sensor DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2035 of 2895

(8) With shifter lever in the:

²PARK position - Apply upward force on the shift

arm and remove pressure. Engine starts must be

possible.

²PARK position - Apply downward force on the

shift arm and remove pressure. Engine starts must

be possible.

²NEUTRAL position - Normal position. Engine

starts must be possible.

²NEUTRAL position - Engine running and brakes

applied, apply upward force on the shift arm. Trans-

mission shall not be able to shift from neutral to

reverse.

ELECTRONIC GOVERNOR

DESCRIPTION

Governor pressure is controlled electronically. Com-

ponents used for governor pressure control include:

²Governor body

²Valve body transfer plate

²Governor pressure solenoid valve

²Governor pressure sensor

²Fluid temperature thermistor

²Throttle position sensor (TPS)

²Transmission speed sensor

²Powertrain control module (PCM)

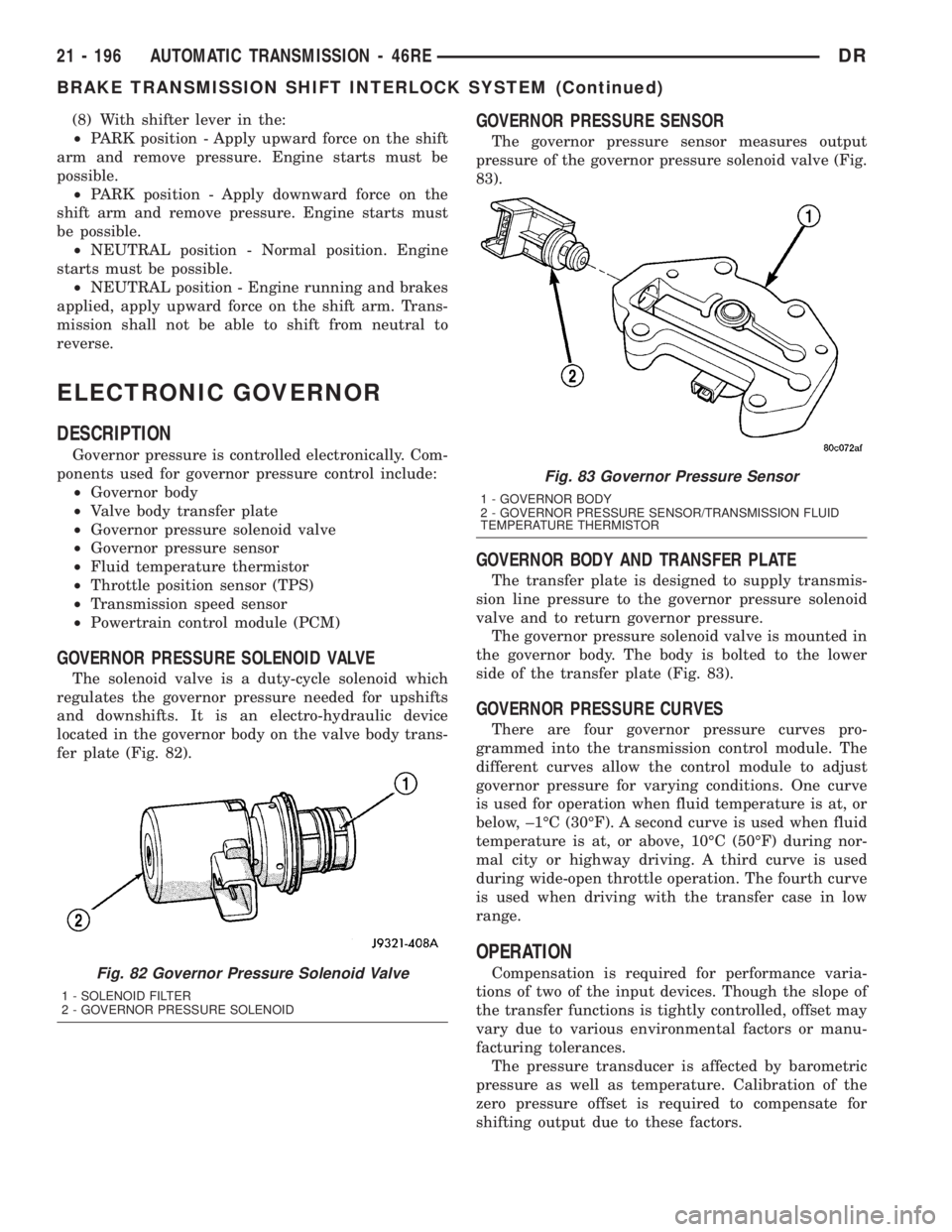

GOVERNOR PRESSURE SOLENOID VALVE

The solenoid valve is a duty-cycle solenoid which

regulates the governor pressure needed for upshifts

and downshifts. It is an electro-hydraulic device

located in the governor body on the valve body trans-

fer plate (Fig. 82).

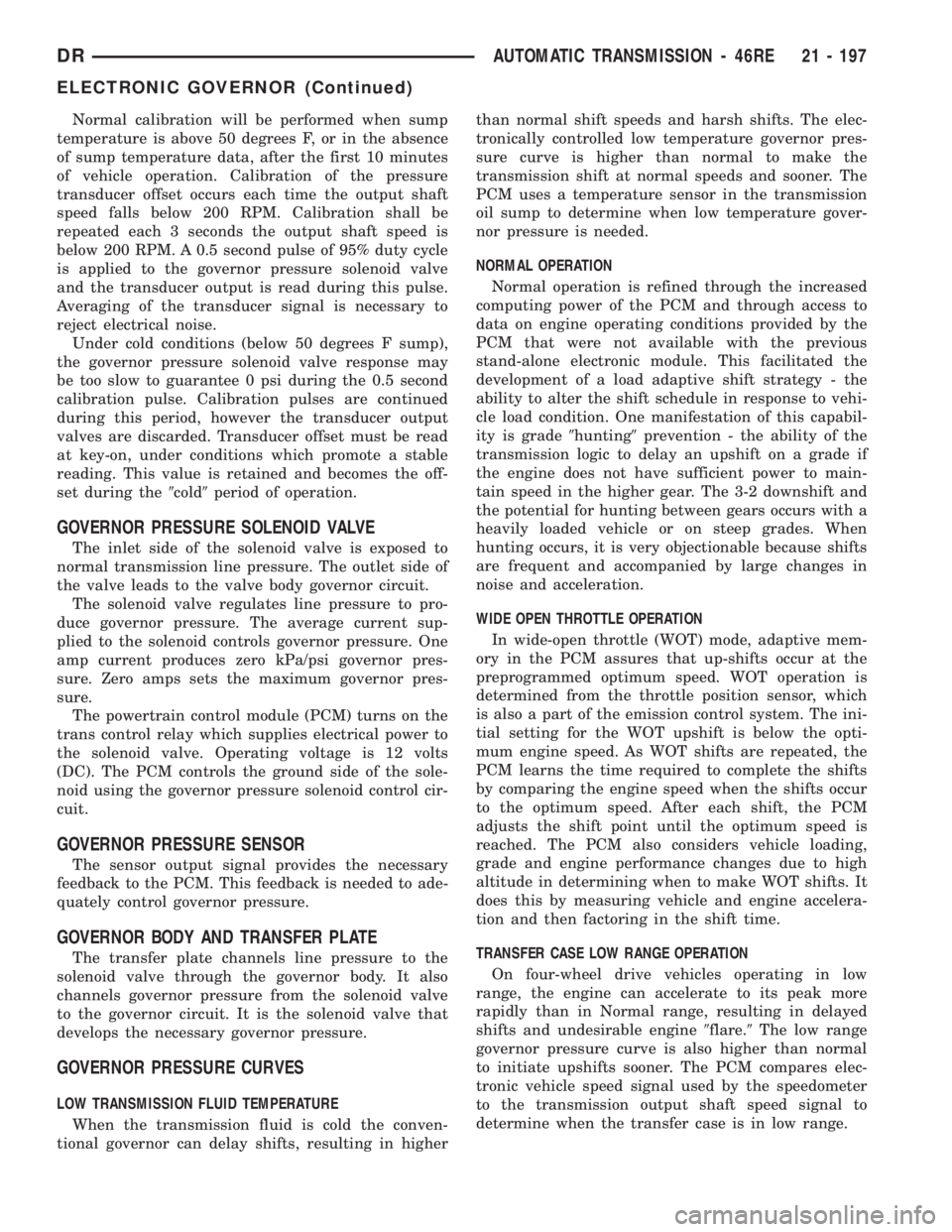

GOVERNOR PRESSURE SENSOR

The governor pressure sensor measures output

pressure of the governor pressure solenoid valve (Fig.

