 39).

Fig. 37 ADJUSTER LOCK BOLT

1 - DIFFERENTIAL CASE

2 - ADJUSTER LOCK

3 - ADJUSTER LOCK BOLT

4 - BEARING CAP BOLT

Fig. 38 LOCATION SCREWS

1 - DIFFERENTIAL COVER

2 - LOCATION SCREWS

DRREAR AXLE - 11 1/2 AA 3 - 145

DIFFERENTIAL (Continued)

Page 226 of 2895

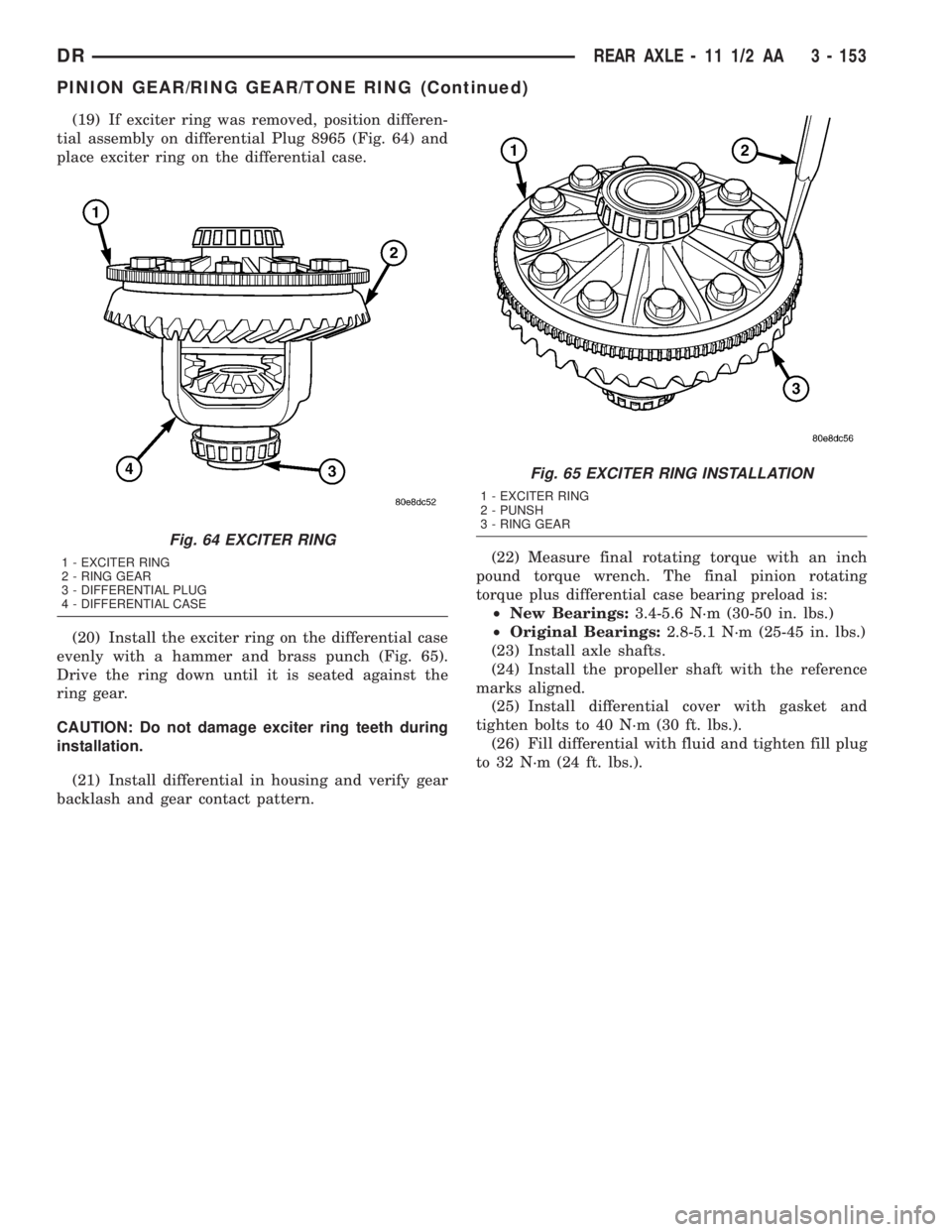

(19) If exciter ring was removed, position differen-

tial assembly on differential Plug 8965 (Fig. 64) and

place exciter ring on the differential case.

