Cooler DODGE RAM 2003 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1570 of 2895

(14) Install the fan support/hub assembly and

tighten bolts to 33 N´m (24 ft. lbs.) torque.

(15) Install the power steering pump.

(16) Install accessory drive belt tensioner. Torque

bolt to 43 Nm (43 ft. lbs.).

(17) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(18) Install the charge air cooler (with a/c con-

denser and auxiliary transmission oil cooler, if

equipped) and tighten the mounting bolts to 2 N´m

(17 in. lbs.) torque.

(19) Connect charge air cooler inlet and outlet

pipes. Tighten clamps to 11 N´m (95 in. lbs.) torque.

(20) Install the radiator upper support panel.

(21) Close radiator petcock and lower the radiator

into the engine compartment. Tighten the mounting

bolts to 11 N´m (95 in. lbs.) torque.

(22) Raise vehicle on hoist.

(23)

Connect radiator lower hose and install clamp.

(24) Connect transmission auxiliary oil cooler lines

(if equipped).

(25) Lower vehicle.

(26) Install the fan shroud and tighten the mount-

ing screws to 6 N´m (50 in. lbs.) torque.

(27) Install the electronically controlled viscous

fan/drive assembly. Connect harness connector.(Refer

to 7 - COOLING/ENGINE/RADIATOR FAN -

INSTALLATION).

(28) Install the coolant recovery and windshield

washer fluid reservoirs to the fan shroud.

(29) Connect the coolant recovery hose to the radi-

ator filler neck.

(30) Add engine coolant (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(31) Charge A/C system with refrigerant (if A/C

equipped) (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE).

(32) Connect the battery negative cables.

(33) Start engine and check for engine oil and cool-

ant leaks.

CONNECTING ROD BEARINGS

STANDARD PROCEDURE - CONNECTING ROD

BEARING AND CRANKSHAFT JOURNAL

CLEARANCE

(1) Measure the connecting rod bore with bearings

removedand the bolts tightened to 100 N´m (73 ft.

lbs.) torque..

(2) Measure the connecting rod bore with the bear-

ingsinstalledand the bolts tightened to 100 N´m

(73 ft. lbs.) torque.

Measure within 20É arc from each side of the part-

ing line. Also measure 90É from parting line.Record the smallest and largest diameter.

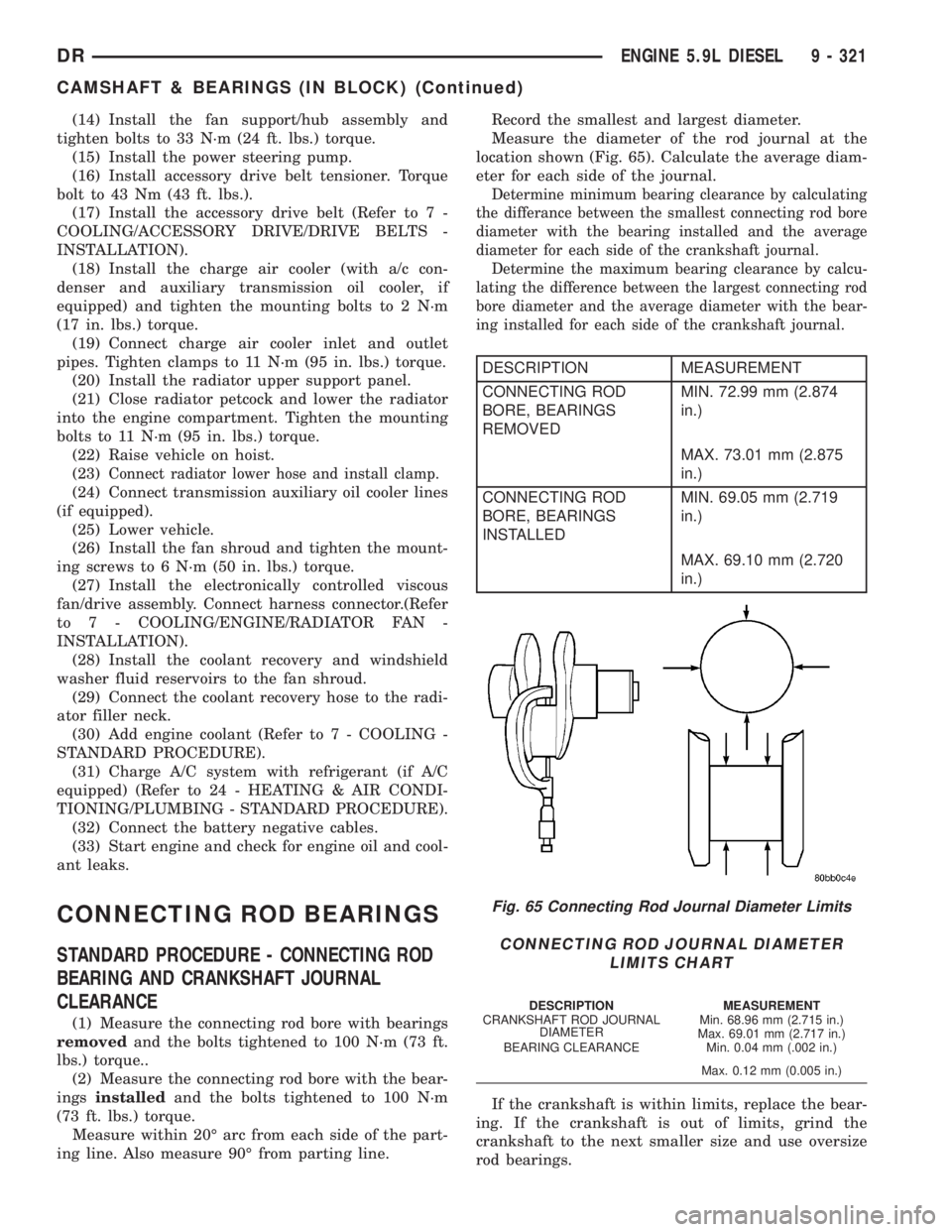

Measure the diameter of the rod journal at the

location shown (Fig. 65). Calculate the average diam-

eter for each side of the journal.

Determine minimum bearing clearance by calculating

the differance between the smallest connecting rod bore

diameter with the bearing installed and the average

diameter for each side of the crankshaft journal.

Determine the maximum bearing clearance by calcu-

lating the difference between the largest connecting rod

bore diameter and the average diameter with the bear-

ing installed for each side of the crankshaft journal.

DESCRIPTION MEASUREMENT

CONNECTING ROD

BORE, BEARINGS

REMOVEDMIN. 72.99 mm (2.874

in.)

MAX. 73.01 mm (2.875

in.)

CONNECTING ROD

BORE, BEARINGS

INSTALLEDMIN. 69.05 mm (2.719

in.)

MAX. 69.10 mm (2.720

in.)

If the crankshaft is within limits, replace the bear-

ing. If the crankshaft is out of limits, grind the

crankshaft to the next smaller size and use oversize

rod bearings.

Fig. 65 Connecting Rod Journal Diameter Limits

CONNECTING ROD JOURNAL DIAMETER

LIMITS CHART

DESCRIPTION MEASUREMENT

CRANKSHAFT ROD JOURNAL

DIAMETERMin. 68.96 mm (2.715 in.)

Max. 69.01 mm (2.717 in.)

BEARING CLEARANCE Min. 0.04 mm (.002 in.)

Max. 0.12 mm (0.005 in.)