83).

GOVERNOR BODY AND TRANSFER PLATE

The transfer plate is designed to supply transmis-

sion line pressure to the governor pressure solenoid

valve and to return governor pressure.

The governor pressure solenoid valve is mounted in

the governor body. The body is bolted to the lower

side of the transfer plate (Fig. 83).

GOVERNOR PRESSURE CURVES

There are four governor pressure curves pro-

grammed into the transmission control module. The

different curves allow the control module to adjust

governor pressure for varying conditions. One curve

is used for operation when fluid temperature is at, or

below, ±1ÉC (30ÉF). A second curve is used when fluid

temperature is at, or above, 10ÉC (50ÉF) during nor-

mal city or highway driving. A third curve is used

during wide-open throttle operation. The fourth curve

is used when driving with the transfer case in low

range.

OPERATION

Compensation is required for performance varia-

tions of two of the input devices. Though the slope of

the transfer functions is tightly controlled, offset may

vary due to various environmental factors or manu-

facturing tolerances.

The pressure transducer is affected by barometric

pressure as well as temperature. Calibration of the

zero pressure offset is required to compensate for

shifting output due to these factors.Fig. 82 Governor Pressure Solenoid Valve

1 - SOLENOID FILTER

2 - GOVERNOR PRESSURE SOLENOID

Fig. 83 Governor Pressure Sensor

1 - GOVERNOR BODY

2 - GOVERNOR PRESSURE SENSOR/TRANSMISSION FLUID

TEMPERATURE THERMISTOR

21 - 196 AUTOMATIC TRANSMISSION - 46REDR

BRAKE TRANSMISSION SHIFT INTERLOCK SYSTEM (Continued)

Page 2036 of 2895

Normal calibration will be performed when sump

temperature is above 50 degrees F, or in the absence

of sump temperature data, after the first 10 minutes

of vehicle operation. Calibration of the pressure

transducer offset occurs each time the output shaft

speed falls below 200 RPM. Calibration shall be

repeated each 3 seconds the output shaft speed is

below 200 RPM. A 0.5 second pulse of 95% duty cycle

is applied to the governor pressure solenoid valve

and the transducer output is read during this pulse.

Averaging of the transducer signal is necessary to

reject electrical noise.

Under cold conditions (below 50 degrees F sump),

the governor pressure solenoid valve response may

be too slow to guarantee 0 psi during the 0.5 second

calibration pulse. Calibration pulses are continued

during this period, however the transducer output

valves are discarded. Transducer offset must be read

at key-on, under conditions which promote a stable

reading. This value is retained and becomes the off-

set during the9cold9period of operation.

GOVERNOR PRESSURE SOLENOID VALVE

The inlet side of the solenoid valve is exposed to

normal transmission line pressure. The outlet side of

the valve leads to the valve body governor circuit.

The solenoid valve regulates line pressure to pro-

duce governor pressure. The average current sup-

plied to the solenoid controls governor pressure. One

amp current produces zero kPa/psi governor pres-

sure. Zero amps sets the maximum governor pres-

sure.

The powertrain control module (PCM) turns on the

trans control relay which supplies electrical power to

the solenoid valve. Operating voltage is 12 volts

(DC). The PCM controls the ground side of the sole-

noid using the governor pressure solenoid control cir-

cuit.

GOVERNOR PRESSURE SENSOR

The sensor output signal provides the necessary

feedback to the PCM. This feedback is needed to ade-

quately control governor pressure.

GOVERNOR BODY AND TRANSFER PLATE

The transfer plate channels line pressure to the

solenoid valve through the governor body. It also

channels governor pressure from the solenoid valve

to the governor circuit. It is the solenoid valve that

develops the necessary governor pressure.

GOVERNOR PRESSURE CURVES

LOW TRANSMISSION FLUID TEMPERATURE

When the transmission fluid is cold the conven-

tional governor can delay shifts, resulting in higherthan normal shift speeds and harsh shifts. The elec-

tronically controlled low temperature governor pres-

sure curve is higher than normal to make the

transmission shift at normal speeds and sooner. The

PCM uses a temperature sensor in the transmission

oil sump to determine when low temperature gover-

nor pressure is needed.

NORMAL OPERATION

Normal operation is refined through the increased

computing power of the PCM and through access to

data on engine operating conditions provided by the

PCM that were not available with the previous

stand-alone electronic module. This facilitated the

development of a load adaptive shift strategy - the

ability to alter the shift schedule in response to vehi-

cle load condition. One manifestation of this capabil-

ity is grade9hunting9prevention - the ability of the

transmission logic to delay an upshift on a grade if

the engine does not have sufficient power to main-

tain speed in the higher gear. The 3-2 downshift and

the potential for hunting between gears occurs with a

heavily loaded vehicle or on steep grades. When

hunting occurs, it is very objectionable because shifts

are frequent and accompanied by large changes in

noise and acceleration.

WIDE OPEN THROTTLE OPERATION

In wide-open throttle (WOT) mode, adaptive mem-

ory in the PCM assures that up-shifts occur at the

preprogrammed optimum speed. WOT operation is

determined from the throttle position sensor, which

is also a part of the emission control system. The ini-

tial setting for the WOT upshift is below the opti-

mum engine speed. As WOT shifts are repeated, the

PCM learns the time required to complete the shifts

by comparing the engine speed when the shifts occur

to the optimum speed. After each shift, the PCM

adjusts the shift point until the optimum speed is

reached. The PCM also considers vehicle loading,

grade and engine performance changes due to high

altitude in determining when to make WOT shifts. It

does this by measuring vehicle and engine accelera-

tion and then factoring in the shift time.

TRANSFER CASE LOW RANGE OPERATION

On four-wheel drive vehicles operating in low

range, the engine can accelerate to its peak more

rapidly than in Normal range, resulting in delayed

shifts and undesirable engine9flare.9The low range

governor pressure curve is also higher than normal

to initiate upshifts sooner. The PCM compares elec-

tronic vehicle speed signal used by the speedometer

to the transmission output shaft speed signal to

determine when the transfer case is in low range.

