Diesel DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2818 of 2895

NOTE: If the condenser is replaced, add 30 millili-

ters (1 fluid ounce) of refrigerant oil to the refriger-

ant system. Use only refrigerant oil of the type

recommended for the compressor in the vehicle(Re-

fer to 24 - HEATING & AIR CONDITIONING/PLUMB-

ING/REFRIGERANT OIL - DESCRIPTION).

(8) Charge the a/c system(Refer to 24 - HEATING

& AIR CONDITIONING/PLUMBING - STANDARD

PROCEDURE).

(9) Install the battery negative cable.

A/C CONDENSER FAN

REMOVAL - CONDENSER FAN (GAS ENGINE

ONLY - 3.7, 4.7 & 5.7L)

(1) Remove and isolate negative battery cable.

(2) Remove condenser assembly(Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/A/C

CONDENSER - REMOVAL).

(3) Place condenser assembly on a flat work area

and remove screws holding fan assembly to con-

denser.

(4) Separate fan assembly from condenser noting

location of all seals for reinstallation.

INSTALLATION - CONDENSER FAN (GAS

ENGINE ONLY - 3.7, 4.7 & 5.7L)

(1) Position fan assembly on to the condenser.

(2) Check all fan shroud seals and replace as

required then install retainer screws to hold fan

assembly to condenser.

(3) Install condenser and fan assembly to vehi-

cle(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/A/C CONDENSER - INSTALLATION).

(4) Install battery negative cable.

A/C DISCHARGE LINE

REMOVAL

REMOVAL

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

(1) Disconnect and isolate the battery negative

cable.

(2) Recover the refrigerant from the refrigerant

system. (Refer to 24 - HEATING & AIR CONDI-TIONING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY)

(3) Unplug the wire harness connector from the

high pressure transducer.

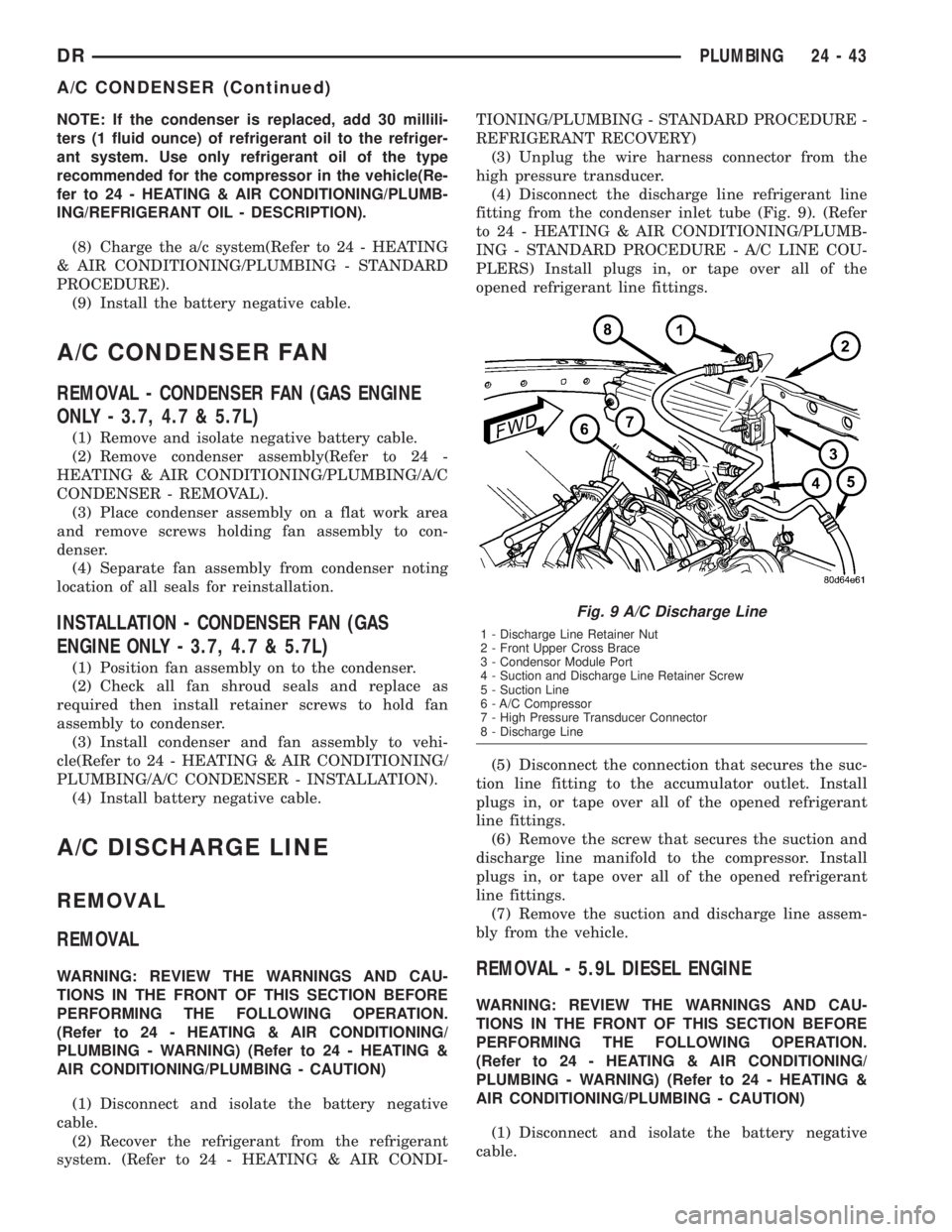

(4) Disconnect the discharge line refrigerant line

fitting from the condenser inlet tube (Fig. 9). (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMB-

ING - STANDARD PROCEDURE - A/C LINE COU-

PLERS) Install plugs in, or tape over all of the

opened refrigerant line fittings.

(5) Disconnect the connection that secures the suc-

tion line fitting to the accumulator outlet. Install

plugs in, or tape over all of the opened refrigerant

line fittings.

(6) Remove the screw that secures the suction and

discharge line manifold to the compressor. Install

plugs in, or tape over all of the opened refrigerant

line fittings.

(7) Remove the suction and discharge line assem-

bly from the vehicle.REMOVAL - 5.9L DIESEL ENGINE

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

(1) Disconnect and isolate the battery negative

cable.

Fig. 9 A/C Discharge Line

1 - Discharge Line Retainer Nut

2 - Front Upper Cross Brace

3 - Condensor Module Port

4 - Suction and Discharge Line Retainer Screw

5 - Suction Line

6 - A/C Compressor

7 - High Pressure Transducer Connector

8 - Discharge Line

DRPLUMBING 24 - 43

A/C CONDENSER (Continued)

Page 2819 of 2895

(2) Recover the refrigerant from the refrigerant

system. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY)

(3) Unplug the wire harness connector from the a/c

high pressure switch.

(4) Disconnect the suction line refrigerant line cou-

pler at the accumulator. (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - STANDARD

PROCEDURE - A/C LINE COUPLER) Install plugs

in, or tape over all of the opened refrigerant line fit-

tings.

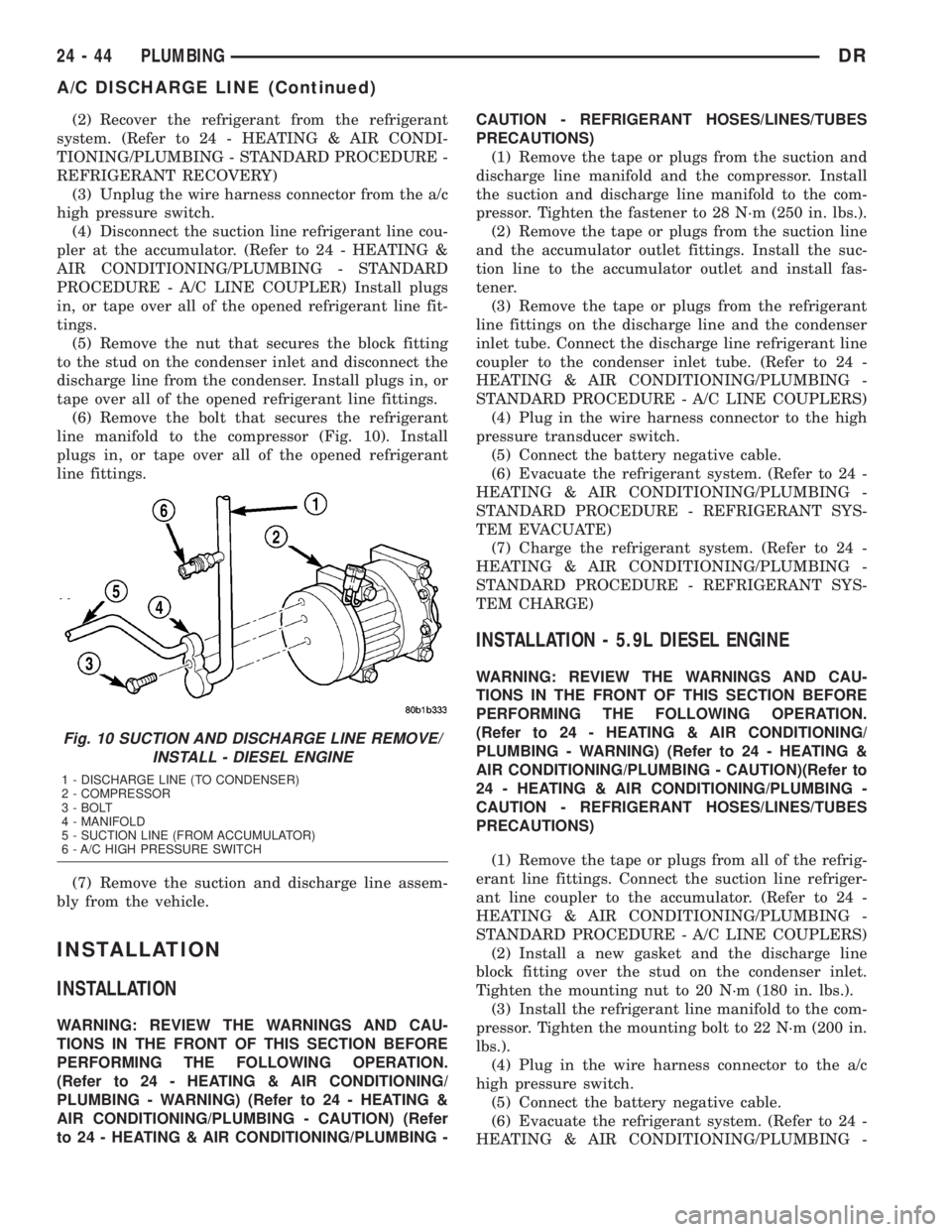

(5) Remove the nut that secures the block fitting

to the stud on the condenser inlet and disconnect the

discharge line from the condenser. Install plugs in, or

tape over all of the opened refrigerant line fittings.

(6) Remove the bolt that secures the refrigerant

line manifold to the compressor (Fig. 10). Install

plugs in, or tape over all of the opened refrigerant

line fittings.

(7) Remove the suction and discharge line assem-

bly from the vehicle.

INSTALLATION

INSTALLATION

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION) (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -CAUTION - REFRIGERANT HOSES/LINES/TUBES

PRECAUTIONS)

(1) Remove the tape or plugs from the suction and

discharge line manifold and the compressor. Install

the suction and discharge line manifold to the com-

pressor. Tighten the fastener to 28 N´m (250 in. lbs.).

(2) Remove the tape or plugs from the suction line

and the accumulator outlet fittings. Install the suc-

tion line to the accumulator outlet and install fas-

tener.

(3) Remove the tape or plugs from the refrigerant

line fittings on the discharge line and the condenser

inlet tube. Connect the discharge line refrigerant line

coupler to the condenser inlet tube. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - A/C LINE COUPLERS)

(4) Plug in the wire harness connector to the high

pressure transducer switch.

(5) Connect the battery negative cable.

(6) Evacuate the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE)

(7) Charge the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE)

INSTALLATION - 5.9L DIESEL ENGINE

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)(Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING -

CAUTION - REFRIGERANT HOSES/LINES/TUBES

PRECAUTIONS)

(1) Remove the tape or plugs from all of the refrig-

erant line fittings. Connect the suction line refriger-

ant line coupler to the accumulator. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - A/C LINE COUPLERS)

(2) Install a new gasket and the discharge line

block fitting over the stud on the condenser inlet.

Tighten the mounting nut to 20 N´m (180 in. lbs.).

(3) Install the refrigerant line manifold to the com-

pressor. Tighten the mounting bolt to 22 N´m (200 in.

lbs.).