DRENGINE 5.9L DIESEL 9 - 321

CAMSHAFT & BEARINGS (IN BLOCK) (Continued)

Page 1581 of 2895

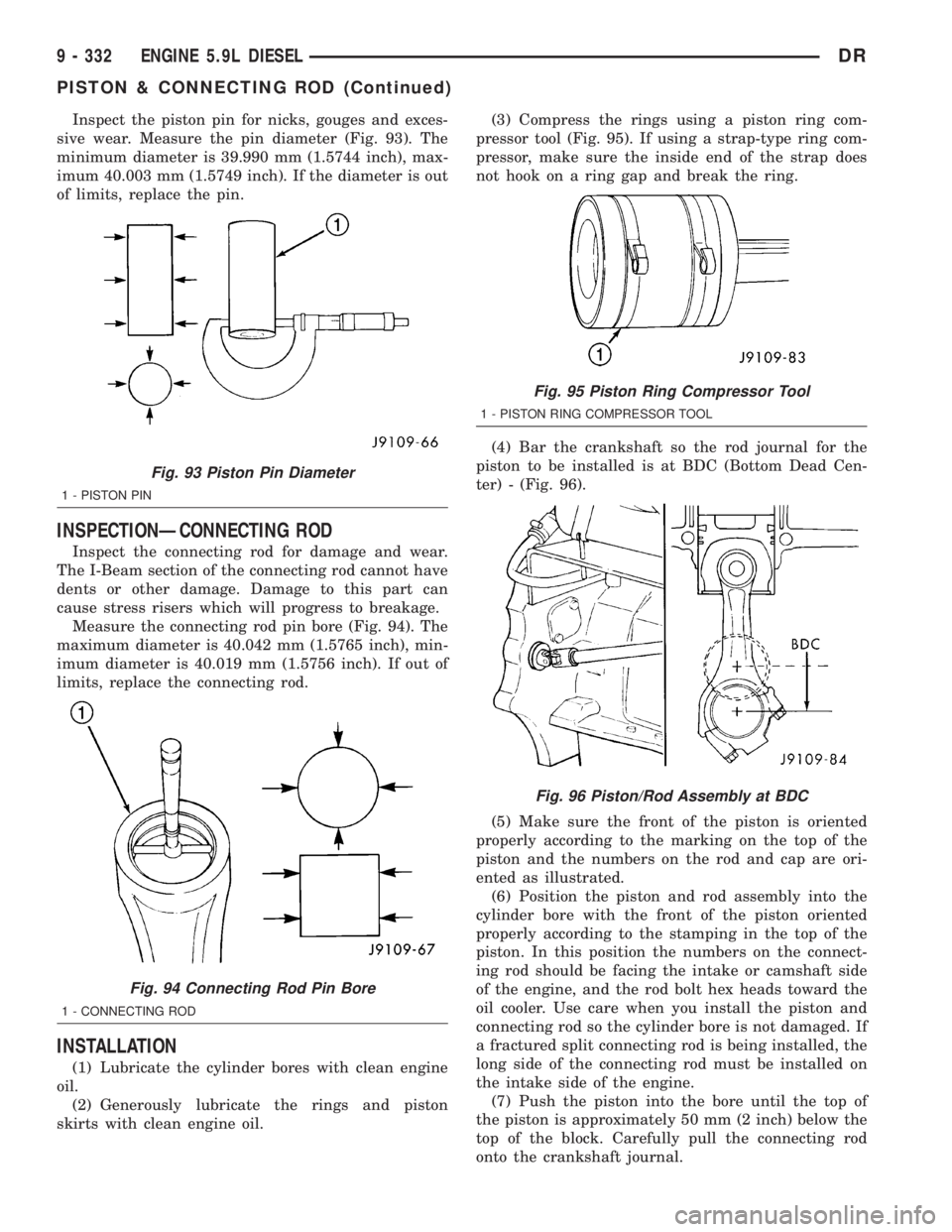

Inspect the piston pin for nicks, gouges and exces-

sive wear. Measure the pin diameter (Fig. 93). The

minimum diameter is 39.990 mm (1.5744 inch), max-

imum 40.003 mm (1.5749 inch). If the diameter is out

of limits, replace the pin.

INSPECTIONÐCONNECTING ROD

Inspect the connecting rod for damage and wear.

The I-Beam section of the connecting rod cannot have

dents or other damage. Damage to this part can

cause stress risers which will progress to breakage.

Measure the connecting rod pin bore (Fig. 94). The

maximum diameter is 40.042 mm (1.5765 inch), min-

imum diameter is 40.019 mm (1.5756 inch). If out of

limits, replace the connecting rod.

INSTALLATION

(1) Lubricate the cylinder bores with clean engine

oil.

(2) Generously lubricate the rings and piston

skirts with clean engine oil.(3) Compress the rings using a piston ring com-

pressor tool (Fig. 95). If using a strap-type ring com-

pressor, make sure the inside end of the strap does

not hook on a ring gap and break the ring.

(4) Bar the crankshaft so the rod journal for the

piston to be installed is at BDC (Bottom Dead Cen-

ter) - (Fig. 96).

(5) Make sure the front of the piston is oriented

properly according to the marking on the top of the

piston and the numbers on the rod and cap are ori-

ented as illustrated.

(6) Position the piston and rod assembly into the

cylinder bore with the front of the piston oriented

properly according to the stamping in the top of the

piston. In this position the numbers on the connect-

ing rod should be facing the intake or camshaft side

of the engine, and the rod bolt hex heads toward the

oil cooler. Use care when you install the piston and

connecting rod so the cylinder bore is not damaged. If

a fractured split connecting rod is being installed, the

long side of the connecting rod must be installed on

the intake side of the engine.

(7) Push the piston into the bore until the top of

the piston is approximately 50 mm (2 inch) below the

top of the block. Carefully pull the connecting rod

onto the crankshaft journal.

Fig. 93 Piston Pin Diameter

1 - PISTON PIN

Fig. 94 Connecting Rod Pin Bore

1 - CONNECTING ROD

Fig. 95 Piston Ring Compressor Tool

1 - PISTON RING COMPRESSOR TOOL

Fig. 96 Piston/Rod Assembly at BDC

9 - 332 ENGINE 5.9L DIESELDR

PISTON & CONNECTING ROD (Continued)

Page 1582 of 2895

(8) Use clean engine oil to lubricate the threads

and under the heads of the connecting rod bolts.

