weight DODGE RAM 2003 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1501 of 2895

CRANKSHAFT

DESCRIPTION

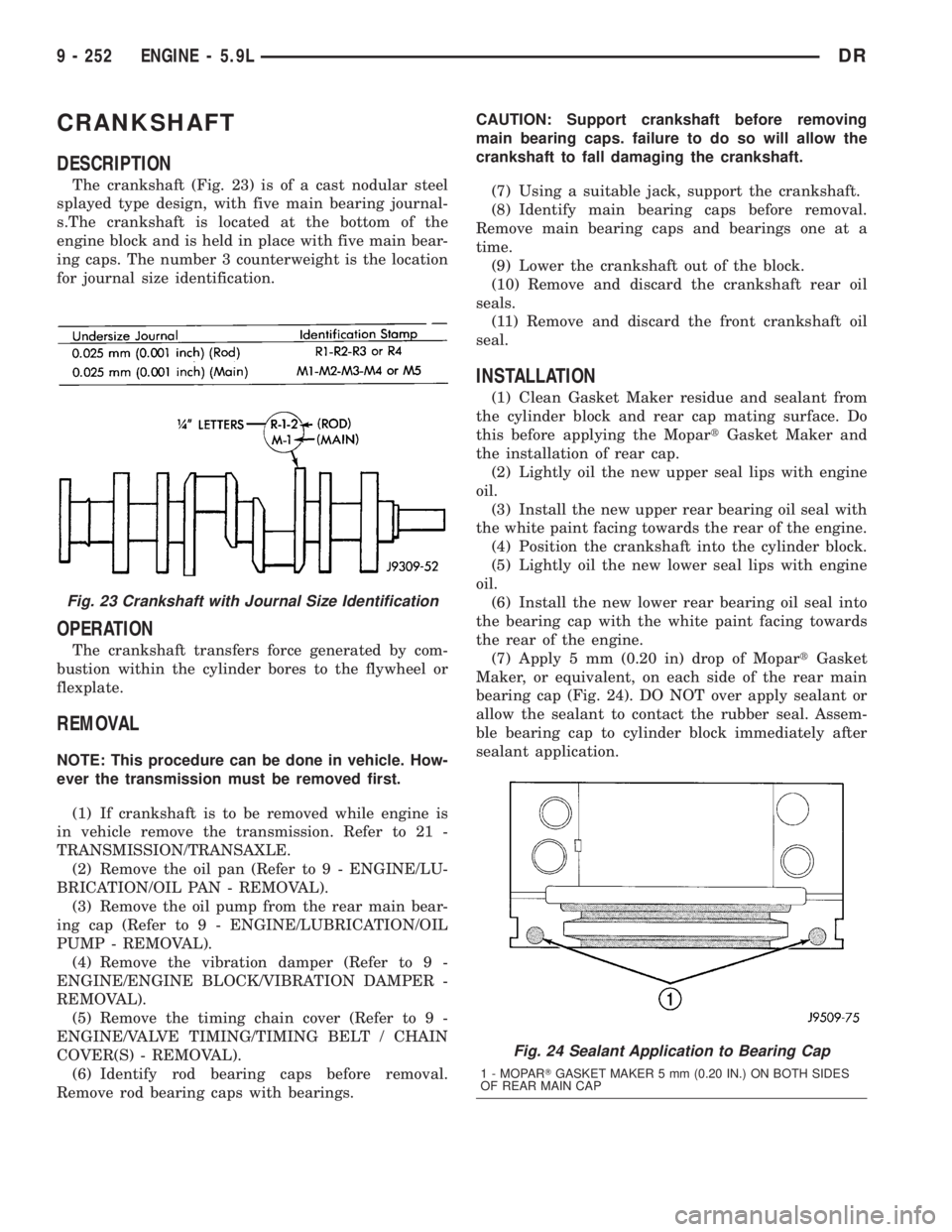

The crankshaft (Fig. 23) is of a cast nodular steel

splayed type design, with five main bearing journal-

s.The crankshaft is located at the bottom of the

engine block and is held in place with five main bear-

ing caps. The number 3 counterweight is the location

for journal size identification.

OPERATION

The crankshaft transfers force generated by com-

bustion within the cylinder bores to the flywheel or

flexplate.

REMOVAL

NOTE: This procedure can be done in vehicle. How-

ever the transmission must be removed first.

(1) If crankshaft is to be removed while engine is

in vehicle remove the transmission. Refer to 21 -

TRANSMISSION/TRANSAXLE.

(2) Remove the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL).

(3) Remove the oil pump from the rear main bear-

ing cap (Refer to 9 - ENGINE/LUBRICATION/OIL

PUMP - REMOVAL).

(4) Remove the vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(5) Remove the timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(6) Identify rod bearing caps before removal.

Remove rod bearing caps with bearings.CAUTION: Support crankshaft before removing

main bearing caps. failure to do so will allow the

crankshaft to fall damaging the crankshaft.

(7) Using a suitable jack, support the crankshaft.

(8) Identify main bearing caps before removal.

Remove main bearing caps and bearings one at a

time.

(9) Lower the crankshaft out of the block.

(10) Remove and discard the crankshaft rear oil

seals.

(11) Remove and discard the front crankshaft oil

seal.

INSTALLATION

(1) Clean Gasket Maker residue and sealant from

the cylinder block and rear cap mating surface. Do

this before applying the MopartGasket Maker and

the installation of rear cap.

(2) Lightly oil the new upper seal lips with engine

oil.

(3) Install the new upper rear bearing oil seal with

the white paint facing towards the rear of the engine.

(4) Position the crankshaft into the cylinder block.

(5) Lightly oil the new lower seal lips with engine

oil.

(6) Install the new lower rear bearing oil seal into

the bearing cap with the white paint facing towards

the rear of the engine.

(7) Apply 5 mm (0.20 in) drop of MopartGasket

Maker, or equivalent, on each side of the rear main

bearing cap (Fig. 24). DO NOT over apply sealant or

allow the sealant to contact the rubber seal. Assem-

ble bearing cap to cylinder block immediately after

sealant application.

Fig. 23 Crankshaft with Journal Size Identification

Fig. 24 Sealant Application to Bearing Cap

1 - MOPARTGASKET MAKER 5 mm (0.20 IN.) ON BOTH SIDES

OF REAR MAIN CAP

9 - 252 ENGINE - 5.9LDR

Page 1508 of 2895

intake side of oil pump through which air can be

drawn will create the same tappet action. Check the

lubrication system from the intake strainer to the

pump cover, including the relief valve retainer cap.

When tappet noise is due to aeration, it may be

intermittent or constant, and usually more than one

tappet will be noisy. When oil level and leaks have

been corrected, operate the engine at fast idle. Run

engine for a sufficient time to allow all of the air

inside the tappets to be bled out.

TAPPET NOISE DIAGNOSIS

(1) To determine source of tappet noise, operate

engine at idle with cylinder head covers removed.

(2) Feel each valve spring or rocker arm to detect

noisy tappet. The noisy tappet will cause the affected

spring and/or rocker arm to vibrate or feel rough in

operation.

NOTE: Worn valve guides or cocked springs are

sometimes mistaken for noisy tappets. If such is

the case, noise may be dampened by applying side

thrust on the valve spring. If noise is not apprecia-

bly reduced, it can be assumed the noise is in the

tappet. Inspect the rocker arm push rod sockets

and push rod ends for wear.

(3) Valve tappet noise ranges from light noise to a

heavy click. A light noise is usually caused by exces-

sive leak-down around the unit plunger, or by the

plunger partially sticking in the tappet body cylinder.

The tappet should be replaced. A heavy click is

caused by a tappet check valve not seating, or by for-

eign particles wedged between the plunger and the

tappet body. This will cause the plunger to stick in

the down position. This heavy click will be accompa-

nied by excessive clearance between the valve stem

and rocker arm as valve closes. In either case, tappet

assembly should be removed for inspection and clean-

ing.

(4) The valve train generates a noise very much

like a light tappet noise during normal operation.

Care must be taken to ensure that tappets are mak-

ing the noise. If more than one tappet seems to be

noisy, it's probably not the tappets.