(4) Plug in the wire harness connector to the a/c

high pressure switch.

(5) Connect the battery negative cable.

(6) Evacuate the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

Fig. 10 SUCTION AND DISCHARGE LINE REMOVE/

INSTALL - DIESEL ENGINE

1 - DISCHARGE LINE (TO CONDENSER)

2 - COMPRESSOR

3 - BOLT

4 - MANIFOLD

5 - SUCTION LINE (FROM ACCUMULATOR)

6 - A/C HIGH PRESSURE SWITCH

24 - 44 PLUMBINGDR

A/C DISCHARGE LINE (Continued)

Page 2820 of 2895

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE)

(7) Charge the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE)

LIQUID LINE

REMOVAL

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

(1) Disconnect and isolate the battery negative

cable.

NOTE: Removal of the second battery and battery

tray is required on the diesel equipped vehicles.

(2) Remove rightside battery(Refer to 8 - ELEC-

TRICAL/BATTERY SYSTEM/BATTERY - REMOV-

AL).

(3) Remove rightside battery tray(Refer to 8 -

ELECTRICAL/BATTERY SYSTEM/TRAY - REMOV-

AL).

(4) Recover the refrigerant from the refrigerant

system. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY)

(5) Disconnect the liquid line refrigerant line cou-

plers at the condenser outlet the mid point connec-

tion and the evaporator inlet. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - A/C LINE COUPLERS)

Install plugs in, or tape over all of the opened refrig-

erant line fittings.

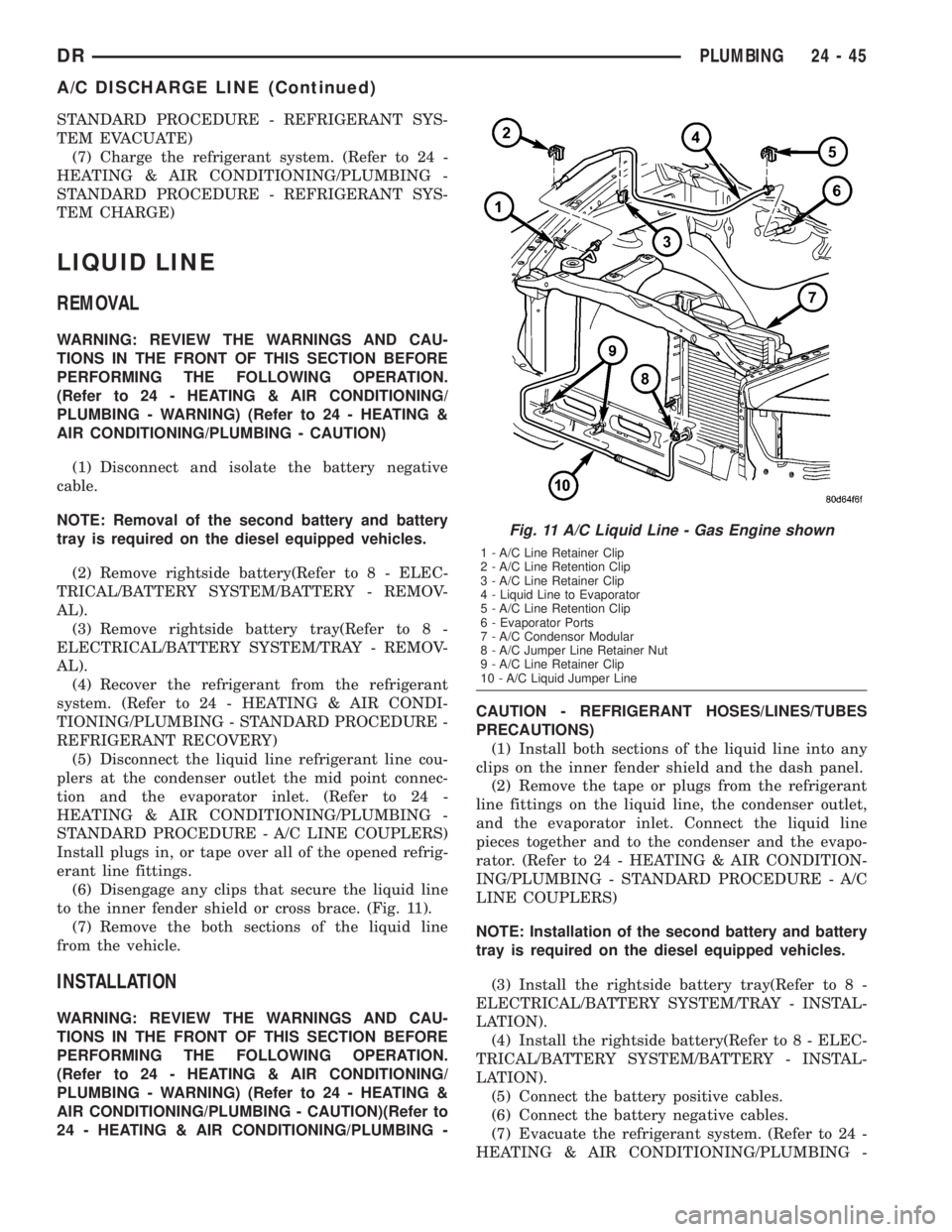

(6) Disengage any clips that secure the liquid line

to the inner fender shield or cross brace. (Fig. 11).

(7) Remove the both sections of the liquid line

from the vehicle.

INSTALLATION

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)(Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING -CAUTION - REFRIGERANT HOSES/LINES/TUBES

PRECAUTIONS)

(1) Install both sections of the liquid line into any

clips on the inner fender shield and the dash panel.

(2) Remove the tape or plugs from the refrigerant

line fittings on the liquid line, the condenser outlet,

and the evaporator inlet. Connect the liquid line

pieces together and to the condenser and the evapo-

rator. (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - STANDARD PROCEDURE - A/C

LINE COUPLERS)

NOTE: Installation of the second battery and battery

tray is required on the diesel equipped vehicles.

(3) Install the rightside battery tray(Refer to 8 -

ELECTRICAL/BATTERY SYSTEM/TRAY - INSTAL-

LATION).

(4) Install the rightside battery(Refer to 8 - ELEC-

TRICAL/BATTERY SYSTEM/BATTERY - INSTAL-

LATION).

(5) Connect the battery positive cables.

(6) Connect the battery negative cables.

(7) Evacuate the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

Fig. 11 A/C Liquid Line - Gas Engine shown

1 - A/C Line Retainer Clip

2 - A/C Line Retention Clip

3 - A/C Line Retainer Clip

4 - Liquid Line to Evaporator

5 - A/C Line Retention Clip

6 - Evaporator Ports

7 - A/C Condensor Modular

8 - A/C Jumper Line Retainer Nut

9 - A/C Line Retainer Clip

10 - A/C Liquid Jumper Line

DRPLUMBING 24 - 45

A/C DISCHARGE LINE (Continued)

Page 2821 of 2895

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE)

(8) Charge the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE)

SUCTION LINE

REMOVAL

REMOVAL

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

(1) Disconnect and isolate the battery negative

cable.

(2) Recover the refrigerant from the refrigerant

system. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY)

(3) Unplug the wire harness connector from the a/c

high pressure transducer.

(4) Disconnect the suction line refrigerant line cou-

pler at the accumulator. (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - STANDARD

PROCEDURE - A/C LINE COUPLER) Install plugs

in, or tape over all of the opened refrigerant line fit-

tings.

(5) Remove the nut that secures the condenser

inlet and disconnect the discharge line from the con-

denser. Install plugs in, or tape over all of the opened

refrigerant line fittings.

(6) Remove the suction and discharge line assem-

bly from the vehicle.

REMOVAL - 5.9L DIESEL ENGINE

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

(1) Disconnect and isolate the battery negative

cable.

(2) Recover the refrigerant from the refrigerant

system. (Refer to 24 - HEATING & AIR CONDI-TIONING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY)

(3) Unplug the wire harness connector from the a/c

high pressure switch.

(4) Disconnect the suction line refrigerant line cou-

pler at the accumulator. (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - STANDARD

PROCEDURE - A/C LINE COUPLER) Install plugs

in, or tape over all of the opened refrigerant line fit-

tings.

(5) Remove the nut that secures the block fitting

to the stud on the condenser inlet and disconnect the

discharge line from the condenser. Install plugs in, or

tape over all of the opened refrigerant line fittings.

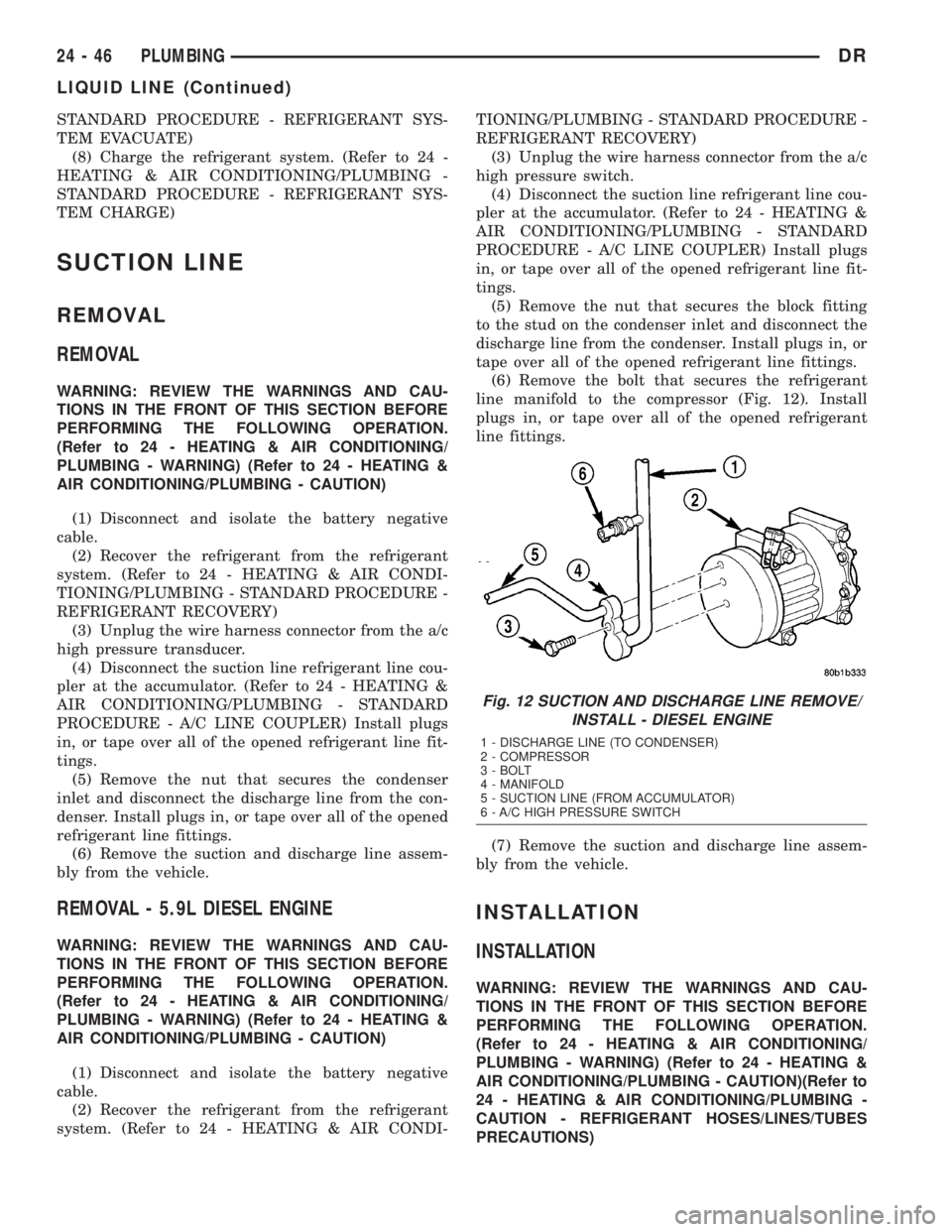

(6) Remove the bolt that secures the refrigerant

line manifold to the compressor (Fig. 12). Install

plugs in, or tape over all of the opened refrigerant

line fittings.

(7) Remove the suction and discharge line assem-

bly from the vehicle.

