Transmission DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1947 of 2895

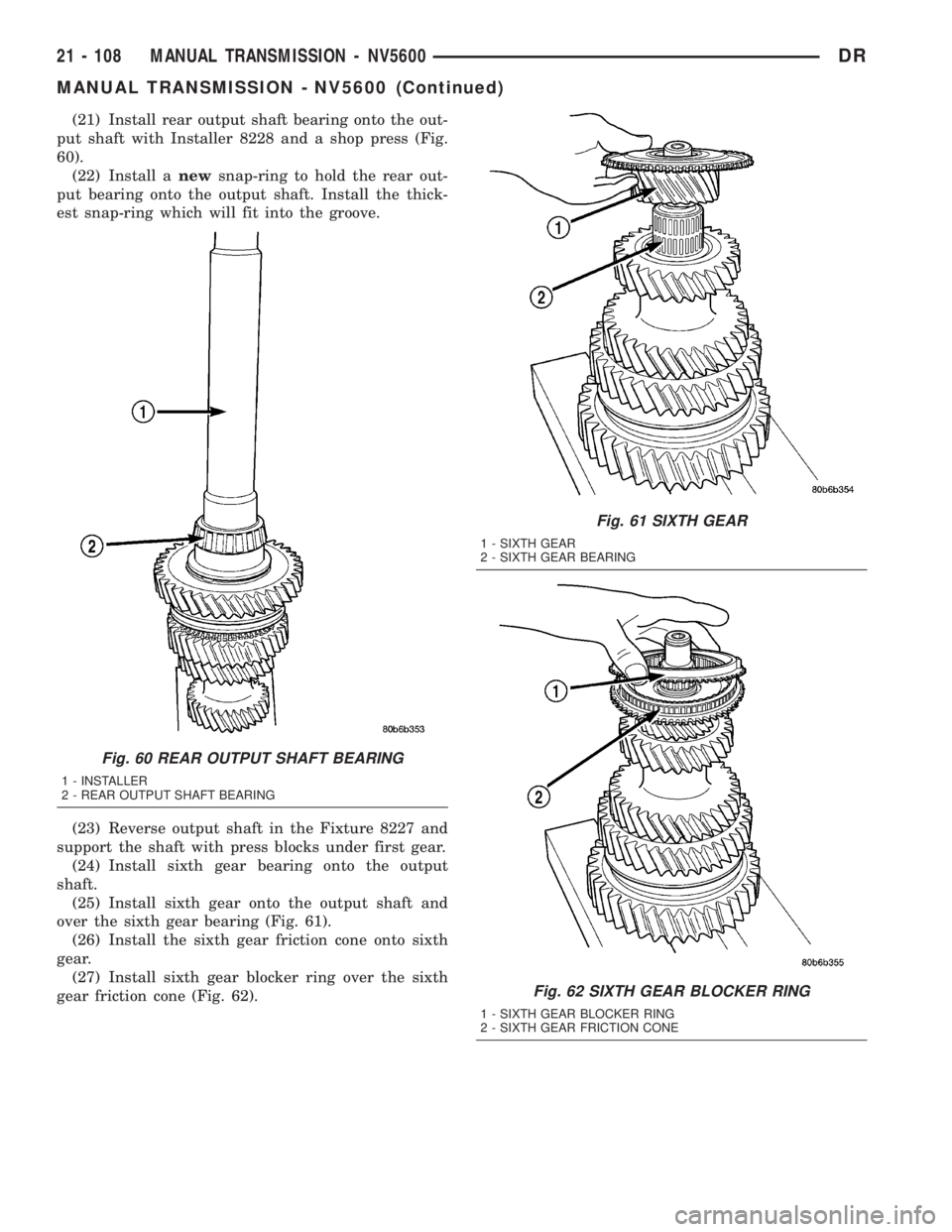

(21) Install rear output shaft bearing onto the out-

put shaft with Installer 8228 and a shop press (Fig.

60).

(22) Install anewsnap-ring to hold the rear out-

put bearing onto the output shaft. Install the thick-

est snap-ring which will fit into the groove.

(23) Reverse output shaft in the Fixture 8227 and

support the shaft with press blocks under first gear.

(24) Install sixth gear bearing onto the output

shaft.

(25) Install sixth gear onto the output shaft and

over the sixth gear bearing (Fig. 61).

(26) Install the sixth gear friction cone onto sixth

gear.

(27) Install sixth gear blocker ring over the sixth

gear friction cone (Fig. 62).

Fig. 60 REAR OUTPUT SHAFT BEARING

1 - INSTALLER

2 - REAR OUTPUT SHAFT BEARING

Fig. 61 SIXTH GEAR

1 - SIXTH GEAR

2 - SIXTH GEAR BEARING

Fig. 62 SIXTH GEAR BLOCKER RING

1 - SIXTH GEAR BLOCKER RING

2 - SIXTH GEAR FRICTION CONE

21 - 108 MANUAL TRANSMISSION - NV5600DR

MANUAL TRANSMISSION - NV5600 (Continued)