DRAUTOMATIC TRANSMISSION - 46RE 21 - 197

ELECTRONIC GOVERNOR (Continued)

Page 2037 of 2895

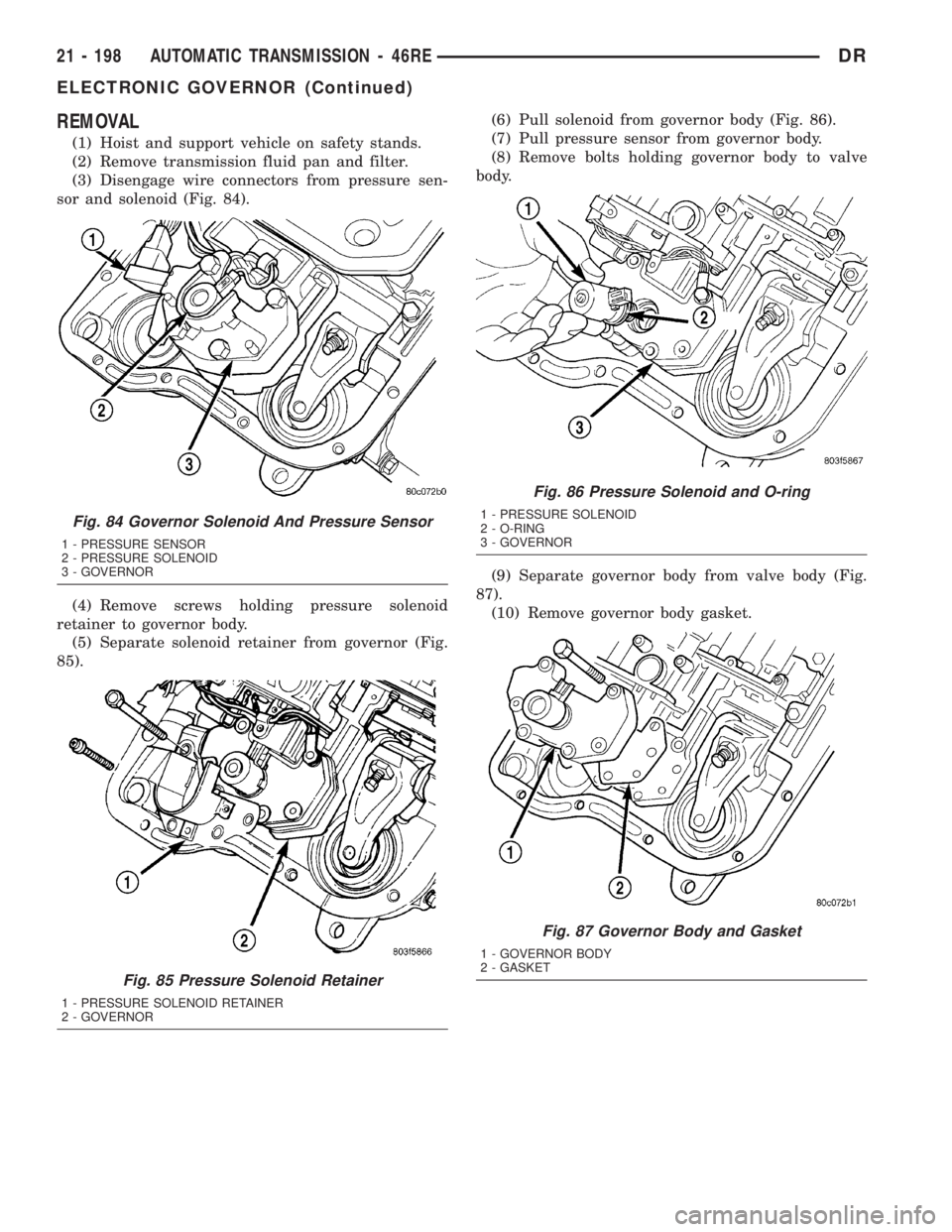

REMOVAL

(1) Hoist and support vehicle on safety stands.

(2) Remove transmission fluid pan and filter.

(3) Disengage wire connectors from pressure sen-

sor and solenoid (Fig. 84).

(4) Remove screws holding pressure solenoid

retainer to governor body.

(5) Separate solenoid retainer from governor (Fig.

85).(6) Pull solenoid from governor body (Fig. 86).

(7) Pull pressure sensor from governor body.

(8) Remove bolts holding governor body to valve

body.

(9) Separate governor body from valve body (Fig.

87).

(10) Remove governor body gasket.

Fig. 84 Governor Solenoid And Pressure Sensor

1 - PRESSURE SENSOR

2 - PRESSURE SOLENOID

3 - GOVERNOR

Fig. 85 Pressure Solenoid Retainer

1 - PRESSURE SOLENOID RETAINER

2 - GOVERNOR

Fig. 86 Pressure Solenoid and O-ring

1 - PRESSURE SOLENOID

2 - O-RING

3 - GOVERNOR

Fig. 87 Governor Body and Gasket

1 - GOVERNOR BODY

2 - GASKET

21 - 198 AUTOMATIC TRANSMISSION - 46REDR

ELECTRONIC GOVERNOR (Continued)

Page 2038 of 2895

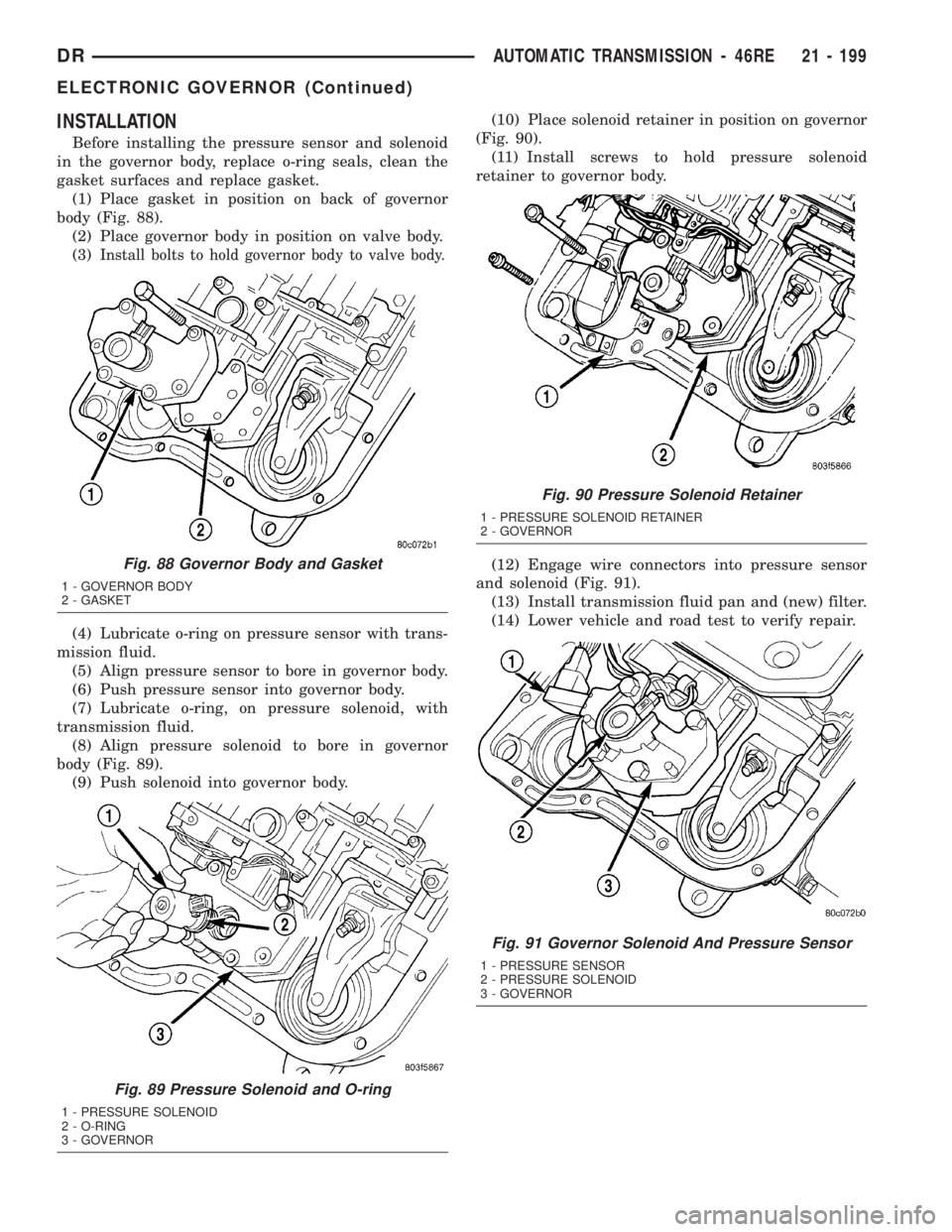

INSTALLATION

Before installing the pressure sensor and solenoid

in the governor body, replace o-ring seals, clean the

gasket surfaces and replace gasket.