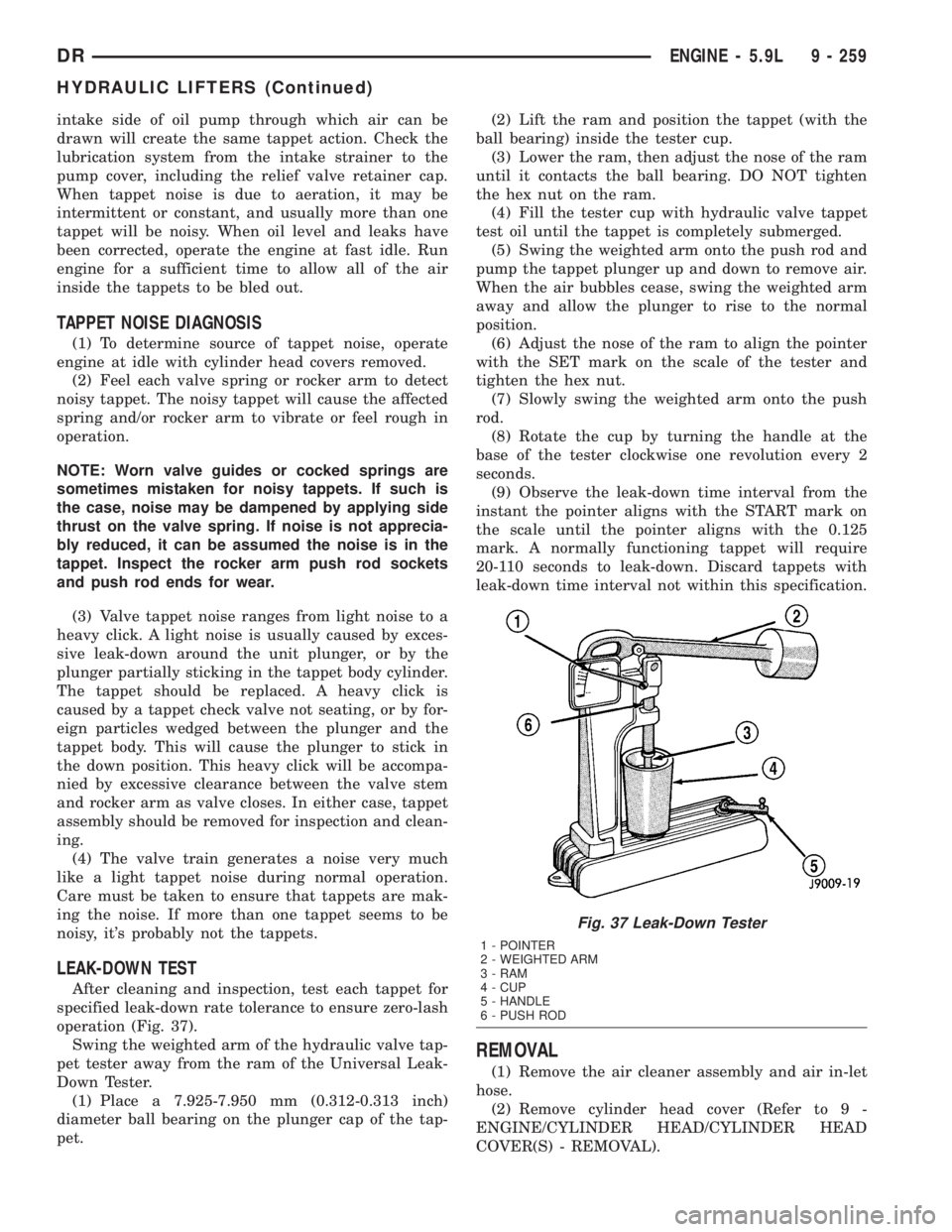

LEAK-DOWN TEST

After cleaning and inspection, test each tappet for

specified leak-down rate tolerance to ensure zero-lash

operation (Fig. 37).

Swing the weighted arm of the hydraulic valve tap-

pet tester away from the ram of the Universal Leak-

Down Tester.

(1) Place a 7.925-7.950 mm (0.312-0.313 inch)

diameter ball bearing on the plunger cap of the tap-

pet.(2) Lift the ram and position the tappet (with the

ball bearing) inside the tester cup.

(3) Lower the ram, then adjust the nose of the ram

until it contacts the ball bearing. DO NOT tighten

the hex nut on the ram.

(4) Fill the tester cup with hydraulic valve tappet

test oil until the tappet is completely submerged.

(5) Swing the weighted arm onto the push rod and

pump the tappet plunger up and down to remove air.

When the air bubbles cease, swing the weighted arm

away and allow the plunger to rise to the normal

position.

(6) Adjust the nose of the ram to align the pointer

with the SET mark on the scale of the tester and

tighten the hex nut.

(7) Slowly swing the weighted arm onto the push

rod.

(8) Rotate the cup by turning the handle at the

base of the tester clockwise one revolution every 2

seconds.

(9) Observe the leak-down time interval from the

instant the pointer aligns with the START mark on

the scale until the pointer aligns with the 0.125

mark. A normally functioning tappet will require

20-110 seconds to leak-down. Discard tappets with

leak-down time interval not within this specification.

REMOVAL

(1) Remove the air cleaner assembly and air in-let

hose.

(2) Remove cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

Fig. 37 Leak-Down Tester

1 - POINTER

2 - WEIGHTED ARM

3 - RAM

4 - CUP

5 - HANDLE

6 - PUSH ROD

DRENGINE - 5.9L 9 - 259

HYDRAULIC LIFTERS (Continued)