Page 1948 of 2895

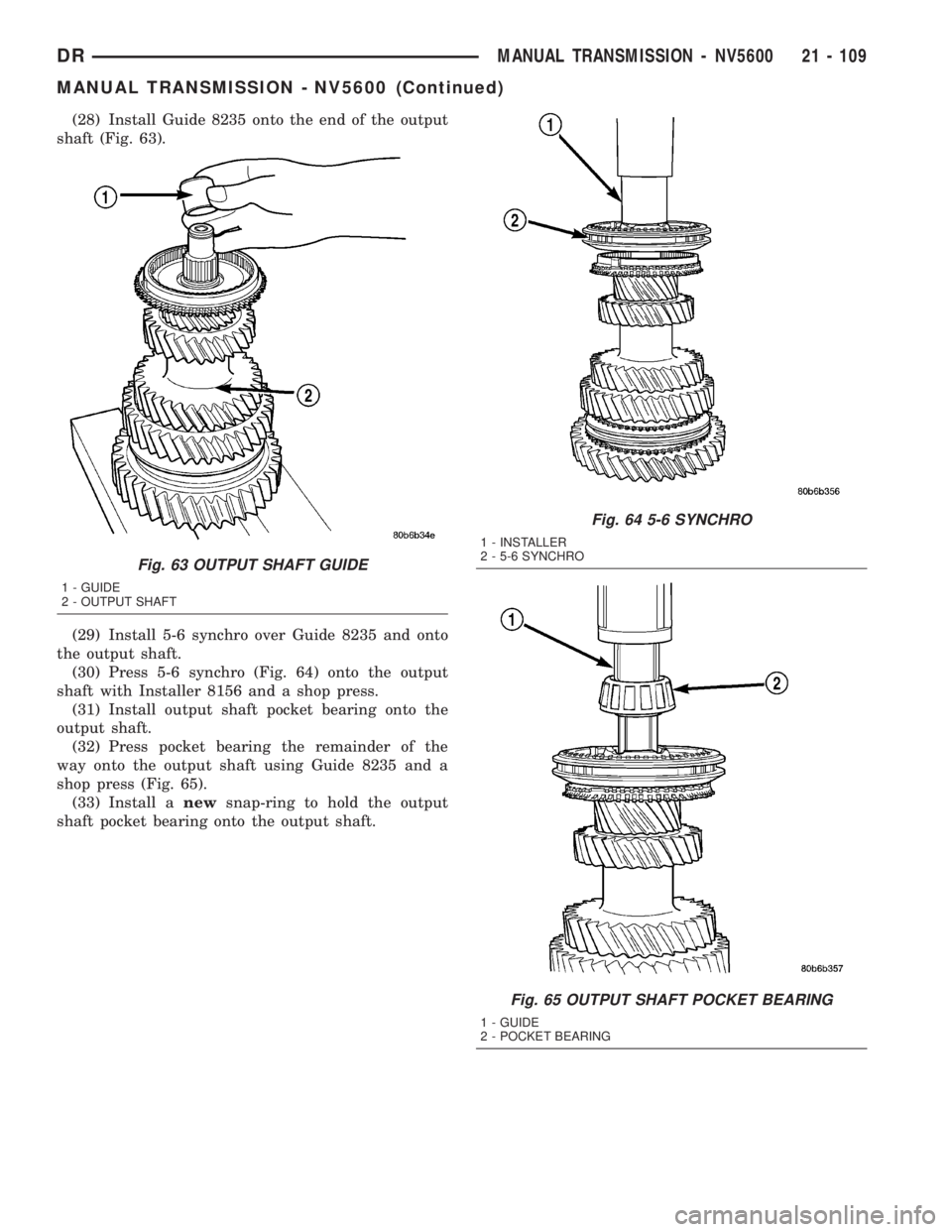

(28) Install Guide 8235 onto the end of the output

shaft (Fig. 63).

(29) Install 5-6 synchro over Guide 8235 and onto

the output shaft.

(30) Press 5-6 synchro (Fig. 64) onto the output

shaft with Installer 8156 and a shop press.

(31) Install output shaft pocket bearing onto the

output shaft.

(32) Press pocket bearing the remainder of the

way onto the output shaft using Guide 8235 and a

shop press (Fig. 65).

(33) Install anewsnap-ring to hold the output

shaft pocket bearing onto the output shaft.

Fig. 63 OUTPUT SHAFT GUIDE

1 - GUIDE

2 - OUTPUT SHAFT

Fig. 64 5-6 SYNCHRO

1 - INSTALLER

2 - 5-6 SYNCHRO

Fig. 65 OUTPUT SHAFT POCKET BEARING

1 - GUIDE

2 - POCKET BEARING

DRMANUAL TRANSMISSION - NV5600 21 - 109

MANUAL TRANSMISSION - NV5600 (Continued)

Page 1949 of 2895

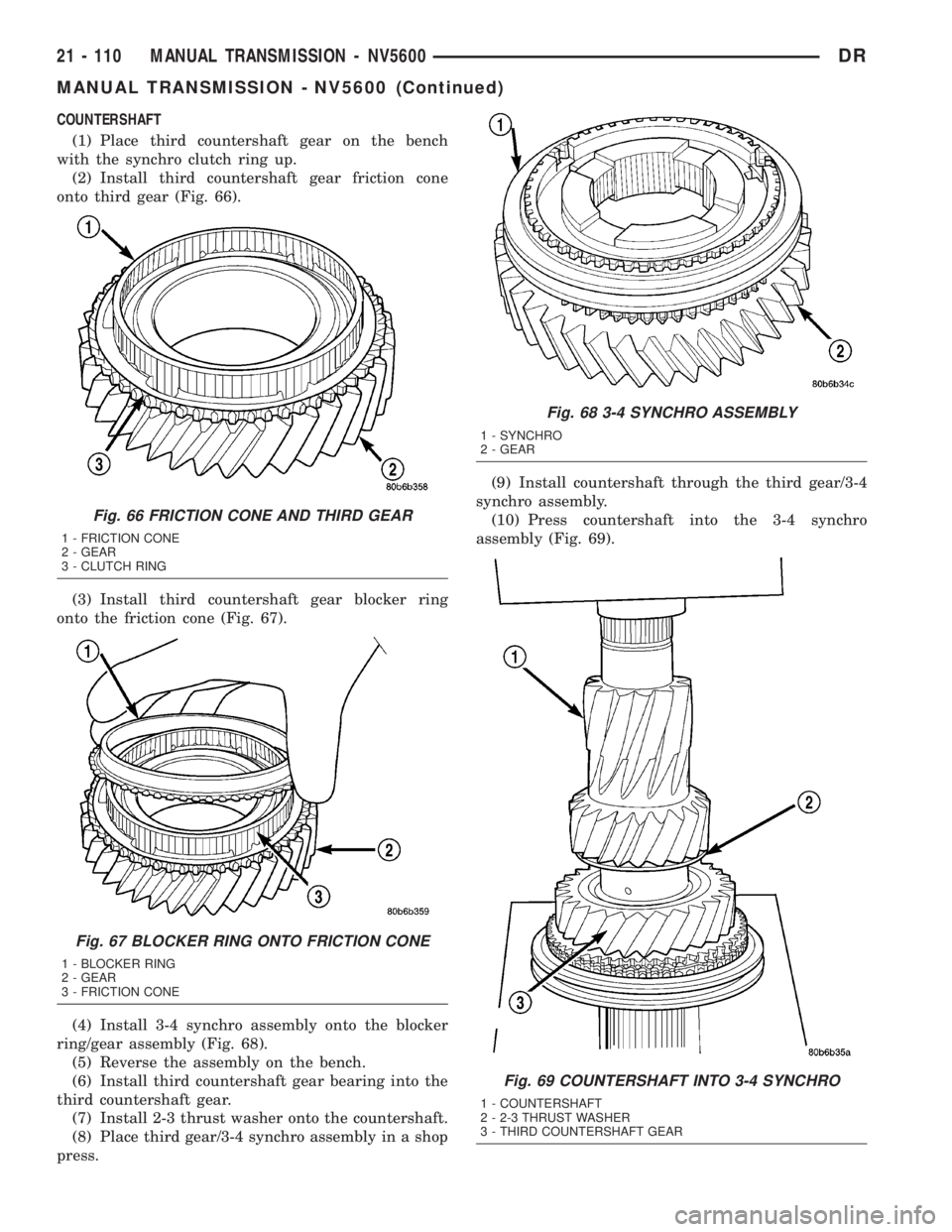

COUNTERSHAFT

(1) Place third countershaft gear on the bench

with the synchro clutch ring up.

