child restraint DODGE RAM 2003 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 642 of 2895

WARNING: DURING AND FOLLOWING ANY SEAT

BELT OR CHILD RESTRAINT ANCHOR SERVICE,

CAREFULLY INSPECT ALL SEAT BELTS, BUCKLES,

MOUNTING HARDWARE, RETRACTORS, TETHER

STRAPS, AND ANCHORS FOR PROPER INSTALLA-

TION, OPERATION, OR DAMAGE. REPLACE ANY

BELT THAT IS CUT, FRAYED, OR TORN.

STRAIGHTEN ANY BELT THAT IS TWISTED.

TIGHTEN ANY LOOSE FASTENERS. REPLACE ANY

BELT THAT HAS A DAMAGED OR INOPERATIVE

BUCKLE OR RETRACTOR. REPLACE ANY BELT

THAT HAS A BENT OR DAMAGED LATCH PLATE

OR ANCHOR PLATE. REPLACE ANY CHILD

RESTRAINT ANCHOR OR THE UNIT TO WHICH THE

ANCHOR IS INTEGRAL THAT HAS BEEN BENT OR

DAMAGED. NEVER ATTEMPT TO REPAIR A SEAT

BELT OR CHILD RESTRAINT COMPONENT.

ALWAYS REPLACE DAMAGED OR FAULTY SEAT

BELT AND CHILD RESTRAINT COMPONENTS WITH

THE CORRECT, NEW AND UNUSED REPLACEMENT

PARTS LISTED IN THE DAIMLERCHRYSLER MOPAR

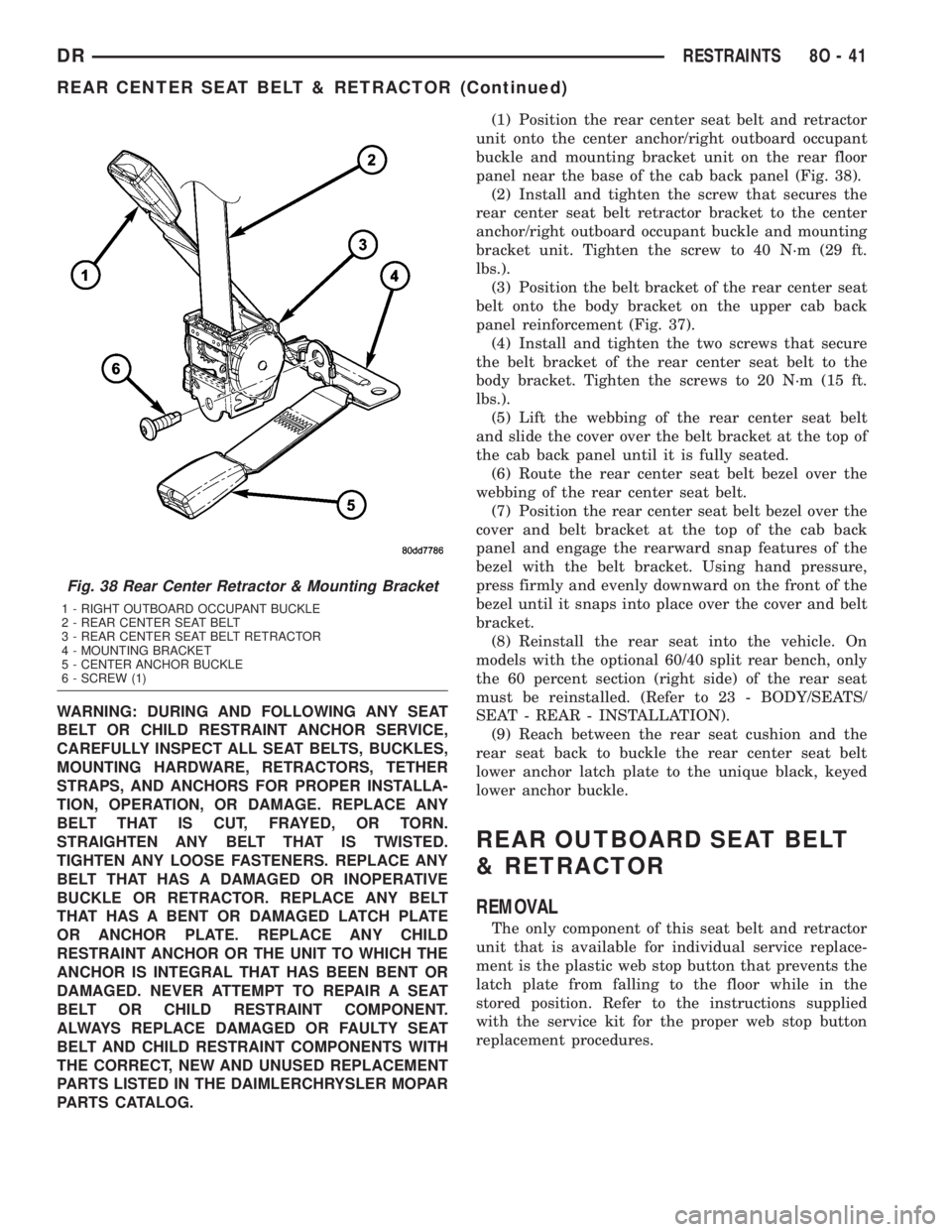

PARTS CATALOG.(1) Position the rear center seat belt and retractor

unit onto the center anchor/right outboard occupant

buckle and mounting bracket unit on the rear floor

panel near the base of the cab back panel (Fig. 38).

(2) Install and tighten the screw that secures the

rear center seat belt retractor bracket to the center

anchor/right outboard occupant buckle and mounting

bracket unit. Tighten the screw to 40 N´m (29 ft.

lbs.).

(3) Position the belt bracket of the rear center seat

belt onto the body bracket on the upper cab back

panel reinforcement (Fig. 37).

(4) Install and tighten the two screws that secure

the belt bracket of the rear center seat belt to the

body bracket. Tighten the screws to 20 N´m (15 ft.

lbs.).

(5) Lift the webbing of the rear center seat belt

and slide the cover over the belt bracket at the top of

the cab back panel until it is fully seated.

(6) Route the rear center seat belt bezel over the

webbing of the rear center seat belt.

(7) Position the rear center seat belt bezel over the

cover and belt bracket at the top of the cab back

panel and engage the rearward snap features of the

bezel with the belt bracket. Using hand pressure,

press firmly and evenly downward on the front of the

bezel until it snaps into place over the cover and belt

bracket.

(8) Reinstall the rear seat into the vehicle. On

models with the optional 60/40 split rear bench, only

the 60 percent section (right side) of the rear seat

must be reinstalled. (Refer to 23 - BODY/SEATS/

SEAT - REAR - INSTALLATION).

(9) Reach between the rear seat cushion and the

rear seat back to buckle the rear center seat belt

lower anchor latch plate to the unique black, keyed

lower anchor buckle.

REAR OUTBOARD SEAT BELT

& RETRACTOR

REMOVAL

The only component of this seat belt and retractor

unit that is available for individual service replace-

ment is the plastic web stop button that prevents the

latch plate from falling to the floor while in the

stored position. Refer to the instructions supplied

with the service kit for the proper web stop button

replacement procedures.

Fig. 38 Rear Center Retractor & Mounting Bracket

1 - RIGHT OUTBOARD OCCUPANT BUCKLE

2 - REAR CENTER SEAT BELT

3 - REAR CENTER SEAT BELT RETRACTOR

4 - MOUNTING BRACKET

5 - CENTER ANCHOR BUCKLE

6 - SCREW (1)

DRRESTRAINTS 8O - 41

REAR CENTER SEAT BELT & RETRACTOR (Continued)

Page 643 of 2895

WARNING: DURING AND FOLLOWING ANY SEAT

BELT OR CHILD RESTRAINT ANCHOR SERVICE,

CAREFULLY INSPECT ALL SEAT BELTS, BUCKLES,

MOUNTING HARDWARE, RETRACTORS, TETHER

STRAPS, AND ANCHORS FOR PROPER INSTALLA-

TION, OPERATION, OR DAMAGE. REPLACE ANY

BELT THAT IS CUT, FRAYED, OR TORN.

STRAIGHTEN ANY BELT THAT IS TWISTED.

TIGHTEN ANY LOOSE FASTENERS. REPLACE ANY

BELT THAT HAS A DAMAGED OR INOPERATIVE

BUCKLE OR RETRACTOR. REPLACE ANY BELT

THAT HAS A BENT OR DAMAGED LATCH PLATE

OR ANCHOR PLATE. REPLACE ANY CHILD

RESTRAINT ANCHOR OR THE UNIT TO WHICH THE

ANCHOR IS INTEGRAL THAT HAS BEEN BENT OR

DAMAGED. NEVER ATTEMPT TO REPAIR A SEAT

BELT OR CHILD RESTRAINT COMPONENT.

ALWAYS REPLACE DAMAGED OR FAULTY SEAT

BELT AND CHILD RESTRAINT COMPONENTS WITH

THE CORRECT, NEW AND UNUSED REPLACEMENT

PARTS LISTED IN THE DAIMLERCHRYSLER MOPAR

PARTS CATALOG.

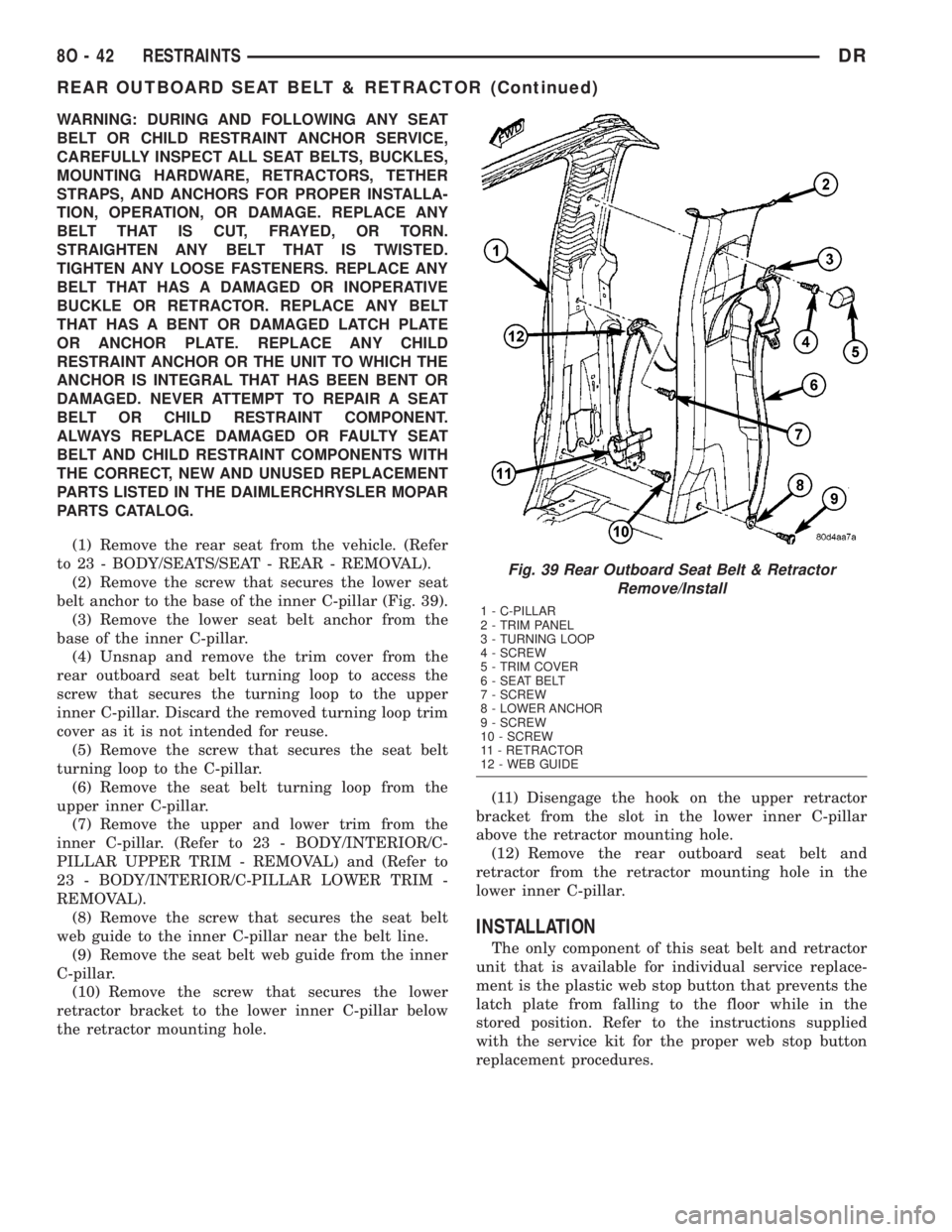

(1) Remove the rear seat from the vehicle. (Refer

to 23 - BODY/SEATS/SEAT - REAR - REMOVAL).

