Actuator DODGE RAM 2003 Service Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1162 of 2895

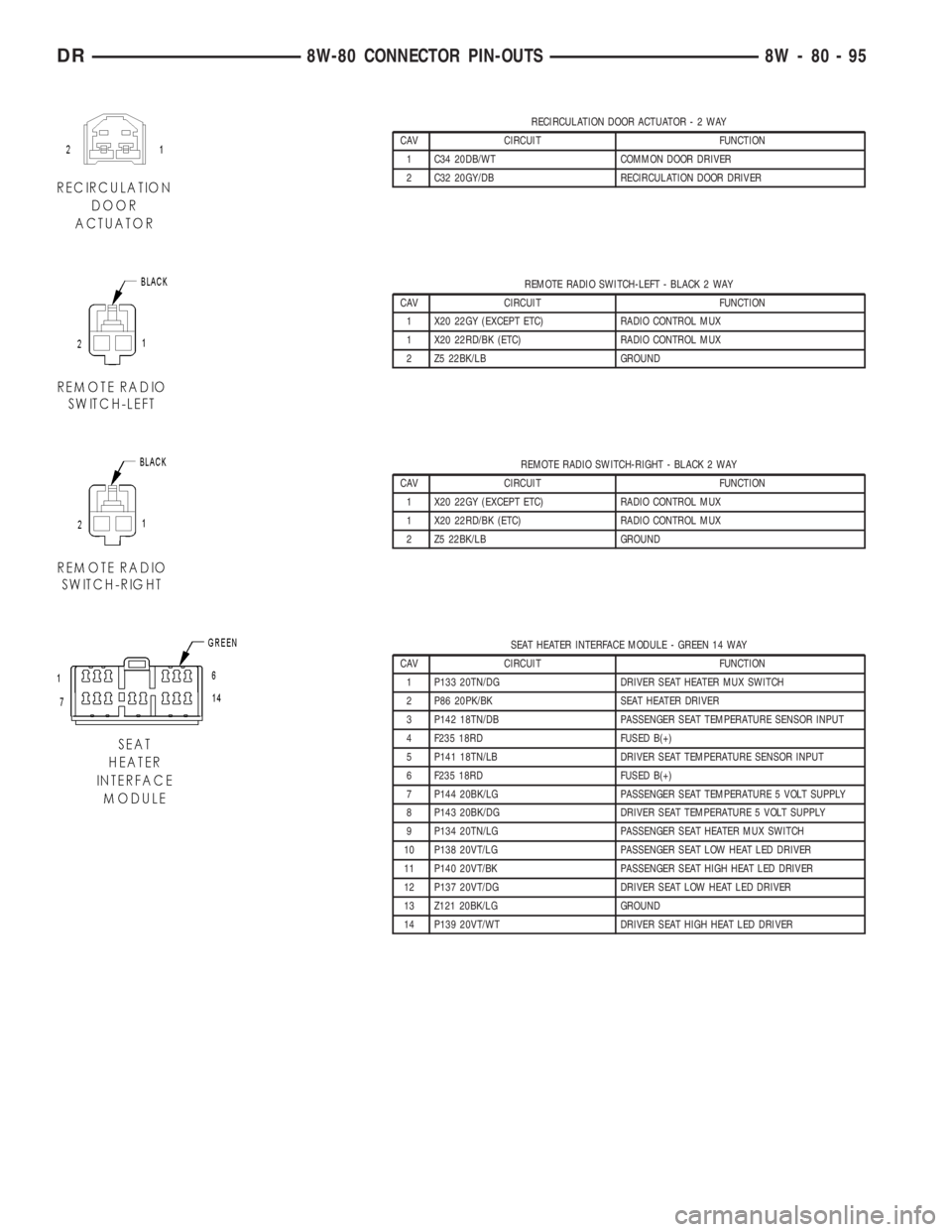

RECIRCULATION DOOR ACTUATOR-2WAY

CAV CIRCUIT FUNCTION

1 C34 20DB/WT COMMON DOOR DRIVER

2 C32 20GY/DB RECIRCULATION DOOR DRIVER

REMOTE RADIO SWITCH-LEFT - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 X20 22GY (EXCEPT ETC) RADIO CONTROL MUX

1 X20 22RD/BK (ETC) RADIO CONTROL MUX

2 Z5 22BK/LB GROUND

REMOTE RADIO SWITCH-RIGHT - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 X20 22GY (EXCEPT ETC) RADIO CONTROL MUX

1 X20 22RD/BK (ETC) RADIO CONTROL MUX

2 Z5 22BK/LB GROUND

SEAT HEATER INTERFACE MODULE - GREEN 14 WAY

CAV CIRCUIT FUNCTION

1 P133 20TN/DG DRIVER SEAT HEATER MUX SWITCH

2 P86 20PK/BK SEAT HEATER DRIVER

3 P142 18TN/DB PASSENGER SEAT TEMPERATURE SENSOR INPUT

4 F235 18RD FUSED B(+)

5 P141 18TN/LB DRIVER SEAT TEMPERATURE SENSOR INPUT

6 F235 18RD FUSED B(+)

7 P144 20BK/LG PASSENGER SEAT TEMPERATURE 5 VOLT SUPPLY