(2) Install third countershaft gear friction cone

onto third gear (Fig. 66).

(3) Install third countershaft gear blocker ring

onto the friction cone (Fig. 67).

(4) Install 3-4 synchro assembly onto the blocker

ring/gear assembly (Fig. 68).

(5) Reverse the assembly on the bench.

(6) Install third countershaft gear bearing into the

third countershaft gear.

(7) Install 2-3 thrust washer onto the countershaft.

(8) Place third gear/3-4 synchro assembly in a shop

press.(9) Install countershaft through the third gear/3-4

synchro assembly.

(10) Press countershaft into the 3-4 synchro

assembly (Fig. 69).

Fig. 66 FRICTION CONE AND THIRD GEAR

1 - FRICTION CONE

2 - GEAR

3 - CLUTCH RING

Fig. 67 BLOCKER RING ONTO FRICTION CONE

1 - BLOCKER RING

2 - GEAR

3 - FRICTION CONE

Fig. 68 3-4 SYNCHRO ASSEMBLY

1 - SYNCHRO

2 - GEAR

Fig. 69 COUNTERSHAFT INTO 3-4 SYNCHRO

1 - COUNTERSHAFT

2 - 2-3 THRUST WASHER

3 - THIRD COUNTERSHAFT GEAR

21 - 110 MANUAL TRANSMISSION - NV5600DR

MANUAL TRANSMISSION - NV5600 (Continued)

Page 1950 of 2895

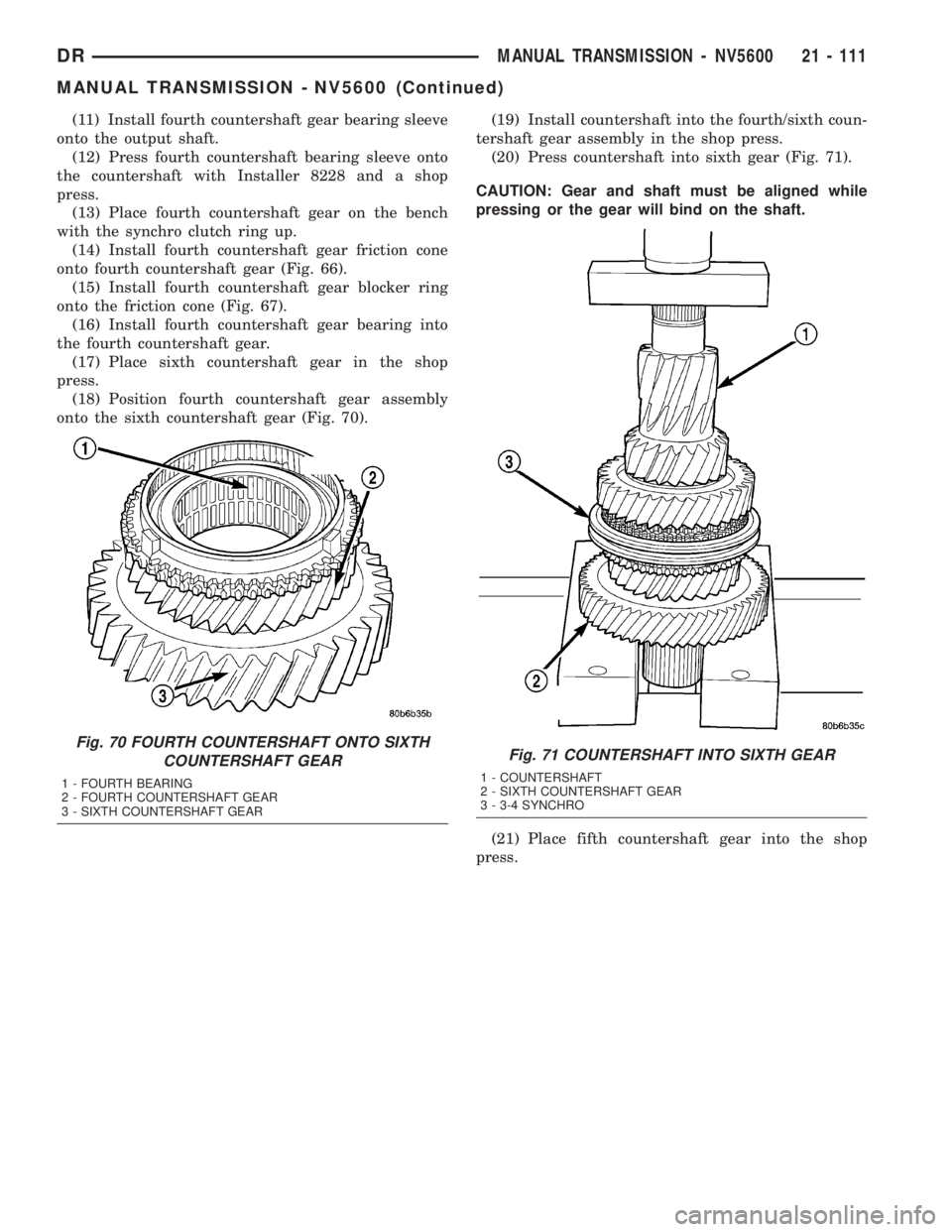

(11) Install fourth countershaft gear bearing sleeve

onto the output shaft.

(12) Press fourth countershaft bearing sleeve onto

the countershaft with Installer 8228 and a shop

press.

(13) Place fourth countershaft gear on the bench

with the synchro clutch ring up.

(14) Install fourth countershaft gear friction cone

onto fourth countershaft gear (Fig. 66).

(15) Install fourth countershaft gear blocker ring

onto the friction cone (Fig. 67).

(16) Install fourth countershaft gear bearing into

the fourth countershaft gear.

(17) Place sixth countershaft gear in the shop

press.

(18) Position fourth countershaft gear assembly

onto the sixth countershaft gear (Fig. 70).(19) Install countershaft into the fourth/sixth coun-

tershaft gear assembly in the shop press.

