bumper DODGE RAM 2003 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1314 of 2895

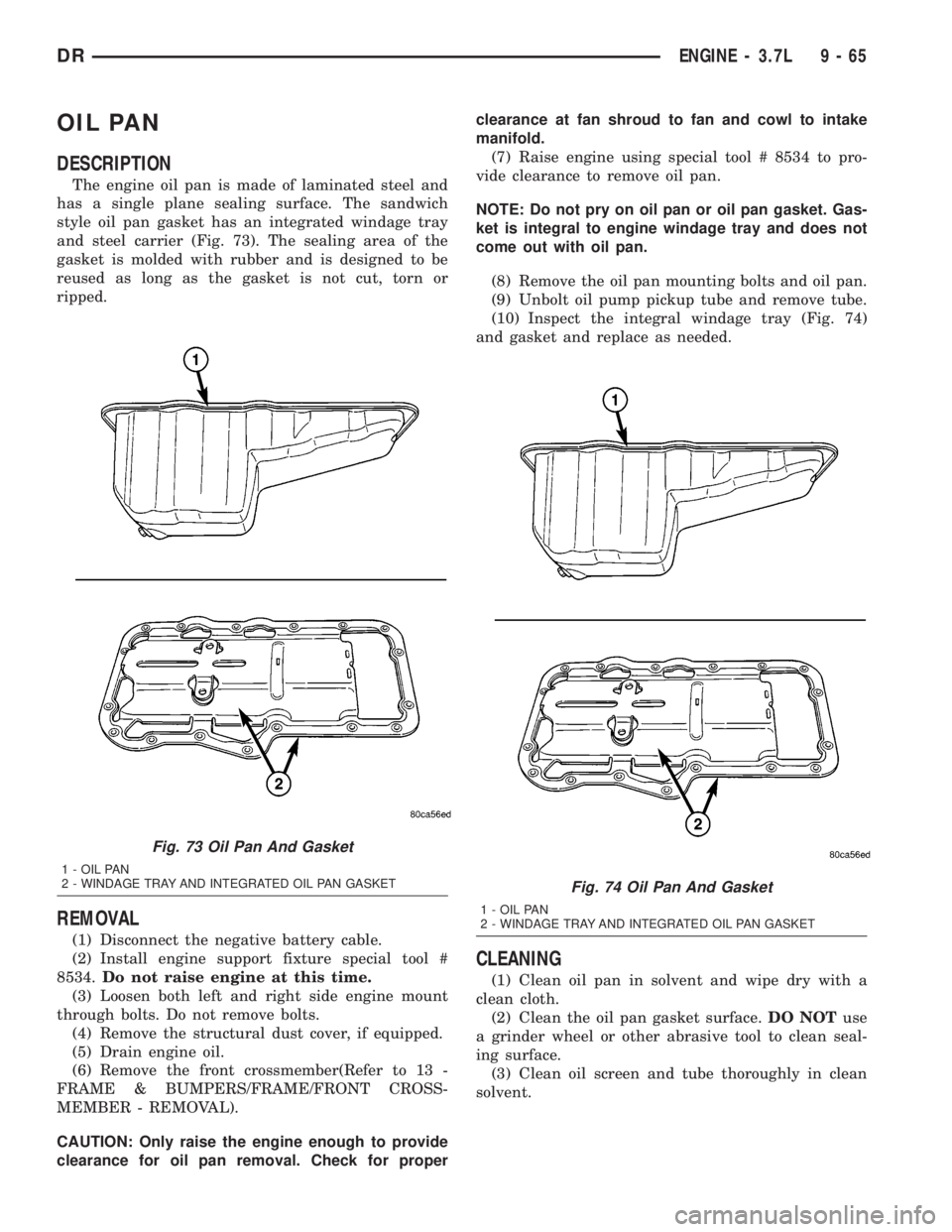

OIL PAN

DESCRIPTION

The engine oil pan is made of laminated steel and

has a single plane sealing surface. The sandwich

style oil pan gasket has an integrated windage tray

and steel carrier (Fig. 73). The sealing area of the

gasket is molded with rubber and is designed to be

reused as long as the gasket is not cut, torn or

ripped.

REMOVAL

(1) Disconnect the negative battery cable.

(2) Install engine support fixture special tool #

8534.Do not raise engine at this time.

(3) Loosen both left and right side engine mount

through bolts. Do not remove bolts.

(4) Remove the structural dust cover, if equipped.

(5) Drain engine oil.

(6) Remove the front crossmember(Refer to 13 -

FRAME & BUMPERS/FRAME/FRONT CROSS-

MEMBER - REMOVAL).

CAUTION: Only raise the engine enough to provide

clearance for oil pan removal. Check for properclearance at fan shroud to fan and cowl to intake

manifold.

(7) Raise engine using special tool # 8534 to pro-

vide clearance to remove oil pan.

NOTE: Do not pry on oil pan or oil pan gasket. Gas-

ket is integral to engine windage tray and does not

come out with oil pan.

(8) Remove the oil pan mounting bolts and oil pan.

(9) Unbolt oil pump pickup tube and remove tube.

(10) Inspect the integral windage tray (Fig. 74)

and gasket and replace as needed.

CLEANING

(1) Clean oil pan in solvent and wipe dry with a

clean cloth.

(2) Clean the oil pan gasket surface.DO NOTuse

a grinder wheel or other abrasive tool to clean seal-

ing surface.

(3) Clean oil screen and tube thoroughly in clean

solvent.

Fig. 73 Oil Pan And Gasket

1 - OIL PAN

2 - WINDAGE TRAY AND INTEGRATED OIL PAN GASKET

Fig. 74 Oil Pan And Gasket

1 - OIL PAN

2 - WINDAGE TRAY AND INTEGRATED OIL PAN GASKET

DRENGINE - 3.7L 9 - 65

Page 1315 of 2895

INSPECTION

(1) Inspect oil drain plug and plug hole for

stripped or damaged threads. Repair as necessary.

(2) Inspect the oil pan mounting flange for bends

or distortion. Straighten flange, if necessary.