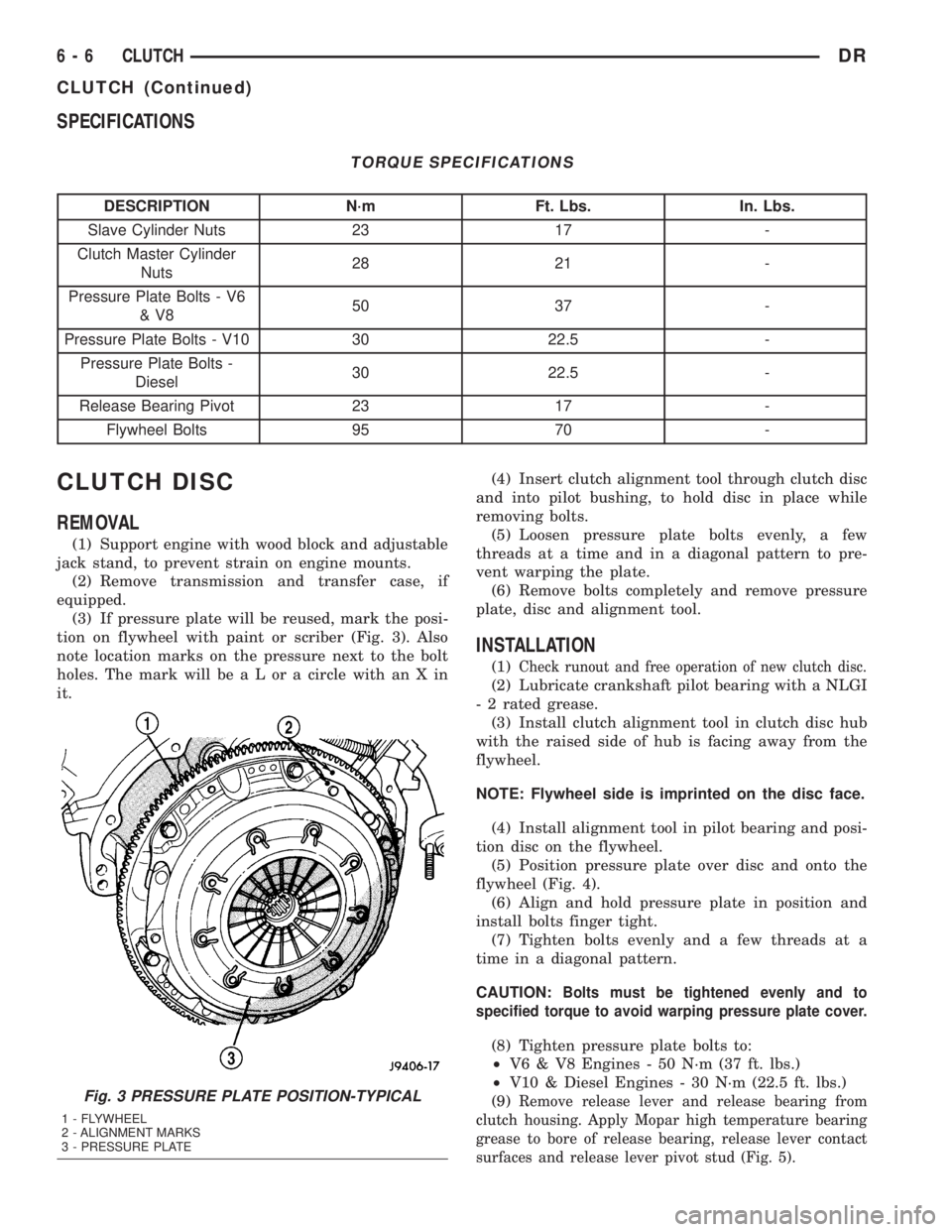

(20) Install the exciter ring on the differential case

evenly with a hammer and brass punch (Fig. 65).

Drive the ring down until it is seated against the

ring gear.

CAUTION: Do not damage exciter ring teeth during

installation.

(21) Install differential in housing and verify gear

backlash and gear contact pattern.(22) Measure final rotating torque with an inch

pound torque wrench. The final pinion rotating

torque plus differential case bearing preload is:

²New Bearings:3.4-5.6 N´m (30-50 in. lbs.)

²Original Bearings:2.8-5.1 N´m (25-45 in. lbs.)

(23) Install axle shafts.

(24) Install the propeller shaft with the reference

marks aligned.

(25) Install differential cover with gasket and

tighten bolts to 40 N´m (30 ft. lbs.).

(26) Fill differential with fluid and tighten fill plug

to 32 N´m (24 ft. lbs.).

Fig. 64 EXCITER RING

1 - EXCITER RING

2 - RING GEAR

3 - DIFFERENTIAL PLUG

4 - DIFFERENTIAL CASE

Fig. 65 EXCITER RING INSTALLATION

1 - EXCITER RING

2 - PUNSH

3 - RING GEAR

DRREAR AXLE - 11 1/2 AA 3 - 153

PINION GEAR/RING GEAR/TONE RING (Continued)

Page 279 of 2895

SPECIFICATIONS

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Slave Cylinder Nuts 23 17 -

Clutch Master Cylinder

Nuts28 21 -

Pressure Plate Bolts - V6

&V850 37 -

Pressure Plate Bolts - V10 30 22.5 -

Pressure Plate Bolts -

Diesel30 22.5 -

Release Bearing Pivot 23 17 -

Flywheel Bolts 95 70 -

CLUTCH DISC

REMOVAL

(1) Support engine with wood block and adjustable

jack stand, to prevent strain on engine mounts.

