weight DODGE RAM 2003 Service Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1288 of 2895

(4) Determine taper by subtracting the smaller

diameter from the larger diameter.

(5) Rotate measuring device 90É and repeat steps

above.

(6) Determine out-of-roundness by comparing the

difference between each measurement.

(7) If cylinder bore taper does not exceed 0.025

mm (0.001 inch) and out-of-roundness does not

exceed 0.025 mm (0.001 inch), the cylinder bore can

be honed. If the cylinder bore taper or out- of-round

condition exceeds these maximum limits, the cylinder

block must be replaced. A slight amount of taper

always exists in the cylinder bore after the engine

has been in use for a period of time.

CRANKSHAFT

DESCRIPTION

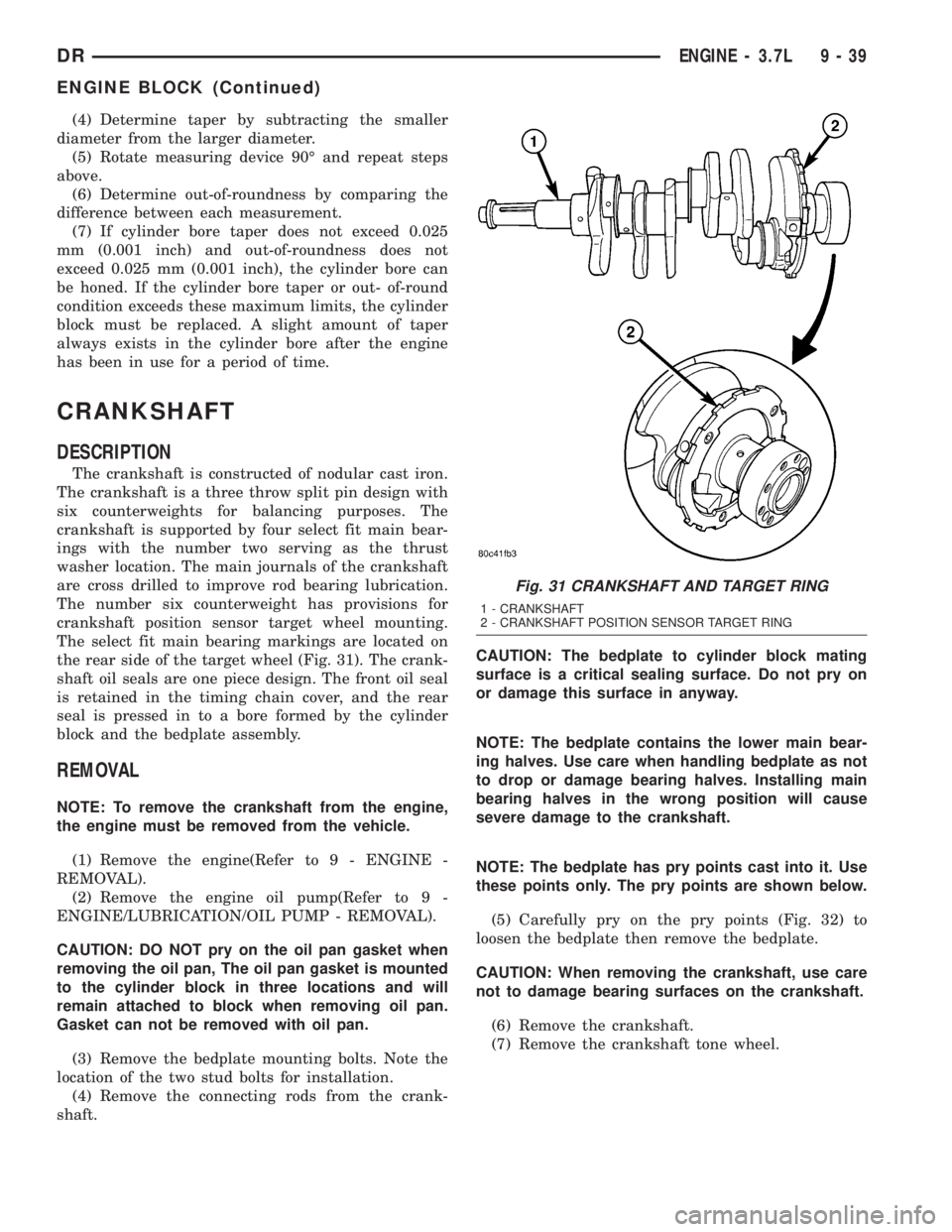

The crankshaft is constructed of nodular cast iron.

The crankshaft is a three throw split pin design with

six counterweights for balancing purposes. The

crankshaft is supported by four select fit main bear-

ings with the number two serving as the thrust

washer location. The main journals of the crankshaft

are cross drilled to improve rod bearing lubrication.

The number six counterweight has provisions for

crankshaft position sensor target wheel mounting.

The select fit main bearing markings are located on

the rear side of the target wheel (Fig. 31). The crank-

shaft oil seals are one piece design. The front oil seal

is retained in the timing chain cover, and the rear

seal is pressed in to a bore formed by the cylinder

block and the bedplate assembly.

REMOVAL

NOTE: To remove the crankshaft from the engine,

the engine must be removed from the vehicle.

(1) Remove the engine(Refer to 9 - ENGINE -

REMOVAL).

(2) Remove the engine oil pump(Refer to 9 -

ENGINE/LUBRICATION/OIL PUMP - REMOVAL).

CAUTION: DO NOT pry on the oil pan gasket when

removing the oil pan, The oil pan gasket is mounted

to the cylinder block in three locations and will

remain attached to block when removing oil pan.

Gasket can not be removed with oil pan.

(3) Remove the bedplate mounting bolts. Note the

location of the two stud bolts for installation.

(4) Remove the connecting rods from the crank-

shaft.CAUTION: The bedplate to cylinder block mating

surface is a critical sealing surface. Do not pry on

or damage this surface in anyway.

NOTE: The bedplate contains the lower main bear-

ing halves. Use care when handling bedplate as not

to drop or damage bearing halves. Installing main

bearing halves in the wrong position will cause

severe damage to the crankshaft.

NOTE: The bedplate has pry points cast into it. Use

these points only. The pry points are shown below.

(5) Carefully pry on the pry points (Fig. 32) to

loosen the bedplate then remove the bedplate.

CAUTION: When removing the crankshaft, use care

not to damage bearing surfaces on the crankshaft.

(6) Remove the crankshaft.

(7) Remove the crankshaft tone wheel.

Fig. 31 CRANKSHAFT AND TARGET RING

1 - CRANKSHAFT

2 - CRANKSHAFT POSITION SENSOR TARGET RING

DRENGINE - 3.7L 9 - 39

ENGINE BLOCK (Continued)