(1) Place gasket in position on back of governor

body (Fig. 88).

(2) Place governor body in position on valve body.

(3)

Install bolts to hold governor body to valve body.

(4) Lubricate o-ring on pressure sensor with trans-

mission fluid.

(5) Align pressure sensor to bore in governor body.

(6) Push pressure sensor into governor body.

(7) Lubricate o-ring, on pressure solenoid, with

transmission fluid.

(8) Align pressure solenoid to bore in governor

body (Fig. 89).

(9) Push solenoid into governor body.(10) Place solenoid retainer in position on governor

(Fig. 90).

(11) Install screws to hold pressure solenoid

retainer to governor body.

(12) Engage wire connectors into pressure sensor

and solenoid (Fig. 91).

(13) Install transmission fluid pan and (new) filter.

(14) Lower vehicle and road test to verify repair.

Fig. 88 Governor Body and Gasket

1 - GOVERNOR BODY

2 - GASKET

Fig. 89 Pressure Solenoid and O-ring

1 - PRESSURE SOLENOID

2 - O-RING

3 - GOVERNOR

Fig. 90 Pressure Solenoid Retainer

1 - PRESSURE SOLENOID RETAINER

2 - GOVERNOR

Fig. 91 Governor Solenoid And Pressure Sensor

1 - PRESSURE SENSOR

2 - PRESSURE SOLENOID

3 - GOVERNOR

DRAUTOMATIC TRANSMISSION - 46RE 21 - 199

ELECTRONIC GOVERNOR (Continued)

Page 2041 of 2895

vehicle if necessary to bring fluid temperature up to

normal hot operating temperature of 82ÉC (180ÉF).

(2) Position vehicle on level surface.

(3) Start and run engine at curb idle speed.

(4) Apply parking brakes.

(5) Shift transmission momentarily into all gear

ranges. Then shift transmission back to NEUTRAL.

(6) Clean top of filler tube and dipstick to keep

dirt from entering tube.

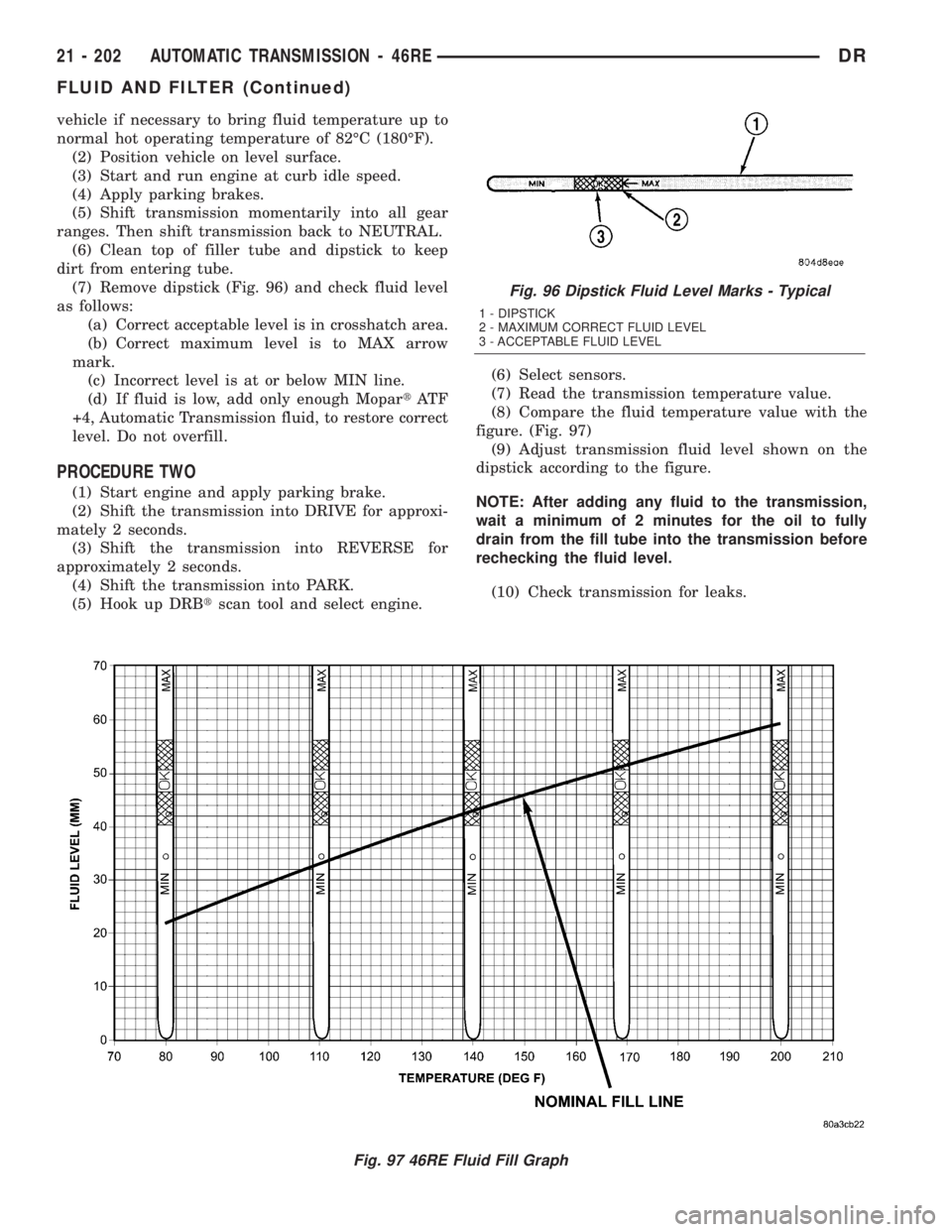

(7) Remove dipstick (Fig. 96) and check fluid level

as follows:

(a) Correct acceptable level is in crosshatch area.

(b) Correct maximum level is to MAX arrow

mark.

(c) Incorrect level is at or below MIN line.

(d) If fluid is low, add only enough MopartAT F

+4, Automatic Transmission fluid, to restore correct

level. Do not overfill.

