light DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2632 of 2895

(11) Install the right a-pillar trim panel. (Refer to

23 - BODY/INTERIOR/A-PILLAR TRIM - INSTAL-

LATION)

(12) Position the right end cap and seat the

attachment clips fully.

(13) Install the one HVAC mounting screw.

(14) Connect the radio antenna.

(15) Connect the two electrical connectors at the

right cowl panel.

(16) Install the right cowl trim cover. (Refer to 23 -

BODY/INTERIOR/COWL TRIM - INSTALLATION)

(17) Connect the air bag control module electrical

connector.

(18) Install the center bracket bolts and tighten to

12 N´m (9 ft. lbs.).

(19) Install the floor console, if equipped. (Refer to

23 - BODY/INTERIOR/FLOOR CONSOLE - INSTAL-

LATION)

(20) Install the air bag control module cover, if

equipped.

(21) Connect the park brake release handle actua-

tor rod.

(22) Install the hood release handle and tighten

the screws.

(23) Install the two bolts at the column support

bracket and tighten to 14 N´m (10 ft. lbs.).

(24) Install the steering column. (Refer to 19 -

STEERING/COLUMN - INSTALLATION)

(25) Connect the wire harness electrical connectors

above the brake pedal.

(26) Install the two top instrument panel bolts and

tighten to 12 N´m (9 ft. lbs.).

(27) Install the four top instrument panel screws.

(28) Install the instrument panel top cover. (Refer

to 23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL TOP COVER - INSTALLATION)

INSTRUMENT PANEL

HEADLAMP SWITCH BEZEL

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULDRESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

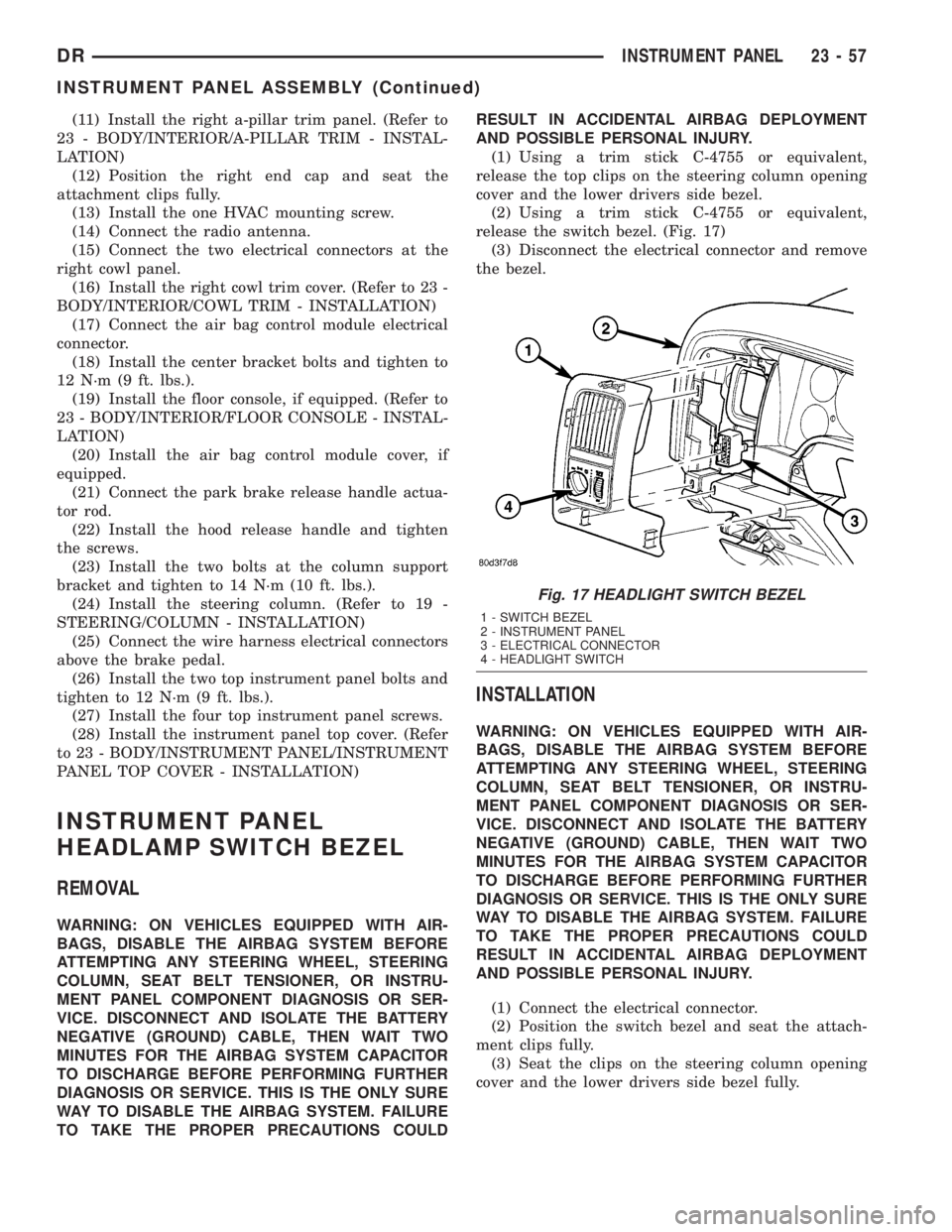

(1) Using a trim stick C-4755 or equivalent,

release the top clips on the steering column opening

cover and the lower drivers side bezel.

(2) Using a trim stick C-4755 or equivalent,

release the switch bezel. (Fig. 17)

(3) Disconnect the electrical connector and remove

the bezel.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Connect the electrical connector.

(2) Position the switch bezel and seat the attach-

ment clips fully.

(3) Seat the clips on the steering column opening

cover and the lower drivers side bezel fully.

Fig. 17 HEADLIGHT SWITCH BEZEL

1 - SWITCH BEZEL

2 - INSTRUMENT PANEL

3 - ELECTRICAL CONNECTOR

4 - HEADLIGHT SWITCH

DRINSTRUMENT PANEL 23 - 57

INSTRUMENT PANEL ASSEMBLY (Continued)

Page 2644 of 2895

HEADLINER

REMOVAL

(1) Remove the a-pillar trim. (Refer to 23 - BODY/

INTERIOR/A-PILLAR TRIM - REMOVAL)

(2) Remove the upper b-pillar trim. (Refer to 23 -

BODY/INTERIOR/B-PILLAR UPPER TRIM -

REMOVAL)

(3) Remove the upper c-pillar trim, if equipped.

(Refer to 23 - BODY/INTERIOR/C-PILLAR TRIM -

REMOVAL)

(4) Remove the coat hooks. (Refer to 23 - BODY/

INTERIOR/COAT HOOK - REMOVAL)

(5) Disconnect the headliner harness electrical con-

nector at the left a-pillar.

(6) Remove the dome lamp. (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - INTERIOR/DOME

LAMP - REMOVAL)

(7) Remove the overhead console. (Refer to 8 -

ELECTRICAL/OVERHEAD CONSOLE - REMOVAL)

(8) Remove the sun visors. (Refer to 23 - BODY/

INTERIOR/SUN VISOR - REMOVAL)

(9) Remove the sun visor supports. (Refer to 23 -

BODY/INTERIOR/SUN VISOR SUPPORT -

REMOVAL)

(10) Lower the headliner and disconnect the center

high mounted stop light.

(11) Lower the front of the headliner down to the

floor just in front of the instrument panel and

remove through the passenger door.

INSTALLATION

(1) Install the headliner into the vehicle through

the passenger door.

(2) Raise the headliner and insert the right side

above right side pillar trim pieces.

(3) Connect the center high mounted stop light

electrical connector.

