service DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1854 of 2895

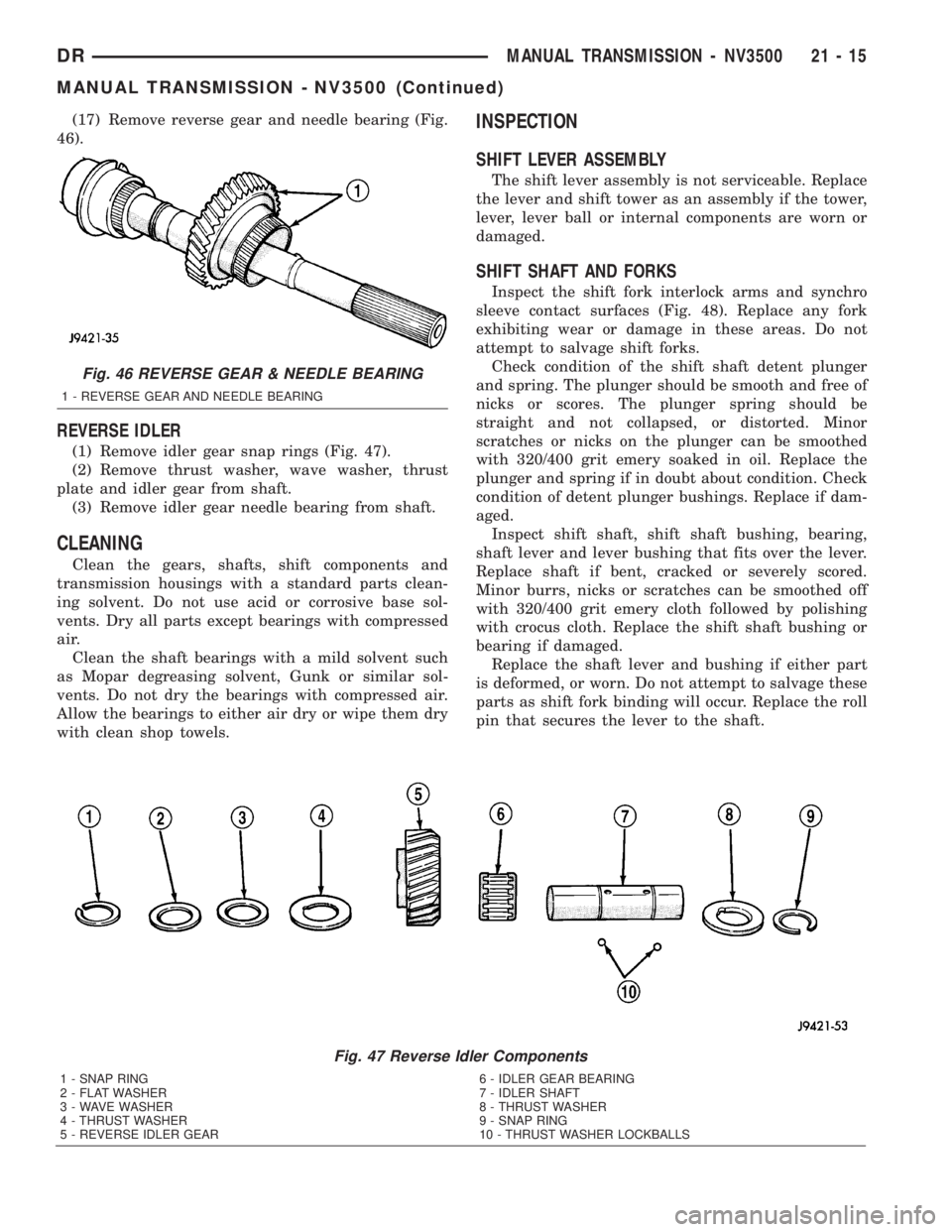

(17) Remove reverse gear and needle bearing (Fig.

46).

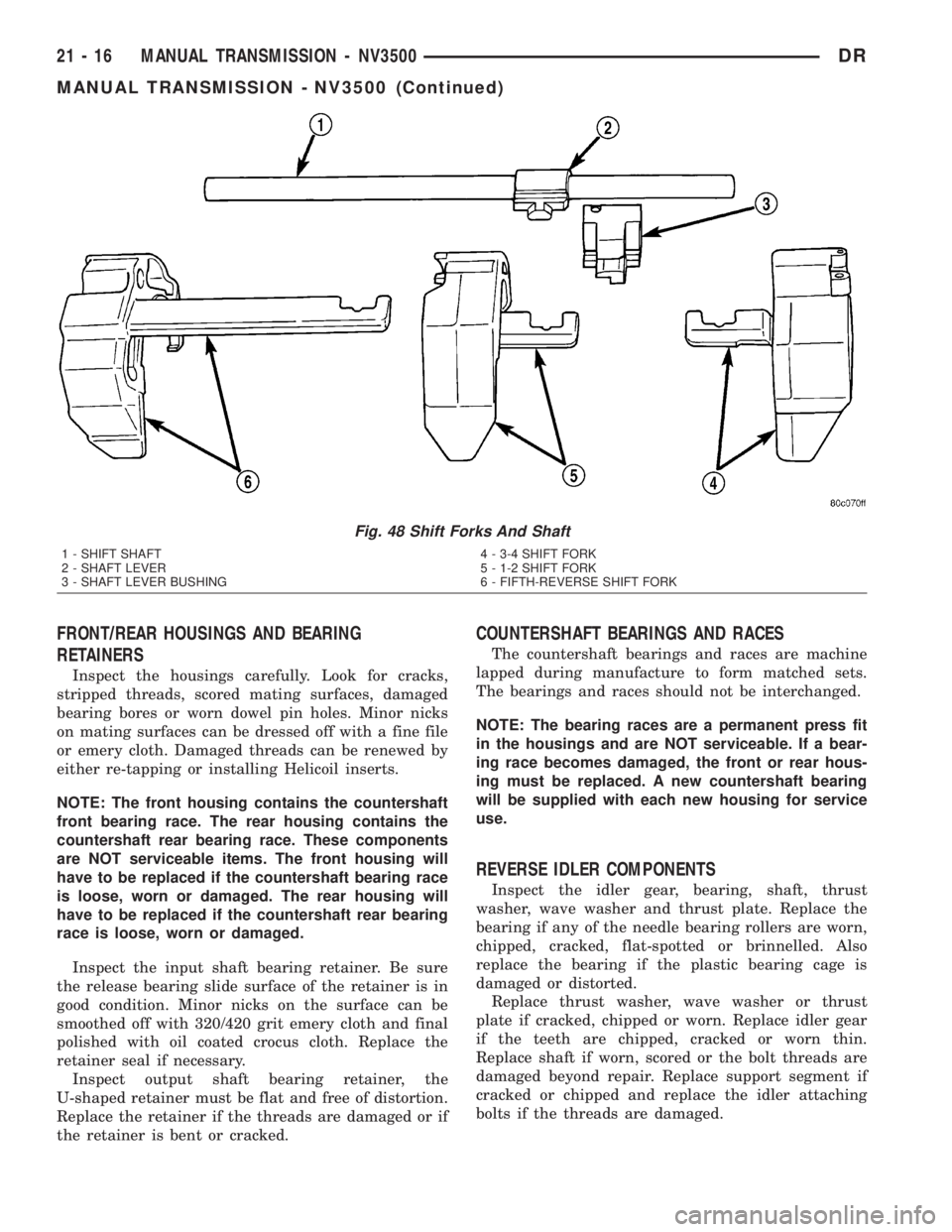

REVERSE IDLER

(1) Remove idler gear snap rings (Fig. 47).

(2) Remove thrust washer, wave washer, thrust

plate and idler gear from shaft.

(3) Remove idler gear needle bearing from shaft.

CLEANING

Clean the gears, shafts, shift components and

transmission housings with a standard parts clean-

ing solvent. Do not use acid or corrosive base sol-

vents. Dry all parts except bearings with compressed

air.

