light DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2186 of 2895

(4) Compress rear servo piston with C-clamp or

Valve Spring Compressor C-3422-B and install servo

piston snap-ring (Fig. 45).

(5) Lubricate front servo piston components and

servo bore in case with transmission fluid.

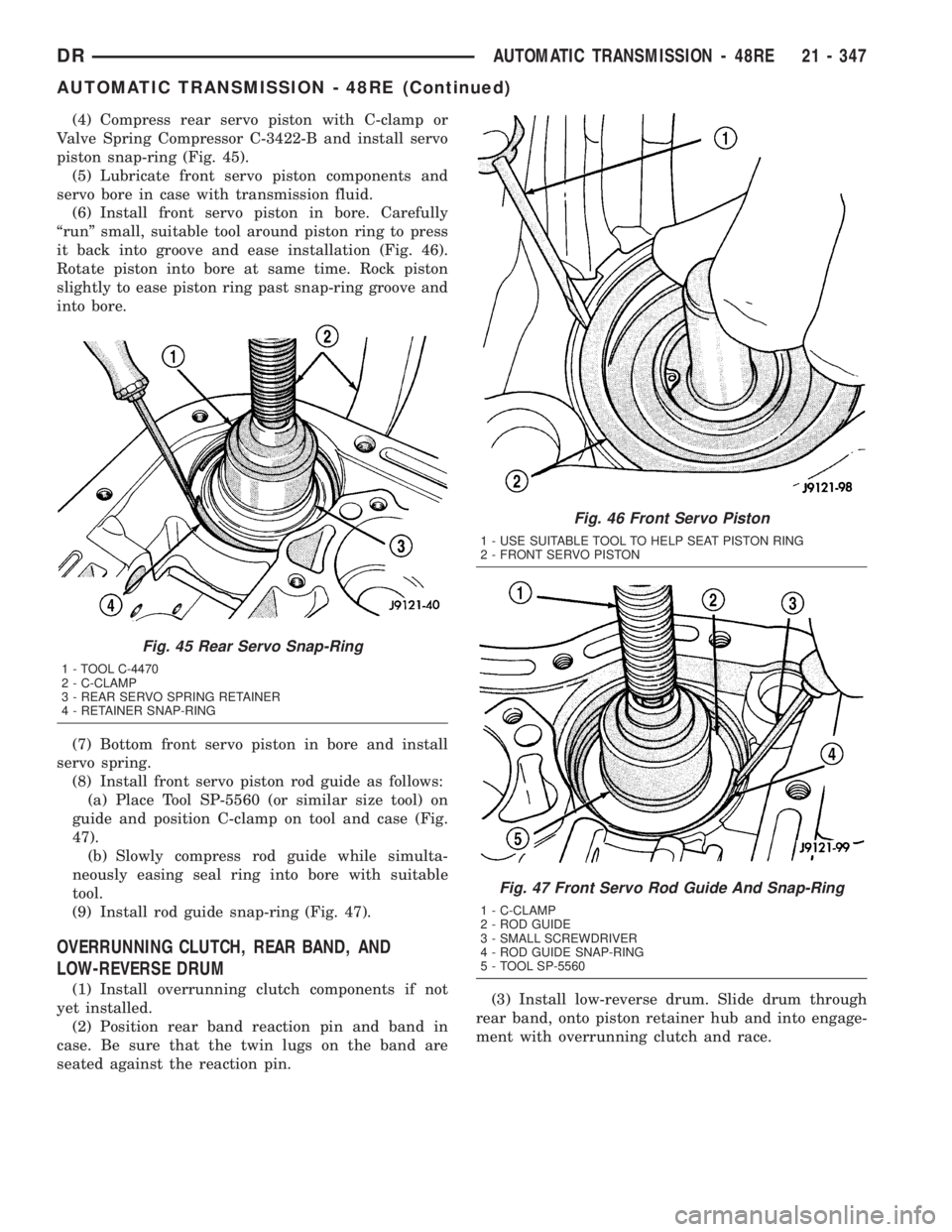

(6) Install front servo piston in bore. Carefully

ªrunº small, suitable tool around piston ring to press

it back into groove and ease installation (Fig. 46).

Rotate piston into bore at same time. Rock piston

slightly to ease piston ring past snap-ring groove and

into bore.

(7) Bottom front servo piston in bore and install

servo spring.

(8) Install front servo piston rod guide as follows:

(a) Place Tool SP-5560 (or similar size tool) on

guide and position C-clamp on tool and case (Fig.

47).

(b) Slowly compress rod guide while simulta-

neously easing seal ring into bore with suitable

tool.

(9) Install rod guide snap-ring (Fig. 47).

OVERRUNNING CLUTCH, REAR BAND, AND

LOW-REVERSE DRUM

(1) Install overrunning clutch components if not

yet installed.

(2) Position rear band reaction pin and band in

case. Be sure that the twin lugs on the band are

seated against the reaction pin.(3) Install low-reverse drum. Slide drum through

rear band, onto piston retainer hub and into engage-

ment with overrunning clutch and race.

Fig. 45 Rear Servo Snap-Ring

1 - TOOL C-4470

2 - C-CLAMP

3 - REAR SERVO SPRING RETAINER

4 - RETAINER SNAP-RING

Fig. 46 Front Servo Piston

1 - USE SUITABLE TOOL TO HELP SEAT PISTON RING

2 - FRONT SERVO PISTON

Fig. 47 Front Servo Rod Guide And Snap-Ring

1 - C-CLAMP

2 - ROD GUIDE

3 - SMALL SCREWDRIVER

4 - ROD GUIDE SNAP-RING

5 - TOOL SP-5560

DRAUTOMATIC TRANSMISSION - 48RE 21 - 347

AUTOMATIC TRANSMISSION - 48RE (Continued)

Page 2192 of 2895

(10) Install torque converter. Use C-clamp or metal

strap to hold converter in place for installation.

BAND ADJUSTMENT AND FINAL

(1) Adjust front and rear bands as follows:

(a) Loosen locknut on each band adjusting screw

4-5 turns.

(b) Tighten both adjusting screws to 8 N´m (72

in. lbs.).

(c) Back off front band adjusting screw 1-3/4

turns.

(d) Back off rear band adjusting screw 3 turns.

(e) Hold each adjusting screw in position and

tighten locknut to 34 N´m (25 ft. lbs.) torque.

(2) Install magnet in oil pan. Magnet seats on

small protrusion at corner of pan.

(3) Position new oil pan gasket on case and install

oil pan. Tighten pan bolts to 13.6 N´m (125 in. lbs.).

(4) Install throttle valve and shift selector levers

on valve body manual lever shaft.

(5) Apply small quantity of dielectric grease to ter-

minal pins of solenoid case connector and neutral

switch.

(6) Fill transmission with recommended fluid.

INSTALLATION

(1) Check torque converter hub inner and outer

diameters and hub drive notches for sharp edges

burrs, scratches, or nicks. Polish the hub and notches

with 320/400 grit paper and crocus cloth if necessary.

The hub must be smooth to avoid damaging pump

seal at installation.

(2) Lubricate pocket in the rear oil pump seal lip

with transmission fluid.

(3) Lubricate converter pilot hub of the crankshaft

with a light coating of MopartHigh Temp Grease.

(4) Align and install converter in oil pump.

(5) Carefully insert converter in oil pump. Then

rotate converter back and forth until fully seated in

pump gears.

(6) Check converter seating with steel scale and

straightedge (Fig. 65). Surface of converter lugs

should be 19mm (0.75 in.) to rear of straightedge

when converter is fully seated.

(7) Temporarily secure converter with C-clamp.

(8) Position transmission on jack and secure it

with chains.