Page 1510 of 2895

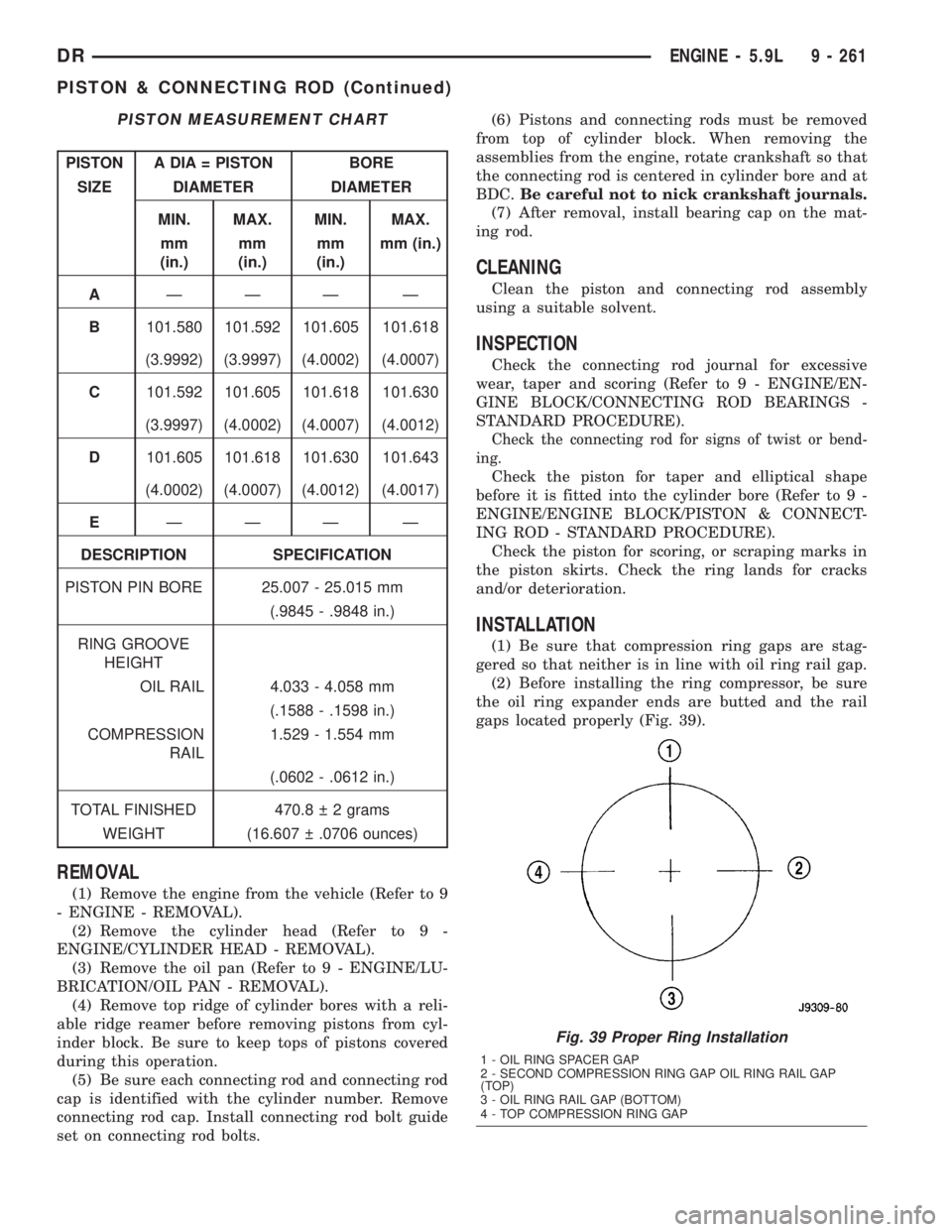

PISTON MEASUREMENT CHART

PISTON A DIA = PISTON BORE

SIZE DIAMETER DIAMETER

MIN. MAX. MIN. MAX.

mm

(in.)mm

(in.)mm

(in.)mm (in.)

AÐÐÐ Ð

B101.580 101.592 101.605 101.618

(3.9992) (3.9997) (4.0002) (4.0007)

C101.592 101.605 101.618 101.630

(3.9997) (4.0002) (4.0007) (4.0012)

D101.605 101.618 101.630 101.643

(4.0002) (4.0007) (4.0012) (4.0017)

EÐÐÐ Ð

DESCRIPTION SPECIFICATION

PISTON PIN BORE 25.007 - 25.015 mm

(.9845 - .9848 in.)

RING GROOVE

HEIGHT

OIL RAIL 4.033 - 4.058 mm

(.1588 - .1598 in.)

COMPRESSION

RAIL1.529 - 1.554 mm

(.0602 - .0612 in.)

TOTAL FINISHED 470.8 2 grams

WEIGHT (16.607 .0706 ounces)

REMOVAL

(1) Remove the engine from the vehicle (Refer to 9

- ENGINE - REMOVAL).

(2) Remove the cylinder head (Refer to 9 -

ENGINE/CYLINDER HEAD - REMOVAL).

(3) Remove the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL).

(4) Remove top ridge of cylinder bores with a reli-

able ridge reamer before removing pistons from cyl-

inder block. Be sure to keep tops of pistons covered

during this operation.

(5) Be sure each connecting rod and connecting rod

cap is identified with the cylinder number. Remove

connecting rod cap. Install connecting rod bolt guide

set on connecting rod bolts.(6) Pistons and connecting rods must be removed

from top of cylinder block. When removing the

assemblies from the engine, rotate crankshaft so that

the connecting rod is centered in cylinder bore and at

BDC.Be careful not to nick crankshaft journals.

(7) After removal, install bearing cap on the mat-

ing rod.

CLEANING

Clean the piston and connecting rod assembly

using a suitable solvent.

INSPECTION

Check the connecting rod journal for excessive

wear, taper and scoring (Refer to 9 - ENGINE/EN-

GINE BLOCK/CONNECTING ROD BEARINGS -

STANDARD PROCEDURE).

Check the connecting rod for signs of twist or bend-

ing.

Check the piston for taper and elliptical shape

before it is fitted into the cylinder bore (Refer to 9 -

ENGINE/ENGINE BLOCK/PISTON & CONNECT-

ING ROD - STANDARD PROCEDURE).

Check the piston for scoring, or scraping marks in

the piston skirts. Check the ring lands for cracks

and/or deterioration.

INSTALLATION

(1) Be sure that compression ring gaps are stag-

gered so that neither is in line with oil ring rail gap.

(2) Before installing the ring compressor, be sure

the oil ring expander ends are butted and the rail

gaps located properly (Fig. 39).

Fig. 39 Proper Ring Installation

1 - OIL RING SPACER GAP

2 - SECOND COMPRESSION RING GAP OIL RING RAIL GAP

(TOP)

3 - OIL RING RAIL GAP (BOTTOM)

4 - TOP COMPRESSION RING GAP

DRENGINE - 5.9L 9 - 261

PISTON & CONNECTING ROD (Continued)

Page 1602 of 2895

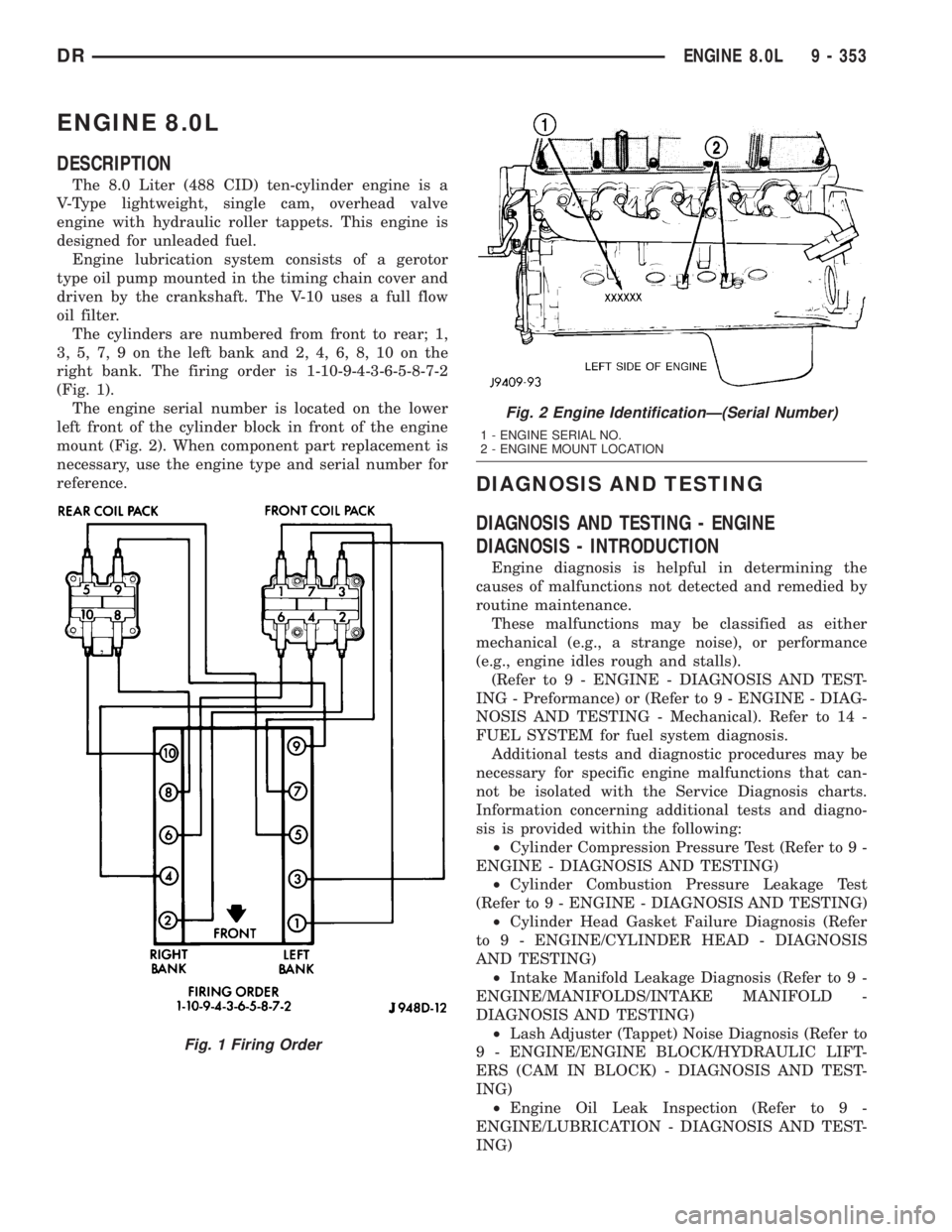

ENGINE 8.0L

DESCRIPTION

The 8.0 Liter (488 CID) ten-cylinder engine is a

V-Type lightweight, single cam, overhead valve

engine with hydraulic roller tappets. This engine is

designed for unleaded fuel.