Clean the shaft bearings with a mild solvent such

as Mopar degreasing solvent, Gunk or similar sol-

vents. Do not dry the bearings with compressed air.

Allow the bearings to either air dry or wipe them dry

with clean shop towels.

INSPECTION

SHIFT LEVER ASSEMBLY

The shift lever assembly is not serviceable. Replace

the lever and shift tower as an assembly if the tower,

lever, lever ball or internal components are worn or

damaged.

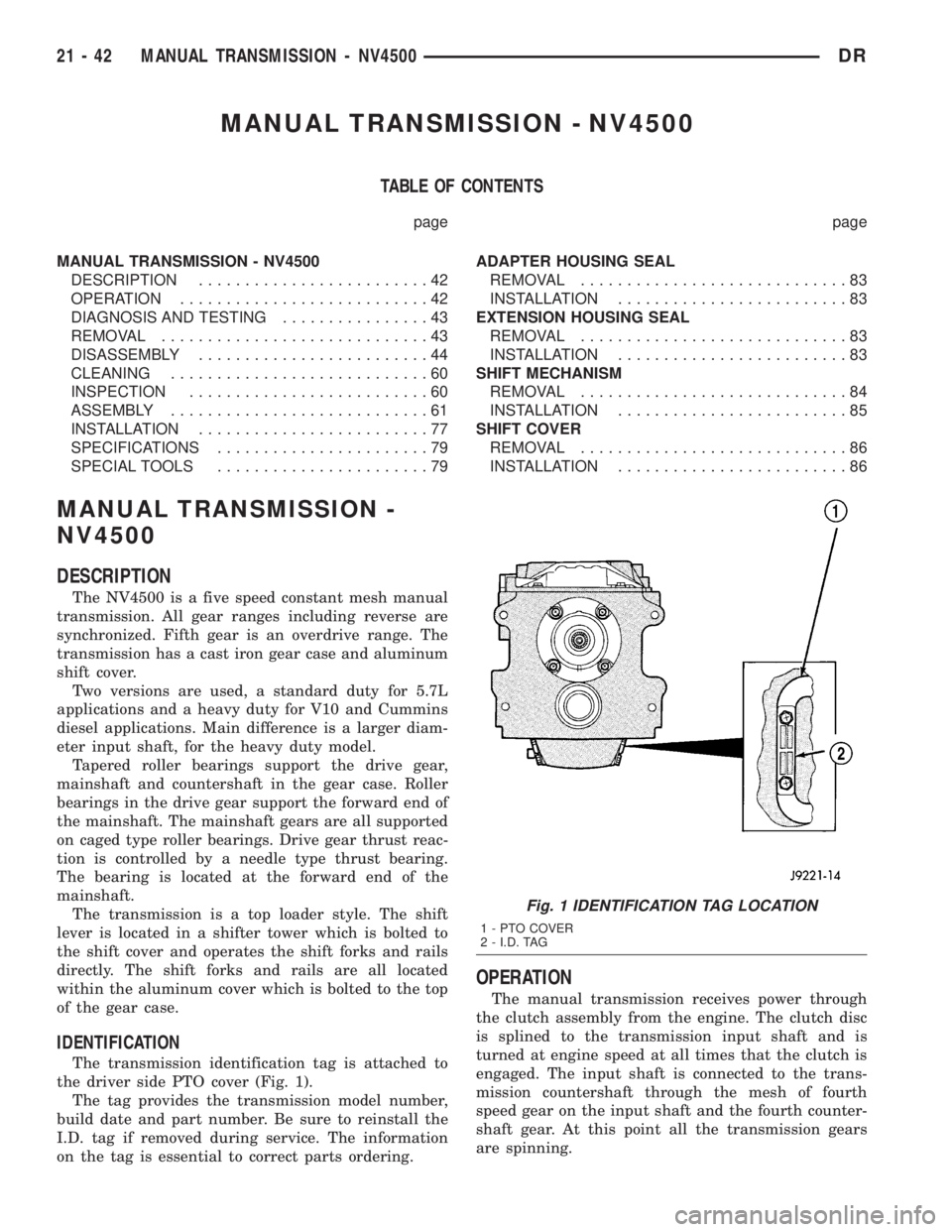

SHIFT SHAFT AND FORKS

Inspect the shift fork interlock arms and synchro

sleeve contact surfaces (Fig. 48). Replace any fork

exhibiting wear or damage in these areas. Do not

attempt to salvage shift forks.

Check condition of the shift shaft detent plunger

and spring. The plunger should be smooth and free of

nicks or scores. The plunger spring should be

straight and not collapsed, or distorted. Minor

scratches or nicks on the plunger can be smoothed

with 320/400 grit emery soaked in oil. Replace the

plunger and spring if in doubt about condition. Check

condition of detent plunger bushings. Replace if dam-

aged.

Inspect shift shaft, shift shaft bushing, bearing,

shaft lever and lever bushing that fits over the lever.

Replace shaft if bent, cracked or severely scored.

Minor burrs, nicks or scratches can be smoothed off

with 320/400 grit emery cloth followed by polishing

with crocus cloth. Replace the shift shaft bushing or

bearing if damaged.

Replace the shaft lever and bushing if either part

is deformed, or worn. Do not attempt to salvage these

parts as shift fork binding will occur. Replace the roll

pin that secures the lever to the shaft.

Fig. 47 Reverse Idler Components

1 - SNAP RING

2 - FLAT WASHER

3 - WAVE WASHER

4 - THRUST WASHER

5 - REVERSE IDLER GEAR6 - IDLER GEAR BEARING

7 - IDLER SHAFT

8 - THRUST WASHER

9 - SNAP RING

10 - THRUST WASHER LOCKBALLS

Fig. 46 REVERSE GEAR & NEEDLE BEARING

1 - REVERSE GEAR AND NEEDLE BEARING

DRMANUAL TRANSMISSION - NV3500 21 - 15

MANUAL TRANSMISSION - NV3500 (Continued)

Page 1855 of 2895

FRONT/REAR HOUSINGS AND BEARING

RETAINERS

Inspect the housings carefully. Look for cracks,

stripped threads, scored mating surfaces, damaged

bearing bores or worn dowel pin holes. Minor nicks

on mating surfaces can be dressed off with a fine file

or emery cloth. Damaged threads can be renewed by

either re-tapping or installing Helicoil inserts.

NOTE: The front housing contains the countershaft

front bearing race. The rear housing contains the

countershaft rear bearing race. These components

are NOT serviceable items. The front housing will

have to be replaced if the countershaft bearing race

is loose, worn or damaged. The rear housing will

have to be replaced if the countershaft rear bearing

race is loose, worn or damaged.

Inspect the input shaft bearing retainer. Be sure

the release bearing slide surface of the retainer is in

good condition. Minor nicks on the surface can be

smoothed off with 320/420 grit emery cloth and final

polished with oil coated crocus cloth. Replace the

retainer seal if necessary.

Inspect output shaft bearing retainer, the

U-shaped retainer must be flat and free of distortion.

Replace the retainer if the threads are damaged or if

the retainer is bent or cracked.

COUNTERSHAFT BEARINGS AND RACES

The countershaft bearings and races are machine

lapped during manufacture to form matched sets.

The bearings and races should not be interchanged.

NOTE: The bearing races are a permanent press fit

in the housings and are NOT serviceable. If a bear-

ing race becomes damaged, the front or rear hous-

ing must be replaced. A new countershaft bearing

will be supplied with each new housing for service

use.

REVERSE IDLER COMPONENTS

Inspect the idler gear, bearing, shaft, thrust

washer, wave washer and thrust plate. Replace the

bearing if any of the needle bearing rollers are worn,

chipped, cracked, flat-spotted or brinnelled. Also

replace the bearing if the plastic bearing cage is

damaged or distorted.

Replace thrust washer, wave washer or thrust

plate if cracked, chipped or worn. Replace idler gear

if the teeth are chipped, cracked or worn thin.