(2) Remove transmission and transfer case, if

equipped.

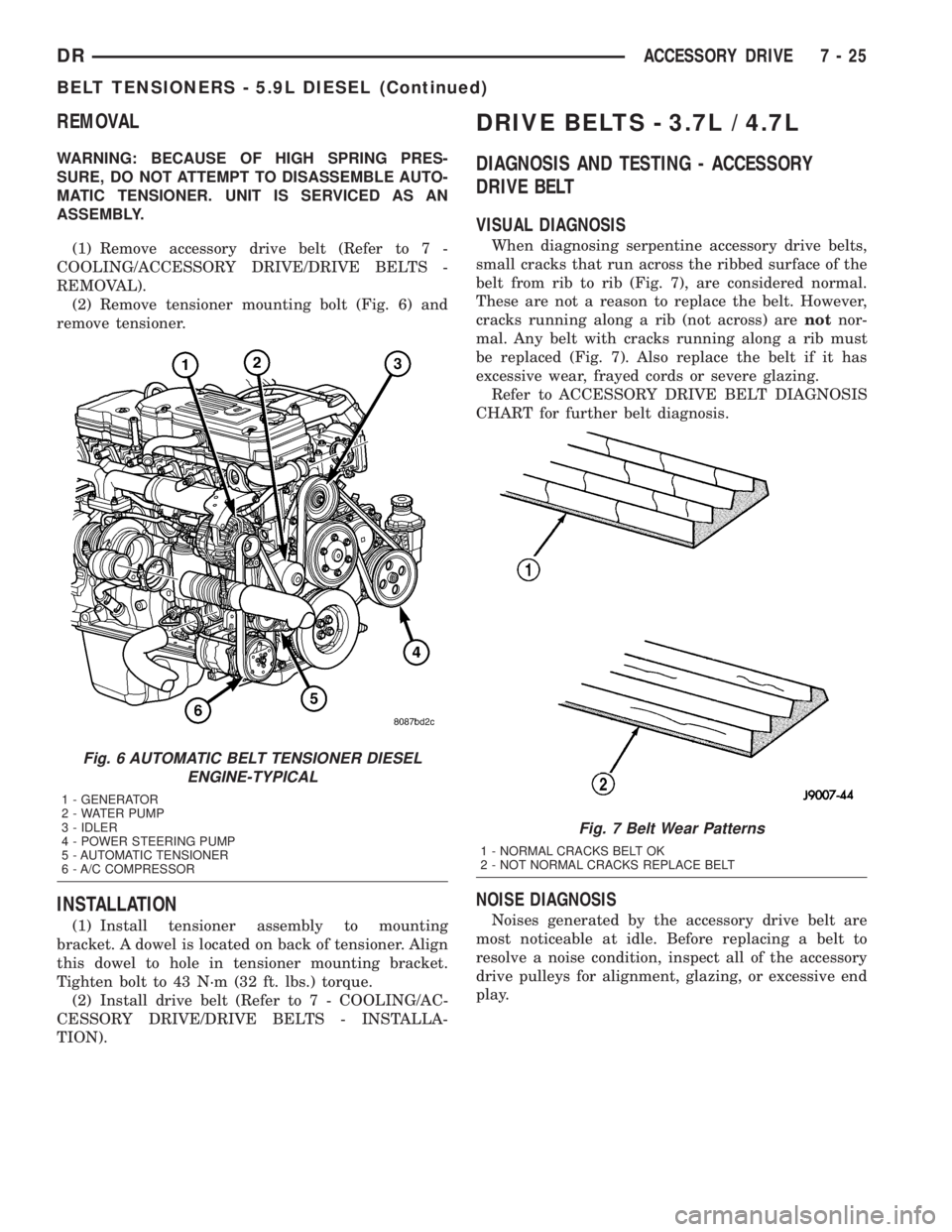

(3) If pressure plate will be reused, mark the posi-

tion on flywheel with paint or scriber (Fig. 3). Also

note location marks on the pressure next to the bolt

holes. The mark will be a L or a circle with an X in

it.(4) Insert clutch alignment tool through clutch disc

and into pilot bushing, to hold disc in place while

removing bolts.

(5) Loosen pressure plate bolts evenly, a few

threads at a time and in a diagonal pattern to pre-

vent warping the plate.