(20) Press countershaft into sixth gear (Fig. 71).

CAUTION: Gear and shaft must be aligned while

pressing or the gear will bind on the shaft.

(21) Place fifth countershaft gear into the shop

press.

Fig. 70 FOURTH COUNTERSHAFT ONTO SIXTH

COUNTERSHAFT GEAR

1 - FOURTH BEARING

2 - FOURTH COUNTERSHAFT GEAR

3 - SIXTH COUNTERSHAFT GEAR

Fig. 71 COUNTERSHAFT INTO SIXTH GEAR

1 - COUNTERSHAFT

2 - SIXTH COUNTERSHAFT GEAR

3 - 3-4 SYNCHRO

DRMANUAL TRANSMISSION - NV5600 21 - 111

MANUAL TRANSMISSION - NV5600 (Continued)

Page 1951 of 2895

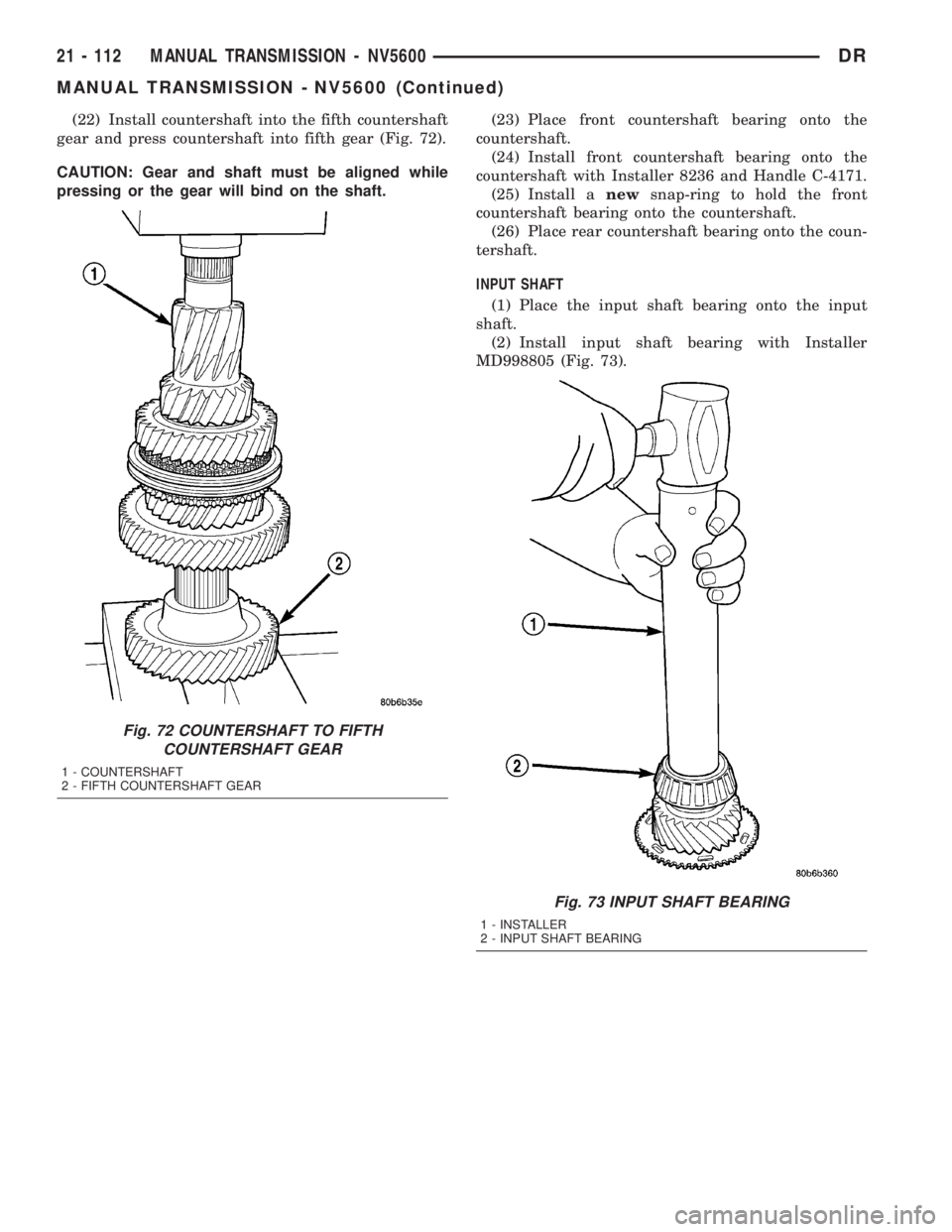

(22) Install countershaft into the fifth countershaft

gear and press countershaft into fifth gear (Fig. 72).

CAUTION: Gear and shaft must be aligned while

pressing or the gear will bind on the shaft.(23) Place front countershaft bearing onto the

countershaft.

(24) Install front countershaft bearing onto the

countershaft with Installer 8236 and Handle C-4171.

(25) Install anewsnap-ring to hold the front

countershaft bearing onto the countershaft.

(26) Place rear countershaft bearing onto the coun-

tershaft.