Page 1292 of 2895

CRANKSHAFT MAIN

BEARINGS

STANDARD PROCEDURE

MAIN BEARING FITTING

SELECT FIT IDENTIFICATION

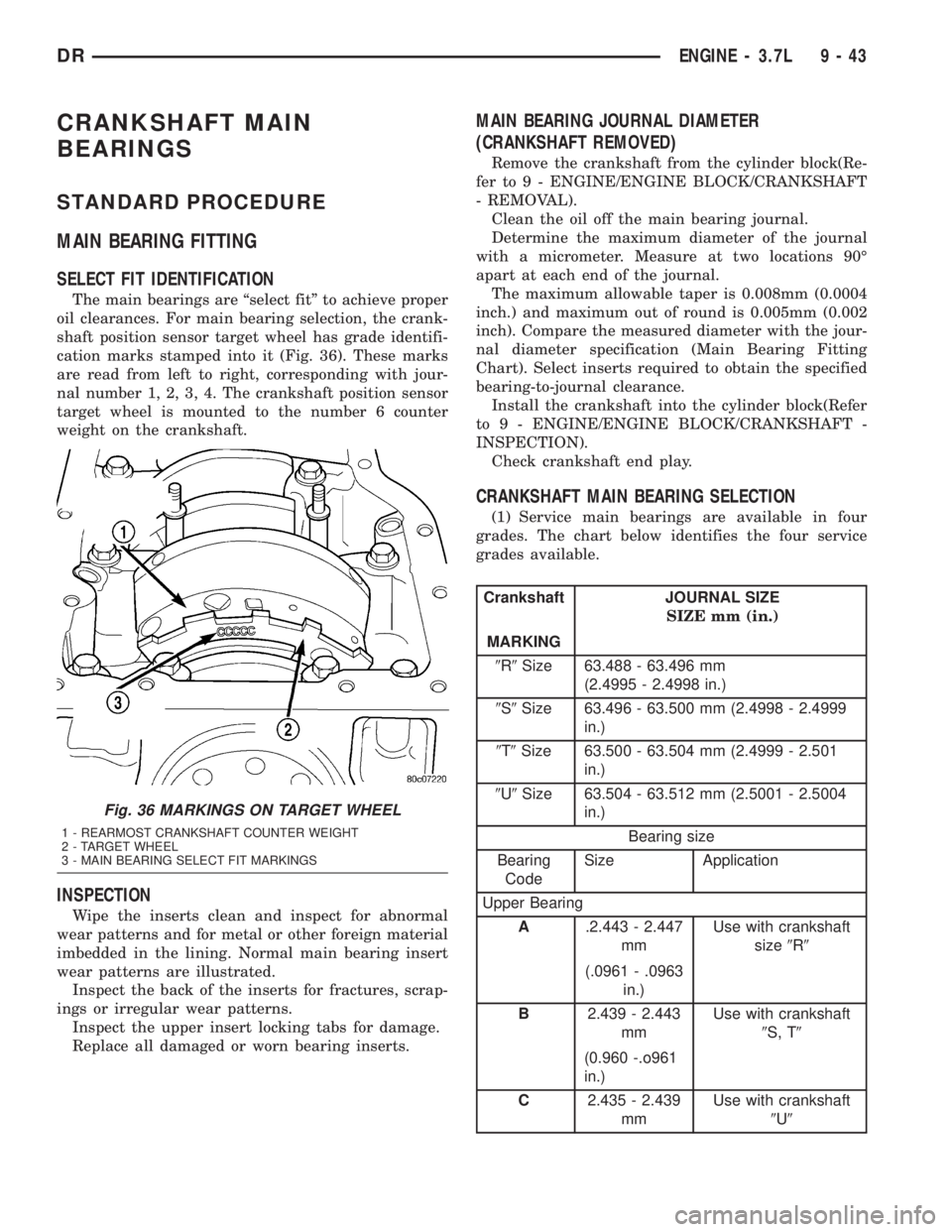

The main bearings are ªselect fitº to achieve proper

oil clearances. For main bearing selection, the crank-

shaft position sensor target wheel has grade identifi-

cation marks stamped into it (Fig. 36). These marks

are read from left to right, corresponding with jour-

nal number 1, 2, 3, 4. The crankshaft position sensor

target wheel is mounted to the number 6 counter

weight on the crankshaft.

INSPECTION

Wipe the inserts clean and inspect for abnormal

wear patterns and for metal or other foreign material

imbedded in the lining. Normal main bearing insert

wear patterns are illustrated.

Inspect the back of the inserts for fractures, scrap-

ings or irregular wear patterns.

Inspect the upper insert locking tabs for damage.

Replace all damaged or worn bearing inserts.

MAIN BEARING JOURNAL DIAMETER

(CRANKSHAFT REMOVED)

Remove the crankshaft from the cylinder block(Re-

fer to 9 - ENGINE/ENGINE BLOCK/CRANKSHAFT

- REMOVAL).

Clean the oil off the main bearing journal.

Determine the maximum diameter of the journal

with a micrometer. Measure at two locations 90É

apart at each end of the journal.

The maximum allowable taper is 0.008mm (0.0004

inch.) and maximum out of round is 0.005mm (0.002

inch). Compare the measured diameter with the jour-

nal diameter specification (Main Bearing Fitting

Chart). Select inserts required to obtain the specified

bearing-to-journal clearance.

Install the crankshaft into the cylinder block(Refer

to 9 - ENGINE/ENGINE BLOCK/CRANKSHAFT -

INSPECTION).

Check crankshaft end play.

CRANKSHAFT MAIN BEARING SELECTION

(1) Service main bearings are available in four

grades. The chart below identifies the four service

grades available.

Crankshaft JOURNAL SIZE

SIZE mm (in.)

MARKING

9R9Size 63.488 - 63.496 mm

(2.4995 - 2.4998 in.)

9S9Size 63.496 - 63.500 mm (2.4998 - 2.4999

in.)

9T9Size 63.500 - 63.504 mm (2.4999 - 2.501

in.)

9U9Size 63.504 - 63.512 mm (2.5001 - 2.5004

in.)

Bearing size

Bearing

CodeSize Application

Upper Bearing

A.2.443 - 2.447

mmUse with crankshaft

size9R9

(.0961 - .0963

in.)

B2.439 - 2.443

mmUse with crankshaft

9S, T9

(0.960 -.o961

in.)