Replace shaft if worn, scored or the bolt threads are

damaged beyond repair. Replace support segment if

cracked or chipped and replace the idler attaching

bolts if the threads are damaged.

Fig. 48 Shift Forks And Shaft

1 - SHIFT SHAFT

2 - SHAFT LEVER

3 - SHAFT LEVER BUSHING4 - 3-4 SHIFT FORK

5 - 1-2 SHIFT FORK

6 - FIFTH-REVERSE SHIFT FORK

21 - 16 MANUAL TRANSMISSION - NV3500DR

MANUAL TRANSMISSION - NV3500 (Continued)

Page 1881 of 2895

MANUAL TRANSMISSION - NV4500

TABLE OF CONTENTS

page page

MANUAL TRANSMISSION - NV4500

DESCRIPTION.........................42

OPERATION...........................42

DIAGNOSIS AND TESTING................43

REMOVAL.............................43

DISASSEMBLY.........................44

CLEANING............................60

INSPECTION..........................60

ASSEMBLY............................61

INSTALLATION.........................77

SPECIFICATIONS.......................79

SPECIAL TOOLS.......................79ADAPTER HOUSING SEAL

REMOVAL.............................83

INSTALLATION.........................83

EXTENSION HOUSING SEAL

REMOVAL.............................83

INSTALLATION.........................83

SHIFT MECHANISM

REMOVAL.............................84

INSTALLATION.........................85

SHIFT COVER

REMOVAL.............................86

INSTALLATION.........................86

MANUAL TRANSMISSION -

NV4500

DESCRIPTION

The NV4500 is a five speed constant mesh manual

transmission. All gear ranges including reverse are

synchronized. Fifth gear is an overdrive range. The

transmission has a cast iron gear case and aluminum

shift cover.

Two versions are used, a standard duty for 5.7L

applications and a heavy duty for V10 and Cummins

diesel applications. Main difference is a larger diam-

eter input shaft, for the heavy duty model.

Tapered roller bearings support the drive gear,

mainshaft and countershaft in the gear case. Roller

bearings in the drive gear support the forward end of

the mainshaft. The mainshaft gears are all supported

on caged type roller bearings. Drive gear thrust reac-

tion is controlled by a needle type thrust bearing.

The bearing is located at the forward end of the

mainshaft.

The transmission is a top loader style. The shift

lever is located in a shifter tower which is bolted to

the shift cover and operates the shift forks and rails

directly. The shift forks and rails are all located

within the aluminum cover which is bolted to the top

of the gear case.

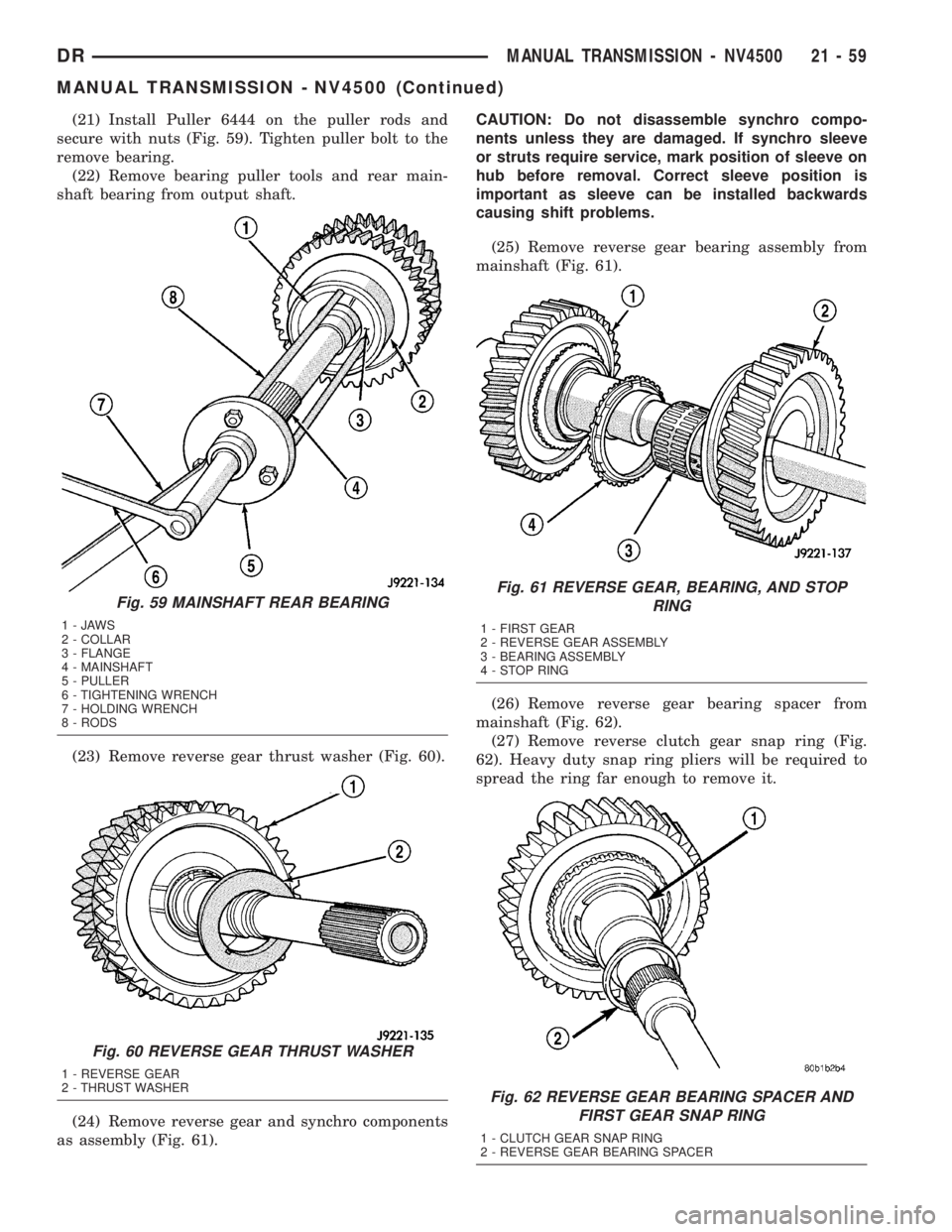

IDENTIFICATION

The transmission identification tag is attached to

the driver side PTO cover (Fig. 1).

The tag provides the transmission model number,

build date and part number. Be sure to reinstall the

I.D. tag if removed during service. The information

on the tag is essential to correct parts ordering.

OPERATION

The manual transmission receives power through

the clutch assembly from the engine. The clutch disc

is splined to the transmission input shaft and is

turned at engine speed at all times that the clutch is

engaged. The input shaft is connected to the trans-

mission countershaft through the mesh of fourth

speed gear on the input shaft and the fourth counter-

shaft gear. At this point all the transmission gears

are spinning.

Fig. 1 IDENTIFICATION TAG LOCATION

1 - PTO COVER

2 - I.D. TAG

21 - 42 MANUAL TRANSMISSION - NV4500DR

Page 1898 of 2895

(21) Install Puller 6444 on the puller rods and

secure with nuts (Fig. 59). Tighten puller bolt to the

remove bearing.

(22) Remove bearing puller tools and rear main-

shaft bearing from output shaft.

(23) Remove reverse gear thrust washer (Fig. 60).

(24) Remove reverse gear and synchro components

as assembly (Fig. 61).CAUTION: Do not disassemble synchro compo-

nents unless they are damaged. If synchro sleeve

or struts require service, mark position of sleeve on

hub before removal. Correct sleeve position is

important as sleeve can be installed backwards

causing shift problems.

(25) Remove reverse gear bearing assembly from

mainshaft (Fig. 61).

(26) Remove reverse gear bearing spacer from

mainshaft (Fig. 62).

(27) Remove reverse clutch gear snap ring (Fig.

62). Heavy duty snap ring pliers will be required to

spread the ring far enough to remove it.