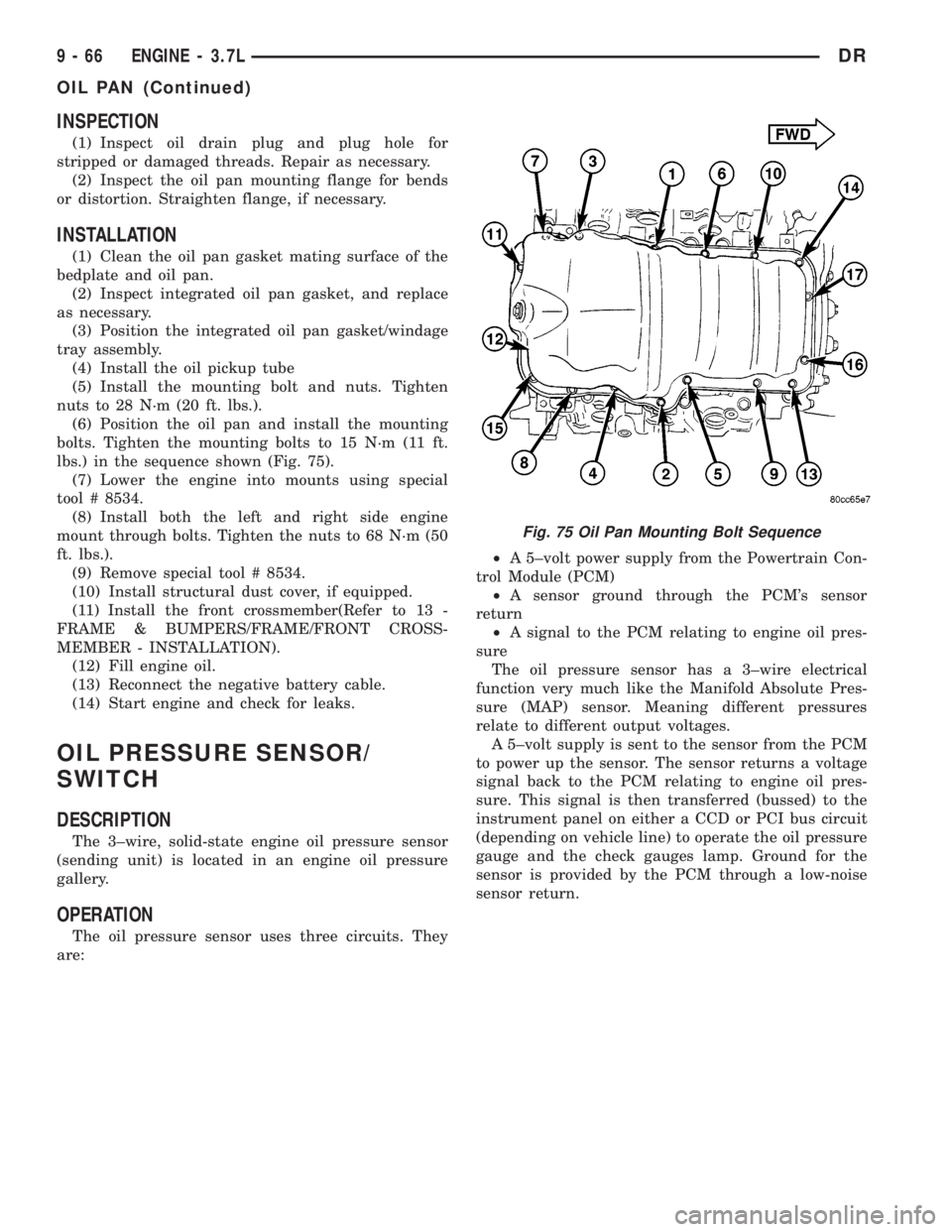

INSTALLATION

(1) Clean the oil pan gasket mating surface of the

bedplate and oil pan.

(2) Inspect integrated oil pan gasket, and replace

as necessary.

(3) Position the integrated oil pan gasket/windage

tray assembly.

(4) Install the oil pickup tube

(5) Install the mounting bolt and nuts. Tighten

nuts to 28 N´m (20 ft. lbs.).

(6) Position the oil pan and install the mounting

bolts. Tighten the mounting bolts to 15 N´m (11 ft.

lbs.) in the sequence shown (Fig. 75).

(7) Lower the engine into mounts using special

tool # 8534.

(8) Install both the left and right side engine

mount through bolts. Tighten the nuts to 68 N´m (50

ft. lbs.).

(9) Remove special tool # 8534.

(10) Install structural dust cover, if equipped.

(11) Install the front crossmember(Refer to 13 -

FRAME & BUMPERS/FRAME/FRONT CROSS-

MEMBER - INSTALLATION).

(12) Fill engine oil.

(13) Reconnect the negative battery cable.

(14) Start engine and check for leaks.

OIL PRESSURE SENSOR/

SWITCH

DESCRIPTION

The 3±wire, solid-state engine oil pressure sensor

(sending unit) is located in an engine oil pressure

gallery.

OPERATION

The oil pressure sensor uses three circuits. They

are:²A 5±volt power supply from the Powertrain Con-

trol Module (PCM)

²A sensor ground through the PCM's sensor

return

²A signal to the PCM relating to engine oil pres-

sure

The oil pressure sensor has a 3±wire electrical

function very much like the Manifold Absolute Pres-

sure (MAP) sensor. Meaning different pressures

relate to different output voltages.

A 5±volt supply is sent to the sensor from the PCM

to power up the sensor. The sensor returns a voltage

signal back to the PCM relating to engine oil pres-

sure. This signal is then transferred (bussed) to the

instrument panel on either a CCD or PCI bus circuit

(depending on vehicle line) to operate the oil pressure

gauge and the check gauges lamp. Ground for the

sensor is provided by the PCM through a low-noise

sensor return.

Fig. 75 Oil Pan Mounting Bolt Sequence

9 - 66 ENGINE - 3.7LDR

OIL PAN (Continued)

Page 1402 of 2895

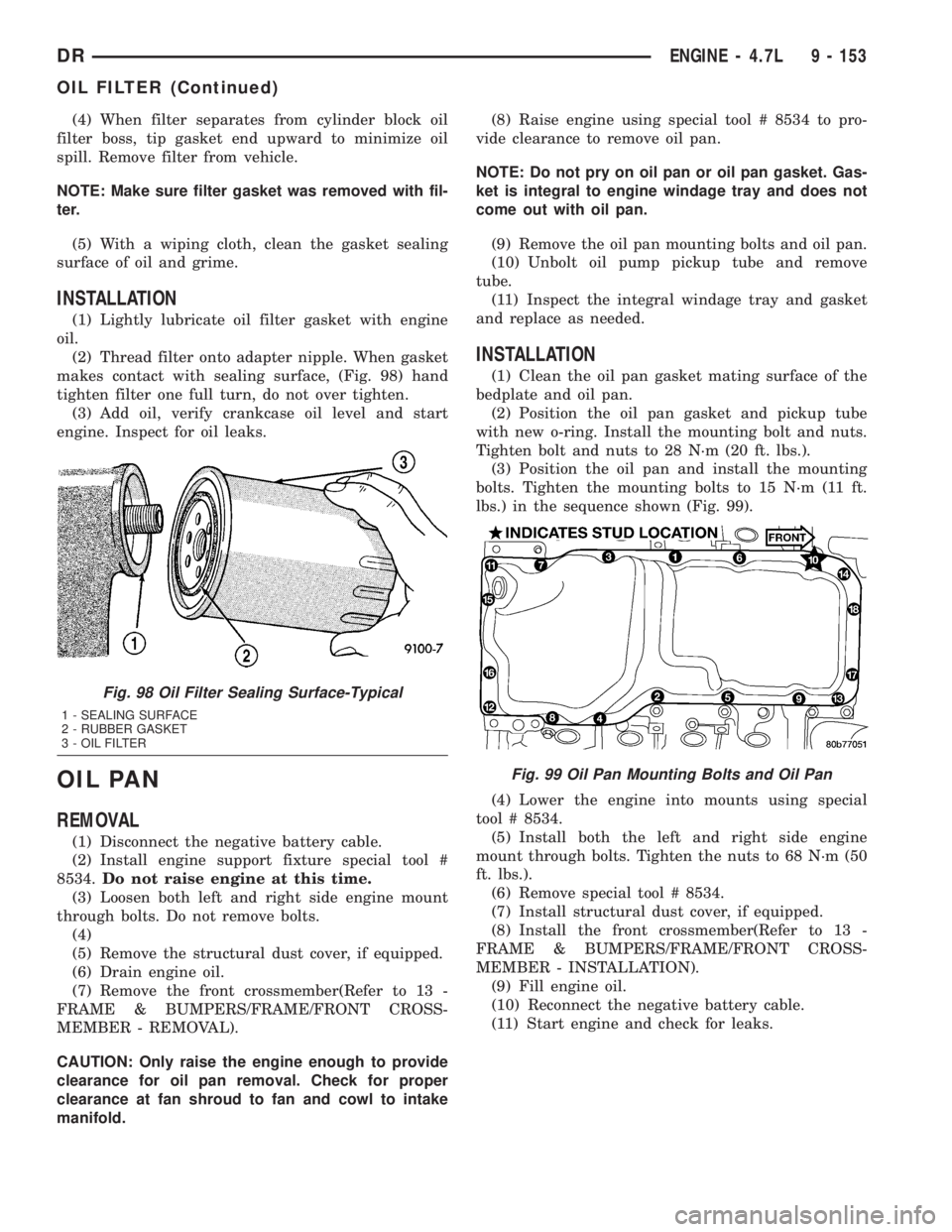

(4) When filter separates from cylinder block oil

filter boss, tip gasket end upward to minimize oil

spill. Remove filter from vehicle.