C2.435 - 2.439

mmUse with crankshaft

9U9

Fig. 36 MARKINGS ON TARGET WHEEL

1 - REARMOST CRANKSHAFT COUNTER WEIGHT

2 - TARGET WHEEL

3 - MAIN BEARING SELECT FIT MARKINGS

DRENGINE - 3.7L 9 - 43

Page 1347 of 2895

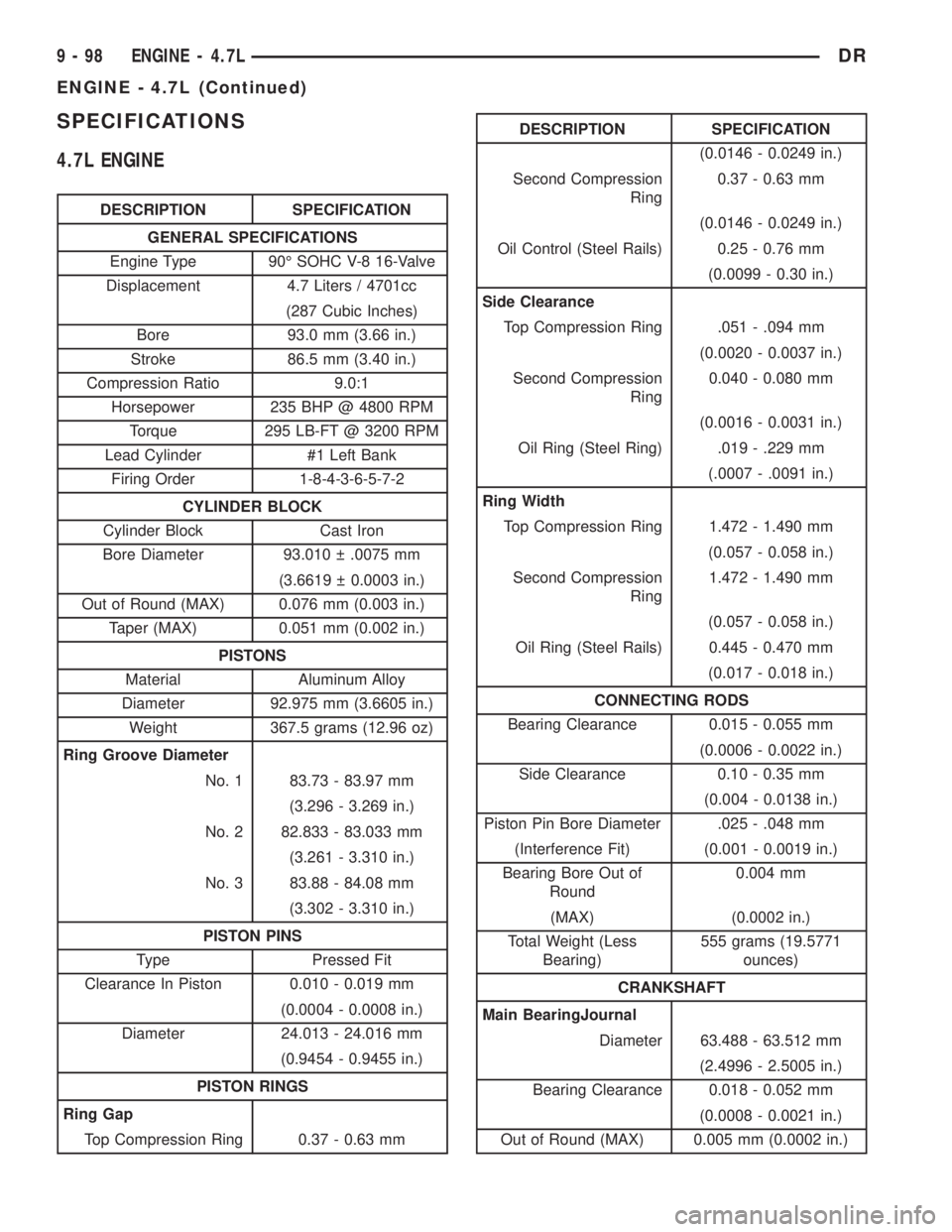

SPECIFICATIONS

4.7L ENGINE

DESCRIPTION SPECIFICATION

GENERAL SPECIFICATIONS

Engine Type 90É SOHC V-8 16-Valve

Displacement 4.7 Liters / 4701cc

(287 Cubic Inches)

Bore 93.0 mm (3.66 in.)

Stroke 86.5 mm (3.40 in.)

Compression Ratio 9.0:1

Horsepower 235 BHP @ 4800 RPM

Torque 295 LB-FT @ 3200 RPM

Lead Cylinder #1 Left Bank

Firing Order 1-8-4-3-6-5-7-2

CYLINDER BLOCK

Cylinder Block Cast Iron

Bore Diameter 93.010 .0075 mm

(3.6619 0.0003 in.)

Out of Round (MAX) 0.076 mm (0.003 in.)

Taper (MAX) 0.051 mm (0.002 in.)

PISTONS

Material Aluminum Alloy

Diameter 92.975 mm (3.6605 in.)

Weight 367.5 grams (12.96 oz)

Ring Groove Diameter

No. 1 83.73 - 83.97 mm

(3.296 - 3.269 in.)

No. 2 82.833 - 83.033 mm

(3.261 - 3.310 in.)

No. 3 83.88 - 84.08 mm

(3.302 - 3.310 in.)

PISTON PINS

Type Pressed Fit

Clearance In Piston 0.010 - 0.019 mm

(0.0004 - 0.0008 in.)

Diameter 24.013 - 24.016 mm

(0.9454 - 0.9455 in.)

PISTON RINGS

Ring Gap

Top Compression Ring 0.37 - 0.63 mm

DESCRIPTION SPECIFICATION

(0.0146 - 0.0249 in.)

Second Compression

Ring0.37 - 0.63 mm

(0.0146 - 0.0249 in.)

Oil Control (Steel Rails) 0.25 - 0.76 mm

(0.0099 - 0.30 in.)

Side Clearance

Top Compression Ring .051 - .094 mm

(0.0020 - 0.0037 in.)

Second Compression

Ring0.040 - 0.080 mm

(0.0016 - 0.0031 in.)

Oil Ring (Steel Ring) .019 - .229 mm

(.0007 - .0091 in.)

Ring Width

Top Compression Ring 1.472 - 1.490 mm

(0.057 - 0.058 in.)

Second Compression

Ring1.472 - 1.490 mm

(0.057 - 0.058 in.)

Oil Ring (Steel Rails) 0.445 - 0.470 mm

(0.017 - 0.018 in.)

CONNECTING RODS

Bearing Clearance 0.015 - 0.055 mm

(0.0006 - 0.0022 in.)

Side Clearance 0.10 - 0.35 mm

(0.004 - 0.0138 in.)

Piston Pin Bore Diameter .025 - .048 mm

(Interference Fit) (0.001 - 0.0019 in.)

Bearing Bore Out of

Round0.004 mm

(MAX) (0.0002 in.)

Total Weight (Less

Bearing)555 grams (19.5771

ounces)

CRANKSHAFT

Main BearingJournal

Diameter 63.488 - 63.512 mm

(2.4996 - 2.5005 in.)

Bearing Clearance 0.018 - 0.052 mm

(0.0008 - 0.0021 in.)

Out of Round (MAX) 0.005 mm (0.0002 in.)

9 - 98 ENGINE - 4.7LDR

ENGINE - 4.7L (Continued)

Page 1379 of 2895

INSTALLATION

NOTE: Thoroughly clean core plug bore, remove all

of the old sealer.

(1)

Coat the edges of the engine core plug and the

core plug bore with Mopar Gasket Maker, or equivalent.

NOTE: It is not necessary to wait for the sealant to

cure on the core plugs. The cooling system can be

filled and the vehicle returned to service immediately.

(2) Using proper plug driver, drive core plug into

the core plug bore. The sharp edge of the core plug

should be at least 0.50 mm (0.020 in.) inside the lead

in chamfer.

(3) Refill the cooling system (Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

CRANKSHAFT

DESCRIPTION

The crankshaft is constructed of nodular cast iron.

The crankshaft is a crosshaped four throw design with

eight counterweights for balancing purposes. The crank-

shaft is supported by five select fit main bearings with

the number three serving as the thrust washer location.

The main journals of the crankshaft are cross drilled to

improve rod bearing lubrication. The number eight

counterweight has provisions for crankshaft position

sensor target wheel mounting. The select fit main bear-

ing markings are located on the rear side of the target

wheel. The crankshaft oil seals are one piece design.

The front oil seal is retained in the timing chain cover,

and the rear seal is pressed in to a bore formed by the

cylinder block and the bedplate assembly.

REMOVAL

NOTE: To remove the crankshaft from the engine,

the engine must be removed from the vehicle.

(1) Remove the engine. (Refer to 9 - ENGINE -

REMOVAL).

(2) Remove the engine oil pump.(Refer to 9 -

ENGINE/LUBRICATION/OIL PUMP - REMOVAL).

CAUTION: DO NOT pry on the oil pan gasket when

removing the oil pan, The oil pan gasket is mounted

to the cylinder block in three locations and will

remain attached to block when removing oil pan.

Gasket can not be removed with oil pan.

(3) Remove oil pan. (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - REMOVAL).(4) Remove the oil pump pickup tube and oil pan

gasket /windage tray.