Fig. 59 MAINSHAFT REAR BEARING

1-JAWS

2 - COLLAR

3 - FLANGE

4 - MAINSHAFT

5 - PULLER

6 - TIGHTENING WRENCH

7 - HOLDING WRENCH

8 - RODS

Fig. 60 REVERSE GEAR THRUST WASHER

1 - REVERSE GEAR

2 - THRUST WASHER

Fig. 61 REVERSE GEAR, BEARING, AND STOP

RING

1 - FIRST GEAR

2 - REVERSE GEAR ASSEMBLY

3 - BEARING ASSEMBLY

4 - STOP RING

Fig. 62 REVERSE GEAR BEARING SPACER AND

FIRST GEAR SNAP RING

1 - CLUTCH GEAR SNAP RING

2 - REVERSE GEAR BEARING SPACER

DRMANUAL TRANSMISSION - NV4500 21 - 59

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1904 of 2895

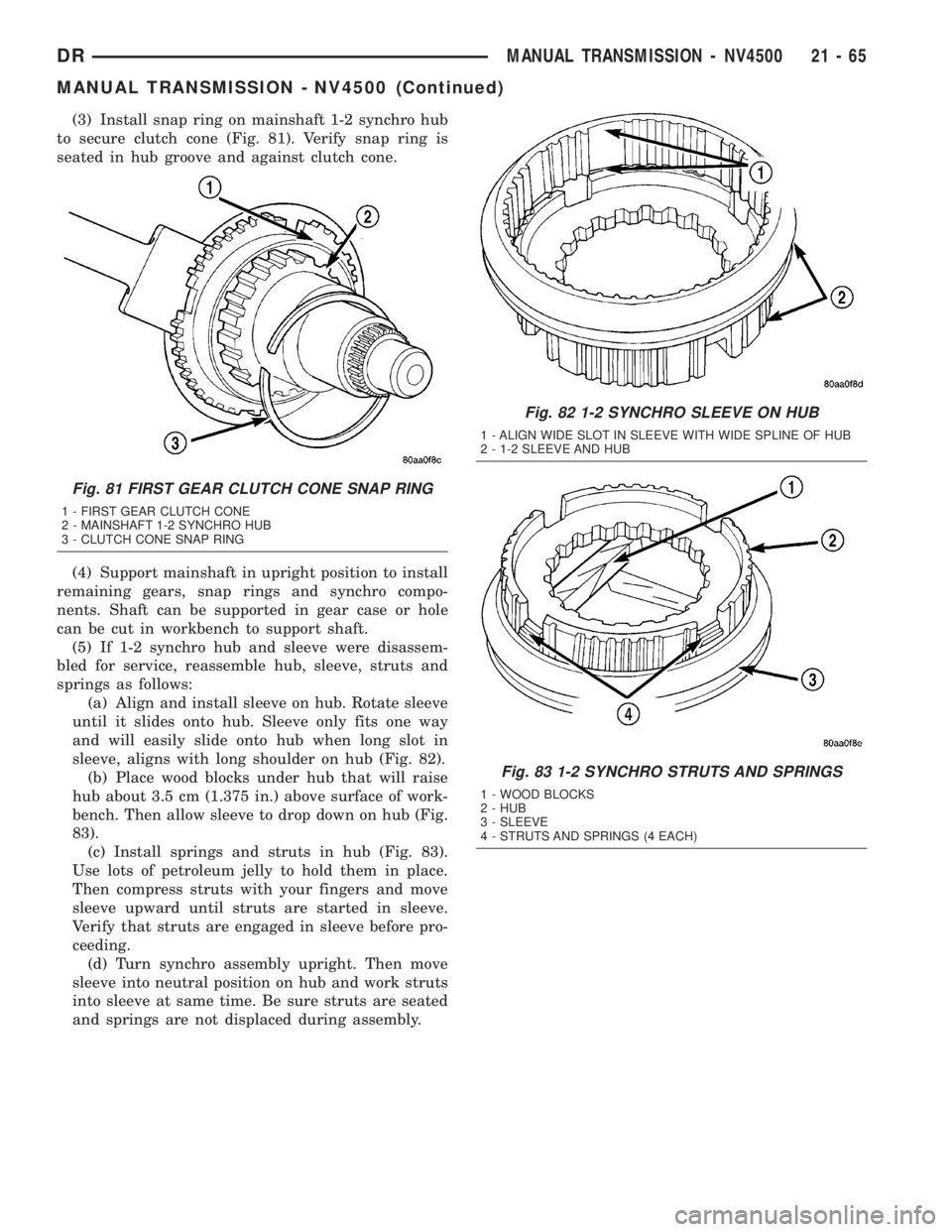

(3) Install snap ring on mainshaft 1-2 synchro hub

to secure clutch cone (Fig. 81). Verify snap ring is

seated in hub groove and against clutch cone.

(4) Support mainshaft in upright position to install

remaining gears, snap rings and synchro compo-

nents. Shaft can be supported in gear case or hole

can be cut in workbench to support shaft.

(5) If 1-2 synchro hub and sleeve were disassem-

bled for service, reassemble hub, sleeve, struts and

springs as follows:

(a) Align and install sleeve on hub. Rotate sleeve

until it slides onto hub. Sleeve only fits one way

and will easily slide onto hub when long slot in

sleeve, aligns with long shoulder on hub (Fig. 82).

(b) Place wood blocks under hub that will raise

hub about 3.5 cm (1.375 in.) above surface of work-

bench. Then allow sleeve to drop down on hub (Fig.

83).

(c) Install springs and struts in hub (Fig. 83).

Use lots of petroleum jelly to hold them in place.

Then compress struts with your fingers and move

sleeve upward until struts are started in sleeve.

Verify that struts are engaged in sleeve before pro-

ceeding.

(d) Turn synchro assembly upright. Then move

sleeve into neutral position on hub and work struts

into sleeve at same time. Be sure struts are seated

and springs are not displaced during assembly.

Fig. 81 FIRST GEAR CLUTCH CONE SNAP RING

1 - FIRST GEAR CLUTCH CONE

2 - MAINSHAFT 1-2 SYNCHRO HUB

3 - CLUTCH CONE SNAP RING

Fig. 82 1-2 SYNCHRO SLEEVE ON HUB

1 - ALIGN WIDE SLOT IN SLEEVE WITH WIDE SPLINE OF HUB

2 - 1-2 SLEEVE AND HUB

Fig. 83 1-2 SYNCHRO STRUTS AND SPRINGS

1 - WOOD BLOCKS

2 - HUB

3 - SLEEVE

4 - STRUTS AND SPRINGS (4 EACH)