Engine lubrication system consists of a gerotor

type oil pump mounted in the timing chain cover and

driven by the crankshaft. The V-10 uses a full flow

oil filter.

The cylinders are numbered from front to rear; 1,

3, 5, 7, 9 on the left bank and 2, 4, 6, 8, 10 on the

right bank. The firing order is 1-10-9-4-3-6-5-8-7-2

(Fig. 1).

The engine serial number is located on the lower

left front of the cylinder block in front of the engine

mount (Fig. 2). When component part replacement is

necessary, use the engine type and serial number for

reference.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - INTRODUCTION

Engine diagnosis is helpful in determining the

causes of malfunctions not detected and remedied by

routine maintenance.

These malfunctions may be classified as either

mechanical (e.g., a strange noise), or performance

(e.g., engine idles rough and stalls).

(Refer to 9 - ENGINE - DIAGNOSIS AND TEST-

ING - Preformance) or (Refer to 9 - ENGINE - DIAG-

NOSIS AND TESTING - Mechanical). Refer to 14 -

FUEL SYSTEM for fuel system diagnosis.

Additional tests and diagnostic procedures may be

necessary for specific engine malfunctions that can-

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagno-

sis is provided within the following:

²Cylinder Compression Pressure Test (Refer to 9 -

ENGINE - DIAGNOSIS AND TESTING)

²Cylinder Combustion Pressure Leakage Test

(Refer to 9 - ENGINE - DIAGNOSIS AND TESTING)

²Cylinder Head Gasket Failure Diagnosis (Refer

to 9 - ENGINE/CYLINDER HEAD - DIAGNOSIS

AND TESTING)

²Intake Manifold Leakage Diagnosis (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

DIAGNOSIS AND TESTING)

²Lash Adjuster (Tappet) Noise Diagnosis (Refer to

9 - ENGINE/ENGINE BLOCK/HYDRAULIC LIFT-

ERS (CAM IN BLOCK) - DIAGNOSIS AND TEST-

ING)

²Engine Oil Leak Inspection (Refer to 9 -

ENGINE/LUBRICATION - DIAGNOSIS AND TEST-

ING)

Fig. 1 Firing Order

Fig. 2 Engine IdentificationÐ(Serial Number)

1 - ENGINE SERIAL NO.

2 - ENGINE MOUNT LOCATION

DRENGINE 8.0L 9 - 353

Page 1614 of 2895

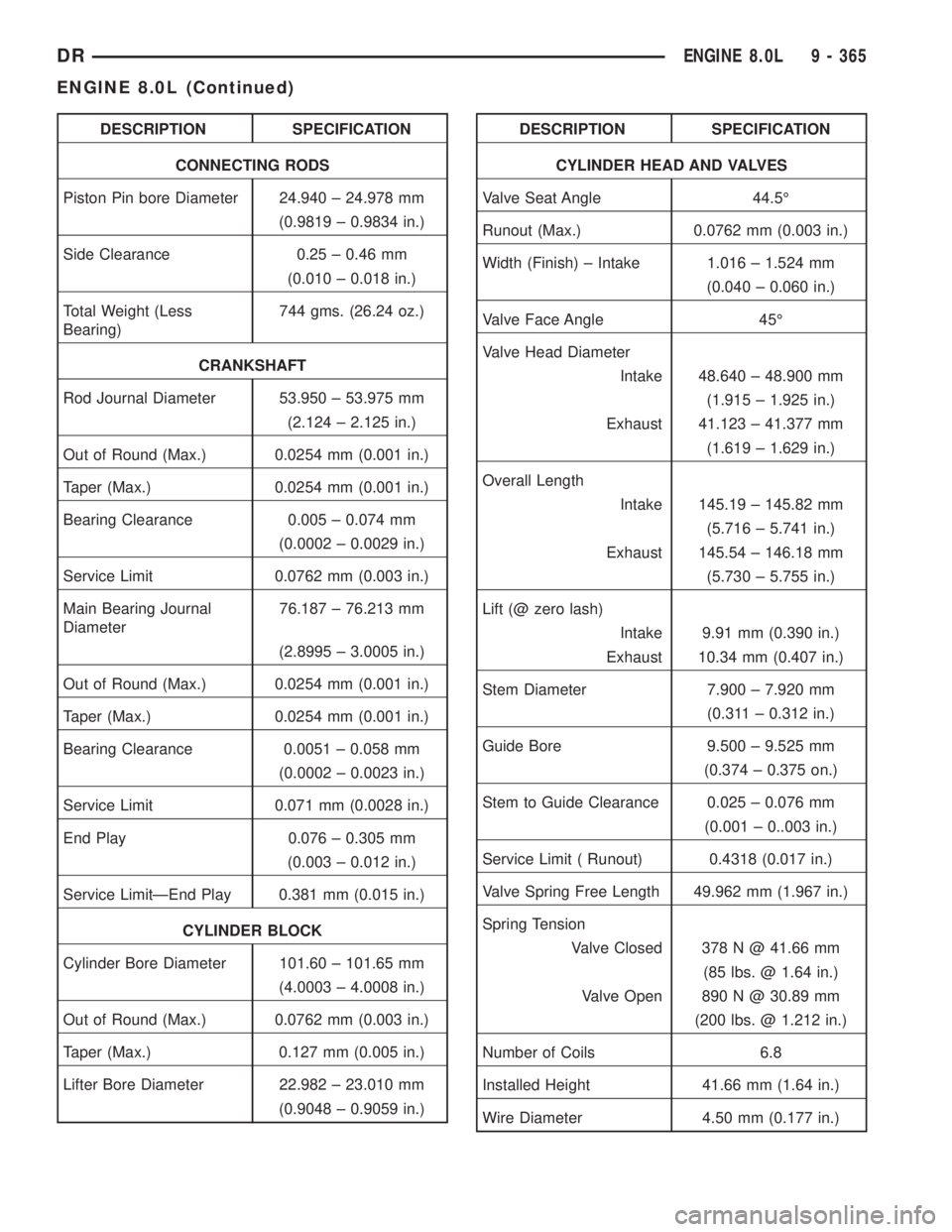

DESCRIPTION SPECIFICATION

CONNECTING RODS

Piston Pin bore Diameter 24.940 ± 24.978 mm

(0.9819 ± 0.9834 in.)

Side Clearance 0.25 ± 0.46 mm

(0.010 ± 0.018 in.)

Total Weight (Less

Bearing)744 gms. (26.24 oz.)

CRANKSHAFT

Rod Journal Diameter 53.950 ± 53.975 mm

(2.124 ± 2.125 in.)

Out of Round (Max.) 0.0254 mm (0.001 in.)

Taper (Max.) 0.0254 mm (0.001 in.)

Bearing Clearance 0.005 ± 0.074 mm

(0.0002 ± 0.0029 in.)

Service Limit 0.0762 mm (0.003 in.)

Main Bearing Journal

Diameter76.187 ± 76.213 mm

(2.8995 ± 3.0005 in.)

Out of Round (Max.) 0.0254 mm (0.001 in.)

Taper (Max.) 0.0254 mm (0.001 in.)

Bearing Clearance 0.0051 ± 0.058 mm

(0.0002 ± 0.0023 in.)

Service Limit 0.071 mm (0.0028 in.)

End Play 0.076 ± 0.305 mm

(0.003 ± 0.012 in.)

Service LimitÐEnd Play 0.381 mm (0.015 in.)

CYLINDER BLOCK

Cylinder Bore Diameter 101.60 ± 101.65 mm

(4.0003 ± 4.0008 in.)

Out of Round (Max.) 0.0762 mm (0.003 in.)

Taper (Max.) 0.127 mm (0.005 in.)

Lifter Bore Diameter 22.982 ± 23.010 mm

(0.9048 ± 0.9059 in.)DESCRIPTION SPECIFICATION

CYLINDER HEAD AND VALVES

Valve Seat Angle 44.5É

Runout (Max.) 0.0762 mm (0.003 in.)