NOTE: Make sure filter gasket was removed with fil-

ter.

(5) With a wiping cloth, clean the gasket sealing

surface of oil and grime.

INSTALLATION

(1) Lightly lubricate oil filter gasket with engine

oil.

(2) Thread filter onto adapter nipple. When gasket

makes contact with sealing surface, (Fig. 98) hand

tighten filter one full turn, do not over tighten.

(3) Add oil, verify crankcase oil level and start

engine. Inspect for oil leaks.

OIL PAN

REMOVAL

(1) Disconnect the negative battery cable.

(2) Install engine support fixture special tool #

8534.Do not raise engine at this time.

(3) Loosen both left and right side engine mount

through bolts. Do not remove bolts.

(4)

(5) Remove the structural dust cover, if equipped.

(6) Drain engine oil.

(7) Remove the front crossmember(Refer to 13 -

FRAME & BUMPERS/FRAME/FRONT CROSS-

MEMBER - REMOVAL).

CAUTION: Only raise the engine enough to provide

clearance for oil pan removal. Check for proper

clearance at fan shroud to fan and cowl to intake

manifold.(8) Raise engine using special tool # 8534 to pro-

vide clearance to remove oil pan.

NOTE: Do not pry on oil pan or oil pan gasket. Gas-

ket is integral to engine windage tray and does not

come out with oil pan.

(9) Remove the oil pan mounting bolts and oil pan.

(10) Unbolt oil pump pickup tube and remove

tube.

(11) Inspect the integral windage tray and gasket

and replace as needed.

INSTALLATION

(1) Clean the oil pan gasket mating surface of the

bedplate and oil pan.

(2) Position the oil pan gasket and pickup tube

with new o-ring. Install the mounting bolt and nuts.

Tighten bolt and nuts to 28 N´m (20 ft. lbs.).

(3) Position the oil pan and install the mounting

bolts. Tighten the mounting bolts to 15 N´m (11 ft.

lbs.) in the sequence shown (Fig. 99).

(4) Lower the engine into mounts using special

tool # 8534.

(5) Install both the left and right side engine

mount through bolts. Tighten the nuts to 68 N´m (50

ft. lbs.).

(6) Remove special tool # 8534.

(7) Install structural dust cover, if equipped.

(8) Install the front crossmember(Refer to 13 -

FRAME & BUMPERS/FRAME/FRONT CROSS-

MEMBER - INSTALLATION).

(9) Fill engine oil.

(10) Reconnect the negative battery cable.

(11) Start engine and check for leaks.

Fig. 98 Oil Filter Sealing Surface-Typical

1 - SEALING SURFACE

2 - RUBBER GASKET

3 - OIL FILTER

Fig. 99 Oil Pan Mounting Bolts and Oil Pan

DRENGINE - 4.7L 9 - 153

OIL FILTER (Continued)

Page 1460 of 2895

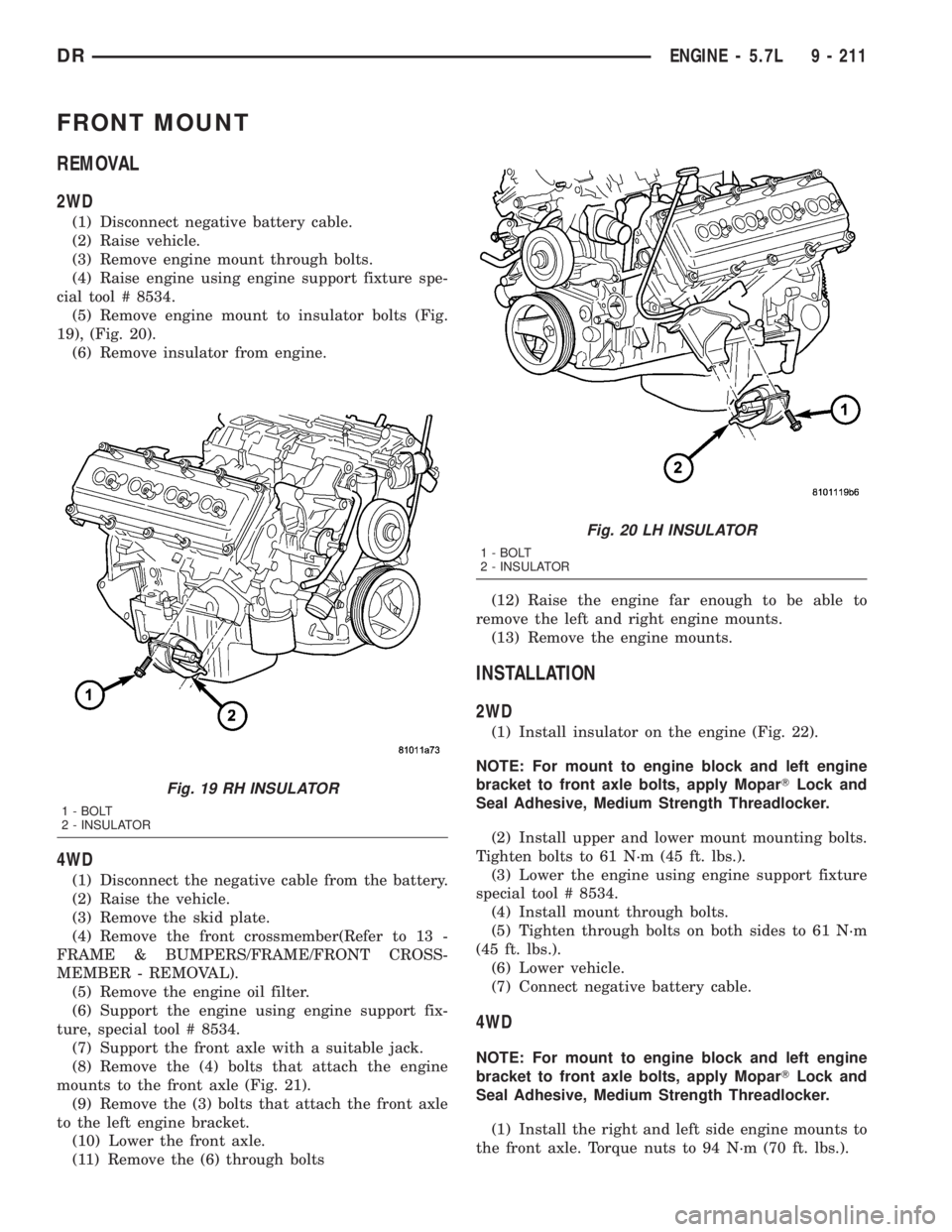

FRONT MOUNT

REMOVAL

2WD

(1) Disconnect negative battery cable.

