service DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1671 of 2895

(1) Disconnect the battery negative cables.

(2) Discharge the A/C system (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - STAN-

DARD PROCEDURE) and remove the A/C condenser

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/A/C CONDENSER - REMOVAL) (if A/C

equipped).

(3) Remove the transmission auxiliary cooler

(Refer to 7 - COOLING/TRANSMISSION/TRANS

COOLER - REMOVAL).

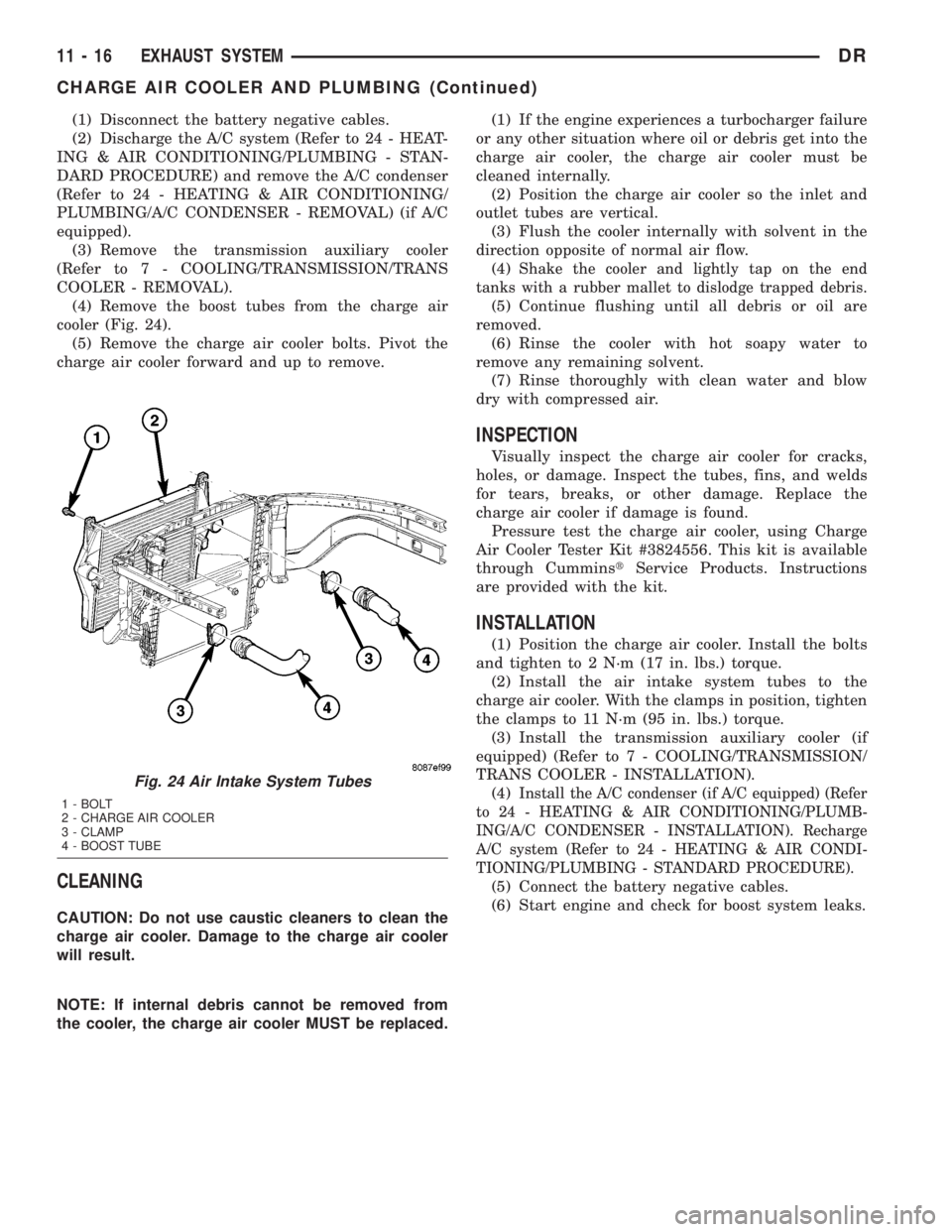

(4) Remove the boost tubes from the charge air

cooler (Fig. 24).

(5) Remove the charge air cooler bolts. Pivot the

charge air cooler forward and up to remove.

CLEANING

CAUTION: Do not use caustic cleaners to clean the

charge air cooler. Damage to the charge air cooler

will result.

NOTE: If internal debris cannot be removed from

the cooler, the charge air cooler MUST be replaced.(1) If the engine experiences a turbocharger failure

or any other situation where oil or debris get into the

charge air cooler, the charge air cooler must be

cleaned internally.

(2) Position the charge air cooler so the inlet and

outlet tubes are vertical.

(3) Flush the cooler internally with solvent in the

direction opposite of normal air flow.

(4)

Shake the cooler and lightly tap on the end

tanks with a rubber mallet to dislodge trapped debris.

(5) Continue flushing until all debris or oil are

removed.

(6) Rinse the cooler with hot soapy water to

remove any remaining solvent.

(7) Rinse thoroughly with clean water and blow

dry with compressed air.

INSPECTION

Visually inspect the charge air cooler for cracks,

holes, or damage. Inspect the tubes, fins, and welds

for tears, breaks, or other damage. Replace the

charge air cooler if damage is found.

Pressure test the charge air cooler, using Charge

Air Cooler Tester Kit #3824556. This kit is available

through CumminstService Products. Instructions

are provided with the kit.

INSTALLATION

(1) Position the charge air cooler. Install the bolts

and tighten to 2 N´m (17 in. lbs.) torque.

(2) Install the air intake system tubes to the

charge air cooler. With the clamps in position, tighten

the clamps to 11 N´m (95 in. lbs.) torque.

(3) Install the transmission auxiliary cooler (if

equipped) (Refer to 7 - COOLING/TRANSMISSION/

TRANS COOLER - INSTALLATION).

(4)

Install the A/C condenser (if A/C equipped) (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMB-

ING/A/C CONDENSER - INSTALLATION). Recharge

A/C system (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE).

(5) Connect the battery negative cables.

(6) Start engine and check for boost system leaks.

Fig. 24 Air Intake System Tubes

1 - BOLT

2 - CHARGE AIR COOLER

3 - CLAMP

4 - BOOST TUBE

11 - 16 EXHAUST SYSTEMDR

CHARGE AIR COOLER AND PLUMBING (Continued)

Page 1675 of 2895

REAR BUMPER

REMOVAL

(1) Raise and support the vehicle. (Refer to

LUBRICATION & MAINTENANCE/HOISTING -

STANDARD PROCEDURE)

(2) Remove the license plate.

(3) Remove the bolts behind the plate.

(4) Disconnect the license plate light electrical con-

nectors.

(5) Disconnect the trailer light connector electrical

connection, if equipped.

(6) Remove the two bolts along the front upper

edge of the bumper near the frame tips.

(7)

Support the bumper with a suitable lifting device.