Width (Finish) ± Intake 1.016 ± 1.524 mm

(0.040 ± 0.060 in.)

Valve Face Angle 45É

Valve Head Diameter

Intake 48.640 ± 48.900 mm

(1.915 ± 1.925 in.)

Exhaust 41.123 ± 41.377 mm

(1.619 ± 1.629 in.)

Overall Length

Intake 145.19 ± 145.82 mm

(5.716 ± 5.741 in.)

Exhaust 145.54 ± 146.18 mm

(5.730 ± 5.755 in.)

Lift (@ zero lash)

Intake 9.91 mm (0.390 in.)

Exhaust 10.34 mm (0.407 in.)

Stem Diameter 7.900 ± 7.920 mm

(0.311 ± 0.312 in.)

Guide Bore 9.500 ± 9.525 mm

(0.374 ± 0.375 on.)

Stem to Guide Clearance 0.025 ± 0.076 mm

(0.001 ± 0..003 in.)

Service Limit ( Runout) 0.4318 (0.017 in.)

Valve Spring Free Length 49.962 mm (1.967 in.)

Spring Tension

Valve Closed 378 N @ 41.66 mm

(85 lbs. @ 1.64 in.)

Valve Open 890 N @ 30.89 mm

(200 lbs. @ 1.212 in.)

Number of Coils 6.8

Installed Height 41.66 mm (1.64 in.)

Wire Diameter 4.50 mm (0.177 in.)

DRENGINE 8.0L 9 - 365

ENGINE 8.0L (Continued)

Page 1615 of 2895

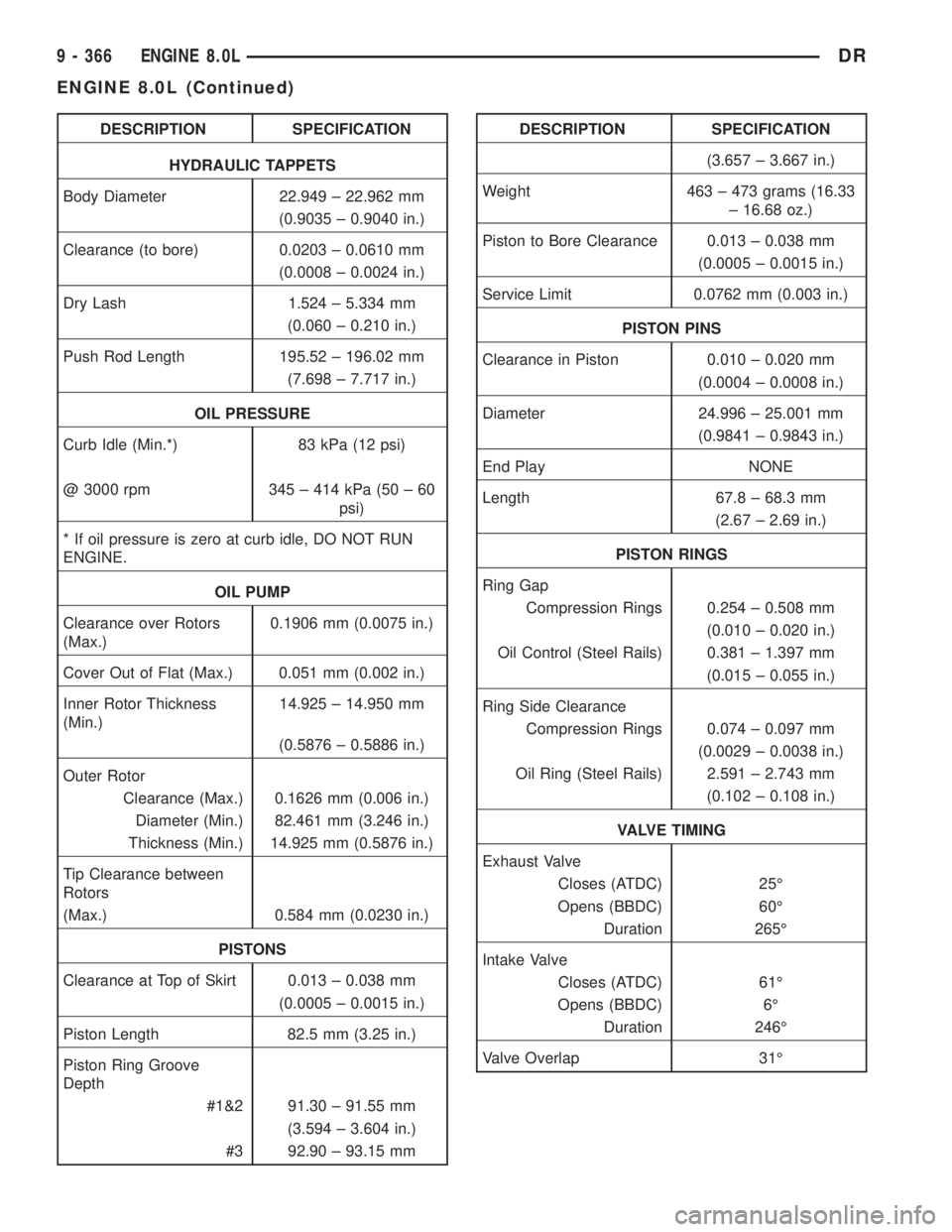

DESCRIPTION SPECIFICATION

HYDRAULIC TAPPETS

Body Diameter 22.949 ± 22.962 mm

(0.9035 ± 0.9040 in.)

Clearance (to bore) 0.0203 ± 0.0610 mm

(0.0008 ± 0.0024 in.)

Dry Lash 1.524 ± 5.334 mm

(0.060 ± 0.210 in.)

Push Rod Length 195.52 ± 196.02 mm

(7.698 ± 7.717 in.)

OIL PRESSURE

Curb Idle (Min.*) 83 kPa (12 psi)

@ 3000 rpm 345 ± 414 kPa (50 ± 60

psi)

* If oil pressure is zero at curb idle, DO NOT RUN

ENGINE.

OIL PUMP

Clearance over Rotors

(Max.)0.1906 mm (0.0075 in.)

Cover Out of Flat (Max.) 0.051 mm (0.002 in.)

Inner Rotor Thickness

(Min.)14.925 ± 14.950 mm

(0.5876 ± 0.5886 in.)

Outer Rotor

Clearance (Max.) 0.1626 mm (0.006 in.)

Diameter (Min.) 82.461 mm (3.246 in.)

Thickness (Min.) 14.925 mm (0.5876 in.)

Tip Clearance between

Rotors

(Max.) 0.584 mm (0.0230 in.)

PISTONS

Clearance at Top of Skirt 0.013 ± 0.038 mm

(0.0005 ± 0.0015 in.)

Piston Length 82.5 mm (3.25 in.)

Piston Ring Groove

Depth

#1&2 91.30 ± 91.55 mm

(3.594 ± 3.604 in.)

#3 92.90 ± 93.15 mmDESCRIPTION SPECIFICATION

(3.657 ± 3.667 in.)

Weight 463 ± 473 grams (16.33

± 16.68 oz.)

Piston to Bore Clearance 0.013 ± 0.038 mm

(0.0005 ± 0.0015 in.)

Service Limit 0.0762 mm (0.003 in.)

PISTON PINS

Clearance in Piston 0.010 ± 0.020 mm

(0.0004 ± 0.0008 in.)

Diameter 24.996 ± 25.001 mm

(0.9841 ± 0.9843 in.)

End Play NONE

Length 67.8 ± 68.3 mm

(2.67 ± 2.69 in.)

PISTON RINGS

Ring Gap

Compression Rings 0.254 ± 0.508 mm

(0.010 ± 0.020 in.)

Oil Control (Steel Rails) 0.381 ± 1.397 mm

(0.015 ± 0.055 in.)

Ring Side Clearance

Compression Rings 0.074 ± 0.097 mm

(0.0029 ± 0.0038 in.)

Oil Ring (Steel Rails) 2.591 ± 2.743 mm

(0.102 ± 0.108 in.)