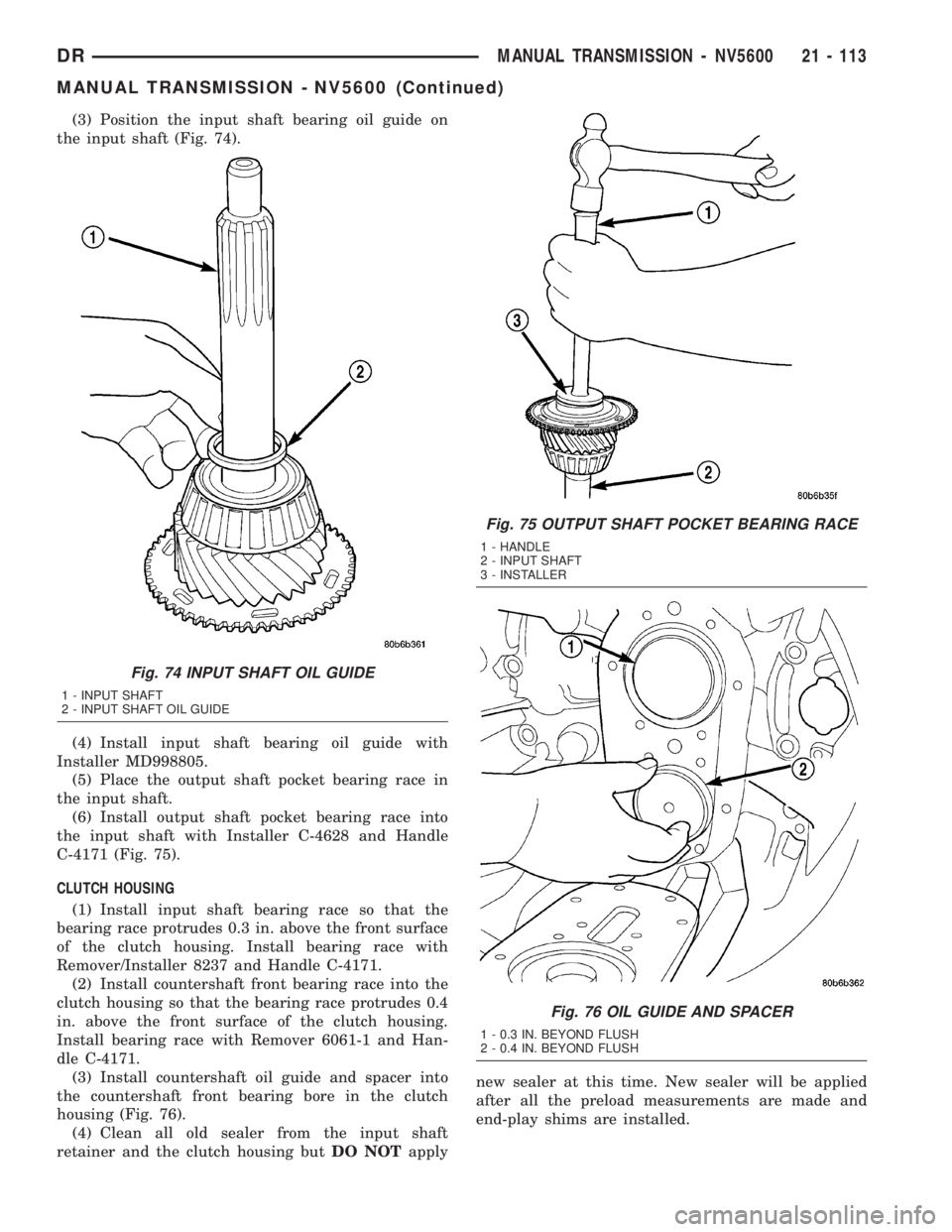

INPUT SHAFT

(1) Place the input shaft bearing onto the input

shaft.

(2) Install input shaft bearing with Installer

MD998805 (Fig. 73).

Fig. 72 COUNTERSHAFT TO FIFTH

COUNTERSHAFT GEAR

1 - COUNTERSHAFT

2 - FIFTH COUNTERSHAFT GEAR

Fig. 73 INPUT SHAFT BEARING

1 - INSTALLER

2 - INPUT SHAFT BEARING

21 - 112 MANUAL TRANSMISSION - NV5600DR

MANUAL TRANSMISSION - NV5600 (Continued)

Page 1952 of 2895

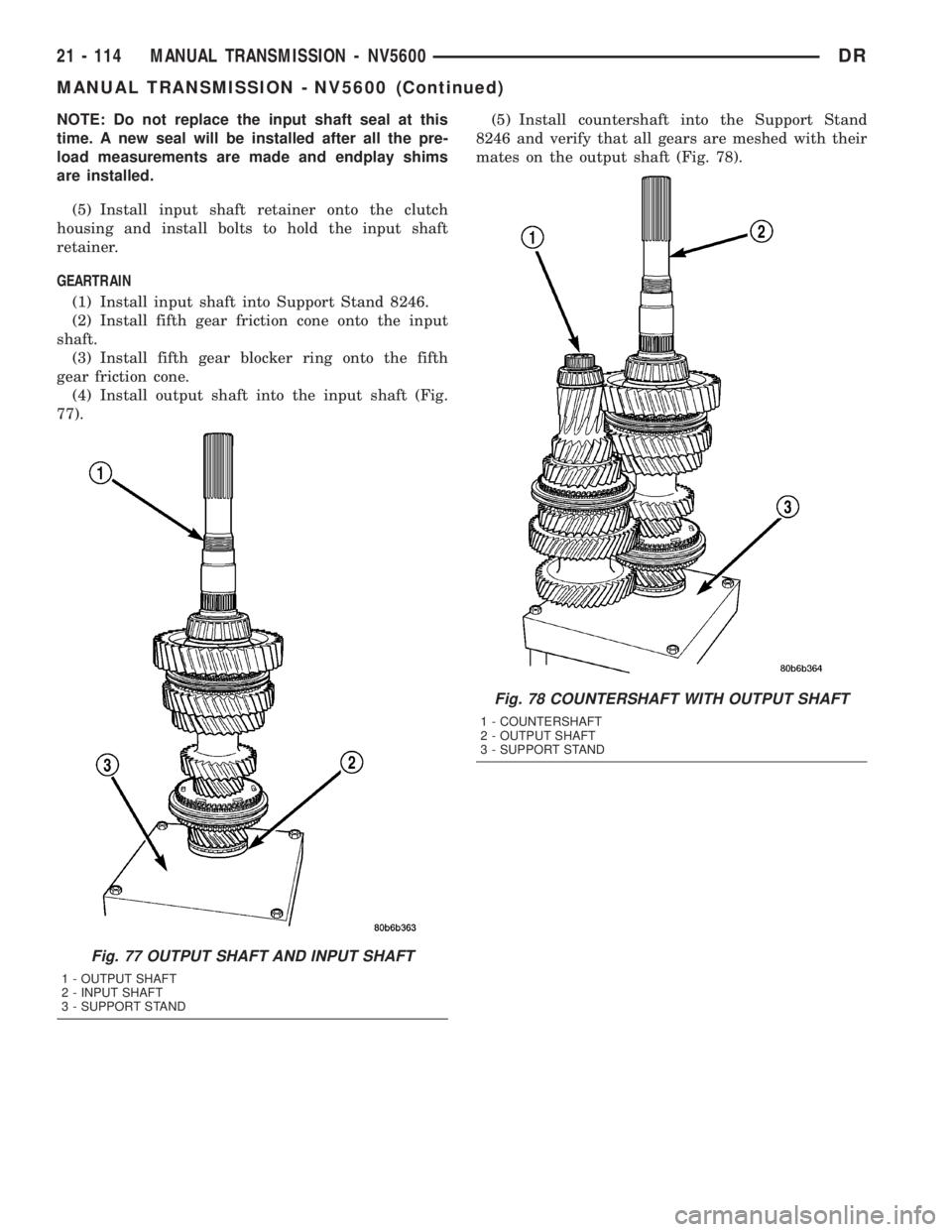

(3) Position the input shaft bearing oil guide on

the input shaft (Fig. 74).