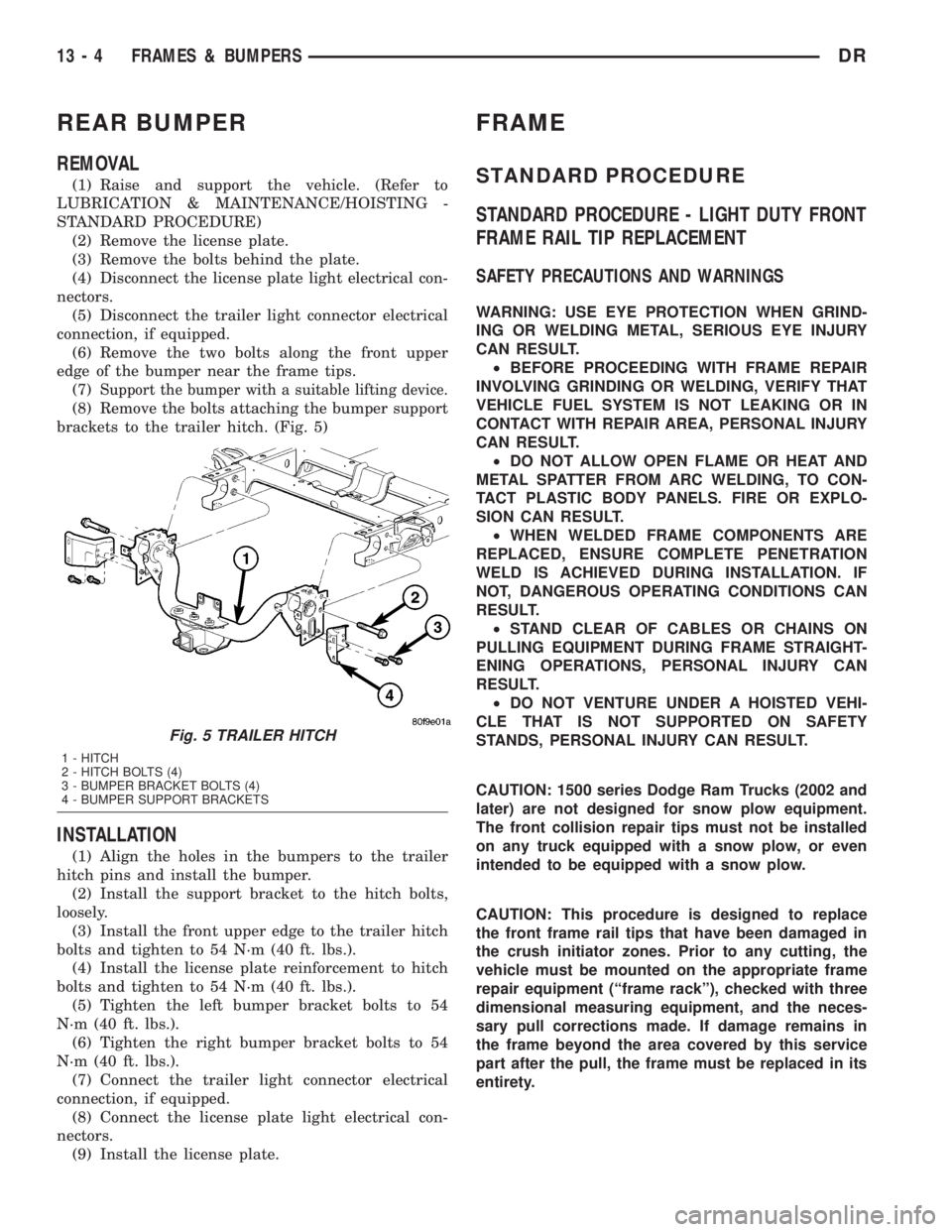

(8) Remove the bolts attaching the bumper support

brackets to the trailer hitch. (Fig. 5)

INSTALLATION

(1) Align the holes in the bumpers to the trailer

hitch pins and install the bumper.

(2) Install the support bracket to the hitch bolts,

loosely.

(3) Install the front upper edge to the trailer hitch

bolts and tighten to 54 N´m (40 ft. lbs.).

(4) Install the license plate reinforcement to hitch

bolts and tighten to 54 N´m (40 ft. lbs.).

(5) Tighten the left bumper bracket bolts to 54

N´m (40 ft. lbs.).

(6) Tighten the right bumper bracket bolts to 54

N´m (40 ft. lbs.).

(7) Connect the trailer light connector electrical

connection, if equipped.

(8) Connect the license plate light electrical con-

nectors.

(9) Install the license plate.

FRAME

STANDARD PROCEDURE

STANDARD PROCEDURE - LIGHT DUTY FRONT

FRAME RAIL TIP REPLACEMENT

SAFETY PRECAUTIONS AND WARNINGS

WARNING: USE EYE PROTECTION WHEN GRIND-

ING OR WELDING METAL, SERIOUS EYE INJURY

CAN RESULT.

²BEFORE PROCEEDING WITH FRAME REPAIR

INVOLVING GRINDING OR WELDING, VERIFY THAT

VEHICLE FUEL SYSTEM IS NOT LEAKING OR IN

CONTACT WITH REPAIR AREA, PERSONAL INJURY

CAN RESULT.

²DO NOT ALLOW OPEN FLAME OR HEAT AND

METAL SPATTER FROM ARC WELDING, TO CON-

TACT PLASTIC BODY PANELS. FIRE OR EXPLO-

SION CAN RESULT.

²WHEN WELDED FRAME COMPONENTS ARE

REPLACED, ENSURE COMPLETE PENETRATION

WELD IS ACHIEVED DURING INSTALLATION. IF

NOT, DANGEROUS OPERATING CONDITIONS CAN

RESULT.

²STAND CLEAR OF CABLES OR CHAINS ON

PULLING EQUIPMENT DURING FRAME STRAIGHT-

ENING OPERATIONS, PERSONAL INJURY CAN

RESULT.

²DO NOT VENTURE UNDER A HOISTED VEHI-

CLE THAT IS NOT SUPPORTED ON SAFETY

STANDS, PERSONAL INJURY CAN RESULT.

CAUTION: 1500 series Dodge Ram Trucks (2002 and

later) are not designed for snow plow equipment.

The front collision repair tips must not be installed

on any truck equipped with a snow plow, or even

intended to be equipped with a snow plow.

CAUTION: This procedure is designed to replace

the front frame rail tips that have been damaged in

the crush initiator zones. Prior to any cutting, the

vehicle must be mounted on the appropriate frame

repair equipment (ªframe rackº), checked with three

dimensional measuring equipment, and the neces-

sary pull corrections made. If damage remains in

the frame beyond the area covered by this service

part after the pull, the frame must be replaced in its

entirety.

Fig. 5 TRAILER HITCH

1 - HITCH

2 - HITCH BOLTS (4)

3 - BUMPER BRACKET BOLTS (4)

4 - BUMPER SUPPORT BRACKETS

13 - 4 FRAMES & BUMPERSDR

Page 1676 of 2895

CAUTION: Do not reuse damaged fasteners, quality

of repair would be suspect. Failure to use only pro-

duction fasteners or fasteners of equivalent hard-

ness can result in loosening or failure. Do not drill

any holes in the frame that are not specifically out-

lined in this or other, DaimlerChrysler procedure as

frame rail failure can result. When using heat to

straighten frame components do not exceed 566ÉC

(1050ÉF), metal fatigue can result.

NOTE: Procedures for 4X2 and 4X4 are common

except as noted in this procedure.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the front wheelhouse splash shield.

(Refer to 23 - BODY/EXTERIOR/FRONT WHEEL-

HOUSE SPLASH SHIELD - REMOVAL)

(3) Remove the bolts and position aside the wire

harness and grounds, if required.

(4) Remove the front bumper. (Refer to 13 -

FRAME & BUMPERS/BUMPERS/FRONT BUMPER

- REMOVAL)

(5) Loosen and lower the stabilizer bar mount and

bar. (Refer to 2 - SUSPENSION/FRONT/STABI-

LIZER BAR - REMOVAL)