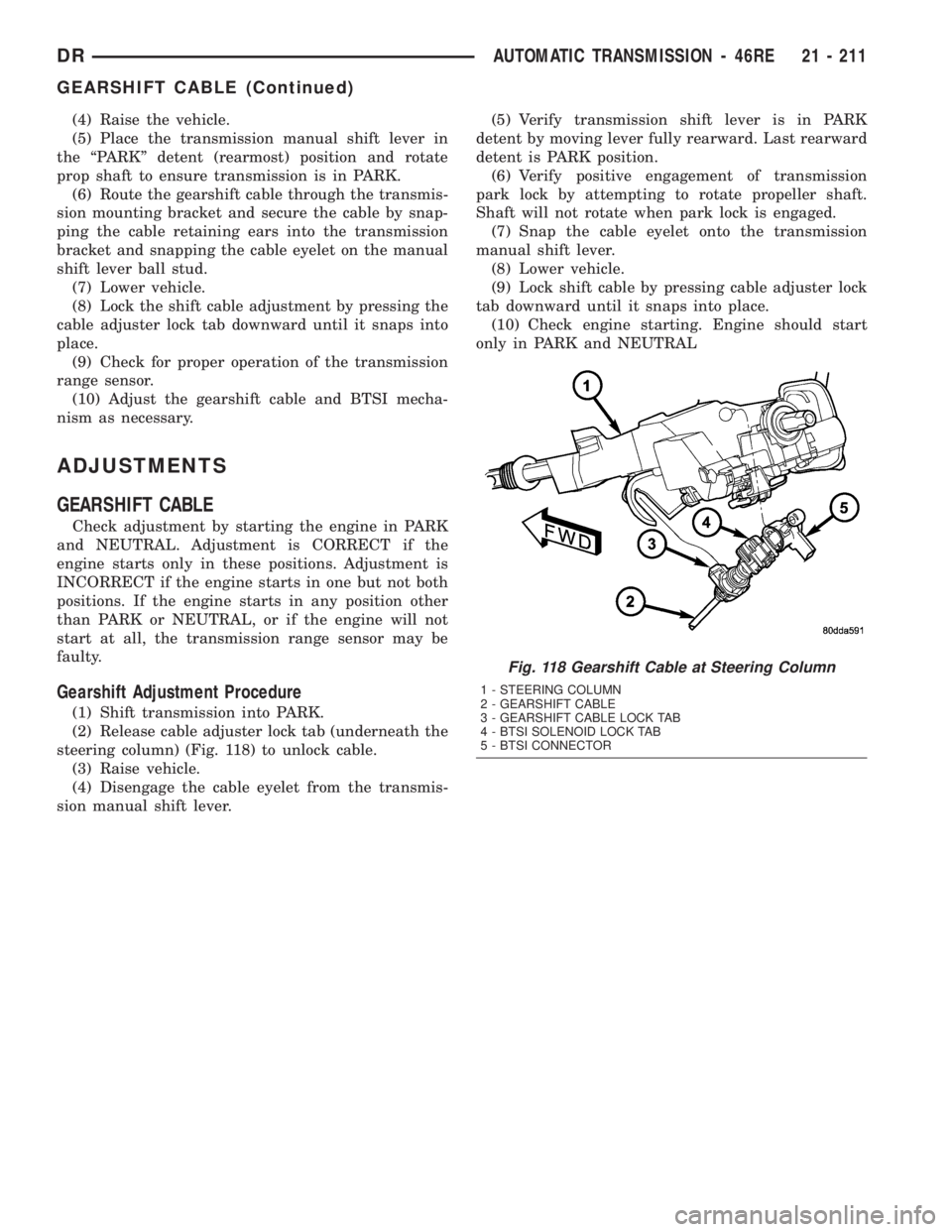

PROCEDURE TWO

(1) Start engine and apply parking brake.

(2) Shift the transmission into DRIVE for approxi-

mately 2 seconds.

(3) Shift the transmission into REVERSE for

approximately 2 seconds.

(4) Shift the transmission into PARK.

(5) Hook up DRBtscan tool and select engine.(6) Select sensors.

(7) Read the transmission temperature value.

(8) Compare the fluid temperature value with the

figure. (Fig. 97)

(9) Adjust transmission fluid level shown on the

dipstick according to the figure.

NOTE: After adding any fluid to the transmission,

wait a minimum of 2 minutes for the oil to fully

drain from the fill tube into the transmission before

rechecking the fluid level.

(10) Check transmission for leaks.

Fig. 96 Dipstick Fluid Level Marks - Typical

1 - DIPSTICK

2 - MAXIMUM CORRECT FLUID LEVEL

3 - ACCEPTABLE FLUID LEVEL

Fig. 97 46RE Fluid Fill Graph

21 - 202 AUTOMATIC TRANSMISSION - 46REDR

FLUID AND FILTER (Continued)

Page 2050 of 2895

(4) Raise the vehicle.

(5) Place the transmission manual shift lever in

the ªPARKº detent (rearmost) position and rotate

prop shaft to ensure transmission is in PARK.

(6) Route the gearshift cable through the transmis-

sion mounting bracket and secure the cable by snap-

ping the cable retaining ears into the transmission

bracket and snapping the cable eyelet on the manual

shift lever ball stud.

(7) Lower vehicle.

(8) Lock the shift cable adjustment by pressing the

cable adjuster lock tab downward until it snaps into

place.

(9) Check for proper operation of the transmission

range sensor.

(10) Adjust the gearshift cable and BTSI mecha-

nism as necessary.

ADJUSTMENTS

GEARSHIFT CABLE

Check adjustment by starting the engine in PARK

and NEUTRAL. Adjustment is CORRECT if the

engine starts only in these positions. Adjustment is

INCORRECT if the engine starts in one but not both

positions. If the engine starts in any position other

than PARK or NEUTRAL, or if the engine will not

start at all, the transmission range sensor may be

faulty.

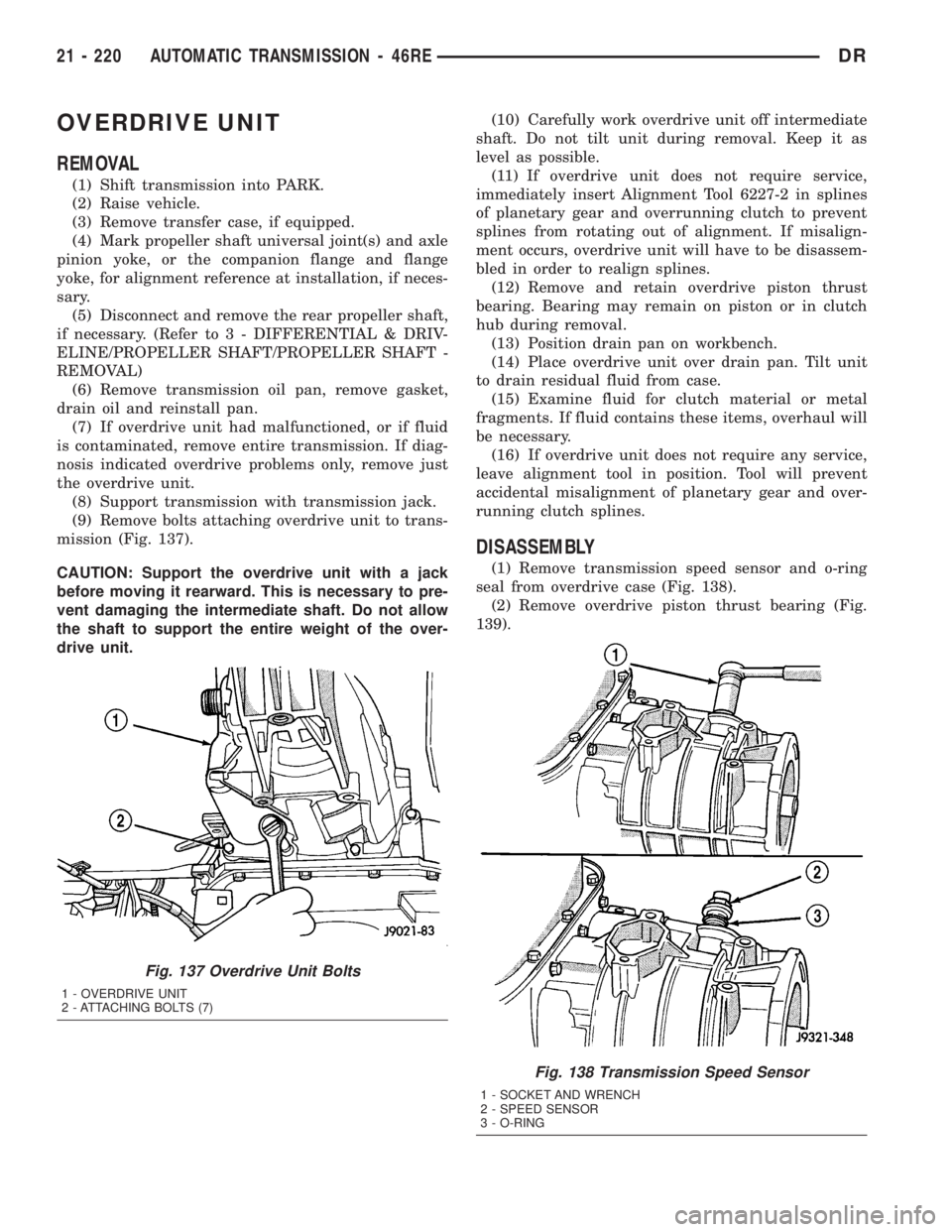

Gearshift Adjustment Procedure

(1) Shift transmission into PARK.