(2) Remove the screw that secures the lower seat

belt anchor to the base of the inner C-pillar (Fig. 39).

(3) Remove the lower seat belt anchor from the

base of the inner C-pillar.

(4) Unsnap and remove the trim cover from the

rear outboard seat belt turning loop to access the

screw that secures the turning loop to the upper

inner C-pillar. Discard the removed turning loop trim

cover as it is not intended for reuse.

(5) Remove the screw that secures the seat belt

turning loop to the C-pillar.

(6) Remove the seat belt turning loop from the

upper inner C-pillar.

(7) Remove the upper and lower trim from the

inner C-pillar. (Refer to 23 - BODY/INTERIOR/C-

PILLAR UPPER TRIM - REMOVAL) and (Refer to

23 - BODY/INTERIOR/C-PILLAR LOWER TRIM -

REMOVAL).

(8) Remove the screw that secures the seat belt

web guide to the inner C-pillar near the belt line.

(9) Remove the seat belt web guide from the inner

C-pillar.

(10) Remove the screw that secures the lower

retractor bracket to the lower inner C-pillar below

the retractor mounting hole.(11) Disengage the hook on the upper retractor

bracket from the slot in the lower inner C-pillar

above the retractor mounting hole.

(12) Remove the rear outboard seat belt and

retractor from the retractor mounting hole in the

lower inner C-pillar.

INSTALLATION

The only component of this seat belt and retractor

unit that is available for individual service replace-

ment is the plastic web stop button that prevents the

latch plate from falling to the floor while in the

stored position. Refer to the instructions supplied

with the service kit for the proper web stop button

replacement procedures.

Fig. 39 Rear Outboard Seat Belt & Retractor

Remove/Install

1 - C-PILLAR

2 - TRIM PANEL

3 - TURNING LOOP

4 - SCREW

5 - TRIM COVER

6 - SEAT BELT

7 - SCREW

8 - LOWER ANCHOR

9 - SCREW

10 - SCREW

11 - RETRACTOR

12 - WEB GUIDE

8O - 42 RESTRAINTSDR

REAR OUTBOARD SEAT BELT & RETRACTOR (Continued)

Page 644 of 2895

WARNING: DURING AND FOLLOWING ANY SEAT

BELT OR CHILD RESTRAINT ANCHOR SERVICE,

CAREFULLY INSPECT ALL SEAT BELTS, BUCKLES,

MOUNTING HARDWARE, RETRACTORS, TETHER

STRAPS, AND ANCHORS FOR PROPER INSTALLA-

TION, OPERATION, OR DAMAGE. REPLACE ANY

BELT THAT IS CUT, FRAYED, OR TORN.

STRAIGHTEN ANY BELT THAT IS TWISTED.

TIGHTEN ANY LOOSE FASTENERS. REPLACE ANY

BELT THAT HAS A DAMAGED OR INOPERATIVE

BUCKLE OR RETRACTOR. REPLACE ANY BELT

THAT HAS A BENT OR DAMAGED LATCH PLATE

OR ANCHOR PLATE. REPLACE ANY CHILD

RESTRAINT ANCHOR OR THE UNIT TO WHICH THE

ANCHOR IS INTEGRAL THAT HAS BEEN BENT OR

DAMAGED. NEVER ATTEMPT TO REPAIR A SEAT

BELT OR CHILD RESTRAINT COMPONENT.

ALWAYS REPLACE DAMAGED OR FAULTY SEAT

BELT AND CHILD RESTRAINT COMPONENTS WITH

THE CORRECT, NEW AND UNUSED REPLACEMENT

PARTS LISTED IN THE DAIMLERCHRYSLER MOPAR

PARTS CATALOG.

(1) Position the rear outboard seat belt and retrac-

tor to the retractor mounting hole in the lower inner

C-pillar (Fig. 39).

(2) Engage the hook on the upper retractor bracket

into the slot in the lower inner C-pillar above the

retractor mounting hole.

(3) Install and tighten the screw that secures the

lower retractor bracket to the lower inner C-pillar

below the retractor mounting hole. Tighten the screw

to 40 N´m (29 ft. lbs.).

(4) Position the seat belt web guide to the inner

C-pillar near the belt line.

(5) Install and tighten the screw that secures the

seat belt web guide to the inner C-pillar. Tighten the

screw to 2 N´m (20 in. lbs.).

(6) Reinstall the upper and lower trim onto the

inner C-pillar. (Refer to 23 - BODY/INTERIOR/C-

PILLAR UPPER TRIM - INSTALLATION) and

(Refer to 23 - BODY/INTERIOR/C-PILLAR LOWER

TRIM - INSTALLATION).

(7) Position the seat belt turning loop onto the

upper inner C-pillar.

(8) Install and tighten the screw that secures the

seat belt turning loop to the C-pillar. Tighten the

screw to 40 N´m (29 ft. lbs.).

(9) Engage the lower snap features of the new trim

cover over the rear outboard seat belt turning loop

and, using hand pressure, press firmly and evenly on

the top of the trim cover until it snaps into place.

(10) Position the lower seat belt anchor to the base

of the inner C-pillar.

(11) Install and tighten the screw that secures the

lower seat belt anchor to the base of the inner C-pil-

lar. Tighten the screw to 40 N´m (29 ft. lbs.).(12) Reinstall the rear seat into the vehicle. (Refer

to 23 - BODY/SEATS/SEAT - REAR - INSTALLA-

TION).

REAR SEAT BELT BUCKLE

REMOVAL

REMOVAL - CENTER & LEFT OUTBOARD

WARNING: DURING AND FOLLOWING ANY SEAT

BELT OR CHILD RESTRAINT ANCHOR SERVICE,

CAREFULLY INSPECT ALL SEAT BELTS, BUCKLES,

MOUNTING HARDWARE, RETRACTORS, TETHER

STRAPS, AND ANCHORS FOR PROPER INSTALLA-

TION, OPERATION, OR DAMAGE. REPLACE ANY

BELT THAT IS CUT, FRAYED, OR TORN.

STRAIGHTEN ANY BELT THAT IS TWISTED.

TIGHTEN ANY LOOSE FASTENERS. REPLACE ANY

BELT THAT HAS A DAMAGED OR INOPERATIVE

BUCKLE OR RETRACTOR. REPLACE ANY BELT

THAT HAS A BENT OR DAMAGED LATCH PLATE

OR ANCHOR PLATE. REPLACE ANY CHILD

RESTRAINT ANCHOR OR THE UNIT TO WHICH THE

ANCHOR IS INTEGRAL THAT HAS BEEN BENT OR

DAMAGED. NEVER ATTEMPT TO REPAIR A SEAT

BELT OR CHILD RESTRAINT COMPONENT.

ALWAYS REPLACE DAMAGED OR FAULTY SEAT

BELT AND CHILD RESTRAINT COMPONENTS WITH

THE CORRECT, NEW AND UNUSED REPLACEMENT

PARTS LISTED IN THE DAIMLERCHRYSLER MOPAR

PARTS CATALOG.