INSTALLATION

INSTALLATION

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)(Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING -

CAUTION - REFRIGERANT HOSES/LINES/TUBES

PRECAUTIONS)

Fig. 12 SUCTION AND DISCHARGE LINE REMOVE/

INSTALL - DIESEL ENGINE

1 - DISCHARGE LINE (TO CONDENSER)

2 - COMPRESSOR

3 - BOLT

4 - MANIFOLD

5 - SUCTION LINE (FROM ACCUMULATOR)

6 - A/C HIGH PRESSURE SWITCH

24 - 46 PLUMBINGDR

LIQUID LINE (Continued)

Page 2858 of 2895

BACK LID - INSTALLATION, CENTER

SEAT ..............................23-80

BACK LID - REMOVAL, CENTER SEAT....23-80

BACK PANEL TRIM - INSTALLATION,

REAR CAB..........................23-70

BACK PANEL TRIM - REMOVAL, REAR

CAB ...............................23-70

BACK REAR - FOOTMANS LOOP

BRACKETS - INSTALLATION, SEAT.......23-85

BACK REAR - FOOTMANS LOOP

BRACKETS - REMOVAL, SEAT...........23-85

BACKLITE - INSTALLATION.............23-86

BACKLITE - REMOVAL.................23-86

BACKLITE VENT GLASS - INSTALLATION . . 23-87

BACKLITE VENT GLASS - REMOVAL......23-87

BACKUP LAMP - INSTALLATION..........8L-7

BACKUP LAMP - REMOVAL.............8L-7

BACKUP LAMP SWITCH - DESCRIPTION . . . 8L-7

BACKUP LAMP SWITCH - DIAGNOSIS

AND TESTING........................8L-8

BACKUP LAMP SWITCH - OPERATION.....8L-8

BALANCE - STANDARD PROCEDURE,

TIRE AND WHEEL.....................22-4

BALANCE SHAFT - INSTALLATION........9-79

BALANCE SHAFT - REMOVAL............9-79

BALL JOINT - DIAGNOSIS AND TESTING,

LOWER.............................2-18

BALL JOINT - DIAGNOSIS AND TESTING,

UPPER..............................2-26

BALL JOINT - INSTALLATION, LOWER . . 2-19,2-33

BALL JOINT - INSTALLATION, UPPER.....2-33

BALL JOINT - REMOVAL, LOWER.....2-18,2-32

BALL JOINT - REMOVAL, UPPER.........2-33

BAND OPERATION - DIAGNOSIS AND

TESTING, AIR TESTING

TRANSMISSION CLUTCH.......21-143,21-324

BANDS - ADJUSTMENT.........21-193,21-374

BANDS - DESCRIPTION.........21-193,21-373

BANDS - OPERATION..........21-193,21-374

BAR - DESCRIPTION, STABILIZER........2-24

BAR - DESCRIPTION, TORSION..........2-25

BAR - INSTALLATION, STABILIZER....2-24,2-37

BAR - INSTALLATION, TORSION..........2-26

BAR - INSTALLATION, TRACK...........19-37

BAR - OPERATION, STABILIZER..........2-24

BAR - OPERATION, TORSION............2-25

BAR - REMOVAL, STABILIZER.......2-24,2-37

BAR - REMOVAL, TORSION.............2-25

BAR - REMOVAL, TRACK..............19-37

BAR CROSS MEMBER BUSHING -

INSTALLATION, TORSION...............2-14

BAR CROSSMEMBER BUSHING -

REMOVAL, TORSION...................2-12

BASE BRAKE, SPECIFICATIONS............5-7

BASE BRAKE SYSTEM - DIAGNOSIS AND

TESTING.............................5-2

BASE BRAKES, SPECIAL TOOLS...........5-5

BASECOAT/CLEARCOAT FINISH -

DESCRIPTION.......................23-74

BATTERIES - STANDARD PROCEDURE,

RKE TRANSMITTER...................8N-9

BATTERY - DESCRIPTION...............8F-7

BATTERY - DIAGNOSIS AND TESTING.....8F-7

BATTERY CABLES - DESCRIPTION.......8F-14

BATTERY CABLES - DIAGNOSIS AND

TESTING...........................8F-15

BATTERY CABLES - INSTALLATION.......8F-17

BATTERY CABLES - OPERATION.........8F-14

BATTERY CABLES - REMOVAL..........8F-16

BATTERY CHARGING - STANDARD

PROCEDURE.........................8F-8

BATTERY HOLDDOWN - DESCRIPTION....8F-14

BATTERY HOLDDOWN - INSTALLATION . . . 8F-14

BATTERY HOLDDOWN - OPERATION.....8F-14

BATTERY HOLDDOWN - REMOVAL.......8F-14

BATTERY SYSTEM - CLEANING...........8F-4

BATTERY SYSTEM - DESCRIPTION........8F-1

BATTERY SYSTEM - DIAGNOSIS AND

TESTING............................8F-2

BATTERY SYSTEM - INSPECTION.........8F-6

BATTERY SYSTEM - OPERATION

.........8F-2

BATTERY SYSTEM - SPECIFICATIONS

......8F-6

BATTERY SYSTEM SPECIAL TOOLS,

SPECIAL TOOLS

......................8F-7

BATTERY TEMPERATURE SENSOR -

DESCRIPTION

.......................8F-21

BATTERY TEMPERATURE SENSOR -

INSTALLATION

.......................8F-21BATTERY TEMPERATURE SENSOR -

OPERATION.........................8F-21

BATTERY TEMPERATURE SENSOR -

REMOVAL..........................8F-21

BATTERY TESTER - STANDARD

PROCEDURE, USING MICRO 420........8F-12

BATTERY TRAY - DESCRIPTION.........8F-17

BATTERY TRAY - INSTALLATION.........8F-18

BATTERY TRAY - OPERATION...........8F-17

BATTERY TRAY - REMOVAL............8F-17

BEAM INDICATOR - DESCRIPTION, HIGH . . 8J-27

BEAM INDICATOR - OPERATION, HIGH....8J-28

BEARING - ADJUSTMENTS, CENTER.......3-8

BEARING - FITTING - STANDARD

PROCEDURE, CRANKSHAFT MAIN . . 9-133,9-202

BEARING - INSTALLATION, CENTER........3-8

BEARING - INSTALLATION, CLUTCH

RELEASE............................6-11

BEARING - INSTALLATION, HUB..........2-31

BEARING - INSTALLATION, OUTPUT

SHAFT FRONT................21-217,21-395

BEARING - INSTALLATION, OUTPUT

SHAFT REAR.................21-217,21-396

BEARING - INSTALLATION, PILOT........6-12

BEARING - REMOVAL, CENTER...........3-8

BEARING - REMOVAL, CLUTCH RELEASE . . . 6-11

BEARING - REMOVAL, HUB.............2-30

BEARING - REMOVAL, OUTPUT SHAFT

FRONT......................21-217,21-395

BEARING - REMOVAL, OUTPUT SHAFT

REAR.......................21-217,21-395

BEARING - REMOVAL, PILOT............6-12

BEARING AND CRANKSHAFT JOURNAL

CLEARANCE - STANDARD

PROCEDURE, CONNECTING ROD........9-321

BEARING CLEARANCE - STANDARD

PROCEDURE, MAIN...................9-322

BEARING FITTING - STANDARD

PROCEDURE, CONNECTING ROD . . . 9-128,9-251,

9-382

BEARING FITTING - STANDARD

PROCEDURE, CRANKSHAFT MAIN.......9-253

BEARING FITTING, STANDARD

PROCEDURE - CONNECTING ROD........9-48

BEARING FITTING, STANDARD

PROCEDURE - MAIN...................9-43

BEARINGS - DESCRIPTION,

CRANKSHAFT MAIN..................9-253

BEARINGS - INSPECTION, CRANKSHAFT

MAIN.........................9-133,9-203

BEARINGS - INSTALLATION, AXLE . . 3-112,3-139,

3-34,3-84

BEARINGS - INSTALLATION, CAMSHAFT . . 9-320,

9-381

BEARINGS - INSTALLATION,

CRANKSHAFT MAIN.............9-254,9-383

BEARINGS - INSTALLATION,

DIFFERENTIAL CASE . 3-121,3-148,3-39,3-65,3-94

BEARINGS - OPERATION, CRANKSHAFT

MAIN..............................9-253

BEARINGS - REMOVAL, AXLE . 3-112,3-138,3-33,

3-84

BEARINGS - REMOVAL, CAMSHAFT . 9-317,9-380

BEARINGS - REMOVAL, CRANKSHAFT

MAIN.........................9-254,9-383

BEARINGS - REMOVAL, DIFFERENTIAL

CASE.............3-121,3-148,3-39,3-64,3-93

BEARINGS - STANDARD PROCEDURE,

FITTING CRANKSHAFT MAIN...........9-383

BELT / CHAIN COVER(S) -

INSTALLATION, TIMING . 9-169,9-278,9-404,9-81

BELT / CHAIN COVER(S) - REMOVAL,

TIMING..............9-168,9-278,9-404,9-80

BELT - DIAGNOSIS AND TESTING,

ACCESSORY DRIVE............7-25,7-28,7-31

BELT - INSTALLATION, FRONT CENTER

SEAT ..............................8O-27

BELT - REMOVAL, FRONT CENTER SEAT . . 8O-26

BELT & RETRACTOR - INSTALLATION,

FRONT CENTER SEAT

.................8O-26

BELT & RETRACTOR - INSTALLATION,

REAR CENTER SEAT

..................8O-40

BELT & RETRACTOR - INSTALLATION,

REAR OUTBOARD SEAT

...............8O-42

BELT & RETRACTOR - REMOVAL, FRONT

CENTER SEAT

.......................8O-25

BELT & RETRACTOR - REMOVAL, REAR

CENTER SEAT

.......................8O-39BELT & RETRACTOR - REMOVAL, REAR

OUTBOARD SEAT....................8O-41

BELT BUCKLE - INSTALLATION, FRONT

OUTBOARD SEAT....................8O-34

BELT BUCKLE - REMOVAL, FRONT

OUTBOARD SEAT....................8O-33

BELT MOLDING - INSTALLATION, FRONT

DOOR INNER........................23-93

BELT MOLDING - INSTALLATION, FRONT

DOOR OUTER.......................23-93

BELT MOLDING - INSTALLATION, REAR

DOOR INNER........................23-94

BELT MOLDING - INSTALLATION, REAR

DOOR OUTER.......................23-94

BELT MOLDING - REMOVAL, FRONT

DOOR INNER........................23-93

BELT MOLDING - REMOVAL, FRONT

DOOR OUTER.......................23-93

BELT MOLDING - REMOVAL, REAR

DOOR INNER........................23-94

BELT MOLDING - REMOVAL, REAR

DOOR OUTER.......................23-94

BELT SWITCH - DESCRIPTION, SEAT.....8O-46

BELT SWITCH - DIAGNOSIS AND

TESTING, SEAT......................8O-47

BELT SWITCH - OPERATION, SEAT.......8O-46

BELT TENSION REDUCER -

DESCRIPTION, SEAT..................8O-48

BELT TENSION REDUCER - DIAGNOSIS

AND TESTING, SEAT..................8O-49

BELT TENSION REDUCER - OPERATION,

SEAT ..............................8O-49

BELT TENSIONER - DESCRIPTION, SEAT....8O-47