(6) Remove bolts completely and remove pressure

plate, disc and alignment tool.

INSTALLATION

(1)Check runout and free operation of new clutch disc.

(2) Lubricate crankshaft pilot bearing with a NLGI

- 2 rated grease.

(3) Install clutch alignment tool in clutch disc hub

with the raised side of hub is facing away from the

flywheel.

NOTE: Flywheel side is imprinted on the disc face.

(4) Install alignment tool in pilot bearing and posi-

tion disc on the flywheel.

(5) Position pressure plate over disc and onto the

flywheel (Fig. 4).

(6) Align and hold pressure plate in position and

install bolts finger tight.

(7) Tighten bolts evenly and a few threads at a

time in a diagonal pattern.

CAUTION:

Bolts must be tightened evenly and to

specified torque to avoid warping pressure plate cover.

(8) Tighten pressure plate bolts to:

²V6 & V8 Engines - 50 N´m (37 ft. lbs.)

²V10 & Diesel Engines - 30 N´m (22.5 ft. lbs.)

(9)

Remove release lever and release bearing from

clutch housing. Apply Mopar high temperature bearing

grease to bore of release bearing, release lever contact

surfaces and release lever pivot stud (Fig. 5).Fig. 3 PRESSURE PLATE POSITION-TYPICAL

1 - FLYWHEEL

2 - ALIGNMENT MARKS

3 - PRESSURE PLATE

6 - 6 CLUTCHDR

CLUTCH (Continued)