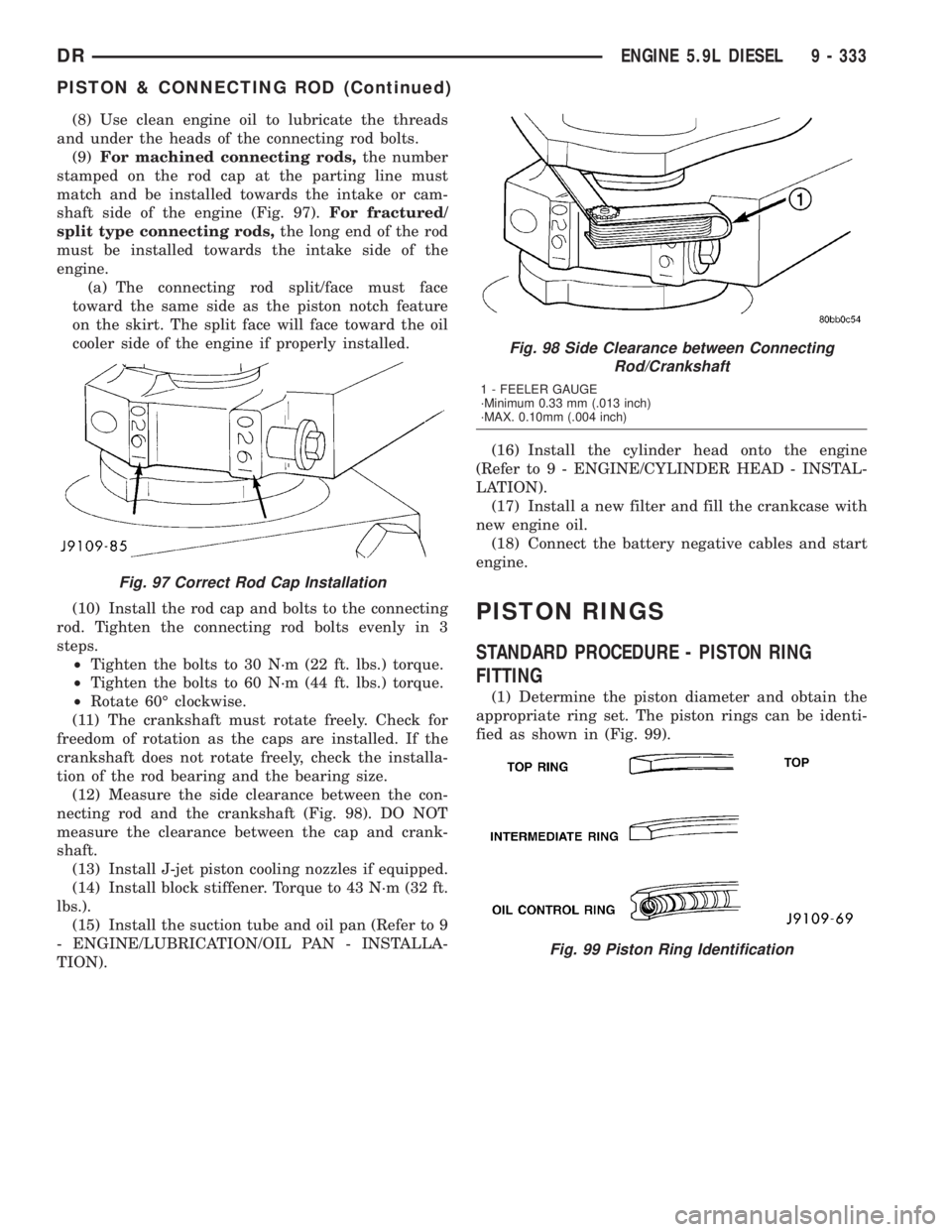

(9)For machined connecting rods,the number

stamped on the rod cap at the parting line must

match and be installed towards the intake or cam-

shaft side of the engine (Fig. 97).For fractured/

split type connecting rods,the long end of the rod

must be installed towards the intake side of the

engine.

(a) The connecting rod split/face must face

toward the same side as the piston notch feature

on the skirt. The split face will face toward the oil

cooler side of the engine if properly installed.

(10) Install the rod cap and bolts to the connecting

rod. Tighten the connecting rod bolts evenly in 3

steps.

²Tighten the bolts to 30 N´m (22 ft. lbs.) torque.

²Tighten the bolts to 60 N´m (44 ft. lbs.) torque.

²Rotate 60É clockwise.

(11) The crankshaft must rotate freely. Check for

freedom of rotation as the caps are installed. If the

crankshaft does not rotate freely, check the installa-

tion of the rod bearing and the bearing size.

(12) Measure the side clearance between the con-

necting rod and the crankshaft (Fig. 98). DO NOT

measure the clearance between the cap and crank-

shaft.

(13) Install J-jet piston cooling nozzles if equipped.

(14) Install block stiffener. Torque to 43 N´m (32 ft.

lbs.).

(15) Install the suction tube and oil pan (Refer to 9

- ENGINE/LUBRICATION/OIL PAN - INSTALLA-

TION).(16) Install the cylinder head onto the engine

(Refer to 9 - ENGINE/CYLINDER HEAD - INSTAL-

LATION).

(17) Install a new filter and fill the crankcase with

new engine oil.

(18) Connect the battery negative cables and start

engine.

PISTON RINGS

STANDARD PROCEDURE - PISTON RING

FITTING

(1) Determine the piston diameter and obtain the

appropriate ring set. The piston rings can be identi-

fied as shown in (Fig. 99).

Fig. 97 Correct Rod Cap Installation

Fig. 98 Side Clearance between Connecting

Rod/Crankshaft

1 - FEELER GAUGE

´Minimum 0.33 mm (.013 inch)

´MAX. 0.10mm (.004 inch)

Fig. 99 Piston Ring Identification

DRENGINE 5.9L DIESEL 9 - 333

PISTON & CONNECTING ROD (Continued)

Page 1586 of 2895

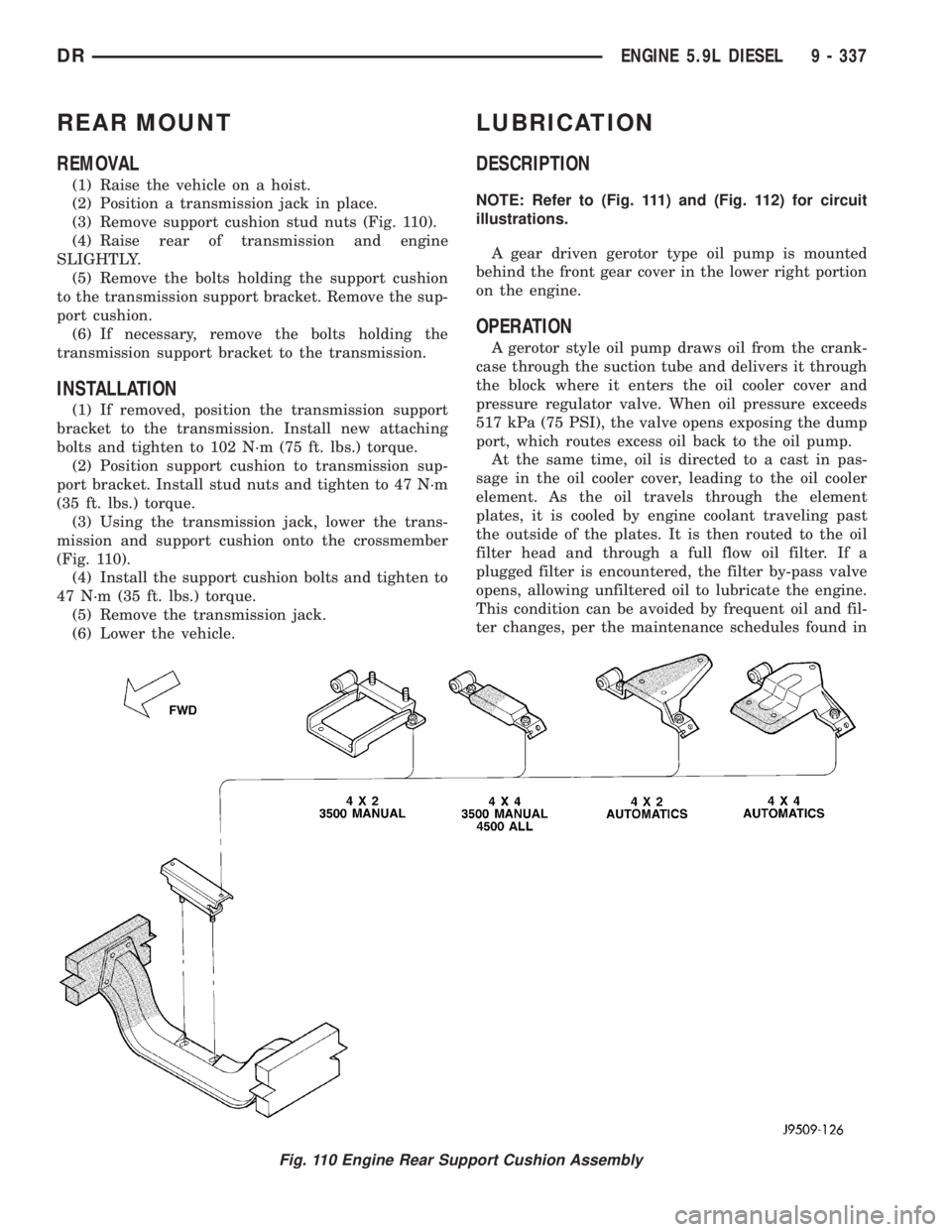

REAR MOUNT

REMOVAL

(1) Raise the vehicle on a hoist.

(2) Position a transmission jack in place.

(3) Remove support cushion stud nuts (Fig. 110).

(4) Raise rear of transmission and engine

SLIGHTLY.

(5) Remove the bolts holding the support cushion

to the transmission support bracket. Remove the sup-

port cushion.

(6) If necessary, remove the bolts holding the

transmission support bracket to the transmission.

INSTALLATION

(1) If removed, position the transmission support

bracket to the transmission. Install new attaching

bolts and tighten to 102 N´m (75 ft. lbs.) torque.