VALVE TIMING

Exhaust Valve

Closes (ATDC) 25É

Opens (BBDC) 60É

Duration 265É

Intake Valve

Closes (ATDC) 61É

Opens (BBDC) 6É

Duration 246É

Valve Overlap 31É

9 - 366 ENGINE 8.0LDR

ENGINE 8.0L (Continued)

Page 1616 of 2895

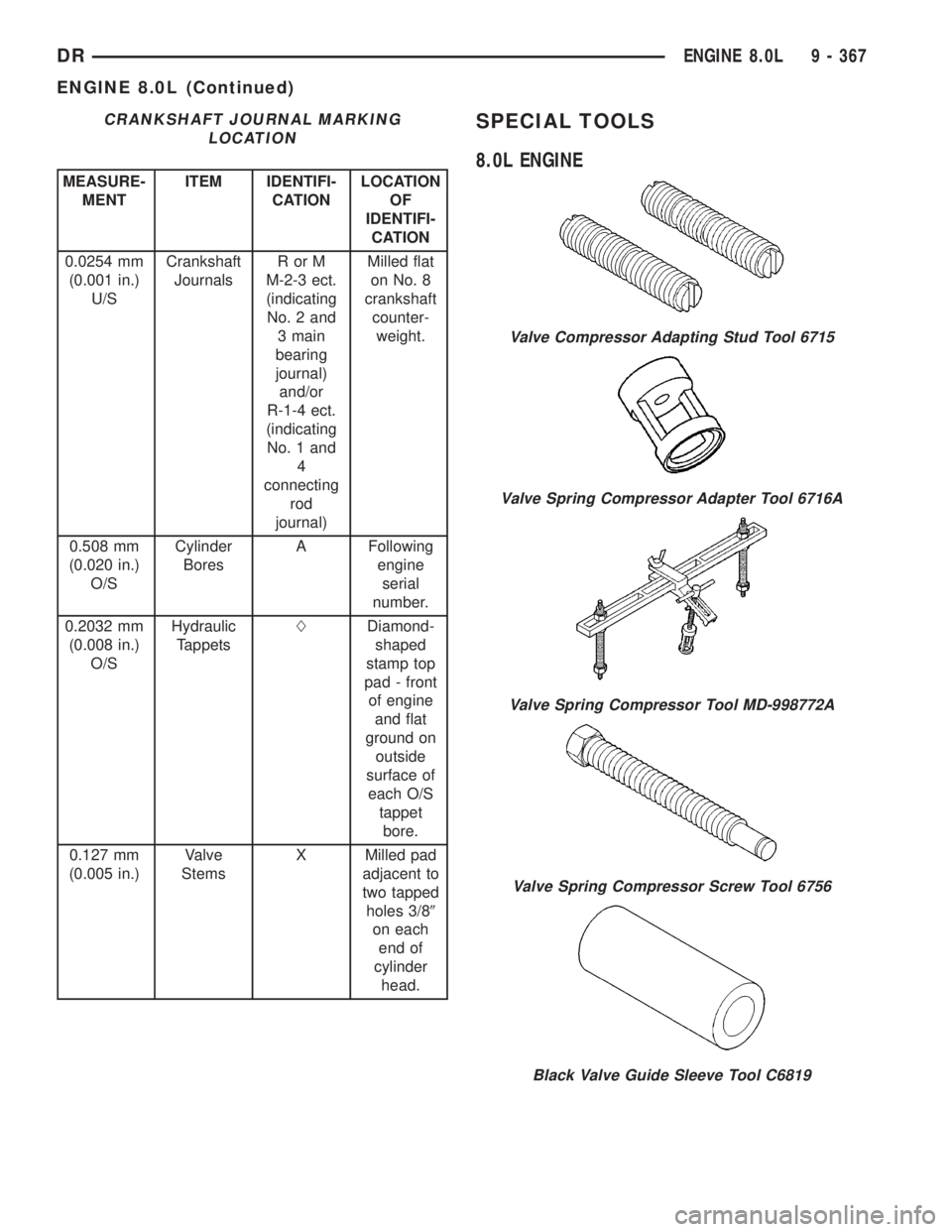

CRANKSHAFT JOURNAL MARKING

LOCATION

MEASURE-

MENTITEM IDENTIFI-

CATIONLOCATION

OF

IDENTIFI-

CATION

0.0254 mm

(0.001 in.)

U/SCrankshaft

JournalsRorM

M-2-3 ect.

(indicating

No. 2 and

3 main

bearing

journal)

and/or

R-1-4 ect.

(indicating

No. 1 and

4

connecting

rod

journal)Milled flat

on No. 8

crankshaft

counter-

weight.

0.508 mm

(0.020 in.)

O/SCylinder

BoresA Following

engine

serial

number.

0.2032 mm

(0.008 in.)

O/SHydraulic

TappetsLDiamond-

shaped

stamp top

pad - front

of engine

and flat

ground on

outside

surface of

each O/S

tappet

bore.

0.127 mm

(0.005 in.)Valve

StemsX Milled pad

adjacent to

two tapped

holes 3/89

on each

end of

cylinder

head.

SPECIAL TOOLS

8.0L ENGINE

Valve Compressor Adapting Stud Tool 6715

Valve Spring Compressor Adapter Tool 6716A

Valve Spring Compressor Tool MD-998772A

Valve Spring Compressor Screw Tool 6756

Black Valve Guide Sleeve Tool C6819

DRENGINE 8.0L 9 - 367

ENGINE 8.0L (Continued)

Page 1636 of 2895

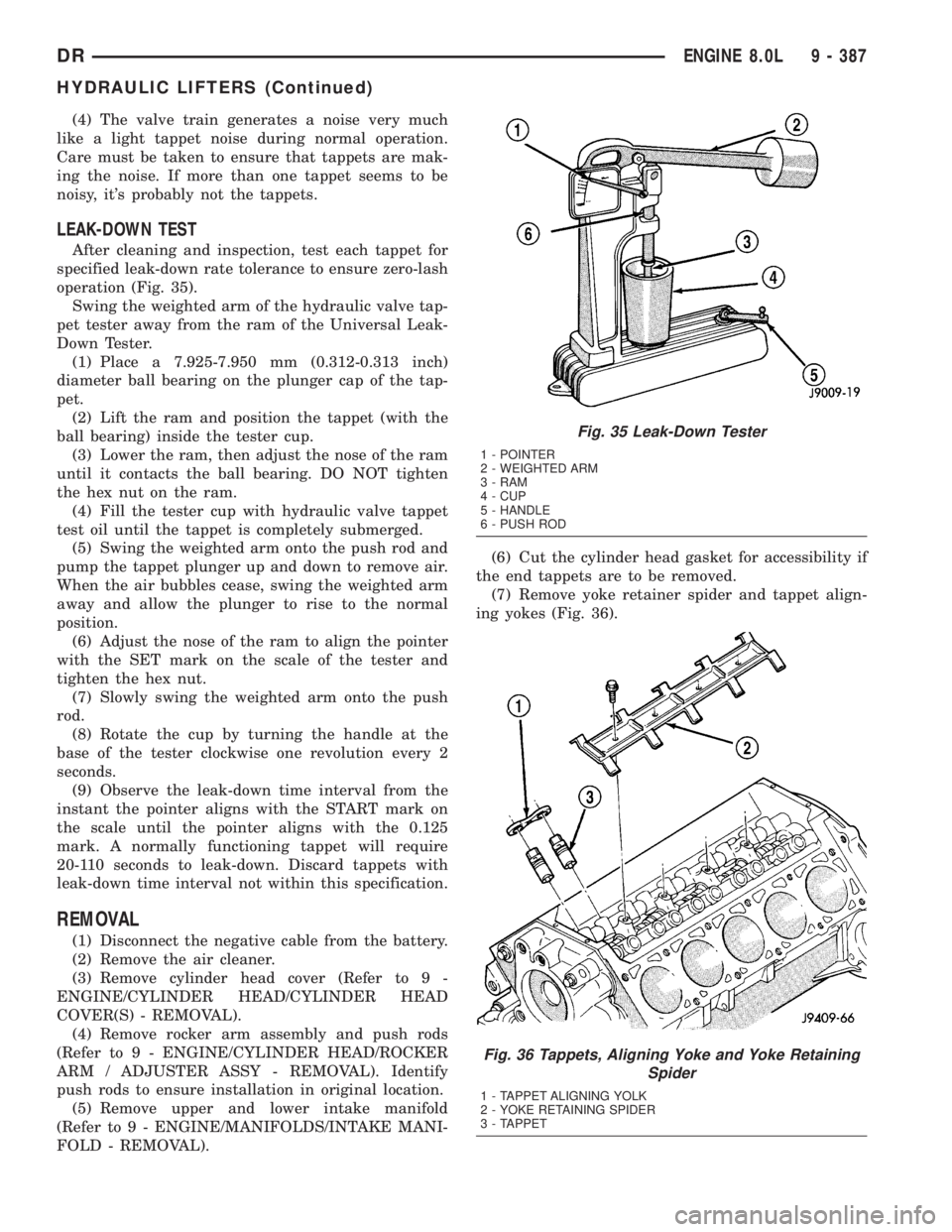

(4) The valve train generates a noise very much

like a light tappet noise during normal operation.