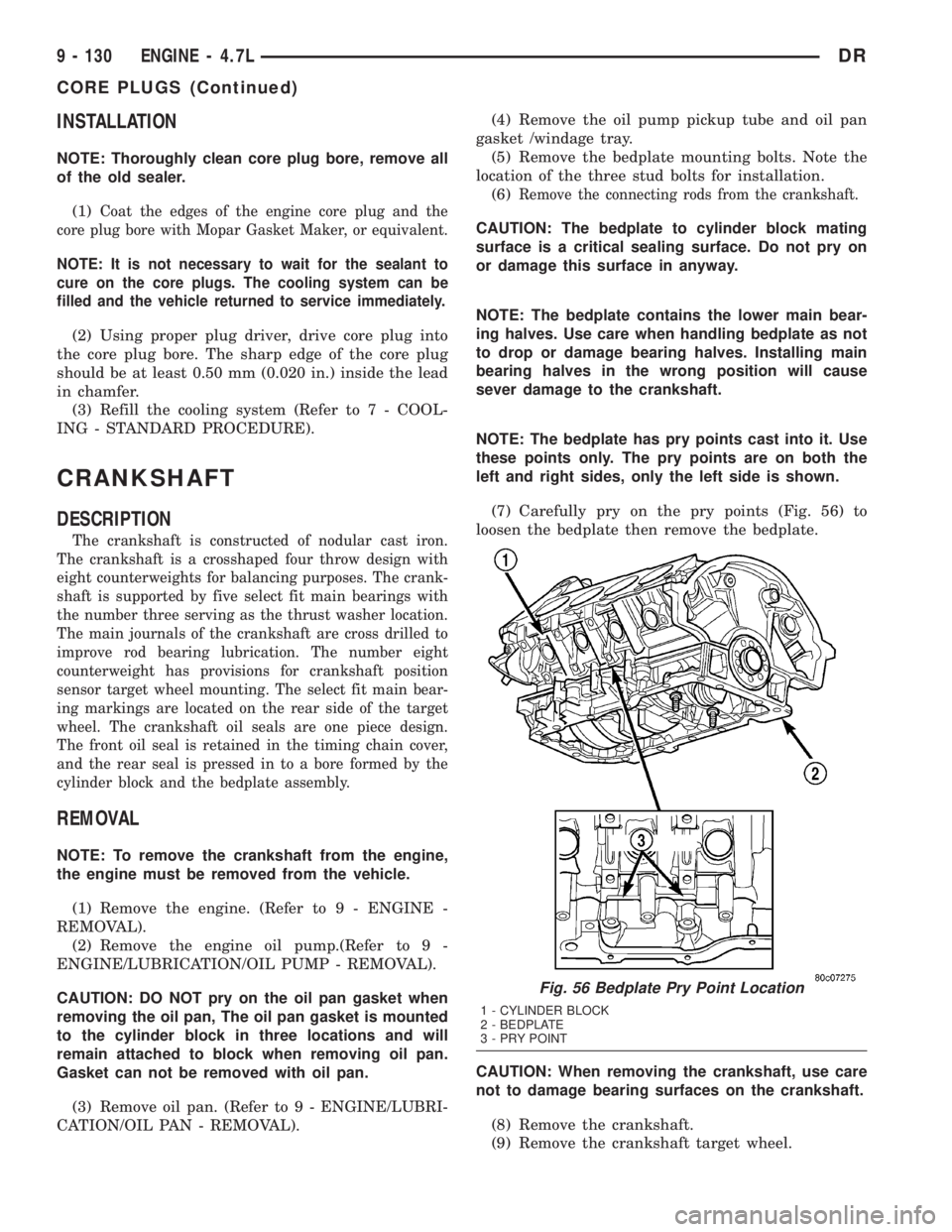

(5) Remove the bedplate mounting bolts. Note the

location of the three stud bolts for installation.

(6)

Remove the connecting rods from the crankshaft.

CAUTION: The bedplate to cylinder block mating

surface is a critical sealing surface. Do not pry on

or damage this surface in anyway.

NOTE: The bedplate contains the lower main bear-

ing halves. Use care when handling bedplate as not

to drop or damage bearing halves. Installing main

bearing halves in the wrong position will cause

sever damage to the crankshaft.

NOTE: The bedplate has pry points cast into it. Use

these points only. The pry points are on both the

left and right sides, only the left side is shown.

(7) Carefully pry on the pry points (Fig. 56) to

loosen the bedplate then remove the bedplate.

CAUTION: When removing the crankshaft, use care

not to damage bearing surfaces on the crankshaft.

(8) Remove the crankshaft.

(9) Remove the crankshaft target wheel.

Fig. 56 Bedplate Pry Point Location

1 - CYLINDER BLOCK

2 - BEDPLATE

3 - PRY POINT

9 - 130 ENGINE - 4.7LDR

CORE PLUGS (Continued)

Page 1382 of 2895

CRANKSHAFT MAIN

BEARINGS

STANDARD PROCEDUREÐCRANKSHAFT MAIN

BEARING - FITTING

MAIN BEARING JOURNAL DIAMETER

(CRANKSHAFT REMOVED)

Crankshaft removed from the cylinder block.

Clean the oil off the main bearing journal.

Determine the maximum diameter of the journal

with a micrometer. Measure at two locations 90É

apart at each end of the journal.

The maximum allowable taper is 0.008mm (0.0004

inch.) and maximum out of round is 0.005mm (0.002

inch). Compare the measured diameter with the jour-

nal diameter specification (Main Bearing Fitting

Chart). Select inserts required to obtain the specified

bearing-to-journal clearance.

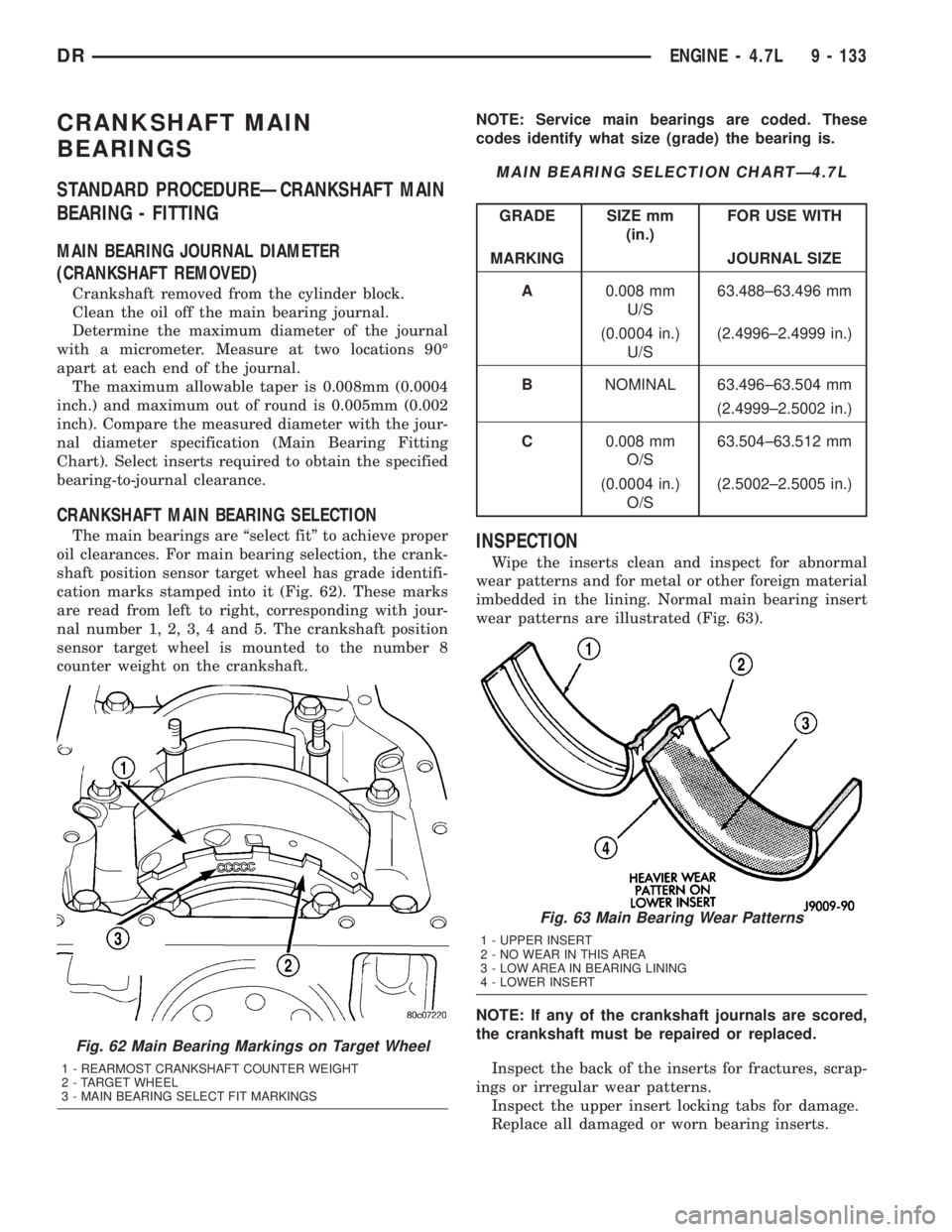

CRANKSHAFT MAIN BEARING SELECTION

The main bearings are ªselect fitº to achieve proper

oil clearances. For main bearing selection, the crank-

shaft position sensor target wheel has grade identifi-

cation marks stamped into it (Fig. 62). These marks

are read from left to right, corresponding with jour-

nal number 1, 2, 3, 4 and 5. The crankshaft position

sensor target wheel is mounted to the number 8

counter weight on the crankshaft.NOTE: Service main bearings are coded. These

codes identify what size (grade) the bearing is.