(2) Release cable adjuster lock tab (underneath the

steering column) (Fig. 118) to unlock cable.

(3) Raise vehicle.

(4) Disengage the cable eyelet from the transmis-

sion manual shift lever.(5) Verify transmission shift lever is in PARK

detent by moving lever fully rearward. Last rearward

detent is PARK position.

(6) Verify positive engagement of transmission

park lock by attempting to rotate propeller shaft.

Shaft will not rotate when park lock is engaged.

(7) Snap the cable eyelet onto the transmission

manual shift lever.

(8) Lower vehicle.

(9) Lock shift cable by pressing cable adjuster lock

tab downward until it snaps into place.

(10) Check engine starting. Engine should start

only in PARK and NEUTRAL

Fig. 118 Gearshift Cable at Steering Column

1 - STEERING COLUMN

2 - GEARSHIFT CABLE

3 - GEARSHIFT CABLE LOCK TAB

4 - BTSI SOLENOID LOCK TAB

5 - BTSI CONNECTOR

DRAUTOMATIC TRANSMISSION - 46RE 21 - 211

GEARSHIFT CABLE (Continued)

Page 2059 of 2895

OVERDRIVE UNIT

REMOVAL

(1) Shift transmission into PARK.

(2) Raise vehicle.

(3) Remove transfer case, if equipped.

(4) Mark propeller shaft universal joint(s) and axle

pinion yoke, or the companion flange and flange

yoke, for alignment reference at installation, if neces-

sary.

(5) Disconnect and remove the rear propeller shaft,

if necessary. (Refer to 3 - DIFFERENTIAL & DRIV-

ELINE/PROPELLER SHAFT/PROPELLER SHAFT -

REMOVAL)

(6) Remove transmission oil pan, remove gasket,

drain oil and reinstall pan.

(7) If overdrive unit had malfunctioned, or if fluid

is contaminated, remove entire transmission. If diag-

nosis indicated overdrive problems only, remove just

the overdrive unit.

(8) Support transmission with transmission jack.

(9) Remove bolts attaching overdrive unit to trans-

mission (Fig. 137).

CAUTION: Support the overdrive unit with a jack

before moving it rearward. This is necessary to pre-

vent damaging the intermediate shaft. Do not allow

the shaft to support the entire weight of the over-

drive unit.(10) Carefully work overdrive unit off intermediate

shaft. Do not tilt unit during removal. Keep it as

level as possible.

(11) If overdrive unit does not require service,

immediately insert Alignment Tool 6227-2 in splines

of planetary gear and overrunning clutch to prevent

splines from rotating out of alignment. If misalign-

ment occurs, overdrive unit will have to be disassem-

bled in order to realign splines.

(12) Remove and retain overdrive piston thrust

bearing. Bearing may remain on piston or in clutch

hub during removal.

(13) Position drain pan on workbench.

(14) Place overdrive unit over drain pan. Tilt unit

to drain residual fluid from case.

(15) Examine fluid for clutch material or metal

fragments. If fluid contains these items, overhaul will

be necessary.

(16) If overdrive unit does not require any service,

leave alignment tool in position. Tool will prevent

accidental misalignment of planetary gear and over-

running clutch splines.

DISASSEMBLY

(1) Remove transmission speed sensor and o-ring

seal from overdrive case (Fig. 138).

(2) Remove overdrive piston thrust bearing (Fig.

139).

Fig. 137 Overdrive Unit Bolts

1 - OVERDRIVE UNIT

2 - ATTACHING BOLTS (7)

Fig. 138 Transmission Speed Sensor

1 - SOCKET AND WRENCH

2 - SPEED SENSOR

3 - O-RING

21 - 220 AUTOMATIC TRANSMISSION - 46REDR

Page 2075 of 2895

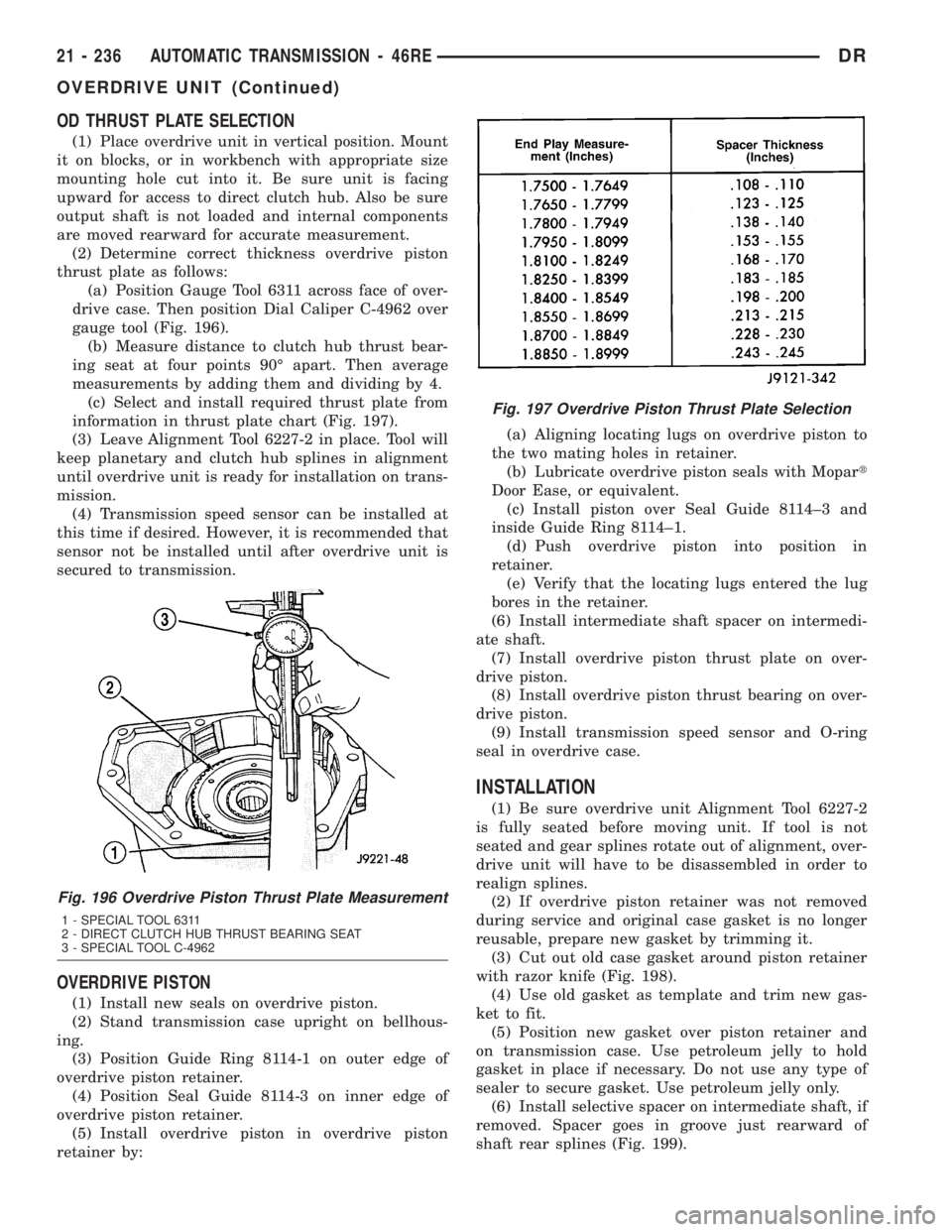

OD THRUST PLATE SELECTION

(1) Place overdrive unit in vertical position. Mount

it on blocks, or in workbench with appropriate size

mounting hole cut into it. Be sure unit is facing

upward for access to direct clutch hub. Also be sure

output shaft is not loaded and internal components

are moved rearward for accurate measurement.

