height DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 30 of 2895

SUSPENSION

TABLE OF CONTENTS

page page

WHEEL ALIGNMENT......................1

FRONT - INDEPENDENT FRONT SUSPENSION..8FRONT - LINK/COIL......................28

REAR.................................38

WHEEL ALIGNMENT

TABLE OF CONTENTS

page page

WHEEL ALIGNMENT

DESCRIPTION..........................1

OPERATION............................2

DIAGNOSIS AND TESTING - PRE-ALIGNMENT

INSPECTION..........................2

STANDARD PROCEDURE

STANDARD PROCEDURE - HEIGHT

MEASUREMENT - 4WD (LD)..............3

STANDARD PROCEDURE - HEIGHT

ADJUSTMENT - 4WD (LD)................3

STANDARD PROCEDURE - CAMBER AND

CASTER ADJUSTMENT..................4STANDARD PROCEDURE - TOE

ADJUSTMENT.........................4

STANDARD PROCEDURE - CAMBER,

CASTER AND TOE ADJUSTMENT..........4

STANDARD PROCEDURE - ALIGNMENT

LINK/COIL SUSPENSION.................5

SPECIFICATIONS

ALIGNMENT..........................6

SPECIAL TOOLS

WHEEL ALIGNMENT....................7

WHEEL ALIGNMENT

DESCRIPTION

NOTE: Suspension components with rubber/ure-

thane bushings should be tightened with the vehi-

cle at normal ride height. It is important to have the

springs supporting the weight of the vehicle when

the fasteners are torqued. If springs are not at their

normal ride position, vehicle ride comfort could be

affected and premature bushing wear may occur.

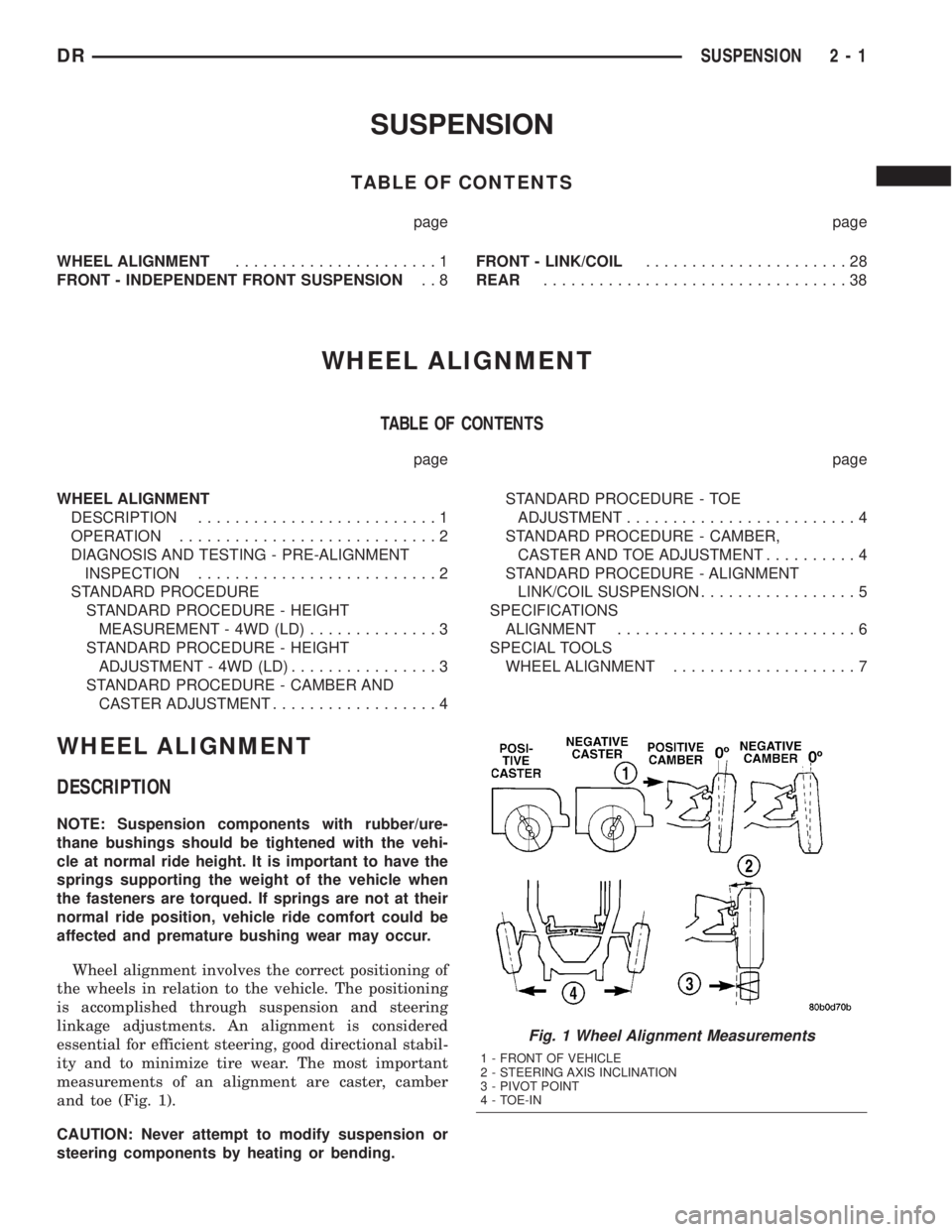

Wheel alignment involves the correct positioning of

the wheels in relation to the vehicle. The positioning

is accomplished through suspension and steering

linkage adjustments. An alignment is considered

essential for efficient steering, good directional stabil-

ity and to minimize tire wear. The most important

measurements of an alignment are caster, camber

and toe (Fig. 1).

CAUTION: Never attempt to modify suspension or

steering components by heating or bending.

Fig. 1 Wheel Alignment Measurements

1 - FRONT OF VEHICLE

2 - STEERING AXIS INCLINATION

3 - PIVOT POINT

4 - TOE-IN

DRSUSPENSION 2 - 1

Page 31 of 2895

OPERATION

²CASTERis the forward or rearward tilt of the

steering knuckle from vertical. Tilting the top of the

knuckle forward provides less positive caster. Tilting

the top of the knuckle rearward provides more posi-

tive caster. Positive caster promotes directional sta-

bility. This angle enables the front wheels to return

to a straight ahead position after turns (Fig. 1)

²CAMBERis the inward or outward tilt of the

wheel relative to the center of the vehicle. Tilting the

top of the wheel inward provides negative camber.

Tilting the top of the wheel outward provides positive

camber. Incorrect camber will cause wear on the

inside or outside edge of the tire (Fig. 1)

²TOEis the difference between the leading inside

edges and trailing inside edges of the front tires.

Wheel toe position out of specification cause's unsta-

ble steering, uneven tire wear and steering wheel off-

center. The wheel toe position is thefinalfront

wheel alignment adjustment (Fig. 1)

²THRUST ANGLEis the angle of the rear axle

relative to the centerline of the vehicle. Incorrect

thrust angle can cause off-center steering and exces-sive tire wear. This angle is not adjustable, damaged

component(s) must be replaced to correct the thrust

angle (Fig. 1)

DIAGNOSIS AND TESTING - PRE-ALIGNMENT

INSPECTION

Before starting wheel alignment, the following

inspection and necessary corrections must be com-

pleted. Refer to Suspension and Steering System

Diagnosis Chart below for additional information.

(1) Inspect tires for size, air pressure and tread

wear.

(2) Inspect front wheel bearings for wear.

(3) Inspect front wheels for excessive radial or lat-

eral runout and balance.

(4) Inspect ball studs, linkage pivot points and

steering gear for looseness, roughness or binding.

(5) Inspect suspension components for wear and

noise.

(6) On 4x4 vehicles check suspension height (LD

only).

(7) Road test the vehicle.

SUSPENSION AND STEERING SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

FRONT END NOISE 1. Loose or worn wheel bearing. 1. Replace wheel bearing.

2. Loose or worn steering or

suspension components.2. Tighten or replace components as

necessary.

3. Loose or worn steering or

suspension components.3. Tighten or replace components as

necessary.

EXCESSIVE PLAY IN

STEERING1. Loose or worn wheel bearing. 1. Replace wheel bearing.

2. Loose or worn steering or

suspension components.2. Tighten or replace components as

necessary.