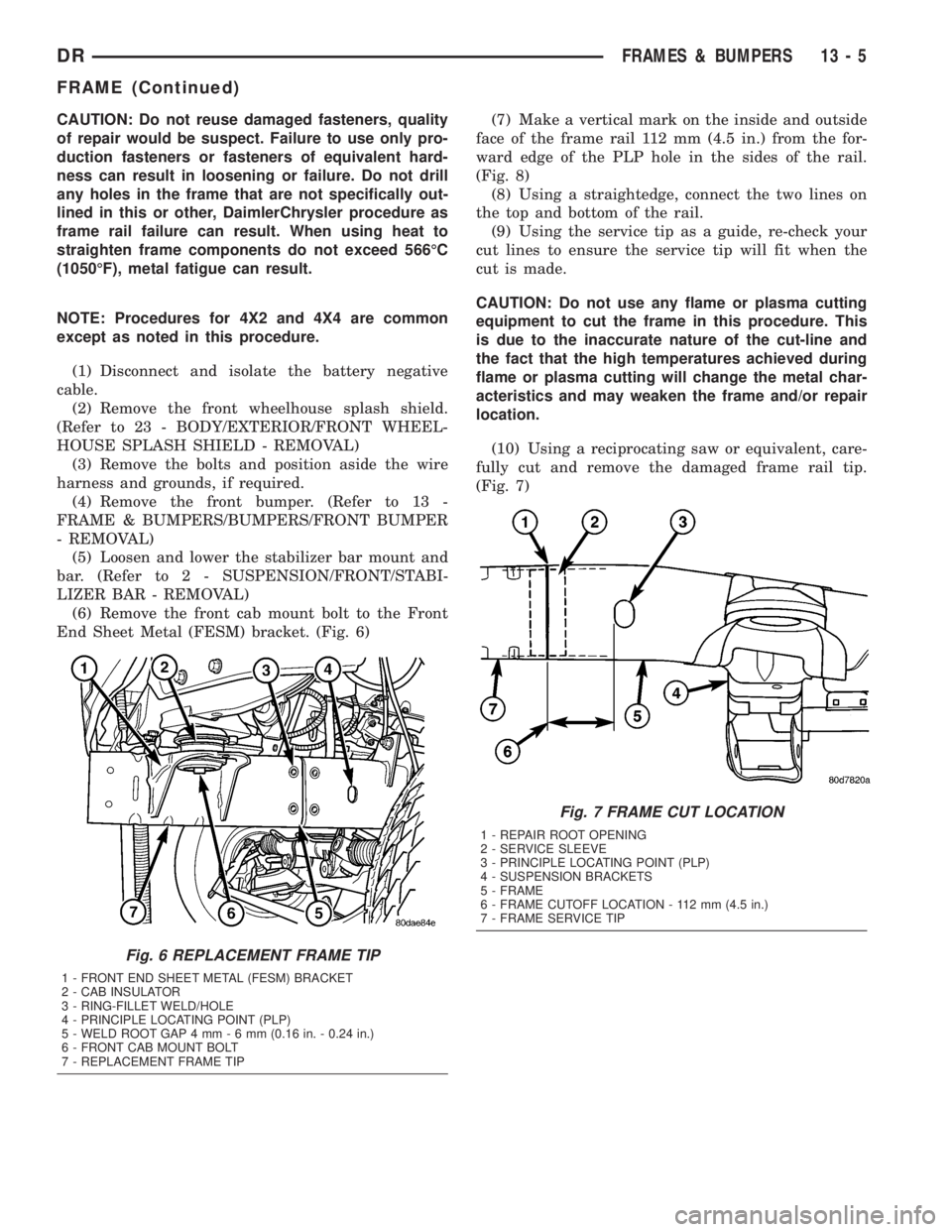

(6) Remove the front cab mount bolt to the Front

End Sheet Metal (FESM) bracket. (Fig. 6)(7) Make a vertical mark on the inside and outside

face of the frame rail 112 mm (4.5 in.) from the for-

ward edge of the PLP hole in the sides of the rail.

(Fig. 8)

(8) Using a straightedge, connect the two lines on

the top and bottom of the rail.

(9) Using the service tip as a guide, re-check your

cut lines to ensure the service tip will fit when the

cut is made.

CAUTION: Do not use any flame or plasma cutting

equipment to cut the frame in this procedure. This

is due to the inaccurate nature of the cut-line and

the fact that the high temperatures achieved during

flame or plasma cutting will change the metal char-

acteristics and may weaken the frame and/or repair

location.

(10) Using a reciprocating saw or equivalent, care-

fully cut and remove the damaged frame rail tip.

(Fig. 7)

Fig. 6 REPLACEMENT FRAME TIP

1 - FRONT END SHEET METAL (FESM) BRACKET

2 - CAB INSULATOR

3 - RING-FILLET WELD/HOLE

4 - PRINCIPLE LOCATING POINT (PLP)

5 - WELD ROOT GAP 4 mm-6mm(0.16 in. - 0.24 in.)

6 - FRONT CAB MOUNT BOLT

7 - REPLACEMENT FRAME TIP

Fig. 7 FRAME CUT LOCATION

1 - REPAIR ROOT OPENING

2 - SERVICE SLEEVE

3 - PRINCIPLE LOCATING POINT (PLP)

4 - SUSPENSION BRACKETS

5 - FRAME

6 - FRAME CUTOFF LOCATION - 112 mm (4.5 in.)

7 - FRAME SERVICE TIP

DRFRAMES & BUMPERS 13 - 5

FRAME (Continued)

Page 1677 of 2895

(11) Assemble the service sleeve. Refer to SER-

VICE SLEEVE ASSEMBLY at the end of this proce-

dure.

NOTE: Any burned surface coatings will need to be

removed from the sleeve prior to installation and

application of corrosion preventative coatings.

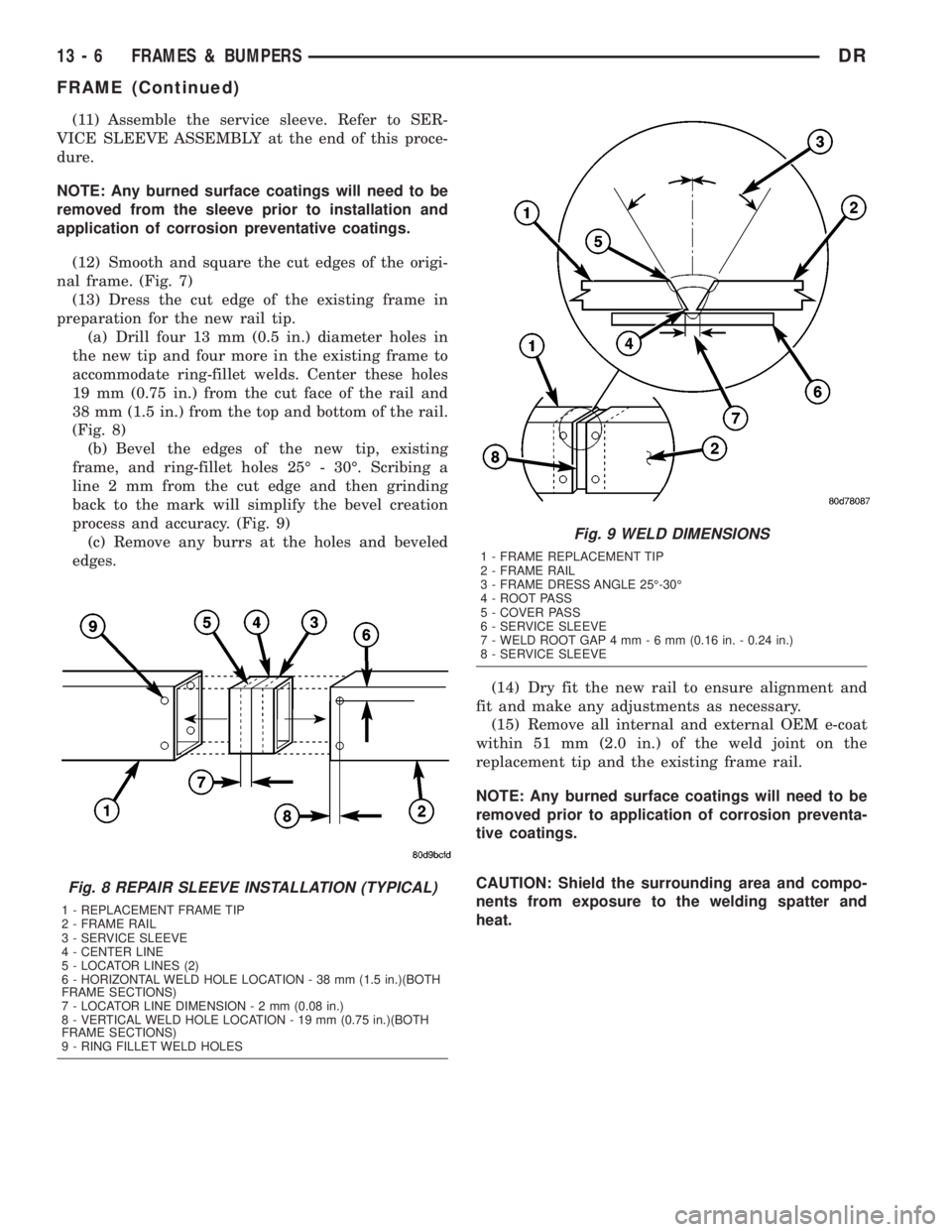

(12) Smooth and square the cut edges of the origi-

nal frame. (Fig. 7)

(13) Dress the cut edge of the existing frame in

preparation for the new rail tip.