(2) Position support cushion to transmission sup-

port bracket. Install stud nuts and tighten to 47 N´m

(35 ft. lbs.) torque.

(3) Using the transmission jack, lower the trans-

mission and support cushion onto the crossmember

(Fig. 110).

(4) Install the support cushion bolts and tighten to

47 N´m (35 ft. lbs.) torque.

(5) Remove the transmission jack.

(6) Lower the vehicle.

LUBRICATION

DESCRIPTION

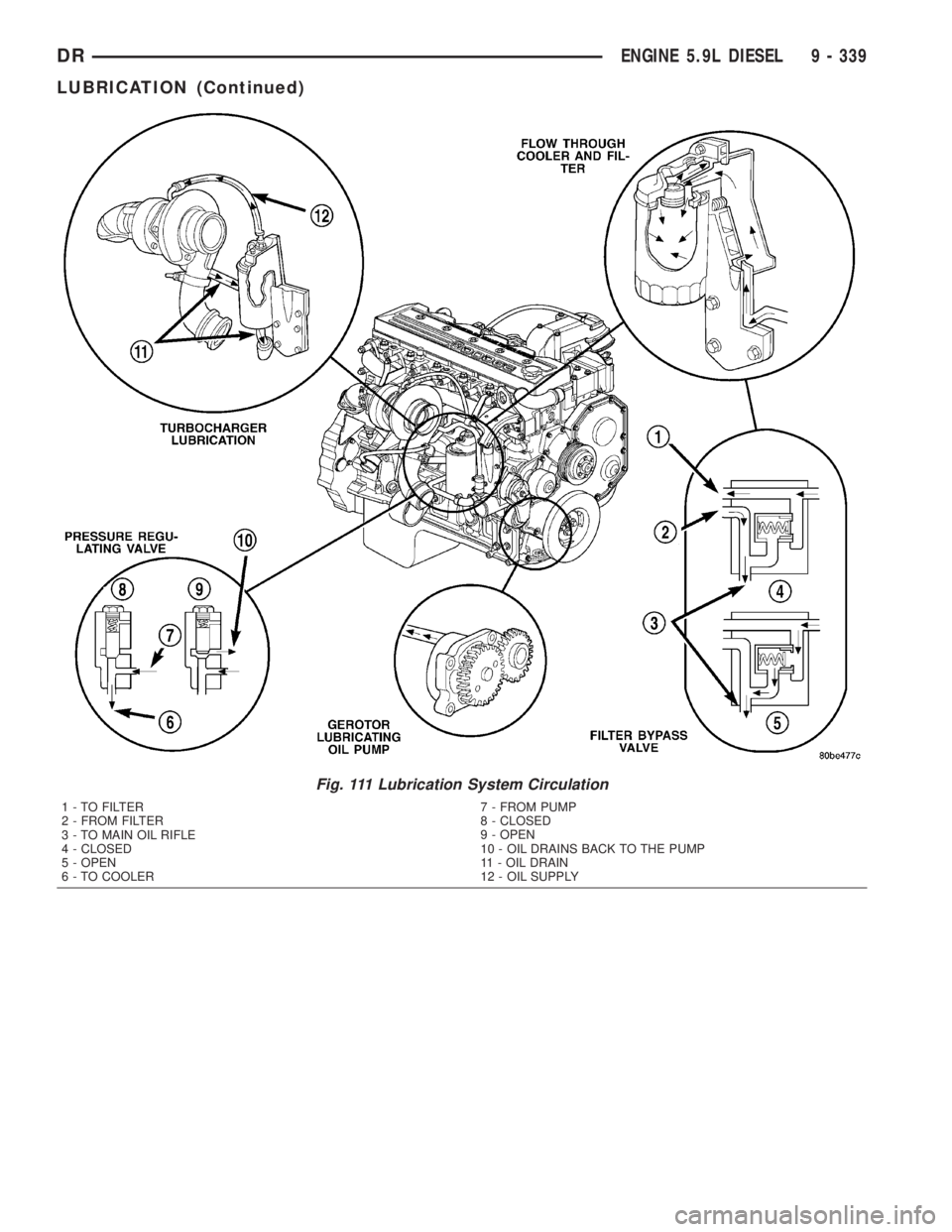

NOTE: Refer to (Fig. 111) and (Fig. 112) for circuit

illustrations.

A gear driven gerotor type oil pump is mounted

behind the front gear cover in the lower right portion

on the engine.

OPERATION

A gerotor style oil pump draws oil from the crank-

case through the suction tube and delivers it through

the block where it enters the oil cooler cover and

pressure regulator valve. When oil pressure exceeds

517 kPa (75 PSI), the valve opens exposing the dump

port, which routes excess oil back to the oil pump.

At the same time, oil is directed to a cast in pas-

sage in the oil cooler cover, leading to the oil cooler

element. As the oil travels through the element

plates, it is cooled by engine coolant traveling past

the outside of the plates. It is then routed to the oil

filter head and through a full flow oil filter. If a

plugged filter is encountered, the filter by-pass valve

opens, allowing unfiltered oil to lubricate the engine.

This condition can be avoided by frequent oil and fil-

ter changes, per the maintenance schedules found in

Fig. 110 Engine Rear Support Cushion Assembly

DRENGINE 5.9L DIESEL 9 - 337

Page 1588 of 2895

Fig. 111 Lubrication System Circulation

1 - TO FILTER

2 - FROM FILTER

3 - TO MAIN OIL RIFLE

4 - CLOSED

5 - OPEN

6 - TO COOLER7 - FROM PUMP

8 - CLOSED

9 - OPEN

10 - OIL DRAINS BACK TO THE PUMP

11 - OIL DRAIN

12 - OIL SUPPLY

DRENGINE 5.9L DIESEL 9 - 339

LUBRICATION (Continued)