Care must be taken to ensure that tappets are mak-

ing the noise. If more than one tappet seems to be

noisy, it's probably not the tappets.

LEAK-DOWN TEST

After cleaning and inspection, test each tappet for

specified leak-down rate tolerance to ensure zero-lash

operation (Fig. 35).

Swing the weighted arm of the hydraulic valve tap-

pet tester away from the ram of the Universal Leak-

Down Tester.

(1) Place a 7.925-7.950 mm (0.312-0.313 inch)

diameter ball bearing on the plunger cap of the tap-

pet.

(2) Lift the ram and position the tappet (with the

ball bearing) inside the tester cup.

(3) Lower the ram, then adjust the nose of the ram

until it contacts the ball bearing. DO NOT tighten

the hex nut on the ram.

(4) Fill the tester cup with hydraulic valve tappet

test oil until the tappet is completely submerged.

(5) Swing the weighted arm onto the push rod and

pump the tappet plunger up and down to remove air.

When the air bubbles cease, swing the weighted arm

away and allow the plunger to rise to the normal

position.

(6) Adjust the nose of the ram to align the pointer

with the SET mark on the scale of the tester and

tighten the hex nut.

(7) Slowly swing the weighted arm onto the push

rod.

(8) Rotate the cup by turning the handle at the

base of the tester clockwise one revolution every 2

seconds.

(9) Observe the leak-down time interval from the

instant the pointer aligns with the START mark on

the scale until the pointer aligns with the 0.125

mark. A normally functioning tappet will require

20-110 seconds to leak-down. Discard tappets with

leak-down time interval not within this specification.

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Remove the air cleaner.

(3) Remove cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(4) Remove rocker arm assembly and push rods

(Refer to 9 - ENGINE/CYLINDER HEAD/ROCKER

ARM / ADJUSTER ASSY - REMOVAL). Identify

push rods to ensure installation in original location.

(5) Remove upper and lower intake manifold

(Refer to 9 - ENGINE/MANIFOLDS/INTAKE MANI-

FOLD - REMOVAL).(6) Cut the cylinder head gasket for accessibility if

the end tappets are to be removed.

(7) Remove yoke retainer spider and tappet align-

ing yokes (Fig. 36).

Fig. 35 Leak-Down Tester

1 - POINTER

2 - WEIGHTED ARM

3 - RAM

4 - CUP

5 - HANDLE

6 - PUSH ROD

Fig. 36 Tappets, Aligning Yoke and Yoke Retaining

Spider

1 - TAPPET ALIGNING YOLK

2 - YOKE RETAINING SPIDER

3 - TAPPET

DRENGINE 8.0L 9 - 387

HYDRAULIC LIFTERS (Continued)

Page 1637 of 2895

(8) Pull tappet out of bore with a twisting motion.

If all tappets are to be removed, identify tappets to

ensure installation in original location.

(9) If the tappet or bore in cylinder block is scored,

scuffed, or shows signs of sticking, ream the bore to

next oversize. Replace with oversize tappet.

(10) Check camshaft lobes for abnormal wear.

CLEANING

Clean tappet with a suitable solvent. Rinse in hot

water and blow dry with a clean shop rag or com-

pressed air.

INSTALLATION

(1) Lubricate tappets.

(2) Install tappets in their original positions.

Ensure that the oil bleed hole (if so equipped)

faces forward.

(3) Install tappet aligning yokes. Position the yoke

retainer spider over the tappet aligning yokes (Fig.

36)Install the yoke retaining spider bolts and tighten

to 22 N´m (16 ft. lbs.) torque.

(4) Install the push rods in their original location.

(5) Install the rocker arms (Refer to 9 - ENGINE/

CYLINDER HEAD/ROCKER ARM / ADJUSTER

ASSY - INSTALLATION).

(6) Install lower and upper intake manifold (Refer

to 9 - ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION).

(7) The cylinder head cover gasket can be used

again. Install the gasket onto the head rail.For the

left side the number tab is at the front of

engine with the number up. For the right side

the number tab is at the rear of engine with the

number up.

(8) Install cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(9) Install the air cleaner.

CAUTION: To prevent damage to valve mechanism,

engine must not be run above fast idle until all

hydraulic tappets have filled with oil and have

become quiet.

(10) Connect the negative cable to the battery.

(11) Road test vehicle and check for leaks.