(a) Drill four 13 mm (0.5 in.) diameter holes in

the new tip and four more in the existing frame to

accommodate ring-fillet welds. Center these holes

19 mm (0.75 in.) from the cut face of the rail and

38 mm (1.5 in.) from the top and bottom of the rail.

(Fig. 8)

(b) Bevel the edges of the new tip, existing

frame, and ring-fillet holes 25É - 30É. Scribing a

line 2 mm from the cut edge and then grinding

back to the mark will simplify the bevel creation

process and accuracy. (Fig. 9)

(c) Remove any burrs at the holes and beveled

edges.

(14) Dry fit the new rail to ensure alignment and

fit and make any adjustments as necessary.

(15) Remove all internal and external OEM e-coat

within 51 mm (2.0 in.) of the weld joint on the

replacement tip and the existing frame rail.

NOTE: Any burned surface coatings will need to be

removed prior to application of corrosion preventa-

tive coatings.

CAUTION: Shield the surrounding area and compo-

nents from exposure to the welding spatter and

heat.

Fig. 8 REPAIR SLEEVE INSTALLATION (TYPICAL)

1 - REPLACEMENT FRAME TIP

2 - FRAME RAIL

3 - SERVICE SLEEVE

4 - CENTER LINE

5 - LOCATOR LINES (2)

6 - HORIZONTAL WELD HOLE LOCATION - 38 mm (1.5 in.)(BOTH

FRAME SECTIONS)

7 - LOCATOR LINE DIMENSION-2mm(0.08 in.)

8 - VERTICAL WELD HOLE LOCATION - 19 mm (0.75 in.)(BOTH

FRAME SECTIONS)

9 - RING FILLET WELD HOLES

Fig. 9 WELD DIMENSIONS

1 - FRAME REPLACEMENT TIP

2 - FRAME RAIL

3 - FRAME DRESS ANGLE 25É-30É

4 - ROOT PASS

5 - COVER PASS

6 - SERVICE SLEEVE

7 - WELD ROOT GAP 4 mm-6mm(0.16 in. - 0.24 in.)

8 - SERVICE SLEEVE

13 - 6 FRAMES & BUMPERSDR

FRAME (Continued)