(9) Check condition of converter driveplate.

Replace the plate if cracked, distorted or damaged.

Also be sure transmission dowel pins are seated

in engine block and protrude far enough to

hold transmission in alignment.

(10) Raise transmission and align converter with

drive plate and converter housing with engine block.

(11) Move transmission forward. Then raise, lower

or tilt transmission to align converter housing with

engine block dowels.

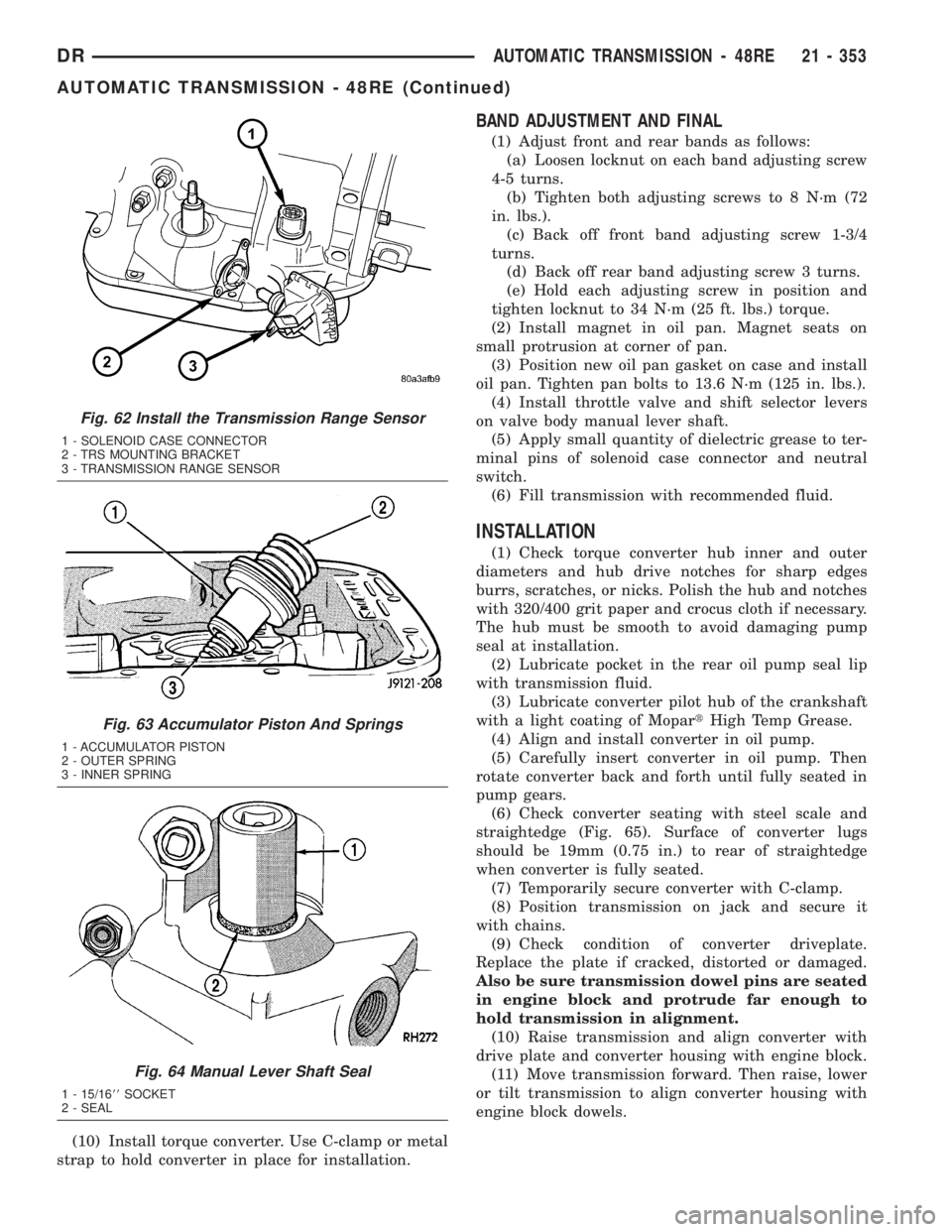

Fig. 62 Install the Transmission Range Sensor

1 - SOLENOID CASE CONNECTOR

2 - TRS MOUNTING BRACKET

3 - TRANSMISSION RANGE SENSOR

Fig. 63 Accumulator Piston And Springs

1 - ACCUMULATOR PISTON

2 - OUTER SPRING

3 - INNER SPRING

Fig. 64 Manual Lever Shaft Seal

1 - 15/1688SOCKET

2 - SEAL

DRAUTOMATIC TRANSMISSION - 48RE 21 - 353

AUTOMATIC TRANSMISSION - 48RE (Continued)