3. Loose or worn steering gear. 3. Replace steering gear.

FRONT WHEELS SHIMMY 1. Loose or worn wheel bearing. 1. Replace wheel bearing.

2. Loose or worn steering or

suspension components.2. Tighten or replace components as

necessary.

3. Tires worn or out of balance. 3. Replace or balance tires.

4. Alignment. 4. Align vehicle to specifications.

VEHICLE INSTABILITY 1. Loose or worn wheel bearing. 1. Replace wheel bearing.

2. Loose or worn steering or

suspension components.2. Tighten or replace components as

necessary.

3. Tire pressure. 3. Adjust tire pressure.

4. Alignment. 4. Align vehicle to specifications.

2 - 2 WHEEL ALIGNMENTDR

WHEEL ALIGNMENT (Continued)

Page 32 of 2895

CONDITION POSSIBLE CAUSES CORRECTION

EXCESSIVE STEERING

EFFORT1. Loose or worn steering gear. 1. Replace steering gear.

2. Column coupler binding. 2. Replace coupler.

3. Tire pressure. 3. Adjust tire pressure.

4. Alignment. 4. Align vehicle to specifications.

VEHICLE PULLS TO ONE

SIDE1. Tire pressure. 1. Adjust tire pressure.

2. Tire. 2. Criss-Cross Front Tires.

3. Alignment. 3. Align vehicle to specifications.

4. Loose or worn steering or

suspension components.4. Tighten or replace components as

necessary.

5. Radial tire lead. 5. Rotate or replace tire as necessary.

6. Brake pull. 6. Repair brake as necessary.

7. Weak or broken spring. 7. Replace spring.

8. Ride height (LD) 4WD only. 8. Measure and adjust ride height. (LD

only)

STANDARD PROCEDURE

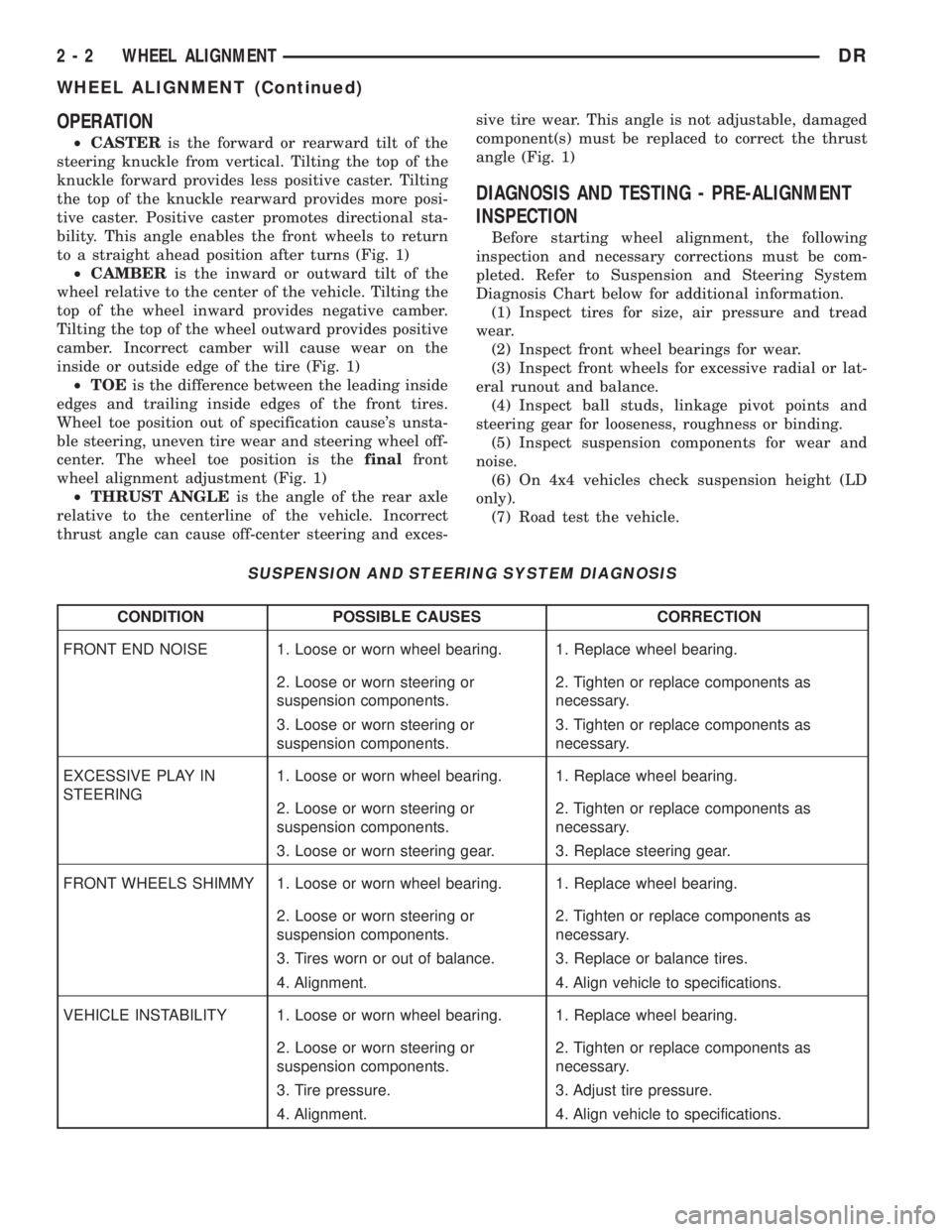

STANDARD PROCEDURE - HEIGHT

MEASUREMENT - 4WD (LD)

The vehicle suspension height MUST be measured

and adjusted before performing wheel alignment pro-

cedure. Also when front suspension components have

been replaced. This measure must be performed with

the vehicle supporting it's own weight and taken on

both sides of the vehicle.

(1) Inspect tires and set to correct pressure.

(2) Jounce the front of the vehicle.

(3) Measure and record the height from the ground

at the centerline of the rear lower control arm bolt

front tip (Fig. 2).

(4) Measure and record the height from the ground

at the front spindle centerline (Static Load Radius)

(Fig. 2).

(5) Subtract the first measurement from the sec-

ond measurement. The difference between the two

measurement should be 58 mm (2.3 inches) 3mm

(0.12 inches).

(6) If value is greater than 61 mm (2.4 inches),

tighten the torsion bar bolt until the specification is

achieved (Refer to 2 - SUSPENSION/WHEEL

ALIGNMENT - STANDARD PROCEDURE).

(7) If value is less than 55 mm (2.1 inches), loosen

the torsion bar bolt until the specification is achieve-

d,(Refer to 2 - SUSPENSION/WHEEL ALIGNMENT

- STANDARD PROCEDURE).

(8) Repeat the previous steps until the ride height

is within specifications.

STANDARD PROCEDURE - HEIGHT

ADJUSTMENT - 4WD (LD)

The vehicle suspension height MUST be measured

and adjusted before performing wheel alignment pro-

cedure (Refer to 2 - SUSPENSION/WHEEL ALIGN-

MENT - STANDARD PROCEDURE). Also when

front suspension components have been replaced.

This measurement must be performed with the vehi-

cle supporting it's own weight and taken on both

sides of the vehicle.

Fig. 2 HEIGHT MESUREMENT

1 - HEIGHT FROM THE GROUND AT THE FRONT SPINDLE

CENTERLINE (STATIC LOAD RADIUS)

2 - CENTERLINE OF THE REAR LOWER CONTROL ARM BOLT

FRONT TIP

3 - GROUND LINE

DRWHEEL ALIGNMENT 2 - 3

WHEEL ALIGNMENT (Continued)

Page 33 of 2895

To adjust the vehicle height turn the torsion bar

adjustment bolt CLOCKWISE to raise the vehicle

and COUNTER CLOCKWISE to lower the vehicle.

CAUTION: ALWAYS raise the vehicle to the correct

suspension height, NEVER lower the vehicle to

obtain the correct suspension height. If the vehicle

suspension height is too high, lower the vehicle

below the height specification. Then raise the vehi-

cle to the correct suspension height specification.

This will insure the vehicle maintains the proper

suspension height.

NOTE: If a height adjustment has been made, per-

form height measurement again on both sides of

the vehicle.