MAIN BEARING SELECTION CHARTÐ4.7L

GRADE SIZE mm

(in.)FOR USE WITH

MARKING JOURNAL SIZE

A0.008 mm

U/S63.488±63.496 mm

(0.0004 in.)

U/S(2.4996±2.4999 in.)

BNOMINAL 63.496±63.504 mm

(2.4999±2.5002 in.)

C0.008 mm

O/S63.504±63.512 mm

(0.0004 in.)

O/S(2.5002±2.5005 in.)

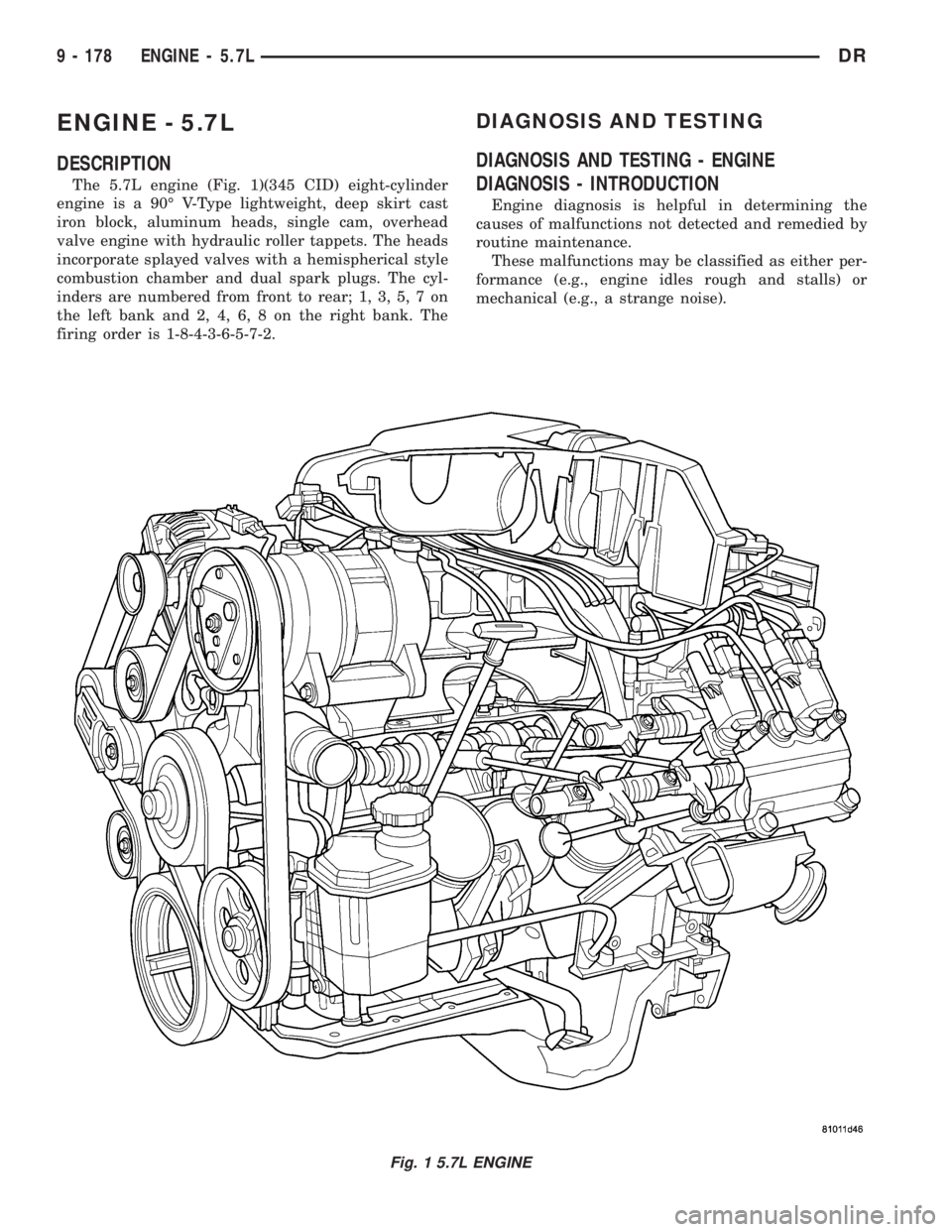

INSPECTION

Wipe the inserts clean and inspect for abnormal

wear patterns and for metal or other foreign material

imbedded in the lining. Normal main bearing insert

wear patterns are illustrated (Fig. 63).

NOTE: If any of the crankshaft journals are scored,

the crankshaft must be repaired or replaced.

Inspect the back of the inserts for fractures, scrap-

ings or irregular wear patterns.

Inspect the upper insert locking tabs for damage.

Replace all damaged or worn bearing inserts.