Page 2213 of 2895

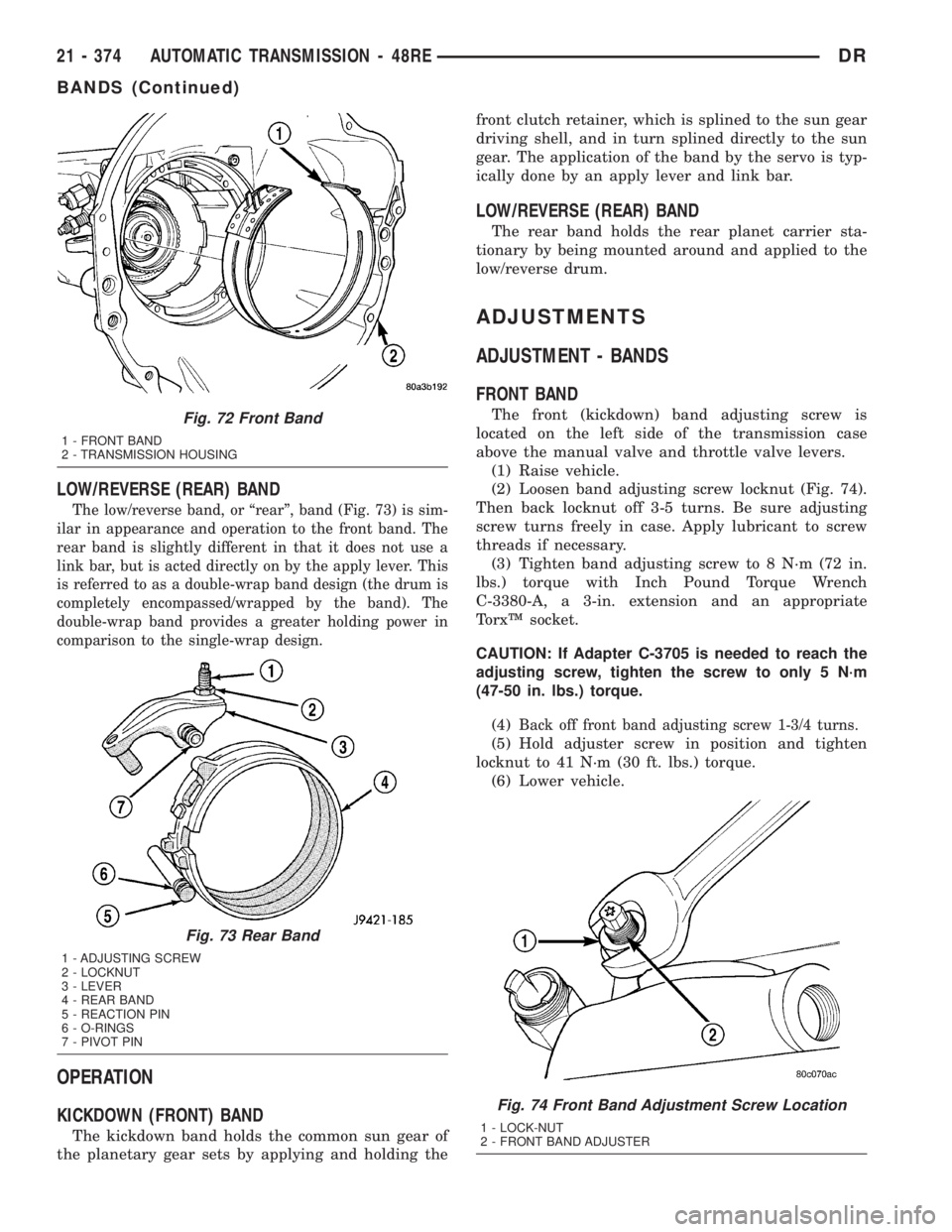

LOW/REVERSE (REAR) BAND

The low/reverse band, or ªrearº, band (Fig. 73) is sim-

ilar in appearance and operation to the front band. The

rear band is slightly different in that it does not use a

link bar, but is acted directly on by the apply lever. This

is referred to as a double-wrap band design (the drum is

completely encompassed/wrapped by the band). The

double-wrap band provides a greater holding power in

comparison to the single-wrap design.

OPERATION

KICKDOWN (FRONT) BAND

The kickdown band holds the common sun gear of

the planetary gear sets by applying and holding thefront clutch retainer, which is splined to the sun gear

driving shell, and in turn splined directly to the sun

gear. The application of the band by the servo is typ-

ically done by an apply lever and link bar.

LOW/REVERSE (REAR) BAND

The rear band holds the rear planet carrier sta-

tionary by being mounted around and applied to the

low/reverse drum.

ADJUSTMENTS

ADJUSTMENT - BANDS

FRONT BAND

The front (kickdown) band adjusting screw is

located on the left side of the transmission case

above the manual valve and throttle valve levers.

(1) Raise vehicle.

(2) Loosen band adjusting screw locknut (Fig. 74).

Then back locknut off 3-5 turns. Be sure adjusting

screw turns freely in case. Apply lubricant to screw

threads if necessary.

(3) Tighten band adjusting screw to 8 N´m (72 in.

lbs.) torque with Inch Pound Torque Wrench

C-3380-A, a 3-in. extension and an appropriate

TorxŸ socket.

CAUTION: If Adapter C-3705 is needed to reach the

adjusting screw, tighten the screw to only 5 N´m

(47-50 in. lbs.) torque.

(4)

Back off front band adjusting screw 1-3/4 turns.

(5) Hold adjuster screw in position and tighten

locknut to 41 N´m (30 ft. lbs.) torque.

(6) Lower vehicle.

Fig. 72 Front Band

1 - FRONT BAND

2 - TRANSMISSION HOUSING

Fig. 73 Rear Band

1 - ADJUSTING SCREW

2 - LOCKNUT

3 - LEVER

4 - REAR BAND

5 - REACTION PIN

6 - O-RINGS

7 - PIVOT PIN

Fig. 74 Front Band Adjustment Screw Location

1 - LOCK-NUT

2 - FRONT BAND ADJUSTER

21 - 374 AUTOMATIC TRANSMISSION - 48REDR

BANDS (Continued)

Page 2236 of 2895

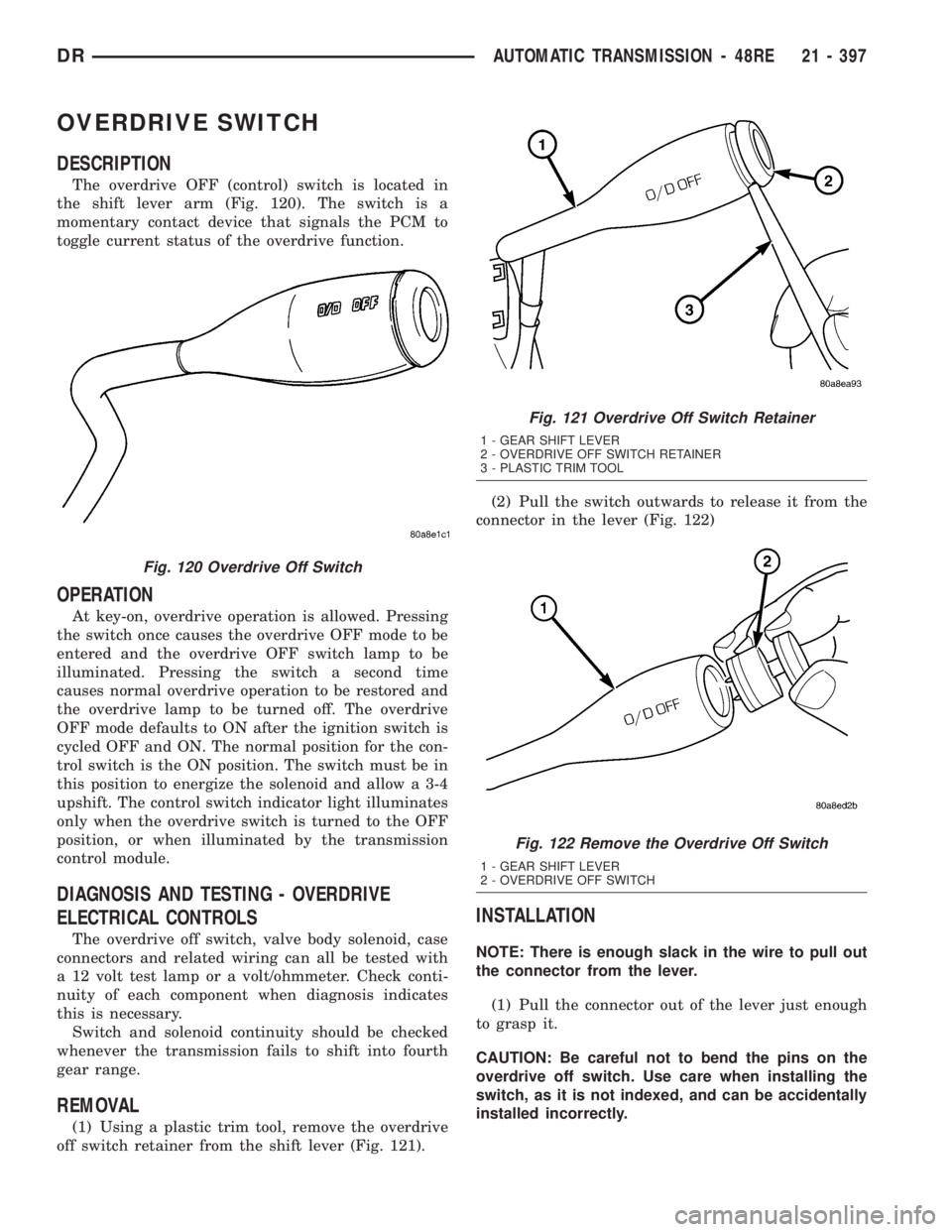

OVERDRIVE SWITCH

DESCRIPTION

The overdrive OFF (control) switch is located in

the shift lever arm (Fig. 120). The switch is a

momentary contact device that signals the PCM to

toggle current status of the overdrive function.

OPERATION

At key-on, overdrive operation is allowed. Pressing

the switch once causes the overdrive OFF mode to be

entered and the overdrive OFF switch lamp to be

illuminated. Pressing the switch a second time

causes normal overdrive operation to be restored and

the overdrive lamp to be turned off. The overdrive

OFF mode defaults to ON after the ignition switch is

cycled OFF and ON. The normal position for the con-

trol switch is the ON position. The switch must be in

this position to energize the solenoid and allow a 3-4

upshift. The control switch indicator light illuminates

only when the overdrive switch is turned to the OFF

position, or when illuminated by the transmission

control module.