DRMANUAL TRANSMISSION - NV4500 21 - 65

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1908 of 2895

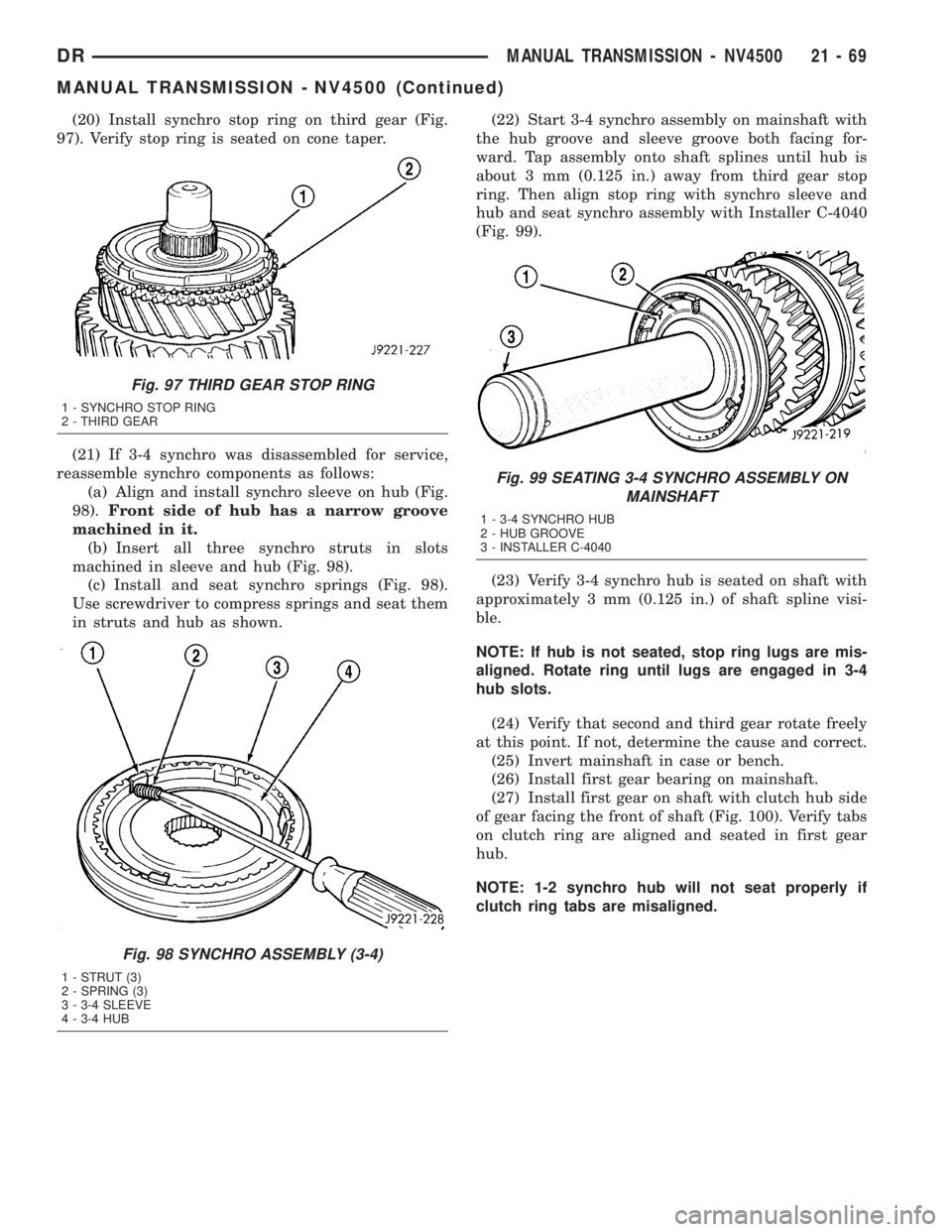

(20) Install synchro stop ring on third gear (Fig.

97). Verify stop ring is seated on cone taper.

(21) If 3-4 synchro was disassembled for service,

reassemble synchro components as follows:

(a) Align and install synchro sleeve on hub (Fig.

98).Front side of hub has a narrow groove

machined in it.

(b) Insert all three synchro struts in slots

machined in sleeve and hub (Fig. 98).

(c) Install and seat synchro springs (Fig. 98).

Use screwdriver to compress springs and seat them

in struts and hub as shown.(22) Start 3-4 synchro assembly on mainshaft with

the hub groove and sleeve groove both facing for-

ward. Tap assembly onto shaft splines until hub is

about 3 mm (0.125 in.) away from third gear stop

ring. Then align stop ring with synchro sleeve and

hub and seat synchro assembly with Installer C-4040

(Fig. 99).

(23) Verify 3-4 synchro hub is seated on shaft with

approximately 3 mm (0.125 in.) of shaft spline visi-

ble.

NOTE: If hub is not seated, stop ring lugs are mis-

aligned. Rotate ring until lugs are engaged in 3-4

hub slots.

(24) Verify that second and third gear rotate freely

at this point. If not, determine the cause and correct.

(25) Invert mainshaft in case or bench.

(26) Install first gear bearing on mainshaft.

(27) Install first gear on shaft with clutch hub side

of gear facing the front of shaft (Fig. 100). Verify tabs

on clutch ring are aligned and seated in first gear

hub.

NOTE: 1-2 synchro hub will not seat properly if

clutch ring tabs are misaligned.

Fig. 97 THIRD GEAR STOP RING

1 - SYNCHRO STOP RING

2 - THIRD GEAR

Fig. 98 SYNCHRO ASSEMBLY (3-4)

1 - STRUT (3)

2 - SPRING (3)

3 - 3-4 SLEEVE

4 - 3-4 HUB

Fig. 99 SEATING 3-4 SYNCHRO ASSEMBLY ON

MAINSHAFT

1 - 3-4 SYNCHRO HUB

2 - HUB GROOVE

3 - INSTALLER C-4040

DRMANUAL TRANSMISSION - NV4500 21 - 69

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1909 of 2895

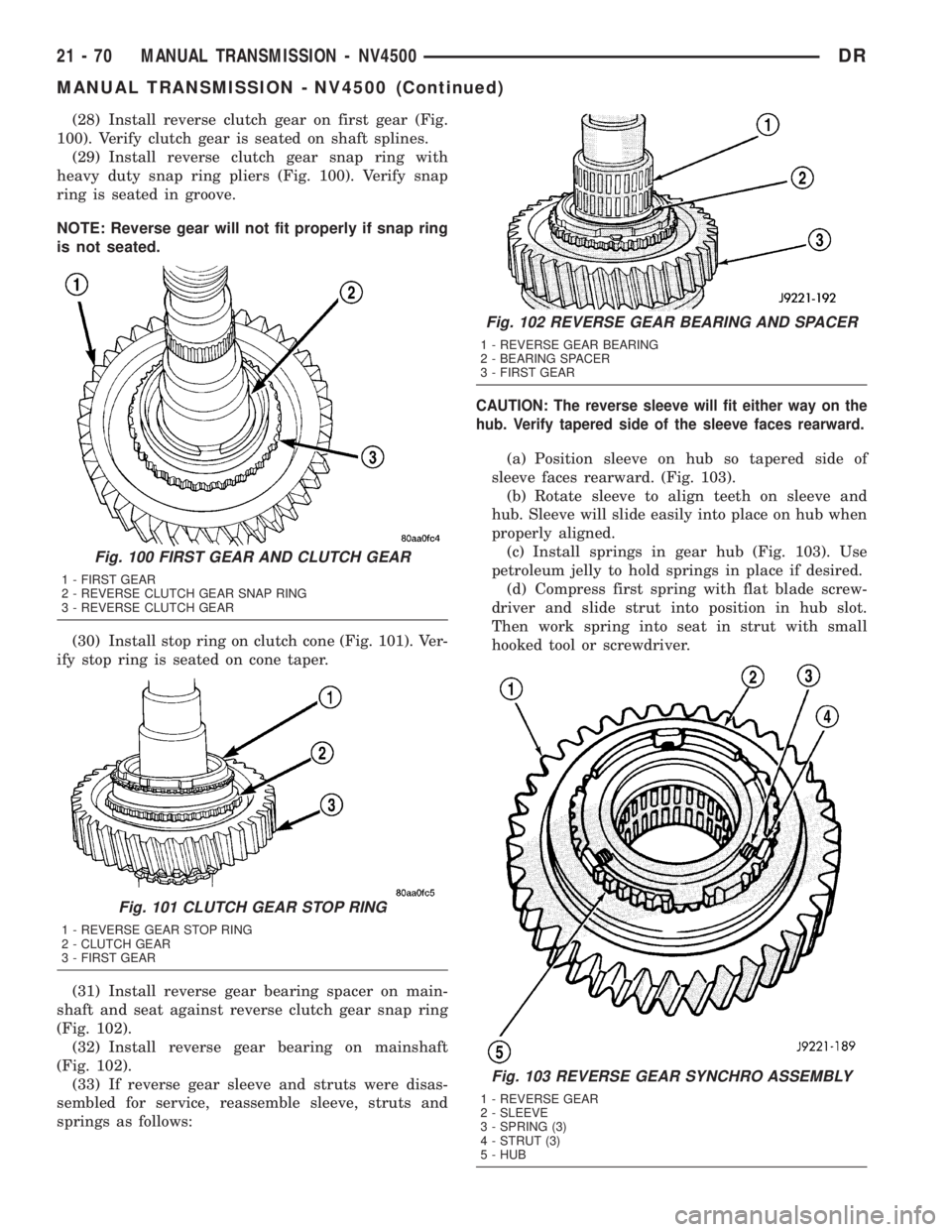

(28) Install reverse clutch gear on first gear (Fig.