Page 312 of 2895

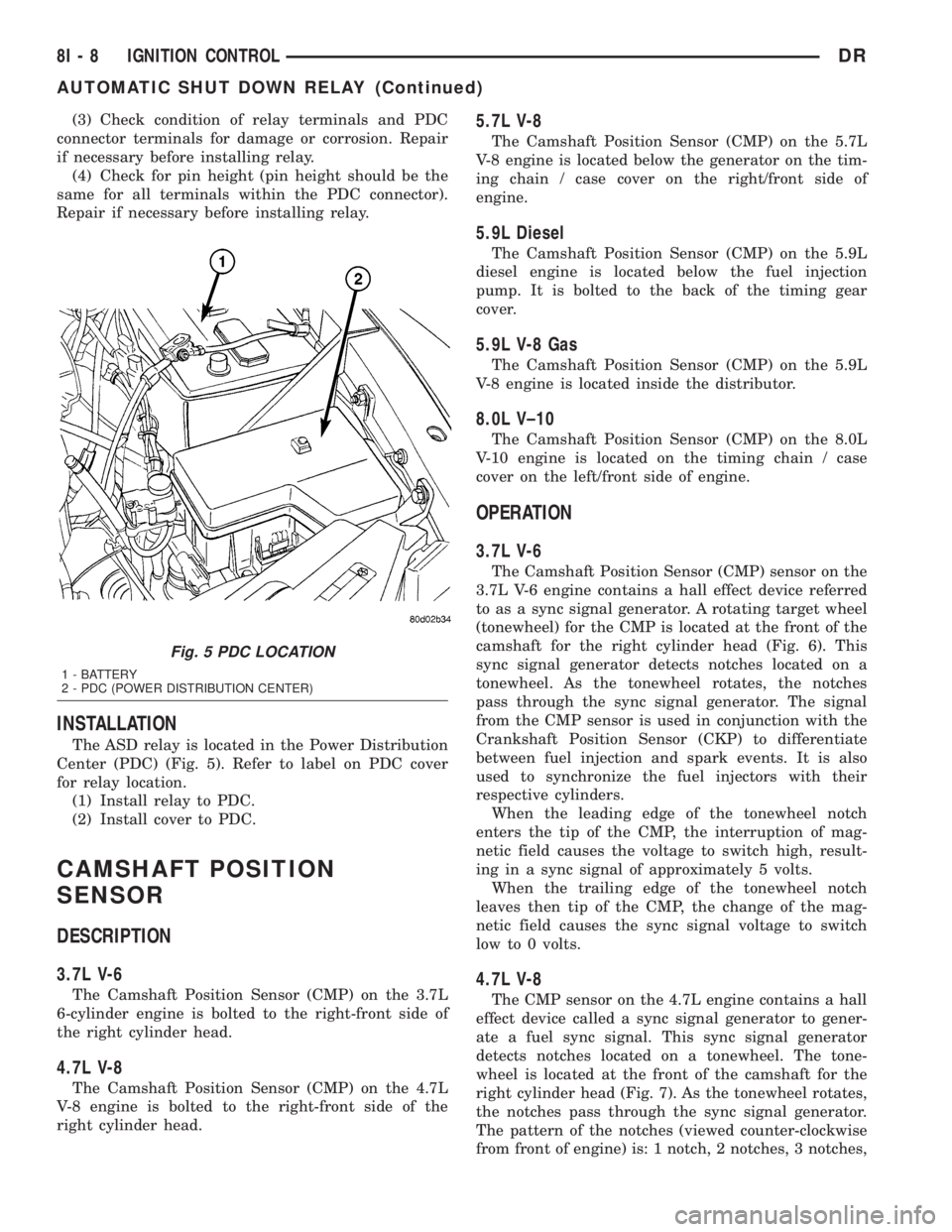

REMOVAL

WARNING: BECAUSE OF HIGH SPRING PRES-

SURE, DO NOT ATTEMPT TO DISASSEMBLE AUTO-

MATIC TENSIONER. UNIT IS SERVICED AS AN

ASSEMBLY.

(1) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(2) Remove tensioner mounting bolt (Fig. 6) and

remove tensioner.

INSTALLATION

(1) Install tensioner assembly to mounting

bracket. A dowel is located on back of tensioner. Align

this dowel to hole in tensioner mounting bracket.

Tighten bolt to 43 N´m (32 ft. lbs.) torque.

(2) Install drive belt (Refer to 7 - COOLING/AC-

CESSORY DRIVE/DRIVE BELTS - INSTALLA-

TION).

DRIVE BELTS - 3.7L / 4.7L

DIAGNOSIS AND TESTING - ACCESSORY

DRIVE BELT

VISUAL DIAGNOSIS

When diagnosing serpentine accessory drive belts,

small cracks that run across the ribbed surface of the

belt from rib to rib (Fig. 7), are considered normal.

These are not a reason to replace the belt. However,

cracks running along a rib (not across) arenotnor-

mal. Any belt with cracks running along a rib must

be replaced (Fig. 7). Also replace the belt if it has

excessive wear, frayed cords or severe glazing.

Refer to ACCESSORY DRIVE BELT DIAGNOSIS

CHART for further belt diagnosis.

NOISE DIAGNOSIS

Noises generated by the accessory drive belt are

most noticeable at idle. Before replacing a belt to

resolve a noise condition, inspect all of the accessory

drive pulleys for alignment, glazing, or excessive end

play.

Fig. 6 AUTOMATIC BELT TENSIONER DIESEL

ENGINE-TYPICAL

1 - GENERATOR

2 - WATER PUMP

3 - IDLER

4 - POWER STEERING PUMP

5 - AUTOMATIC TENSIONER

6 - A/C COMPRESSOR

Fig. 7 Belt Wear Patterns

1 - NORMAL CRACKS BELT OK

2 - NOT NORMAL CRACKS REPLACE BELT

DRACCESSORY DRIVE 7 - 25

BELT TENSIONERS - 5.9L DIESEL (Continued)

Page 465 of 2895

(3) Check condition of relay terminals and PDC

connector terminals for damage or corrosion. Repair

if necessary before installing relay.

(4) Check for pin height (pin height should be the

same for all terminals within the PDC connector).

Repair if necessary before installing relay.

INSTALLATION

The ASD relay is located in the Power Distribution

Center (PDC) (Fig. 5). Refer to label on PDC cover

for relay location.

(1) Install relay to PDC.

(2) Install cover to PDC.

CAMSHAFT POSITION

SENSOR

DESCRIPTION

3.7L V-6

The Camshaft Position Sensor (CMP) on the 3.7L

6-cylinder engine is bolted to the right-front side of

the right cylinder head.

4.7L V-8

The Camshaft Position Sensor (CMP) on the 4.7L

V-8 engine is bolted to the right-front side of the

right cylinder head.

5.7L V-8

The Camshaft Position Sensor (CMP) on the 5.7L

V-8 engine is located below the generator on the tim-

ing chain / case cover on the right/front side of

engine.

5.9L Diesel

The Camshaft Position Sensor (CMP) on the 5.9L

diesel engine is located below the fuel injection

pump. It is bolted to the back of the timing gear

cover.

5.9L V-8 Gas

The Camshaft Position Sensor (CMP) on the 5.9L

V-8 engine is located inside the distributor.

8.0L V±10

The Camshaft Position Sensor (CMP) on the 8.0L

V-10 engine is located on the timing chain / case

cover on the left/front side of engine.

OPERATION

3.7L V-6

The Camshaft Position Sensor (CMP) sensor on the

3.7L V-6 engine contains a hall effect device referred

to as a sync signal generator. A rotating target wheel

(tonewheel) for the CMP is located at the front of the

camshaft for the right cylinder head (Fig. 6). This

sync signal generator detects notches located on a

tonewheel. As the tonewheel rotates, the notches

pass through the sync signal generator. The signal

from the CMP sensor is used in conjunction with the

Crankshaft Position Sensor (CKP) to differentiate

between fuel injection and spark events. It is also

used to synchronize the fuel injectors with their

respective cylinders.