DIAGNOSIS AND TESTING - OVERDRIVE

ELECTRICAL CONTROLS

The overdrive off switch, valve body solenoid, case

connectors and related wiring can all be tested with

a 12 volt test lamp or a volt/ohmmeter. Check conti-

nuity of each component when diagnosis indicates

this is necessary.

Switch and solenoid continuity should be checked

whenever the transmission fails to shift into fourth

gear range.

REMOVAL

(1) Using a plastic trim tool, remove the overdrive

off switch retainer from the shift lever (Fig. 121).(2) Pull the switch outwards to release it from the

connector in the lever (Fig. 122)

INSTALLATION

NOTE: There is enough slack in the wire to pull out

the connector from the lever.

(1) Pull the connector out of the lever just enough

to grasp it.

CAUTION: Be careful not to bend the pins on the

overdrive off switch. Use care when installing the

switch, as it is not indexed, and can be accidentally

installed incorrectly.

Fig. 120 Overdrive Off Switch

Fig. 121 Overdrive Off Switch Retainer

1 - GEAR SHIFT LEVER

2 - OVERDRIVE OFF SWITCH RETAINER

3 - PLASTIC TRIM TOOL

Fig. 122 Remove the Overdrive Off Switch

1 - GEAR SHIFT LEVER

2 - OVERDRIVE OFF SWITCH

DRAUTOMATIC TRANSMISSION - 48RE 21 - 397

Page 2248 of 2895

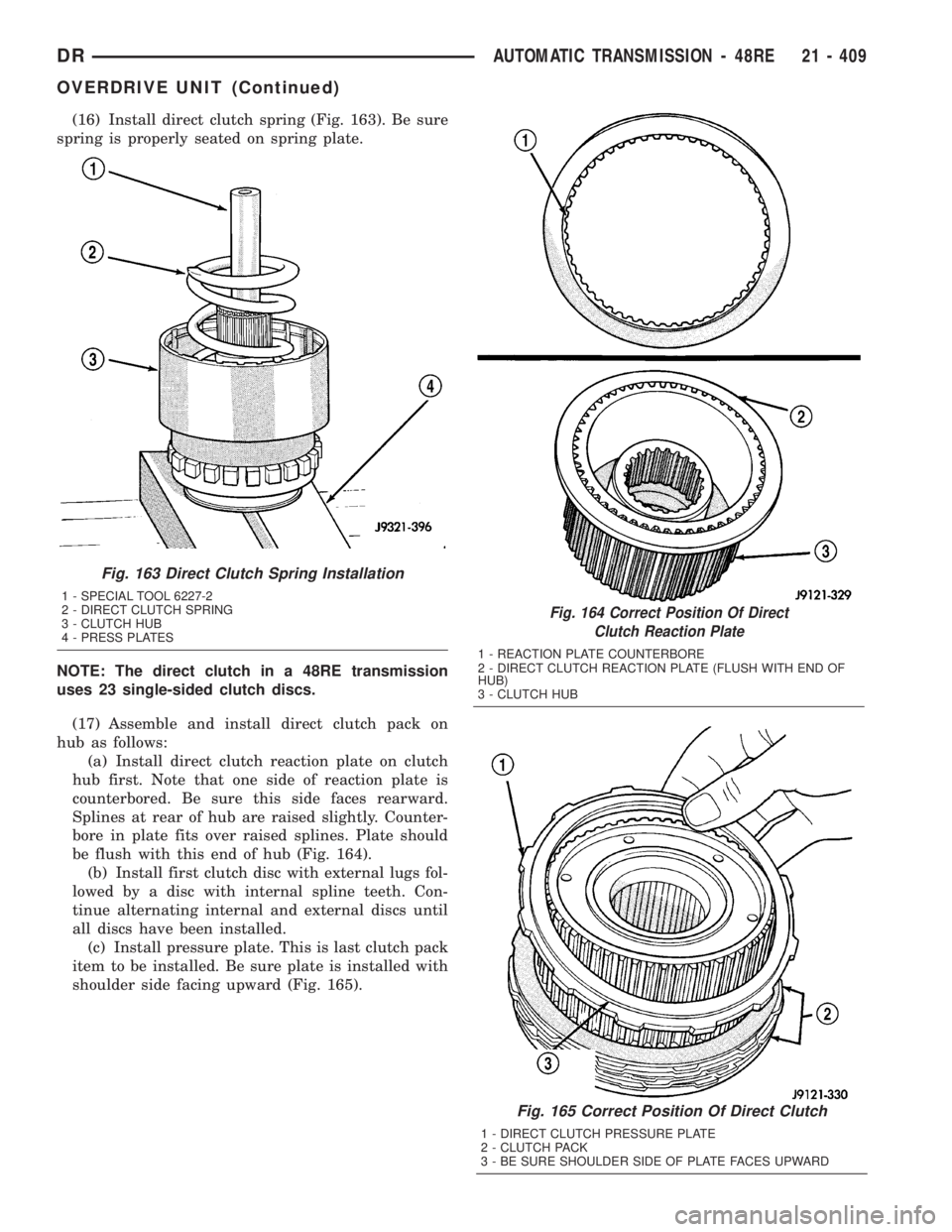

(16) Install direct clutch spring (Fig. 163). Be sure

spring is properly seated on spring plate.

NOTE: The direct clutch in a 48RE transmission

uses 23 single-sided clutch discs.

(17) Assemble and install direct clutch pack on

hub as follows:

(a) Install direct clutch reaction plate on clutch

hub first. Note that one side of reaction plate is

counterbored. Be sure this side faces rearward.

Splines at rear of hub are raised slightly. Counter-

bore in plate fits over raised splines. Plate should

be flush with this end of hub (Fig. 164).

(b) Install first clutch disc with external lugs fol-

lowed by a disc with internal spline teeth. Con-

tinue alternating internal and external discs until

all discs have been installed.

(c) Install pressure plate. This is last clutch pack

item to be installed. Be sure plate is installed with

shoulder side facing upward (Fig. 165).

Fig. 164 Correct Position Of Direct

Clutch Reaction Plate

1 - REACTION PLATE COUNTERBORE

2 - DIRECT CLUTCH REACTION PLATE (FLUSH WITH END OF

HUB)

3 - CLUTCH HUB

Fig. 165 Correct Position Of Direct Clutch

1 - DIRECT CLUTCH PRESSURE PLATE

2 - CLUTCH PACK

3 - BE SURE SHOULDER SIDE OF PLATE FACES UPWARD

Fig. 163 Direct Clutch Spring Installation

1 - SPECIAL TOOL 6227-2

2 - DIRECT CLUTCH SPRING

3 - CLUTCH HUB

4 - PRESS PLATES

DRAUTOMATIC TRANSMISSION - 48RE 21 - 409

OVERDRIVE UNIT (Continued)