100). Verify clutch gear is seated on shaft splines.

(29) Install reverse clutch gear snap ring with

heavy duty snap ring pliers (Fig. 100). Verify snap

ring is seated in groove.

NOTE: Reverse gear will not fit properly if snap ring

is not seated.

(30) Install stop ring on clutch cone (Fig. 101). Ver-

ify stop ring is seated on cone taper.

(31) Install reverse gear bearing spacer on main-

shaft and seat against reverse clutch gear snap ring

(Fig. 102).

(32) Install reverse gear bearing on mainshaft

(Fig. 102).

(33) If reverse gear sleeve and struts were disas-

sembled for service, reassemble sleeve, struts and

springs as follows:

CAUTION: The reverse sleeve will fit either way on the

hub. Verify tapered side of the sleeve faces rearward.

(a) Position sleeve on hub so tapered side of

sleeve faces rearward. (Fig. 103).

(b) Rotate sleeve to align teeth on sleeve and

hub. Sleeve will slide easily into place on hub when

properly aligned.

(c) Install springs in gear hub (Fig. 103). Use

petroleum jelly to hold springs in place if desired.

(d) Compress first spring with flat blade screw-

driver and slide strut into position in hub slot.

Then work spring into seat in strut with small

hooked tool or screwdriver.

Fig. 103 REVERSE GEAR SYNCHRO ASSEMBLY

1 - REVERSE GEAR

2 - SLEEVE

3 - SPRING (3)

4 - STRUT (3)

5 - HUB

Fig. 100 FIRST GEAR AND CLUTCH GEAR

1 - FIRST GEAR

2 - REVERSE CLUTCH GEAR SNAP RING

3 - REVERSE CLUTCH GEAR

Fig. 101 CLUTCH GEAR STOP RING

1 - REVERSE GEAR STOP RING

2 - CLUTCH GEAR

3 - FIRST GEAR

Fig. 102 REVERSE GEAR BEARING AND SPACER

1 - REVERSE GEAR BEARING

2 - BEARING SPACER

3 - FIRST GEAR

21 - 70 MANUAL TRANSMISSION - NV4500DR

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1981 of 2895

Test Four - Transmission In Reverse

This test checks pump output, pressure regulation

and the front clutch and rear servo circuits. Use 300

psi Test Gauge C-3293-SP for this test.

(1) Leave vehicle on hoist and leave gauge C-3292

in place at accumulator port.

(2) Move 300 psi Gauge C-3293-SP back to rear

servo port.

(3) Have helper start and run engine at 1600 rpm

for test.

(4) Move transmission shift lever four detents

rearward from full forward position. This is Reverse

range.

(5) Move transmission throttle lever fully forward

then fully rearward and note reading at Gauge

C-3293-SP.

(6) Pressure should be 145 - 175 psi (1000-1207

kPa) with throttle lever forward and increase to 230 -

280 psi (1586-1931 kPa) as lever is gradually moved

rearward.

Test Five - Governor Pressure

This test checks governor operation by measuring

governor pressure response to changes in vehicle

speed. It is usually not necessary to check governor

operation unless shift speeds are incorrect or if the

transmission will not downshift. The test should be

performed on the road or on a hoist that will allow

the rear wheels to rotate freely.

(1) Move 100 psi Test Gauge C-3292 to governor

pressure port.

(2) Move transmission shift lever two detents rear-

ward from full forward position. This is D range.

(3) Have helper start and run engine at curb idle

speed. Then firmly apply service brakes so wheels

will not rotate.

(4) Note governor pressure:

²Governor pressure should be no more than 20.6

kPa (3 psi) at curb idle speed and wheels not rotat-

ing.

²If pressure exceeds 20.6 kPa (3 psi), a fault

exists in governor pressure control system.

(5) Release brakes, slowly increase engine speed,

and observe speedometer and pressure test gauge (do

not exceed 30 mph on speedometer). Governor pres-

sure should increase in proportion to vehicle speed.

Or approximately 6.89 kPa (1 psi) for every 1 mph.

(6) Governor pressure rise should be smooth and

drop back to no more than 20.6 kPa (3 psi), after

engine returns to curb idle and brakes are applied to

prevent wheels from rotating.

(7) Compare results of pressure test with analysis

chart.Test Six - Transmission In Overdrive Fourth Gear

This test checks line pressure at the overdrive

clutch in fourth gear range. Use 300 psi Test Gauge

C-3293-SP for this test. The test should be performed

on the road or on a chassis dyno.

(1) Remove tachometer; it is not needed for this

test.

(2) Move 300 psi Gauge to overdrive clutch pres-

sure test port. Then remove other gauge and reinstall

test port plug.

(3) Lower vehicle.

(4) Turn OD switch on.

(5) Secure test gauge so it can be viewed from

drivers seat.

(6) Start engine and shift into D range.

(7) Increase vehicle speed gradually until 3-4 shift

occurs and note gauge pressure.

(8) Pressure should be 469-496 kPa (68-72 psi)

with closed throttle and increase to 620-827 kPa (90-

120 psi) at 1/2 to 3/4 throttle. Note that pressure can

increase to around 896 kPa (130 psi) at full throttle.

(9) Return to shop or move vehicle off chassis

dyno.