(4) Install the sun visor supports. (Refer to 23 -

BODY/INTERIOR/SUN VISOR SUPPORT - INSTAL-

LATION)

(5) Install the coat hooks. (Refer to 23 - BODY/IN-

TERIOR/COAT HOOK - INSTALLATION)

(6) Install the sun visors. (Refer to 23 - BODY/IN-

TERIOR/SUN VISOR - INSTALLATION)

(7) Install the overhead console. (Refer to 8 -

ELECTRICAL/OVERHEAD CONSOLE - INSTALLA-

TION)

(8) Install the dome lamp. (Refer to 8 - ELECTRI-

CAL/LAMPS/LIGHTING - INTERIOR/DOME LAMP

- INSTALLATION)(9) Connect the headliner harness electrical con-

nector at the left a-pillar.

(10) Install the upper c-pillar trim, if equipped.

(Refer to 23 - BODY/INTERIOR/C-PILLAR TRIM -

INSTALLATION)

(11) Install the upper b-pillar trim. (Refer to 23 -

BODY/INTERIOR/B-PILLAR UPPER TRIM -

INSTALLATION)

(12) Install the upper a-pillar trim. (Refer to 23 -

BODY/INTERIOR/A-PILLAR TRIM - INSTALLA-

TION)

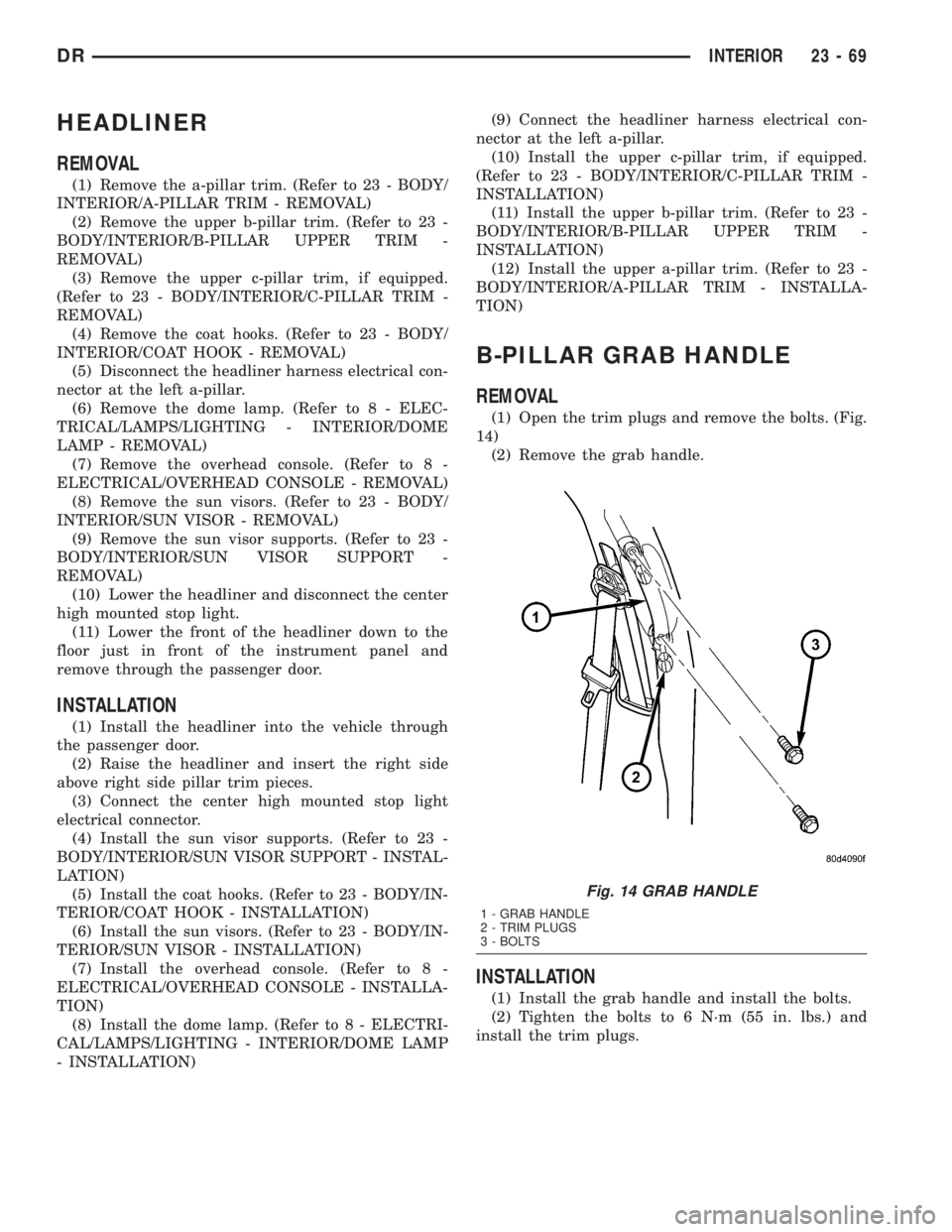

B-PILLAR GRAB HANDLE

REMOVAL

(1) Open the trim plugs and remove the bolts. (Fig.

14)

(2) Remove the grab handle.

INSTALLATION

(1) Install the grab handle and install the bolts.

(2) Tighten the bolts to 6 N´m (55 in. lbs.) and

install the trim plugs.