Page 2266 of 2895

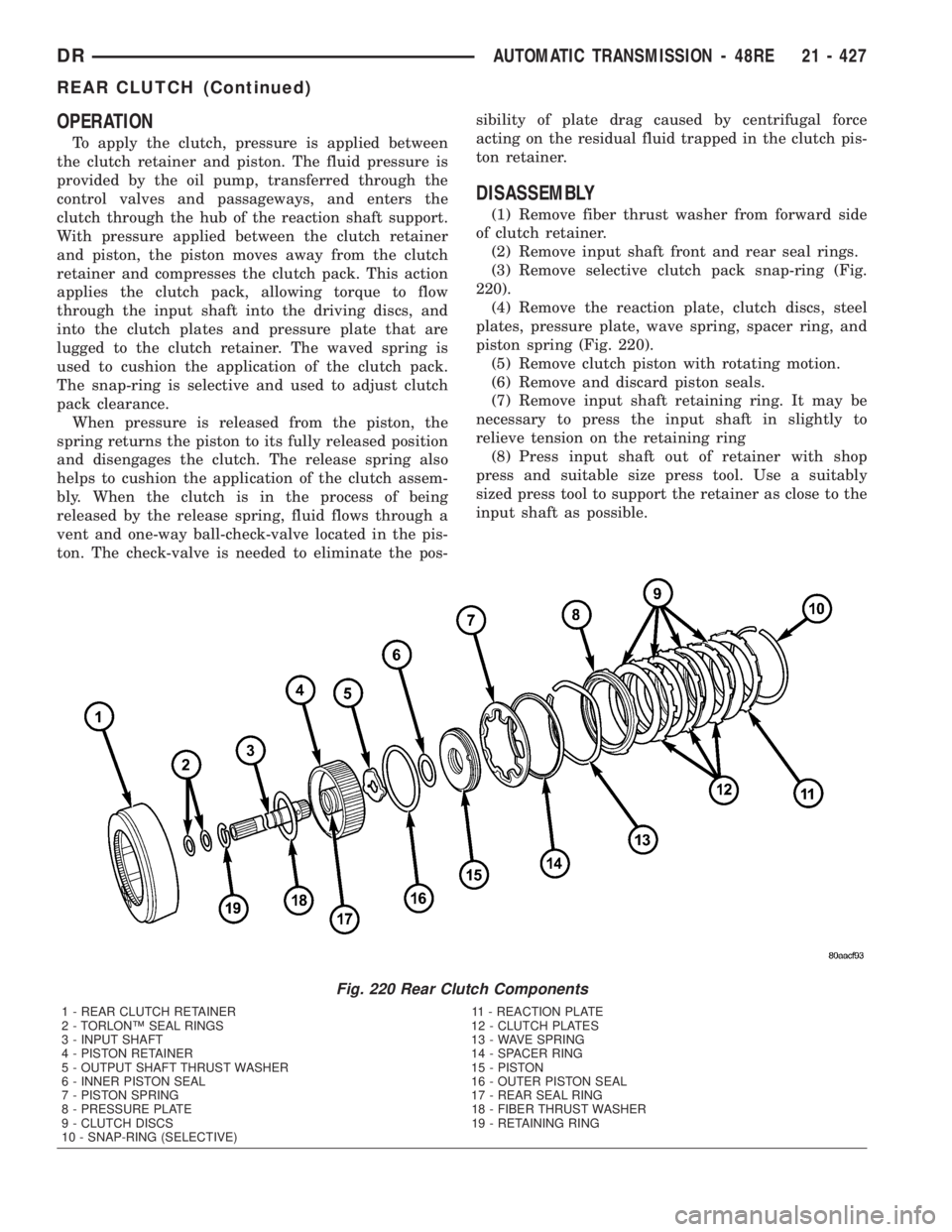

OPERATION

To apply the clutch, pressure is applied between

the clutch retainer and piston. The fluid pressure is

provided by the oil pump, transferred through the

control valves and passageways, and enters the

clutch through the hub of the reaction shaft support.

With pressure applied between the clutch retainer

and piston, the piston moves away from the clutch

retainer and compresses the clutch pack. This action

applies the clutch pack, allowing torque to flow

through the input shaft into the driving discs, and

into the clutch plates and pressure plate that are

lugged to the clutch retainer. The waved spring is

used to cushion the application of the clutch pack.

The snap-ring is selective and used to adjust clutch

pack clearance.

When pressure is released from the piston, the

spring returns the piston to its fully released position

and disengages the clutch. The release spring also

helps to cushion the application of the clutch assem-

bly. When the clutch is in the process of being

released by the release spring, fluid flows through a

vent and one-way ball-check-valve located in the pis-

ton. The check-valve is needed to eliminate the pos-sibility of plate drag caused by centrifugal force

acting on the residual fluid trapped in the clutch pis-

ton retainer.

DISASSEMBLY

(1) Remove fiber thrust washer from forward side

of clutch retainer.

(2) Remove input shaft front and rear seal rings.

(3) Remove selective clutch pack snap-ring (Fig.

220).

(4) Remove the reaction plate, clutch discs, steel

plates, pressure plate, wave spring, spacer ring, and

piston spring (Fig. 220).

(5) Remove clutch piston with rotating motion.

(6) Remove and discard piston seals.

(7) Remove input shaft retaining ring. It may be

necessary to press the input shaft in slightly to

relieve tension on the retaining ring

(8) Press input shaft out of retainer with shop

press and suitable size press tool. Use a suitably

sized press tool to support the retainer as close to the

input shaft as possible.

Fig. 220 Rear Clutch Components

1 - REAR CLUTCH RETAINER 11 - REACTION PLATE

2 - TORLONŸ SEAL RINGS 12 - CLUTCH PLATES

3 - INPUT SHAFT 13 - WAVE SPRING

4 - PISTON RETAINER 14 - SPACER RING

5 - OUTPUT SHAFT THRUST WASHER 15 - PISTON

6 - INNER PISTON SEAL 16 - OUTER PISTON SEAL

7 - PISTON SPRING 17 - REAR SEAL RING

8 - PRESSURE PLATE 18 - FIBER THRUST WASHER

9 - CLUTCH DISCS 19 - RETAINING RING

10 - SNAP-RING (SELECTIVE)

DRAUTOMATIC TRANSMISSION - 48RE 21 - 427

REAR CLUTCH (Continued)

Page 2267 of 2895

CLEANING

Clean the clutch components with solvent and dry

them with compressed air. Do not use rags or shop

towels to dry any of the clutch parts. Lint from such

materials will adhere to component surfaces and

could restrict or block fluid passages after assembly.

INSPECTION

Replace the clutch discs if warped, worn, scored,

burned/charred, the lugs are damaged, or if the fac-

ing is flaking off. Replace the top and bottom pres-

sure plates if scored, warped, or cracked. Be sure the

driving lugs on the pressure and clutch plates are

also in good condition. The lugs must not be bent,

cracked or damaged in any way.

Replace the piston spring and wave spring if either

part is distorted, warped or broken.

Check the lug grooves in the clutch retainer. The

clutch and pressure plates should slide freely in the

slots. Replace the retainer if the grooves are worn or

damaged. Also check action of the check balls in the

retainer and piston. Each check ball must move

freely and not stick.

Replace the retainer bushing if worn, scored, or

doubt exists about bushing condition.

Inspect the piston and retainer seal surfaces for

nicks or scratches. Minor scratches can be removed

with crocus cloth. However, replace the piston and/or

retainer if the seal surfaces are seriously scored.

Check condition of the fiber thrust washer and

metal output shaft thrust washer. Replace either

washer if worn or damaged.

Check condition of the seal rings on the input shaft

and clutch retainer hub. Replace the seal rings only

if worn, distorted, or damaged. The input shaft front

seal ring is teflon with chamfered ends. The rear ring

is metal with interlocking ends.

Check the input shaft for wear, or damage. Replace

the shaft if worn, scored or damaged in any way.