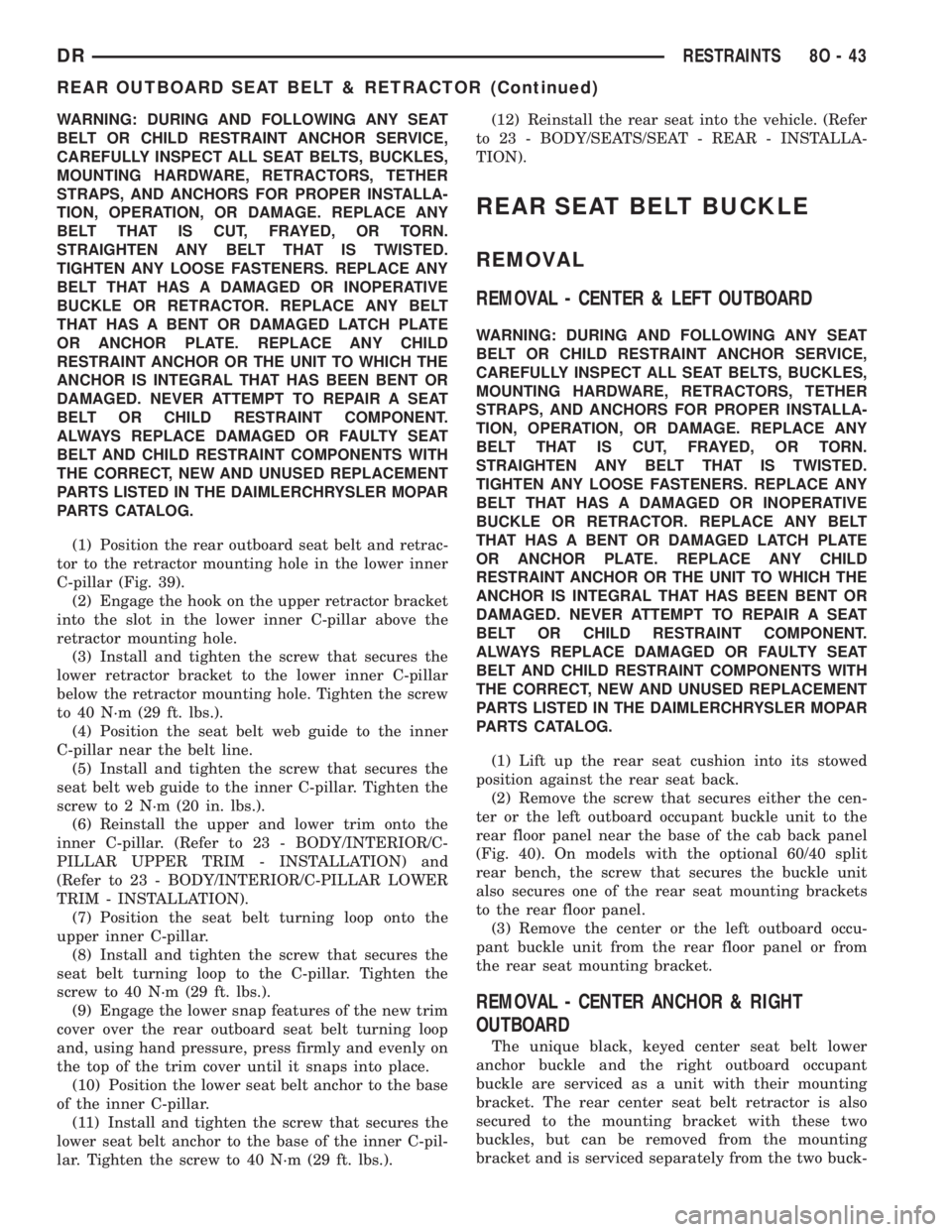

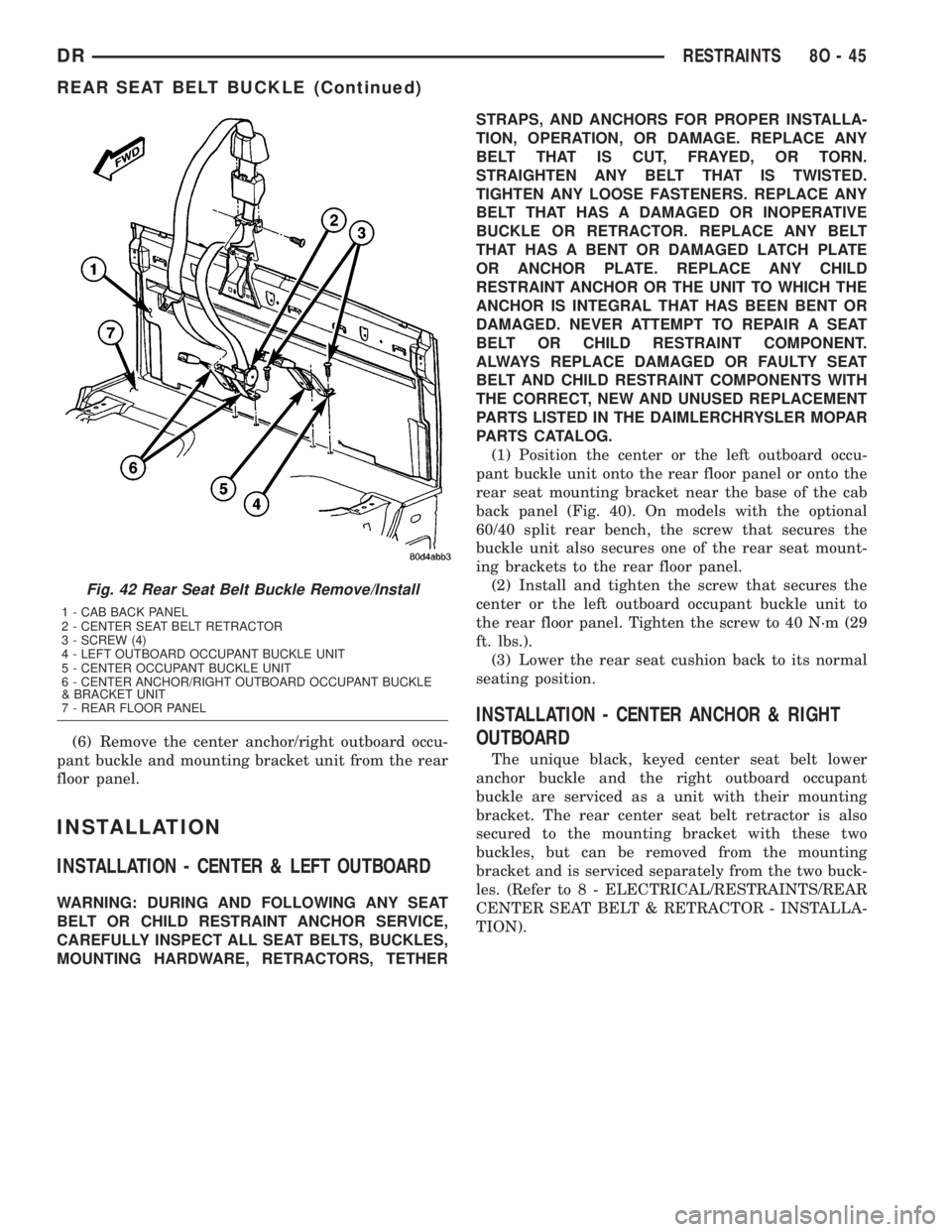

(1) Lift up the rear seat cushion into its stowed

position against the rear seat back.

(2) Remove the screw that secures either the cen-

ter or the left outboard occupant buckle unit to the

rear floor panel near the base of the cab back panel

(Fig. 40). On models with the optional 60/40 split

rear bench, the screw that secures the buckle unit

also secures one of the rear seat mounting brackets

to the rear floor panel.

(3) Remove the center or the left outboard occu-

pant buckle unit from the rear floor panel or from

the rear seat mounting bracket.

REMOVAL - CENTER ANCHOR & RIGHT

OUTBOARD

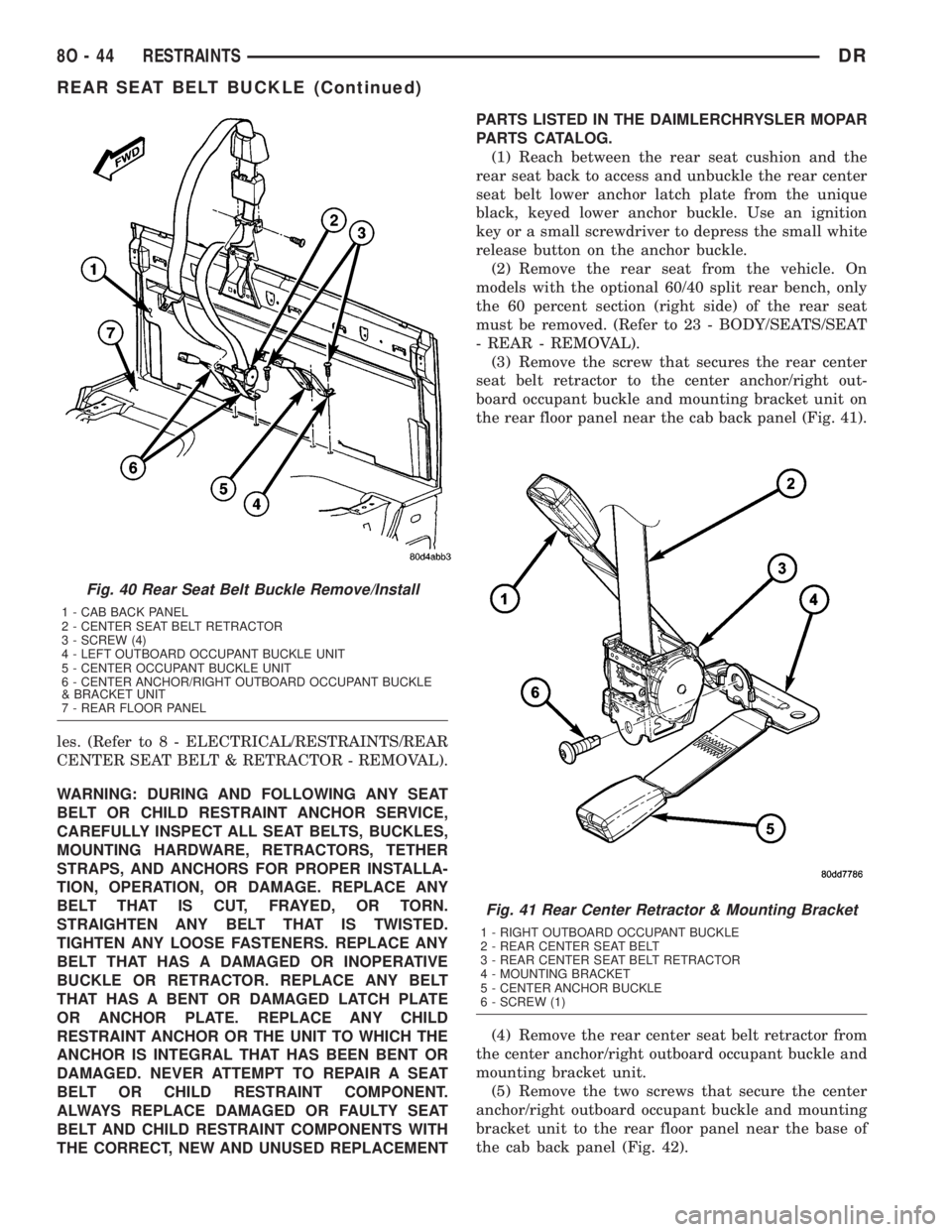

The unique black, keyed center seat belt lower

anchor buckle and the right outboard occupant

buckle are serviced as a unit with their mounting

bracket. The rear center seat belt retractor is also

secured to the mounting bracket with these two

buckles, but can be removed from the mounting

bracket and is serviced separately from the two buck-

DRRESTRAINTS 8O - 43

REAR OUTBOARD SEAT BELT & RETRACTOR (Continued)

Page 645 of 2895

les. (Refer to 8 - ELECTRICAL/RESTRAINTS/REAR

CENTER SEAT BELT & RETRACTOR - REMOVAL).

WARNING: DURING AND FOLLOWING ANY SEAT

BELT OR CHILD RESTRAINT ANCHOR SERVICE,

CAREFULLY INSPECT ALL SEAT BELTS, BUCKLES,

MOUNTING HARDWARE, RETRACTORS, TETHER

STRAPS, AND ANCHORS FOR PROPER INSTALLA-

TION, OPERATION, OR DAMAGE. REPLACE ANY

BELT THAT IS CUT, FRAYED, OR TORN.

STRAIGHTEN ANY BELT THAT IS TWISTED.

TIGHTEN ANY LOOSE FASTENERS. REPLACE ANY

BELT THAT HAS A DAMAGED OR INOPERATIVE

BUCKLE OR RETRACTOR. REPLACE ANY BELT

THAT HAS A BENT OR DAMAGED LATCH PLATE

OR ANCHOR PLATE. REPLACE ANY CHILD

RESTRAINT ANCHOR OR THE UNIT TO WHICH THE

ANCHOR IS INTEGRAL THAT HAS BEEN BENT OR

DAMAGED. NEVER ATTEMPT TO REPAIR A SEAT

BELT OR CHILD RESTRAINT COMPONENT.

ALWAYS REPLACE DAMAGED OR FAULTY SEAT

BELT AND CHILD RESTRAINT COMPONENTS WITH

THE CORRECT, NEW AND UNUSED REPLACEMENTPARTS LISTED IN THE DAIMLERCHRYSLER MOPAR

PARTS CATALOG.

(1) Reach between the rear seat cushion and the

rear seat back to access and unbuckle the rear center

seat belt lower anchor latch plate from the unique

black, keyed lower anchor buckle. Use an ignition

key or a small screwdriver to depress the small white

release button on the anchor buckle.

(2) Remove the rear seat from the vehicle. On

models with the optional 60/40 split rear bench, only

the 60 percent section (right side) of the rear seat

must be removed. (Refer to 23 - BODY/SEATS/SEAT

- REAR - REMOVAL).

(3) Remove the screw that secures the rear center

seat belt retractor to the center anchor/right out-

board occupant buckle and mounting bracket unit on

the rear floor panel near the cab back panel (Fig. 41).

(4) Remove the rear center seat belt retractor from

the center anchor/right outboard occupant buckle and

mounting bracket unit.

(5) Remove the two screws that secure the center

anchor/right outboard occupant buckle and mounting

bracket unit to the rear floor panel near the base of

the cab back panel (Fig. 42).

Fig. 40 Rear Seat Belt Buckle Remove/Install

1 - CAB BACK PANEL

2 - CENTER SEAT BELT RETRACTOR

3 - SCREW (4)

4 - LEFT OUTBOARD OCCUPANT BUCKLE UNIT

5 - CENTER OCCUPANT BUCKLE UNIT

6 - CENTER ANCHOR/RIGHT OUTBOARD OCCUPANT BUCKLE

& BRACKET UNIT

7 - REAR FLOOR PANEL

Fig. 41 Rear Center Retractor & Mounting Bracket

1 - RIGHT OUTBOARD OCCUPANT BUCKLE

2 - REAR CENTER SEAT BELT

3 - REAR CENTER SEAT BELT RETRACTOR

4 - MOUNTING BRACKET

5 - CENTER ANCHOR BUCKLE

6 - SCREW (1)

8O - 44 RESTRAINTSDR

REAR SEAT BELT BUCKLE (Continued)

Page 646 of 2895

(6) Remove the center anchor/right outboard occu-

pant buckle and mounting bracket unit from the rear

floor panel.

INSTALLATION

INSTALLATION - CENTER & LEFT OUTBOARD

WARNING: DURING AND FOLLOWING ANY SEAT

BELT OR CHILD RESTRAINT ANCHOR SERVICE,

CAREFULLY INSPECT ALL SEAT BELTS, BUCKLES,

MOUNTING HARDWARE, RETRACTORS, TETHERSTRAPS, AND ANCHORS FOR PROPER INSTALLA-

TION, OPERATION, OR DAMAGE. REPLACE ANY

BELT THAT IS CUT, FRAYED, OR TORN.