Fig. 14 GRAB HANDLE

1 - GRAB HANDLE

2 - TRIM PLUGS

3 - BOLTS

DRINTERIOR 23 - 69

Page 2649 of 2895

PAINT

TABLE OF CONTENTS

page page

PAINT

SPECIFICATIONS - PAINT CODES..........74

PAINT CODE

DESCRIPTION.........................74

BASECOAT/CLEARCOAT FINISH

DESCRIPTION.........................74PAINT TOUCH-UP

DESCRIPTION.........................75

STANDARD PROCEDURE - PAINT TOUCH-UP . 75

FINESSE SANDING/BUFFING & POLISHING

DESCRIPTION.........................75

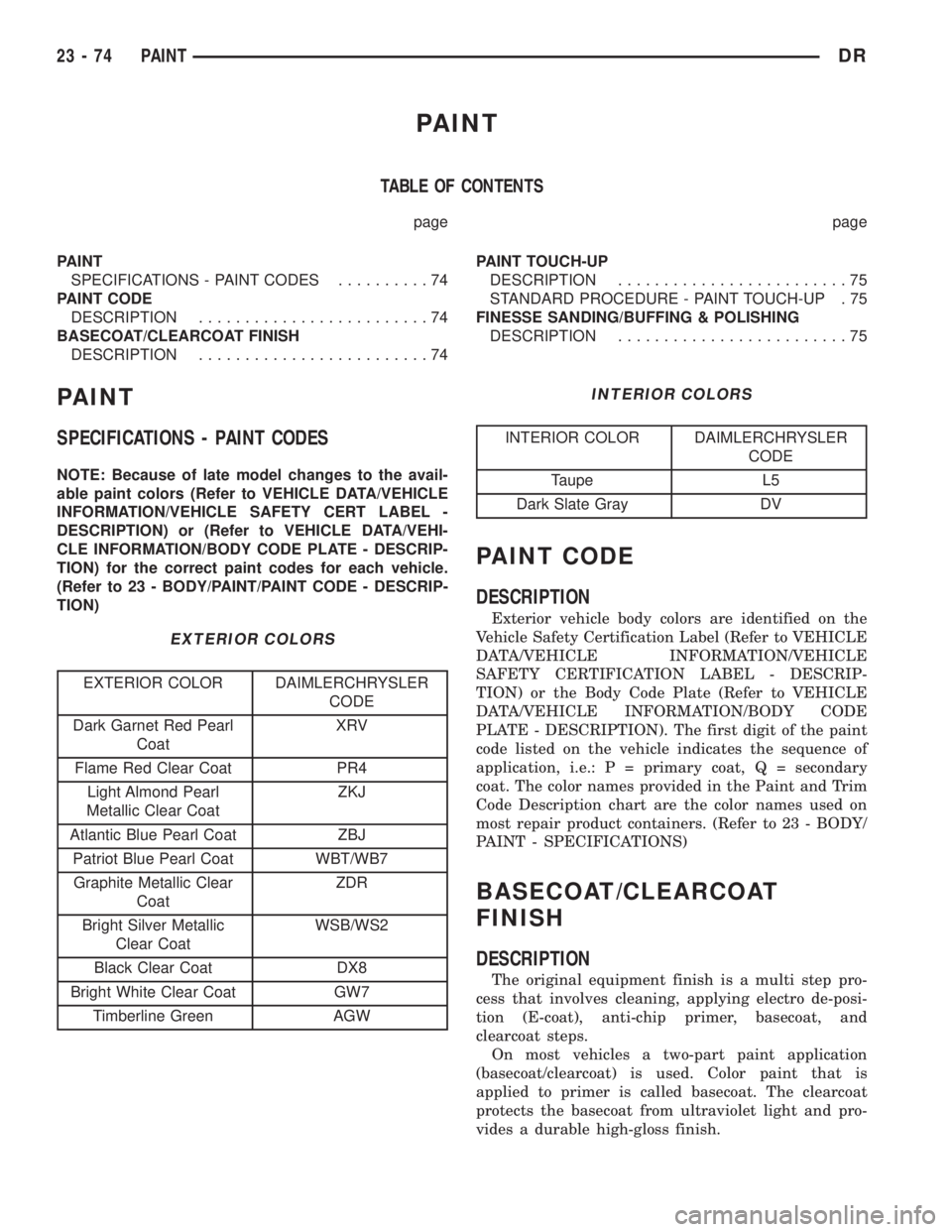

PAINT

SPECIFICATIONS - PAINT CODES

NOTE: Because of late model changes to the avail-

able paint colors (Refer to VEHICLE DATA/VEHICLE

INFORMATION/VEHICLE SAFETY CERT LABEL -

DESCRIPTION) or (Refer to VEHICLE DATA/VEHI-

CLE INFORMATION/BODY CODE PLATE - DESCRIP-

TION) for the correct paint codes for each vehicle.

(Refer to 23 - BODY/PAINT/PAINT CODE - DESCRIP-

TION)

EXTERIOR COLORS

EXTERIOR COLOR DAIMLERCHRYSLER

CODE

Dark Garnet Red Pearl

CoatXRV

Flame Red Clear Coat PR4

Light Almond Pearl

Metallic Clear CoatZKJ

Atlantic Blue Pearl Coat ZBJ

Patriot Blue Pearl Coat WBT/WB7

Graphite Metallic Clear

CoatZDR

Bright Silver Metallic

Clear CoatWSB/WS2

Black Clear Coat DX8

Bright White Clear Coat GW7

Timberline Green AGW

INTERIOR COLORS

INTERIOR COLOR DAIMLERCHRYSLER

CODE

Taupe L5

Dark Slate Gray DV

PAINT CODE

DESCRIPTION

Exterior vehicle body colors are identified on the

Vehicle Safety Certification Label (Refer to VEHICLE

DATA/VEHICLE INFORMATION/VEHICLE

SAFETY CERTIFICATION LABEL - DESCRIP-

TION) or the Body Code Plate (Refer to VEHICLE

DATA/VEHICLE INFORMATION/BODY CODE

PLATE - DESCRIPTION). The first digit of the paint

code listed on the vehicle indicates the sequence of

application, i.e.: P = primary coat, Q = secondary

coat. The color names provided in the Paint and Trim

Code Description chart are the color names used on

most repair product containers. (Refer to 23 - BODY/

PAINT - SPECIFICATIONS)

BASECOAT/CLEARCOAT

FINISH

DESCRIPTION

The original equipment finish is a multi step pro-

cess that involves cleaning, applying electro de-posi-

tion (E-coat), anti-chip primer, basecoat, and

clearcoat steps.

On most vehicles a two-part paint application

(basecoat/clearcoat) is used. Color paint that is

applied to primer is called basecoat. The clearcoat

protects the basecoat from ultraviolet light and pro-

vides a durable high-gloss finish.

23 - 74 PAINTDR

Page 2650 of 2895

CAUTION: Do not use abrasive chemicals or com-

pounds on painted surfaces. Damage to finish can

result.

Do not use harsh alkaline based cleaning solvents

on painted surfaces. Damage to finish or color can

result.

PAINT TOUCH-UP

DESCRIPTION

When a painted metal surface has been scratched

or chipped, it should be touched-up as soon as possi-

ble to avoid corrosion. For best results, use MOPARt

Scratch Filler/Primer, Touch-Up Paints and Clear Top

Coat. (Refer to VEHICLE DATA/VEHICLE INFOR-

MATION/BODY CODE PLATE - DESCRIPTION) for

Body Code Plate information.

WARNING: USE AN OSHA APPROVED RESPIRATOR

AND SAFETY GLASSES WHEN SPRAYING PAINT

OR SOLVENTS IN A CONFINED AREA. PERSONAL

INJURY CAN RESULT.

STANDARD PROCEDURE - PAINT TOUCH-UP

(1) Scrape loose paint and corrosion from inside

scratch or chip.

(2) Clean affected area with MOPARtTar/Road

Oil Remover or equivalent, and allow to dry.

(3) Fill the inside of the scratch or chip with a coat

of filler/primer. Do not overlap primer onto good sur-

face finish. The applicator brush should be wet

enough to puddle-fill the scratch or chip without run-

ning. Do not stroke brush applicator on body surface.

Allow the filler/primer to dry hard.

(4) Cover the filler/primer with color touch-up

paint. Do not overlap touch-up color onto the original

color coat around the scratch or chip. Butt the newcolor to the original color, if possible. Do not stroke

applicator brush on body surface. Allow touch-up

paint to dry hard.

(5) On vehicles without clearcoat, the touch-up

color can be lightly finesse sanded (1500 grit) and

polished with rubbing compound.

(6) On vehicles with clearcoat, apply clear top coat

to touch-up paint with the same technique as

described in Step 4. Allow clear top coat to dry hard.

If desired, Step 5 can be performed on clear top coat.

WARNING: AVOID PROLONGED SKIN CONTACT

WITH PETROLEUM OR ALCOHOL ± BASED CLEAN-

ING SOLVENTS. PERSONAL INJURY CAN RESULT.

AVOID PROLONGED SKIN CONTACT WITH PETRO-

LEUM OR ALCOHOL ± BASED CLEANING SOL-

VENTS. PERSONAL INJURY CAN RESULT.

FINESSE SANDING/BUFFING &

POLISHING

DESCRIPTION

CAUTION: Do not remove more than .5 mils of

clearcoat finish, if equipped. Basecoat paint must

retain clearcoat for durability.

Use a Paint Thickness Gauge #PR-ETG-2X or equiv-

alent to determine film thickness before and after

the repair.

Minor acid etching, orange peel, or smudging in

clearcoat or single-stage finishes can be reduced with

light finesse sanding, hand buffing, and polishing.If

the finish has been finesse sanded in the past,

it cannot be repeated. Finesse sanding opera-

tion should be performed by a trained automo-

tive paint technician.