(4) Install input shaft bearing oil guide with

Installer MD998805.

(5) Place the output shaft pocket bearing race in

the input shaft.

(6) Install output shaft pocket bearing race into

the input shaft with Installer C-4628 and Handle

C-4171 (Fig. 75).

CLUTCH HOUSING

(1) Install input shaft bearing race so that the

bearing race protrudes 0.3 in. above the front surface

of the clutch housing. Install bearing race with

Remover/Installer 8237 and Handle C-4171.

(2) Install countershaft front bearing race into the

clutch housing so that the bearing race protrudes 0.4

in. above the front surface of the clutch housing.

Install bearing race with Remover 6061-1 and Han-

dle C-4171.

(3) Install countershaft oil guide and spacer into

the countershaft front bearing bore in the clutch

housing (Fig. 76).

(4) Clean all old sealer from the input shaft

retainer and the clutch housing butDO NOTapplynew sealer at this time. New sealer will be applied

after all the preload measurements are made and

end-play shims are installed.

Fig. 74 INPUT SHAFT OIL GUIDE

1 - INPUT SHAFT

2 - INPUT SHAFT OIL GUIDE

Fig. 75 OUTPUT SHAFT POCKET BEARING RACE

1 - HANDLE

2 - INPUT SHAFT

3 - INSTALLER

Fig. 76 OIL GUIDE AND SPACER

1 - 0.3 IN. BEYOND FLUSH

2 - 0.4 IN. BEYOND FLUSH

DRMANUAL TRANSMISSION - NV5600 21 - 113

MANUAL TRANSMISSION - NV5600 (Continued)

Page 1953 of 2895

NOTE: Do not replace the input shaft seal at this

time. A new seal will be installed after all the pre-

load measurements are made and endplay shims

are installed.

(5) Install input shaft retainer onto the clutch

housing and install bolts to hold the input shaft

retainer.

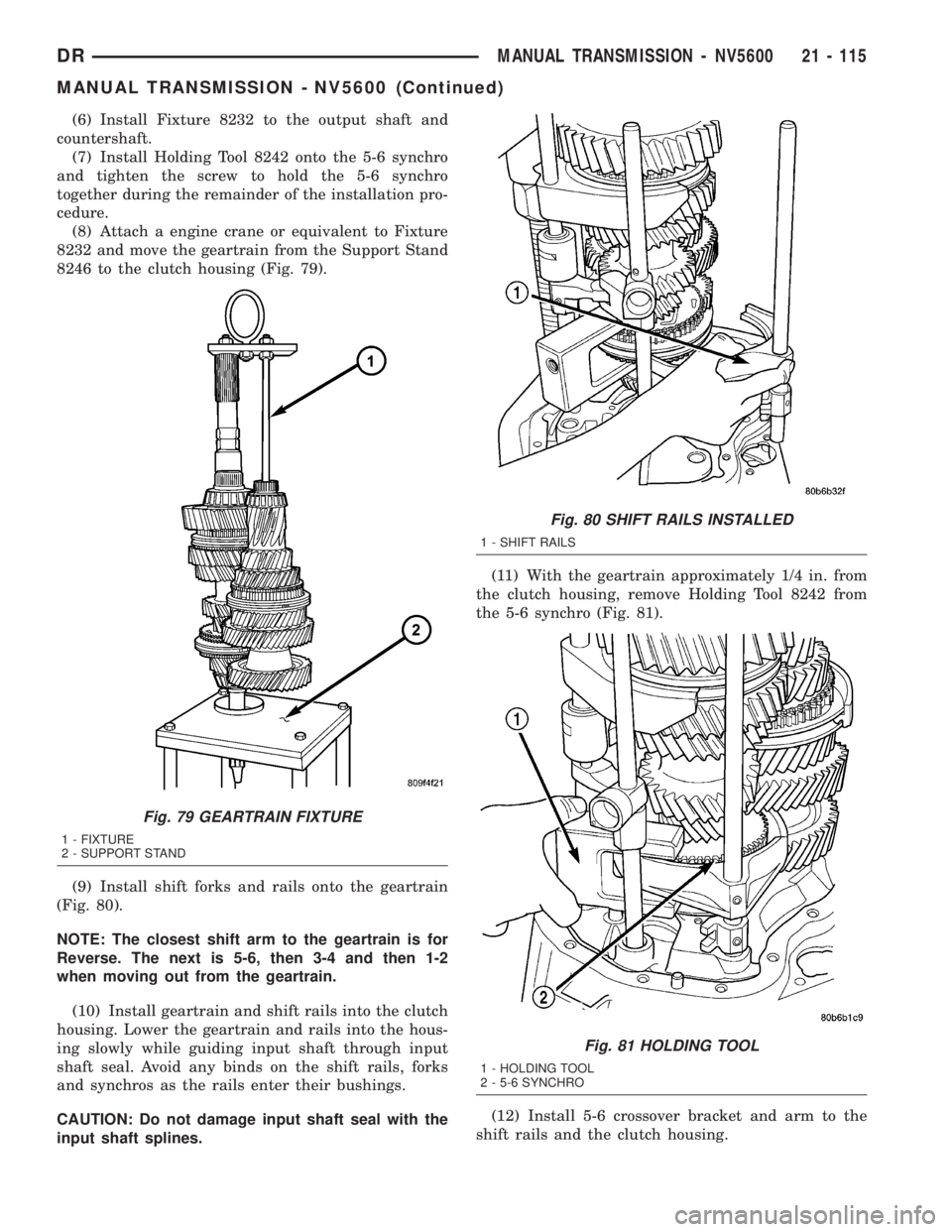

GEARTRAIN

(1) Install input shaft into Support Stand 8246.

(2) Install fifth gear friction cone onto the input

shaft.

(3) Install fifth gear blocker ring onto the fifth

gear friction cone.

(4) Install output shaft into the input shaft (Fig.

77).(5) Install countershaft into the Support Stand

8246 and verify that all gears are meshed with their

mates on the output shaft (Fig. 78).

Fig. 77 OUTPUT SHAFT AND INPUT SHAFT

1 - OUTPUT SHAFT

2 - INPUT SHAFT

3 - SUPPORT STAND

Fig. 78 COUNTERSHAFT WITH OUTPUT SHAFT

1 - COUNTERSHAFT

2 - OUTPUT SHAFT

3 - SUPPORT STAND

21 - 114 MANUAL TRANSMISSION - NV5600DR

MANUAL TRANSMISSION - NV5600 (Continued)

Page 1954 of 2895

(6) Install Fixture 8232 to the output shaft and

countershaft.