Page 1590 of 2895

OIL

STANDARD PROCEDURE

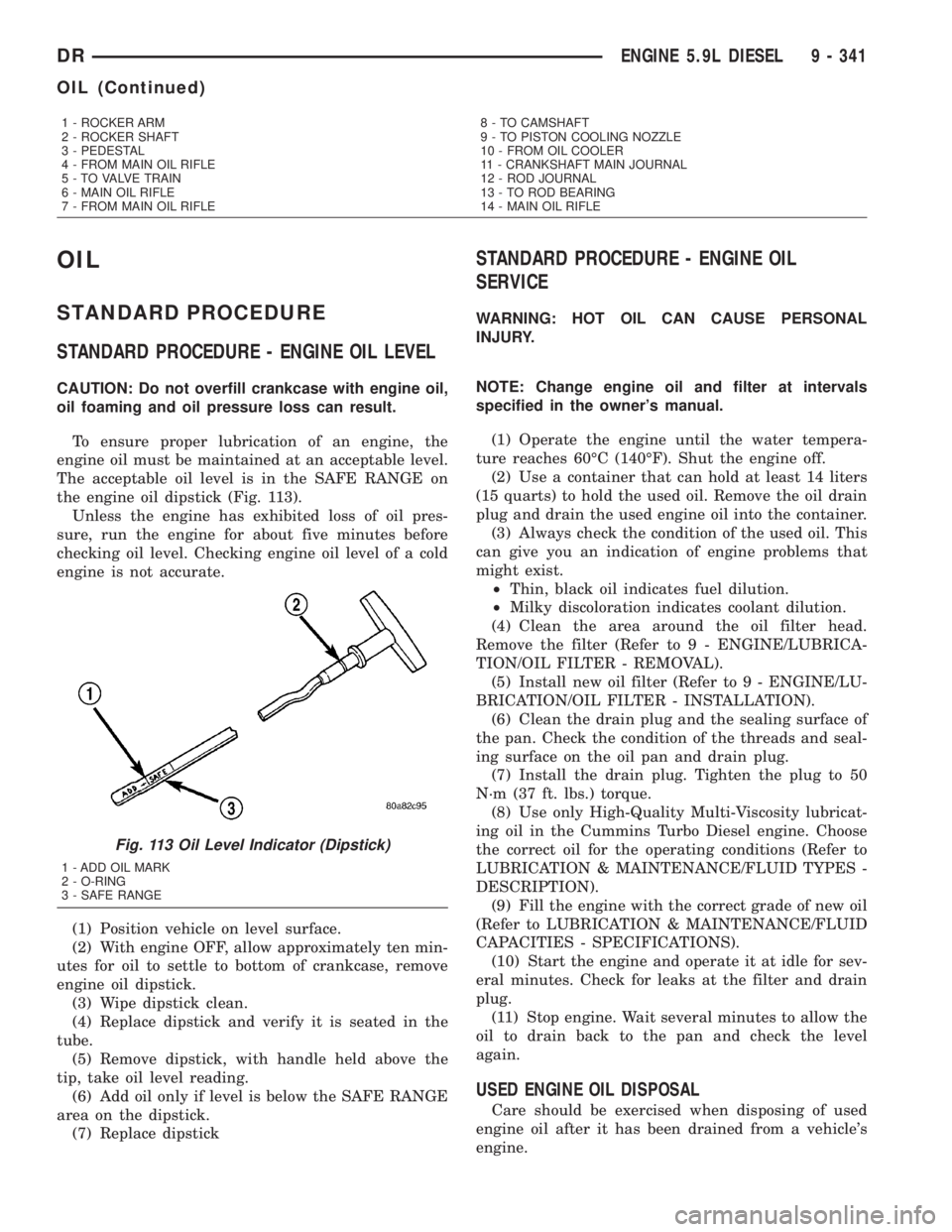

STANDARD PROCEDURE - ENGINE OIL LEVEL

CAUTION: Do not overfill crankcase with engine oil,

oil foaming and oil pressure loss can result.

To ensure proper lubrication of an engine, the

engine oil must be maintained at an acceptable level.

The acceptable oil level is in the SAFE RANGE on

the engine oil dipstick (Fig. 113).

Unless the engine has exhibited loss of oil pres-

sure, run the engine for about five minutes before

checking oil level. Checking engine oil level of a cold

engine is not accurate.

(1) Position vehicle on level surface.

(2) With engine OFF, allow approximately ten min-

utes for oil to settle to bottom of crankcase, remove

engine oil dipstick.

(3) Wipe dipstick clean.

(4) Replace dipstick and verify it is seated in the

tube.

(5) Remove dipstick, with handle held above the

tip, take oil level reading.

(6) Add oil only if level is below the SAFE RANGE

area on the dipstick.

(7) Replace dipstick

STANDARD PROCEDURE - ENGINE OIL

SERVICE

WARNING: HOT OIL CAN CAUSE PERSONAL

INJURY.

NOTE: Change engine oil and filter at intervals

specified in the owner's manual.

(1) Operate the engine until the water tempera-

ture reaches 60ÉC (140ÉF). Shut the engine off.

(2) Use a container that can hold at least 14 liters

(15 quarts) to hold the used oil. Remove the oil drain

plug and drain the used engine oil into the container.

(3) Always check the condition of the used oil. This

can give you an indication of engine problems that

might exist.

²Thin, black oil indicates fuel dilution.

²Milky discoloration indicates coolant dilution.

(4) Clean the area around the oil filter head.

Remove the filter (Refer to 9 - ENGINE/LUBRICA-

TION/OIL FILTER - REMOVAL).

(5) Install new oil filter (Refer to 9 - ENGINE/LU-

BRICATION/OIL FILTER - INSTALLATION).

(6) Clean the drain plug and the sealing surface of

the pan. Check the condition of the threads and seal-

ing surface on the oil pan and drain plug.

(7) Install the drain plug. Tighten the plug to 50

N´m (37 ft. lbs.) torque.

(8) Use only High-Quality Multi-Viscosity lubricat-

ing oil in the Cummins Turbo Diesel engine. Choose

the correct oil for the operating conditions (Refer to

LUBRICATION & MAINTENANCE/FLUID TYPES -

DESCRIPTION).

(9) Fill the engine with the correct grade of new oil

(Refer to LUBRICATION & MAINTENANCE/FLUID

CAPACITIES - SPECIFICATIONS).

(10) Start the engine and operate it at idle for sev-

eral minutes. Check for leaks at the filter and drain

plug.

(11) Stop engine. Wait several minutes to allow the

oil to drain back to the pan and check the level

again.

USED ENGINE OIL DISPOSAL

Care should be exercised when disposing of used

engine oil after it has been drained from a vehicle's

engine.

1 - ROCKER ARM

2 - ROCKER SHAFT

3 - PEDESTAL

4 - FROM MAIN OIL RIFLE

5 - TO VALVE TRAIN

6 - MAIN OIL RIFLE

7 - FROM MAIN OIL RIFLE8 - TO CAMSHAFT

9 - TO PISTON COOLING NOZZLE

10 - FROM OIL COOLER

11 - CRANKSHAFT MAIN JOURNAL

12 - ROD JOURNAL

13 - TO ROD BEARING

14 - MAIN OIL RIFLE

Fig. 113 Oil Level Indicator (Dipstick)

1 - ADD OIL MARK

2 - O-RING

3 - SAFE RANGE

DRENGINE 5.9L DIESEL 9 - 341

OIL (Continued)

Page 1591 of 2895

OIL COOLER & LINES

CLEANING

CLEANING AND INSPECTION

Clean the sealing surfaces.

Apply 483 kPa (70 psi) air pressure to the element

to check for leaks. If the element leaks, replace the

element.

OIL FILTER

REMOVAL

(1) Clean the area around the oil filter head.

Remove the filter from below using a cap-style filter

wrench.

(2) Clean the gasket surface of the filter head. The

filter canister O-Ring seal can stick on the filter

head. Make sure it is removed.

INSTALLATION

(1) Fill the oil filter element with clean oil before

installation. Use the same type oil that will be used

in the engine.

(2) Apply a light film of lubricating oil to the seal-

ing surface before installing the filter.

CAUTION: Mechanical over-tightening may distort

the threads or damage the filter element seal.

(3) Install the filter until it contacts the sealing

surface of the oil filter adapter. Tighten filter an

additional

1¤2turn.

OIL PAN

REMOVAL

(1) Disconnect the battery negative cables.

(2) Install engine support fixture # 8534.

(3) Raise vehicle on hoist.

(4) Disconnect starter cables from starter motor.

(5) Remove starter motor (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - REMOVAL)

and transmission adapter plate assembly.

(6) Remove transmission and transfer case (if

equipped).

(7) Remove flywheel or flexplate.

(8) Remove the transmission adapter plate.

WARNING: HOT OIL CAN CAUSE PERSONAL

INJURY.

(9) Drain the engine oil (Refer to 9 - ENGINE/LU-

BRICATION/OIL - STANDARD PROCEDURE).(10) Install the oil pan drain plug if sealing sur-

face is not damaged and tighten to 50 N´m (57 ft.

lbs.) torque.

(11) Remove oil pan bolts, break the pan to block

seal, and lower pan slightly and remove oil suction

tube fasteners.

(12) Remove oil pan and suction tube.

CLEANING

Remove all gasket material from the oil pan and

cylinder block sealing surfaces. Extra effort may be

required around T-joint areas. Clean oil pan and

flush suction tube with a suitable solvent.

INSPECTION

Inspect the oil pan, suction tube, and tube braces

for cracks and damage. Replace any defective compo-

nent. Inspect the oil drain plug and drain hole

threads. Inspect the oil pan sealing surface for

straightness. Repair any minor imperfections with a

ball-peen hammer. Do not attempt to repair an oil

pan by welding.

INSTALLATION

(1) Fill the T-joint between the pan rail/gear hous-

ing and pan rail/rear seal retainer with sealant. Use

MopartSilicone Rubber Adhesive Sealant or equiva-

lent.

(2) Place suction tube in oil pan and guide them

into place. Using a new tube to block gasket, install

and tighten the suction tube bolts by hand. Starting

with the oil pump inlet bolts, tighten the bolts to 24

N´m (18 ft. lbs.) torque. Tighten the remaining tube

brace bolts to 43 N´m (32 ft. lbs.) torque.