DRPAINT 23 - 75

BASECOAT/CLEARCOAT FINISH (Continued)

Page 2664 of 2895

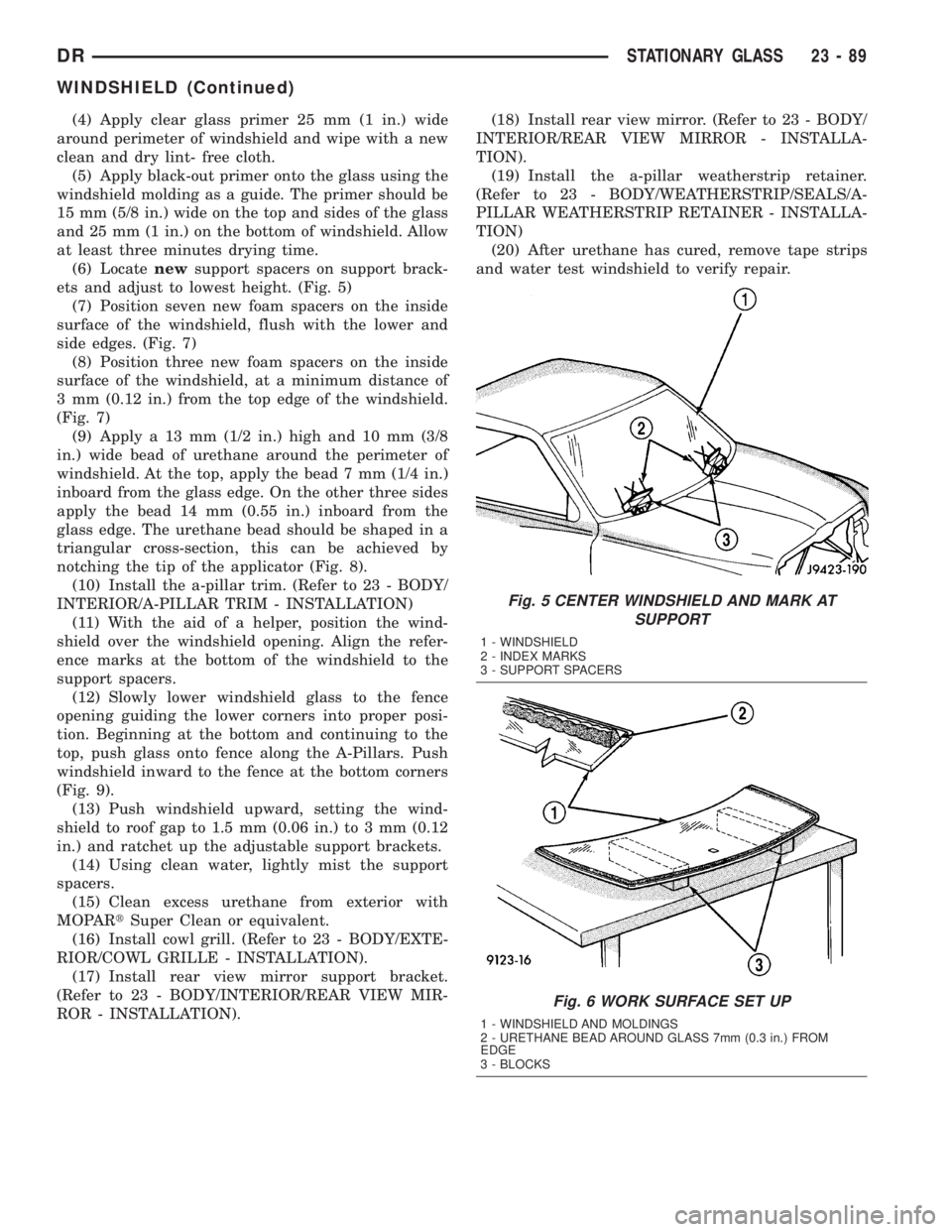

(4) Apply clear glass primer 25 mm (1 in.) wide

around perimeter of windshield and wipe with a new

clean and dry lint- free cloth.

(5) Apply black-out primer onto the glass using the

windshield molding as a guide. The primer should be

15 mm (5/8 in.) wide on the top and sides of the glass

and 25 mm (1 in.) on the bottom of windshield. Allow

at least three minutes drying time.

(6) Locatenewsupport spacers on support brack-

ets and adjust to lowest height. (Fig. 5)

(7) Position seven new foam spacers on the inside

surface of the windshield, flush with the lower and

side edges. (Fig. 7)

(8) Position three new foam spacers on the inside

surface of the windshield, at a minimum distance of

3 mm (0.12 in.) from the top edge of the windshield.

(Fig. 7)

(9) Apply a 13 mm (1/2 in.) high and 10 mm (3/8

in.) wide bead of urethane around the perimeter of

windshield. At the top, apply the bead 7 mm (1/4 in.)

inboard from the glass edge. On the other three sides

apply the bead 14 mm (0.55 in.) inboard from the

glass edge. The urethane bead should be shaped in a

triangular cross-section, this can be achieved by

notching the tip of the applicator (Fig. 8).

(10) Install the a-pillar trim. (Refer to 23 - BODY/

INTERIOR/A-PILLAR TRIM - INSTALLATION)

(11) With the aid of a helper, position the wind-

shield over the windshield opening. Align the refer-

ence marks at the bottom of the windshield to the

support spacers.

(12) Slowly lower windshield glass to the fence

opening guiding the lower corners into proper posi-

tion. Beginning at the bottom and continuing to the

top, push glass onto fence along the A-Pillars. Push

windshield inward to the fence at the bottom corners

(Fig. 9).

(13) Push windshield upward, setting the wind-

shield to roof gap to 1.5 mm (0.06 in.) to 3 mm (0.12

in.) and ratchet up the adjustable support brackets.

(14) Using clean water, lightly mist the support

spacers.

(15) Clean excess urethane from exterior with

MOPARtSuper Clean or equivalent.

(16) Install cowl grill. (Refer to 23 - BODY/EXTE-

RIOR/COWL GRILLE - INSTALLATION).

(17) Install rear view mirror support bracket.

(Refer to 23 - BODY/INTERIOR/REAR VIEW MIR-

ROR - INSTALLATION).(18) Install rear view mirror. (Refer to 23 - BODY/

INTERIOR/REAR VIEW MIRROR - INSTALLA-

TION).

(19) Install the a-pillar weatherstrip retainer.

(Refer to 23 - BODY/WEATHERSTRIP/SEALS/A-

PILLAR WEATHERSTRIP RETAINER - INSTALLA-

TION)

(20) After urethane has cured, remove tape strips

and water test windshield to verify repair.