STRAIGHTEN ANY BELT THAT IS TWISTED.

TIGHTEN ANY LOOSE FASTENERS. REPLACE ANY

BELT THAT HAS A DAMAGED OR INOPERATIVE

BUCKLE OR RETRACTOR. REPLACE ANY BELT

THAT HAS A BENT OR DAMAGED LATCH PLATE

OR ANCHOR PLATE. REPLACE ANY CHILD

RESTRAINT ANCHOR OR THE UNIT TO WHICH THE

ANCHOR IS INTEGRAL THAT HAS BEEN BENT OR

DAMAGED. NEVER ATTEMPT TO REPAIR A SEAT

BELT OR CHILD RESTRAINT COMPONENT.

ALWAYS REPLACE DAMAGED OR FAULTY SEAT

BELT AND CHILD RESTRAINT COMPONENTS WITH

THE CORRECT, NEW AND UNUSED REPLACEMENT

PARTS LISTED IN THE DAIMLERCHRYSLER MOPAR

PARTS CATALOG.

(1) Position the center or the left outboard occu-

pant buckle unit onto the rear floor panel or onto the

rear seat mounting bracket near the base of the cab

back panel (Fig. 40). On models with the optional

60/40 split rear bench, the screw that secures the

buckle unit also secures one of the rear seat mount-

ing brackets to the rear floor panel.

(2) Install and tighten the screw that secures the

center or the left outboard occupant buckle unit to

the rear floor panel. Tighten the screw to 40 N´m (29

ft. lbs.).

(3) Lower the rear seat cushion back to its normal

seating position.

INSTALLATION - CENTER ANCHOR & RIGHT

OUTBOARD

The unique black, keyed center seat belt lower

anchor buckle and the right outboard occupant

buckle are serviced as a unit with their mounting

bracket. The rear center seat belt retractor is also

secured to the mounting bracket with these two

buckles, but can be removed from the mounting

bracket and is serviced separately from the two buck-

les. (Refer to 8 - ELECTRICAL/RESTRAINTS/REAR

CENTER SEAT BELT & RETRACTOR - INSTALLA-

TION).

Fig. 42 Rear Seat Belt Buckle Remove/Install

1 - CAB BACK PANEL

2 - CENTER SEAT BELT RETRACTOR

3 - SCREW (4)

4 - LEFT OUTBOARD OCCUPANT BUCKLE UNIT

5 - CENTER OCCUPANT BUCKLE UNIT

6 - CENTER ANCHOR/RIGHT OUTBOARD OCCUPANT BUCKLE

& BRACKET UNIT

7 - REAR FLOOR PANEL

DRRESTRAINTS 8O - 45

REAR SEAT BELT BUCKLE (Continued)

Page 647 of 2895

WARNING: DURING AND FOLLOWING ANY SEAT

BELT OR CHILD RESTRAINT ANCHOR SERVICE,

CAREFULLY INSPECT ALL SEAT BELTS, BUCKLES,

MOUNTING HARDWARE, RETRACTORS, TETHER

STRAPS, AND ANCHORS FOR PROPER INSTALLA-

TION, OPERATION, OR DAMAGE. REPLACE ANY

BELT THAT IS CUT, FRAYED, OR TORN.

STRAIGHTEN ANY BELT THAT IS TWISTED.

TIGHTEN ANY LOOSE FASTENERS. REPLACE ANY

BELT THAT HAS A DAMAGED OR INOPERATIVE

BUCKLE OR RETRACTOR. REPLACE ANY BELT

THAT HAS A BENT OR DAMAGED LATCH PLATE

OR ANCHOR PLATE. REPLACE ANY CHILD

RESTRAINT ANCHOR OR THE UNIT TO WHICH THE

ANCHOR IS INTEGRAL THAT HAS BEEN BENT OR

DAMAGED. NEVER ATTEMPT TO REPAIR A SEAT

BELT OR CHILD RESTRAINT COMPONENT.

ALWAYS REPLACE DAMAGED OR FAULTY SEAT

BELT AND CHILD RESTRAINT COMPONENTS WITH

THE CORRECT, NEW AND UNUSED REPLACEMENT

PARTS LISTED IN THE DAIMLERCHRYSLER MOPAR

PARTS CATALOG.

(1) Position the center anchor/right outboard occu-

pant buckle and mounting bracket unit onto the rear

floor panel near the base of the cab back panel (Fig.

42).

(2) Install and tighten the two screws that secure

the center anchor/right outboard occupant buckle and

mounting bracket unit to the rear floor panel.

Tighten the screws to 40 N´m (29 ft. lbs.).

(3) Position the rear center seat belt retractor onto

the center anchor/right outboard occupant buckle and

mounting bracket unit (Fig. 41).

(4)

Install and tighten the screw that secures the

rear center seat belt retractor to the center anchor/

right outboard occupant buckle and mounting bracket

unit. Tighten the screw to 40 N´m (29 ft. lbs.).

(5) Reinstall the rear seat into the vehicle. On

models with the optional 60/40 split rear bench, only

the 60 percent section (right side) of the rear seat

must be reinstalled. (Refer to 23 - BODY/SEATS/

SEAT - REAR - INSTALLATION).

(6) Reach between the rear seat cushion and the

rear seat back to access and buckle the rear center

seat belt lower anchor latch plate to the unique

black, keyed lower anchor buckle.

SEAT BELT SWITCH

DESCRIPTION

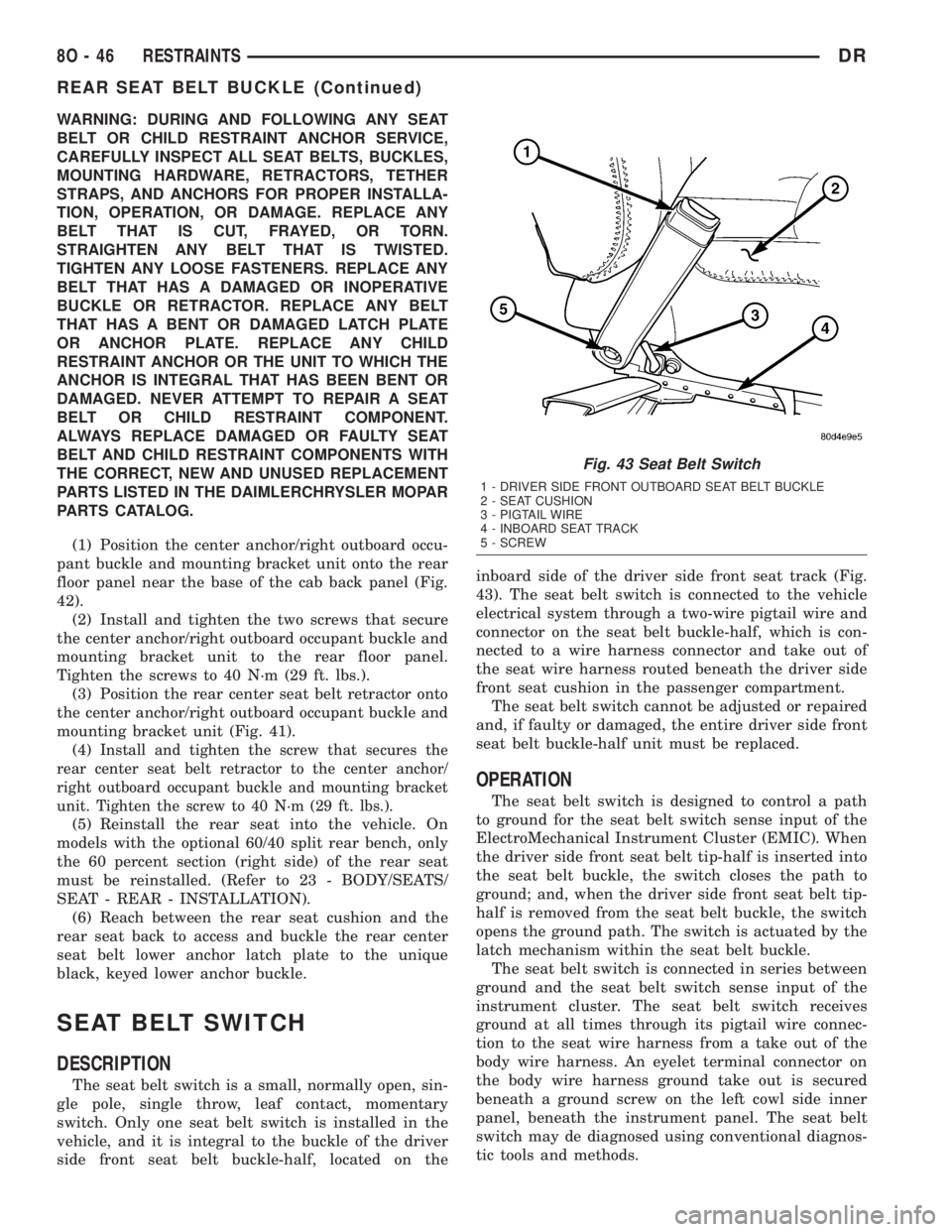

The seat belt switch is a small, normally open, sin-

gle pole, single throw, leaf contact, momentary

switch. Only one seat belt switch is installed in the

vehicle, and it is integral to the buckle of the driver

side front seat belt buckle-half, located on theinboard side of the driver side front seat track (Fig.

43). The seat belt switch is connected to the vehicle

electrical system through a two-wire pigtail wire and

connector on the seat belt buckle-half, which is con-

nected to a wire harness connector and take out of

the seat wire harness routed beneath the driver side

front seat cushion in the passenger compartment.

The seat belt switch cannot be adjusted or repaired

and, if faulty or damaged, the entire driver side front

seat belt buckle-half unit must be replaced.

OPERATION

The seat belt switch is designed to control a path

to ground for the seat belt switch sense input of the

ElectroMechanical Instrument Cluster (EMIC). When

the driver side front seat belt tip-half is inserted into

the seat belt buckle, the switch closes the path to

ground; and, when the driver side front seat belt tip-

half is removed from the seat belt buckle, the switch

opens the ground path. The switch is actuated by the

latch mechanism within the seat belt buckle.

The seat belt switch is connected in series between

ground and the seat belt switch sense input of the

instrument cluster. The seat belt switch receives

ground at all times through its pigtail wire connec-

tion to the seat wire harness from a take out of the

body wire harness. An eyelet terminal connector on

the body wire harness ground take out is secured

beneath a ground screw on the left cowl side inner

panel, beneath the instrument panel. The seat belt

switch may de diagnosed using conventional diagnos-

tic tools and methods.

Fig. 43 Seat Belt Switch

1 - DRIVER SIDE FRONT OUTBOARD SEAT BELT BUCKLE

2 - SEAT CUSHION

3 - PIGTAIL WIRE

4 - INBOARD SEAT TRACK

5 - SCREW

8O - 46 RESTRAINTSDR

REAR SEAT BELT BUCKLE (Continued)

Page 651 of 2895

SEAT BELT TURNING LOOP

ADJUSTER

REMOVAL

WARNING: DURING AND FOLLOWING ANY SEAT

BELT OR CHILD RESTRAINT ANCHOR SERVICE,

CAREFULLY INSPECT ALL SEAT BELTS, BUCKLES,

MOUNTING HARDWARE, RETRACTORS, TETHER

STRAPS, AND ANCHORS FOR PROPER INSTALLA-

TION, OPERATION, OR DAMAGE. REPLACE ANY

BELT THAT IS CUT, FRAYED, OR TORN.

STRAIGHTEN ANY BELT THAT IS TWISTED.

TIGHTEN ANY LOOSE FASTENERS. REPLACE ANY

BELT THAT HAS A DAMAGED OR INOPERATIVE

BUCKLE OR RETRACTOR. REPLACE ANY BELT

THAT HAS A BENT OR DAMAGED LATCH PLATE

OR ANCHOR PLATE. REPLACE ANY CHILD

RESTRAINT ANCHOR OR THE UNIT TO WHICH THE

ANCHOR IS INTEGRAL THAT HAS BEEN BENT OR

DAMAGED. NEVER ATTEMPT TO REPAIR A SEAT

BELT OR CHILD RESTRAINT COMPONENT.