(2) Raise vehicle.

(3) Remove engine mount through bolts.

(4) Raise engine using engine support fixture spe-

cial tool # 8534.

(5) Remove engine mount to insulator bolts (Fig.

19), (Fig. 20).

(6) Remove insulator from engine.

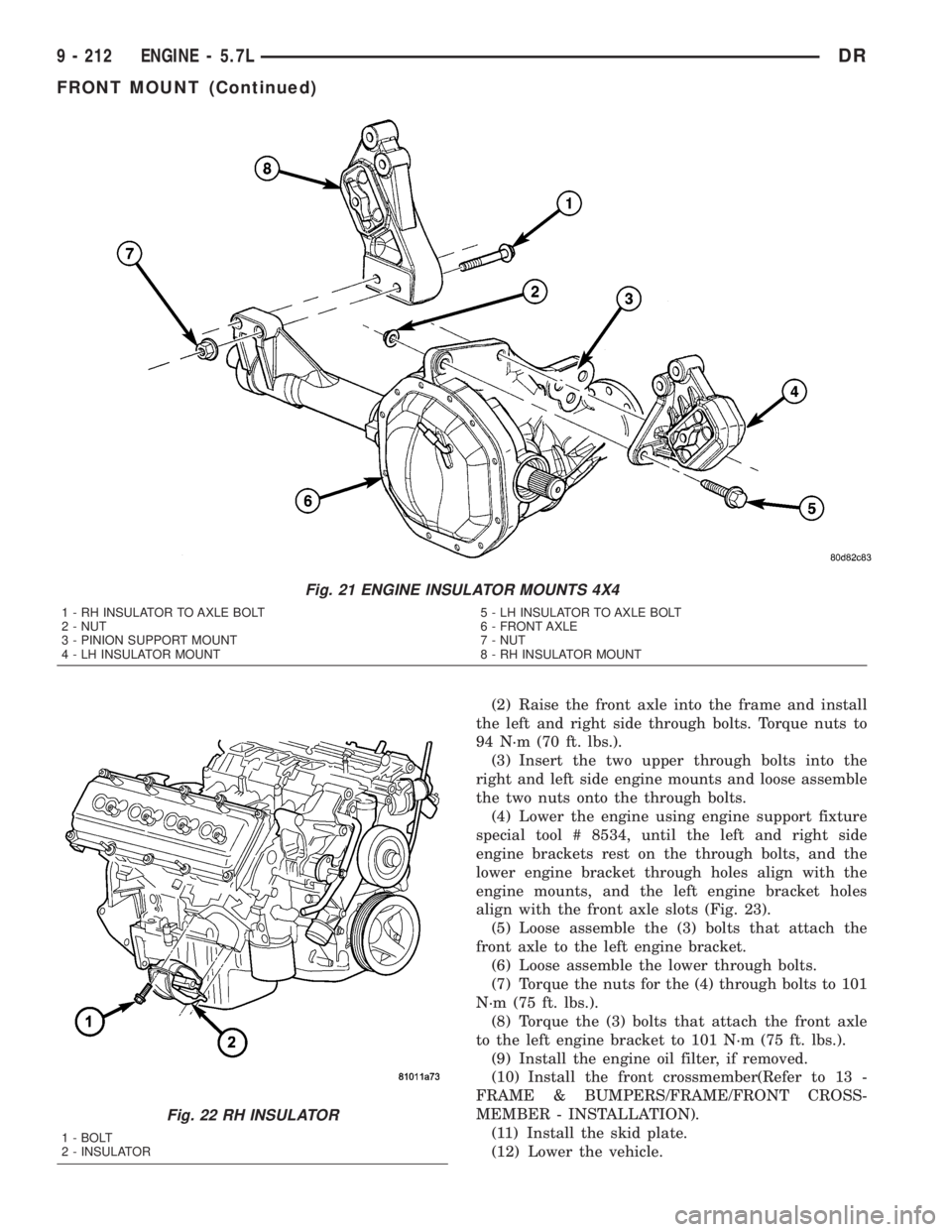

4WD

(1) Disconnect the negative cable from the battery.

(2) Raise the vehicle.

(3) Remove the skid plate.

(4) Remove the front crossmember(Refer to 13 -

FRAME & BUMPERS/FRAME/FRONT CROSS-

MEMBER - REMOVAL).

(5) Remove the engine oil filter.

(6) Support the engine using engine support fix-

ture, special tool # 8534.

(7) Support the front axle with a suitable jack.

(8) Remove the (4) bolts that attach the engine

mounts to the front axle (Fig. 21).

(9) Remove the (3) bolts that attach the front axle

to the left engine bracket.

(10) Lower the front axle.

(11) Remove the (6) through bolts(12) Raise the engine far enough to be able to

remove the left and right engine mounts.

(13) Remove the engine mounts.