Fig. 5 CENTER WINDSHIELD AND MARK AT

SUPPORT

1 - WINDSHIELD

2 - INDEX MARKS

3 - SUPPORT SPACERS

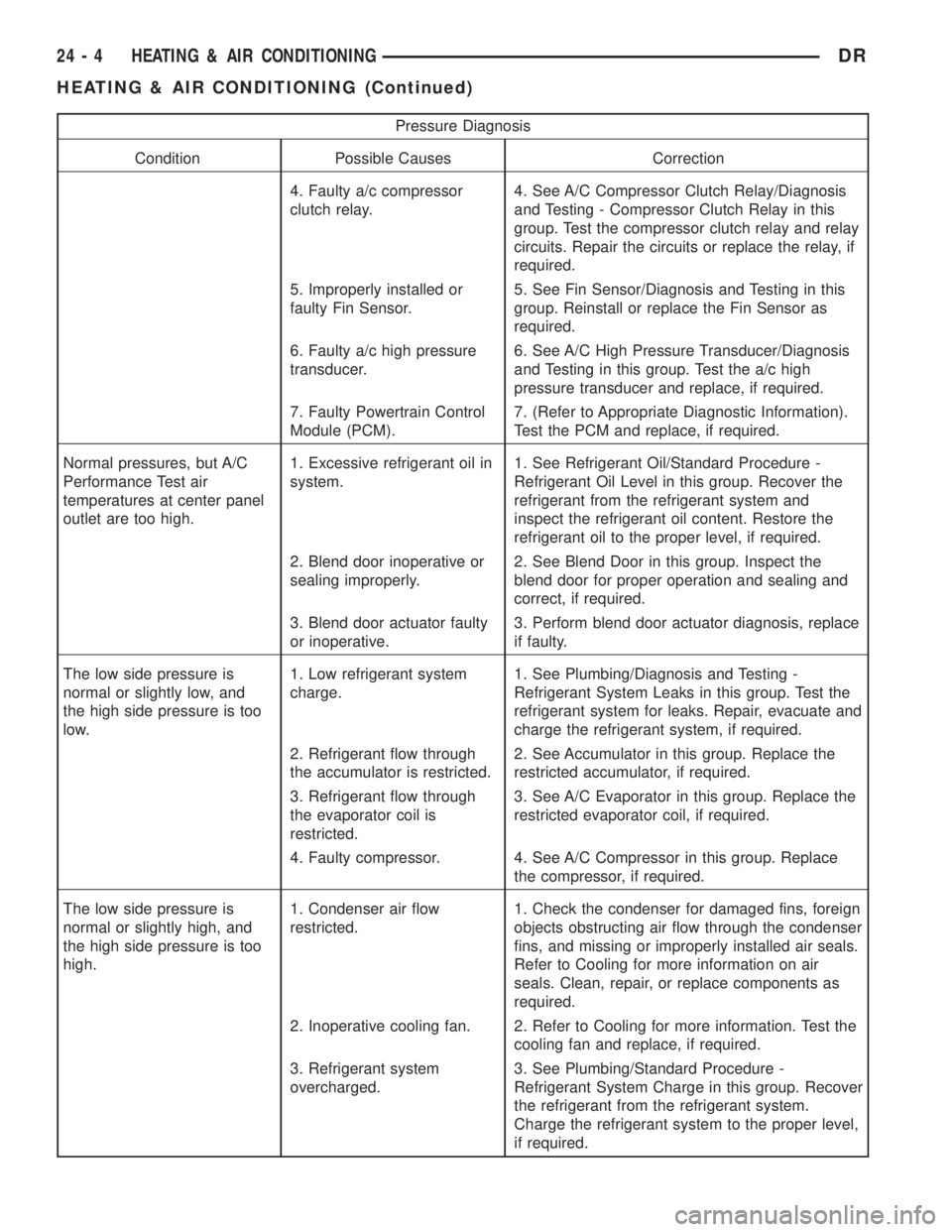

Fig. 6 WORK SURFACE SET UP

1 - WINDSHIELD AND MOLDINGS

2 - URETHANE BEAD AROUND GLASS 7mm (0.3 in.) FROM

EDGE

3 - BLOCKS

DRSTATIONARY GLASS 23 - 89

WINDSHIELD (Continued)

Page 2779 of 2895

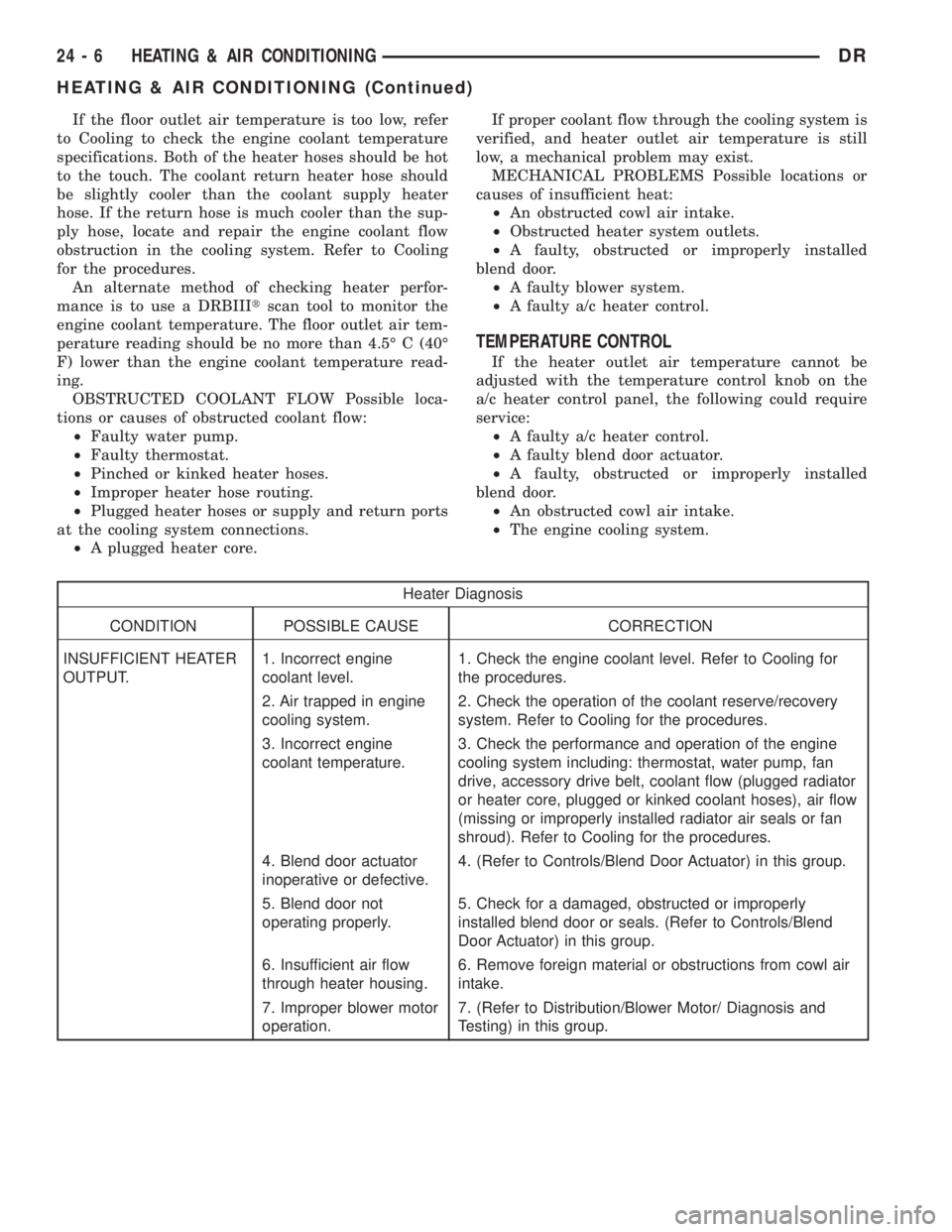

Pressure Diagnosis

Condition Possible Causes Correction

4. Faulty a/c compressor

clutch relay.4. See A/C Compressor Clutch Relay/Diagnosis

and Testing - Compressor Clutch Relay in this

group. Test the compressor clutch relay and relay

circuits. Repair the circuits or replace the relay, if

required.

5. Improperly installed or

faulty Fin Sensor.5. See Fin Sensor/Diagnosis and Testing in this

group. Reinstall or replace the Fin Sensor as

required.

6. Faulty a/c high pressure

transducer.6. See A/C High Pressure Transducer/Diagnosis

and Testing in this group. Test the a/c high

pressure transducer and replace, if required.

7. Faulty Powertrain Control

Module (PCM).7. (Refer to Appropriate Diagnostic Information).

Test the PCM and replace, if required.

Normal pressures, but A/C

Performance Test air

temperatures at center panel

outlet are too high.1. Excessive refrigerant oil in

system.1. See Refrigerant Oil/Standard Procedure -

Refrigerant Oil Level in this group. Recover the

refrigerant from the refrigerant system and

inspect the refrigerant oil content. Restore the

refrigerant oil to the proper level, if required.