(7) Install Holding Tool 8242 onto the 5-6 synchro

and tighten the screw to hold the 5-6 synchro

together during the remainder of the installation pro-

cedure.

(8) Attach a engine crane or equivalent to Fixture

8232 and move the geartrain from the Support Stand

8246 to the clutch housing (Fig. 79).

(9) Install shift forks and rails onto the geartrain

(Fig. 80).

NOTE: The closest shift arm to the geartrain is for

Reverse. The next is 5-6, then 3-4 and then 1-2

when moving out from the geartrain.

(10) Install geartrain and shift rails into the clutch

housing. Lower the geartrain and rails into the hous-

ing slowly while guiding input shaft through input

shaft seal. Avoid any binds on the shift rails, forks

and synchros as the rails enter their bushings.

CAUTION: Do not damage input shaft seal with the

input shaft splines.(11) With the geartrain approximately 1/4 in. from

the clutch housing, remove Holding Tool 8242 from

the 5-6 synchro (Fig. 81).

(12) Install 5-6 crossover bracket and arm to the

shift rails and the clutch housing.

Fig. 79 GEARTRAIN FIXTURE

1 - FIXTURE

2 - SUPPORT STAND

Fig. 80 SHIFT RAILS INSTALLED

1 - SHIFT RAILS

Fig. 81 HOLDING TOOL

1 - HOLDING TOOL

2 - 5-6 SYNCHRO

DRMANUAL TRANSMISSION - NV5600 21 - 115

MANUAL TRANSMISSION - NV5600 (Continued)

Page 1955 of 2895

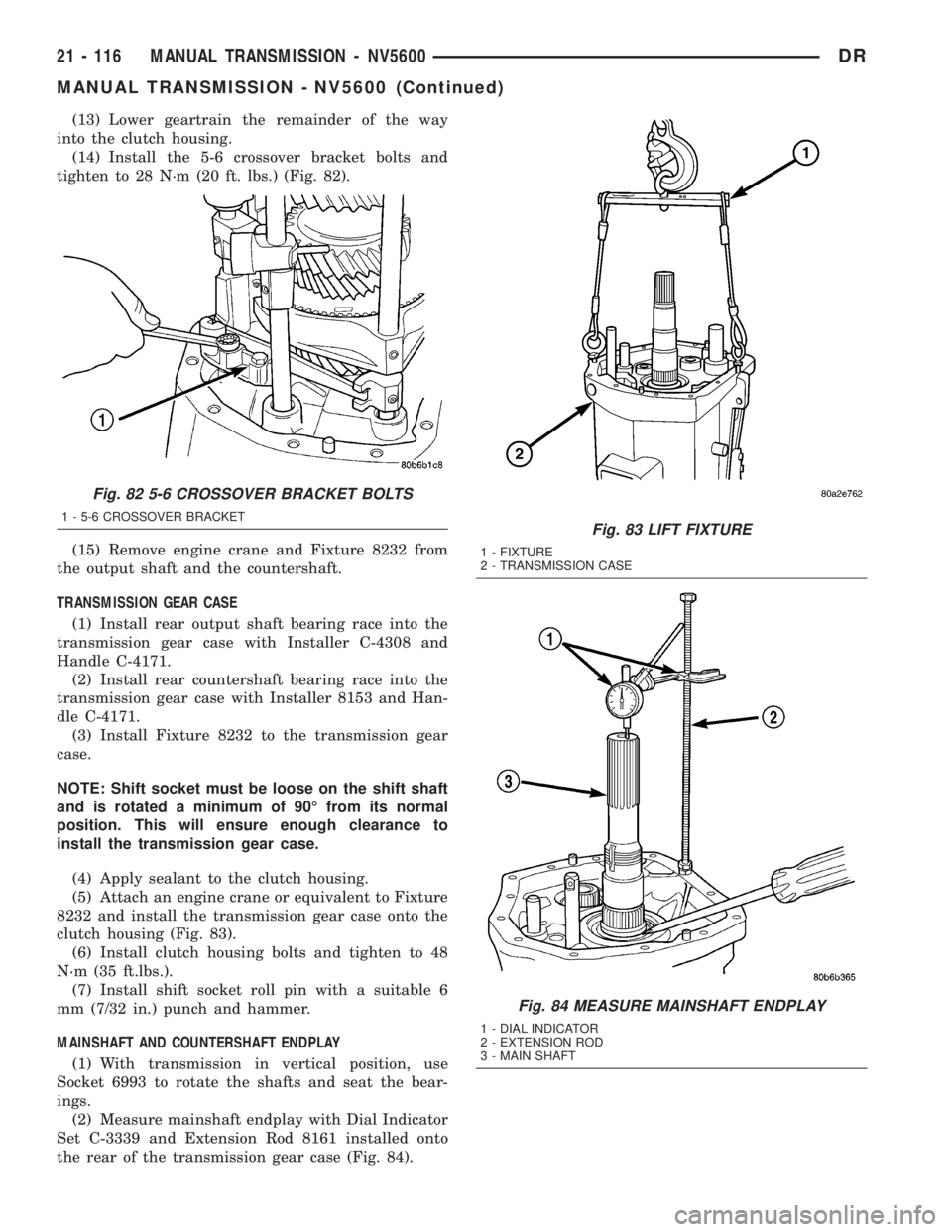

(13) Lower geartrain the remainder of the way

into the clutch housing.

(14) Install the 5-6 crossover bracket bolts and

tighten to 28 N´m (20 ft. lbs.) (Fig. 82).

(15) Remove engine crane and Fixture 8232 from

the output shaft and the countershaft.

TRANSMISSION GEAR CASE

(1) Install rear output shaft bearing race into the

transmission gear case with Installer C-4308 and

Handle C-4171.

(2) Install rear countershaft bearing race into the

transmission gear case with Installer 8153 and Han-

dle C-4171.

(3) Install Fixture 8232 to the transmission gear

case.

NOTE: Shift socket must be loose on the shift shaft

and is rotated a minimum of 90É from its normal

position. This will ensure enough clearance to

install the transmission gear case.

(4) Apply sealant to the clutch housing.

(5) Attach an engine crane or equivalent to Fixture

8232 and install the transmission gear case onto the

clutch housing (Fig. 83).

(6) Install clutch housing bolts and tighten to 48

N´m (35 ft.lbs.).