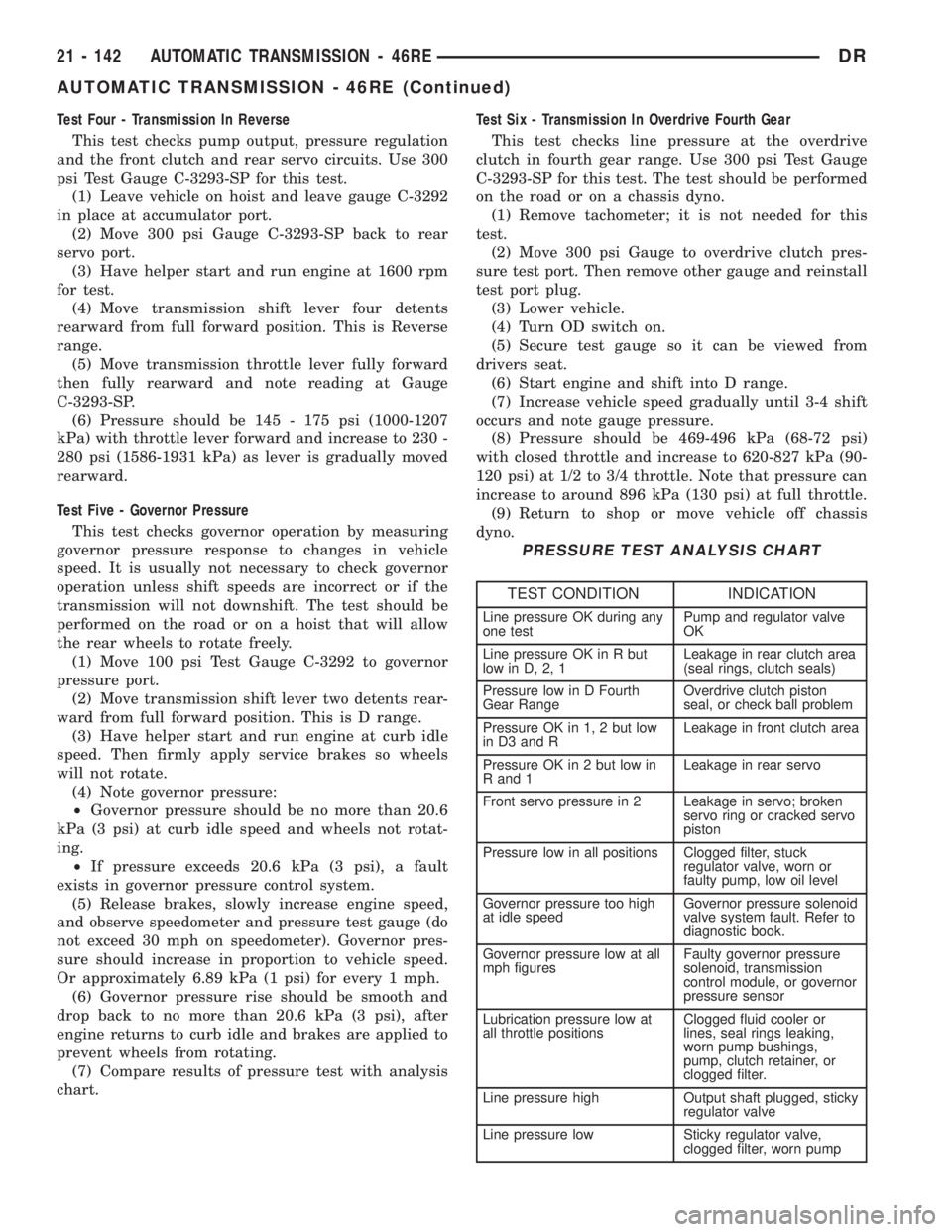

PRESSURE TEST ANALYSIS CHART

TEST CONDITION INDICATION

Line pressure OK during any

one testPump and regulator valve

OK

Line pressure OK in R but

low in D, 2, 1Leakage in rear clutch area

(seal rings, clutch seals)

Pressure low in D Fourth

Gear RangeOverdrive clutch piston

seal, or check ball problem

Pressure OK in 1, 2 but low

in D3 and RLeakage in front clutch area

Pressure OK in 2 but low in

R and 1Leakage in rear servo

Front servo pressure in 2 Leakage in servo; broken

servo ring or cracked servo

piston

Pressure low in all positions Clogged filter, stuck

regulator valve, worn or

faulty pump, low oil level

Governor pressure too high

at idle speedGovernor pressure solenoid

valve system fault. Refer to

diagnostic book.

Governor pressure low at all

mph figuresFaulty governor pressure

solenoid, transmission

control module, or governor

pressure sensor

Lubrication pressure low at

all throttle positionsClogged fluid cooler or

lines, seal rings leaking,

worn pump bushings,

pump, clutch retainer, or

clogged filter.

Line pressure high Output shaft plugged, sticky

regulator valve

Line pressure low Sticky regulator valve,

clogged filter, worn pump

21 - 142 AUTOMATIC TRANSMISSION - 46REDR

AUTOMATIC TRANSMISSION - 46RE (Continued)

Page 1984 of 2895

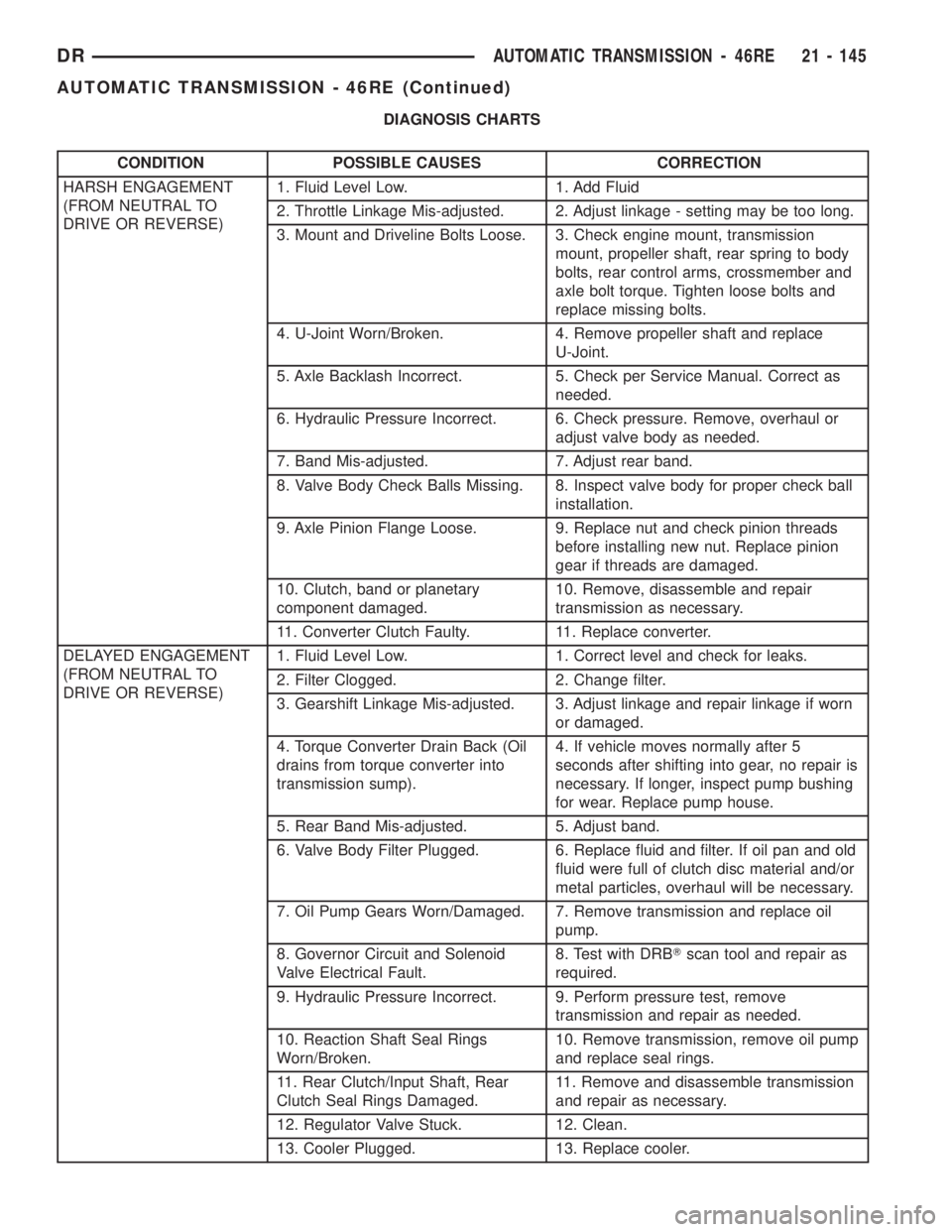

DIAGNOSIS CHARTS

CONDITION POSSIBLE CAUSES CORRECTION

HARSH ENGAGEMENT

(FROM NEUTRAL TO

DRIVE OR REVERSE)1. Fluid Level Low. 1. Add Fluid

2. Throttle Linkage Mis-adjusted. 2. Adjust linkage - setting may be too long.

3. Mount and Driveline Bolts Loose. 3. Check engine mount, transmission

mount, propeller shaft, rear spring to body

bolts, rear control arms, crossmember and

axle bolt torque. Tighten loose bolts and

replace missing bolts.

4. U-Joint Worn/Broken. 4. Remove propeller shaft and replace

U-Joint.

5. Axle Backlash Incorrect. 5. Check per Service Manual. Correct as

needed.

6. Hydraulic Pressure Incorrect. 6. Check pressure. Remove, overhaul or

adjust valve body as needed.

7. Band Mis-adjusted. 7. Adjust rear band.

8. Valve Body Check Balls Missing. 8. Inspect valve body for proper check ball

installation.

9. Axle Pinion Flange Loose. 9. Replace nut and check pinion threads

before installing new nut. Replace pinion

gear if threads are damaged.

10. Clutch, band or planetary

component damaged.10. Remove, disassemble and repair

transmission as necessary.

11. Converter Clutch Faulty. 11. Replace converter.

DELAYED ENGAGEMENT

(FROM NEUTRAL TO

DRIVE OR REVERSE)1. Fluid Level Low. 1. Correct level and check for leaks.