BELT TENSIONER - OPERATION, SEAT....8O-48

BELT TENSIONERS - 3.7L / 4.7L -

DESCRIPTION........................7-22

BELT TENSIONERS - 3.7L / 4.7L -

INSTALLATION........................7-23

BELT TENSIONERS - 3.7L / 4.7L -

OPERATION..........................7-22

BELT TENSIONERS - 3.7L / 4.7L -

REMOVAL...........................7-22

BELT TENSIONERS - 5.9L -

DESCRIPTION........................7-23

BELT TENSIONERS - 5.9L -

INSTALLATION........................7-24

BELT TENSIONERS - 5.9L - OPERATION....7-23

BELT TENSIONERS - 5.9L - REMOVAL.....7-23

BELT TENSIONERS - 5.9L DIESEL -

DESCRIPTION........................7-24

BELT TENSIONERS - 5.9L DIESEL -

INSTALLATION........................7-25

BELT TENSIONERS - 5.9L DIESEL -

OPERATION..........................7-24

BELT TENSIONERS - 5.9L DIESEL -

REMOVAL...........................7-25

BELT TURNING LOOP ADJUSTER -

INSTALLATION, SEAT.................8O-50

BELT TURNING LOOP ADJUSTER -

REMOVAL, SEAT.....................8O-50

BELT/CHAIN AND SPROCKETS -

INSPECTION, TIMING.............9-171,9-83

BELT/CHAIN AND SPROCKETS -

INSTALLATION, TIMING . 9-172,9-279,9-406,9-84

BELT/CHAIN AND SPROCKETS -

REMOVAL, TIMING.....9-169,9-279,9-405,9-81

BELTS - 3.7L / 4.7L - INSTALLATION,

DRIVE..............................7-27

BELTS - 3.7L / 4.7L - REMOVAL, DRIVE....7-27

BELTS - 5.9L - INSTALLATION, DRIVE.....7-31

BELTS - 5.9L - REMOVAL, DRIVE.........7-30

BELTS - 5.9L DIESEL - INSTALLATION,

DRIVE..............................7-34

BELTS - 5.9L DIESEL - REMOVAL, DRIVE . . 7-34

BEZEL - INSTALLATION, CLUSTER.......23-50

BEZEL - INSTALLATION, INSTRUMENT

PANEL CENTER......................23-58

BEZEL - INSTALLATION, INSTRUMENT

PANEL DRIVER SIDE..................23-59

BEZEL - INSTALLATION, INSTRUMENT

PANEL HEADLAMP SWITCH

............23-57

BEZEL - REMOVAL, CLUSTER

...........23-50

BEZEL - REMOVAL, INSTRUMENT PANEL

CENTER

............................23-58

BEZEL - REMOVAL, INSTRUMENT PANEL

DRIVER SIDE

........................23-58

BEZEL - REMOVAL, INSTRUMENT PANEL

HEADLAMP SWITCH

..................23-57

DRINDEX 3

Description Group-Page Description Group-Page Description Group-Page

Page 2859 of 2895

BIN - INSTALLATION, STORAGE.........23-62

BIN - INSTALLATION, UNDER SEAT

STORAGE...........................23-81

BIN - REMOVAL, STORAGE.............23-62

BIN - REMOVAL, UNDER SEAT STORAGE . . 23-81

BIN COVERING - INSTALLATION, UNDER

SEAT STORAGE......................23-81

BIN COVERING - REMOVAL, UNDER

SEAT STORAGE......................23-81

BIN LATCH - INSTALLATION, UNDER

SEAT STORAGE......................23-81

BIN LATCH - REMOVAL, UNDER SEAT

STORAGE...........................23-81

BLADE - DESCRIPTION, WIPER.........8R-19

BLADE - INSTALLATION, WIPER.........8R-20

BLADE - OPERATION, WIPER...........8R-19

BLADE - REMOVAL, WIPER............8R-19

BLEEDING - STANDARD PROCEDURE......5-27

BLEEDING - STANDARD PROCEDURE,

ABS BRAKE..........................5-40

BLEEDING - STANDARD PROCEDURE,

MANUAL.............................5-5

BLEEDING - STANDARD PROCEDURE,

MASTER CYLINDER...................5-20

BLEEDING - STANDARD PROCEDURE,

PRESSURE...........................5-5

BLEND DOOR - INSTALLATION..........24-25

BLEND DOOR - REMOVAL.............24-24

BLEND DOOR ACTUATOR -

DESCRIPTION.......................24-16

BLEND DOOR ACTUATOR -

INSTALLATION.......................24-17

BLEND DOOR ACTUATOR - OPERATION . . . 24-16

BLEND DOOR ACTUATOR - REMOVAL....24-17

BLOCK - CLEANING, ENGINE . 9-127,9-200,9-249,

9-38,9-380

BLOCK - DESCRIPTION, BLOWER

MOTOR RESISTOR...................24-17

BLOCK - DESCRIPTION, ENGINE.....9-126,9-37

BLOCK - INSPECTION, ENGINE....9-127,9-200,

9-249,9-38,9-380

BLOCK - INSTALLATION, BLOWER

MOTOR RESISTOR...................24-18

BLOCK - INSTALLATION, BRAKE

JUNCTION...........................5-19

BLOCK - OPERATION, BLOWER MOTOR

RESISTOR..........................24-17

BLOCK - REMOVAL, BLOWER MOTOR

RESISTOR..........................24-18

BLOCK - REMOVAL, BRAKE JUNCTION....5-19

BLOCK HEATER - 5.9L DIESEL -

DESCRIPTION, ENGINE.................7-43

BLOCK HEATER - 5.9L DIESEL -

INSTALLATION, ENGINE................7-44

BLOCK HEATER - 5.9L DIESEL -

OPERATION, ENGINE...................7-43

BLOCK HEATER - 5.9L DIESEL -

REMOVAL, ENGINE....................7-43

BLOCK HEATER - DESCRIPTION, ENGINE . . . 7-42

BLOCK HEATER - DIAGNOSIS AND

TESTING, ENGINE.....................7-42

BLOCK HEATER - INSTALLATION,

ENGINE.............................7-43

BLOCK HEATER - OPERATION, ENGINE....7-42

BLOCK HEATER - REMOVAL, ENGINE......7-43

BLOCK REFACING - STANDARD

PROCEDURE, CYLINDER

...............9-312

BLOWER MOTOR - DESCRIPTION

.......24-25

BLOWER MOTOR - DIAGNOSIS AND

TESTING

...........................24-26

BLOWER MOTOR - INSTALLATION

.......24-26

BLOWER MOTOR - OPERATION

.........24-25

BLOWER MOTOR - REMOVAL

...........24-26

BLOWER MOTOR RESISTOR -

DIAGNOSIS AND TESTING

.............24-18

BLOWER MOTOR RESISTOR BLOCK -

DESCRIPTION

.......................24-17

BLOWER MOTOR RESISTOR BLOCK -

INSTALLATION

.......................24-18

BLOWER MOTOR RESISTOR BLOCK -

OPERATION

.........................24-17

BLOWER MOTOR RESISTOR BLOCK -

REMOVAL

..........................24-18

BLOWER MOTOR SWITCH -

DESCRIPTION

.......................24-18

BLOWER MOTOR SWITCH - DIAGNOSIS

AND TESTING

.......................24-18BLOWER MOTOR SWITCH -

INSTALLATION.......................24-19

BLOWER MOTOR SWITCH - OPERATION . . 24-18

BLOWER MOTOR SWITCH - REMOVAL . . . 24-19

BODY - ADJUSTMENTS, VALVE . . 21-308,21-487

BODY - ASSEMBLY, VALVE......21-299,21-477,

21-590

BODY & CABLE - DESCRIPTION,

ANTENNA...........................8A-4

BODY & CABLE - INSTALLATION,

ANTENNA...........................8A-6

BODY & CABLE - OPERATION, ANTENNA . . . 8A-4

BODY & CABLE - REMOVAL, ANTENNA....8A-6

BODY - CLEANING, VALVE......21-298,21-476,

21-588

BODY - DESCRIPTION, THROTTLE.......14-45

BODY - DESCRIPTION, VALVE . . . 21-267,21-445,

21-584

BODY - DISASSEMBLY, VALVE . . . 21-287,21-465,

21-586

BODY - INSPECTION, VALVE....21-298,21-476,

21-588

BODY - INSTALLATION, THROTTLE.......14-47

BODY - INSTALLATION, VALVE . . . 21-307,21-486,

21-590

BODY - OPERATION, THROTTLE.........14-45

BODY - OPERATION, VALVE.....21-272,21-450,

21-585

BODY - REMOVAL, THROTTLE..........14-45

BODY - REMOVAL, VALVE . 21-286,21-464,21-585

BODY AND CABLE - DIAGNOSIS AND

TESTING, ANTENNA...................8A-4

BODY CODE PLATE - DESCRIPTION.....Intro.-4

BODY ISOLATORS - INSTALLATION......23-37

BODY ISOLATORS - REMOVAL..........23-36

BODY LUBRICATION - STANDARD

PROCEDURE.........................23-3

BODY OPENING DIMENSIONS -

SPECIFICATIONS.....................23-99

BODY PANEL REPAIR - STANDARD

PROCEDURE, PLASTIC.................23-3

BODY SIDE MOLDINGS - INSTALLATION . . 23-36

BODY SIDE MOLDINGS - REMOVAL......23-36

BODY, SPECIAL TOOLS................23-14

BODY VENT - INSTALLATION...........23-72

BODY VENT - REMOVAL...............23-72

BOOST PRESSURE - DIAGNOSIS AND

TESTING, TURBOCHARGER.............11-10

BOOSTER - DESCRIPTION, POWER

BRAKE..............................5-25

BOOSTER - DIAGNOSIS AND TESTING,

HYDRAULIC..........................5-25

BOOSTER - DIAGNOSIS AND TESTING,

MASTER CYLINDER/POWER.............5-20

BOOSTER - INSTALLATION, HYDRO-

BOOST BRAKE........................5-27

BOOSTER - INSTALLATION, POWER

BRAKE..............................5-25

BOOSTER - OPERATION, POWER BRAKE . . . 5-25

BOOSTER - REMOVAL, HYDRO-BOOST

BRAKE..............................5-27

BOOSTER - REMOVAL, POWER BRAKE....5-25

BOOT - INSTALLATION, 4WD FLOOR

SHIFT..............................23-64

BOOT - INSTALLATION, EXTENSION

HOUSING SEAL AND DUST......21-652,21-716

BOOT - REMOVAL, 4WD FLOOR SHIFT....23-63

BOOT - REMOVAL, EXTENSION HOUSING

SEAL AND DUST..............21-652,21-716

BORE - DE-GLAZE - STANDARD

PROCEDURE, CYLINDER...............9-313

BORE HONING - STANDARD

PROCEDURE, CYLINDER . 9-126,9-233,9-360,9-37

BORE REPAIR - STANDARD

PROCEDURE, CAM...................9-315

BORE REPAIR - STANDARD

PROCEDURE, CYLINDER...............9-313

BOX - INSTALLATION, CARGO..........23-37

BOX - INSTALLATION, GLOVE...........23-53

BOX - REMOVAL, CARGO..............23-37