2. Blend door inoperative or

sealing improperly.2. See Blend Door in this group. Inspect the

blend door for proper operation and sealing and

correct, if required.

3. Blend door actuator faulty

or inoperative.3. Perform blend door actuator diagnosis, replace

if faulty.

The low side pressure is

normal or slightly low, and

the high side pressure is too

low.1. Low refrigerant system

charge.1. See Plumbing/Diagnosis and Testing -

Refrigerant System Leaks in this group. Test the

refrigerant system for leaks. Repair, evacuate and

charge the refrigerant system, if required.

2. Refrigerant flow through

the accumulator is restricted.2. See Accumulator in this group. Replace the

restricted accumulator, if required.

3. Refrigerant flow through

the evaporator coil is

restricted.3. See A/C Evaporator in this group. Replace the

restricted evaporator coil, if required.

4. Faulty compressor. 4. See A/C Compressor in this group. Replace

the compressor, if required.

The low side pressure is

normal or slightly high, and

the high side pressure is too

high.1. Condenser air flow

restricted.1. Check the condenser for damaged fins, foreign

objects obstructing air flow through the condenser

fins, and missing or improperly installed air seals.

Refer to Cooling for more information on air

seals. Clean, repair, or replace components as

required.

2. Inoperative cooling fan. 2. Refer to Cooling for more information. Test the

cooling fan and replace, if required.

3. Refrigerant system

overcharged.3. See Plumbing/Standard Procedure -

Refrigerant System Charge in this group. Recover

the refrigerant from the refrigerant system.

Charge the refrigerant system to the proper level,

if required.

24 - 4 HEATING & AIR CONDITIONINGDR

HEATING & AIR CONDITIONING (Continued)

Page 2781 of 2895

If the floor outlet air temperature is too low, refer

to Cooling to check the engine coolant temperature

specifications. Both of the heater hoses should be hot

to the touch. The coolant return heater hose should

be slightly cooler than the coolant supply heater

hose. If the return hose is much cooler than the sup-

ply hose, locate and repair the engine coolant flow

obstruction in the cooling system. Refer to Cooling

for the procedures.

An alternate method of checking heater perfor-

mance is to use a DRBIIItscan tool to monitor the

engine coolant temperature. The floor outlet air tem-

perature reading should be no more than 4.5É C (40É

F) lower than the engine coolant temperature read-

ing.

OBSTRUCTED COOLANT FLOW Possible loca-

tions or causes of obstructed coolant flow:

²Faulty water pump.

²Faulty thermostat.

²Pinched or kinked heater hoses.

²Improper heater hose routing.

²Plugged heater hoses or supply and return ports

at the cooling system connections.

²A plugged heater core.If proper coolant flow through the cooling system is

verified, and heater outlet air temperature is still

low, a mechanical problem may exist.

MECHANICAL PROBLEMS Possible locations or

causes of insufficient heat:

²An obstructed cowl air intake.

²Obstructed heater system outlets.

²A faulty, obstructed or improperly installed

blend door.

²A faulty blower system.

²A faulty a/c heater control.

TEMPERATURE CONTROL

If the heater outlet air temperature cannot be

adjusted with the temperature control knob on the

a/c heater control panel, the following could require

service:

²A faulty a/c heater control.

²A faulty blend door actuator.

²A faulty, obstructed or improperly installed

blend door.

²An obstructed cowl air intake.

²The engine cooling system.

Heater Diagnosis

CONDITION POSSIBLE CAUSE CORRECTION

INSUFFICIENT HEATER

OUTPUT.1. Incorrect engine

coolant level.1. Check the engine coolant level. Refer to Cooling for

the procedures.

2. Air trapped in engine

cooling system.2. Check the operation of the coolant reserve/recovery

system. Refer to Cooling for the procedures.

3. Incorrect engine

coolant temperature.3. Check the performance and operation of the engine

cooling system including: thermostat, water pump, fan

drive, accessory drive belt, coolant flow (plugged radiator

or heater core, plugged or kinked coolant hoses), air flow

(missing or improperly installed radiator air seals or fan

shroud). Refer to Cooling for the procedures.

4. Blend door actuator

inoperative or defective.4. (Refer to Controls/Blend Door Actuator) in this group.

5. Blend door not

operating properly.5. Check for a damaged, obstructed or improperly

installed blend door or seals. (Refer to Controls/Blend

Door Actuator) in this group.

6. Insufficient air flow

through heater housing.6. Remove foreign material or obstructions from cowl air

intake.

7. Improper blower motor

operation.7. (Refer to Distribution/Blower Motor/ Diagnosis and

Testing) in this group.

24 - 6 HEATING & AIR CONDITIONINGDR

HEATING & AIR CONDITIONING (Continued)

Page 2792 of 2895

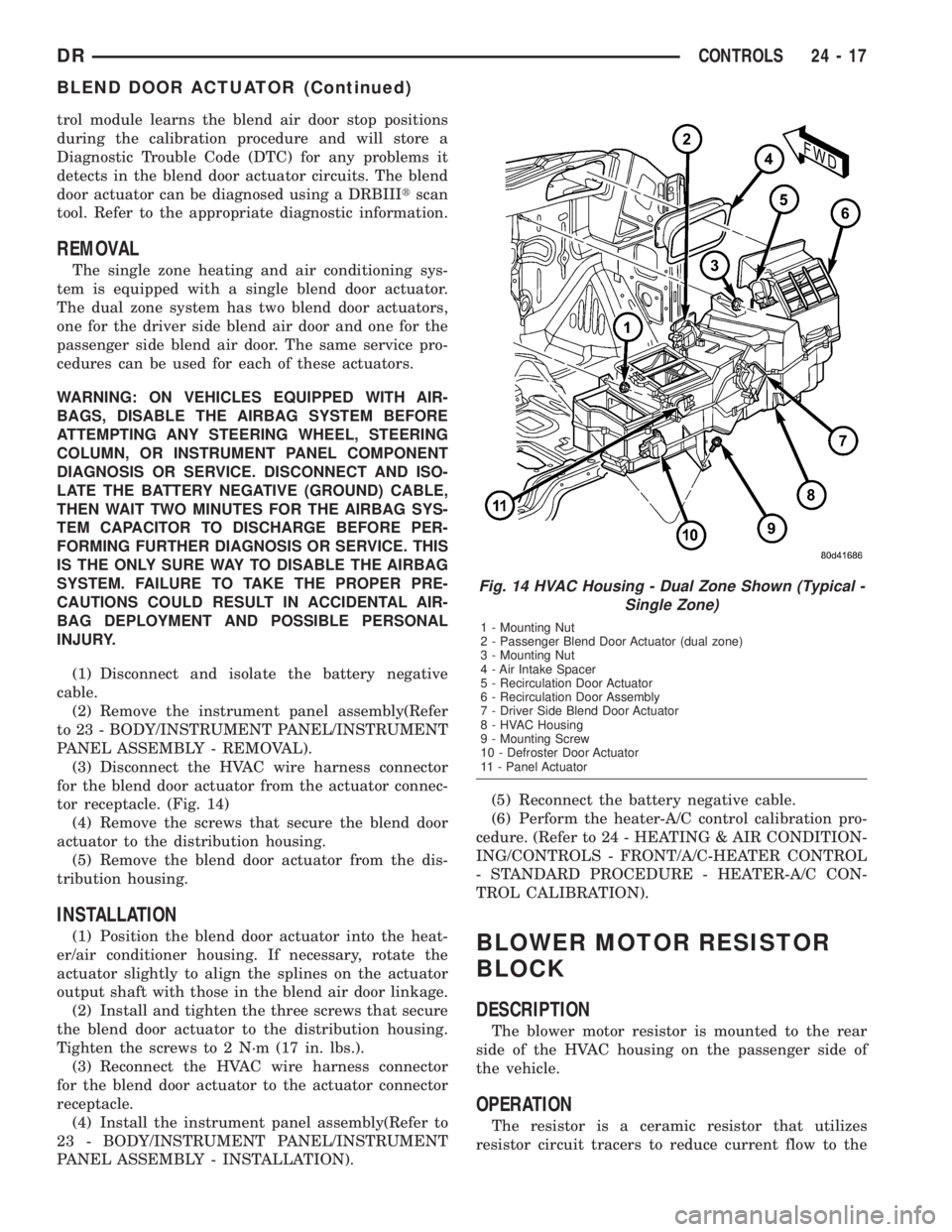

trol module learns the blend air door stop positions

during the calibration procedure and will store a

Diagnostic Trouble Code (DTC) for any problems it

detects in the blend door actuator circuits. The blend

door actuator can be diagnosed using a DRBIIItscan

tool. Refer to the appropriate diagnostic information.