(7) Install shift socket roll pin with a suitable 6

mm (7/32 in.) punch and hammer.

MAINSHAFT AND COUNTERSHAFT ENDPLAY

(1) With transmission in vertical position, use

Socket 6993 to rotate the shafts and seat the bear-

ings.

(2) Measure mainshaft endplay with Dial Indicator

Set C-3339 and Extension Rod 8161 installed onto

the rear of the transmission gear case (Fig. 84).

Fig. 82 5-6 CROSSOVER BRACKET BOLTS

1 - 5-6 CROSSOVER BRACKETFig. 83 LIFT FIXTURE

1 - FIXTURE

2 - TRANSMISSION CASE

Fig. 84 MEASURE MAINSHAFT ENDPLAY

1 - DIAL INDICATOR

2 - EXTENSION ROD

3 - MAIN SHAFT

21 - 116 MANUAL TRANSMISSION - NV5600DR

MANUAL TRANSMISSION - NV5600 (Continued)

Page 1956 of 2895

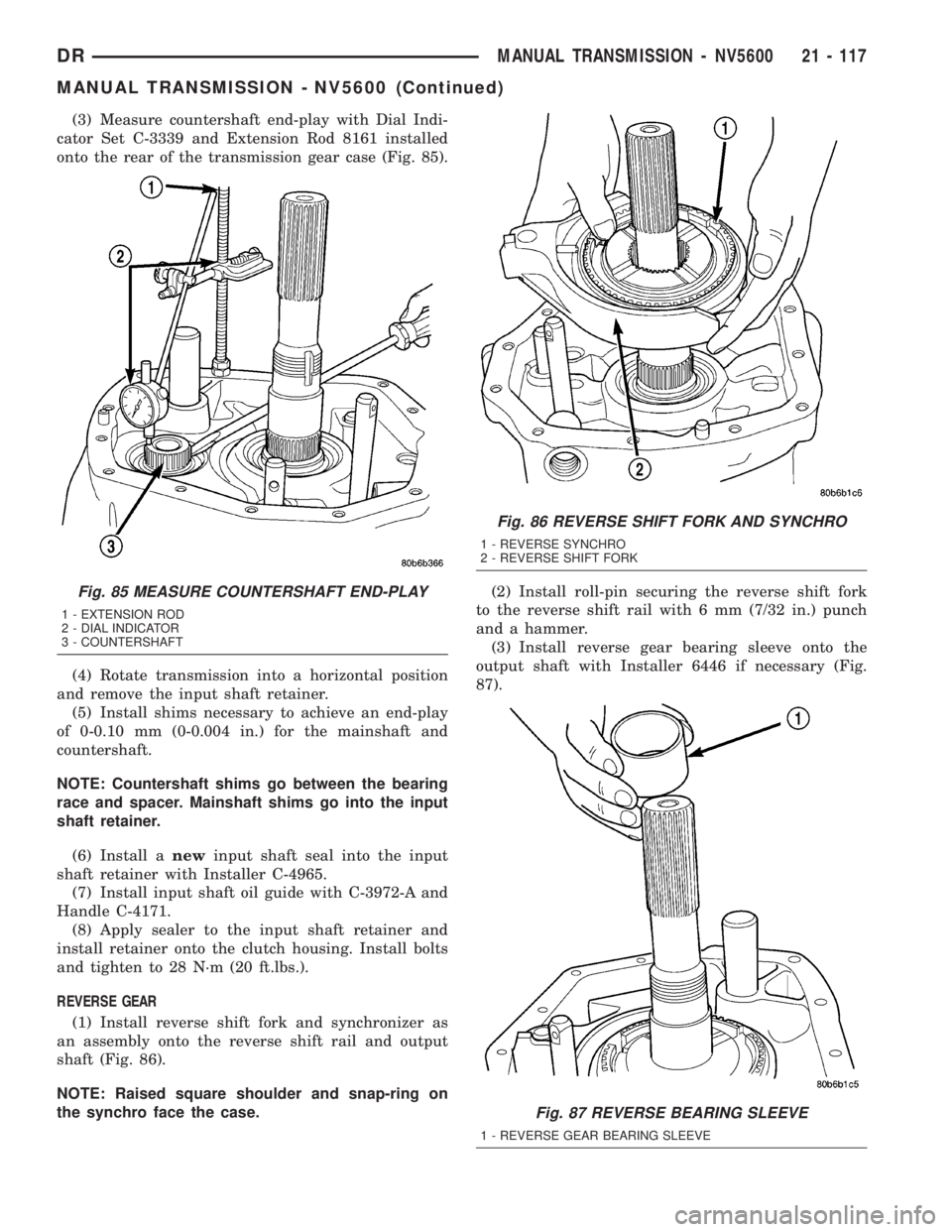

(3) Measure countershaft end-play with Dial Indi-

cator Set C-3339 and Extension Rod 8161 installed

onto the rear of the transmission gear case (Fig. 85).

(4) Rotate transmission into a horizontal position

and remove the input shaft retainer.

(5) Install shims necessary to achieve an end-play

of 0-0.10 mm (0-0.004 in.) for the mainshaft and

countershaft.

NOTE: Countershaft shims go between the bearing

race and spacer. Mainshaft shims go into the input

shaft retainer.

(6) Install anewinput shaft seal into the input

shaft retainer with Installer C-4965.

(7) Install input shaft oil guide with C-3972-A and

Handle C-4171.

(8) Apply sealer to the input shaft retainer and

install retainer onto the clutch housing. Install bolts

and tighten to 28 N´m (20 ft.lbs.).

REVERSE GEAR

(1) Install reverse shift fork and synchronizer as

an assembly onto the reverse shift rail and output

shaft (Fig. 86).

NOTE: Raised square shoulder and snap-ring on

the synchro face the case.(2) Install roll-pin securing the reverse shift fork

to the reverse shift rail with 6 mm (7/32 in.) punch

and a hammer.

(3) Install reverse gear bearing sleeve onto the

output shaft with Installer 6446 if necessary (Fig.

87).

Fig. 85 MEASURE COUNTERSHAFT END-PLAY

1 - EXTENSION ROD

2 - DIAL INDICATOR

3 - COUNTERSHAFT

Fig. 86 REVERSE SHIFT FORK AND SYNCHRO

1 - REVERSE SYNCHRO

2 - REVERSE SHIFT FORK

Fig. 87 REVERSE BEARING SLEEVE

1 - REVERSE GEAR BEARING SLEEVE

DRMANUAL TRANSMISSION - NV5600 21 - 117

MANUAL TRANSMISSION - NV5600 (Continued)