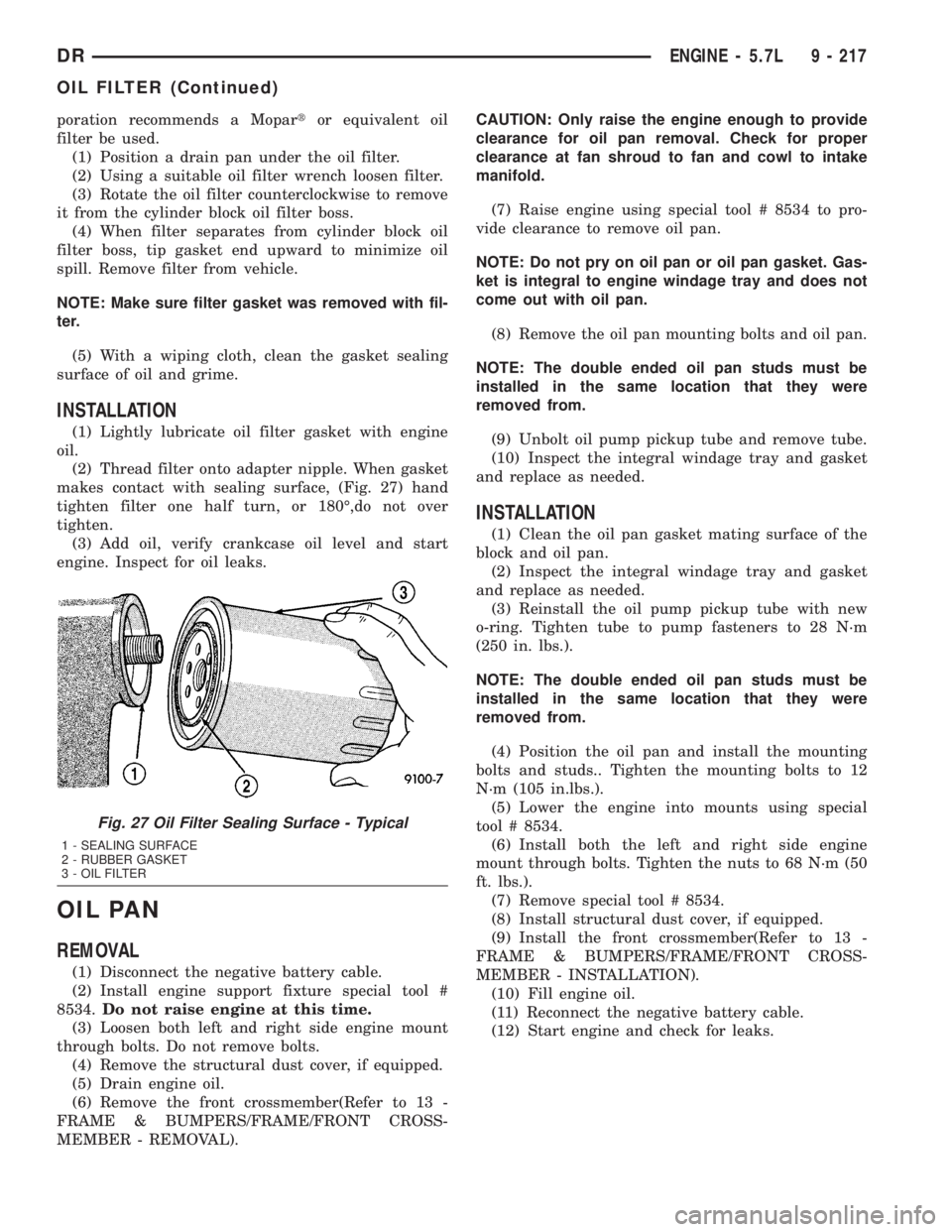

INSTALLATION

2WD

(1) Install insulator on the engine (Fig. 22).

NOTE: For mount to engine block and left engine

bracket to front axle bolts, apply MoparTLock and

Seal Adhesive, Medium Strength Threadlocker.

(2) Install upper and lower mount mounting bolts.

Tighten bolts to 61 N´m (45 ft. lbs.).

(3) Lower the engine using engine support fixture

special tool # 8534.

(4) Install mount through bolts.

(5) Tighten through bolts on both sides to 61 N´m

(45 ft. lbs.).

(6) Lower vehicle.

(7) Connect negative battery cable.

4WD

NOTE: For mount to engine block and left engine

bracket to front axle bolts, apply MoparTLock and

Seal Adhesive, Medium Strength Threadlocker.

(1) Install the right and left side engine mounts to

the front axle. Torque nuts to 94 N´m (70 ft. lbs.).

Fig. 19 RH INSULATOR

1 - BOLT

2 - INSULATOR

Fig. 20 LH INSULATOR

1 - BOLT

2 - INSULATOR

DRENGINE - 5.7L 9 - 211

Page 1461 of 2895

(2) Raise the front axle into the frame and install

the left and right side through bolts. Torque nuts to

94 N´m (70 ft. lbs.).

(3) Insert the two upper through bolts into the

right and left side engine mounts and loose assemble

the two nuts onto the through bolts.

(4) Lower the engine using engine support fixture

special tool # 8534, until the left and right side

engine brackets rest on the through bolts, and the

lower engine bracket through holes align with the

engine mounts, and the left engine bracket holes

align with the front axle slots (Fig. 23).

(5) Loose assemble the (3) bolts that attach the

front axle to the left engine bracket.

(6) Loose assemble the lower through bolts.

(7) Torque the nuts for the (4) through bolts to 101

N´m (75 ft. lbs.).

(8) Torque the (3) bolts that attach the front axle

to the left engine bracket to 101 N´m (75 ft. lbs.).

(9) Install the engine oil filter, if removed.

(10) Install the front crossmember(Refer to 13 -

FRAME & BUMPERS/FRAME/FRONT CROSS-

MEMBER - INSTALLATION).

(11) Install the skid plate.

(12) Lower the vehicle.

Fig. 21 ENGINE INSULATOR MOUNTS 4X4

1 - RH INSULATOR TO AXLE BOLT

2 - NUT

3 - PINION SUPPORT MOUNT

4 - LH INSULATOR MOUNT5 - LH INSULATOR TO AXLE BOLT

6 - FRONT AXLE

7 - NUT

8 - RH INSULATOR MOUNT

Fig. 22 RH INSULATOR

1 - BOLT

2 - INSULATOR

9 - 212 ENGINE - 5.7LDR

FRONT MOUNT (Continued)

Page 1466 of 2895

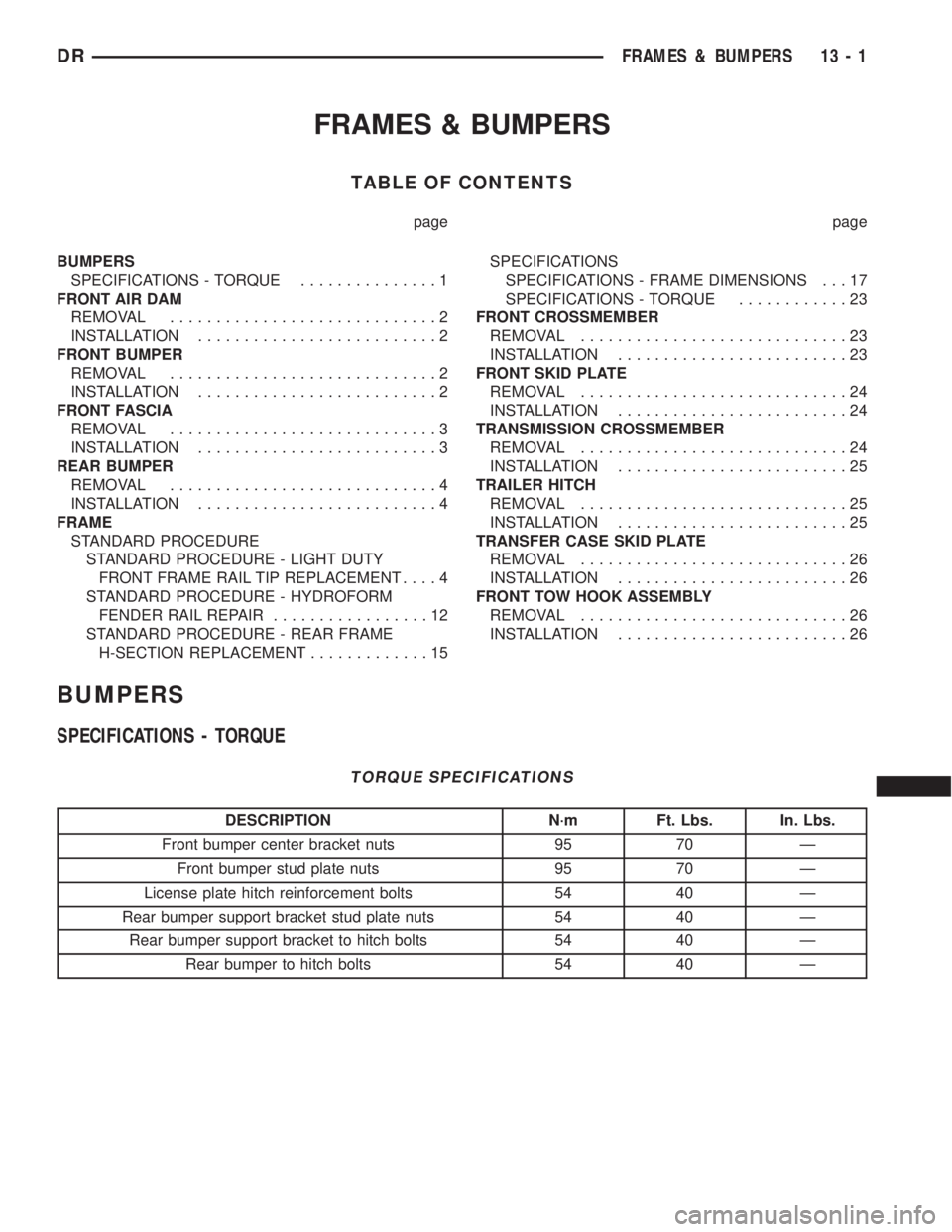

poration recommends a Mopartor equivalent oil

filter be used.