BOX - REMOVAL, GLOVE..............23-53

BOX - TIE DOWN - INSTALLATION,

CARGO

............................23-37

BOX - TIE DOWN - REMOVAL, CARGO

....23-37

BOX LAMP/SWITCH - INSTALLATION,

GLOVE

.............................8L-25

BOX LAMP/SWITCH - REMOVAL, GLOVE

. . 8L-25

BOX LATCH - INSTALLATION, GLOVE

.....23-53BOX LATCH - REMOVAL, GLOVE.........23-53

B-PILLAR GRAB HANDLE -

INSTALLATION.......................23-69

B-PILLAR GRAB HANDLE - REMOVAL....23-69

B-PILLAR LOWER TRIM - INSTALLATION . . 23-65

B-PILLAR LOWER TRIM - REMOVAL.....23-64

B-PILLAR UPPER TRIM - INSTALLATION . . 23-65

B-PILLAR UPPER TRIM - REMOVAL......23-65

BRACKET - INSTALLATION, REARVIEW

MIRROR SUPPORT...................23-71

BRACKET - INSTALLATION, STEERING

COLUMN OPENING SUPPORT...........23-62

BRACKET - REMOVAL, STEERING

COLUMN OPENING SUPPORT...........23-61

BRACKETS - INSTALLATION, SEAT BACK

REAR - FOOTMANS LOOP..............23-85

BRACKETS - REMOVAL, SEAT BACK

REAR - FOOTMANS LOOP..............23-85

BRAKE - CLEANING, REAR DRUM IN

HAT ................................5-33

BRAKE - DESCRIPTION, CONTROLLER

ANTILOCK...........................8E-3

BRAKE - DESCRIPTION, PARKING........5-30

BRAKE - INSPECTION, REAR DRUM IN

HAT ................................5-33

BRAKE - INSTALLATION, CONTROLLER

ANTILOCK...........................8E-3

BRAKE - OPERATION, CONTROLLER

ANTILOCK...........................8E-3

BRAKE - OPERATION, PARKING..........5-30

BRAKE - REMOVAL, CONTROLLER

ANTILOCK...........................8E-3

BRAKE BLEEDING - STANDARD

PROCEDURE, ABS.....................5-40

BRAKE BOOSTER - DESCRIPTION,

POWER.............................5-25

BRAKE BOOSTER - INSTALLATION,

HYDRO-BOOST.......................5-27

BRAKE BOOSTER - INSTALLATION,

POWER.............................5-25

BRAKE BOOSTER - OPERATION, POWER . . . 5-25

BRAKE BOOSTER - REMOVAL,

HYDRO-BOOST.......................5-27

BRAKE BOOSTER - REMOVAL, POWER....5-25

BRAKE CABLE - INSTALLATION, FRONT

PARKING............................5-32

BRAKE CABLE - INSTALLATION, REAR

PARK...............................5-32

BRAKE CABLE - REMOVAL, FRONT

PARKING............................5-31

BRAKE CABLE - REMOVAL, REAR PARK . . . 5-31

BRAKE CALIPER ADAPTER MOUNT -

INSTALLATION, DISC...................5-17

BRAKE CALIPERS - DESCRIPTION, DISC . . . 5-11

BRAKE CALIPERS - OPERATION, DISC.....5-12

BRAKE FLUID CONTAMINATION -

DIAGNOSIS AND TESTING..............5-18

BRAKE FLUID LEVEL - STANDARD

PROCEDURE.........................5-18

BRAKE FLUID, SPECIFICATIONS..........5-18

BRAKE HOSE - INSTALLATION, FRONT......5-9

BRAKE HOSE - INSTALLATION, REAR.......5-9

BRAKE HOSE - REMOVAL, REAR..........5-8

BRAKE INDICATOR - DESCRIPTION,

BRAKE/PARK........................8J-18

BRAKE INDICATOR - DIAGNOSIS AND

TESTING...........................8J-19

BRAKE INDICATOR - OPERATION,

BRAKE/PARK........................8J-19

BRAKE JUNCTION BLOCK -

INSTALLATION........................5-19

BRAKE JUNCTION BLOCK - REMOVAL.....5-19

BRAKE LAMP - INSTALLATION...........8L-8

BRAKE LAMP - REMOVAL...............8L-8

BRAKE LAMP SWITCH - DESCRIPTION....8L-8

BRAKE LAMP SWITCH - DIAGNOSIS

AND TESTING........................8L-9

BRAKE LAMP SWITCH - INSTALLATION . . . 8L-10

BRAKE LAMP SWITCH - OPERATION......8L-8

BRAKE LAMP SWITCH - REMOVAL.......8L-9

BRAKE PADS/SHOES - INSTALLATION.....5-10

BRAKE PADS/SHOES - REMOVAL

.........5-10

BRAKE PROPORTIONING -

DESCRIPTION, ELECTRONIC VARIABLE

....5-43

BRAKE PROPORTIONING - OPERATION,

ELECTRONIC VARIABLE

................5-43

BRAKE SHOES - ADJUSTMENT, PARKING

. . 5-34

BRAKE, SPECIFICATIONS - BASE

..........5-7

4 INDEXDR

Description Group-Page Description Group-Page Description Group-Page

Page 2862 of 2895

CHECKING ENGINE OIL PRESSURE -

DIAGNOSIS AND TESTING....9-150,9-214,9-64

CHECKING TRANSMISSION CLUTCH

OPERATION - DIAGNOSIS AND

TESTING, AIR......................21-494

CHECKS - DIAGNOSIS AND TESTING,

PRELIMINARY........................7-10

CHILD RESTRAINT ANCHOR -

DESCRIPTION.......................8O-14

CHILD RESTRAINT ANCHOR -

INSTALLATION......................8O-17

CHILD RESTRAINT ANCHOR -

OPERATION.........................8O-16

CHILD RESTRAINT ANCHOR - REMOVAL . . 8O-16

CHIME CONDITIONS - DIAGNOSIS AND

TESTING............................8B-2

CHIME/BUZZER - DESCRIPTION..........8B-1

CHIME/BUZZER - OPERATION............8B-1

CIGAR LIGHTER OUTLET - DESCRIPTION . 8W-97-2

CIGAR LIGHTER OUTLET - DIAGNOSIS

AND TESTING.....................8W-97-2

CIGAR LIGHTER OUTLET - OPERATION . 8W-97-2

CIRCUIT - DIAGNOSIS AND TESTING,

AMBIENT TEMPERATURE SENSOR......8M-11

CIRCUIT - OPERATION, FUEL DRAIN.....14-78

CIRCUIT ACTUATION TEST MODE -

DESCRIPTION........................25-1

CIRCUIT FUNCTIONS - DESCRIPTION . . 8W-01-6

CIRCUIT INFORMATION - DESCRIPTION . 8W-01-5

CIRCUIT SENSE - DESCRIPTION,

IGNITION...........................8E-10

CIRCUIT SENSE - OPERATION, IGNITION . . 8E-12

CIRCUITS - OPERATION, NON-

MONITORED.........................25-8

CLAMPS - DESCRIPTION, HOSE...........7-3

CLAMPS - OPERATION, HOSE.............7-5

CLEANING/REVERSE FLUSHING -

STANDARD PROCEDURE, COOLING

SYSTEM............................7-17

CLEARANCE - STANDARD PROCEDURE,

CONNECTING ROD BEARING AND

CRANKSHAFT JOURNAL...............9-321

CLEARANCE - STANDARD PROCEDURE,

MAIN BEARING......................9-322

CLEARANCE LAMP - INSTALLATION, CAB . 8L-10

CLEARANCE LAMP - REMOVAL, CAB.....8L-10

CLOCKSPRING - DESCRIPTION.........8O-18

CLOCKSPRING - INSTALLATION.........8O-21

CLOCKSPRING - OPERATION...........8O-18

CLOCKSPRING - REMOVAL............8O-20

CLOCKSPRING CENTERING - STANDARD

PROCEDURE........................8O-19

CLUSTER - ASSEMBLY, INSTRUMENT....8J-15

CLUSTER - DESCRIPTION, INSTRUMENT . . . 8J-2

CLUSTER - DIAGNOSIS AND TESTING,

INSTRUMENT........................8J-10

CLUSTER - DISASSEMBLY, INSTRUMENT . . 8J-14

CLUSTER - INSTALLATION, INSTRUMENT . 8J-16

CLUSTER - OPERATION, INSTRUMENT.....8J-6

CLUSTER - REMOVAL, INSTRUMENT.....8J-14

CLUSTER BEZEL - INSTALLATION........23-50

CLUSTER BEZEL - REMOVAL...........23-50

CLUTCH - 5.9L DIESEL - DESCRIPTION,

FAN DRIVE VISCOUS...................7-55

CLUTCH - 5.9L DIESEL - OPERATION,

FAN DRIVE VISCOUS...................7-55

CLUTCH - ASSEMBLY, FRONT....21-206,21-386

CLUTCH - ASSEMBLY, LOW/REVERSE . . . 21-561

CLUTCH - ASSEMBLY, REAR.....21-250,21-428

CLUTCH - CLEANING, LOW/REVERSE....21-561

CLUTCH - CLEANING, REAR.....21-250,21-428

CLUTCH - DESCRIPTION.................6-1

CLUTCH - DESCRIPTION, A/C

COMPRESSOR........................24-9

CLUTCH - DESCRIPTION, FAN DRIVE

VISCOUS............................7-54

CLUTCH - DESCRIPTION, FRONT . 21-204,21-384

CLUTCH - DESCRIPTION, OVERDRIVE . . . 21-218,

21-396

CLUTCH - DESCRIPTION, REAR . . 21-248,21-426

CLUTCH - DIAGNOSIS AND TESTING.......6-2

CLUTCH - DISASSEMBLY, FRONT . 21-205,21-384

CLUTCH - DISASSEMBLY, LOW/REVERSE

. 21-560

CLUTCH - DISASSEMBLY, REAR

. . 21-249,21-427

CLUTCH - INSPECTION, A/C

COMPRESSOR

.......................24-12

CLUTCH - INSPECTION, FRONT

. . 21-206,21-385

CLUTCH - INSPECTION, LOW/REVERSE

. . 21-561CLUTCH - INSPECTION, REAR . . . 21-250,21-428

CLUTCH - INSTALLATION, A/C

COMPRESSOR.......................24-12

CLUTCH - OPERATION..................6-1

CLUTCH - OPERATION, A/C

COMPRESSOR........................24-9

CLUTCH - OPERATION, FAN DRIVE

VISCOUS............................7-54

CLUTCH - OPERATION, FRONT . . . 21-204,21-384

CLUTCH - OPERATION, OVERDRIVE....21-218,

21-396

CLUTCH - OPERATION, REAR....21-249,21-427

CLUTCH - REMOVAL, A/C COMPRESSOR . . 24-10

CLUTCH - SPECIFICATIONS...............6-6

CLUTCH - WARNING....................6-2

CLUTCH AND BAND OPERATION -

DIAGNOSIS AND TESTING, AIR

TESTING TRANSMISSION.......21-143,21-324

CLUTCH ASSEMBLY - ASSEMBLY, INPUT . 21-552

CLUTCH ASSEMBLY - DESCRIPTION,

INPUT............................21-549

CLUTCH ASSEMBLY - DISASSEMBLY,

INPUT............................21-550

CLUTCH ASSEMBLY - OPERATION,

INPUT............................21-549

CLUTCH BREAK-IN - STANDARD

PROCEDURE, A/C COMPRESSOR........24-10

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - ASSEMBLY,

OVERRUNNING...............21-239,21-416

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - CLEANING, OVERRUNNING. . . 21-238,