Fig. 62 Main Bearing Markings on Target Wheel

1 - REARMOST CRANKSHAFT COUNTER WEIGHT

2 - TARGET WHEEL

3 - MAIN BEARING SELECT FIT MARKINGS

Fig. 63 Main Bearing Wear Patterns

1 - UPPER INSERT

2 - NO WEAR IN THIS AREA

3 - LOW AREA IN BEARING LINING

4 - LOWER INSERT

DRENGINE - 4.7L 9 - 133

Page 1427 of 2895

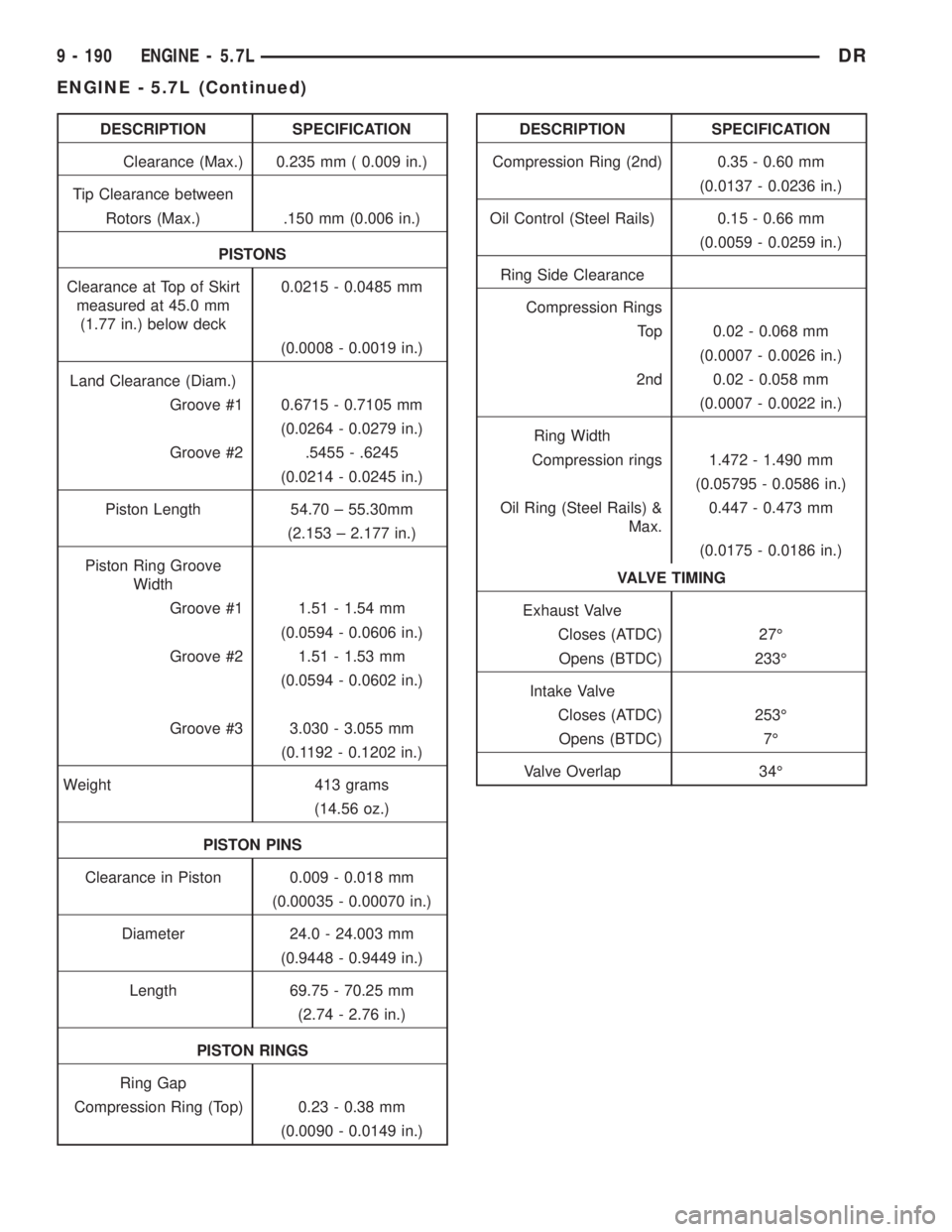

ENGINE - 5.7L

DESCRIPTION

The 5.7L engine (Fig. 1)(345 CID) eight-cylinder

engine is a 90É V-Type lightweight, deep skirt cast

iron block, aluminum heads, single cam, overhead

valve engine with hydraulic roller tappets. The heads

incorporate splayed valves with a hemispherical style

combustion chamber and dual spark plugs. The cyl-

inders are numbered from front to rear; 1, 3, 5, 7 on

the left bank and 2, 4, 6, 8 on the right bank. The

firing order is 1-8-4-3-6-5-7-2.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - INTRODUCTION

Engine diagnosis is helpful in determining the

causes of malfunctions not detected and remedied by

routine maintenance.

These malfunctions may be classified as either per-

formance (e.g., engine idles rough and stalls) or

mechanical (e.g., a strange noise).

Fig. 1 5.7L ENGINE

9 - 178 ENGINE - 5.7LDR

Page 1439 of 2895

DESCRIPTION SPECIFICATION

Clearance (Max.) 0.235 mm ( 0.009 in.)

Tip Clearance between

Rotors (Max.) .150 mm (0.006 in.)

PISTONS

Clearance at Top of Skirt

measured at 45.0 mm

(1.77 in.) below deck0.0215 - 0.0485 mm

(0.0008 - 0.0019 in.)

Land Clearance (Diam.)

Groove #1 0.6715 - 0.7105 mm

(0.0264 - 0.0279 in.)

Groove #2 .5455 - .6245

(0.0214 - 0.0245 in.)

Piston Length 54.70 ± 55.30mm

(2.153 ± 2.177 in.)

Piston Ring Groove

Width

Groove #1 1.51 - 1.54 mm

(0.0594 - 0.0606 in.)

Groove #2 1.51 - 1.53 mm

(0.0594 - 0.0602 in.)

Groove #3 3.030 - 3.055 mm

(0.1192 - 0.1202 in.)

Weight 413 grams

(14.56 oz.)

PISTON PINS

Clearance in Piston 0.009 - 0.018 mm

(0.00035 - 0.00070 in.)

Diameter 24.0 - 24.003 mm

(0.9448 - 0.9449 in.)

Length 69.75 - 70.25 mm

(2.74 - 2.76 in.)

PISTON RINGS

Ring Gap

Compression Ring (Top) 0.23 - 0.38 mm

(0.0090 - 0.0149 in.)DESCRIPTION SPECIFICATION

Compression Ring (2nd) 0.35 - 0.60 mm

(0.0137 - 0.0236 in.)

Oil Control (Steel Rails) 0.15 - 0.66 mm

(0.0059 - 0.0259 in.)

Ring Side Clearance

Compression Rings

Top 0.02 - 0.068 mm

(0.0007 - 0.0026 in.)

2nd 0.02 - 0.058 mm

(0.0007 - 0.0022 in.)

Ring Width

Compression rings 1.472 - 1.490 mm

(0.05795 - 0.0586 in.)

Oil Ring (Steel Rails) &

Max.0.447 - 0.473 mm

(0.0175 - 0.0186 in.)

VALVE TIMING

Exhaust Valve

Closes (ATDC) 27É

Opens (BTDC) 233É

Intake Valve

Closes (ATDC) 253É

Opens (BTDC) 7É

Valve Overlap 34É

9 - 190 ENGINE - 5.7LDR

ENGINE - 5.7L (Continued)

Page 1451 of 2895

(11) Remove the rear oil seal retainer(Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT REAR

OIL SEAL RETAINE - REMOVAL).

(12) Remove and discard the crankshaft rear oil

seal.

(13) Remove and discard the front crankshaft oil

seal.

INSTALLATION

(1) Select the proper main bearings(Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT MAIN

BEARINGS - STANDARD PROCEDURE).

(2) Install main bearings in block and caps, and

lubricate bearings.

(3) Position the crankshaft into the cylinder block.

(4) Install the thrust washers.

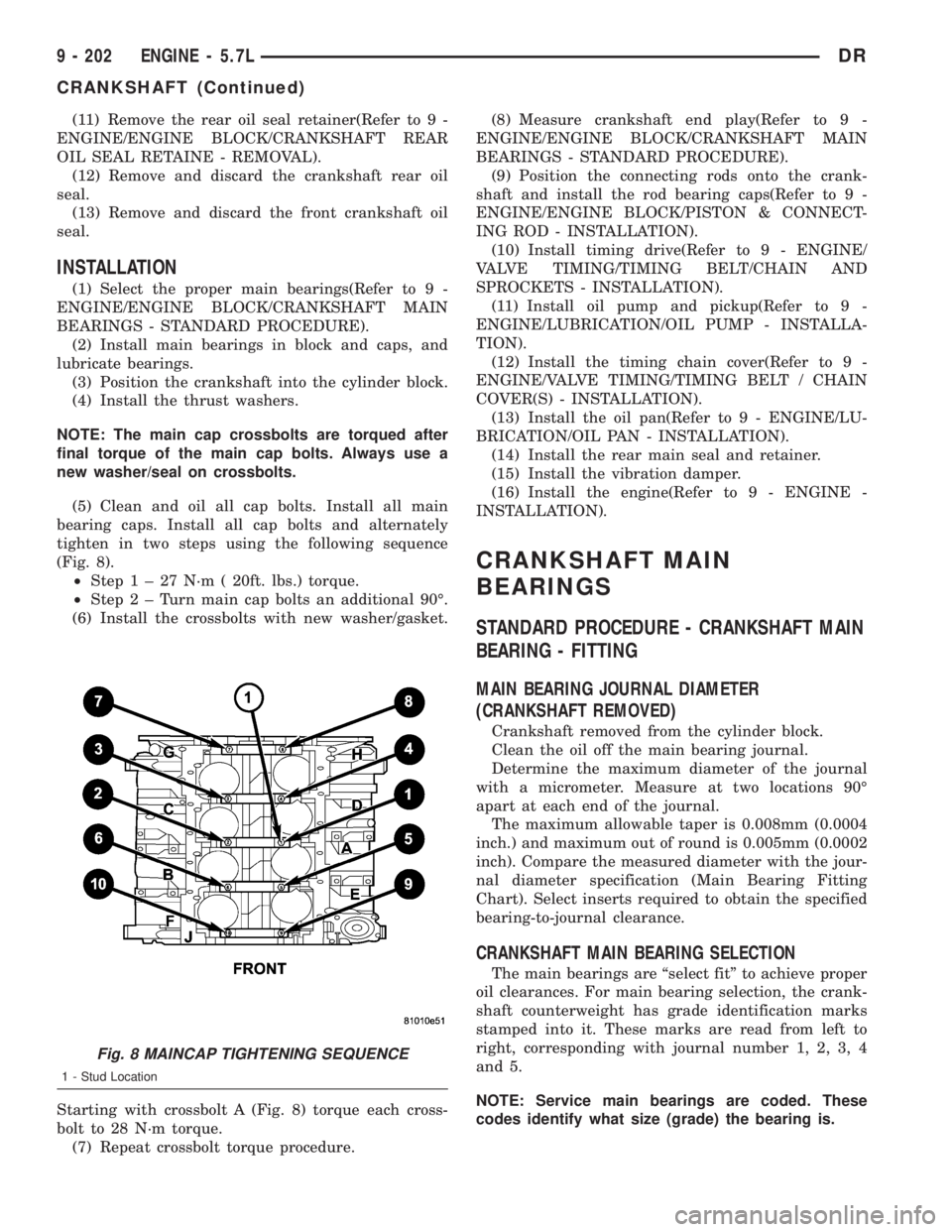

NOTE: The main cap crossbolts are torqued after

final torque of the main cap bolts. Always use a

new washer/seal on crossbolts.