When the leading edge of the tonewheel notch

enters the tip of the CMP, the interruption of mag-

netic field causes the voltage to switch high, result-

ing in a sync signal of approximately 5 volts.

When the trailing edge of the tonewheel notch

leaves then tip of the CMP, the change of the mag-

netic field causes the sync signal voltage to switch

low to 0 volts.

4.7L V-8

The CMP sensor on the 4.7L engine contains a hall

effect device called a sync signal generator to gener-

ate a fuel sync signal. This sync signal generator

detects notches located on a tonewheel. The tone-

wheel is located at the front of the camshaft for the

right cylinder head (Fig. 7). As the tonewheel rotates,

the notches pass through the sync signal generator.

The pattern of the notches (viewed counter-clockwise

from front of engine) is: 1 notch, 2 notches, 3 notches,

Fig. 5 PDC LOCATION

1 - BATTERY

2 - PDC (POWER DISTRIBUTION CENTER)

8I - 8 IGNITION CONTROLDR

AUTOMATIC SHUT DOWN RELAY (Continued)

Page 552 of 2895

(4) Install the cluster bezel onto the instrument

panel (Fig. 9).

(5) Connect the battery negative cable.

HEADLAMP UNIT

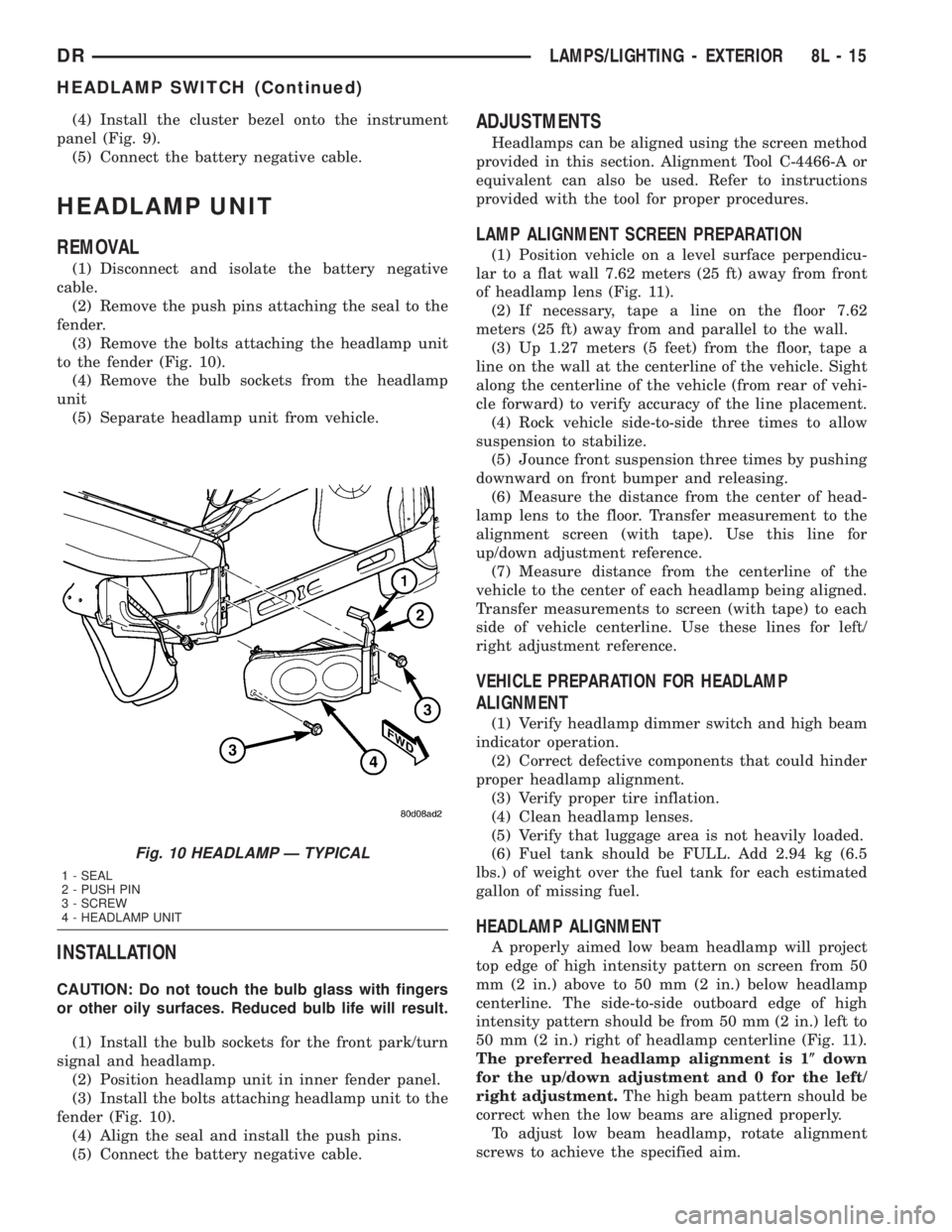

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the push pins attaching the seal to the

fender.