21-416

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - DESCRIPTION,

OVERRUNNING...............21-237,21-415

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - DISASSEMBLY,

OVERRUNNING...............21-238,21-415

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - INSPECTION,

OVERRUNNING...............21-238,21-416

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - OPERATION,

OVERRUNNING...............21-237,21-415

CLUTCH COIL - DIAGNOSIS AND

TESTING, A/C COMPRESSOR...........24-10

CLUTCH DISC - INSTALLATION............6-6

CLUTCH DISC - REMOVAL...............6-6

CLUTCH HOUSING - DIAGNOSIS AND

TESTING.............................6-8

CLUTCH HOUSING - INSTALLATION.......6-10

CLUTCH HOUSING - REMOVAL...........6-10

CLUTCH OPERATION - DIAGNOSIS AND

TESTING, AIR CHECKING

TRANSMISSION.....................21-494

CLUTCH PEDAL POSITION SWITCH -

DESCRIPTION........................6-14

CLUTCH PEDAL POSITION SWITCH -

DIAGNOSIS AND TESTING..............6-14

CLUTCH PEDAL POSITION SWITCH -

OPERATION..........................6-14

CLUTCH RELAY - DESCRIPTION, A/C

COMPRESSOR.......................24-13

CLUTCH RELAY - DIAGNOSIS AND

TESTING, COMPRESSOR...............24-13

CLUTCH RELAY - INSTALLATION, A/C

COMPRESSOR.......................24-14

CLUTCH RELAY - OPERATION, A/C

COMPRESSOR.......................24-13

CLUTCH RELAY - REMOVAL, A/C

COMPRESSOR.......................24-14

CLUTCH RELEASE BEARING -

INSTALLATION........................6-11

CLUTCH RELEASE BEARING - REMOVAL . . . 6-11

CLUTCHES - DESCRIPTION, HOLDING . . . 21-546

CLUTCHES - OPERATION, HOLDING.....21-546

COAT HOOK - INSTALLATION...........23-67

COAT HOOK - REMOVAL...............23-67

CODE - DESCRIPTION, PAINT...........23-74

CODE PLATE - DESCRIPTION, BODY

....Intro.-4

CODES - DESCRIPTION, DIAGNOSTIC

TROUBLE

............................25-1

CODES - SPECIFICATIONS, PAINT

........23-74

CODES - STANDARD PROCEDURE,

ERASING TRANSMITTER

..............8M-12

CODES - STANDARD PROCEDURE,

SETTING TRANSMITTER

..............8M-12COIL - DESCRIPTION, IGNITION.........8I-19

COIL - DIAGNOSIS AND TESTING, A/C

COMPRESSOR CLUTCH...............24-10

COIL - INSTALLATION, IGNITION.........8I-24

COIL - OPERATION, IGNITION...........8I-20

COIL - REMOVAL, IGNITION............8I-23

COIL CAPACITOR - DESCRIPTION,

IGNITION...........................8I-33

COIL CAPACITOR - INSTALLATION,

IGNITION...........................8I-33

COIL CAPACITOR - OPERATION,

IGNITION...........................8I-33

COIL CAPACITOR - REMOVAL, IGNITION . . . 8I-33

COIL RESISTANCE, 3.7L V-6 - IGNITION....8I-6

COIL RESISTANCE, 4.7L V-8 - IGNITION....8I-6

COIL RESISTANCE, 5.7L V-8 - IGNITION....8I-6

COIL RESISTANCE, 5.9L - IGNITION.......8I-6

COIL RESISTANCE, 8.0L V-10 ENGINE -

IGNITION............................8I-6

COLUMN - DESCRIPTION...............19-6

COLUMN - DIAGNOSIS AND TESTING,

STEERING...........................19-7

COLUMN - INSTALLATION...............19-9

COLUMN - REMOVAL..................19-7

COLUMN OPENING COVER -

INSTALLATION, STEERING.............23-61

COLUMN OPENING COVER - REMOVAL,

STEERING..........................23-61

COLUMN OPENING SUPPORT BRACKET

- INSTALLATION, STEERING..............23-62

COLUMN OPENING SUPPORT BRACKET

- REMOVAL, STEERING................23-61

COMBUSTION PRESSURE LEAKAGE -

DIAGNOSIS AND TESTING, CYLINDER....9-182,

9-231,9-359,9-8,9-92

COMMUNICATION - DESCRIPTION........8E-1

COMMUNICATION - OPERATION..........8E-2

COMPASS CALIBRATION - STANDARD

PROCEDURE.........................8M-3

COMPASS DEMAGNETIZING -

STANDARD PROCEDURE...............8M-4

COMPASS MINI-TRIP COMPUTER -

DIAGNOSIS AND TESTING..............8M-7

COMPASS VARIATION ADJUSTMENT -

STANDARD PROCEDURE...............8M-4

COMPASS/MINI-TRIP COMPUTER -

DESCRIPTION........................8M-6

COMPASS/MINI-TRIP COMPUTER -

INSTALLATION.......................8M-7

COMPASS/MINI-TRIP COMPUTER -

OPERATION.........................8M-7

COMPASS/MINI-TRIP COMPUTER -

REMOVAL...........................8M-7

COMPRESSION PRESSURE - DIAGNOSIS

AND TESTING, CYLINDER . . . 9-182,9-231,9-359,

9-8,9-92

COMPRESSION/LEAKAGE TESTS -

DIAGNOSIS AND TESTING, CYLINDER....9-288

COMPRESSOR CLUTCH - DESCRIPTION,

A/C ................................24-9

COMPRESSOR CLUTCH - INSPECTION,

A/C................................24-12

COMPRESSOR CLUTCH - INSTALLATION,

A/C

................................24-12

COMPRESSOR CLUTCH - OPERATION,

A/C

................................24-9

COMPRESSOR CLUTCH - REMOVAL, A/C

. . 24-10

COMPRESSOR CLUTCH BREAK-IN -

STANDARD PROCEDURE, A/C

...........24-10

COMPRESSOR CLUTCH COIL -

DIAGNOSIS AND TESTING, A/C

..........24-10

COMPRESSOR CLUTCH RELAY -

DESCRIPTION, A/C

...................24-13

COMPRESSOR CLUTCH RELAY -

DIAGNOSIS AND TESTING

.............24-13

COMPRESSOR CLUTCH RELAY -

INSTALLATION, A/C

...................24-14

COMPRESSOR CLUTCH RELAY -

OPERATION, A/C

.....................24-13

COMPRESSOR CLUTCH RELAY -

REMOVAL, A/C

......................24-14

COMPRESSOR NOISE - DIAGNOSIS AND

TESTING, A/C

.......................24-36

COMPUTER - DESCRIPTION, COMPASS/

MINI-TRIP

..........................8M-6

COMPUTER - DIAGNOSIS AND TESTING,

COMPASS MINI-TRIP

..................8M-7

DRINDEX 7

Description Group-Page Description Group-Page Description Group-Page

Page 2863 of 2895

COMPUTER - INSTALLATION, COMPASS/

MINI-TRIP..........................8M-7

COMPUTER - OPERATION, COMPASS/

MINI-TRIP..........................8M-7

COMPUTER - REMOVAL, COMPASS/

MINI-TRIP..........................8M-7

CONDENSER - DESCRIPTION, A/C.......24-39

CONDENSER - OPERATION, A/C.........24-39

CONDENSER FAN (GAS ENGINE ONLY -

3.7, 4.7 & 5.7L) - INSTALLATION........24-43

CONDENSER FAN (GAS ENGINE ONLY -

3.7, 4.7 & 5.7L) - REMOVAL............24-43

CONDITIONER - DESCRIPTION, HEATER

AND AIR ............................24-1

CONDITIONER - OPERATION, HEATER

AND AIR ............................24-1

CONDITIONING - INSTALLATION, WATER

PUMP BYPASS HOSE WITH AIR..........7-70

CONDITIONING - INSTALLATION, WATER

PUMP BYPASS HOSE WITHOUT AIR......7-70

CONDITIONING - REMOVAL, WATER

PUMP BYPASS HOSE WITH AIR..........7-68

CONDITIONING - REMOVAL, WATER

PUMP BYPASS HOSE WITHOUT AIR......7-69

CONDITIONS - DIAGNOSIS AND

TESTING, CHIME......................8B-2

CONDITIONS - DIAGNOSIS AND

TESTING, SPARK PLUG................8I-27

CONFIGURING A NEW MODULE /

SWITCH OPERATING MODES,

STANDARD PROCEDURE...............8Q-3

CONNECT FITTING - DESCRIPTION,

QUICK..............................14-8

CONNECTING ROD - CLEANING, PISTON . . 9-331

CONNECTING ROD - CLEANING, PISTON . . 9-138,

9-206,9-261,9-389

CONNECTING ROD - DESCRIPTION,

PISTON....9-137,9-205,9-260,9-329,9-388,9-47

CONNECTING ROD - INSPECTION........9-332

CONNECTING ROD - INSPECTION,

PISTON.............9-138,9-206,9-261,9-389

CONNECTING ROD - INSTALLATION,

PISTON.............9-139,9-207,9-261,9-389

CONNECTING ROD - REMOVAL, PISTON . . 9-137,

9-205,9-261,9-330,9-389

CONNECTING ROD BEARING AND

CRANKSHAFT JOURNAL CLEARANCE -

STANDARD PROCEDURE...............9-321

CONNECTING ROD BEARING FITTING -

STANDARD PROCEDURE.....9-128,9-251,9-382

CONNECTING ROD BEARING FITTING,

STANDARD PROCEDURE................9-48

CONNECTOR - DESCRIPTION, DATA LINK . . 8E-3

CONNECTOR - INSTALLATION.......8W-01-11

CONNECTOR - OPERATION, DATA LINK....8E-3

CONNECTOR - REMOVAL...........8W-01-11

CONNECTOR, GROUND AND SPLICE

INFORMATION - DESCRIPTION........8W-01-7

CONNECTOR/GROUND/SPLICE LOCATION

- DESCRIPTION....................8W-91-1

CONSOLE - DESCRIPTION, OVERHEAD....8M-1

CONSOLE - DIAGNOSIS AND TESTING,

OVERHEAD..........................8M-2

CONSOLE - INSTALLATION, FLOOR......23-68

CONSOLE - OPERATION, OVERHEAD

......8M-2

CONSOLE - REMOVAL, FLOOR

..........23-68

CONSOLE REMOVAL, REMOVAL -

OVERHEAD

..........................8M-5

CONSOLE, SPECIAL TOOLS - OVERHEAD

. . 8M-6

CONTAINER-3.7L/4.7L - DESCRIPTION,

COOLANT DEGAS

.....................7-38

CONTAINER-3.7L/4.7L - INSTALLATION,

COOLANT DEGAS

.....................7-39

CONTAINER-3.7L/4.7L - OPERATION,

COOLANT DEGAS

.....................7-38

CONTAINER-3.7L/4.7L - REMOVAL,

COOLANT DEGAS

.....................7-39

CONTAINER-5.9L - DESCRIPTION,

COOLANT RECOVERY

..................7-38

CONTAINER-5.9L - INSTALLATION,

COOLANT RECOVERY

..................7-38

CONTAINER-5.9L - OPERATION,

COOLANT RECOVERY

..................7-38

CONTAINER-5.9L - REMOVAL, COOLANT

RECOVERY

..........................7-38

CONTAMINATION - DIAGNOSIS AND

TESTING, BRAKE FLUID

................5-18CONTAMINATION - DIAGNOSIS AND

TESTING, FLUID........21-201,21-381,21-541

CONTINUITY - STANDARD PROCEDURE,

TESTING.........................8W-01-9

CONTOLLED VISCOUS FAN DRIVE -

DIAGNOSIS AND TESTING,

ELECTRONICLY.......................7-56

CONTROL ACTUATOR - DESCRIPTION,

FUEL..............................14-85

CONTROL ACTUATOR - INSTALLATION,

FUEL..............................14-85

CONTROL ACTUATOR - OPERATION,

FUEL..............................14-85

CONTROL ACTUATOR - REMOVAL, FUEL . . 14-85

CONTROL ARM - INSTALLATION, UPPER . . . 2-27

CONTROL ARM - REMOVAL, UPPER......2-27

CONTROL ARM BUSHINGS - 2WD (LD) -

INSTALLATION, LOWER.................2-14

CONTROL ARM BUSHINGS - 2WD (LD) -

REMOVAL, LOWER....................2-12

CONTROL ARM BUSHINGS - 4WD (LD) -

INSTALLATION, LOWER.................2-13

CONTROL ARM BUSHINGS - 4WD (LD) -

REMOVAL, LOWER....................2-12

CONTROL CABLE - INSTALLATION,

THROTTLE.....................14-51,14-96

CONTROL CABLE - REMOVAL,

THROTTLE.....................14-49,14-94

CONTROL INFORMATION (VECI) -

DESCRIPTION, VEHICLE EMISSION.....Intro.-3

CONTROL MODULE - DESCRIPTION,

AIRBAG............................8O-10

CONTROL MODULE - DESCRIPTION,

FRONT...........................8W-97-4

CONTROL MODULE - DESCRIPTION,

FRONT..............................8E-5

CONTROL MODULE - DESCRIPTION,

SIDE IMPACT AIRBAG.................8O-53

CONTROL MODULE - DESCRIPTION,

TRANSFER CASE.....................8E-15

CONTROL MODULE - DESCRIPTION,

TRANSMISSION......................8E-19

CONTROL MODULE - DIAGNOSIS AND

TESTING, FRONT...................8W-97-5

CONTROL MODULE - DIAGNOSIS AND

TESTING, FRONT......................8E-6