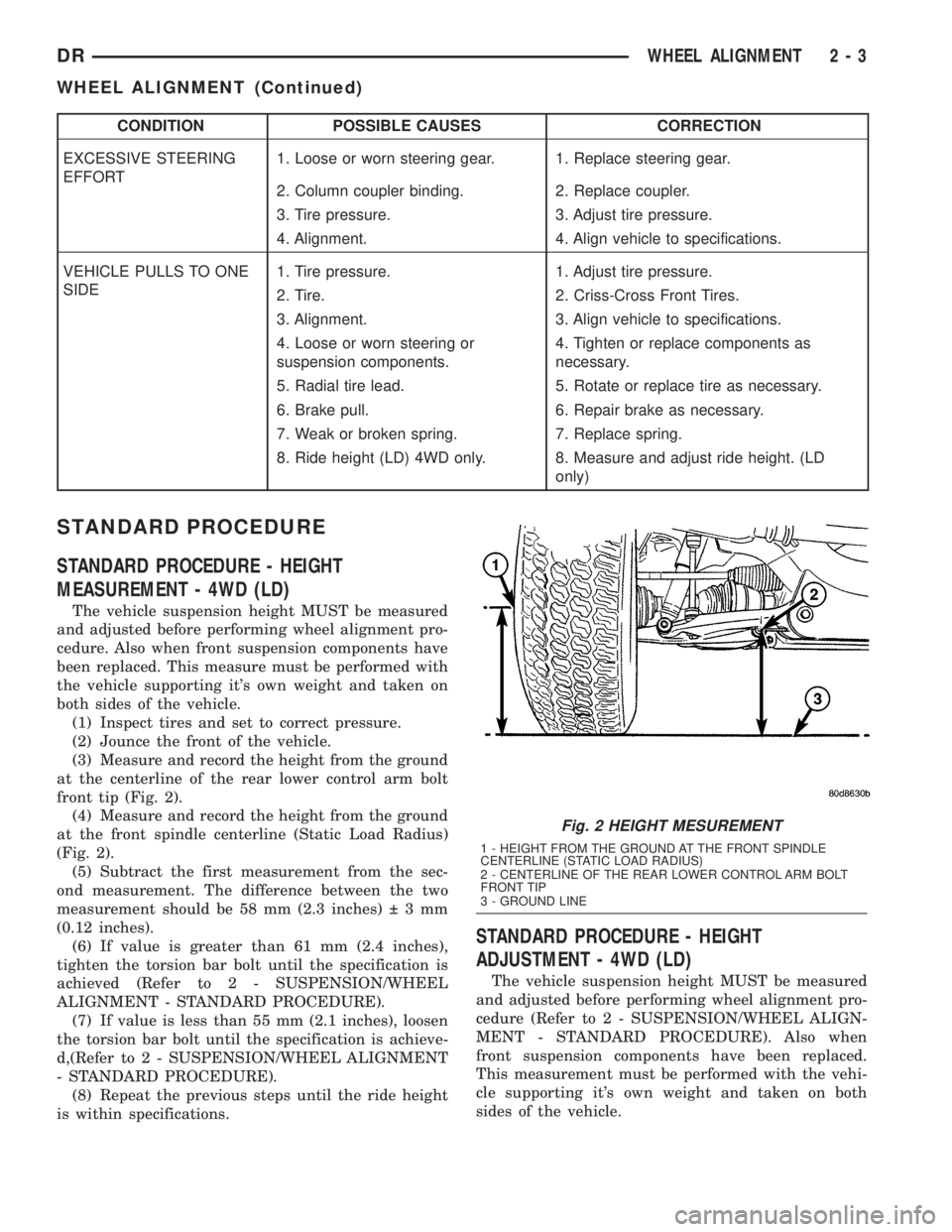

STANDARD PROCEDURE - CAMBER AND

CASTER ADJUSTMENT

NOTE: 4X4 (LD) SUSPENSION HEIGHT MEASURE-

MENT MUST BE PERFORMED BEFORE AN ALIGN-

MENT.

NOTE: When the upper control arm pivot bolts are

loosened the upper control arm will normally go

inwards toward the frame automatically with the

weight of the vehicle.

Camber and caster angle adjustments involve

changing the position of the upper control arm incon-

junction with the slotted holes in the frame brackets,

Install special tool 8876 between the top of the upper

control arm bracket and the upper control arm (on

1500 series 4X2 & 4X4). Install special tool 8876

between the bottom of the upper control arm bracket

pressing the tool against the frame and the upper

control arm (on 2500/3500 series 4X2) in order to

move the upper control arm outwards for proper

adjustment with the vehicle at normal ride height

(Fig. 3).

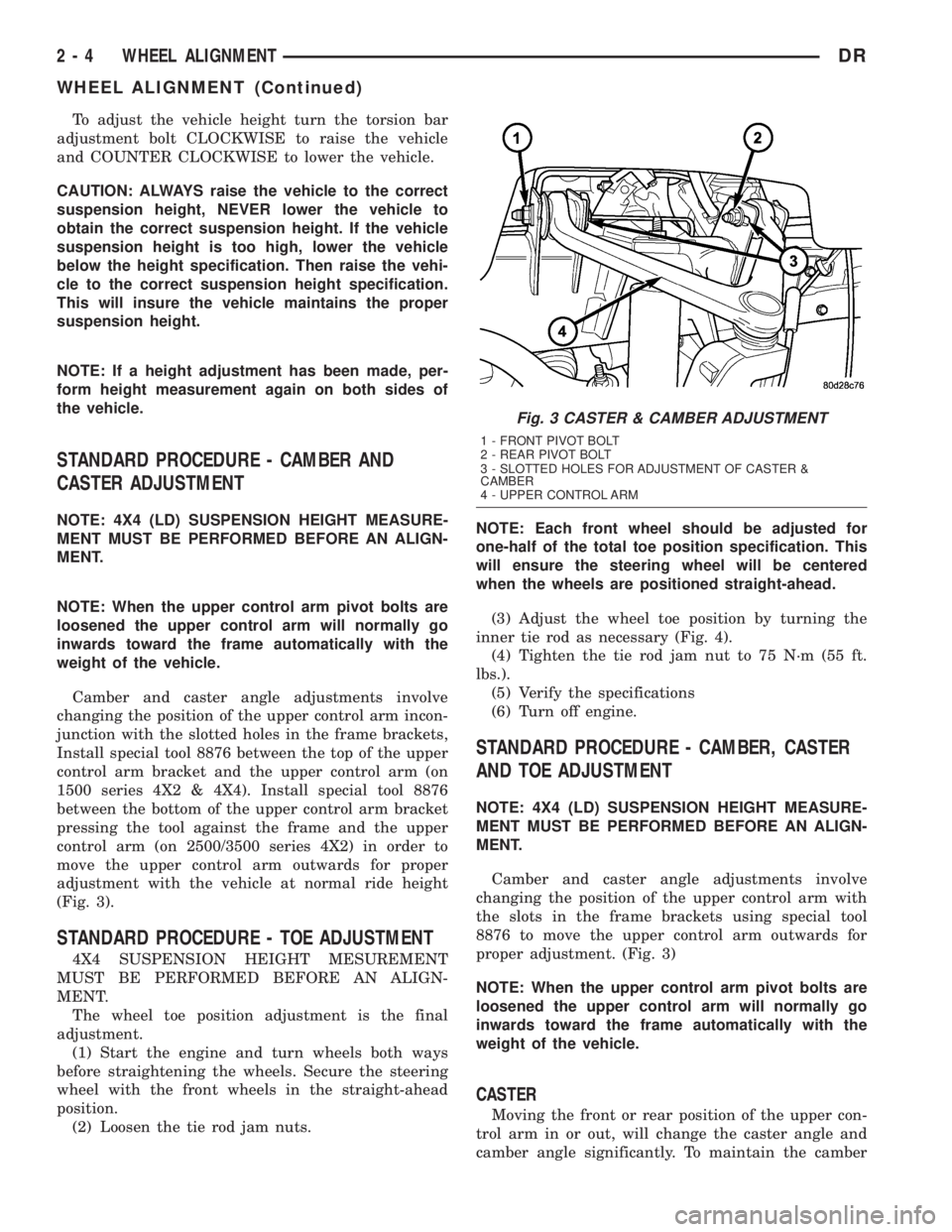

STANDARD PROCEDURE - TOE ADJUSTMENT

4X4 SUSPENSION HEIGHT MESUREMENT

MUST BE PERFORMED BEFORE AN ALIGN-

MENT.