REMOVAL

The single zone heating and air conditioning sys-

tem is equipped with a single blend door actuator.

The dual zone system has two blend door actuators,

one for the driver side blend air door and one for the

passenger side blend air door. The same service pro-

cedures can be used for each of these actuators.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument panel assembly(Refer

to 23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL ASSEMBLY - REMOVAL).

(3) Disconnect the HVAC wire harness connector

for the blend door actuator from the actuator connec-

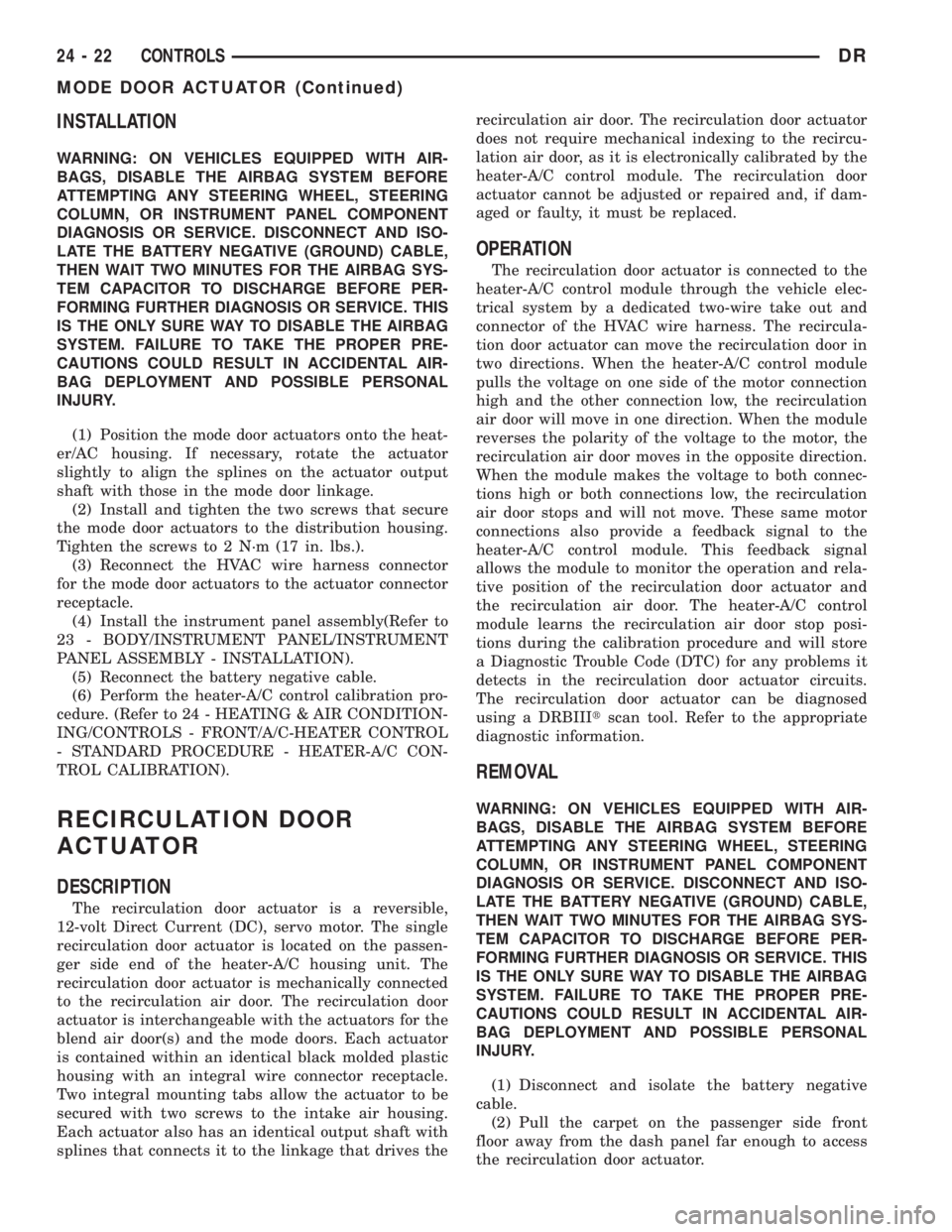

tor receptacle. (Fig. 14)

(4) Remove the screws that secure the blend door

actuator to the distribution housing.

(5) Remove the blend door actuator from the dis-

tribution housing.

INSTALLATION

(1) Position the blend door actuator into the heat-

er/air conditioner housing. If necessary, rotate the

actuator slightly to align the splines on the actuator

output shaft with those in the blend air door linkage.

(2) Install and tighten the three screws that secure

the blend door actuator to the distribution housing.

Tighten the screws to 2 N´m (17 in. lbs.).

(3) Reconnect the HVAC wire harness connector

for the blend door actuator to the actuator connector

receptacle.

(4) Install the instrument panel assembly(Refer to

23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL ASSEMBLY - INSTALLATION).(5) Reconnect the battery negative cable.

(6) Perform the heater-A/C control calibration pro-

cedure. (Refer to 24 - HEATING & AIR CONDITION-

ING/CONTROLS - FRONT/A/C-HEATER CONTROL

- STANDARD PROCEDURE - HEATER-A/C CON-

TROL CALIBRATION).BLOWER MOTOR RESISTOR

BLOCK

DESCRIPTION

The blower motor resistor is mounted to the rear

side of the HVAC housing on the passenger side of

the vehicle.

OPERATION

The resistor is a ceramic resistor that utilizes

resistor circuit tracers to reduce current flow to the

Fig. 14 HVAC Housing - Dual Zone Shown (Typical -

Single Zone)

1 - Mounting Nut

2 - Passenger Blend Door Actuator (dual zone)

3 - Mounting Nut

4 - Air Intake Spacer

5 - Recirculation Door Actuator

6 - Recirculation Door Assembly

7 - Driver Side Blend Door Actuator

8 - HVAC Housing

9 - Mounting Screw

10 - Defroster Door Actuator

11 - Panel Actuator

DRCONTROLS 24 - 17

BLEND DOOR ACTUATOR (Continued)

Page 2797 of 2895

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Position the mode door actuators onto the heat-

er/AC housing. If necessary, rotate the actuator

slightly to align the splines on the actuator output

shaft with those in the mode door linkage.

(2) Install and tighten the two screws that secure

the mode door actuators to the distribution housing.

Tighten the screws to 2 N´m (17 in. lbs.).

(3) Reconnect the HVAC wire harness connector

for the mode door actuators to the actuator connector

receptacle.

(4) Install the instrument panel assembly(Refer to

23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL ASSEMBLY - INSTALLATION).

(5) Reconnect the battery negative cable.

(6) Perform the heater-A/C control calibration pro-

cedure. (Refer to 24 - HEATING & AIR CONDITION-

ING/CONTROLS - FRONT/A/C-HEATER CONTROL

- STANDARD PROCEDURE - HEATER-A/C CON-

TROL CALIBRATION).