(3) Starting in the center and working outward,

tighten the oil pan bolts to 28 N´m (21 ft. lbs.)

torque.

(4) Install the flywheel housing assembly with the

starter motor attached and tighten bolts to 77 N´m

(57 ft. lbs.) torque.

(5) Connect starter motor cables.

(6) Install the flywheel or flexplate. Torque to 137

N´m (101 ft. lbs.).

(7) Install transmission and transfer case (if

equipped).

(8) Lower vehicle.

(9) Remove the engine support fixture # 8534.

(10) Install battery negative cables.

(11) Fill the crankcase with new engine oil.

(12) Start engine and check for leaks. Stop engine,

check oil level, and adjust, if necessary.

9 - 342 ENGINE 5.9L DIESELDR

Page 1594 of 2895

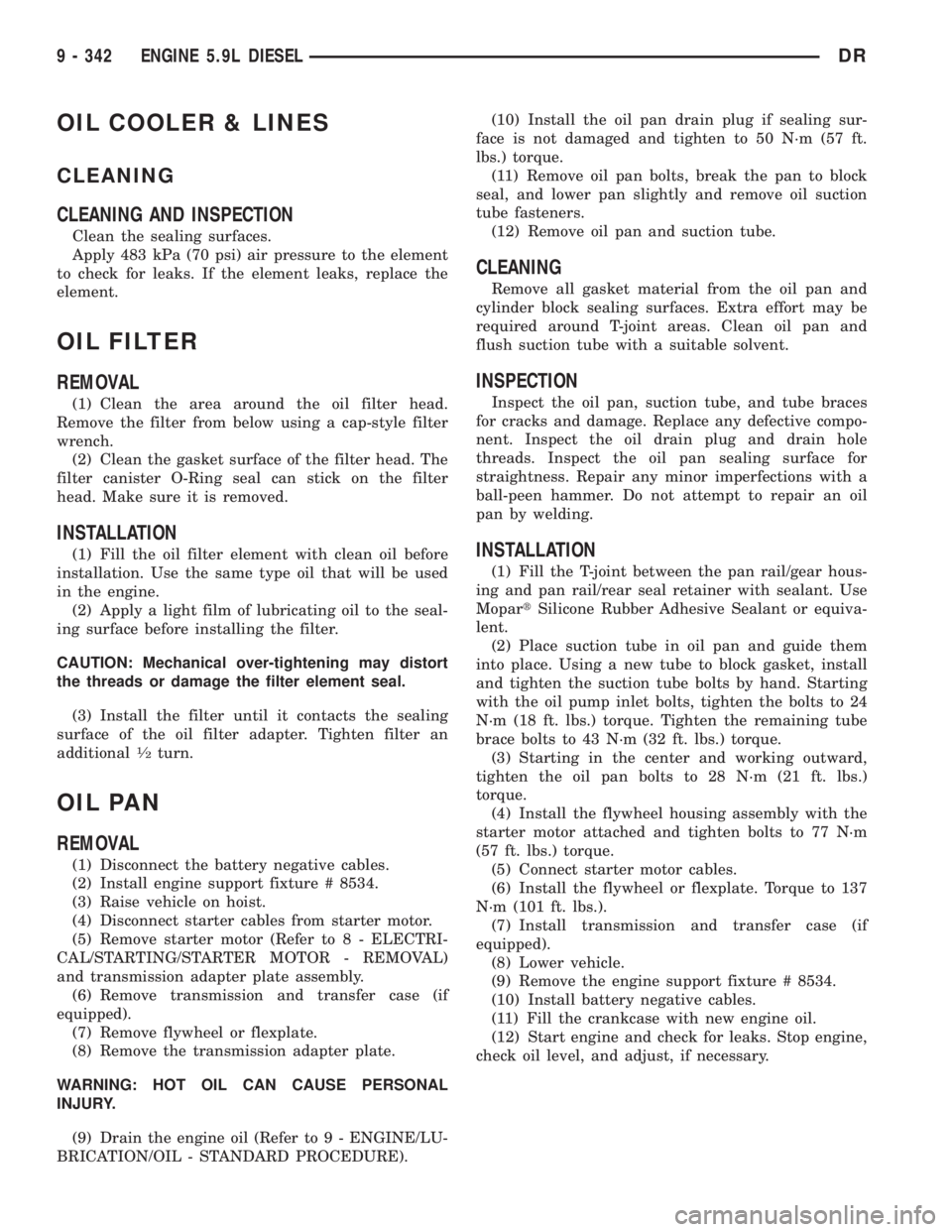

(2) Install the pump (Fig. 116). Verify the idler

gear pin is installed in the locating bore in the cylin-

der block. Tighten the oil pump mounting bolts in

two steps, in the sequence shown in (Fig. 122).

²Step 1ÐTighten to 8 N´m (71 in. lbs.) torque.

²Step 2ÐTighten to 24 N´m (18 ft. lbs.) torque.(3) The back plate on the pump seats against the

bottom of the bore in the cylinder block. When the

pump is correctly installed, the flange on the pump

will not touch the cylinder block.

(4) Measure the idler gear to pump drive gear

backlash and the idler gear to crankshaft gear back-

lash (Fig. 123). The backlash should be 0.15- 0.25

mm (0.006-0.010 inch). If the backlash is out of lim-

its, replace the oil pump.

(5) If the adjoining gear moves when you measure

the backlash, the reading will be incorrect.

(6) Apply a bead of MopartSilicone Rubber Adhe-

sive Sealant or equivalent to the gear housing cover

sealing surface.

(7) Install the gear housing cover (Refer to 9 -

ENGINE/VALVE TIMING/GEAR HOUSING COVER

- INSTALLATION).

(8) Install the vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION) and speed indicator ring.

(9) Install the fan support/hub assembly and

torque bolts to 32 N´m (24 ft. lbs.).

(10) Install hydraulic pump.

(11) Install accessory drive belt tensioner. Torque

bolt to 43 N´m (32 ft. lbs.).

(12) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(13) Install the cooling fan (Refer to 7 - COOLING/

ENGINE/RADIATOR FAN - INSTALLATION).

(14) Connect battery negative cables.

(15) Start engine and check for oil leaks.