2. Filter Clogged. 2. Change filter.

3. Gearshift Linkage Mis-adjusted. 3. Adjust linkage and repair linkage if worn

or damaged.

4. Torque Converter Drain Back (Oil

drains from torque converter into

transmission sump).4. If vehicle moves normally after 5

seconds after shifting into gear, no repair is

necessary. If longer, inspect pump bushing

for wear. Replace pump house.

5. Rear Band Mis-adjusted. 5. Adjust band.

6. Valve Body Filter Plugged. 6. Replace fluid and filter. If oil pan and old

fluid were full of clutch disc material and/or

metal particles, overhaul will be necessary.

7. Oil Pump Gears Worn/Damaged. 7. Remove transmission and replace oil

pump.

8. Governor Circuit and Solenoid

Valve Electrical Fault.8. Test with DRBTscan tool and repair as

required.

9. Hydraulic Pressure Incorrect. 9. Perform pressure test, remove

transmission and repair as needed.

10. Reaction Shaft Seal Rings

Worn/Broken.10. Remove transmission, remove oil pump

and replace seal rings.

11. Rear Clutch/Input Shaft, Rear

Clutch Seal Rings Damaged.11. Remove and disassemble transmission

and repair as necessary.

12. Regulator Valve Stuck. 12. Clean.

13. Cooler Plugged. 13. Replace cooler.

DRAUTOMATIC TRANSMISSION - 46RE 21 - 145

AUTOMATIC TRANSMISSION - 46RE (Continued)

Page 1986 of 2895

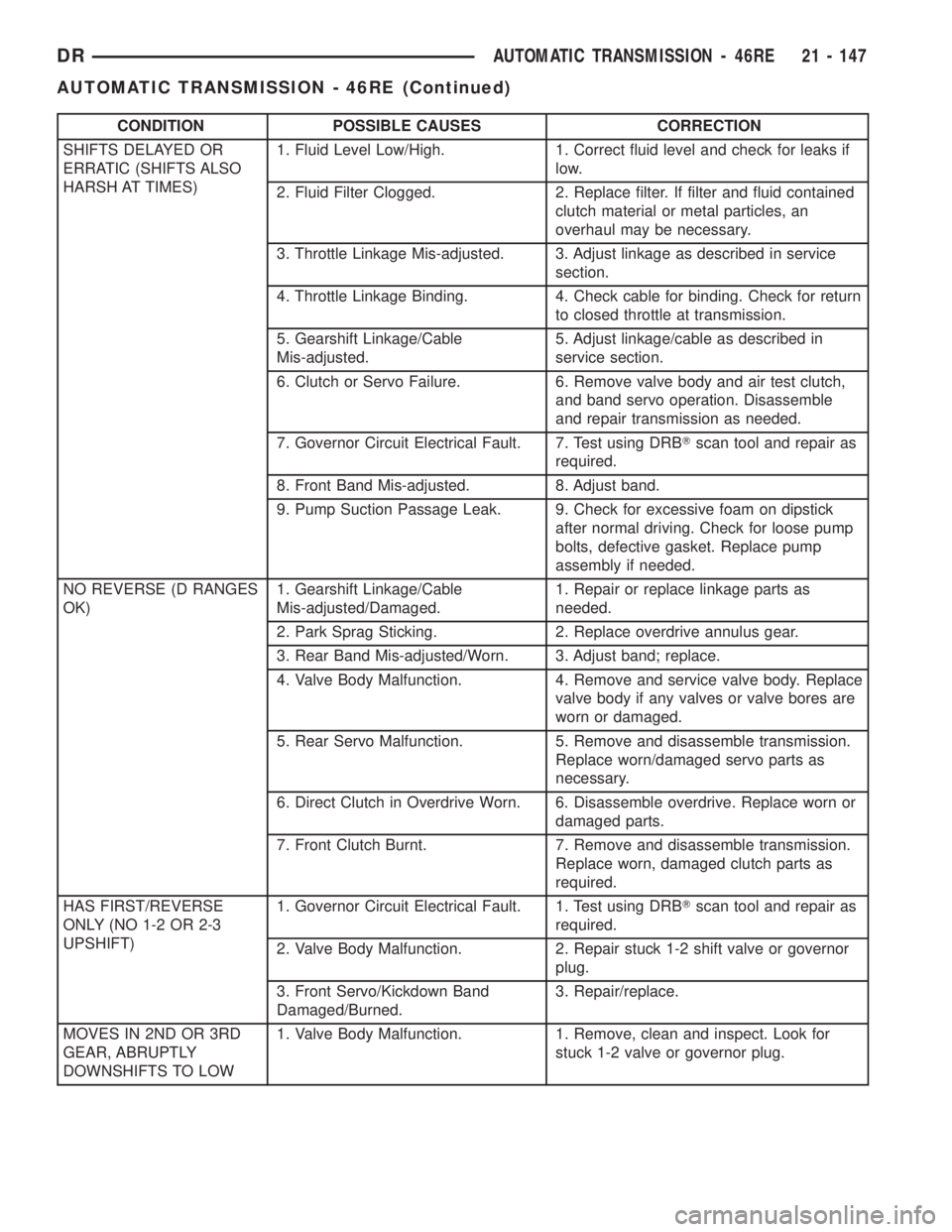

CONDITION POSSIBLE CAUSES CORRECTION

SHIFTS DELAYED OR

ERRATIC (SHIFTS ALSO

HARSH AT TIMES)1. Fluid Level Low/High. 1. Correct fluid level and check for leaks if

low.

2. Fluid Filter Clogged. 2. Replace filter. If filter and fluid contained

clutch material or metal particles, an

overhaul may be necessary.

3. Throttle Linkage Mis-adjusted. 3. Adjust linkage as described in service

section.

4. Throttle Linkage Binding. 4. Check cable for binding. Check for return

to closed throttle at transmission.

5. Gearshift Linkage/Cable

Mis-adjusted.5. Adjust linkage/cable as described in

service section.

6. Clutch or Servo Failure. 6. Remove valve body and air test clutch,

and band servo operation. Disassemble

and repair transmission as needed.

7. Governor Circuit Electrical Fault. 7. Test using DRBTscan tool and repair as

required.

8. Front Band Mis-adjusted. 8. Adjust band.

9. Pump Suction Passage Leak. 9. Check for excessive foam on dipstick

after normal driving. Check for loose pump

bolts, defective gasket. Replace pump

assembly if needed.

NO REVERSE (D RANGES

OK)1. Gearshift Linkage/Cable

Mis-adjusted/Damaged.1. Repair or replace linkage parts as

needed.

2. Park Sprag Sticking. 2. Replace overdrive annulus gear.

3. Rear Band Mis-adjusted/Worn. 3. Adjust band; replace.

4. Valve Body Malfunction. 4. Remove and service valve body. Replace

valve body if any valves or valve bores are

worn or damaged.

5. Rear Servo Malfunction. 5. Remove and disassemble transmission.

Replace worn/damaged servo parts as

necessary.

6. Direct Clutch in Overdrive Worn. 6. Disassemble overdrive. Replace worn or

damaged parts.

7. Front Clutch Burnt. 7. Remove and disassemble transmission.

Replace worn, damaged clutch parts as

required.

HAS FIRST/REVERSE

ONLY (NO 1-2 OR 2-3

UPSHIFT)1. Governor Circuit Electrical Fault. 1. Test using DRBTscan tool and repair as

required.

2. Valve Body Malfunction. 2. Repair stuck 1-2 shift valve or governor

plug.

3. Front Servo/Kickdown Band

Damaged/Burned.3. Repair/replace.

MOVES IN 2ND OR 3RD

GEAR, ABRUPTLY

DOWNSHIFTS TO LOW1. Valve Body Malfunction. 1. Remove, clean and inspect. Look for

stuck 1-2 valve or governor plug.

DRAUTOMATIC TRANSMISSION - 46RE 21 - 147

AUTOMATIC TRANSMISSION - 46RE (Continued)