(1) Position a drain pan under the oil filter.

(2) Using a suitable oil filter wrench loosen filter.

(3) Rotate the oil filter counterclockwise to remove

it from the cylinder block oil filter boss.

(4) When filter separates from cylinder block oil

filter boss, tip gasket end upward to minimize oil

spill. Remove filter from vehicle.

NOTE: Make sure filter gasket was removed with fil-

ter.

(5) With a wiping cloth, clean the gasket sealing

surface of oil and grime.

INSTALLATION

(1) Lightly lubricate oil filter gasket with engine

oil.

(2) Thread filter onto adapter nipple. When gasket

makes contact with sealing surface, (Fig. 27) hand

tighten filter one half turn, or 180É,do not over

tighten.

(3) Add oil, verify crankcase oil level and start

engine. Inspect for oil leaks.

OIL PAN

REMOVAL

(1) Disconnect the negative battery cable.

(2) Install engine support fixture special tool #

8534.Do not raise engine at this time.

(3) Loosen both left and right side engine mount

through bolts. Do not remove bolts.

(4) Remove the structural dust cover, if equipped.

(5) Drain engine oil.

(6) Remove the front crossmember(Refer to 13 -

FRAME & BUMPERS/FRAME/FRONT CROSS-

MEMBER - REMOVAL).CAUTION: Only raise the engine enough to provide

clearance for oil pan removal. Check for proper

clearance at fan shroud to fan and cowl to intake

manifold.

(7) Raise engine using special tool # 8534 to pro-

vide clearance to remove oil pan.

NOTE: Do not pry on oil pan or oil pan gasket. Gas-

ket is integral to engine windage tray and does not

come out with oil pan.

(8) Remove the oil pan mounting bolts and oil pan.

NOTE: The double ended oil pan studs must be

installed in the same location that they were

removed from.

(9) Unbolt oil pump pickup tube and remove tube.

(10) Inspect the integral windage tray and gasket

and replace as needed.

INSTALLATION

(1) Clean the oil pan gasket mating surface of the

block and oil pan.

(2) Inspect the integral windage tray and gasket

and replace as needed.

(3) Reinstall the oil pump pickup tube with new

o-ring. Tighten tube to pump fasteners to 28 N´m

(250 in. lbs.).

NOTE: The double ended oil pan studs must be

installed in the same location that they were

removed from.

(4) Position the oil pan and install the mounting

bolts and studs.. Tighten the mounting bolts to 12

N´m (105 in.lbs.).

(5) Lower the engine into mounts using special

tool # 8534.

(6) Install both the left and right side engine

mount through bolts. Tighten the nuts to 68 N´m (50

ft. lbs.).

(7) Remove special tool # 8534.

(8) Install structural dust cover, if equipped.

(9) Install the front crossmember(Refer to 13 -

FRAME & BUMPERS/FRAME/FRONT CROSS-

MEMBER - INSTALLATION).

(10) Fill engine oil.

(11) Reconnect the negative battery cable.

(12) Start engine and check for leaks.

Fig. 27 Oil Filter Sealing Surface - Typical

1 - SEALING SURFACE

2 - RUBBER GASKET

3 - OIL FILTER

DRENGINE - 5.7L 9 - 217

OIL FILTER (Continued)

Page 1672 of 2895

FRAMES & BUMPERS

TABLE OF CONTENTS

page page

BUMPERS

SPECIFICATIONS - TORQUE...............1

FRONT AIR DAM

REMOVAL.............................2

INSTALLATION..........................2

FRONT BUMPER

REMOVAL.............................2

INSTALLATION..........................2

FRONT FASCIA

REMOVAL.............................3

INSTALLATION..........................3

REAR BUMPER

REMOVAL.............................4

INSTALLATION..........................4

FRAME

STANDARD PROCEDURE

STANDARD PROCEDURE - LIGHT DUTY

FRONT FRAME RAIL TIP REPLACEMENT....4

STANDARD PROCEDURE - HYDROFORM

FENDER RAIL REPAIR.................12

STANDARD PROCEDURE - REAR FRAME

H-SECTION REPLACEMENT.............15SPECIFICATIONS

SPECIFICATIONS - FRAME DIMENSIONS . . . 17

SPECIFICATIONS - TORQUE............23

FRONT CROSSMEMBER

REMOVAL.............................23

INSTALLATION.........................23

FRONT SKID PLATE

REMOVAL.............................24

INSTALLATION.........................24

TRANSMISSION CROSSMEMBER

REMOVAL.............................24

INSTALLATION.........................25

TRAILER HITCH

REMOVAL.............................25

INSTALLATION.........................25

TRANSFER CASE SKID PLATE

REMOVAL.............................26

INSTALLATION.........................26

FRONT TOW HOOK ASSEMBLY

REMOVAL.............................26

INSTALLATION.........................26

BUMPERS

SPECIFICATIONS - TORQUE

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Front bumper center bracket nuts 95 70 Ð

Front bumper stud plate nuts 95 70 Ð

License plate hitch reinforcement bolts 54 40 Ð

Rear bumper support bracket stud plate nuts 54 40 Ð

Rear bumper support bracket to hitch bolts 54 40 Ð

Rear bumper to hitch bolts 54 40 Ð

DRFRAMES & BUMPERS 13 - 1

Page 1673 of 2895

FRONT AIR DAM

REMOVAL

(1) Using a trim stick C-4755 or equivalent,

remove the fog lamp trim bezels. (Fig. 1)

(2) Remove the air dam screws through the fog

lamp opening (1 per side).

(3) Remove the two outboard screws.

(4) Remove the three middle screws and remove

the air dam.

INSTALLATION

(1) Position the air dam onto the bumper and seat

the carrot type fasteners fully.

(2) Starting at the center screw install the three

middle screws.

(3) Install the screws through the fog lamp open-

ing.

(4) Install the two outboard screws.

(5) Position the fog lamp trim bezels into the

bumper and seat fully.

FRONT BUMPER

REMOVAL

(1) Using a grease pencil or equivalent, mark the

position of the bumper on the frame rail tip to aid

installation.

(2) Disconnect the fog lamp electrical connector at

the left frame rail.

(3) Support the bumper with a suitable lifting

device.

(4) Remove the center bracket nuts and bolts and

remove bumper. (Fig. 2)

INSTALLATION

(1) Install the bumper onto the frame rails and

position the wheelhouse splash shield into the sup-

port brackets.

(2) Install the bolts and nuts.

(3) Line up the bumper with the marks made pre-

viously and tighten the bolts and nuts to 95 N´m (70

ft. lbs.).