Page 1678 of 2895

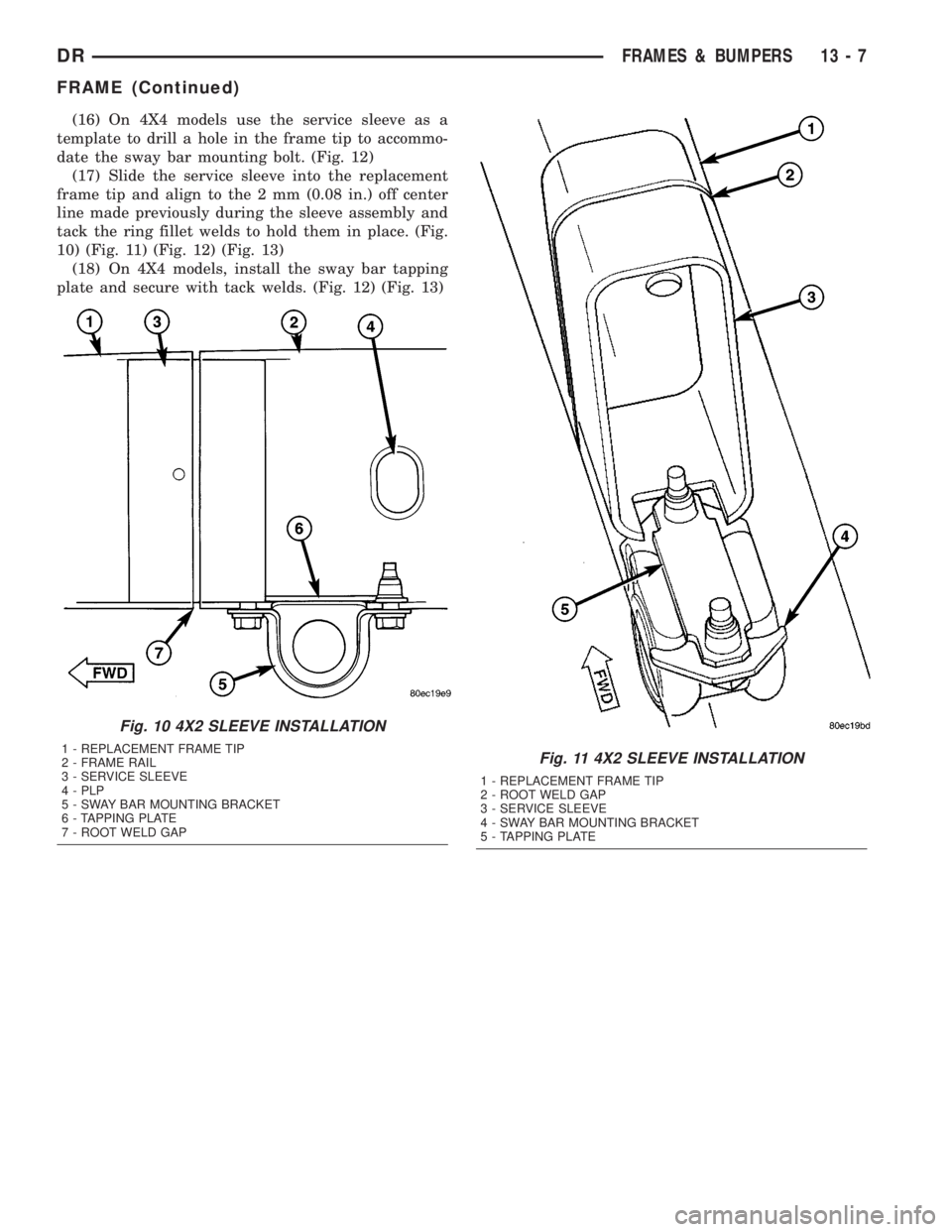

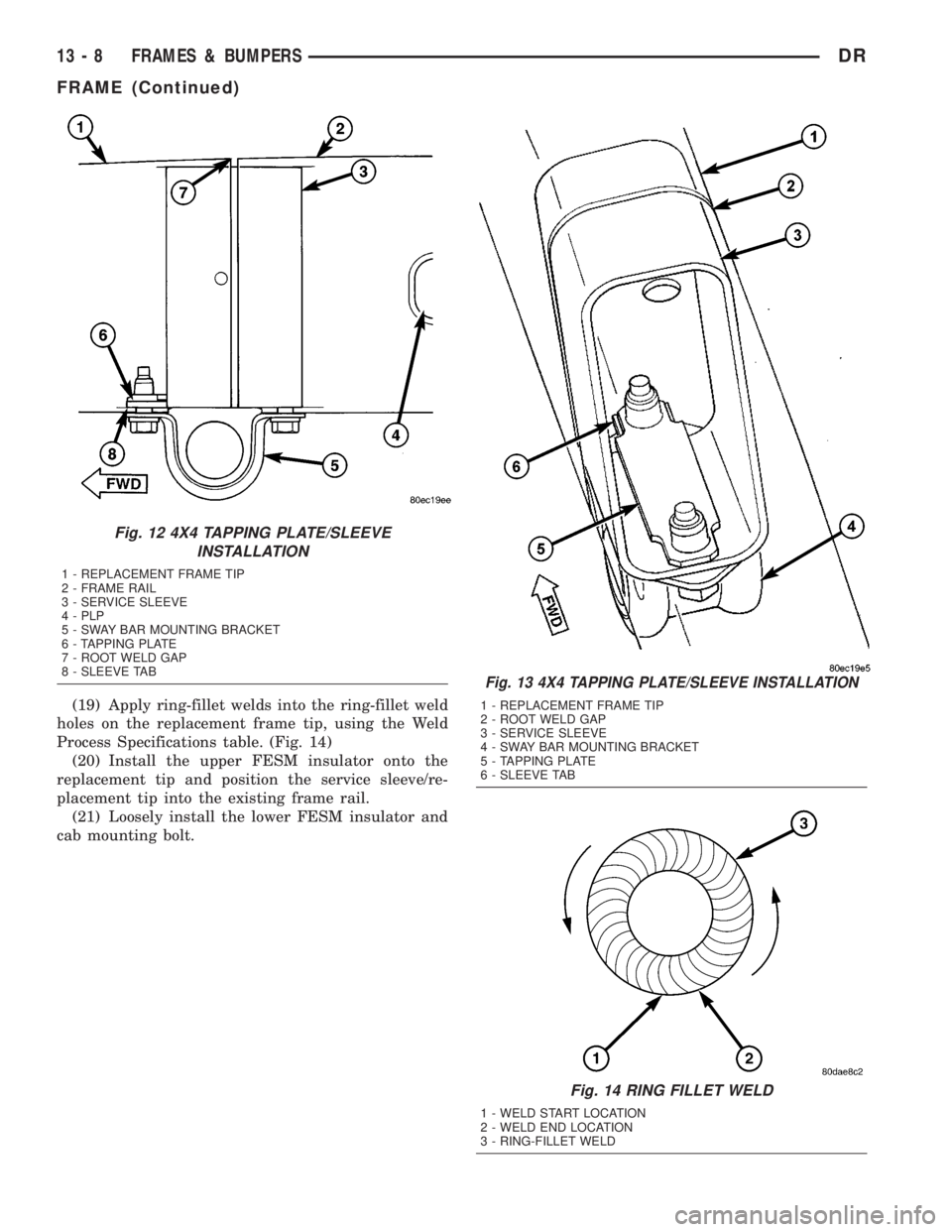

(16) On 4X4 models use the service sleeve as a

template to drill a hole in the frame tip to accommo-

date the sway bar mounting bolt. (Fig. 12)

(17) Slide the service sleeve into the replacement

frame tip and align to the 2 mm (0.08 in.) off center

line made previously during the sleeve assembly and

tack the ring fillet welds to hold them in place. (Fig.

10) (Fig. 11) (Fig. 12) (Fig. 13)

(18) On 4X4 models, install the sway bar tapping

plate and secure with tack welds. (Fig. 12) (Fig. 13)

Fig. 10 4X2 SLEEVE INSTALLATION

1 - REPLACEMENT FRAME TIP

2 - FRAME RAIL

3 - SERVICE SLEEVE

4 - PLP

5 - SWAY BAR MOUNTING BRACKET

6 - TAPPING PLATE

7 - ROOT WELD GAPFig. 11 4X2 SLEEVE INSTALLATION

1 - REPLACEMENT FRAME TIP

2 - ROOT WELD GAP

3 - SERVICE SLEEVE

4 - SWAY BAR MOUNTING BRACKET

5 - TAPPING PLATE

DRFRAMES & BUMPERS 13 - 7

FRAME (Continued)

Page 1679 of 2895

(19) Apply ring-fillet welds into the ring-fillet weld

holes on the replacement frame tip, using the Weld

Process Specifications table. (Fig. 14)

(20) Install the upper FESM insulator onto the

replacement tip and position the service sleeve/re-

placement tip into the existing frame rail.

(21) Loosely install the lower FESM insulator and

cab mounting bolt.

Fig. 12 4X4 TAPPING PLATE/SLEEVE

INSTALLATION

1 - REPLACEMENT FRAME TIP

2 - FRAME RAIL

3 - SERVICE SLEEVE

4 - PLP

5 - SWAY BAR MOUNTING BRACKET

6 - TAPPING PLATE

7 - ROOT WELD GAP

8 - SLEEVE TAB

Fig. 13 4X4 TAPPING PLATE/SLEEVE INSTALLATION

1 - REPLACEMENT FRAME TIP

2 - ROOT WELD GAP

3 - SERVICE SLEEVE

4 - SWAY BAR MOUNTING BRACKET

5 - TAPPING PLATE

6 - SLEEVE TAB

Fig. 14 RING FILLET WELD

1 - WELD START LOCATION

2 - WELD END LOCATION

3 - RING-FILLET WELD

13 - 8 FRAMES & BUMPERSDR

FRAME (Continued)

Page 1682 of 2895

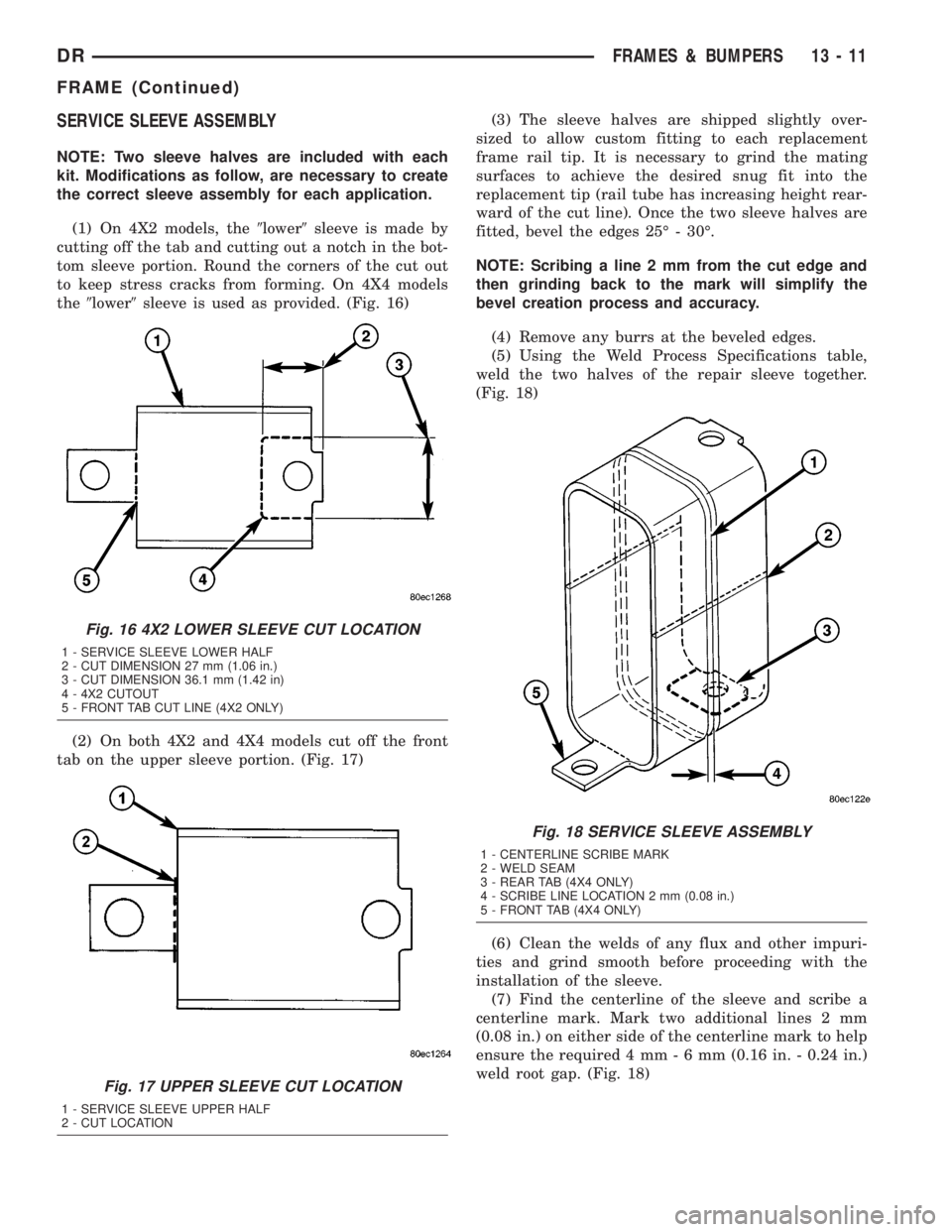

SERVICE SLEEVE ASSEMBLY

NOTE: Two sleeve halves are included with each

kit. Modifications as follow, are necessary to create

the correct sleeve assembly for each application.