(2) Determine correct thickness overdrive piston

thrust plate as follows:

(a) Position Gauge Tool 6311 across face of over-

drive case. Then position Dial Caliper C-4962 over

gauge tool (Fig. 196).

(b) Measure distance to clutch hub thrust bear-

ing seat at four points 90É apart. Then average

measurements by adding them and dividing by 4.

(c) Select and install required thrust plate from

information in thrust plate chart (Fig. 197).

(3) Leave Alignment Tool 6227-2 in place. Tool will

keep planetary and clutch hub splines in alignment

until overdrive unit is ready for installation on trans-

mission.

(4) Transmission speed sensor can be installed at

this time if desired. However, it is recommended that

sensor not be installed until after overdrive unit is

secured to transmission.

OVERDRIVE PISTON

(1) Install new seals on overdrive piston.

(2) Stand transmission case upright on bellhous-

ing.

(3) Position Guide Ring 8114-1 on outer edge of

overdrive piston retainer.

(4) Position Seal Guide 8114-3 on inner edge of

overdrive piston retainer.

(5) Install overdrive piston in overdrive piston

retainer by:(a) Aligning locating lugs on overdrive piston to

the two mating holes in retainer.

(b) Lubricate overdrive piston seals with Mopart

Door Ease, or equivalent.

(c) Install piston over Seal Guide 8114±3 and

inside Guide Ring 8114±1.

(d) Push overdrive piston into position in

retainer.

(e) Verify that the locating lugs entered the lug

bores in the retainer.

(6) Install intermediate shaft spacer on intermedi-

ate shaft.

(7) Install overdrive piston thrust plate on over-

drive piston.

(8) Install overdrive piston thrust bearing on over-

drive piston.

(9) Install transmission speed sensor and O-ring

seal in overdrive case.

INSTALLATION

(1) Be sure overdrive unit Alignment Tool 6227-2

is fully seated before moving unit. If tool is not

seated and gear splines rotate out of alignment, over-

drive unit will have to be disassembled in order to

realign splines.

(2) If overdrive piston retainer was not removed

during service and original case gasket is no longer

reusable, prepare new gasket by trimming it.

(3) Cut out old case gasket around piston retainer

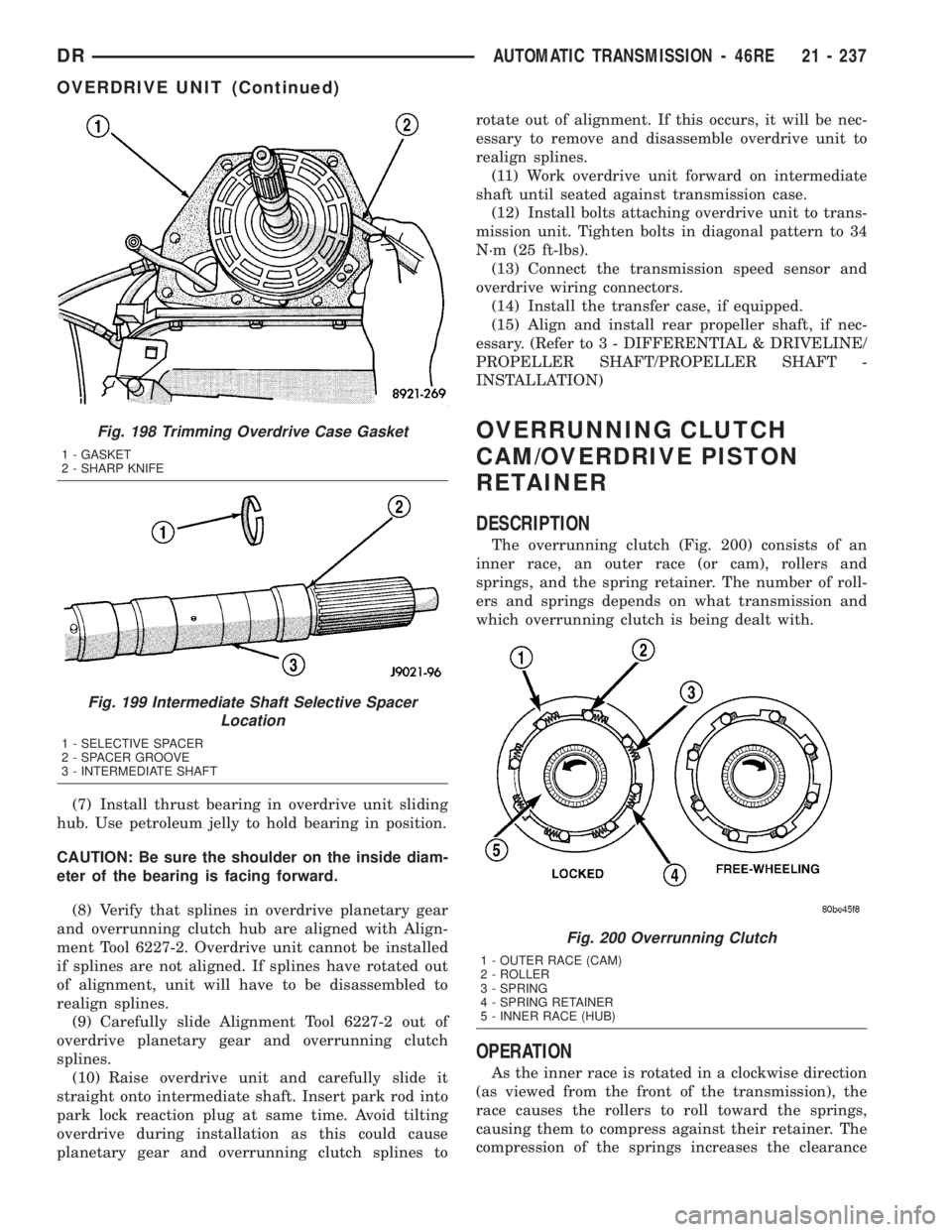

with razor knife (Fig. 198).

(4) Use old gasket as template and trim new gas-

ket to fit.

(5) Position new gasket over piston retainer and

on transmission case. Use petroleum jelly to hold

gasket in place if necessary. Do not use any type of

sealer to secure gasket. Use petroleum jelly only.

(6) Install selective spacer on intermediate shaft, if

removed. Spacer goes in groove just rearward of

shaft rear splines (Fig. 199).

Fig. 196 Overdrive Piston Thrust Plate Measurement

1 - SPECIAL TOOL 6311

2 - DIRECT CLUTCH HUB THRUST BEARING SEAT

3 - SPECIAL TOOL C-4962

Fig. 197 Overdrive Piston Thrust Plate Selection

21 - 236 AUTOMATIC TRANSMISSION - 46REDR

OVERDRIVE UNIT (Continued)

Page 2076 of 2895

(7) Install thrust bearing in overdrive unit sliding

hub. Use petroleum jelly to hold bearing in position.

CAUTION: Be sure the shoulder on the inside diam-

eter of the bearing is facing forward.

(8) Verify that splines in overdrive planetary gear

and overrunning clutch hub are aligned with Align-

ment Tool 6227-2. Overdrive unit cannot be installed

if splines are not aligned. If splines have rotated out

of alignment, unit will have to be disassembled to

realign splines.

(9) Carefully slide Alignment Tool 6227-2 out of

overdrive planetary gear and overrunning clutch

splines.

(10) Raise overdrive unit and carefully slide it

straight onto intermediate shaft. Insert park rod into

park lock reaction plug at same time. Avoid tilting

overdrive during installation as this could cause

planetary gear and overrunning clutch splines torotate out of alignment. If this occurs, it will be nec-

essary to remove and disassemble overdrive unit to

realign splines.

(11) Work overdrive unit forward on intermediate

shaft until seated against transmission case.

(12) Install bolts attaching overdrive unit to trans-

mission unit. Tighten bolts in diagonal pattern to 34

N´m (25 ft-lbs).