8 P143 20BK/DG DRIVER SEAT TEMPERATURE 5 VOLT SUPPLY

9 P134 20TN/LG PASSENGER SEAT HEATER MUX SWITCH

10 P138 20VT/LG PASSENGER SEAT LOW HEAT LED DRIVER

11 P140 20VT/BK PASSENGER SEAT HIGH HEAT LED DRIVER

12 P137 20VT/DG DRIVER SEAT LOW HEAT LED DRIVER

13 Z121 20BK/LG GROUND

14 P139 20VT/WT DRIVER SEAT HIGH HEAT LED DRIVER

DR8W-80 CONNECTOR PIN-OUTS 8W - 80 - 95

Page 1178 of 2895

8W-91 CONNECTOR/GROUND/SPLICE LOCATION

TABLE OF CONTENTS

page

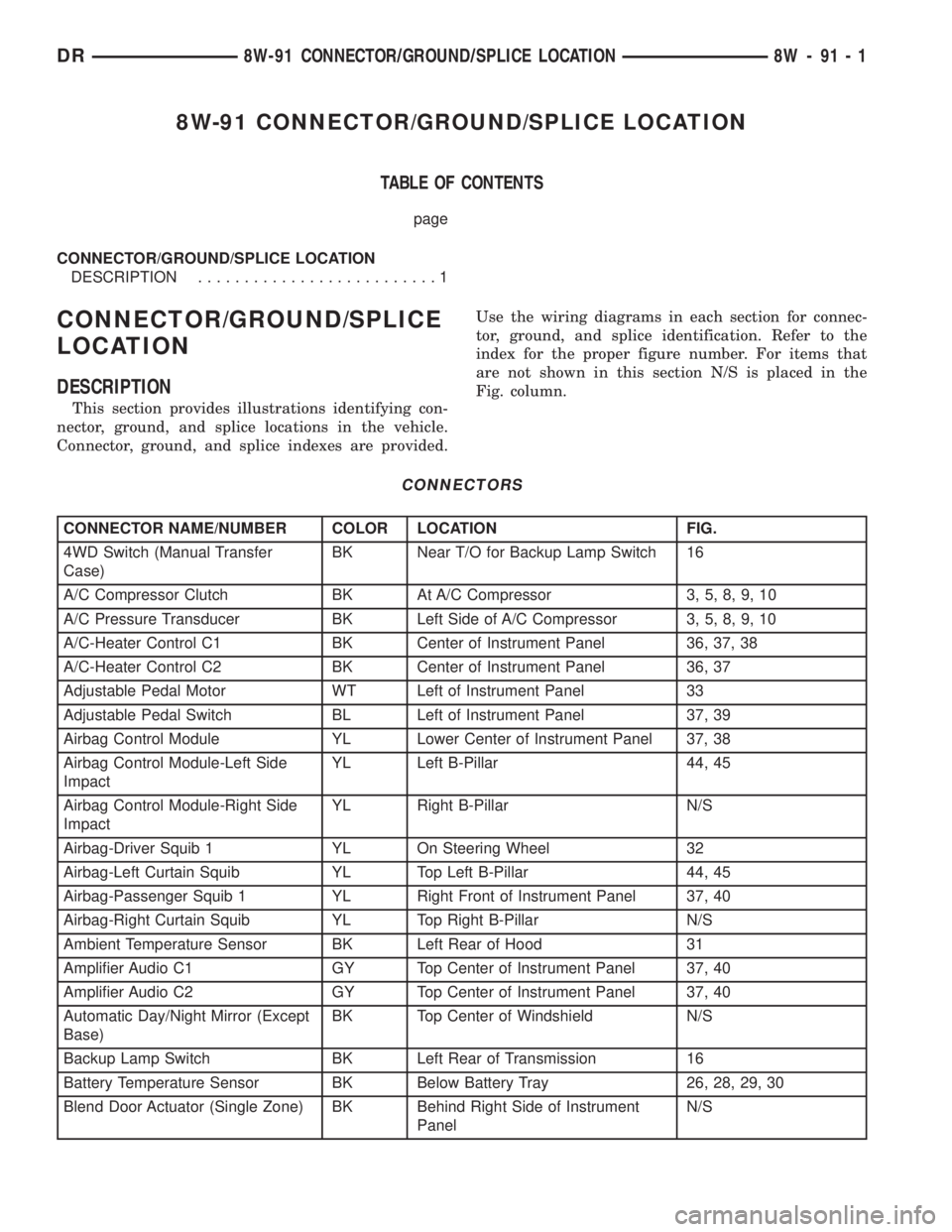

CONNECTOR/GROUND/SPLICE LOCATION

DESCRIPTION..........................1

CONNECTOR/GROUND/SPLICE

LOCATION

DESCRIPTION

This section provides illustrations identifying con-

nector, ground, and splice locations in the vehicle.

Connector, ground, and splice indexes are provided.Use the wiring diagrams in each section for connec-

tor, ground, and splice identification. Refer to the

index for the proper figure number. For items that

are not shown in this section N/S is placed in the

Fig. column.