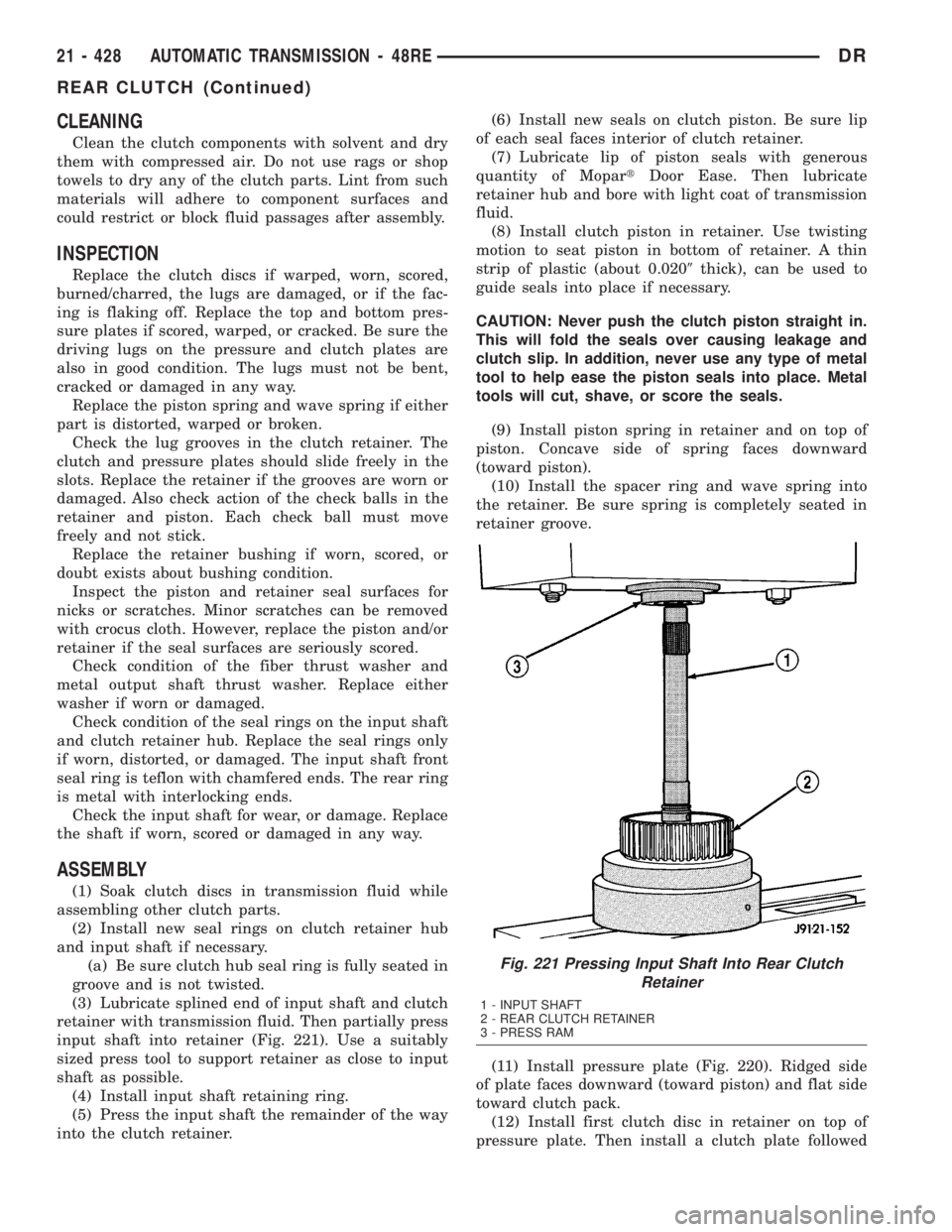

ASSEMBLY

(1) Soak clutch discs in transmission fluid while

assembling other clutch parts.

(2) Install new seal rings on clutch retainer hub

and input shaft if necessary.

(a) Be sure clutch hub seal ring is fully seated in

groove and is not twisted.

(3) Lubricate splined end of input shaft and clutch

retainer with transmission fluid. Then partially press

input shaft into retainer (Fig. 221). Use a suitably

sized press tool to support retainer as close to input

shaft as possible.

(4) Install input shaft retaining ring.

(5) Press the input shaft the remainder of the way

into the clutch retainer.(6) Install new seals on clutch piston. Be sure lip

of each seal faces interior of clutch retainer.

(7) Lubricate lip of piston seals with generous

quantity of MopartDoor Ease. Then lubricate

retainer hub and bore with light coat of transmission

fluid.

(8) Install clutch piston in retainer. Use twisting

motion to seat piston in bottom of retainer. A thin

strip of plastic (about 0.0209thick), can be used to

guide seals into place if necessary.

CAUTION: Never push the clutch piston straight in.

This will fold the seals over causing leakage and

clutch slip. In addition, never use any type of metal

tool to help ease the piston seals into place. Metal

tools will cut, shave, or score the seals.

(9) Install piston spring in retainer and on top of

piston. Concave side of spring faces downward

(toward piston).

(10) Install the spacer ring and wave spring into

the retainer. Be sure spring is completely seated in

retainer groove.

(11) Install pressure plate (Fig. 220). Ridged side

of plate faces downward (toward piston) and flat side

toward clutch pack.

(12) Install first clutch disc in retainer on top of

pressure plate. Then install a clutch plate followed

Fig. 221 Pressing Input Shaft Into Rear Clutch

Retainer

1 - INPUT SHAFT

2 - REAR CLUTCH RETAINER

3 - PRESS RAM

21 - 428 AUTOMATIC TRANSMISSION - 48REDR

REAR CLUTCH (Continued)

Page 2273 of 2895

in an incorrect T.V. cable adjustment.Slide the

sheath of the T.V. cable (D) back and forth until the

centerlines of the T.V. cable end (B) and the throttle

bell crank lever (C) are aligned within one millimeter

(1mm) (Fig. 232).

(7) While holding the T.V. cable in the set position

push the T.V. cable lock (A) into the down position

(Fig. 232). This will lock the present T.V. cable

adjustment.

NOTE: Be sure that as the cable is pulled forward

and centered on the throttle lever stud, the cable

housing moves smoothly with the cable. Due to the

angle at which the cable housing enters the spring

housing, the cable housing may bind slightly and

create an incorrect adjustment.

(8) Reconnect the T.V. cable (B) to the throttle

bellcrank lever (C).

(9) Check cable adjustment. Verify transmission

throttle lever and lever on throttle body move simul-

taneously.