The wheel toe position adjustment is the final

adjustment.

(1) Start the engine and turn wheels both ways

before straightening the wheels. Secure the steering

wheel with the front wheels in the straight-ahead

position.

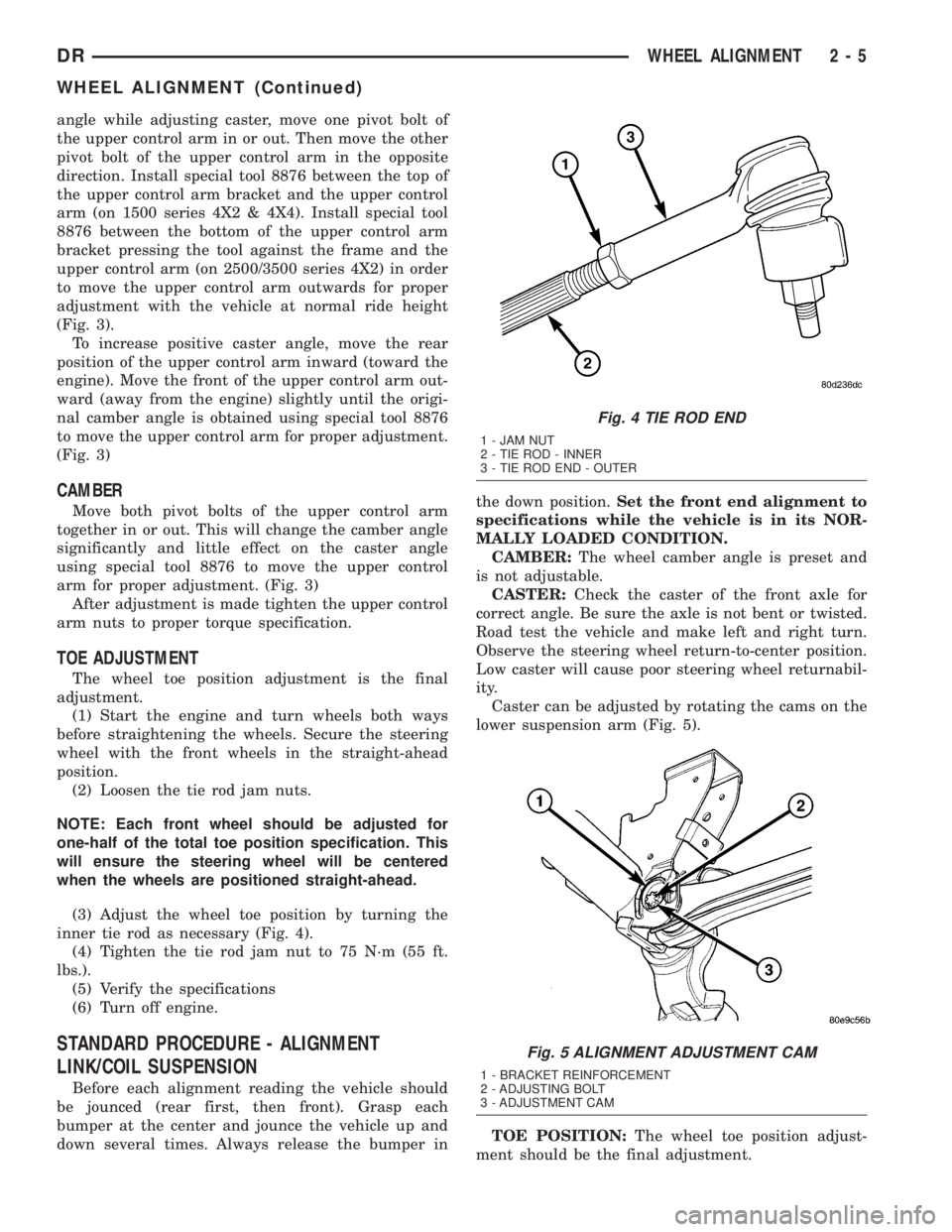

(2) Loosen the tie rod jam nuts.NOTE: Each front wheel should be adjusted for

one-half of the total toe position specification. This

will ensure the steering wheel will be centered

when the wheels are positioned straight-ahead.

(3) Adjust the wheel toe position by turning the

inner tie rod as necessary (Fig. 4).

(4) Tighten the tie rod jam nut to 75 N´m (55 ft.

lbs.).

(5) Verify the specifications

(6) Turn off engine.

STANDARD PROCEDURE - CAMBER, CASTER

AND TOE ADJUSTMENT

NOTE: 4X4 (LD) SUSPENSION HEIGHT MEASURE-

MENT MUST BE PERFORMED BEFORE AN ALIGN-

MENT.

Camber and caster angle adjustments involve

changing the position of the upper control arm with

the slots in the frame brackets using special tool

8876 to move the upper control arm outwards for

proper adjustment. (Fig. 3)

NOTE: When the upper control arm pivot bolts are

loosened the upper control arm will normally go

inwards toward the frame automatically with the

weight of the vehicle.

CASTER

Moving the front or rear position of the upper con-

trol arm in or out, will change the caster angle and

camber angle significantly. To maintain the camber

Fig. 3 CASTER & CAMBER ADJUSTMENT

1 - FRONT PIVOT BOLT

2 - REAR PIVOT BOLT

3 - SLOTTED HOLES FOR ADJUSTMENT OF CASTER &

CAMBER

4 - UPPER CONTROL ARM

2 - 4 WHEEL ALIGNMENTDR

WHEEL ALIGNMENT (Continued)

Page 34 of 2895

angle while adjusting caster, move one pivot bolt of

the upper control arm in or out. Then move the other

pivot bolt of the upper control arm in the opposite

direction. Install special tool 8876 between the top of

the upper control arm bracket and the upper control

arm (on 1500 series 4X2 & 4X4). Install special tool

8876 between the bottom of the upper control arm

bracket pressing the tool against the frame and the

upper control arm (on 2500/3500 series 4X2) in order

to move the upper control arm outwards for proper

adjustment with the vehicle at normal ride height

(Fig. 3).

To increase positive caster angle, move the rear

position of the upper control arm inward (toward the

engine). Move the front of the upper control arm out-

ward (away from the engine) slightly until the origi-

nal camber angle is obtained using special tool 8876

to move the upper control arm for proper adjustment.

(Fig. 3)

CAMBER

Move both pivot bolts of the upper control arm

together in or out. This will change the camber angle

significantly and little effect on the caster angle

using special tool 8876 to move the upper control

arm for proper adjustment. (Fig. 3)

After adjustment is made tighten the upper control

arm nuts to proper torque specification.

TOE ADJUSTMENT

The wheel toe position adjustment is the final

adjustment.

(1) Start the engine and turn wheels both ways

before straightening the wheels. Secure the steering

wheel with the front wheels in the straight-ahead

position.

(2) Loosen the tie rod jam nuts.

NOTE: Each front wheel should be adjusted for

one-half of the total toe position specification. This

will ensure the steering wheel will be centered

when the wheels are positioned straight-ahead.

(3) Adjust the wheel toe position by turning the

inner tie rod as necessary (Fig. 4).

(4) Tighten the tie rod jam nut to 75 N´m (55 ft.

lbs.).

(5) Verify the specifications

(6) Turn off engine.

STANDARD PROCEDURE - ALIGNMENT

LINK/COIL SUSPENSION

Before each alignment reading the vehicle should

be jounced (rear first, then front). Grasp each

bumper at the center and jounce the vehicle up and

down several times. Always release the bumper inthe down position.Set the front end alignment to

specifications while the vehicle is in its NOR-

MALLY LOADED CONDITION.