(4) Check and adjust the bumper alignment as

necessary. (Refer to 23 - BODY/BODY STRUCTURE/

GAP AND FLUSH - SPECIFICATIONS)

Fig. 1 FOG LAMP BEZEL

1 - BUMPER

2 - BEZEL

Fig. 2 BUMPER SUPPORT BRACKET - TYPICAL

1 - FASCIA - SPORT MODEL

2 - SUPPORT BRACKET

3 - FASCIA SUPPORT BRACKET

4 - WHEELHOUSE SPLASH SHIELD SUPPORT BRACKET

5 - BUMPER CENTER BRACKET

6 - NUTS (4 PER SIDE)

7 - FRAME RAIL TIP

8 - CENTER BRACKET NUTS (2 PER SIDE)

9 - CENTER BRACKET BOLTS ASSEMBLY (1 PER SIDE)

10 - FOG LAMP

13 - 2 FRAMES & BUMPERSDR

Page 1674 of 2895

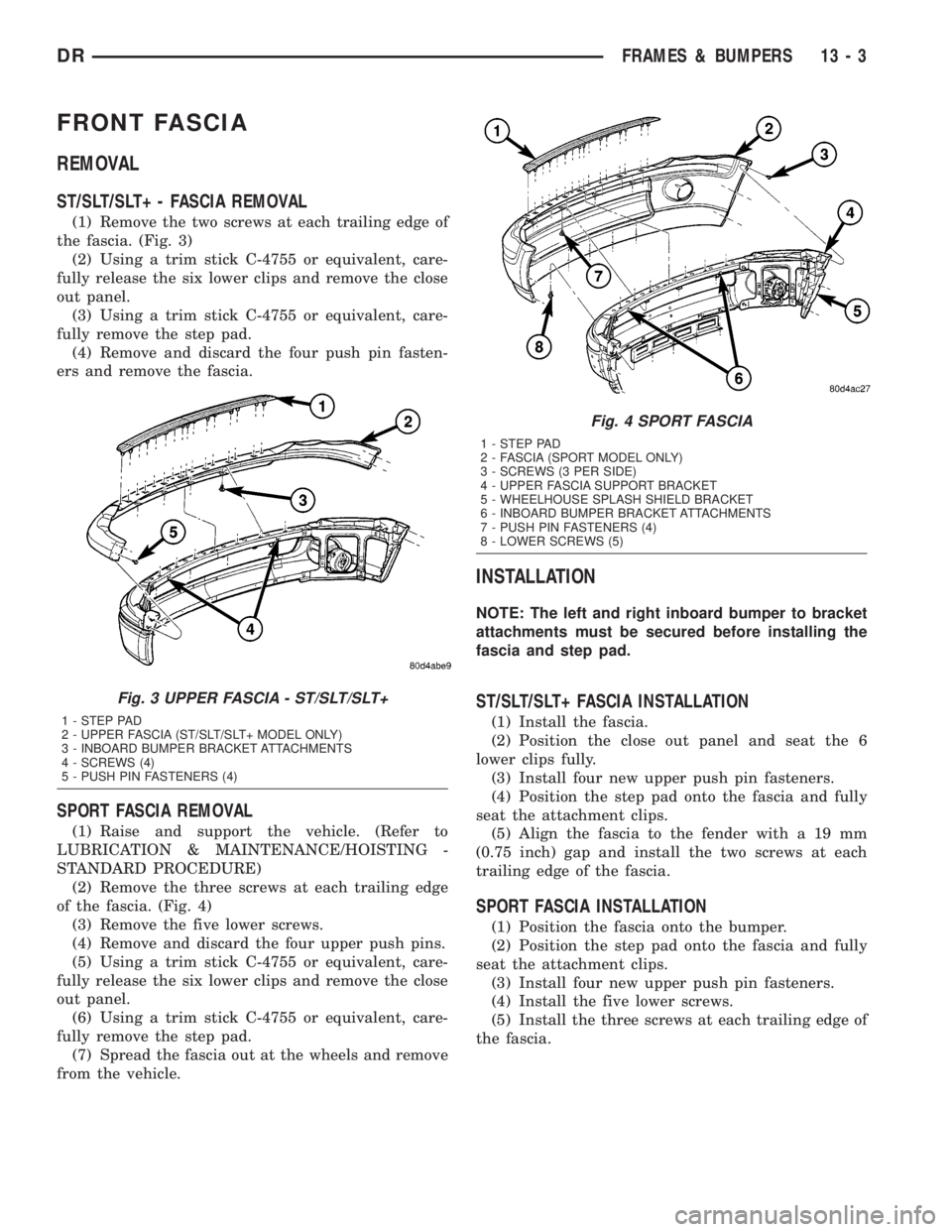

FRONT FASCIA

REMOVAL

ST/SLT/SLT+ - FASCIA REMOVAL

(1) Remove the two screws at each trailing edge of

the fascia. (Fig. 3)

(2) Using a trim stick C-4755 or equivalent, care-

fully release the six lower clips and remove the close

out panel.

(3) Using a trim stick C-4755 or equivalent, care-

fully remove the step pad.

(4) Remove and discard the four push pin fasten-

ers and remove the fascia.

SPORT FASCIA REMOVAL

(1) Raise and support the vehicle. (Refer to

LUBRICATION & MAINTENANCE/HOISTING -

STANDARD PROCEDURE)

(2) Remove the three screws at each trailing edge

of the fascia. (Fig. 4)

(3) Remove the five lower screws.

(4) Remove and discard the four upper push pins.

(5) Using a trim stick C-4755 or equivalent, care-

fully release the six lower clips and remove the close

out panel.

(6) Using a trim stick C-4755 or equivalent, care-

fully remove the step pad.

(7) Spread the fascia out at the wheels and remove

from the vehicle.

INSTALLATION

NOTE: The left and right inboard bumper to bracket

attachments must be secured before installing the

fascia and step pad.

ST/SLT/SLT+ FASCIA INSTALLATION

(1) Install the fascia.

(2) Position the close out panel and seat the 6

lower clips fully.

(3) Install four new upper push pin fasteners.

(4) Position the step pad onto the fascia and fully

seat the attachment clips.

(5) Align the fascia to the fender with a 19 mm

(0.75 inch) gap and install the two screws at each

trailing edge of the fascia.

SPORT FASCIA INSTALLATION

(1) Position the fascia onto the bumper.

(2) Position the step pad onto the fascia and fully

seat the attachment clips.

(3) Install four new upper push pin fasteners.

(4) Install the five lower screws.

(5) Install the three screws at each trailing edge of

the fascia.

Fig. 3 UPPER FASCIA - ST/SLT/SLT+

1 - STEP PAD

2 - UPPER FASCIA (ST/SLT/SLT+ MODEL ONLY)

3 - INBOARD BUMPER BRACKET ATTACHMENTS

4 - SCREWS (4)

5 - PUSH PIN FASTENERS (4)

Fig. 4 SPORT FASCIA

1 - STEP PAD

2 - FASCIA (SPORT MODEL ONLY)

3 - SCREWS (3 PER SIDE)

4 - UPPER FASCIA SUPPORT BRACKET

5 - WHEELHOUSE SPLASH SHIELD BRACKET

6 - INBOARD BUMPER BRACKET ATTACHMENTS

7 - PUSH PIN FASTENERS (4)

8 - LOWER SCREWS (5)

DRFRAMES & BUMPERS 13 - 3

Page 1675 of 2895

REAR BUMPER

REMOVAL

(1) Raise and support the vehicle. (Refer to

LUBRICATION & MAINTENANCE/HOISTING -

STANDARD PROCEDURE)

(2) Remove the license plate.