ALWAYS REPLACE DAMAGED OR FAULTY SEAT

BELT AND CHILD RESTRAINT COMPONENTS WITH

THE CORRECT, NEW AND UNUSED REPLACEMENT

PARTS LISTED IN THE DAIMLERCHRYSLER MOPAR

PARTS CATALOG.

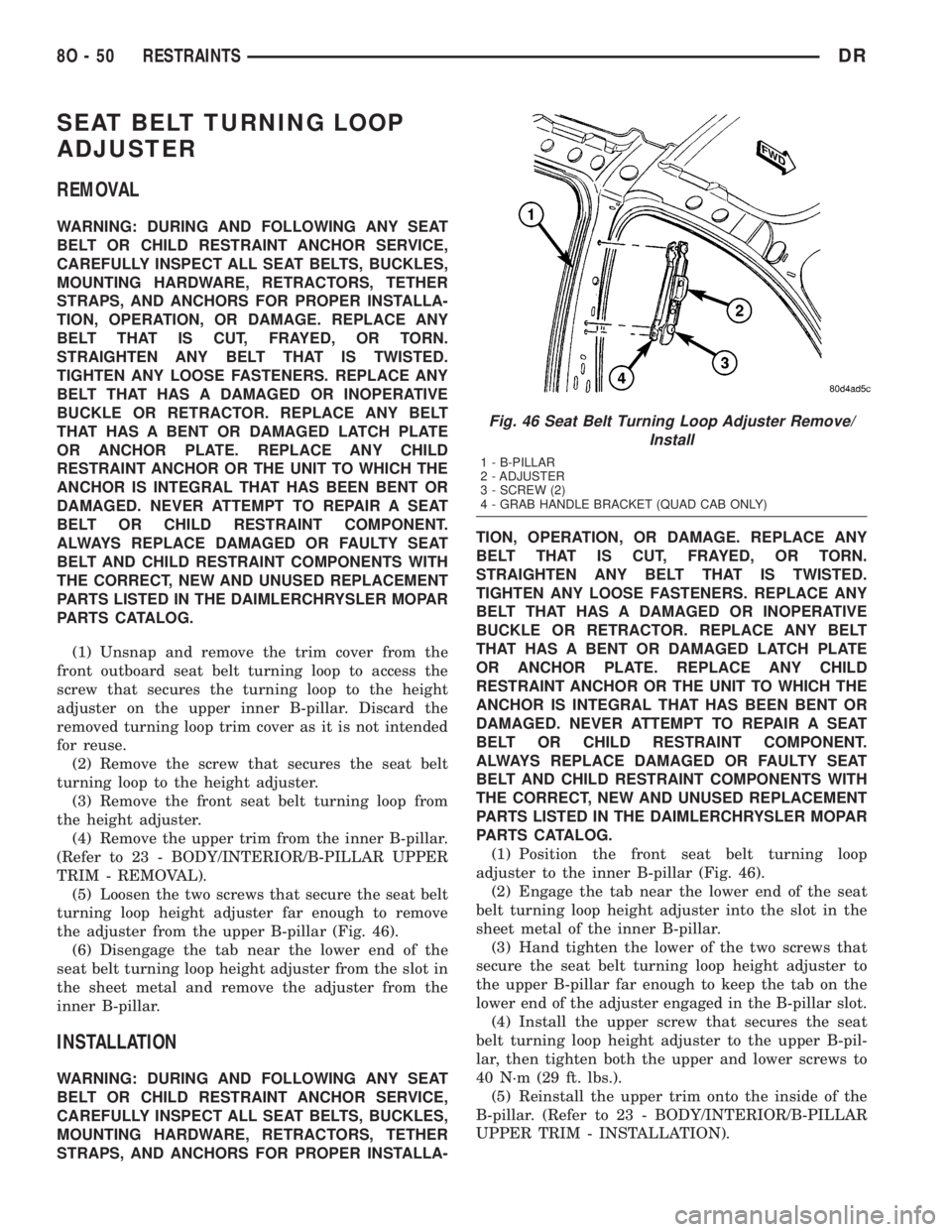

(1) Unsnap and remove the trim cover from the

front outboard seat belt turning loop to access the

screw that secures the turning loop to the height

adjuster on the upper inner B-pillar. Discard the

removed turning loop trim cover as it is not intended

for reuse.

(2) Remove the screw that secures the seat belt

turning loop to the height adjuster.

(3) Remove the front seat belt turning loop from

the height adjuster.

(4) Remove the upper trim from the inner B-pillar.

(Refer to 23 - BODY/INTERIOR/B-PILLAR UPPER

TRIM - REMOVAL).

(5) Loosen the two screws that secure the seat belt

turning loop height adjuster far enough to remove

the adjuster from the upper B-pillar (Fig. 46).

(6) Disengage the tab near the lower end of the

seat belt turning loop height adjuster from the slot in

the sheet metal and remove the adjuster from the

inner B-pillar.

INSTALLATION

WARNING: DURING AND FOLLOWING ANY SEAT

BELT OR CHILD RESTRAINT ANCHOR SERVICE,

CAREFULLY INSPECT ALL SEAT BELTS, BUCKLES,

MOUNTING HARDWARE, RETRACTORS, TETHER

STRAPS, AND ANCHORS FOR PROPER INSTALLA-TION, OPERATION, OR DAMAGE. REPLACE ANY

BELT THAT IS CUT, FRAYED, OR TORN.

STRAIGHTEN ANY BELT THAT IS TWISTED.

TIGHTEN ANY LOOSE FASTENERS. REPLACE ANY

BELT THAT HAS A DAMAGED OR INOPERATIVE

BUCKLE OR RETRACTOR. REPLACE ANY BELT

THAT HAS A BENT OR DAMAGED LATCH PLATE

OR ANCHOR PLATE. REPLACE ANY CHILD

RESTRAINT ANCHOR OR THE UNIT TO WHICH THE

ANCHOR IS INTEGRAL THAT HAS BEEN BENT OR

DAMAGED. NEVER ATTEMPT TO REPAIR A SEAT

BELT OR CHILD RESTRAINT COMPONENT.

ALWAYS REPLACE DAMAGED OR FAULTY SEAT

BELT AND CHILD RESTRAINT COMPONENTS WITH

THE CORRECT, NEW AND UNUSED REPLACEMENT

PARTS LISTED IN THE DAIMLERCHRYSLER MOPAR

PARTS CATALOG.

(1) Position the front seat belt turning loop

adjuster to the inner B-pillar (Fig. 46).

(2) Engage the tab near the lower end of the seat

belt turning loop height adjuster into the slot in the

sheet metal of the inner B-pillar.

(3) Hand tighten the lower of the two screws that

secure the seat belt turning loop height adjuster to

the upper B-pillar far enough to keep the tab on the

lower end of the adjuster engaged in the B-pillar slot.

(4) Install the upper screw that secures the seat

belt turning loop height adjuster to the upper B-pil-

lar, then tighten both the upper and lower screws to

40 N´m (29 ft. lbs.).

(5) Reinstall the upper trim onto the inside of the

B-pillar. (Refer to 23 - BODY/INTERIOR/B-PILLAR

UPPER TRIM - INSTALLATION).

Fig. 46 Seat Belt Turning Loop Adjuster Remove/

Install

1 - B-PILLAR

2 - ADJUSTER

3 - SCREW (2)

4 - GRAB HANDLE BRACKET (QUAD CAB ONLY)

8O - 50 RESTRAINTSDR

Page 2645 of 2895

REAR CAB BACK PANEL TRIM

REMOVAL

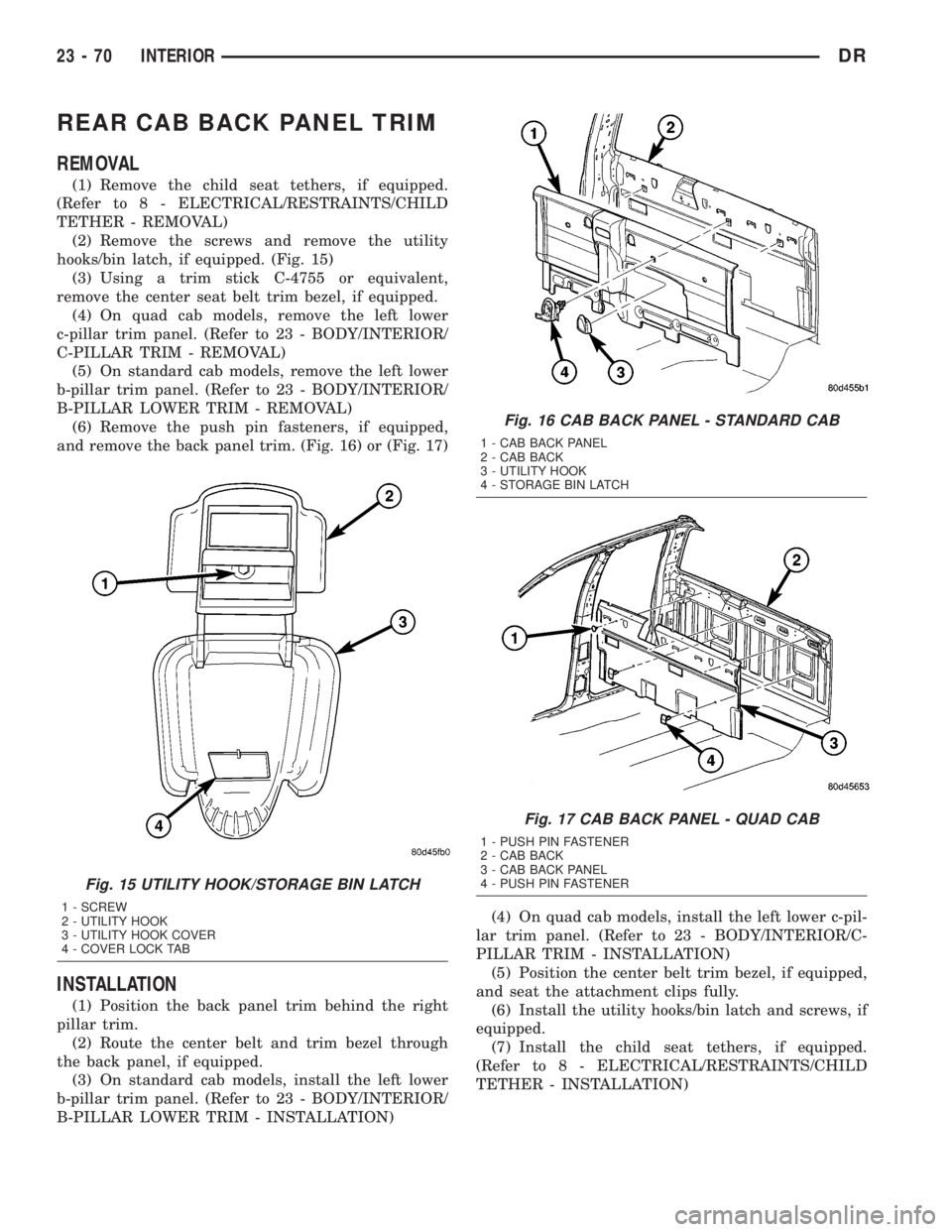

(1) Remove the child seat tethers, if equipped.

(Refer to 8 - ELECTRICAL/RESTRAINTS/CHILD

TETHER - REMOVAL)

(2) Remove the screws and remove the utility

hooks/bin latch, if equipped. (Fig. 15)

(3) Using a trim stick C-4755 or equivalent,

remove the center seat belt trim bezel, if equipped.

(4) On quad cab models, remove the left lower

c-pillar trim panel. (Refer to 23 - BODY/INTERIOR/

C-PILLAR TRIM - REMOVAL)

(5) On standard cab models, remove the left lower

b-pillar trim panel. (Refer to 23 - BODY/INTERIOR/

B-PILLAR LOWER TRIM - REMOVAL)

(6) Remove the push pin fasteners, if equipped,

and remove the back panel trim. (Fig. 16) or (Fig. 17)

INSTALLATION

(1) Position the back panel trim behind the right

pillar trim.