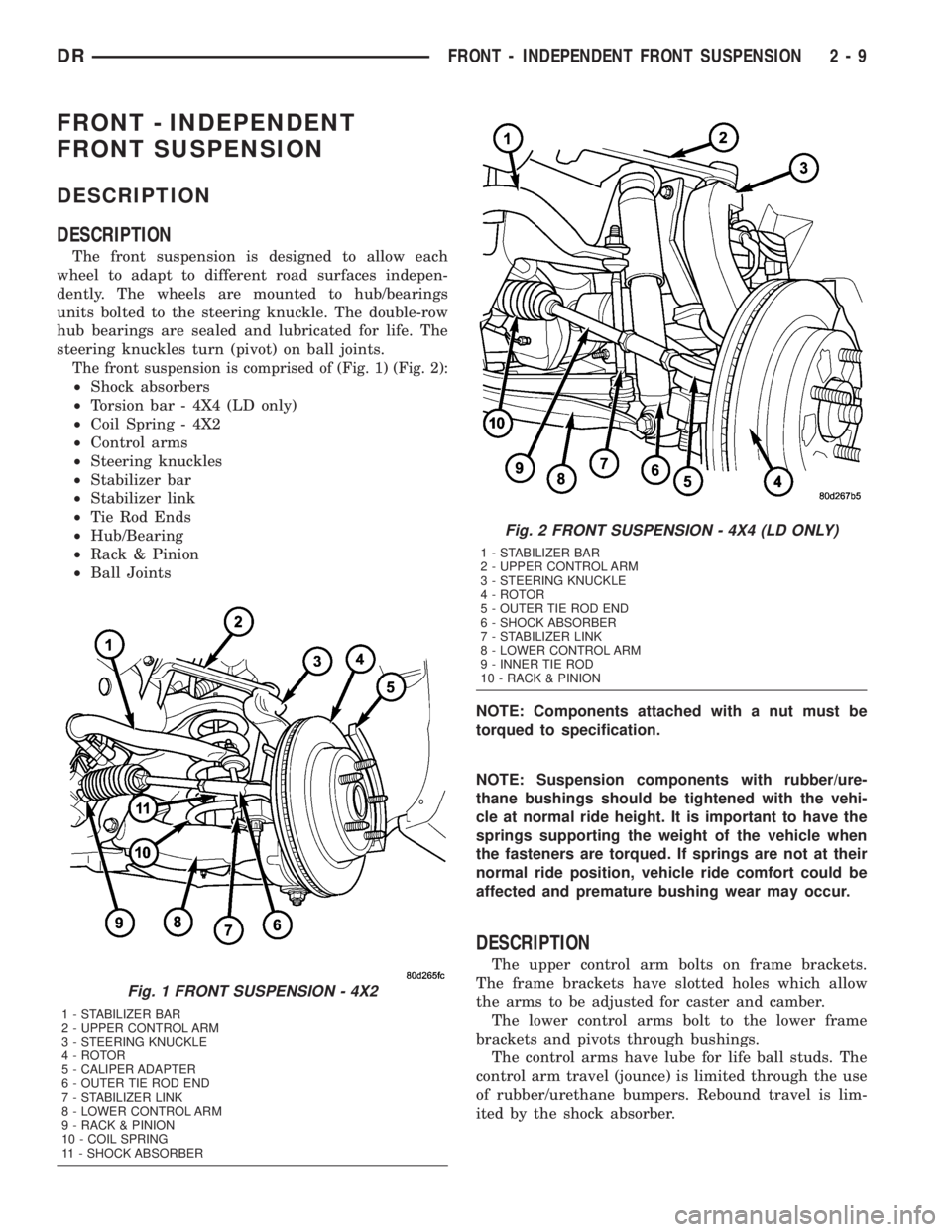

CAMBER:The wheel camber angle is preset and

is not adjustable.

CASTER:Check the caster of the front axle for

correct angle. Be sure the axle is not bent or twisted.

Road test the vehicle and make left and right turn.

Observe the steering wheel return-to-center position.

Low caster will cause poor steering wheel returnabil-

ity.

Caster can be adjusted by rotating the cams on the

lower suspension arm (Fig. 5).

TOE POSITION:The wheel toe position adjust-

ment should be the final adjustment.

Fig. 4 TIE ROD END

1 - JAM NUT

2 - TIE ROD - INNER

3 - TIE ROD END - OUTER

Fig. 5 ALIGNMENT ADJUSTMENT CAM

1 - BRACKET REINFORCEMENT

2 - ADJUSTING BOLT

3 - ADJUSTMENT CAM

DRWHEEL ALIGNMENT 2 - 5

WHEEL ALIGNMENT (Continued)

Page 38 of 2895

FRONT - INDEPENDENT

FRONT SUSPENSION

DESCRIPTION

DESCRIPTION

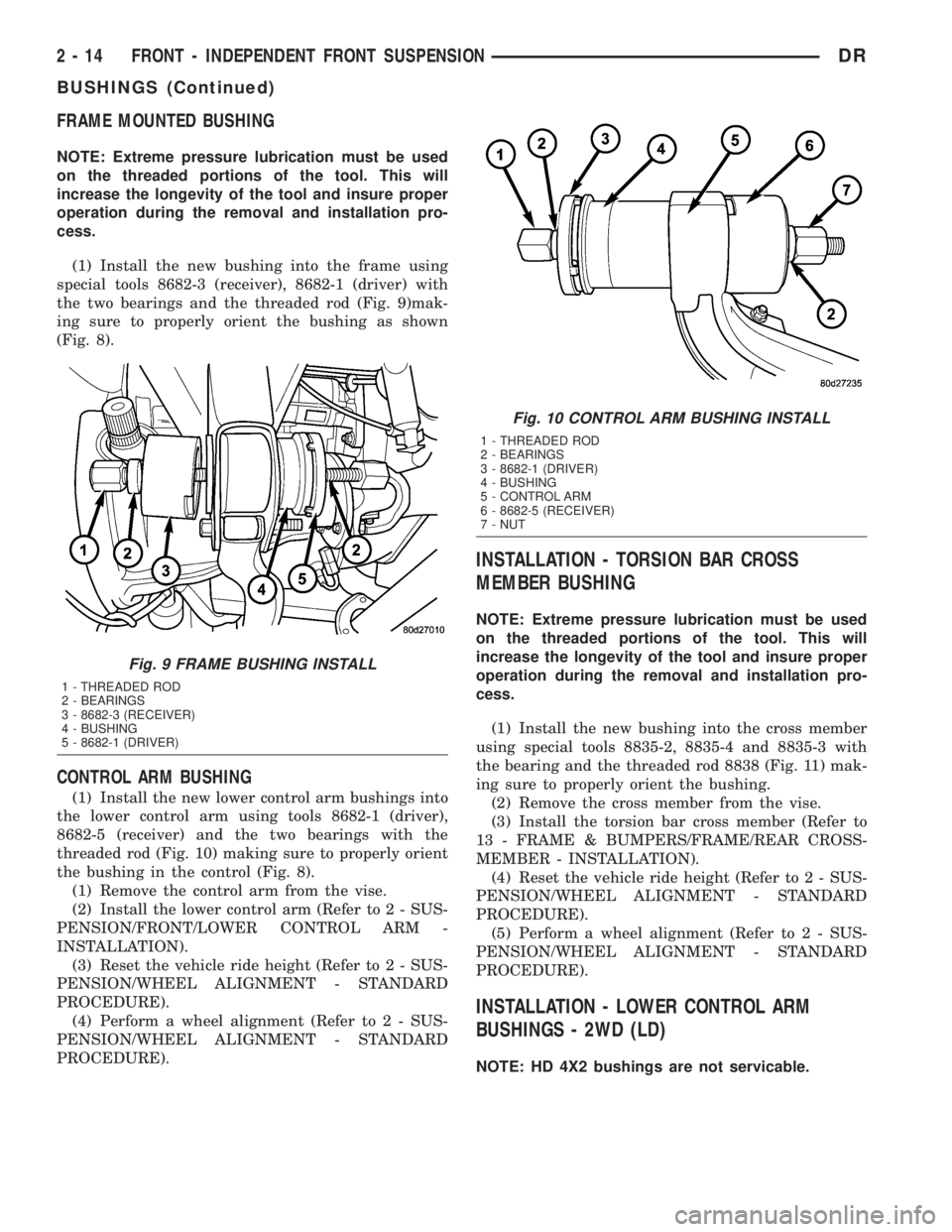

The front suspension is designed to allow each

wheel to adapt to different road surfaces indepen-

dently. The wheels are mounted to hub/bearings

units bolted to the steering knuckle. The double-row

hub bearings are sealed and lubricated for life. The

steering knuckles turn (pivot) on ball joints.