CONTROL MODULE - INSTALLATION,

AIRBAG............................8O-12

CONTROL MODULE - INSTALLATION,

ENGINE.............................8E-5

CONTROL MODULE - INSTALLATION,

FRONT...........................8W-97-5

CONTROL MODULE - INSTALLATION,

FRONT..............................8E-6

CONTROL MODULE - OPERATION,

AIRBAG............................8O-10

CONTROL MODULE - OPERATION,

FRONT...........................8W-97-5

CONTROL MODULE - OPERATION,

FRONT..............................8E-5

CONTROL MODULE - OPERATION, SIDE

IMPACT AIRBAG.....................8O-54

CONTROL MODULE - OPERATION,

TRANSFER CASE.....................8E-15

CONTROL MODULE - OPERATION,

TRANSMISSION......................8E-19

CONTROL MODULE - REMOVAL, AIRBAG

. 8O-11

CONTROL MODULE - REMOVAL, ENGINE

. . . 8E-4

CONTROL MODULE - REMOVAL, FRONT

. 8W-97-5

CONTROL MODULE - REMOVAL, FRONT

. . . 8E-6

CONTROL MOTOR - DESCRIPTION, IDLE

AIR

...............................14-33

CONTROL MOTOR - INSTALLATION, IDLE

AIR

...............................14-35

CONTROL MOTOR - OPERATION, IDLE

AIR

...............................14-33

CONTROL MOTOR - REMOVAL, IDLE AIR

. . 14-34

CONTROL RELAY - DESCRIPTION,

TRANSMISSION

.....................21-581

CONTROL RELAY - OPERATION,

TRANSMISSION

.....................21-581

CONTROL SWITCH - DESCRIPTION,

LUMBAR

...........................8N-19

CONTROL SWITCH - OPERATION,

LUMBAR

...........................8N-19

CONTROL SWITCH - REMOVAL,

LUMBAR

...........................8N-19CONTROLLER ANTILOCK BRAKE -

DESCRIPTION........................8E-3

CONTROLLER ANTILOCK BRAKE -

INSTALLATION........................8E-3

CONTROLLER ANTILOCK BRAKE -

OPERATION..........................8E-3

CONTROLLER ANTILOCK BRAKE -

REMOVAL...........................8E-3

CONTROLS - DIAGNOSIS AND TESTING,

OVERDRIVE ELECTRICAL.......21-219,21-397

CONVERTER - DESCRIPTION, CATALYTIC . . . 11-4

CONVERTER - DESCRIPTION, TORQUE . . 21-257,

21-434,21-575

CONVERTER - INSTALLATION, TORQUE . . 21-262,

21-439,21-580

CONVERTER - OPERATION, CATALYTIC....11-4

CONVERTER - OPERATION, TORQUE....21-261,

21-438,21-579

CONVERTER - REMOVAL, TORQUE.....21-262,

21-439,21-580

CONVERTER DRAINBACK VALVE -

DESCRIPTION, TORQUE........21-262,21-440

CONVERTER DRAINBACK VALVE -

OPERATION, TORQUE..........21-262,21-440

CONVERTER DRAINBACK VALVE -

STANDARD PROCEDURE, TORQUE.....21-262,

21-440

CONVERTER HOUSING FLUID LEAK -

DIAGNOSIS AND TESTING......21-143,21-324,

21-495

COOLANT - DESCRIPTION, ENGINE.......7-36

COOLANT - DESCRIPTION, ENGINE........0-3

COOLANT - DESCRIPTION, HOAT...........7-37

COOLANT - STANDARD PROCEDURE,

ADDING ADDITIONAL..................7-19

COOLANT DEGAS CONTAINER-3.7L/4.7L

- DESCRIPTION.......................7-38

COOLANT DEGAS CONTAINER-3.7L/4.7L

- INSTALLATION......................7-39

COOLANT DEGAS CONTAINER-3.7L/4.7L

- OPERATION.........................7-38

COOLANT DEGAS CONTAINER-3.7L/4.7L

- REMOVAL..........................7-39

COOLANT FLOW - DIAGNOSIS AND

TESTING, RADIATOR...............7-57,7-59

COOLANT LEVEL CHECK - STANDARD

PROCEDURE.........................7-17

COOLANT RECOVERY CONTAINER-5.9L -

DESCRIPTION........................7-38

COOLANT RECOVERY CONTAINER-5.9L -

INSTALLATION........................7-38

COOLANT RECOVERY CONTAINER-5.9L -

OPERATION..........................7-38

COOLANT RECOVERY CONTAINER-5.9L -

REMOVAL...........................7-38

COOLANT TEMPERATURE SENSOR -

DESCRIPTION, ENGINE.................7-44

COOLANT TEMPERATURE SENSOR -

INSTALLATION, ENGINE................7-47

COOLANT TEMPERATURE SENSOR -

OPERATION, ENGINE...................7-44

COOLANT TEMPERATURE SENSOR -

REMOVAL, ENGINE

....................7-44

COOLANT THERMOSTAT - 3.7L/4.7L -

DESCRIPTION, ENGINE

.................7-50

COOLANT THERMOSTAT - 3.7L/4.7L -

INSTALLATION, ENGINE

................7-51

COOLANT THERMOSTAT - 3.7L/4.7L -

OPERATION, ENGINE

...................7-51

COOLANT THERMOSTAT - 3.7L/4.7L -

REMOVAL, ENGINE

....................7-51

COOLANT THERMOSTAT - 5.9L DIESEL -

DESCRIPTION, ENGINE

.................7-52

COOLANT THERMOSTAT - 5.9L DIESEL -

INSTALLATION, ENGINE

................7-53

COOLANT THERMOSTAT - 5.9L DIESEL -

OPERATION, ENGINE

...................7-52

COOLANT THERMOSTAT - 5.9L DIESEL -

REMOVAL, ENGINE

....................7-53

COOLANT THERMOSTAT-5.7L/5.9L -

DESCRIPTION, ENGINE

.................7-47

COOLANT THERMOSTAT-5.7L/5.9L -

INSTALLATION, ENGINE

................7-49

COOLANT THERMOSTAT-5.7L/5.9L -

OPERATION, ENGINE

...................7-48

COOLANT THERMOSTAT-5.7L/5.9L -

REMOVAL, ENGINE

....................7-48

8 INDEXDR

Description Group-Page Description Group-Page Description Group-Page

Page 2864 of 2895

COOLER - 5.9L DIESEL - DESCRIPTION,

TRANS..............................7-73

COOLER - 5.9L DIESEL - OPERATION,

TRANS..............................7-74

COOLER - INSTALLATION, AIR TO OIL.....7-75

COOLER - INSTALLATION, FLUID........19-42

COOLER - INSTALLATION, RETURN

HOSE - GEAR TO................19-43,19-44

COOLER - INSTALLATION, RETURN

HOSE - RESERVOIR TO...........19-43,19-44

COOLER - REMOVAL, AIR TO OIL.........7-74

COOLER - REMOVAL, FLUID............19-42

COOLER - REMOVAL, RETURN HOSE -

GEAR TO...........................19-43

COOLER - REMOVAL, RETURN HOSE -

RESERVOIR TO.................19-43,19-44

COOLER - REMOVAL, WATER TO OIL......7-74

COOLER AND PLUMBING - CLEANING,

CHARGE AIR........................11-16

COOLER AND PLUMBING -

DESCRIPTION, CHARGE AIR............11-15

COOLER AND PLUMBING - INSPECTION,

CHARGE AIR........................11-16

COOLER AND PLUMBING -

INSTALLATION, CHARGE AIR...........11-16

COOLER AND PLUMBING - OPERATION,

CHARGE AIR........................11-15

COOLER AND PLUMBING - REMOVAL,

CHARGE AIR........................11-15

COOLER SYSTEM - LEAKS - DIAGNOSIS

AND TESTING, CHARGE AIR............11-15

COOLING, SPECIAL TOOLS...............7-20

COOLING SYSTEM - OPERATION..........7-3

COOLING SYSTEM - TESTING FOR

LEAKS - DIAGNOSIS AND TESTING........7-5

COOLING SYSTEM 3.7L/4.7L/5.7L

ENGINE - STANDARD PROCEDURE,

DRAINING...........................7-18

COOLING SYSTEM 3.7L/4.7L/5.7L

ENGINE - STANDARD PROCEDURE,

REFILLING...........................7-18

COOLING SYSTEM 5.9L DIESEL ENGINE

- STANDARD PROCEDURE, DRAINING.....7-19

COOLING SYSTEM 5.9L DIESEL ENGINE

- STANDARD PROCEDURE, REFILLING.....7-19

COOLING SYSTEM 5.9L/8.0L ENGINE -

STANDARD PROCEDURE, DRAINING......7-18

COOLING SYSTEM 5.9L/8.0L ENGINE -

STANDARD PROCEDURE, REFILLING......7-18

COOLING SYSTEM CLEANING/REVERSE

FLUSHING - STANDARD PROCEDURE.....7-17

COOLING SYSTEM DIESEL ENGINE -

DIAGNOSIS AND TESTING...............7-7

COOLING SYSTEM FLOW - 5.9L DIESEL

- DESCRIPTION........................7-2

COOLING SYSTEM FLOW - 5.9L ENGINE

- DESCRIPTION........................7-1

COOLING SYSTEM FLOW 3.7L/4.7L

ENGINE - DESCRIPTION.................7-1

COOLING SYSTEM REQUIREMENTS -

DESCRIPTION........................24-1

CORE - DESCRIPTION, HEATER.........24-50

CORE - INSTALLATION, HEATER.........24-50

CORE - OPERATION, HEATER...........24-50

CORE - REMOVAL, HEATER

............24-50

CORE HOLE PLUG - INSTALLATION,

CAMSHAFT

.........................9-201

CORE HOLE PLUG - REMOVAL,

CAMSHAFT

.........................9-200

CORE PLUGS - INSTALLATION

..........9-130

CORE PLUGS - REMOVAL

..............9-129

COUPLER - DESCRIPTION,

REFRIGERANT LINE

...................24-52

COUPLER - INSTALLATION,

REFRIGERANT LINE

...................24-53

COUPLER - OPERATION, REFRIGERANT

LINE

...............................24-52

COUPLER - REMOVAL, REFRIGERANT

LINE

...............................24-52

COUPLING - INSTALLATION, UPPER

STEERING

..........................19-14

COUPLING - REMOVAL, UPPER

STEERING

..........................19-13

COVER - DESCRIPTION, STRUCTURAL

. . . 9-143,

9-210,9-56

COVER - FRONT - INSTALLATION, SEAT

BACK CUSHION

......................23-83COVER - FRONT - INSTALLATION, SEAT

CUSHION...........................23-83

COVER - FRONT - REMOVAL, SEAT BACK

CUSHION...........................23-83

COVER - FRONT - REMOVAL, SEAT

CUSHION...........................23-83

COVER - INSTALLATION...............23-16

COVER - INSTALLATION, ACM...........8O-9

COVER - INSTALLATION, CENTER SEAT

BACK INERTIA HINGE.................23-78

COVER - INSTALLATION, CENTER SEAT

CUSHION...........................23-81

COVER - INSTALLATION, CYLINDER

HEAD..............................9-304

COVER - INSTALLATION, GEAR HOUSING . 9-350

COVER - INSTALLATION, INSTRUMENT

PANEL TOP.........................23-60

COVER - INSTALLATION, REAR DOOR

SILL TRIM..........................23-72

COVER - INSTALLATION, SHIFT . . . 21-128,21-86

COVER - INSTALLATION, STEERING

COLUMN OPENING...................23-61

COVER - INSTALLATION, STRUCTURAL . . . 9-143,

9-210,9-56

COVER - INSTALLATION, TIMING/CHAIN . . 9-221

COVER - OPERATION, STRUCTURAL.....9-143,

9-210,9-56

COVER - REAR - INSTALLATION, SEAT

BACK CUSHION......................23-85

COVER - REAR - INSTALLATION, SEAT

CUSHION...........................23-85

COVER - REAR - REMOVAL, SEAT BACK

CUSHION...........................23-85

COVER - REAR - REMOVAL, SEAT

CUSHION...........................23-85

COVER - REMOVAL...................23-16

COVER - REMOVAL, ACM...............8O-9

COVER - REMOVAL, CENTER SEAT BACK

INERTIA HINGE......................23-78

COVER - REMOVAL, CENTER SEAT

CUSHION...........................23-81

COVER - REMOVAL, CYLINDER HEAD....9-304

COVER - REMOVAL, GEAR HOUSING.....9-349

COVER - REMOVAL, INSTRUMENT

PANEL TOP.........................23-59

COVER - REMOVAL, REAR DOOR SILL

TRIM..............................23-72

COVER - REMOVAL, SHIFT.......21-128,21-86

COVER - REMOVAL, STEERING COLUMN

OPENING...........................23-61

COVER - REMOVAL, STRUCTURAL . 9-143,9-210,

9-56

COVER - REMOVAL, TIMING/CHAIN......9-220

COVER - REMOVAL, WHEEL............22-14

COVER GASKET - DESCRIPTION,

CYLINDER HEAD.....................9-243

COVER GASKET - OPERATION,

CYLINDER HEAD.....................9-243

COVER INSTALLED - INSTALLATION,

FRONT OIL SEAL - FRONT.............9-384

COVER INSTALLED - REMOVAL, FRONT

OIL SEAL - FRONT...................9-384