(2) Route the center belt and trim bezel through

the back panel, if equipped.

(3) On standard cab models, install the left lower

b-pillar trim panel. (Refer to 23 - BODY/INTERIOR/

B-PILLAR LOWER TRIM - INSTALLATION)(4) On quad cab models, install the left lower c-pil-

lar trim panel. (Refer to 23 - BODY/INTERIOR/C-

PILLAR TRIM - INSTALLATION)

(5) Position the center belt trim bezel, if equipped,

and seat the attachment clips fully.

(6) Install the utility hooks/bin latch and screws, if

equipped.

(7) Install the child seat tethers, if equipped.

(Refer to 8 - ELECTRICAL/RESTRAINTS/CHILD

TETHER - INSTALLATION)

Fig. 15 UTILITY HOOK/STORAGE BIN LATCH

1 - SCREW

2 - UTILITY HOOK

3 - UTILITY HOOK COVER

4 - COVER LOCK TAB

Fig. 16 CAB BACK PANEL - STANDARD CAB

1 - CAB BACK PANEL

2 - CAB BACK

3 - UTILITY HOOK

4 - STORAGE BIN LATCH

Fig. 17 CAB BACK PANEL - QUAD CAB

1 - PUSH PIN FASTENER

2 - CAB BACK

3 - CAB BACK PANEL

4 - PUSH PIN FASTENER

23 - 70 INTERIORDR

Page 2857 of 2895

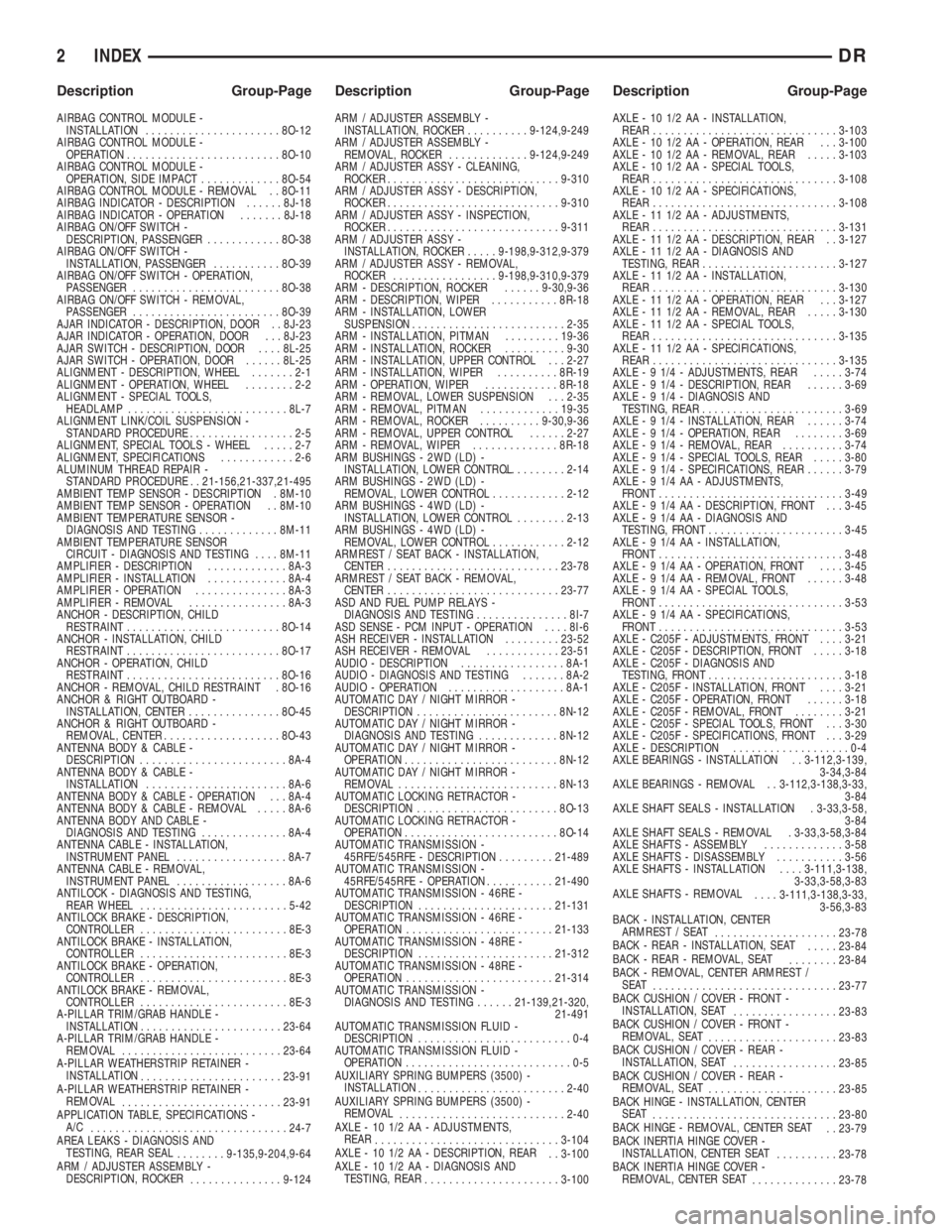

AIRBAG CONTROL MODULE -

INSTALLATION......................8O-12

AIRBAG CONTROL MODULE -

OPERATION.........................8O-10

AIRBAG CONTROL MODULE -

OPERATION, SIDE IMPACT.............8O-54

AIRBAG CONTROL MODULE - REMOVAL . . 8O-11

AIRBAG INDICATOR - DESCRIPTION......8J-18

AIRBAG INDICATOR - OPERATION.......8J-18

AIRBAG ON/OFF SWITCH -

DESCRIPTION, PASSENGER............8O-38

AIRBAG ON/OFF SWITCH -

INSTALLATION, PASSENGER...........8O-39

AIRBAG ON/OFF SWITCH - OPERATION,

PASSENGER........................8O-38

AIRBAG ON/OFF SWITCH - REMOVAL,

PASSENGER........................8O-39

AJAR INDICATOR - DESCRIPTION, DOOR . . 8J-23

AJAR INDICATOR - OPERATION, DOOR . . . 8J-23

AJAR SWITCH - DESCRIPTION, DOOR....8L-25

AJAR SWITCH - OPERATION, DOOR......8L-25

ALIGNMENT - DESCRIPTION, WHEEL.......2-1

ALIGNMENT - OPERATION, WHEEL........2-2

ALIGNMENT - SPECIAL TOOLS,

HEADLAMP..........................8L-7

ALIGNMENT LINK/COIL SUSPENSION -

STANDARD PROCEDURE.................2-5

ALIGNMENT, SPECIAL TOOLS - WHEEL.....2-7

ALIGNMENT, SPECIFICATIONS............2-6

ALUMINUM THREAD REPAIR -

STANDARD PROCEDURE . . 21-156,21-337,21-495

AMBIENT TEMP SENSOR - DESCRIPTION . 8M-10

AMBIENT TEMP SENSOR - OPERATION . . 8M-10

AMBIENT TEMPERATURE SENSOR -

DIAGNOSIS AND TESTING.............8M-11

AMBIENT TEMPERATURE SENSOR

CIRCUIT - DIAGNOSIS AND TESTING....8M-11

AMPLIFIER - DESCRIPTION.............8A-3

AMPLIFIER - INSTALLATION.............8A-4

AMPLIFIER - OPERATION...............8A-3

AMPLIFIER - REMOVAL................8A-3

ANCHOR - DESCRIPTION, CHILD

RESTRAINT.........................8O-14

ANCHOR - INSTALLATION, CHILD

RESTRAINT.........................8O-17

ANCHOR - OPERATION, CHILD

RESTRAINT.........................8O-16

ANCHOR - REMOVAL, CHILD RESTRAINT . 8O-16

ANCHOR & RIGHT OUTBOARD -

INSTALLATION, CENTER...............8O-45

ANCHOR & RIGHT OUTBOARD -

REMOVAL, CENTER...................8O-43

ANTENNA BODY & CABLE -

DESCRIPTION........................8A-4

ANTENNA BODY & CABLE -

INSTALLATION.......................8A-6

ANTENNA BODY & CABLE - OPERATION . . . 8A-4

ANTENNA BODY & CABLE - REMOVAL.....8A-6

ANTENNA BODY AND CABLE -

DIAGNOSIS AND TESTING..............8A-4

ANTENNA CABLE - INSTALLATION,

INSTRUMENT PANEL..................8A-7

ANTENNA CABLE - REMOVAL,

INSTRUMENT PANEL..................8A-6

ANTILOCK - DIAGNOSIS AND TESTING,

REAR WHEEL........................5-42

ANTILOCK BRAKE - DESCRIPTION,

CONTROLLER........................8E-3

ANTILOCK BRAKE - INSTALLATION,

CONTROLLER........................8E-3

ANTILOCK BRAKE - OPERATION,

CONTROLLER........................8E-3

ANTILOCK BRAKE - REMOVAL,

CONTROLLER........................8E-3

A-PILLAR TRIM/GRAB HANDLE -

INSTALLATION.......................23-64

A-PILLAR TRIM/GRAB HANDLE -

REMOVAL..........................23-64

A-PILLAR WEATHERSTRIP RETAINER -

INSTALLATION

.......................23-91

A-PILLAR WEATHERSTRIP RETAINER -

REMOVAL

..........................23-91

APPLICATION TABLE, SPECIFICATIONS -

A/C

................................24-7

AREA LEAKS - DIAGNOSIS AND

TESTING, REAR SEAL

........9-135,9-204,9-64

ARM / ADJUSTER ASSEMBLY -

DESCRIPTION, ROCKER

...............9-124ARM / ADJUSTER ASSEMBLY -

INSTALLATION, ROCKER..........9-124,9-249

ARM / ADJUSTER ASSEMBLY -

REMOVAL, ROCKER.............9-124,9-249

ARM / ADJUSTER ASSY - CLEANING,

ROCKER............................9-310

ARM / ADJUSTER ASSY - DESCRIPTION,

ROCKER............................9-310

ARM / ADJUSTER ASSY - INSPECTION,

ROCKER............................9-311

ARM / ADJUSTER ASSY -

INSTALLATION, ROCKER.....9-198,9-312,9-379

ARM / ADJUSTER ASSY - REMOVAL,

ROCKER.................9-198,9-310,9-379

ARM - DESCRIPTION, ROCKER......9-30,9-36

ARM - DESCRIPTION, WIPER...........8R-18

ARM - INSTALLATION, LOWER

SUSPENSION.........................2-35

ARM - INSTALLATION, PITMAN.........19-36

ARM - INSTALLATION, ROCKER..........9-30

ARM - INSTALLATION, UPPER CONTROL . . . 2-27

ARM - INSTALLATION, WIPER..........8R-19

ARM - OPERATION, WIPER............8R-18

ARM - REMOVAL, LOWER SUSPENSION . . . 2-35

ARM - REMOVAL, PITMAN.............19-35

ARM - REMOVAL, ROCKER..........9-30,9-36

ARM - REMOVAL, UPPER CONTROL......2-27

ARM - REMOVAL, WIPER..............8R-18

ARM BUSHINGS - 2WD (LD) -

INSTALLATION, LOWER CONTROL..........2-14

ARM BUSHINGS - 2WD (LD) -

REMOVAL, LOWER CONTROL............2-12

ARM BUSHINGS - 4WD (LD) -

INSTALLATION, LOWER CONTROL........2-13

ARM BUSHINGS - 4WD (LD) -

REMOVAL, LOWER CONTROL............2-12

ARMREST / SEAT BACK - INSTALLATION,

CENTER............................23-78

ARMREST / SEAT BACK - REMOVAL,

CENTER............................23-77

ASD AND FUEL PUMP RELAYS -

DIAGNOSIS AND TESTING...............8I-7

ASD SENSE - PCM INPUT - OPERATION....8I-6

ASH RECEIVER - INSTALLATION.........23-52

ASH RECEIVER - REMOVAL............23-51

AUDIO - DESCRIPTION.................8A-1

AUDIO - DIAGNOSIS AND TESTING.......8A-2

AUDIO - OPERATION...................8A-1

AUTOMATIC DAY / NIGHT MIRROR -

DESCRIPTION.......................8N-12

AUTOMATIC DAY / NIGHT MIRROR -

DIAGNOSIS AND TESTING.............8N-12

AUTOMATIC DAY / NIGHT MIRROR -

OPERATION.........................8N-12

AUTOMATIC DAY / NIGHT MIRROR -

REMOVAL..........................8N-13

AUTOMATIC LOCKING RETRACTOR -

DESCRIPTION.......................8O-13

AUTOMATIC LOCKING RETRACTOR -

OPERATION.........................8O-14

AUTOMATIC TRANSMISSION -

45RFE/545RFE - DESCRIPTION.........21-489

AUTOMATIC TRANSMISSION -

45RFE/545RFE - OPERATION...........21-490

AUTOMATIC TRANSMISSION - 46RE -

DESCRIPTION......................21-131

AUTOMATIC TRANSMISSION - 46RE -

OPERATION........................21-133

AUTOMATIC TRANSMISSION - 48RE -

DESCRIPTION......................21-312

AUTOMATIC TRANSMISSION - 48RE -

OPERATION........................21-314

AUTOMATIC TRANSMISSION -