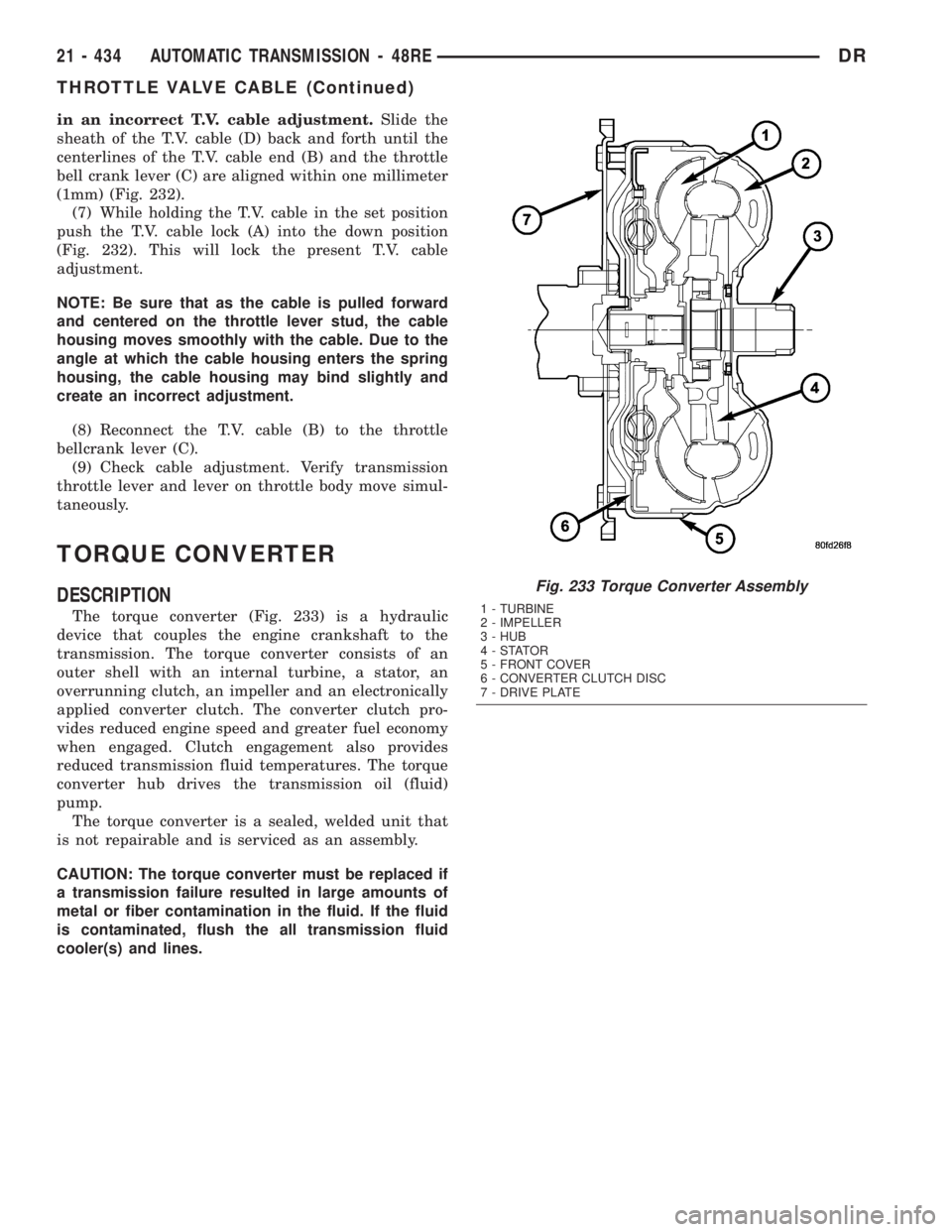

TORQUE CONVERTER

DESCRIPTION

The torque converter (Fig. 233) is a hydraulic

device that couples the engine crankshaft to the

transmission. The torque converter consists of an

outer shell with an internal turbine, a stator, an

overrunning clutch, an impeller and an electronically

applied converter clutch. The converter clutch pro-

vides reduced engine speed and greater fuel economy

when engaged. Clutch engagement also provides

reduced transmission fluid temperatures. The torque

converter hub drives the transmission oil (fluid)

pump.

The torque converter is a sealed, welded unit that

is not repairable and is serviced as an assembly.

CAUTION: The torque converter must be replaced if

a transmission failure resulted in large amounts of

metal or fiber contamination in the fluid. If the fluid

is contaminated, flush the all transmission fluid

cooler(s) and lines.

Fig. 233 Torque Converter Assembly

1 - TURBINE

2 - IMPELLER

3 - HUB

4-STATOR

5 - FRONT COVER

6 - CONVERTER CLUTCH DISC

7 - DRIVE PLATE

21 - 434 AUTOMATIC TRANSMISSION - 48REDR

THROTTLE VALVE CABLE (Continued)

Page 2277 of 2895

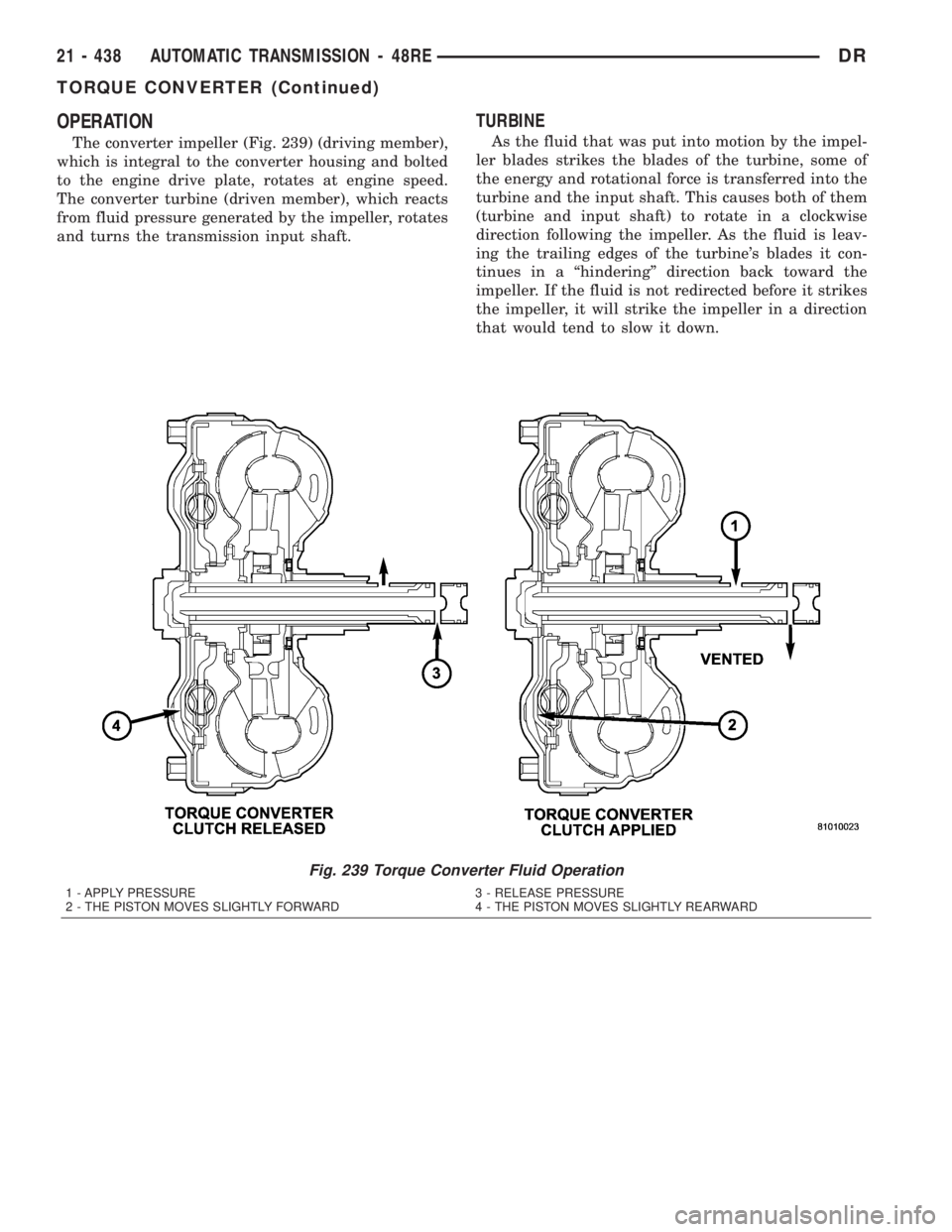

OPERATION

The converter impeller (Fig. 239) (driving member),

which is integral to the converter housing and bolted

to the engine drive plate, rotates at engine speed.

The converter turbine (driven member), which reacts

from fluid pressure generated by the impeller, rotates

and turns the transmission input shaft.

TURBINE

As the fluid that was put into motion by the impel-

ler blades strikes the blades of the turbine, some of

the energy and rotational force is transferred into the

turbine and the input shaft. This causes both of them

(turbine and input shaft) to rotate in a clockwise

direction following the impeller. As the fluid is leav-

ing the trailing edges of the turbine's blades it con-

tinues in a ªhinderingº direction back toward the

impeller. If the fluid is not redirected before it strikes

the impeller, it will strike the impeller in a direction

that would tend to slow it down.