The front suspension is comprised of (Fig. 1) (Fig. 2):

²Shock absorbers

²Torsion bar - 4X4 (LD only)

²Coil Spring - 4X2

²Control arms

²Steering knuckles

²Stabilizer bar

²Stabilizer link

²Tie Rod Ends

²Hub/Bearing

²Rack & Pinion

²Ball Joints

NOTE: Components attached with a nut must be

torqued to specification.

NOTE: Suspension components with rubber/ure-

thane bushings should be tightened with the vehi-

cle at normal ride height. It is important to have the

springs supporting the weight of the vehicle when

the fasteners are torqued. If springs are not at their

normal ride position, vehicle ride comfort could be

affected and premature bushing wear may occur.

DESCRIPTION

The upper control arm bolts on frame brackets.

The frame brackets have slotted holes which allow

the arms to be adjusted for caster and camber.

The lower control arms bolt to the lower frame

brackets and pivots through bushings.

The control arms have lube for life ball studs. The

control arm travel (jounce) is limited through the use

of rubber/urethane bumpers. Rebound travel is lim-

ited by the shock absorber.

Fig. 1 FRONT SUSPENSION - 4X2

1 - STABILIZER BAR

2 - UPPER CONTROL ARM

3 - STEERING KNUCKLE

4 - ROTOR

5 - CALIPER ADAPTER

6 - OUTER TIE ROD END

7 - STABILIZER LINK

8 - LOWER CONTROL ARM

9 - RACK & PINION

10 - COIL SPRING

11 - SHOCK ABSORBER

Fig. 2 FRONT SUSPENSION - 4X4 (LD ONLY)

1 - STABILIZER BAR

2 - UPPER CONTROL ARM

3 - STEERING KNUCKLE

4 - ROTOR

5 - OUTER TIE ROD END

6 - SHOCK ABSORBER

7 - STABILIZER LINK

8 - LOWER CONTROL ARM

9 - INNER TIE ROD

10 - RACK & PINION

DRFRONT - INDEPENDENT FRONT SUSPENSION 2 - 9

Page 43 of 2895

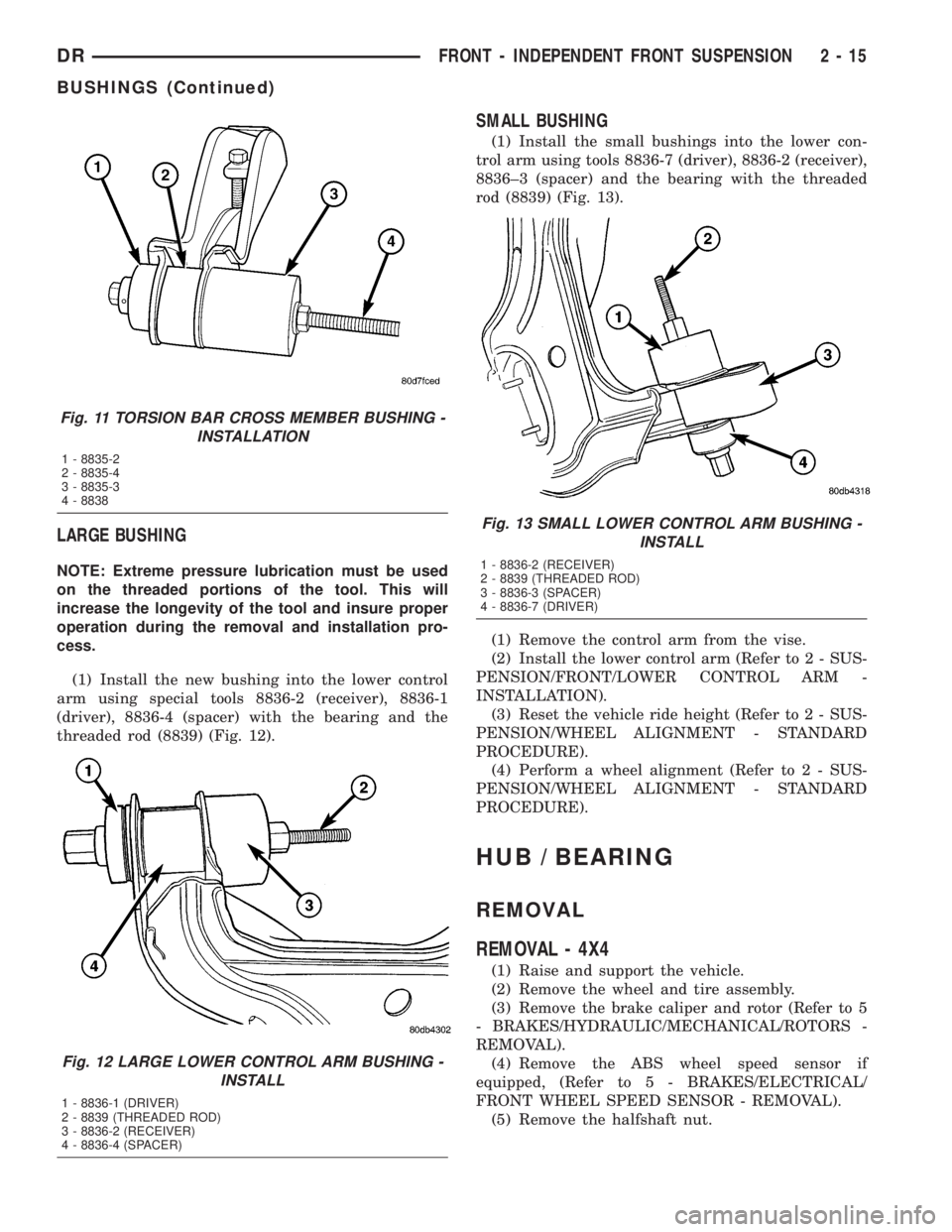

FRAME MOUNTED BUSHING

NOTE: Extreme pressure lubrication must be used

on the threaded portions of the tool. This will

increase the longevity of the tool and insure proper

operation during the removal and installation pro-

cess.

(1) Install the new bushing into the frame using

special tools 8682-3 (receiver), 8682-1 (driver) with

the two bearings and the threaded rod (Fig. 9)mak-

ing sure to properly orient the bushing as shown

(Fig. 8).

CONTROL ARM BUSHING

(1) Install the new lower control arm bushings into

the lower control arm using tools 8682-1 (driver),

8682-5 (receiver) and the two bearings with the

threaded rod (Fig. 10) making sure to properly orient

the bushing in the control (Fig. 8).

(1) Remove the control arm from the vise.

(2) Install the lower control arm (Refer to 2 - SUS-

PENSION/FRONT/LOWER CONTROL ARM -

INSTALLATION).

(3) Reset the vehicle ride height (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

(4) Perform a wheel alignment (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

INSTALLATION - TORSION BAR CROSS

MEMBER BUSHING

NOTE: Extreme pressure lubrication must be used

on the threaded portions of the tool. This will

increase the longevity of the tool and insure proper

operation during the removal and installation pro-

cess.

(1) Install the new bushing into the cross member

using special tools 8835-2, 8835-4 and 8835-3 with

the bearing and the threaded rod 8838 (Fig. 11) mak-

ing sure to properly orient the bushing.

(2) Remove the cross member from the vise.

(3) Install the torsion bar cross member (Refer to

13 - FRAME & BUMPERS/FRAME/REAR CROSS-

MEMBER - INSTALLATION).

(4) Reset the vehicle ride height (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

(5) Perform a wheel alignment (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

INSTALLATION - LOWER CONTROL ARM

BUSHINGS - 2WD (LD)

NOTE: HD 4X2 bushings are not servicable.

Fig. 9 FRAME BUSHING INSTALL

1 - THREADED ROD

2 - BEARINGS

3 - 8682-3 (RECEIVER)

4 - BUSHING

5 - 8682-1 (DRIVER)

Fig. 10 CONTROL ARM BUSHING INSTALL

1 - THREADED ROD

2 - BEARINGS

3 - 8682-1 (DRIVER)

4 - BUSHING

5 - CONTROL ARM

6 - 8682-5 (RECEIVER)

7 - NUT

2 - 14 FRONT - INDEPENDENT FRONT SUSPENSIONDR

BUSHINGS (Continued)

Page 44 of 2895

LARGE BUSHING

NOTE: Extreme pressure lubrication must be used

on the threaded portions of the tool. This will

increase the longevity of the tool and insure proper

operation during the removal and installation pro-

cess.