DIAGNOSIS AND TESTING......21-139,21-320,

21-491

AUTOMATIC TRANSMISSION FLUID -

DESCRIPTION.........................0-4

AUTOMATIC TRANSMISSION FLUID -

OPERATION...........................0-5

AUXILIARY SPRING BUMPERS (3500) -

INSTALLATION

........................2-40

AUXILIARY SPRING BUMPERS (3500) -

REMOVAL

...........................2-40

AXLE - 10 1/2 AA - ADJUSTMENTS,

REAR

..............................3-104

AXLE - 10 1/2 AA - DESCRIPTION, REAR

. . 3-100

AXLE - 10 1/2 AA - DIAGNOSIS AND

TESTING, REAR

......................3-100AXLE - 10 1/2 AA - INSTALLATION,

REAR..............................3-103

AXLE - 10 1/2 AA - OPERATION, REAR . . . 3-100

AXLE - 10 1/2 AA - REMOVAL, REAR.....3-103

AXLE - 10 1/2 AA - SPECIAL TOOLS,

REAR..............................3-108

AXLE - 10 1/2 AA - SPECIFICATIONS,

REAR..............................3-108

AXLE - 11 1/2 AA - ADJUSTMENTS,

REAR..............................3-131

AXLE - 11 1/2 AA - DESCRIPTION, REAR . . 3-127

AXLE - 11 1/2 AA - DIAGNOSIS AND

TESTING, REAR......................3-127

AXLE - 11 1/2 AA - INSTALLATION,

REAR..............................3-130

AXLE - 11 1/2 AA - OPERATION, REAR . . . 3-127

AXLE - 11 1/2 AA - REMOVAL, REAR.....3-130

AXLE - 11 1/2 AA - SPECIAL TOOLS,

REAR..............................3-135

AXLE - 11 1/2 AA - SPECIFICATIONS,

REAR..............................3-135

AXLE - 9 1/4 - ADJUSTMENTS, REAR.....3-74

AXLE - 9 1/4 - DESCRIPTION, REAR......3-69

AXLE - 9 1/4 - DIAGNOSIS AND

TESTING, REAR.......................3-69

AXLE - 9 1/4 - INSTALLATION, REAR......3-74

AXLE - 9 1/4 - OPERATION, REAR........3-69

AXLE - 9 1/4 - REMOVAL, REAR..........3-74

AXLE - 9 1/4 - SPECIAL TOOLS, REAR.....3-80

AXLE - 9 1/4 - SPECIFICATIONS, REAR......3-79

AXLE - 9 1/4 AA - ADJUSTMENTS,

FRONT..............................3-49

AXLE - 9 1/4 AA - DESCRIPTION, FRONT . . . 3-45

AXLE - 9 1/4 AA - DIAGNOSIS AND

TESTING, FRONT......................3-45

AXLE - 9 1/4 AA - INSTALLATION,

FRONT..............................3-48

AXLE - 9 1/4 AA - OPERATION, FRONT....3-45

AXLE - 9 1/4 AA - REMOVAL, FRONT......3-48

AXLE - 9 1/4 AA - SPECIAL TOOLS,

FRONT..............................3-53

AXLE - 9 1/4 AA - SPECIFICATIONS,

FRONT..............................3-53

AXLE - C205F - ADJUSTMENTS, FRONT....3-21

AXLE - C205F - DESCRIPTION, FRONT.....3-18

AXLE - C205F - DIAGNOSIS AND

TESTING, FRONT......................3-18

AXLE - C205F - INSTALLATION, FRONT....3-21

AXLE - C205F - OPERATION, FRONT......3-18

AXLE - C205F - REMOVAL, FRONT........3-21

AXLE - C205F - SPECIAL TOOLS, FRONT . . . 3-30

AXLE - C205F - SPECIFICATIONS, FRONT . . . 3-29

AXLE - DESCRIPTION...................0-4

AXLE BEARINGS - INSTALLATION . . 3-112,3-139,

3-34,3-84

AXLE BEARINGS - REMOVAL . . 3-112,3-138,3-33,

3-84

AXLE SHAFT SEALS - INSTALLATION . 3-33,3-58,

3-84

AXLE SHAFT SEALS - REMOVAL . 3-33,3-58,3-84

AXLE SHAFTS - ASSEMBLY.............3-58

AXLE SHAFTS - DISASSEMBLY...........3-56

AXLE SHAFTS - INSTALLATION....3-111,3-138,

3-33,3-58,3-83

AXLE SHAFTS - REMOVAL

....3-111,3-138,3-33,

3-56,3-83

BACK - INSTALLATION, CENTER

ARMREST / SEAT

....................23-78

BACK - REAR - INSTALLATION, SEAT

.....23-84

BACK - REAR - REMOVAL, SEAT

........23-84

BACK - REMOVAL, CENTER ARMREST /

SEAT

..............................23-77

BACK CUSHION / COVER - FRONT -

INSTALLATION, SEAT

.................23-83

BACK CUSHION / COVER - FRONT -

REMOVAL, SEAT

.....................23-83

BACK CUSHION / COVER - REAR -

INSTALLATION, SEAT

.................23-85

BACK CUSHION / COVER - REAR -

REMOVAL, SEAT

.....................23-85

BACK HINGE - INSTALLATION, CENTER

SEAT

..............................23-80

BACK HINGE - REMOVAL, CENTER SEAT

. . 23-79

BACK INERTIA HINGE COVER -

INSTALLATION, CENTER SEAT

..........23-78

BACK INERTIA HINGE COVER -

REMOVAL, CENTER SEAT

..............23-78

2 INDEXDR

Description Group-Page Description Group-Page Description Group-Page

Page 2862 of 2895

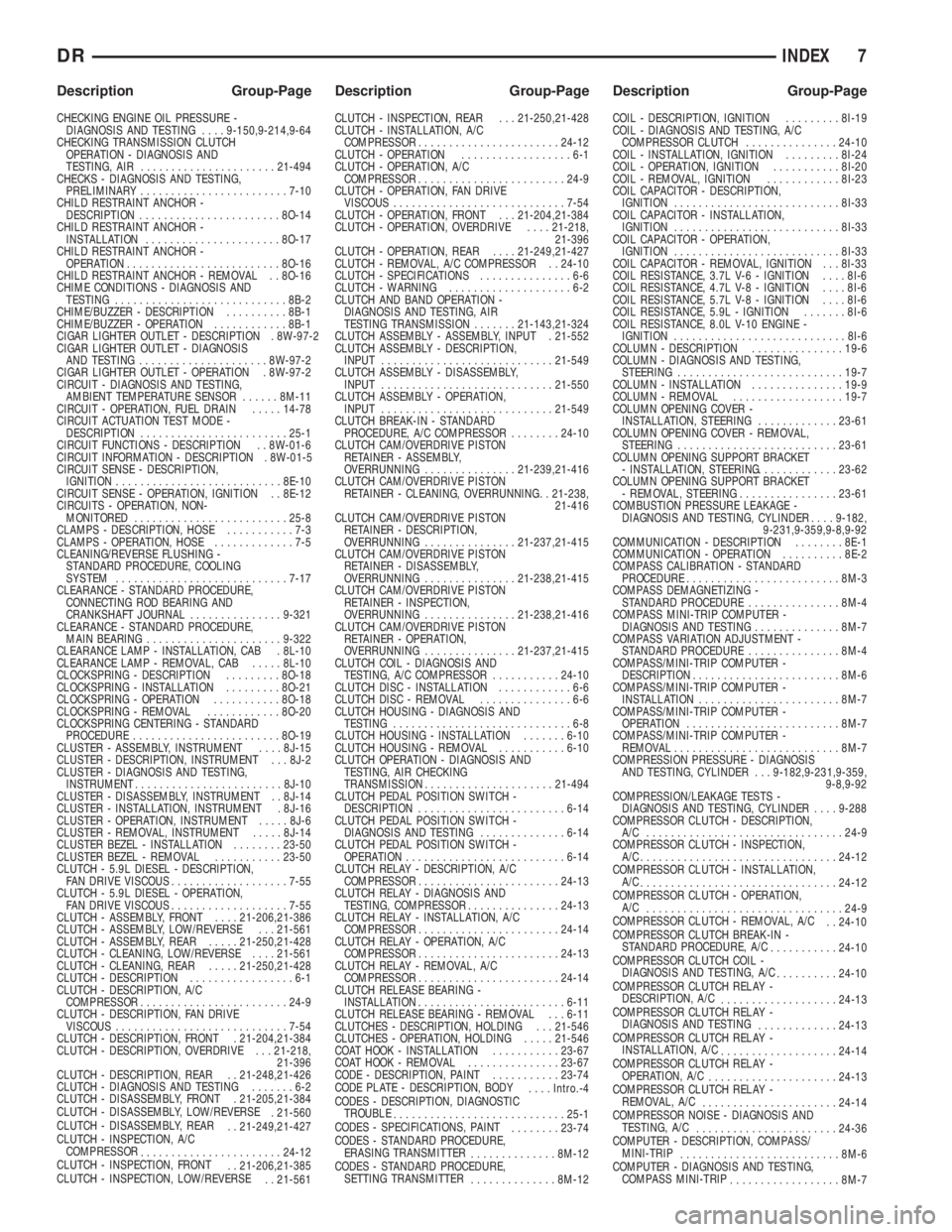

CHECKING ENGINE OIL PRESSURE -

DIAGNOSIS AND TESTING....9-150,9-214,9-64

CHECKING TRANSMISSION CLUTCH

OPERATION - DIAGNOSIS AND

TESTING, AIR......................21-494

CHECKS - DIAGNOSIS AND TESTING,

PRELIMINARY........................7-10

CHILD RESTRAINT ANCHOR -

DESCRIPTION.......................8O-14

CHILD RESTRAINT ANCHOR -

INSTALLATION......................8O-17

CHILD RESTRAINT ANCHOR -

OPERATION.........................8O-16

CHILD RESTRAINT ANCHOR - REMOVAL . . 8O-16

CHIME CONDITIONS - DIAGNOSIS AND

TESTING............................8B-2

CHIME/BUZZER - DESCRIPTION..........8B-1

CHIME/BUZZER - OPERATION............8B-1

CIGAR LIGHTER OUTLET - DESCRIPTION . 8W-97-2

CIGAR LIGHTER OUTLET - DIAGNOSIS

AND TESTING.....................8W-97-2

CIGAR LIGHTER OUTLET - OPERATION . 8W-97-2

CIRCUIT - DIAGNOSIS AND TESTING,

AMBIENT TEMPERATURE SENSOR......8M-11

CIRCUIT - OPERATION, FUEL DRAIN.....14-78

CIRCUIT ACTUATION TEST MODE -

DESCRIPTION........................25-1

CIRCUIT FUNCTIONS - DESCRIPTION . . 8W-01-6

CIRCUIT INFORMATION - DESCRIPTION . 8W-01-5

CIRCUIT SENSE - DESCRIPTION,

IGNITION...........................8E-10

CIRCUIT SENSE - OPERATION, IGNITION . . 8E-12

CIRCUITS - OPERATION, NON-

MONITORED.........................25-8

CLAMPS - DESCRIPTION, HOSE...........7-3

CLAMPS - OPERATION, HOSE.............7-5

CLEANING/REVERSE FLUSHING -

STANDARD PROCEDURE, COOLING

SYSTEM............................7-17

CLEARANCE - STANDARD PROCEDURE,

CONNECTING ROD BEARING AND

CRANKSHAFT JOURNAL...............9-321

CLEARANCE - STANDARD PROCEDURE,

MAIN BEARING......................9-322

CLEARANCE LAMP - INSTALLATION, CAB . 8L-10

CLEARANCE LAMP - REMOVAL, CAB.....8L-10

CLOCKSPRING - DESCRIPTION.........8O-18

CLOCKSPRING - INSTALLATION.........8O-21

CLOCKSPRING - OPERATION...........8O-18

CLOCKSPRING - REMOVAL............8O-20

CLOCKSPRING CENTERING - STANDARD

PROCEDURE........................8O-19

CLUSTER - ASSEMBLY, INSTRUMENT....8J-15

CLUSTER - DESCRIPTION, INSTRUMENT . . . 8J-2

CLUSTER - DIAGNOSIS AND TESTING,

INSTRUMENT........................8J-10

CLUSTER - DISASSEMBLY, INSTRUMENT . . 8J-14

CLUSTER - INSTALLATION, INSTRUMENT . 8J-16

CLUSTER - OPERATION, INSTRUMENT.....8J-6

CLUSTER - REMOVAL, INSTRUMENT.....8J-14

CLUSTER BEZEL - INSTALLATION........23-50

CLUSTER BEZEL - REMOVAL...........23-50

CLUTCH - 5.9L DIESEL - DESCRIPTION,

FAN DRIVE VISCOUS...................7-55

CLUTCH - 5.9L DIESEL - OPERATION,

FAN DRIVE VISCOUS...................7-55

CLUTCH - ASSEMBLY, FRONT....21-206,21-386

CLUTCH - ASSEMBLY, LOW/REVERSE . . . 21-561

CLUTCH - ASSEMBLY, REAR.....21-250,21-428

CLUTCH - CLEANING, LOW/REVERSE....21-561

CLUTCH - CLEANING, REAR.....21-250,21-428

CLUTCH - DESCRIPTION.................6-1

CLUTCH - DESCRIPTION, A/C

COMPRESSOR........................24-9

CLUTCH - DESCRIPTION, FAN DRIVE

VISCOUS............................7-54

CLUTCH - DESCRIPTION, FRONT . 21-204,21-384