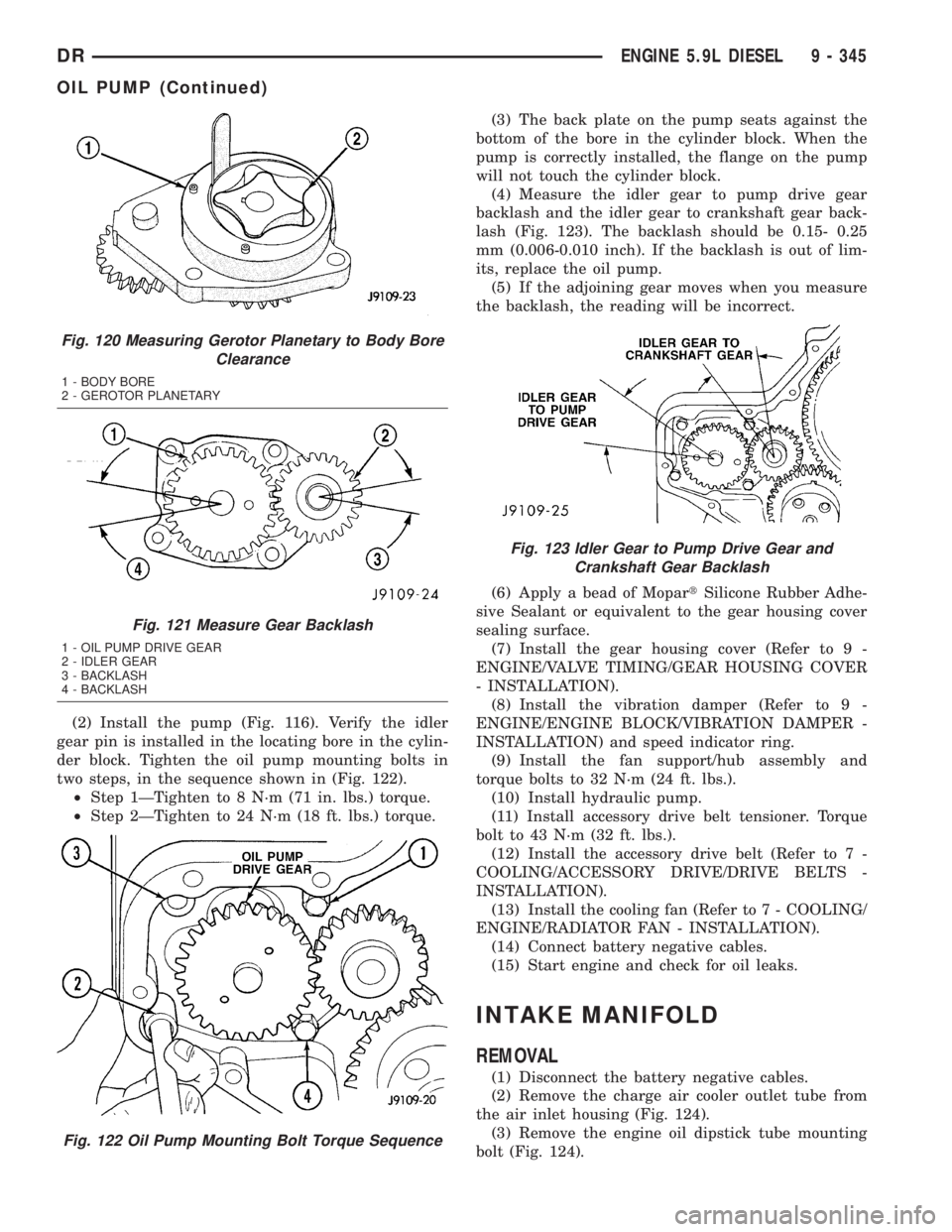

INTAKE MANIFOLD

REMOVAL

(1) Disconnect the battery negative cables.

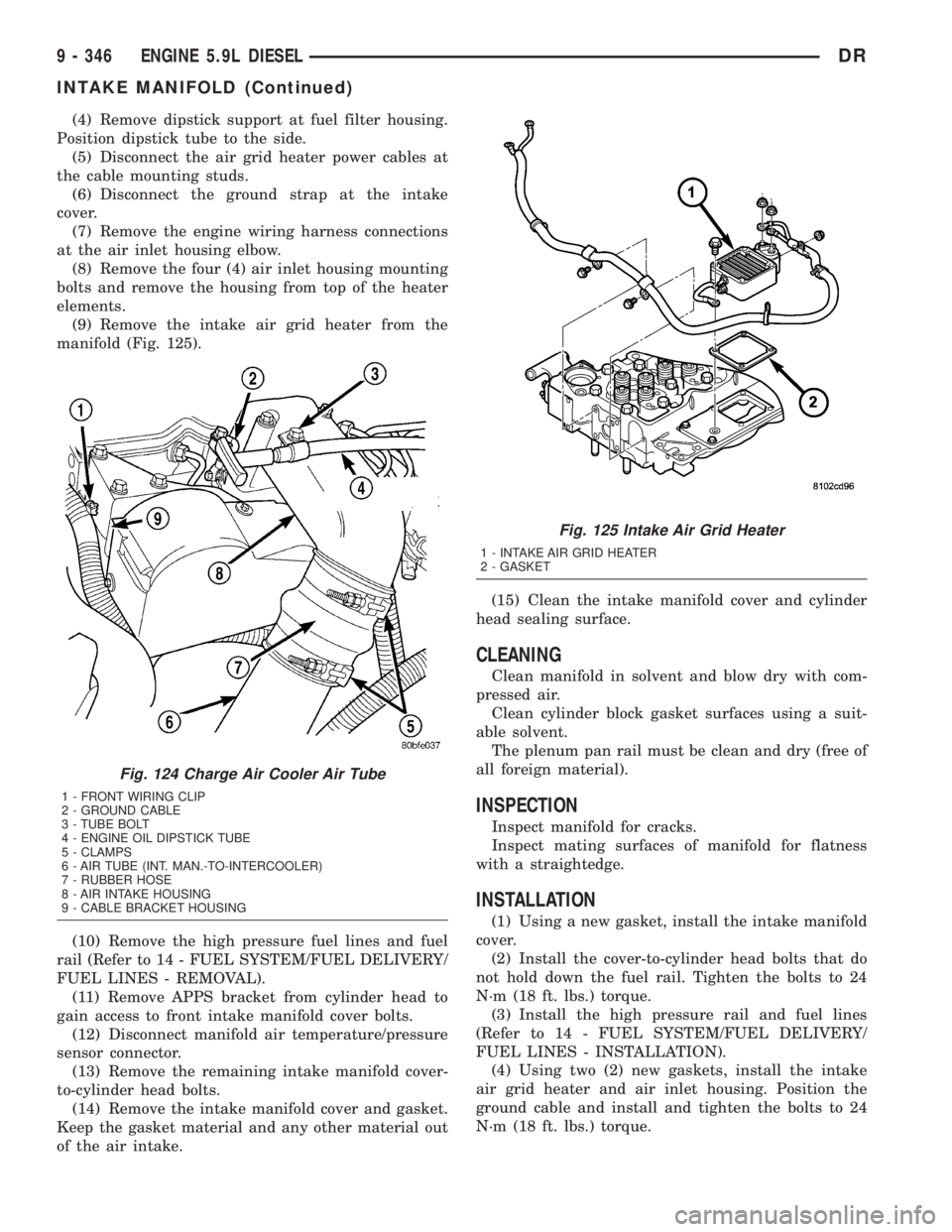

(2) Remove the charge air cooler outlet tube from

the air inlet housing (Fig. 124).

(3) Remove the engine oil dipstick tube mounting

bolt (Fig. 124).

Fig. 120 Measuring Gerotor Planetary to Body Bore

Clearance

1 - BODY BORE

2 - GEROTOR PLANETARY

Fig. 121 Measure Gear Backlash

1 - OIL PUMP DRIVE GEAR

2 - IDLER GEAR

3 - BACKLASH

4 - BACKLASH

Fig. 122 Oil Pump Mounting Bolt Torque Sequence

Fig. 123 Idler Gear to Pump Drive Gear and

Crankshaft Gear Backlash

DRENGINE 5.9L DIESEL 9 - 345

OIL PUMP (Continued)

Page 1595 of 2895

(4) Remove dipstick support at fuel filter housing.

Position dipstick tube to the side.

(5) Disconnect the air grid heater power cables at

the cable mounting studs.

(6) Disconnect the ground strap at the intake

cover.

(7) Remove the engine wiring harness connections

at the air inlet housing elbow.

(8) Remove the four (4) air inlet housing mounting

bolts and remove the housing from top of the heater

elements.

(9) Remove the intake air grid heater from the

manifold (Fig. 125).

(10) Remove the high pressure fuel lines and fuel

rail (Refer to 14 - FUEL SYSTEM/FUEL DELIVERY/

FUEL LINES - REMOVAL).

(11) Remove APPS bracket from cylinder head to

gain access to front intake manifold cover bolts.

(12) Disconnect manifold air temperature/pressure

sensor connector.

(13) Remove the remaining intake manifold cover-

to-cylinder head bolts.

(14) Remove the intake manifold cover and gasket.

Keep the gasket material and any other material out

of the air intake.(15) Clean the intake manifold cover and cylinder

head sealing surface.

CLEANING

Clean manifold in solvent and blow dry with com-

pressed air.

Clean cylinder block gasket surfaces using a suit-

able solvent.

The plenum pan rail must be clean and dry (free of

all foreign material).

INSPECTION

Inspect manifold for cracks.

Inspect mating surfaces of manifold for flatness

with a straightedge.

INSTALLATION

(1) Using a new gasket, install the intake manifold

cover.