(3) Remove the bolts attaching the headlamp unit

to the fender (Fig. 10).

(4) Remove the bulb sockets from the headlamp

unit

(5) Separate headlamp unit from vehicle.

INSTALLATION

CAUTION: Do not touch the bulb glass with fingers

or other oily surfaces. Reduced bulb life will result.

(1) Install the bulb sockets for the front park/turn

signal and headlamp.

(2) Position headlamp unit in inner fender panel.

(3) Install the bolts attaching headlamp unit to the

fender (Fig. 10).

(4) Align the seal and install the push pins.

(5) Connect the battery negative cable.

ADJUSTMENTS

Headlamps can be aligned using the screen method

provided in this section. Alignment Tool C-4466-A or

equivalent can also be used. Refer to instructions

provided with the tool for proper procedures.

LAMP ALIGNMENT SCREEN PREPARATION

(1) Position vehicle on a level surface perpendicu-

lar to a flat wall 7.62 meters (25 ft) away from front

of headlamp lens (Fig. 11).

(2) If necessary, tape a line on the floor 7.62

meters (25 ft) away from and parallel to the wall.

(3) Up 1.27 meters (5 feet) from the floor, tape a

line on the wall at the centerline of the vehicle. Sight

along the centerline of the vehicle (from rear of vehi-

cle forward) to verify accuracy of the line placement.

(4) Rock vehicle side-to-side three times to allow

suspension to stabilize.

(5) Jounce front suspension three times by pushing

downward on front bumper and releasing.

(6) Measure the distance from the center of head-

lamp lens to the floor. Transfer measurement to the

alignment screen (with tape). Use this line for

up/down adjustment reference.

(7) Measure distance from the centerline of the

vehicle to the center of each headlamp being aligned.

Transfer measurements to screen (with tape) to each

side of vehicle centerline. Use these lines for left/

right adjustment reference.

VEHICLE PREPARATION FOR HEADLAMP

ALIGNMENT

(1) Verify headlamp dimmer switch and high beam

indicator operation.

(2) Correct defective components that could hinder

proper headlamp alignment.

(3) Verify proper tire inflation.

(4) Clean headlamp lenses.

(5) Verify that luggage area is not heavily loaded.

(6) Fuel tank should be FULL. Add 2.94 kg (6.5

lbs.) of weight over the fuel tank for each estimated

gallon of missing fuel.

HEADLAMP ALIGNMENT

A properly aimed low beam headlamp will project

top edge of high intensity pattern on screen from 50

mm (2 in.) above to 50 mm (2 in.) below headlamp

centerline. The side-to-side outboard edge of high

intensity pattern should be from 50 mm (2 in.) left to

50 mm (2 in.) right of headlamp centerline (Fig. 11).

The preferred headlamp alignment is 1(down

for the up/down adjustment and 0 for the left/

right adjustment.The high beam pattern should be

correct when the low beams are aligned properly.

To adjust low beam headlamp, rotate alignment

screws to achieve the specified aim.

Fig. 10 HEADLAMP Ð TYPICAL

1 - SEAL

2 - PUSH PIN

3 - SCREW

4 - HEADLAMP UNIT

DRLAMPS/LIGHTING - EXTERIOR 8L - 15

HEADLAMP SWITCH (Continued)