COVER REMOVED - INSTALLATION,

FRONT OIL SEAL - FRONT.............9-384

COVER REMOVED - REMOVAL, FRONT

OIL SEAL - FRONT...................9-384

COVERING - INSTALLATION, UNDER

SEAT STORAGE BIN..................23-81

COVERING - REMOVAL, UNDER SEAT

STORAGE BIN.......................23-81

COVER(S) - CLEANING, CYLINDER HEAD . 9-245,

9-374

COVER(S) - DESCRIPTION, CYLINDER

HEAD.....................9-121,9-26,9-373

COVER(S) - INSPECTION, CYLINDER

HEAD.........................9-245,9-374

COVER(S) - INSTALLATION, CYLINDER

HEAD............9-196,9-245,9-27,9-36,9-374

COVER(S) - INSTALLATION, TIMING

BELT / CHAIN.........9-169,9-278,9-404,9-81

COVER(S) - REMOVAL, CYLINDER HEAD . 9-196,

9-245,9-26,9-35,9-373

COVER(S) - REMOVAL, TIMING BELT /

CHAIN

...............9-168,9-278,9-404,9-80

COWL GRILLE - INSTALLATION

.........23-38

COWL GRILLE - REMOVAL

.............23-38

COWL TRIM - INSTALLATION

...........23-67

COWL TRIM - REMOVAL

...............23-67C-PILLAR LOWER TRIM - INSTALLATION . . 23-68

C-PILLAR LOWER TRIM - REMOVAL.....23-67

C-PILLAR UPPER TRIM - INSTALLATION . . 23-68

C-PILLAR UPPER TRIM - REMOVAL......23-68

CRANKCASE BREATHER - INSTALLATION . . 9-292

CRANKCASE BREATHER - REMOVAL.....9-291

CRANKSHAFT - DESCRIPTION . 9-130,9-252,9-39

CRANKSHAFT - INSPECTION........9-131,9-40

CRANKSHAFT - INSTALLATION....9-131,9-202,

9-252,9-383,9-41

CRANKSHAFT - OPERATION............9-252

CRANKSHAFT - REMOVAL . . . 9-130,9-201,9-252,

9-382,9-39

CRANKSHAFT AND GEAR -

DESCRIPTION.......................9-322

CRANKSHAFT JOURNAL CLEARANCE -

STANDARD PROCEDURE, CONNECTING

ROD BEARING.......................9-321

CRANKSHAFT MAIN BEARING - FITTING

- STANDARD PROCEDURE........9-133,9-202

CRANKSHAFT MAIN BEARING FITTING -

STANDARD PROCEDURE...............9-253

CRANKSHAFT MAIN BEARINGS -

DESCRIPTION.......................9-253

CRANKSHAFT MAIN BEARINGS -

INSPECTION...................9-133,9-203

CRANKSHAFT MAIN BEARINGS -

INSTALLATION..................9-254,9-383

CRANKSHAFT MAIN BEARINGS -

OPERATION.........................9-253

CRANKSHAFT MAIN BEARINGS -

REMOVAL.....................9-254,9-383

CRANKSHAFT MAIN BEARINGS -

STANDARD PROCEDURE, FITTING.......9-383

CRANKSHAFT OIL SEAL - FRONT -

DESCRIPTION.......................9-254

CRANKSHAFT OIL SEAL - FRONT -

INSTALLATION . . . 9-134,9-203,9-255,9-324,9-45

CRANKSHAFT OIL SEAL - FRONT -

OPERATION.........................9-254

CRANKSHAFT OIL SEAL - FRONT -

REMOVAL.......9-134,9-203,9-254,9-323,9-44

CRANKSHAFT OIL SEAL - REAR -

DESCRIPTION.......................9-255

CRANKSHAFT OIL SEAL - REAR -

INSTALLATION . . 9-136,9-204,9-256,9-325,9-385,

9-46

CRANKSHAFT OIL SEAL - REAR -

OPERATION.........................9-255

CRANKSHAFT OIL SEAL - REAR -

REMOVAL . . 9-135,9-204,9-255,9-325,9-385,9-45

CRANKSHAFT POSITION SENSOR -

DESCRIPTION..................14-26,14-83

CRANKSHAFT POSITION SENSOR -

INSTALLATION..................14-30,14-84

CRANKSHAFT POSITION SENSOR -

OPERATION....................14-26,14-83

CRANKSHAFT POSITION SENSOR -

REMOVAL.....................14-29,14-84

CRANKSHAFT REAR OIL SEAL RETAINER

- INSTALLATION...........9-205,9-326,9-386

CRANKSHAFT REAR OIL SEAL RETAINER

- REMOVAL...............9-204,9-326,9-386

CROSS MEMBER BUSHING -

INSTALLATION, TORSION BAR...........2-14

CROSSHEADS - CLEANING.............9-300

CROSSHEADS - INSPECTION...........9-301

CROSSMEMBER - INSTALLATION, FRONT . 13-23

CROSSMEMBER - INSTALLATION,

TRANSMISSION......................13-25

CROSSMEMBER - INSTALLATION,

UPPER RADIATOR

....................23-42

CROSSMEMBER - REMOVAL, FRONT

.....13-23

CROSSMEMBER - REMOVAL,

TRANSMISSION

......................13-24

CROSSMEMBER - REMOVAL, UPPER

RADIATOR

..........................23-42

CROSSMEMBER BUSHING - REMOVAL,

TORSION BAR

........................2-12

CRUISE INDICATOR - DESCRIPTION

......8J-22

CRUISE INDICATOR - OPERATION

.......8J-22

CUP HOLDER - INSTALLATION

..........23-52

CUP HOLDER - REMOVAL

..............23-52

CURTAIN AIRBAG - DESCRIPTION, SIDE

. . 8O-51

CURTAIN AIRBAG - INSTALLATION, SIDE

. . 8O-53

CURTAIN AIRBAG - OPERATION, SIDE

....8O-51

CURTAIN AIRBAG - REMOVAL, SIDE

.....8O-52

DRINDEX 9

Description Group-Page Description Group-Page Description Group-Page

Page 2865 of 2895

CUSHION / COVER - FRONT -

INSTALLATION, SEAT.................23-83

CUSHION / COVER - FRONT -

INSTALLATION, SEAT BACK............23-83

CUSHION / COVER - FRONT - REMOVAL,

SEAT ..............................23-83

CUSHION / COVER - FRONT - REMOVAL,

SEAT BACK.........................23-83

CUSHION / COVER - REAR -

INSTALLATION, SEAT.................23-85

CUSHION / COVER - REAR -

INSTALLATION, SEAT BACK............23-85

CUSHION / COVER - REAR - REMOVAL,

SEAT ..............................23-85

CUSHION / COVER - REAR - REMOVAL,

SEAT BACK.........................23-85

CUSHION - INSTALLATION, CENTER

SEAT ..............................23-80

CUSHION - REMOVAL, CENTER SEAT.....23-80

CUSHION COVER - INSTALLATION,

CENTER SEAT.......................23-81

CUSHION COVER - REMOVAL, CENTER

SEAT ..............................23-81

CUSHION FRAME - REAR -

INSTALLATION, SEAT.................23-85

CUSHION FRAME - REAR - REMOVAL,

SEAT ..............................23-85

CUSTOMER PREFERENCES - STANDARD

PROCEDURE, RKE TRANSMITTER........8N-9

CV JOINT-INNER - INSTALLATION........3-16

CV JOINT-INNER - REMOVAL............3-16

CV JOINT-OUTER - INSTALLATION........3-13

CV JOINT-OUTER - REMOVAL............3-13

CYLINDER - DESCRIPTION, MASTER......5-19

CYLINDER - DIAGNOSIS AND TESTING,

IGNITION SWITCH AND KEY LOCK.......19-11

CYLINDER - INSTALLATION, KEY........19-12

CYLINDER - INSTALLATION, LOAD

FLOOR SUPPORT....................23-73

CYLINDER - INSTALLATION, LOCK.......23-24

CYLINDER - INSTALLATION, SUPPORT....23-49

CYLINDER - OPERATION, MASTER........5-20

CYLINDER - REMOVAL, KEY............19-12

CYLINDER - REMOVAL, LOAD FLOOR

SUPPORT..........................23-73

CYLINDER - REMOVAL, LOCK...........23-24

CYLINDER - REMOVAL, SUPPORT.......23-48

CYLINDER BLEEDING - STANDARD

PROCEDURE, MASTER.................5-20

CYLINDER BLOCK REFACING -

STANDARD PROCEDURE...............9-312

CYLINDER BORE - DE-GLAZE -

STANDARD PROCEDURE...............9-313

CYLINDER BORE HONING - STANDARD

PROCEDURE..........9-126,9-233,9-360,9-37

CYLINDER BORE REPAIR - STANDARD

PROCEDURE........................9-313

CYLINDER COMBUSTION PRESSURE

LEAKAGE - DIAGNOSIS AND TESTING....9-182,

9-231,9-359,9-8,9-92

CYLINDER COMPRESSION PRESSURE -

DIAGNOSIS AND TESTING . . . 9-182,9-231,9-359,

9-8,9-92

CYLINDER COMPRESSION/LEAKAGE

TESTS - DIAGNOSIS AND TESTING......9-288

CYLINDER HEAD - CLEANING . 9-195,9-300,9-372

CYLINDER HEAD - DESCRIPTION . . 9-106,9-243,

9-298,9-370

CYLINDER HEAD - INSPECTION....9-195,9-301,

9-372

CYLINDER HEAD - INSTALLATION . . 9-195,9-372

CYLINDER HEAD - INSTALLATION, LEFT . . 9-110

CYLINDER HEAD - INSTALLATION,

RIGHT.............................9-111

CYLINDER HEAD - LEFT - INSTALLATION . . . 9-23

CYLINDER HEAD - LEFT - REMOVAL......9-21

CYLINDER HEAD - OPERATION.....9-194,9-243

CYLINDER HEAD - REMOVAL . 9-195,9-298,9-371

CYLINDER HEAD - REMOVAL, LEFT......9-106

CYLINDER HEAD - REMOVAL, RIGHT.....9-108

CYLINDER HEAD - RIGHT -

INSTALLATION

........................9-32

CYLINDER HEAD - RIGHT - REMOVAL

.....9-32

CYLINDER HEAD COVER -

INSTALLATION

.......................9-304

CYLINDER HEAD COVER - REMOVAL

.....9-304

CYLINDER HEAD COVER GASKET -

DESCRIPTION

.......................9-243CYLINDER HEAD COVER GASKET -

OPERATION.........................9-243

CYLINDER HEAD COVER(S) - CLEANING . . 9-245,

9-374

CYLINDER HEAD COVER(S) -

DESCRIPTION..............9-121,9-26,9-373

CYLINDER HEAD COVER(S) -

INSPECTION...................9-245,9-374

CYLINDER HEAD COVER(S) -

INSTALLATION....9-196,9-245,9-27,9-36,9-374

CYLINDER HEAD COVER(S) - REMOVAL . . 9-196,

9-245,9-26,9-35,9-373

CYLINDER HEAD GASKET - DIAGNOSIS

AND TESTING........................9-20

CYLINDER HEAD GASKET FAILURE -

DIAGNOSIS AND TESTING . . . 9-194,9-243,9-370

CYLINDER/POWER BOOSTER -

DIAGNOSIS AND TESTING, MASTER......5-20

DAM - INSTALLATION, FRONT AIR........13-2

DAM - REMOVAL, FRONT AIR...........13-2

DAMAGED OR WORN THREADS -

STANDARD PROCEDURE, REPAIR . . 9-186,9-232,

9-289,9-361,9-9,9-93

DAMPER - INSPECTION, VIBRATION.....9-335

DAMPER - INSTALLATION..............19-35

DAMPER - INSTALLATION, VIBRATION . . . 9-142,

9-209,9-263,9-335,9-392,9-55

DAMPER - REMOVAL.................19-35

DAMPER - REMOVAL, VIBRATION . . 9-141,9-209,

9-263,9-335,9-392,9-54

DATA LINK CONNECTOR - DESCRIPTION . . . 8E-3

DATA LINK CONNECTOR - OPERATION......8E-3

DATA PLATE - DESCRIPTION, ENGINE....9-297

DAY / NIGHT MIRROR - DESCRIPTION,

AUTOMATIC........................8N-12

DAY / NIGHT MIRROR - DIAGNOSIS AND

TESTING, AUTOMATIC................8N-12

DAY / NIGHT MIRROR - OPERATION,

AUTOMATIC........................8N-12

DAY / NIGHT MIRROR - REMOVAL,

AUTOMATIC........................8N-13

DEFINITION - DESCRIPTION, TRIP........25-4

DEFROST DOOR - INSTALLATION........24-27

DEFROST DOOR - INSTALLATION, FLOOR . 24-30

DEFROST DOOR - REMOVAL...........24-27

DEFROST DOOR - REMOVAL, FLOOR.....24-30

DEFROST DOOR ACTUATOR -

INSTALLATION, FLOOR................24-20

DEFROST DOOR ACTUATOR - REMOVAL,

FLOOR.............................24-19

DEGAS CONTAINER-3.7L/4.7L -

DESCRIPTION, COOLANT...............7-38

DEGAS CONTAINER-3.7L/4.7L -

INSTALLATION, COOLANT...............7-39

DEGAS CONTAINER-3.7L/4.7L -

OPERATION, COOLANT.................7-38

DEGAS CONTAINER-3.7L/4.7L -

REMOVAL, COOLANT..................7-39

DE-GLAZE - STANDARD PROCEDURE,

CYLINDER BORE.....................9-313

DEMAGNETIZING - STANDARD

PROCEDURE, COMPASS...............8M-4

DEPLOYMENT - STANDARD

PROCEDURE, SERVICE AFTER A

SUPPLEMENTAL RESTRAINT

............8O-7

DETECTION ASSY - DESCRIPTION,

NATURAL VAC LEAK

..................25-23

DETECTION ASSY - INSTALLATION,

NATURAL VAC LEAK

..................25-24

DETECTION ASSY - OPERATION,

NATURAL VAC LEAK

..................25-23

DETECTION ASSY - REMOVAL, NATURAL

VAC LEAK

..........................25-24

DETECTION PUMP - DESCRIPTION, LEAK

. 25-13

DETECTION PUMP - INSTALLATION,

LEAK

..............................25-16