(13) Connect the transmission speed sensor and

overdrive wiring connectors.

(14) Install the transfer case, if equipped.

(15) Align and install rear propeller shaft, if nec-

essary. (Refer to 3 - DIFFERENTIAL & DRIVELINE/

PROPELLER SHAFT/PROPELLER SHAFT -

INSTALLATION)

OVERRUNNING CLUTCH

CAM/OVERDRIVE PISTON

RETAINER

DESCRIPTION

The overrunning clutch (Fig. 200) consists of an

inner race, an outer race (or cam), rollers and

springs, and the spring retainer. The number of roll-

ers and springs depends on what transmission and

which overrunning clutch is being dealt with.

OPERATION

As the inner race is rotated in a clockwise direction

(as viewed from the front of the transmission), the

race causes the rollers to roll toward the springs,

causing them to compress against their retainer. The

compression of the springs increases the clearance

Fig. 198 Trimming Overdrive Case Gasket

1 - GASKET

2 - SHARP KNIFE

Fig. 199 Intermediate Shaft Selective Spacer

Location

1 - SELECTIVE SPACER

2 - SPACER GROOVE

3 - INTERMEDIATE SHAFT

Fig. 200 Overrunning Clutch

1 - OUTER RACE (CAM)

2 - ROLLER

3 - SPRING

4 - SPRING RETAINER

5 - INNER RACE (HUB)

DRAUTOMATIC TRANSMISSION - 46RE 21 - 237

OVERDRIVE UNIT (Continued)

Page 2093 of 2895

stant ON, or duty cycle. The variable force and pulse-

width modulated versions utilize similar methods to

control the current flow through the solenoid to posi-

tion the solenoid plunger at a desired position some-

where between full ON and full OFF. The constant

ON and duty cycled versions control the voltage

across the solenoid to allow either full flow or no flow

through the solenoid's valve.

OPERATION

When an electrical current is applied to the sole-

noid coil, a magnetic field is created which produces

an attraction to the plunger, causing the plunger to

move and work against the spring pressure and the

load applied by the fluid the valve is controlling. The

plunger is normally directly attached to the valve

which it is to operate. When the current is removed

from the coil, the attraction is removed and the

plunger will return to its original position due to

spring pressure.

The plunger is made of a conductive material and

accomplishes this movement by providing a path for

the magnetic field to flow. By keeping the air gap

between the plunger and the coil to the minimum

necessary to allow free movement of the plunger, the

magnetic field is maximized.

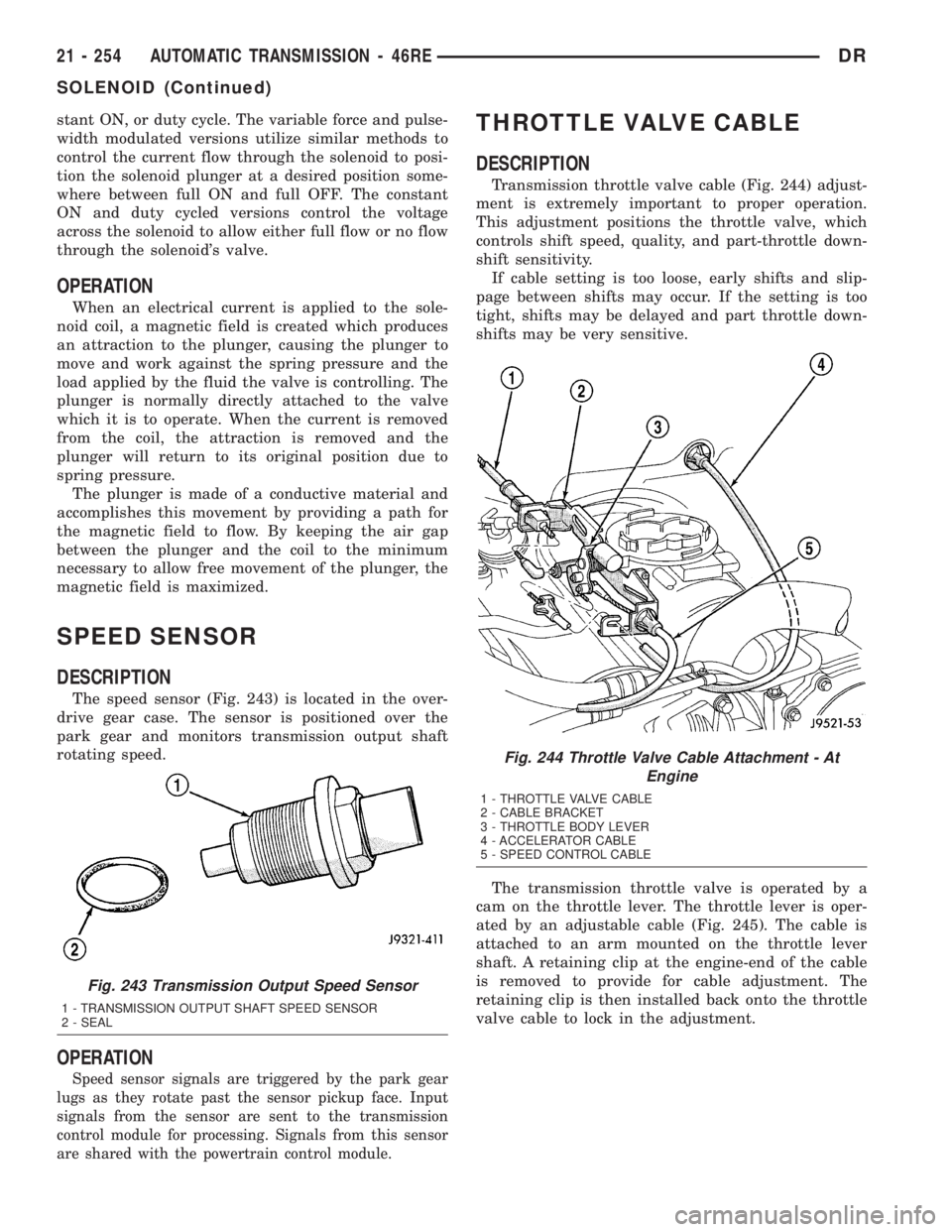

SPEED SENSOR

DESCRIPTION

The speed sensor (Fig. 243) is located in the over-

drive gear case. The sensor is positioned over the

park gear and monitors transmission output shaft

rotating speed.

OPERATION

Speed sensor signals are triggered by the park gear

lugs as they rotate past the sensor pickup face. Input

signals from the sensor are sent to the transmission

control module for processing. Signals from this sensor

are shared with the powertrain control module.

THROTTLE VALVE CABLE

DESCRIPTION

Transmission throttle valve cable (Fig. 244) adjust-

ment is extremely important to proper operation.

This adjustment positions the throttle valve, which

controls shift speed, quality, and part-throttle down-

shift sensitivity.

If cable setting is too loose, early shifts and slip-

page between shifts may occur. If the setting is too

tight, shifts may be delayed and part throttle down-

shifts may be very sensitive.

The transmission throttle valve is operated by a

cam on the throttle lever. The throttle lever is oper-

ated by an adjustable cable (Fig. 245). The cable is

attached to an arm mounted on the throttle lever

shaft. A retaining clip at the engine-end of the cable

is removed to provide for cable adjustment. The

retaining clip is then installed back onto the throttle

valve cable to lock in the adjustment.

Fig. 243 Transmission Output Speed Sensor

1 - TRANSMISSION OUTPUT SHAFT SPEED SENSOR

2 - SEAL

Fig. 244 Throttle Valve Cable Attachment - At

Engine

1 - THROTTLE VALVE CABLE

2 - CABLE BRACKET

3 - THROTTLE BODY LEVER

4 - ACCELERATOR CABLE

5 - SPEED CONTROL CABLE

21 - 254 AUTOMATIC TRANSMISSION - 46REDR

SOLENOID (Continued)