CONNECTORS

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

4WD Switch (Manual Transfer

Case)BK Near T/O for Backup Lamp Switch 16

A/C Compressor Clutch BK At A/C Compressor 3, 5, 8, 9, 10

A/C Pressure Transducer BK Left Side of A/C Compressor 3, 5, 8, 9, 10

A/C-Heater Control C1 BK Center of Instrument Panel 36, 37, 38

A/C-Heater Control C2 BK Center of Instrument Panel 36, 37

Adjustable Pedal Motor WT Left of Instrument Panel 33

Adjustable Pedal Switch BL Left of Instrument Panel 37, 39

Airbag Control Module YL Lower Center of Instrument Panel 37, 38

Airbag Control Module-Left Side

ImpactYL Left B-Pillar 44, 45

Airbag Control Module-Right Side

ImpactYL Right B-Pillar N/S

Airbag-Driver Squib 1 YL On Steering Wheel 32

Airbag-Left Curtain Squib YL Top Left B-Pillar 44, 45

Airbag-Passenger Squib 1 YL Right Front of Instrument Panel 37, 40

Airbag-Right Curtain Squib YL Top Right B-Pillar N/S

Ambient Temperature Sensor BK Left Rear of Hood 31

Amplifier Audio C1 GY Top Center of Instrument Panel 37, 40

Amplifier Audio C2 GY Top Center of Instrument Panel 37, 40