RECIRCULATION DOOR

ACTUATOR

DESCRIPTION

The recirculation door actuator is a reversible,

12-volt Direct Current (DC), servo motor. The single

recirculation door actuator is located on the passen-

ger side end of the heater-A/C housing unit. The

recirculation door actuator is mechanically connected

to the recirculation air door. The recirculation door

actuator is interchangeable with the actuators for the

blend air door(s) and the mode doors. Each actuator

is contained within an identical black molded plastic

housing with an integral wire connector receptacle.

Two integral mounting tabs allow the actuator to be

secured with two screws to the intake air housing.

Each actuator also has an identical output shaft with

splines that connects it to the linkage that drives therecirculation air door. The recirculation door actuator

does not require mechanical indexing to the recircu-

lation air door, as it is electronically calibrated by the

heater-A/C control module. The recirculation door

actuator cannot be adjusted or repaired and, if dam-

aged or faulty, it must be replaced.

OPERATION

The recirculation door actuator is connected to the

heater-A/C control module through the vehicle elec-

trical system by a dedicated two-wire take out and

connector of the HVAC wire harness. The recircula-

tion door actuator can move the recirculation door in

two directions. When the heater-A/C control module

pulls the voltage on one side of the motor connection

high and the other connection low, the recirculation

air door will move in one direction. When the module

reverses the polarity of the voltage to the motor, the

recirculation air door moves in the opposite direction.

When the module makes the voltage to both connec-

tions high or both connections low, the recirculation

air door stops and will not move. These same motor

connections also provide a feedback signal to the

heater-A/C control module. This feedback signal

allows the module to monitor the operation and rela-

tive position of the recirculation door actuator and

the recirculation air door. The heater-A/C control

module learns the recirculation air door stop posi-

tions during the calibration procedure and will store

a Diagnostic Trouble Code (DTC) for any problems it

detects in the recirculation door actuator circuits.

The recirculation door actuator can be diagnosed

using a DRBIIItscan tool. Refer to the appropriate

diagnostic information.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Pull the carpet on the passenger side front

floor away from the dash panel far enough to access

the recirculation door actuator.

24 - 22 CONTROLSDR

MODE DOOR ACTUATOR (Continued)

Page 2798 of 2895

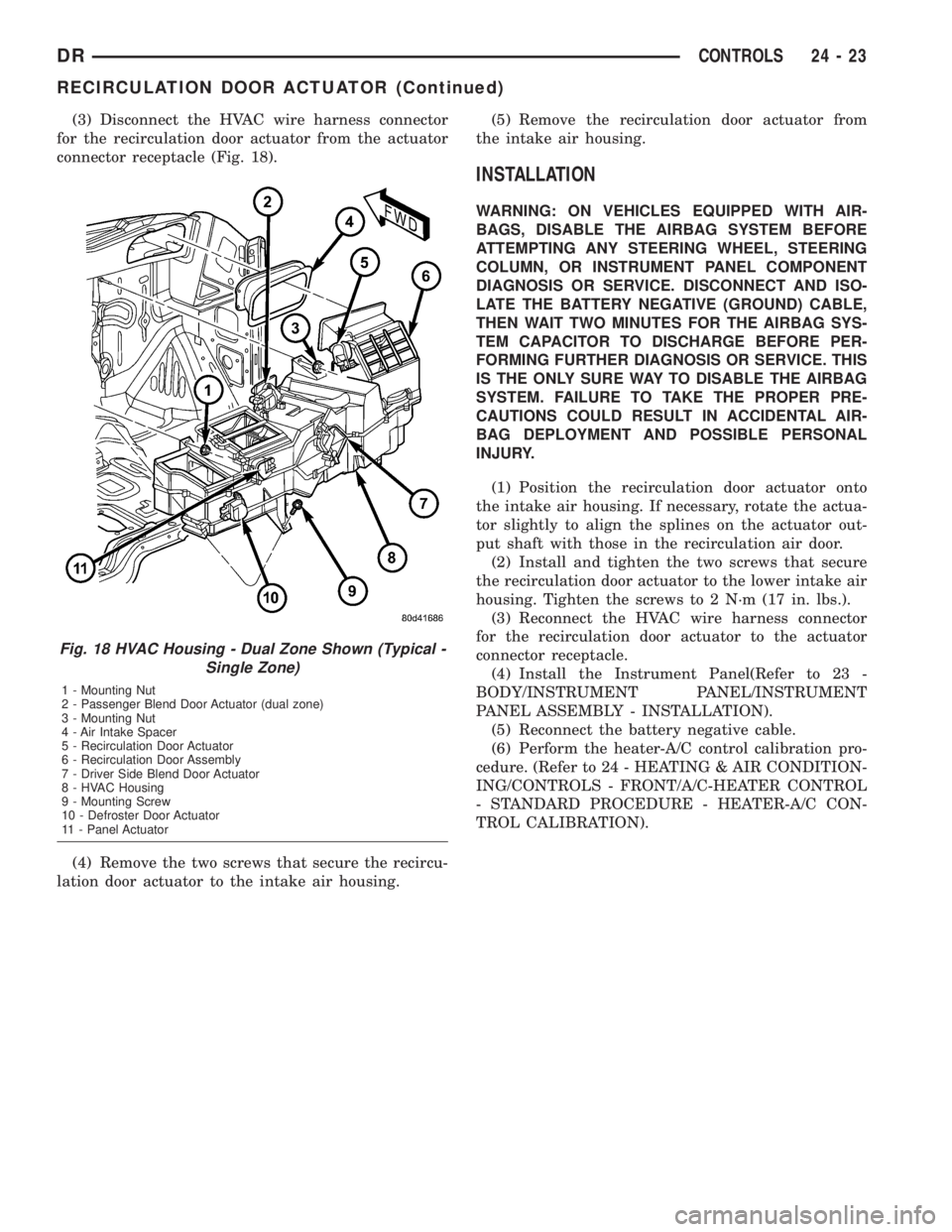

(3) Disconnect the HVAC wire harness connector

for the recirculation door actuator from the actuator

connector receptacle (Fig. 18).

(4) Remove the two screws that secure the recircu-

lation door actuator to the intake air housing.(5) Remove the recirculation door actuator from

the intake air housing.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Position the recirculation door actuator onto

the intake air housing. If necessary, rotate the actua-

tor slightly to align the splines on the actuator out-

put shaft with those in the recirculation air door.

(2) Install and tighten the two screws that secure

the recirculation door actuator to the lower intake air

housing. Tighten the screws to 2 N´m (17 in. lbs.).

(3) Reconnect the HVAC wire harness connector

for the recirculation door actuator to the actuator

connector receptacle.

(4) Install the Instrument Panel(Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL ASSEMBLY - INSTALLATION).

(5) Reconnect the battery negative cable.

(6) Perform the heater-A/C control calibration pro-

cedure. (Refer to 24 - HEATING & AIR CONDITION-

ING/CONTROLS - FRONT/A/C-HEATER CONTROL

- STANDARD PROCEDURE - HEATER-A/C CON-

TROL CALIBRATION).

Fig. 18 HVAC Housing - Dual Zone Shown (Typical -

Single Zone)

1 - Mounting Nut

2 - Passenger Blend Door Actuator (dual zone)

3 - Mounting Nut

4 - Air Intake Spacer

5 - Recirculation Door Actuator

6 - Recirculation Door Assembly

7 - Driver Side Blend Door Actuator

8 - HVAC Housing

9 - Mounting Screw

10 - Defroster Door Actuator

11 - Panel Actuator

DRCONTROLS 24 - 23

RECIRCULATION DOOR ACTUATOR (Continued)