CLUTCH - DESCRIPTION, OVERDRIVE . . . 21-218,

21-396

CLUTCH - DESCRIPTION, REAR . . 21-248,21-426

CLUTCH - DIAGNOSIS AND TESTING.......6-2

CLUTCH - DISASSEMBLY, FRONT . 21-205,21-384

CLUTCH - DISASSEMBLY, LOW/REVERSE

. 21-560

CLUTCH - DISASSEMBLY, REAR

. . 21-249,21-427

CLUTCH - INSPECTION, A/C

COMPRESSOR

.......................24-12

CLUTCH - INSPECTION, FRONT

. . 21-206,21-385

CLUTCH - INSPECTION, LOW/REVERSE

. . 21-561CLUTCH - INSPECTION, REAR . . . 21-250,21-428

CLUTCH - INSTALLATION, A/C

COMPRESSOR.......................24-12

CLUTCH - OPERATION..................6-1

CLUTCH - OPERATION, A/C

COMPRESSOR........................24-9

CLUTCH - OPERATION, FAN DRIVE

VISCOUS............................7-54

CLUTCH - OPERATION, FRONT . . . 21-204,21-384

CLUTCH - OPERATION, OVERDRIVE....21-218,

21-396

CLUTCH - OPERATION, REAR....21-249,21-427

CLUTCH - REMOVAL, A/C COMPRESSOR . . 24-10

CLUTCH - SPECIFICATIONS...............6-6

CLUTCH - WARNING....................6-2

CLUTCH AND BAND OPERATION -

DIAGNOSIS AND TESTING, AIR

TESTING TRANSMISSION.......21-143,21-324

CLUTCH ASSEMBLY - ASSEMBLY, INPUT . 21-552

CLUTCH ASSEMBLY - DESCRIPTION,

INPUT............................21-549

CLUTCH ASSEMBLY - DISASSEMBLY,

INPUT............................21-550

CLUTCH ASSEMBLY - OPERATION,

INPUT............................21-549

CLUTCH BREAK-IN - STANDARD

PROCEDURE, A/C COMPRESSOR........24-10

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - ASSEMBLY,

OVERRUNNING...............21-239,21-416

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - CLEANING, OVERRUNNING. . . 21-238,

21-416

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - DESCRIPTION,

OVERRUNNING...............21-237,21-415

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - DISASSEMBLY,

OVERRUNNING...............21-238,21-415

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - INSPECTION,

OVERRUNNING...............21-238,21-416

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - OPERATION,

OVERRUNNING...............21-237,21-415

CLUTCH COIL - DIAGNOSIS AND

TESTING, A/C COMPRESSOR...........24-10

CLUTCH DISC - INSTALLATION............6-6

CLUTCH DISC - REMOVAL...............6-6

CLUTCH HOUSING - DIAGNOSIS AND

TESTING.............................6-8

CLUTCH HOUSING - INSTALLATION.......6-10

CLUTCH HOUSING - REMOVAL...........6-10

CLUTCH OPERATION - DIAGNOSIS AND

TESTING, AIR CHECKING

TRANSMISSION.....................21-494

CLUTCH PEDAL POSITION SWITCH -

DESCRIPTION........................6-14

CLUTCH PEDAL POSITION SWITCH -

DIAGNOSIS AND TESTING..............6-14

CLUTCH PEDAL POSITION SWITCH -

OPERATION..........................6-14

CLUTCH RELAY - DESCRIPTION, A/C

COMPRESSOR.......................24-13

CLUTCH RELAY - DIAGNOSIS AND

TESTING, COMPRESSOR...............24-13

CLUTCH RELAY - INSTALLATION, A/C

COMPRESSOR.......................24-14

CLUTCH RELAY - OPERATION, A/C

COMPRESSOR.......................24-13

CLUTCH RELAY - REMOVAL, A/C

COMPRESSOR.......................24-14

CLUTCH RELEASE BEARING -

INSTALLATION........................6-11

CLUTCH RELEASE BEARING - REMOVAL . . . 6-11

CLUTCHES - DESCRIPTION, HOLDING . . . 21-546

CLUTCHES - OPERATION, HOLDING.....21-546

COAT HOOK - INSTALLATION...........23-67

COAT HOOK - REMOVAL...............23-67

CODE - DESCRIPTION, PAINT...........23-74

CODE PLATE - DESCRIPTION, BODY

....Intro.-4

CODES - DESCRIPTION, DIAGNOSTIC

TROUBLE

............................25-1

CODES - SPECIFICATIONS, PAINT

........23-74

CODES - STANDARD PROCEDURE,

ERASING TRANSMITTER

..............8M-12

CODES - STANDARD PROCEDURE,

SETTING TRANSMITTER

..............8M-12COIL - DESCRIPTION, IGNITION.........8I-19

COIL - DIAGNOSIS AND TESTING, A/C

COMPRESSOR CLUTCH...............24-10

COIL - INSTALLATION, IGNITION.........8I-24

COIL - OPERATION, IGNITION...........8I-20

COIL - REMOVAL, IGNITION............8I-23

COIL CAPACITOR - DESCRIPTION,

IGNITION...........................8I-33

COIL CAPACITOR - INSTALLATION,

IGNITION...........................8I-33

COIL CAPACITOR - OPERATION,

IGNITION...........................8I-33

COIL CAPACITOR - REMOVAL, IGNITION . . . 8I-33

COIL RESISTANCE, 3.7L V-6 - IGNITION....8I-6

COIL RESISTANCE, 4.7L V-8 - IGNITION....8I-6

COIL RESISTANCE, 5.7L V-8 - IGNITION....8I-6

COIL RESISTANCE, 5.9L - IGNITION.......8I-6

COIL RESISTANCE, 8.0L V-10 ENGINE -

IGNITION............................8I-6

COLUMN - DESCRIPTION...............19-6

COLUMN - DIAGNOSIS AND TESTING,

STEERING...........................19-7

COLUMN - INSTALLATION...............19-9

COLUMN - REMOVAL..................19-7

COLUMN OPENING COVER -

INSTALLATION, STEERING.............23-61

COLUMN OPENING COVER - REMOVAL,

STEERING..........................23-61

COLUMN OPENING SUPPORT BRACKET

- INSTALLATION, STEERING..............23-62

COLUMN OPENING SUPPORT BRACKET

- REMOVAL, STEERING................23-61

COMBUSTION PRESSURE LEAKAGE -

DIAGNOSIS AND TESTING, CYLINDER....9-182,

9-231,9-359,9-8,9-92

COMMUNICATION - DESCRIPTION........8E-1

COMMUNICATION - OPERATION..........8E-2

COMPASS CALIBRATION - STANDARD

PROCEDURE.........................8M-3

COMPASS DEMAGNETIZING -

STANDARD PROCEDURE...............8M-4

COMPASS MINI-TRIP COMPUTER -

DIAGNOSIS AND TESTING..............8M-7

COMPASS VARIATION ADJUSTMENT -

STANDARD PROCEDURE...............8M-4

COMPASS/MINI-TRIP COMPUTER -

DESCRIPTION........................8M-6

COMPASS/MINI-TRIP COMPUTER -

INSTALLATION.......................8M-7

COMPASS/MINI-TRIP COMPUTER -

OPERATION.........................8M-7

COMPASS/MINI-TRIP COMPUTER -

REMOVAL...........................8M-7

COMPRESSION PRESSURE - DIAGNOSIS

AND TESTING, CYLINDER . . . 9-182,9-231,9-359,

9-8,9-92

COMPRESSION/LEAKAGE TESTS -

DIAGNOSIS AND TESTING, CYLINDER....9-288

COMPRESSOR CLUTCH - DESCRIPTION,

A/C ................................24-9

COMPRESSOR CLUTCH - INSPECTION,

A/C................................24-12

COMPRESSOR CLUTCH - INSTALLATION,

A/C

................................24-12

COMPRESSOR CLUTCH - OPERATION,

A/C

................................24-9

COMPRESSOR CLUTCH - REMOVAL, A/C

. . 24-10

COMPRESSOR CLUTCH BREAK-IN -

STANDARD PROCEDURE, A/C

...........24-10

COMPRESSOR CLUTCH COIL -

DIAGNOSIS AND TESTING, A/C

..........24-10

COMPRESSOR CLUTCH RELAY -

DESCRIPTION, A/C

...................24-13

COMPRESSOR CLUTCH RELAY -

DIAGNOSIS AND TESTING

.............24-13

COMPRESSOR CLUTCH RELAY -

INSTALLATION, A/C

...................24-14

COMPRESSOR CLUTCH RELAY -

OPERATION, A/C

.....................24-13

COMPRESSOR CLUTCH RELAY -

REMOVAL, A/C

......................24-14

COMPRESSOR NOISE - DIAGNOSIS AND

TESTING, A/C

.......................24-36

COMPUTER - DESCRIPTION, COMPASS/

MINI-TRIP

..........................8M-6

COMPUTER - DIAGNOSIS AND TESTING,

COMPASS MINI-TRIP

..................8M-7

DRINDEX 7

Description Group-Page Description Group-Page Description Group-Page