(1) Install the new bushing into the lower control

arm using special tools 8836-2 (receiver), 8836-1

(driver), 8836-4 (spacer) with the bearing and the

threaded rod (8839) (Fig. 12).

SMALL BUSHING

(1) Install the small bushings into the lower con-

trol arm using tools 8836-7 (driver), 8836-2 (receiver),

8836±3 (spacer) and the bearing with the threaded

rod (8839) (Fig. 13).

(1) Remove the control arm from the vise.

(2) Install the lower control arm (Refer to 2 - SUS-

PENSION/FRONT/LOWER CONTROL ARM -

INSTALLATION).

(3) Reset the vehicle ride height (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

(4) Perform a wheel alignment (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

HUB / BEARING

REMOVAL

REMOVAL - 4X4

(1) Raise and support the vehicle.

(2) Remove the wheel and tire assembly.

(3) Remove the brake caliper and rotor (Refer to 5

- BRAKES/HYDRAULIC/MECHANICAL/ROTORS -

REMOVAL).

(4) Remove the ABS wheel speed sensor if

equipped, (Refer to 5 - BRAKES/ELECTRICAL/

FRONT WHEEL SPEED SENSOR - REMOVAL).

(5) Remove the halfshaft nut.

Fig. 11 TORSION BAR CROSS MEMBER BUSHING -

INSTALLATION

1 - 8835-2

2 - 8835-4

3 - 8835-3

4 - 8838

Fig. 12 LARGE LOWER CONTROL ARM BUSHING -

INSTALL

1 - 8836-1 (DRIVER)

2 - 8839 (THREADED ROD)

3 - 8836-2 (RECEIVER)

4 - 8836-4 (SPACER)

Fig. 13 SMALL LOWER CONTROL ARM BUSHING -

INSTALL

1 - 8836-2 (RECEIVER)

2 - 8839 (THREADED ROD)

3 - 8836-3 (SPACER)

4 - 8836-7 (DRIVER)

DRFRONT - INDEPENDENT FRONT SUSPENSION 2 - 15

BUSHINGS (Continued)

Page 48 of 2895

NOTE: Extreme pressure lubrication must be used

on the threaded portions of the tool. This will

increase the longevity of the tool and insure proper

operation during the removal and installation pro-

cess.

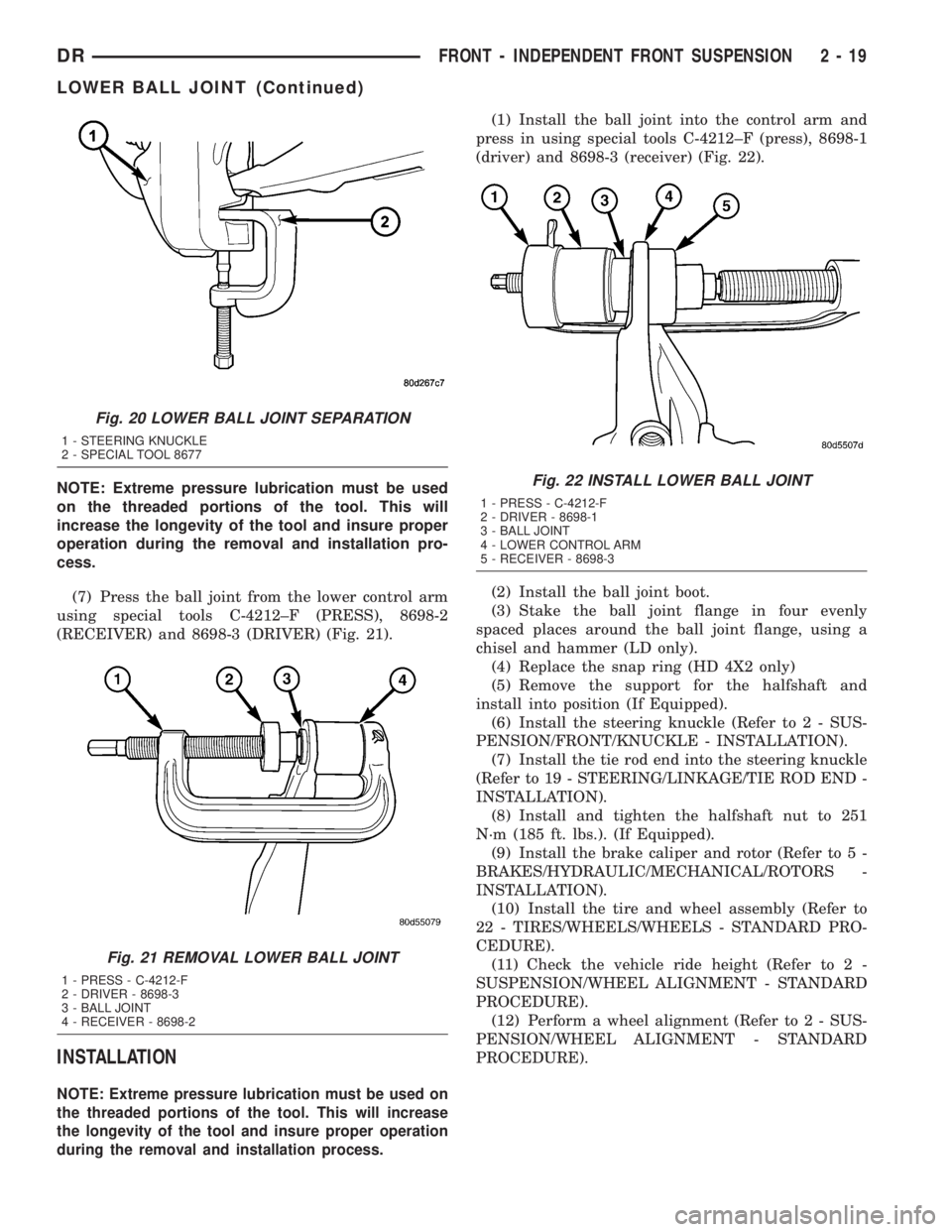

(7) Press the ball joint from the lower control arm

using special tools C-4212±F (PRESS), 8698-2

(RECEIVER) and 8698-3 (DRIVER) (Fig. 21).

INSTALLATION

NOTE: Extreme pressure lubrication must be used on

the threaded portions of the tool. This will increase

the longevity of the tool and insure proper operation

during the removal and installation process.

(1) Install the ball joint into the control arm and

press in using special tools C-4212±F (press), 8698-1

(driver) and 8698-3 (receiver) (Fig. 22).

(2) Install the ball joint boot.

(3) Stake the ball joint flange in four evenly

spaced places around the ball joint flange, using a

chisel and hammer (LD only).

(4) Replace the snap ring (HD 4X2 only)

(5) Remove the support for the halfshaft and

install into position (If Equipped).

(6) Install the steering knuckle (Refer to 2 - SUS-

PENSION/FRONT/KNUCKLE - INSTALLATION).

(7) Install the tie rod end into the steering knuckle

(Refer to 19 - STEERING/LINKAGE/TIE ROD END -

INSTALLATION).

(8) Install and tighten the halfshaft nut to 251

N´m (185 ft. lbs.). (If Equipped).

(9) Install the brake caliper and rotor (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/ROTORS -

INSTALLATION).

(10) Install the tire and wheel assembly (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE).