Page 1297 of 2895

STANDARD PROCEDURE

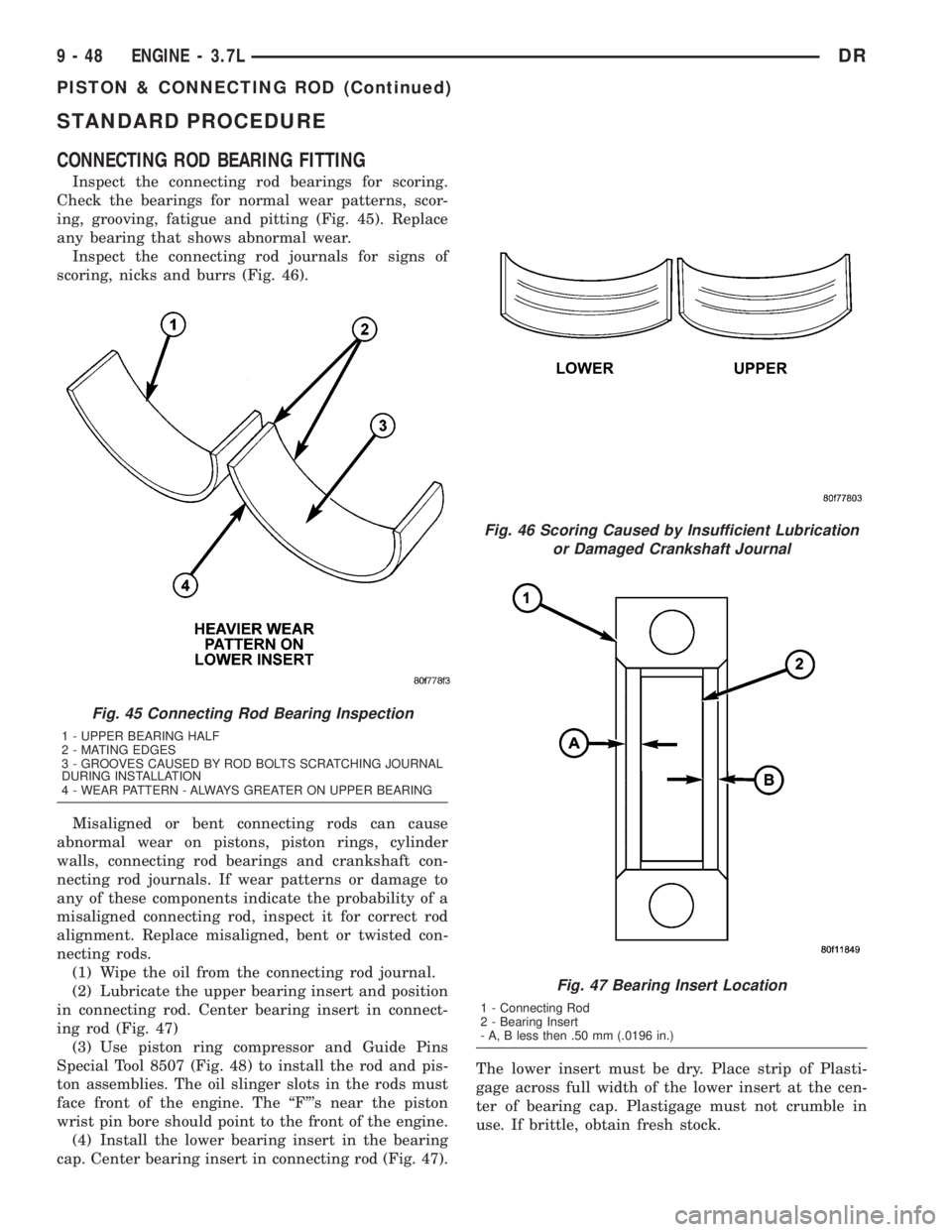

CONNECTING ROD BEARING FITTING

Inspect the connecting rod bearings for scoring.

Check the bearings for normal wear patterns, scor-

ing, grooving, fatigue and pitting (Fig. 45). Replace

any bearing that shows abnormal wear.

Inspect the connecting rod journals for signs of

scoring, nicks and burrs (Fig. 46).

Misaligned or bent connecting rods can cause

abnormal wear on pistons, piston rings, cylinder

walls, connecting rod bearings and crankshaft con-

necting rod journals. If wear patterns or damage to

any of these components indicate the probability of a

misaligned connecting rod, inspect it for correct rod

alignment. Replace misaligned, bent or twisted con-

necting rods.

(1) Wipe the oil from the connecting rod journal.

(2) Lubricate the upper bearing insert and position

in connecting rod. Center bearing insert in connect-

ing rod (Fig. 47)

(3) Use piston ring compressor and Guide Pins

Special Tool 8507 (Fig. 48) to install the rod and pis-

ton assemblies. The oil slinger slots in the rods must

face front of the engine. The ªFº's near the piston

wrist pin bore should point to the front of the engine.

(4) Install the lower bearing insert in the bearing

cap. Center bearing insert in connecting rod (Fig. 47).The lower insert must be dry. Place strip of Plasti-

gage across full width of the lower insert at the cen-

ter of bearing cap. Plastigage must not crumble in

use. If brittle, obtain fresh stock.

Fig. 45 Connecting Rod Bearing Inspection

1 - UPPER BEARING HALF

2 - MATING EDGES

3 - GROOVES CAUSED BY ROD BOLTS SCRATCHING JOURNAL

DURING INSTALLATION

4 - WEAR PATTERN - ALWAYS GREATER ON UPPER BEARING

Fig. 46 Scoring Caused by Insufficient Lubrication

or Damaged Crankshaft Journal

Fig. 47 Bearing Insert Location

1 - Connecting Rod

2 - Bearing Insert

- A, B less then .50 mm (.0196 in.)

9 - 48 ENGINE - 3.7LDR

PISTON & CONNECTING ROD (Continued)