(1) On 4X2 models, the9lower9sleeve is made by

cutting off the tab and cutting out a notch in the bot-

tom sleeve portion. Round the corners of the cut out

to keep stress cracks from forming. On 4X4 models

the9lower9sleeve is used as provided. (Fig. 16)

(2) On both 4X2 and 4X4 models cut off the front

tab on the upper sleeve portion. (Fig. 17)(3) The sleeve halves are shipped slightly over-

sized to allow custom fitting to each replacement

frame rail tip. It is necessary to grind the mating

surfaces to achieve the desired snug fit into the

replacement tip (rail tube has increasing height rear-

ward of the cut line). Once the two sleeve halves are

fitted, bevel the edges 25É - 30É.

NOTE: Scribing a line 2 mm from the cut edge and

then grinding back to the mark will simplify the

bevel creation process and accuracy.

(4) Remove any burrs at the beveled edges.

(5) Using the Weld Process Specifications table,

weld the two halves of the repair sleeve together.

(Fig. 18)

(6) Clean the welds of any flux and other impuri-

ties and grind smooth before proceeding with the

installation of the sleeve.

(7) Find the centerline of the sleeve and scribe a

centerline mark. Mark two additional lines 2 mm

(0.08 in.) on either side of the centerline mark to help

ensure the required 4 mm-6mm(0.16 in. - 0.24 in.)

weld root gap. (Fig. 18)

Fig. 16 4X2 LOWER SLEEVE CUT LOCATION

1 - SERVICE SLEEVE LOWER HALF

2 - CUT DIMENSION 27 mm (1.06 in.)

3 - CUT DIMENSION 36.1 mm (1.42 in)

4 - 4X2 CUTOUT

5 - FRONT TAB CUT LINE (4X2 ONLY)

Fig. 17 UPPER SLEEVE CUT LOCATION

1 - SERVICE SLEEVE UPPER HALF

2 - CUT LOCATION

Fig. 18 SERVICE SLEEVE ASSEMBLY

1 - CENTERLINE SCRIBE MARK

2 - WELD SEAM

3 - REAR TAB (4X4 ONLY)

4 - SCRIBE LINE LOCATION 2 mm (0.08 in.)

5 - FRONT TAB (4X4 ONLY)

DRFRAMES & BUMPERS 13 - 11

FRAME (Continued)

Page 1683 of 2895

STANDARD PROCEDURE - HYDROFORM

FENDER RAIL REPAIR

SAFETY PRECAUTIONS AND WARNINGS

WARNING: USE EYE PROTECTION WHEN GRIND-

ING OR WELDING METAL, SERIOUS EYE INJURY

CAN RESULT.

²BEFORE PROCEEDING WITH FRAME REPAIR

INVOLVING GRINDING OR WELDING, VERIFY THAT

VEHICLE FUEL SYSTEM IS NOT LEAKING OR IN

CONTACT WITH REPAIR AREA, PERSONAL INJURY

CAN RESULT.

²DO NOT ALLOW OPEN FLAME OR HEAT AND

METAL SPATTER FROM ARC WELDING, TO CON-

TACT PLASTIC BODY PANELS. FIRE OR EXPLO-

SION CAN RESULT.

²WHEN WELDED FRAME COMPONENTS ARE

REPLACED, ENSURE COMPLETE PENETRATION

WELD IS ACHIEVED DURING INSTALLATION. IF

NOT, DANGEROUS OPERATING CONDITIONS CAN

RESULT.

²STAND CLEAR OF CABLES OR CHAINS ON

PULLING EQUIPMENT DURING FRAME STRAIGHT-

ENING OPERATIONS, PERSONAL INJURY CAN

RESULT.

²DO NOT VENTURE UNDER A HOISTED VEHI-

CLE THAT IS NOT SUPPORTED ON SAFETY

STANDS, PERSONAL INJURY CAN RESULT.

CAUTION: Do not reuse damaged fasteners, quality

of repair would be suspect. Failure to use only pro-

duction fasteners or fasteners of equivalent hard-

ness can result in loosening or failure. Do not drill

holes in top or bottom frame rail flanges, frame rail

failure can result. When using heat to straighten

frame components do not exceed 566ÉC (1050ÉF),

metal fatigue can result.