Fig. 239 Torque Converter Fluid Operation

1 - APPLY PRESSURE 3 - RELEASE PRESSURE

2 - THE PISTON MOVES SLIGHTLY FORWARD 4 - THE PISTON MOVES SLIGHTLY REARWARD

21 - 438 AUTOMATIC TRANSMISSION - 48REDR

TORQUE CONVERTER (Continued)

Page 2315 of 2895

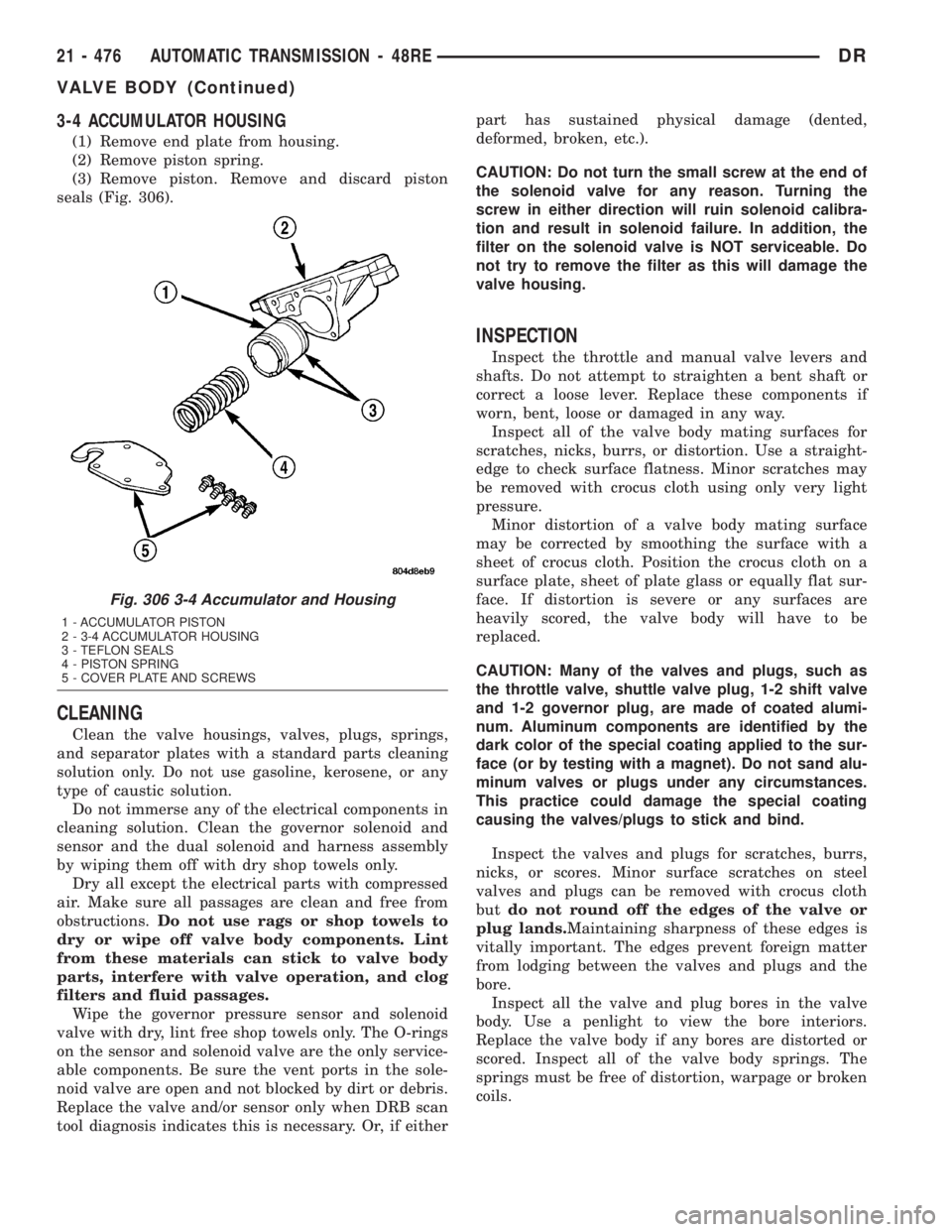

3-4 ACCUMULATOR HOUSING

(1) Remove end plate from housing.

(2) Remove piston spring.

(3) Remove piston. Remove and discard piston

seals (Fig. 306).

CLEANING

Clean the valve housings, valves, plugs, springs,

and separator plates with a standard parts cleaning

solution only. Do not use gasoline, kerosene, or any

type of caustic solution.

Do not immerse any of the electrical components in

cleaning solution. Clean the governor solenoid and

sensor and the dual solenoid and harness assembly

by wiping them off with dry shop towels only.

Dry all except the electrical parts with compressed

air. Make sure all passages are clean and free from

obstructions.Do not use rags or shop towels to

dry or wipe off valve body components. Lint

from these materials can stick to valve body

parts, interfere with valve operation, and clog

filters and fluid passages.

Wipe the governor pressure sensor and solenoid

valve with dry, lint free shop towels only. The O-rings

on the sensor and solenoid valve are the only service-

able components. Be sure the vent ports in the sole-

noid valve are open and not blocked by dirt or debris.

Replace the valve and/or sensor only when DRB scan

tool diagnosis indicates this is necessary. Or, if eitherpart has sustained physical damage (dented,

deformed, broken, etc.).

CAUTION: Do not turn the small screw at the end of

the solenoid valve for any reason. Turning the

screw in either direction will ruin solenoid calibra-

tion and result in solenoid failure. In addition, the

filter on the solenoid valve is NOT serviceable. Do

not try to remove the filter as this will damage the

valve housing.

INSPECTION

Inspect the throttle and manual valve levers and

shafts. Do not attempt to straighten a bent shaft or

correct a loose lever. Replace these components if

worn, bent, loose or damaged in any way.

Inspect all of the valve body mating surfaces for

scratches, nicks, burrs, or distortion. Use a straight-

edge to check surface flatness. Minor scratches may

be removed with crocus cloth using only very light

pressure.

Minor distortion of a valve body mating surface

may be corrected by smoothing the surface with a

sheet of crocus cloth. Position the crocus cloth on a

surface plate, sheet of plate glass or equally flat sur-

face. If distortion is severe or any surfaces are

heavily scored, the valve body will have to be

replaced.

CAUTION: Many of the valves and plugs, such as

the throttle valve, shuttle valve plug, 1-2 shift valve

and 1-2 governor plug, are made of coated alumi-

num. Aluminum components are identified by the

dark color of the special coating applied to the sur-

face (or by testing with a magnet). Do not sand alu-

minum valves or plugs under any circumstances.

This practice could damage the special coating

causing the valves/plugs to stick and bind.

Inspect the valves and plugs for scratches, burrs,

nicks, or scores. Minor surface scratches on steel

valves and plugs can be removed with crocus cloth

butdo not round off the edges of the valve or

plug lands.Maintaining sharpness of these edges is

vitally important. The edges prevent foreign matter

from lodging between the valves and plugs and the

bore.

Inspect all the valve and plug bores in the valve

body. Use a penlight to view the bore interiors.

Replace the valve body if any bores are distorted or

scored. Inspect all of the valve body springs. The

springs must be free of distortion, warpage or broken

coils.

Fig. 306 3-4 Accumulator and Housing

1 - ACCUMULATOR PISTON

2 - 3-4 ACCUMULATOR HOUSING

3 - TEFLON SEALS

4 - PISTON SPRING

5 - COVER PLATE AND SCREWS

21 - 476 AUTOMATIC TRANSMISSION - 48REDR

VALVE BODY (Continued)