(3) Remove the bolts behind the plate.

(4) Disconnect the license plate light electrical con-

nectors.

(5) Disconnect the trailer light connector electrical

connection, if equipped.

(6) Remove the two bolts along the front upper

edge of the bumper near the frame tips.

(7)

Support the bumper with a suitable lifting device.

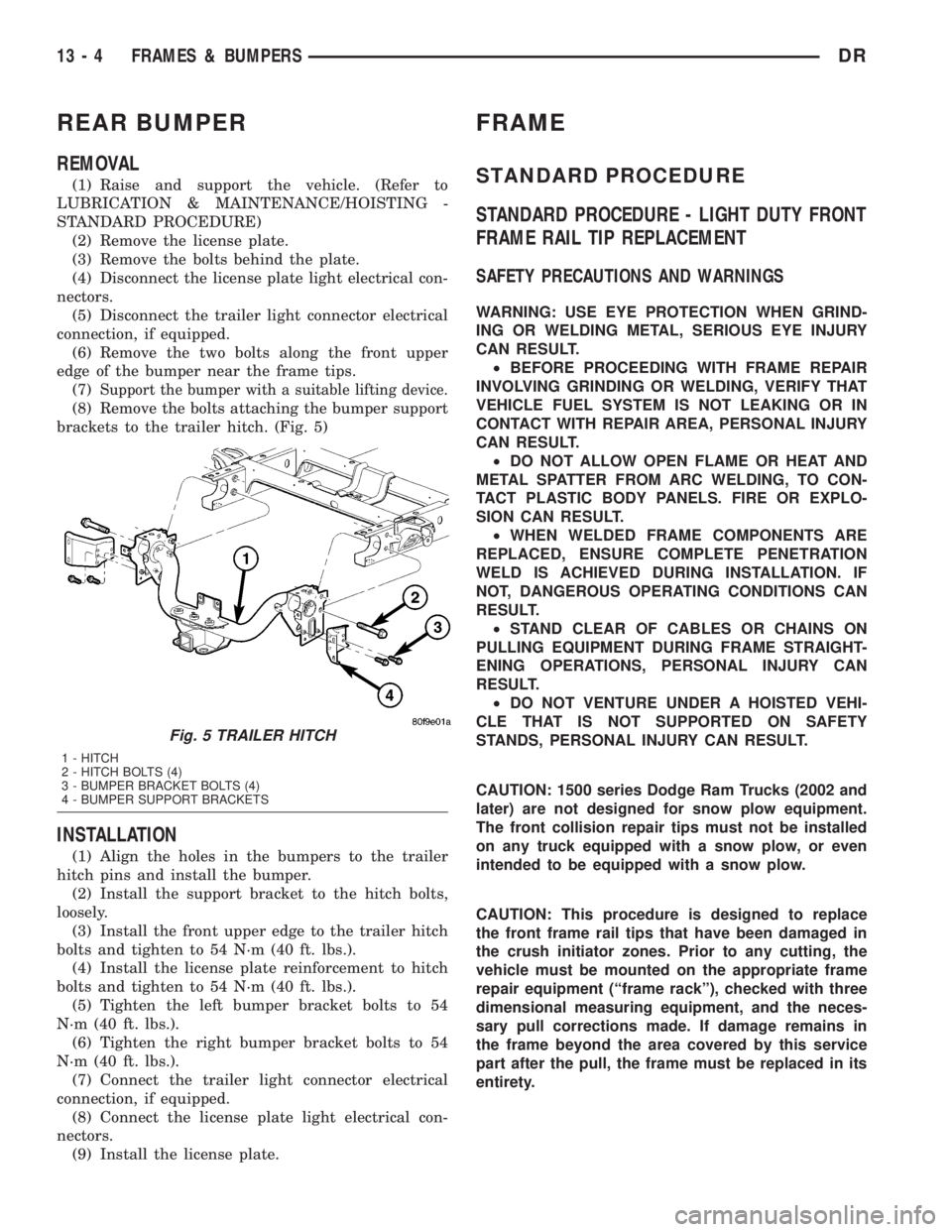

(8) Remove the bolts attaching the bumper support

brackets to the trailer hitch. (Fig. 5)

INSTALLATION

(1) Align the holes in the bumpers to the trailer

hitch pins and install the bumper.

(2) Install the support bracket to the hitch bolts,

loosely.

(3) Install the front upper edge to the trailer hitch

bolts and tighten to 54 N´m (40 ft. lbs.).

(4) Install the license plate reinforcement to hitch

bolts and tighten to 54 N´m (40 ft. lbs.).

(5) Tighten the left bumper bracket bolts to 54

N´m (40 ft. lbs.).

(6) Tighten the right bumper bracket bolts to 54

N´m (40 ft. lbs.).

(7) Connect the trailer light connector electrical

connection, if equipped.

(8) Connect the license plate light electrical con-

nectors.

(9) Install the license plate.

FRAME

STANDARD PROCEDURE

STANDARD PROCEDURE - LIGHT DUTY FRONT

FRAME RAIL TIP REPLACEMENT

SAFETY PRECAUTIONS AND WARNINGS

WARNING: USE EYE PROTECTION WHEN GRIND-

ING OR WELDING METAL, SERIOUS EYE INJURY

CAN RESULT.

²BEFORE PROCEEDING WITH FRAME REPAIR

INVOLVING GRINDING OR WELDING, VERIFY THAT

VEHICLE FUEL SYSTEM IS NOT LEAKING OR IN

CONTACT WITH REPAIR AREA, PERSONAL INJURY

CAN RESULT.

²DO NOT ALLOW OPEN FLAME OR HEAT AND

METAL SPATTER FROM ARC WELDING, TO CON-

TACT PLASTIC BODY PANELS. FIRE OR EXPLO-

SION CAN RESULT.

²WHEN WELDED FRAME COMPONENTS ARE

REPLACED, ENSURE COMPLETE PENETRATION

WELD IS ACHIEVED DURING INSTALLATION. IF

NOT, DANGEROUS OPERATING CONDITIONS CAN

RESULT.

²STAND CLEAR OF CABLES OR CHAINS ON

PULLING EQUIPMENT DURING FRAME STRAIGHT-

ENING OPERATIONS, PERSONAL INJURY CAN

RESULT.

²DO NOT VENTURE UNDER A HOISTED VEHI-

CLE THAT IS NOT SUPPORTED ON SAFETY

STANDS, PERSONAL INJURY CAN RESULT.

CAUTION: 1500 series Dodge Ram Trucks (2002 and

later) are not designed for snow plow equipment.

The front collision repair tips must not be installed

on any truck equipped with a snow plow, or even

intended to be equipped with a snow plow.

CAUTION: This procedure is designed to replace

the front frame rail tips that have been damaged in

the crush initiator zones. Prior to any cutting, the

vehicle must be mounted on the appropriate frame

repair equipment (ªframe rackº), checked with three

dimensional measuring equipment, and the neces-

sary pull corrections made. If damage remains in

the frame beyond the area covered by this service

part after the pull, the frame must be replaced in its

entirety.

Fig. 5 TRAILER HITCH

1 - HITCH

2 - HITCH BOLTS (4)

3 - BUMPER BRACKET BOLTS (4)

4 - BUMPER SUPPORT BRACKETS

13 - 4 FRAMES & BUMPERSDR