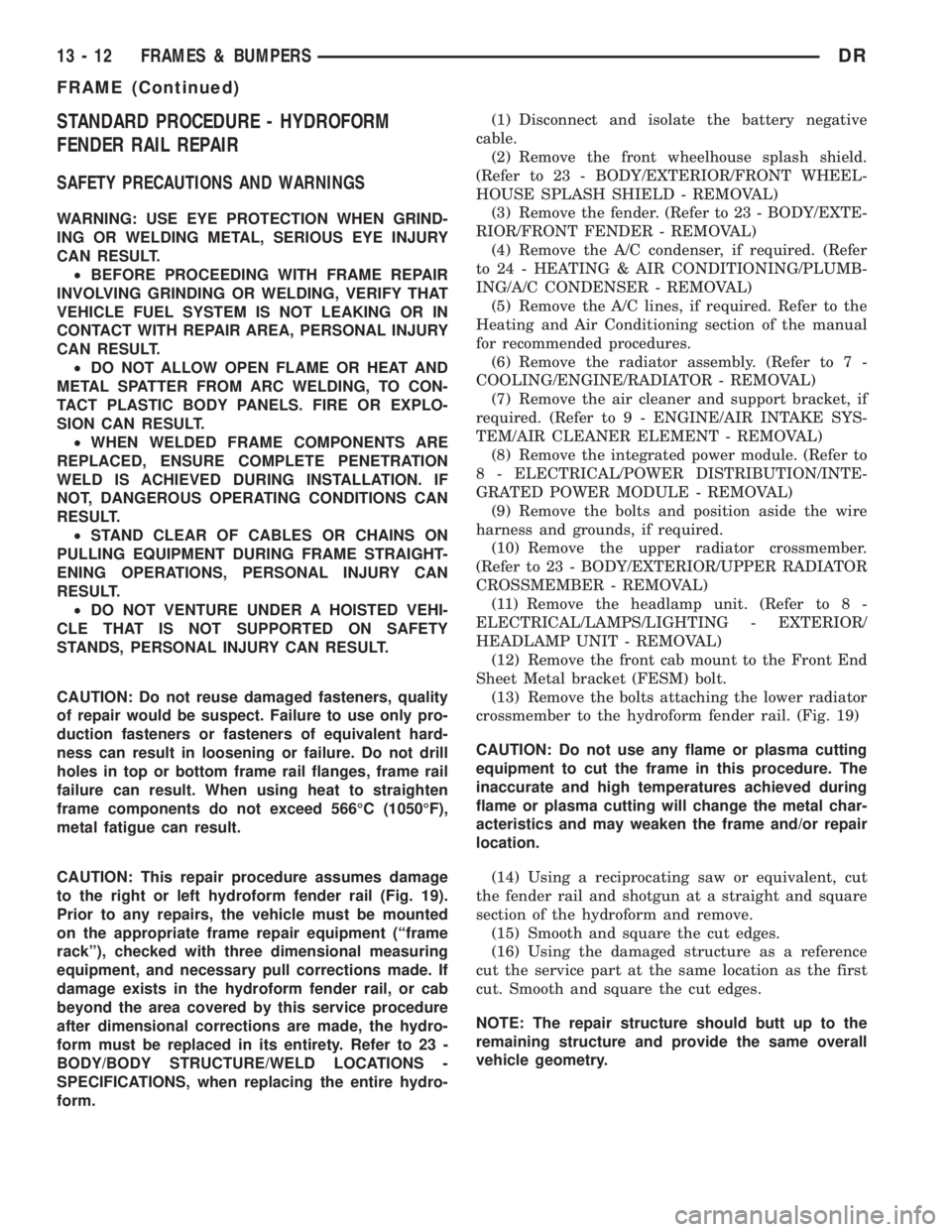

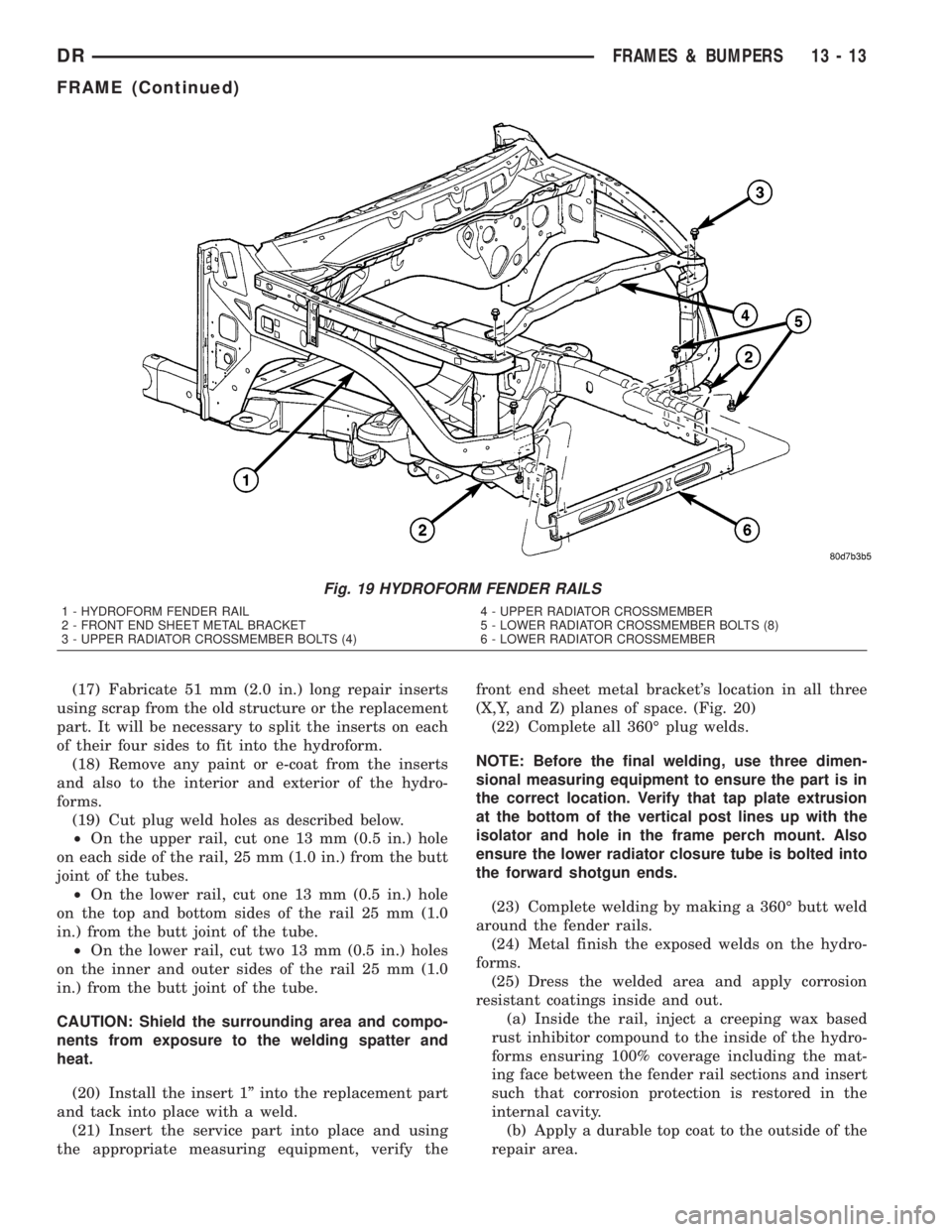

CAUTION: This repair procedure assumes damage

to the right or left hydroform fender rail (Fig. 19).

Prior to any repairs, the vehicle must be mounted

on the appropriate frame repair equipment (ªframe

rackº), checked with three dimensional measuring

equipment, and necessary pull corrections made. If

damage exists in the hydroform fender rail, or cab

beyond the area covered by this service procedure

after dimensional corrections are made, the hydro-

form must be replaced in its entirety. Refer to 23 -

BODY/BODY STRUCTURE/WELD LOCATIONS -

SPECIFICATIONS, when replacing the entire hydro-

form.(1) Disconnect and isolate the battery negative

cable.

(2) Remove the front wheelhouse splash shield.

(Refer to 23 - BODY/EXTERIOR/FRONT WHEEL-

HOUSE SPLASH SHIELD - REMOVAL)

(3) Remove the fender. (Refer to 23 - BODY/EXTE-

RIOR/FRONT FENDER - REMOVAL)

(4) Remove the A/C condenser, if required. (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMB-

ING/A/C CONDENSER - REMOVAL)

(5) Remove the A/C lines, if required. Refer to the

Heating and Air Conditioning section of the manual

for recommended procedures.

(6) Remove the radiator assembly. (Refer to 7 -

COOLING/ENGINE/RADIATOR - REMOVAL)

(7) Remove the air cleaner and support bracket, if

required. (Refer to 9 - ENGINE/AIR INTAKE SYS-

TEM/AIR CLEANER ELEMENT - REMOVAL)

(8) Remove the integrated power module. (Refer to

8 - ELECTRICAL/POWER DISTRIBUTION/INTE-

GRATED POWER MODULE - REMOVAL)

(9) Remove the bolts and position aside the wire

harness and grounds, if required.

(10) Remove the upper radiator crossmember.

(Refer to 23 - BODY/EXTERIOR/UPPER RADIATOR

CROSSMEMBER - REMOVAL)

(11) Remove the headlamp unit. (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

HEADLAMP UNIT - REMOVAL)

(12) Remove the front cab mount to the Front End

Sheet Metal bracket (FESM) bolt.

(13) Remove the bolts attaching the lower radiator

crossmember to the hydroform fender rail. (Fig. 19)

CAUTION: Do not use any flame or plasma cutting

equipment to cut the frame in this procedure. The

inaccurate and high temperatures achieved during

flame or plasma cutting will change the metal char-

acteristics and may weaken the frame and/or repair

location.

(14) Using a reciprocating saw or equivalent, cut

the fender rail and shotgun at a straight and square

section of the hydroform and remove.

(15) Smooth and square the cut edges.

(16) Using the damaged structure as a reference

cut the service part at the same location as the first

cut. Smooth and square the cut edges.

NOTE: The repair structure should butt up to the

remaining structure and provide the same overall

vehicle geometry.

13 - 12 FRAMES & BUMPERSDR

FRAME (Continued)

Page 1684 of 2895

(17) Fabricate 51 mm (2.0 in.) long repair inserts

using scrap from the old structure or the replacement

part. It will be necessary to split the inserts on each

of their four sides to fit into the hydroform.

(18) Remove any paint or e-coat from the inserts

and also to the interior and exterior of the hydro-

forms.

(19) Cut plug weld holes as described below.

²On the upper rail, cut one 13 mm (0.5 in.) hole

on each side of the rail, 25 mm (1.0 in.) from the butt

joint of the tubes.

²On the lower rail, cut one 13 mm (0.5 in.) hole

on the top and bottom sides of the rail 25 mm (1.0

in.) from the butt joint of the tube.

²On the lower rail, cut two 13 mm (0.5 in.) holes

on the inner and outer sides of the rail 25 mm (1.0

in.) from the butt joint of the tube.

CAUTION: Shield the surrounding area and compo-

nents from exposure to the welding spatter and

heat.

(20) Install the insert 1º into the replacement part

and tack into place with a weld.

(21) Insert the service part into place and using

the appropriate measuring equipment, verify thefront end sheet metal bracket's location in all three

(X,Y, and Z) planes of space. (Fig. 20)

(22) Complete all 360É plug welds.

NOTE: Before the final welding, use three dimen-

sional measuring equipment to ensure the part is in

the correct location. Verify that tap plate extrusion

at the bottom of the vertical post lines up with the

isolator and hole in the frame perch mount. Also

ensure the lower radiator closure tube is bolted into

the forward shotgun ends.