(5) Clean and oil all cap bolts. Install all main

bearing caps. Install all cap bolts and alternately

tighten in two steps using the following sequence

(Fig. 8).

²Step1±27N´m(20ft. lbs.) torque.

²Step2±Turnmain cap bolts an additional 90É.

(6) Install the crossbolts with new washer/gasket.

Starting with crossbolt A (Fig. 8) torque each cross-

bolt to 28 N´m torque.

(7) Repeat crossbolt torque procedure.(8) Measure crankshaft end play(Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT MAIN

BEARINGS - STANDARD PROCEDURE).

(9) Position the connecting rods onto the crank-

shaft and install the rod bearing caps(Refer to 9 -

ENGINE/ENGINE BLOCK/PISTON & CONNECT-

ING ROD - INSTALLATION).

(10) Install timing drive(Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION).

(11) Install oil pump and pickup(Refer to 9 -

ENGINE/LUBRICATION/OIL PUMP - INSTALLA-

TION).

(12) Install the timing chain cover(Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(13) Install the oil pan(Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - INSTALLATION).

(14) Install the rear main seal and retainer.

(15) Install the vibration damper.

(16) Install the engine(Refer to 9 - ENGINE -

INSTALLATION).

CRANKSHAFT MAIN

BEARINGS

STANDARD PROCEDURE - CRANKSHAFT MAIN

BEARING - FITTING

MAIN BEARING JOURNAL DIAMETER

(CRANKSHAFT REMOVED)

Crankshaft removed from the cylinder block.

Clean the oil off the main bearing journal.

Determine the maximum diameter of the journal

with a micrometer. Measure at two locations 90É

apart at each end of the journal.

The maximum allowable taper is 0.008mm (0.0004

inch.) and maximum out of round is 0.005mm (0.0002

inch). Compare the measured diameter with the jour-

nal diameter specification (Main Bearing Fitting

Chart). Select inserts required to obtain the specified

bearing-to-journal clearance.

CRANKSHAFT MAIN BEARING SELECTION

The main bearings are ªselect fitº to achieve proper

oil clearances. For main bearing selection, the crank-

shaft counterweight has grade identification marks

stamped into it. These marks are read from left to

right, corresponding with journal number 1, 2, 3, 4

and 5.

NOTE: Service main bearings are coded. These

codes identify what size (grade) the bearing is.

Fig. 8 MAINCAP TIGHTENING SEQUENCE

1 - Stud Location

9 - 202 ENGINE - 5.7LDR

CRANKSHAFT (Continued)

Page 1473 of 2895

HYDRAULIC LIFTERS

DIAGNOSIS AND TESTINGÐHYDRAULIC

TAPPETS...........................258

REMOVAL............................259

CLEANING...........................260

INSTALLATION........................260

PISTON & CONNECTING ROD

DESCRIPTION........................260

STANDARD PROCEDURE - PISTON FITTING . 260

REMOVAL............................261

CLEANING...........................261

INSPECTION.........................261

INSTALLATION........................261

PISTON RINGS

STANDARD PROCEDURE - PISTON RING

FITTING............................262

VIBRATION DAMPER

REMOVAL............................263

INSTALLATION........................263

FRONT MOUNT

REMOVAL............................264

INSTALLATION........................265

REAR MOUNT

REMOVAL............................266

INSTALLATION........................267

LUBRICATION

DESCRIPTION........................267

OPERATION..........................267

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTINGÐENGINE OIL

LEAKS.............................269

DIAGNOSIS AND TESTINGÐENGINE OIL

PRESSURE.........................269

OIL

STANDARD PROCEDURE - ENGINE OIL....269

OIL FILTER

REMOVAL............................270INSTALLATION........................270

OIL PAN

REMOVAL............................270

CLEANING...........................270

INSPECTION.........................271

INSTALLATION........................271

OIL PUMP

REMOVAL............................272

DISASSEMBLY........................272

INSPECTION.........................272

ASSEMBLY...........................274

INSTALLATION........................274

INTAKE MANIFOLD

DESCRIPTION........................274

OPERATION..........................274

DIAGNOSIS AND TESTINGÐINTAKE

MANIFOLD LEAKAGE.................274

REMOVAL............................275

CLEANING...........................275

INSPECTION.........................275

INSTALLATION........................275

EXHAUST MANIFOLD

DESCRIPTION........................277

OPERATION..........................277

REMOVAL............................277

CLEANING...........................277

INSPECTION.........................277

INSTALLATION........................277

TIMING BELT / CHAIN COVER(S)