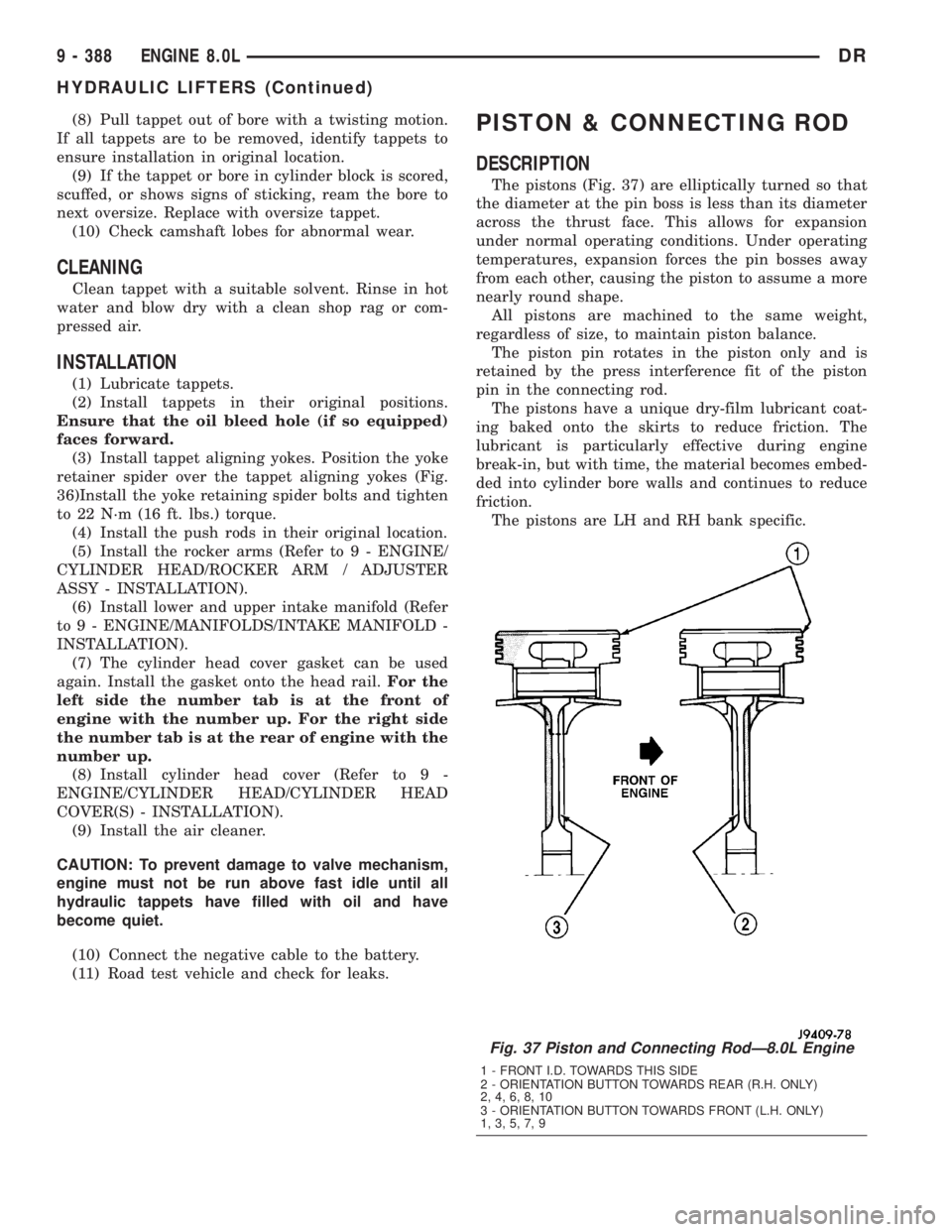

PISTON & CONNECTING ROD

DESCRIPTION

The pistons (Fig. 37) are elliptically turned so that

the diameter at the pin boss is less than its diameter

across the thrust face. This allows for expansion

under normal operating conditions. Under operating

temperatures, expansion forces the pin bosses away

from each other, causing the piston to assume a more

nearly round shape.

All pistons are machined to the same weight,

regardless of size, to maintain piston balance.

The piston pin rotates in the piston only and is

retained by the press interference fit of the piston

pin in the connecting rod.

The pistons have a unique dry-film lubricant coat-

ing baked onto the skirts to reduce friction. The

lubricant is particularly effective during engine

break-in, but with time, the material becomes embed-

ded into cylinder bore walls and continues to reduce

friction.

The pistons are LH and RH bank specific.

Fig. 37 Piston and Connecting RodÐ8.0L Engine

1 - FRONT I.D. TOWARDS THIS SIDE

2 - ORIENTATION BUTTON TOWARDS REAR (R.H. ONLY)

2, 4, 6, 8, 10

3 - ORIENTATION BUTTON TOWARDS FRONT (L.H. ONLY)

1, 3, 5, 7, 9

9 - 388 ENGINE 8.0LDR

HYDRAULIC LIFTERS (Continued)

Page 1824 of 2895

LINKAGE - INDEPENDENT FRONT SUSPENSION

TABLE OF CONTENTS

page page

LINKAGE - INDEPENDENT FRONT

SUSPENSION

DIAGNOSIS AND TESTING - OUTER TIE ROD

END ................................31TIE ROD END

REMOVAL - OUTER TIE ROD END..........31

INSTALLATION - OUTER TIE ROD END......32

LINKAGE - INDEPENDENT

FRONT SUSPENSION

DIAGNOSIS AND TESTING - OUTER TIE ROD

END

NOTE: If the outer tie rod end is equipped with a

lubrication fitting, grease the joint then road test

the vehicle before performing test.

(1) Raise the front of the vehicle. Place safety floor

stands under both lower control arms as far outboard

as possible. Lower the vehicle to allow the stands to

support some or all of the vehicle weight.

(2) Remove the front tires.

(3) Mount a dial indicator solidly to the vehicle

steering knuckle and then zero the dial indicator.

(4) Position indicator plunger on the topside of the

outer tie rod end.

NOTE: The dial indicator plunger must be perpen-

dicular to the machined surface of the outer tie rod

end.

(5) Position a pry bar in order to pry downwards

on the outer tie rod end.

(6) If the travel exceeds 0.5 mm (0.020 in.), replace

the outer tie rod end (Refer to 19 - STEERING/

LINKAGE/TIE ROD END - REMOVAL).

(7) If the outer tie rod end is within specs reinstall

the front tires (Refer to 22 - TIRES/WHEELS/

WHEELS - STANDARD PROCEDURE).

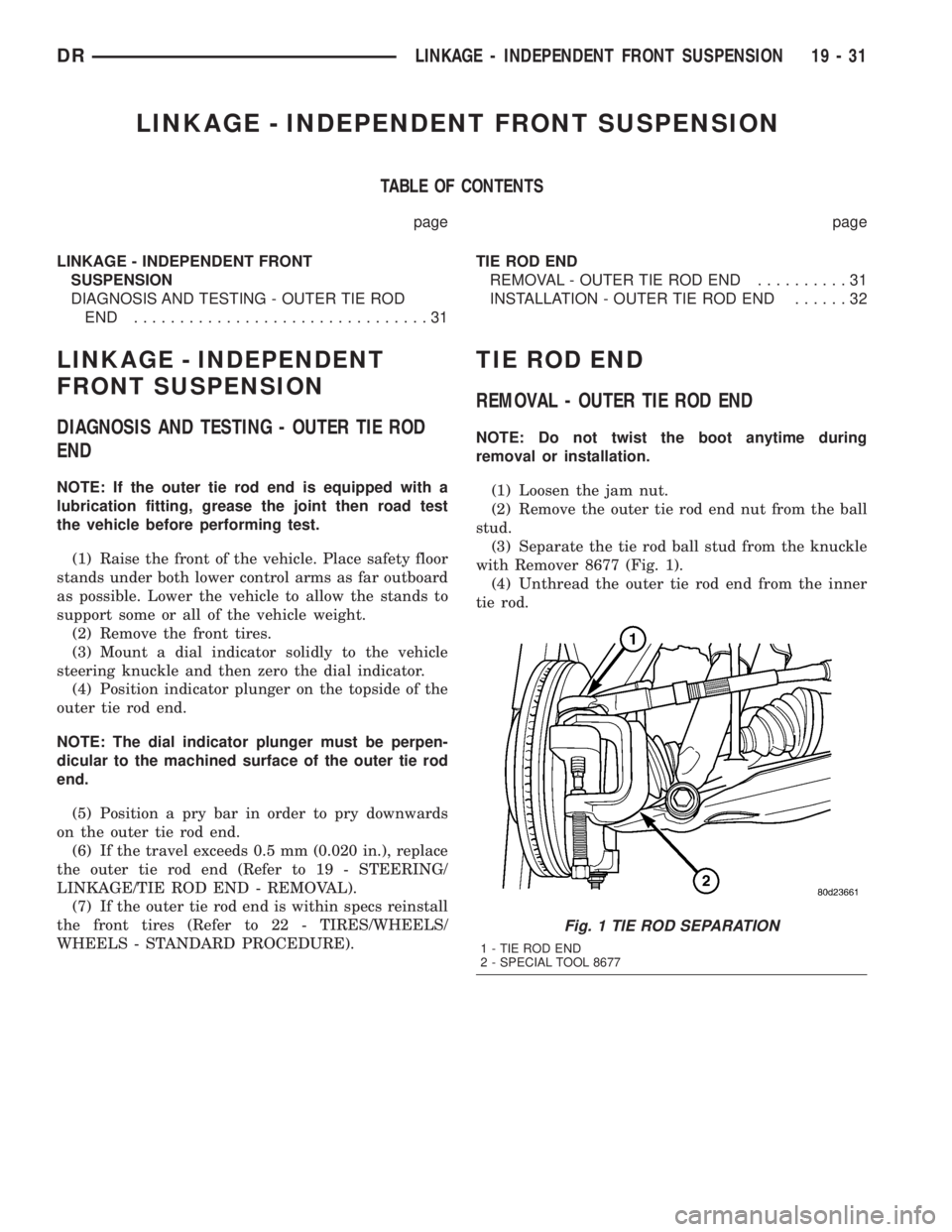

TIE ROD END

REMOVAL - OUTER TIE ROD END

NOTE: Do not twist the boot anytime during

removal or installation.

(1) Loosen the jam nut.

(2) Remove the outer tie rod end nut from the ball

stud.

(3) Separate the tie rod ball stud from the knuckle

with Remover 8677 (Fig. 1).

(4) Unthread the outer tie rod end from the inner

tie rod.

Fig. 1 TIE ROD SEPARATION

1 - TIE ROD END

2 - SPECIAL TOOL 8677

DRLINKAGE - INDEPENDENT FRONT SUSPENSION 19 - 31