(2) Install the cover-to-cylinder head bolts that do

not hold down the fuel rail. Tighten the bolts to 24

N´m (18 ft. lbs.) torque.

(3) Install the high pressure rail and fuel lines

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY/

FUEL LINES - INSTALLATION).

(4) Using two (2) new gaskets, install the intake

air grid heater and air inlet housing. Position the

ground cable and install and tighten the bolts to 24

N´m (18 ft. lbs.) torque.

Fig. 124 Charge Air Cooler Air Tube

1 - FRONT WIRING CLIP

2 - GROUND CABLE

3 - TUBE BOLT

4 - ENGINE OIL DIPSTICK TUBE

5 - CLAMPS

6 - AIR TUBE (INT. MAN.-TO-INTERCOOLER)

7 - RUBBER HOSE

8 - AIR INTAKE HOUSING

9 - CABLE BRACKET HOUSING

Fig. 125 Intake Air Grid Heater

1 - INTAKE AIR GRID HEATER

2 - GASKET

9 - 346 ENGINE 5.9L DIESELDR

INTAKE MANIFOLD (Continued)

Page 1596 of 2895

(5) Connect the manifold air temperature/pressure

sensor connector.

(6) Install and tighten the air intake heater power

supply nuts to 14 N´m (120 in. lbs.) torque.

(7) Install the APPS bracket. Torque fasteners to

43 N´m (32ft lbs.) torque.

(8) Install oil dipstick tube support at fuel filter

housing.

(9) Install the engine oil dipstick tube and mount-

ing bolt.

(10) Position the charge air cooler outlet tube onto

the air inlet housing. Tighten the clamps to 8 N´m

(72 in. lbs.) torque.

(11) Attach the engine wire harness to the air inlet

housing at two locations.

(12) Prime the fuel system. Refer to the fuel prim-

ing procedure in Group 14, Fuel System.

(13) Connect the battery negative cables.

EXHAUST MANIFOLD

REMOVAL

(1) Disconnect the battery negative cables.

(2) Raise vehicle on hoist.

(3) Disconnect the exhaust pipe from the turbo-

charger elbow.

(4) Lower vehicle.

(5) Disconnect the turbocharger air inlet hose.

(6) Remove air cleaner assembly.

(7) Disconnect the turbocharger oil supply line and

the oil drain tube from the turbocharger.

(8) Disconnect the charge air cooler inlet pipe from

the turbocharger.

(9) Remove the turbocharger and gasket from the

exhaust manifold.

(10) Remove the cab heater return pipe nuts from

the exhaust manifold stud. Position the tube out of

the way.

(11) Remove heat shield.

(12) Remove exhaust manifold bolt lockplates.

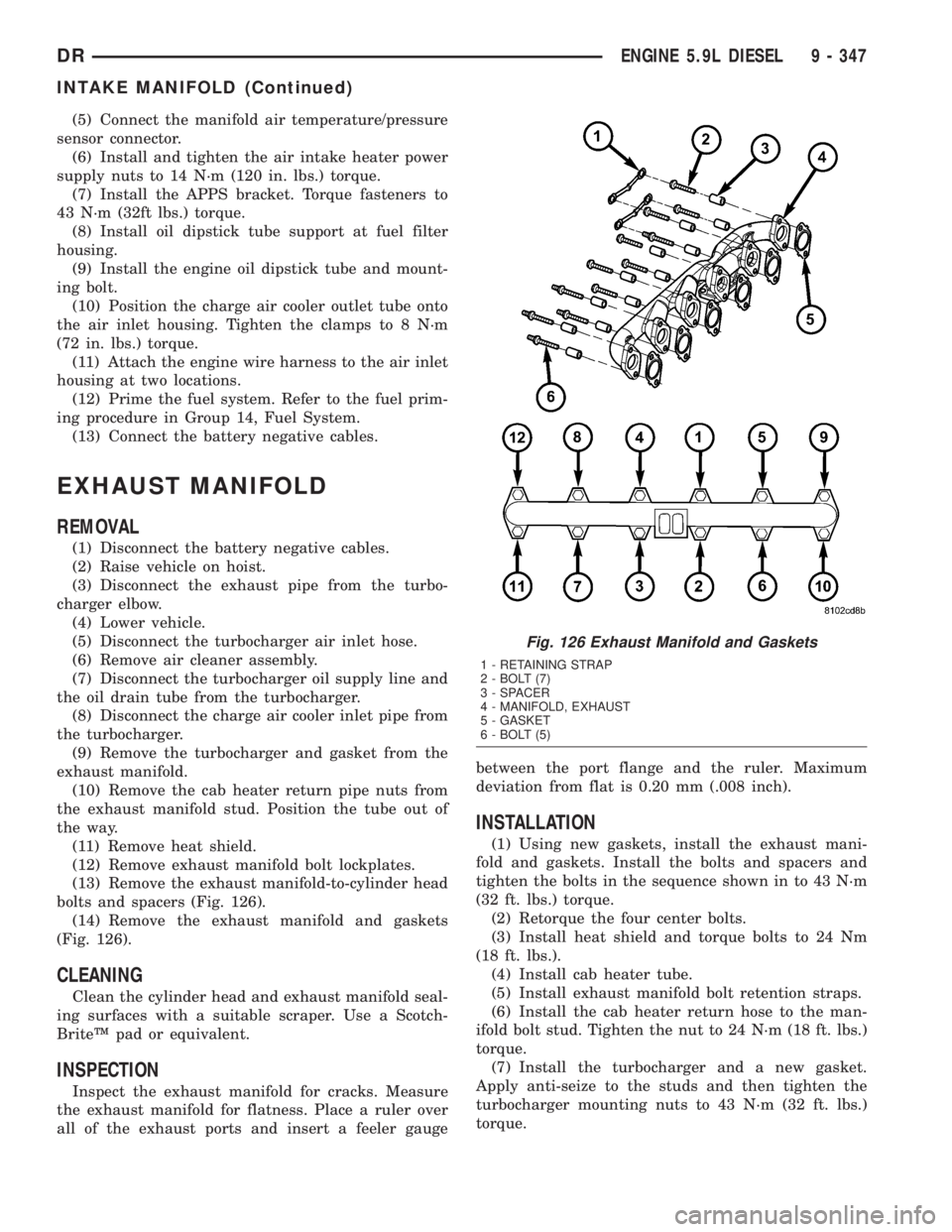

(13) Remove the exhaust manifold-to-cylinder head

bolts and spacers (Fig. 126).

(14) Remove the exhaust manifold and gaskets

(Fig. 126).

CLEANING

Clean the cylinder head and exhaust manifold seal-

ing surfaces with a suitable scraper. Use a Scotch-

BriteŸ pad or equivalent.

INSPECTION

Inspect the exhaust manifold for cracks. Measure

the exhaust manifold for flatness. Place a ruler over

all of the exhaust ports and insert a feeler gaugebetween the port flange and the ruler. Maximum

deviation from flat is 0.20 mm (.008 inch).

INSTALLATION

(1) Using new gaskets, install the exhaust mani-

fold and gaskets. Install the bolts and spacers and

tighten the bolts in the sequence shown in to 43 N´m

(32 ft. lbs.) torque.

(2) Retorque the four center bolts.

(3) Install heat shield and torque bolts to 24 Nm

(18 ft. lbs.).

(4) Install cab heater tube.

(5) Install exhaust manifold bolt retention straps.

(6) Install the cab heater return hose to the man-

ifold bolt stud. Tighten the nut to 24 N´m (18 ft. lbs.)

torque.

(7) Install the turbocharger and a new gasket.

Apply anti-seize to the studs and then tighten the

turbocharger mounting nuts to 43 N´m (32 ft. lbs.)

torque.

Fig. 126 Exhaust Manifold and Gaskets

1 - RETAINING STRAP

2 - BOLT (7)

3 - SPACER

4 - MANIFOLD, EXHAUST

5 - GASKET

6 - BOLT (5)

DRENGINE 5.9L DIESEL 9 - 347

INTAKE MANIFOLD (Continued)