REMOVAL............................278

INSTALLATION........................278

TIMING BELT/CHAIN AND SPROCKETS

REMOVAL............................279

INSPECTIONÐMEASURING TIMING CHAIN

STRETCH..........................279

INSTALLATION........................279

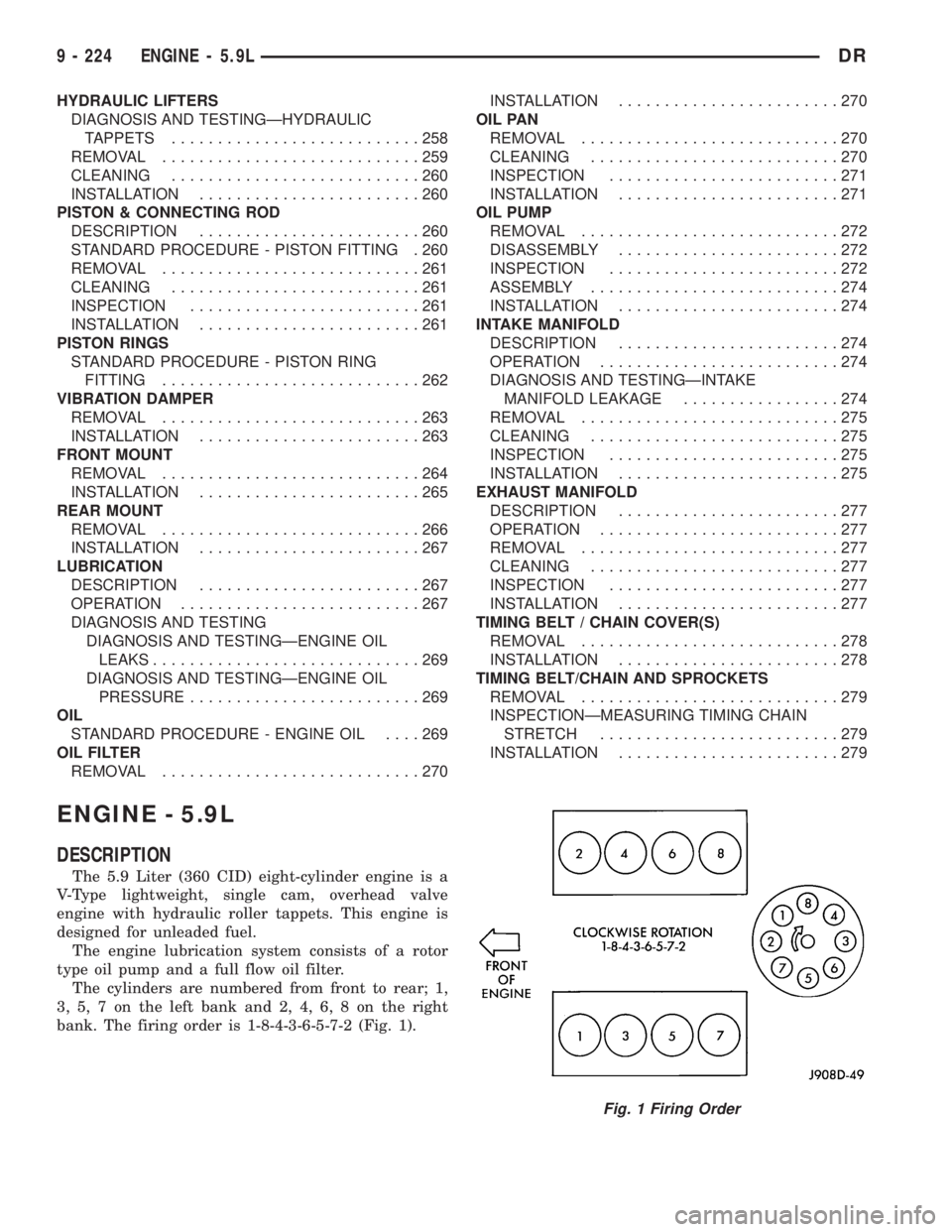

ENGINE - 5.9L

DESCRIPTION

The 5.9 Liter (360 CID) eight-cylinder engine is a

V-Type lightweight, single cam, overhead valve

engine with hydraulic roller tappets. This engine is

designed for unleaded fuel.

The engine lubrication system consists of a rotor

type oil pump and a full flow oil filter.

The cylinders are numbered from front to rear; 1,

3, 5, 7 on the left bank and 2, 4, 6, 8 on the right

bank. The firing order is 1-8-4-3-6-5-7-2 (Fig. 1).

Fig. 1 Firing Order

9 - 224 ENGINE - 5.9LDR

Page 1487 of 2895

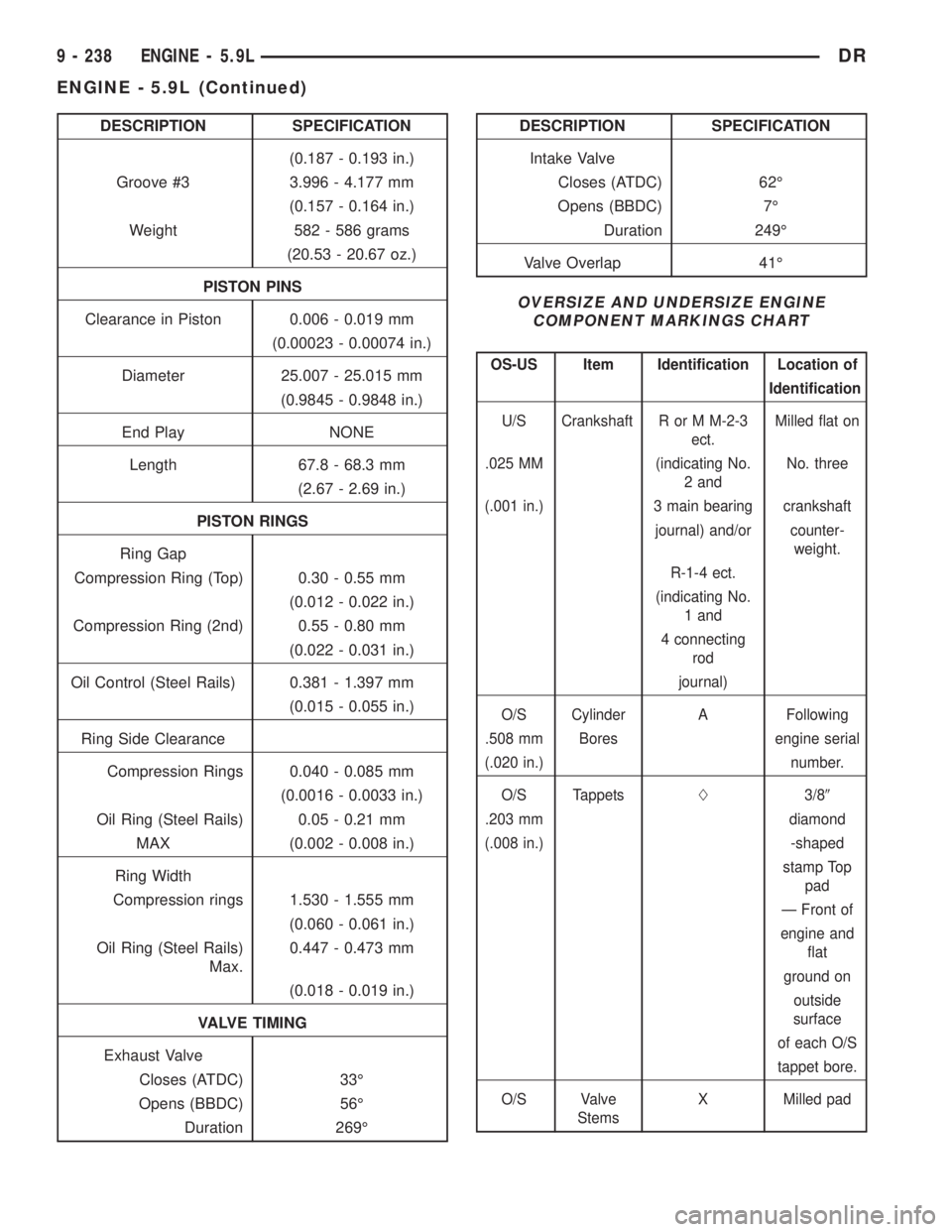

DESCRIPTION SPECIFICATION

(0.187 - 0.193 in.)

Groove #3 3.996 - 4.177 mm

(0.157 - 0.164 in.)

Weight 582 - 586 grams

(20.53 - 20.67 oz.)

PISTON PINS

Clearance in Piston 0.006 - 0.019 mm

(0.00023 - 0.00074 in.)

Diameter 25.007 - 25.015 mm

(0.9845 - 0.9848 in.)

End Play NONE

Length 67.8 - 68.3 mm

(2.67 - 2.69 in.)

PISTON RINGS

Ring Gap

Compression Ring (Top) 0.30 - 0.55 mm

(0.012 - 0.022 in.)

Compression Ring (2nd) 0.55 - 0.80 mm

(0.022 - 0.031 in.)

Oil Control (Steel Rails) 0.381 - 1.397 mm

(0.015 - 0.055 in.)

Ring Side Clearance

Compression Rings 0.040 - 0.085 mm

(0.0016 - 0.0033 in.)

Oil Ring (Steel Rails) 0.05 - 0.21 mm

MAX (0.002 - 0.008 in.)

Ring Width

Compression rings 1.530 - 1.555 mm

(0.060 - 0.061 in.)

Oil Ring (Steel Rails)

Max.0.447 - 0.473 mm

(0.018 - 0.019 in.)

VALVE TIMING

Exhaust Valve

Closes (ATDC) 33É

Opens (BBDC) 56É

Duration 269ÉDESCRIPTION SPECIFICATION

Intake Valve

Closes (ATDC) 62É

Opens (BBDC) 7É

Duration 249É

Valve Overlap 41É

OVERSIZE AND UNDERSIZE ENGINE

COMPONENT MARKINGS CHART

OS-US Item Identification Location of

Identification

U/S Crankshaft R or M M-2-3

ect.Milled flat on

.025 MM (indicating No.

2 andNo. three

(.001 in.) 3 main bearing crankshaft

journal) and/or counter-

weight.

R-1-4 ect.

(indicating No.

1 and

4 connecting

rod

journal)

O/S Cylinder A Following

.508 mm Bores engine serial

(.020 in.) number.

O/S TappetsL3/89

.203 mm diamond

(.008 in.) -shaped

stamp Top

pad

Ð Front of

engine and

flat

ground on

outside

surface

of each O/S

tappet bore.

O/S Valve

StemsX Milled pad

9 - 238 ENGINE - 5.9LDR

ENGINE - 5.9L (Continued)