(11) Check the vehicle ride height (Refer to 2 -

SUSPENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

(12) Perform a wheel alignment (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

Fig. 20 LOWER BALL JOINT SEPARATION

1 - STEERING KNUCKLE

2 - SPECIAL TOOL 8677

Fig. 21 REMOVAL LOWER BALL JOINT

1 - PRESS - C-4212-F

2 - DRIVER - 8698-3

3 - BALL JOINT

4 - RECEIVER - 8698-2

Fig. 22 INSTALL LOWER BALL JOINT

1 - PRESS - C-4212-F

2 - DRIVER - 8698-1

3 - BALL JOINT

4 - LOWER CONTROL ARM

5 - RECEIVER - 8698-3

DRFRONT - INDEPENDENT FRONT SUSPENSION 2 - 19

LOWER BALL JOINT (Continued)

Page 50 of 2895

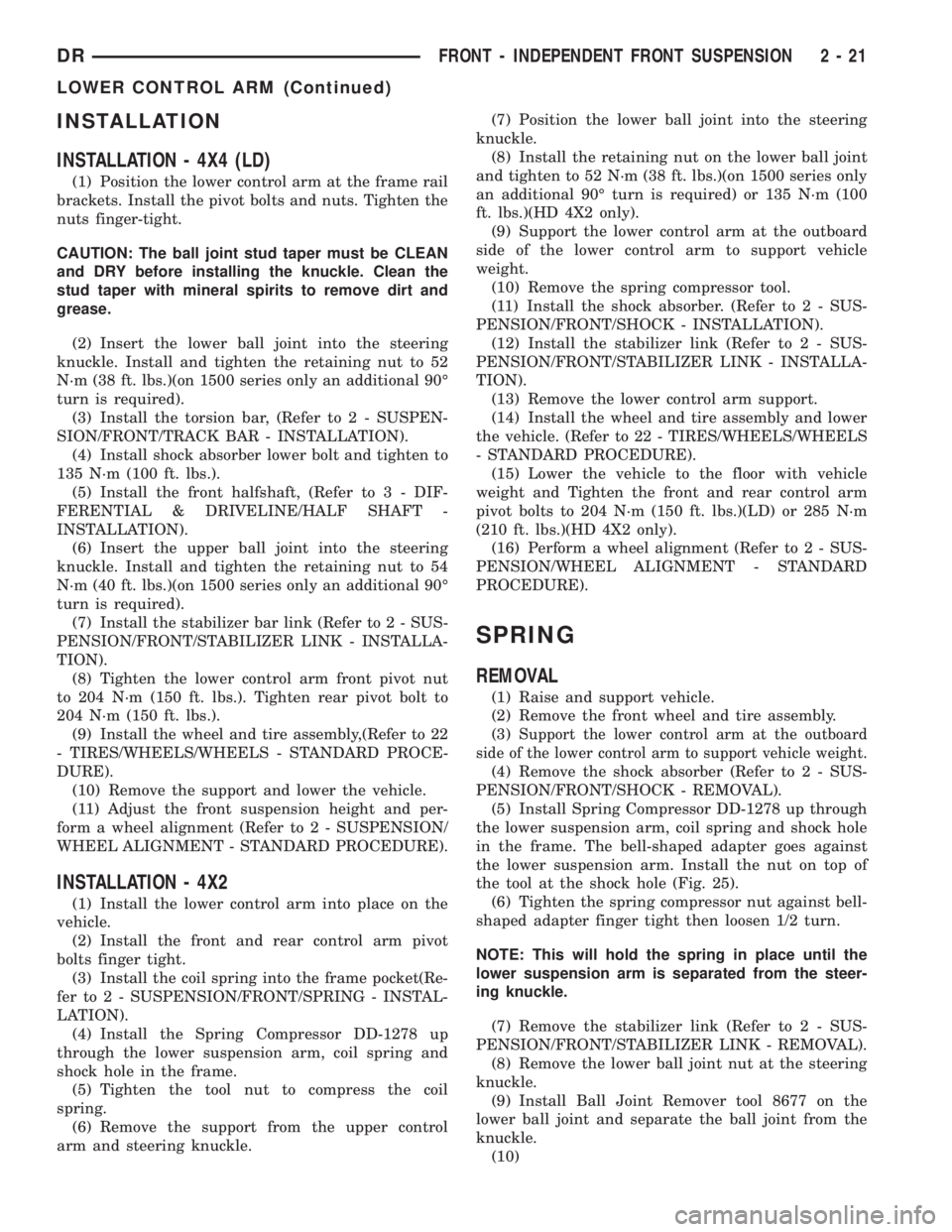

INSTALLATION

INSTALLATION - 4X4 (LD)

(1) Position the lower control arm at the frame rail

brackets. Install the pivot bolts and nuts. Tighten the

nuts finger-tight.

CAUTION: The ball joint stud taper must be CLEAN

and DRY before installing the knuckle. Clean the

stud taper with mineral spirits to remove dirt and

grease.

(2) Insert the lower ball joint into the steering

knuckle. Install and tighten the retaining nut to 52

N´m (38 ft. lbs.)(on 1500 series only an additional 90É

turn is required).

(3) Install the torsion bar, (Refer to 2 - SUSPEN-

SION/FRONT/TRACK BAR - INSTALLATION).

(4) Install shock absorber lower bolt and tighten to

135 N´m (100 ft. lbs.).

(5) Install the front halfshaft, (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/HALF SHAFT -

INSTALLATION).

(6) Insert the upper ball joint into the steering

knuckle. Install and tighten the retaining nut to 54

N´m (40 ft. lbs.)(on 1500 series only an additional 90É

turn is required).

(7) Install the stabilizer bar link (Refer to 2 - SUS-

PENSION/FRONT/STABILIZER LINK - INSTALLA-

TION).

(8) Tighten the lower control arm front pivot nut

to 204 N´m (150 ft. lbs.). Tighten rear pivot bolt to

204 N´m (150 ft. lbs.).

(9) Install the wheel and tire assembly,(Refer to 22

- TIRES/WHEELS/WHEELS - STANDARD PROCE-

DURE).

(10) Remove the support and lower the vehicle.

(11) Adjust the front suspension height and per-

form a wheel alignment (Refer to 2 - SUSPENSION/

WHEEL ALIGNMENT - STANDARD PROCEDURE).

INSTALLATION - 4X2

(1) Install the lower control arm into place on the

vehicle.

(2) Install the front and rear control arm pivot

bolts finger tight.

(3) Install the coil spring into the frame pocket(Re-

fer to 2 - SUSPENSION/FRONT/SPRING - INSTAL-

LATION).

(4) Install the Spring Compressor DD-1278 up

through the lower suspension arm, coil spring and

shock hole in the frame.

(5) Tighten the tool nut to compress the coil

spring.

(6) Remove the support from the upper control

arm and steering knuckle.(7) Position the lower ball joint into the steering

knuckle.

(8) Install the retaining nut on the lower ball joint

and tighten to 52 N´m (38 ft. lbs.)(on 1500 series only

an additional 90É turn is required) or 135 N´m (100

ft. lbs.)(HD 4X2 only).

(9) Support the lower control arm at the outboard

side of the lower control arm to support vehicle

weight.

(10) Remove the spring compressor tool.

(11) Install the shock absorber. (Refer to 2 - SUS-

PENSION/FRONT/SHOCK - INSTALLATION).

(12) Install the stabilizer link (Refer to 2 - SUS-

PENSION/FRONT/STABILIZER LINK - INSTALLA-

TION).

(13) Remove the lower control arm support.

(14) Install the wheel and tire assembly and lower

the vehicle. (Refer to 22 - TIRES/WHEELS/WHEELS

- STANDARD PROCEDURE).

(15) Lower the vehicle to the floor with vehicle

weight and Tighten the front and rear control arm

pivot bolts to 204 N´m (150 ft. lbs.)(LD) or 285 N´m

(210 ft. lbs.)(HD 4X2 only).

(16) Perform a wheel alignment (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

SPRING

REMOVAL

(1) Raise and support vehicle.

(2) Remove the front wheel and tire assembly.

(3)

Support the lower control arm at the outboard

side of the lower control arm to support vehicle weight.

(4) Remove the shock absorber (Refer to 2 - SUS-

PENSION/FRONT/SHOCK - REMOVAL).

(5) Install Spring Compressor DD-1278 up through

the lower suspension arm, coil spring and shock hole

in the frame. The bell-shaped adapter goes against

the lower suspension arm. Install the nut on top of

the tool at the shock hole (Fig. 25).

(6) Tighten the spring compressor nut against bell-

shaped adapter finger tight then loosen 1/2 turn.

NOTE: This will hold the spring in place until the

lower suspension arm is separated from the steer-

ing knuckle.

(7) Remove the stabilizer link (Refer to 2 - SUS-

PENSION/FRONT/STABILIZER LINK - REMOVAL).

(8) Remove the lower ball joint nut at the steering

knuckle.

(9) Install Ball Joint Remover tool 8677 on the

lower ball joint and separate the ball joint from the

knuckle.

(10)

DRFRONT - INDEPENDENT FRONT SUSPENSION 2 - 21

LOWER CONTROL ARM (Continued)