(23) Complete welding by making a 360É butt weld

around the fender rails.

(24) Metal finish the exposed welds on the hydro-

forms.

(25) Dress the welded area and apply corrosion

resistant coatings inside and out.

(a) Inside the rail, inject a creeping wax based

rust inhibitor compound to the inside of the hydro-

forms ensuring 100% coverage including the mat-

ing face between the fender rail sections and insert

such that corrosion protection is restored in the

internal cavity.

(b) Apply a durable top coat to the outside of the

repair area.

Fig. 19 HYDROFORM FENDER RAILS

1 - HYDROFORM FENDER RAIL

2 - FRONT END SHEET METAL BRACKET

3 - UPPER RADIATOR CROSSMEMBER BOLTS (4)4 - UPPER RADIATOR CROSSMEMBER

5 - LOWER RADIATOR CROSSMEMBER BOLTS (8)

6 - LOWER RADIATOR CROSSMEMBER

DRFRAMES & BUMPERS 13 - 13

FRAME (Continued)

Page 1686 of 2895

STANDARD PROCEDURE - REAR FRAME

H-SECTION REPLACEMENT

SAFETY PRECAUTIONS AND WARNINGS

WARNING: USE EYE PROTECTION WHEN GRIND-

ING OR WELDING METAL, SERIOUS EYE INJURY

CAN RESULT.

²BEFORE PROCEEDING WITH FRAME REPAIR

INVOLVING GRINDING OR WELDING, VERIFY THAT

VEHICLE FUEL SYSTEM IS NOT LEAKING OR IN

CONTACT WITH REPAIR AREA, PERSONAL INJURY

CAN RESULT.

²DO NOT ALLOW OPEN FLAME OR HEAT AND

METAL SPATTER FROM ARC WELDING, TO CON-

TACT PLASTIC BODY PANELS. FIRE OR EXPLO-

SION CAN RESULT.

²WHEN WELDED FRAME COMPONENTS ARE

REPLACED, ENSURE COMPLETE PENETRATION

WELD IS ACHIEVED DURING INSTALLATION. IF

NOT, DANGEROUS OPERATING CONDITIONS CAN

RESULT.

²STAND CLEAR OF CABLES OR CHAINS ON

PULLING EQUIPMENT DURING FRAME STRAIGHT-

ENING OPERATIONS, PERSONAL INJURY CAN

RESULT.

²DO NOT VENTURE UNDER A HOISTED VEHI-

CLE THAT IS NOT SUPPORTED ON SAFETY

STANDS, PERSONAL INJURY CAN RESULT.

CAUTION: Do not reuse damaged fasteners, quality

of repair would be suspect. Failure to use only pro-

duction fasteners or fasteners of equivalent hard-

ness can result in loosening or failure. Do not drill

holes in top or bottom frame rail flanges, frame rail

failure can result. When using heat to straighten

frame components do not exceed 566ÉC (1050ÉF),

metal fatigue can result.

CAUTION: This procedure is designed to replace

the H-section/spare tire support located at the rear

of the frame assembly. Prior to any cutting, the

vehicle must be mounted on the appropriate frame

repair equipment (ªframe rackº), checked with three

dimensional measuring equipment, and the neces-

sary pull corrections made. If damage remains in

the frame beyond the area covered by this service

part after the pull, the frame must be replaced in its

entirety.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cargo box. (Refer to 23 - BODY/EX-

TERIOR/CARGO BOX - REMOVAL)(3) Remove the trailer hitch. (Refer to 13 - FRAME

& BUMPERS/FRAME/TRAILER HITCH -

REMOVAL)

(4) Raise and support the frame so the tires are off

floor.

(5) Remove the shock absorbers. (Refer to 2 - SUS-

PENSION/REAR/SHOCK - REMOVAL)

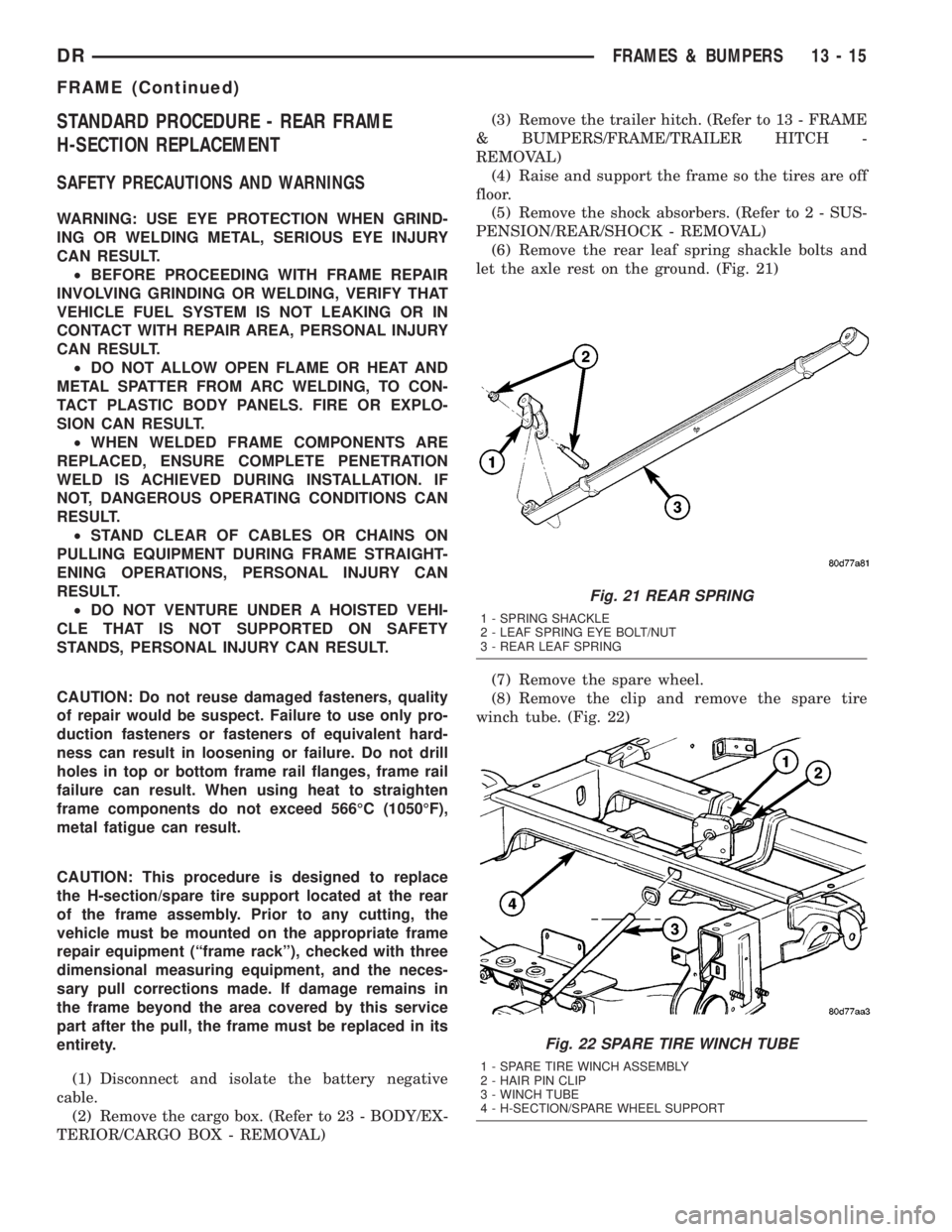

(6) Remove the rear leaf spring shackle bolts and

let the axle rest on the ground. (Fig. 21)

(7) Remove the spare wheel.

(8) Remove the clip and remove the spare tire

winch tube. (Fig. 22)

Fig. 21 REAR SPRING

1 - SPRING SHACKLE

2 - LEAF SPRING EYE BOLT/NUT

3 - REAR LEAF SPRING

Fig. 22 SPARE TIRE WINCH TUBE

1 - SPARE TIRE WINCH ASSEMBLY

2 - HAIR PIN CLIP

3 - WINCH TUBE

4 - H-SECTION/SPARE WHEEL SUPPORT

DRFRAMES & BUMPERS 13 - 15

FRAME (Continued)