Automatic Day/Night Mirror (Except

Base)BK Top Center of Windshield N/S

Backup Lamp Switch BK Left Rear of Transmission 16

Battery Temperature Sensor BK Below Battery Tray 26, 28, 29, 30

Blend Door Actuator (Single Zone) BK Behind Right Side of Instrument

PanelN/S

DR8W-91 CONNECTOR/GROUND/SPLICE LOCATION 8W - 91 - 1

Page 1181 of 2895

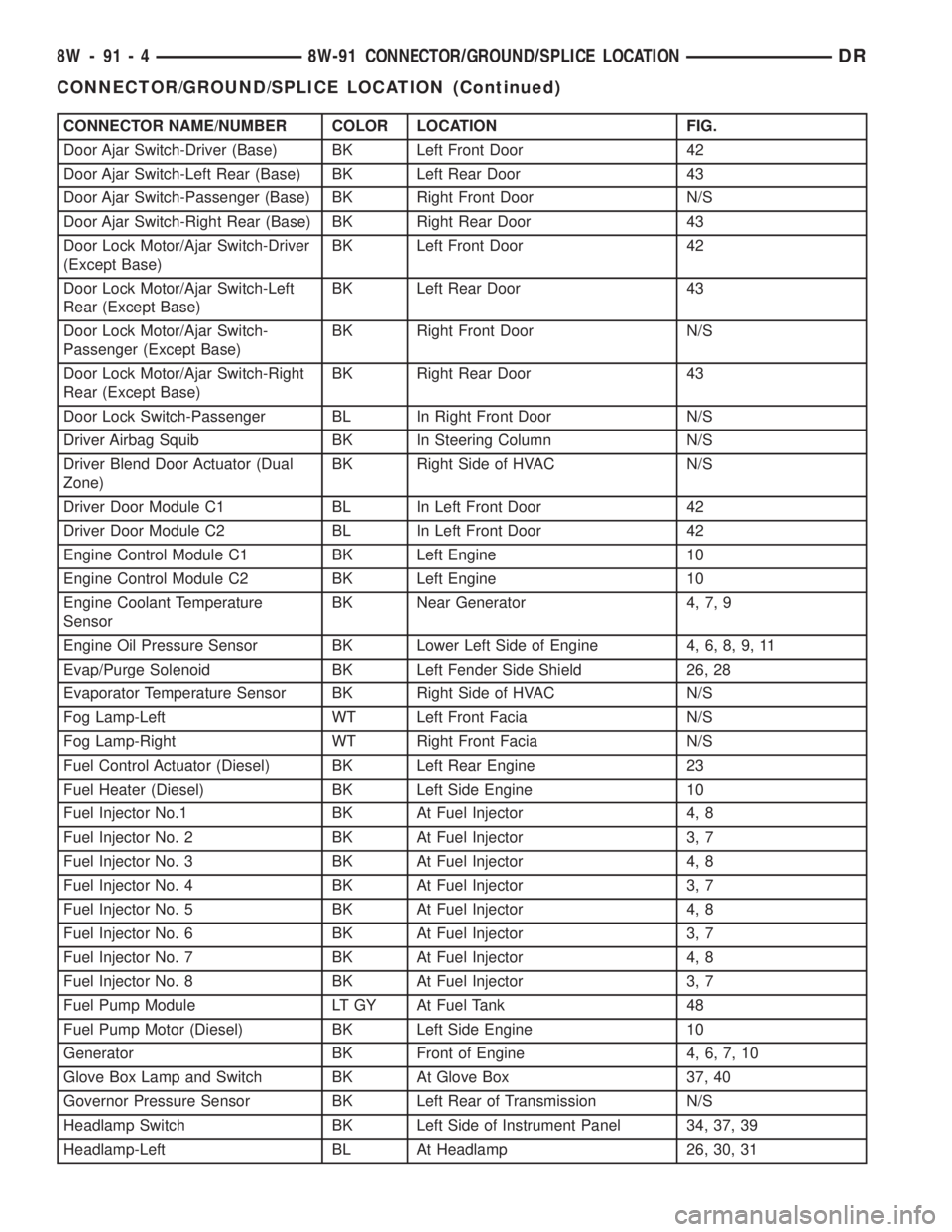

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Door Ajar Switch-Driver (Base) BK Left Front Door 42

Door Ajar Switch-Left Rear (Base) BK Left Rear Door 43

Door Ajar Switch-Passenger (Base) BK Right Front Door N/S

Door Ajar Switch-Right Rear (Base) BK Right Rear Door 43

Door Lock Motor/Ajar Switch-Driver

(Except Base)BK Left Front Door 42

Door Lock Motor/Ajar Switch-Left

Rear (Except Base)BK Left Rear Door 43

Door Lock Motor/Ajar Switch-

Passenger (Except Base)BK Right Front Door N/S

Door Lock Motor/Ajar Switch-Right

Rear (Except Base)BK Right Rear Door 43

Door Lock Switch-Passenger BL In Right Front Door N/S

Driver Airbag Squib BK In Steering Column N/S

Driver Blend Door Actuator (Dual

Zone)BK Right Side of HVAC N/S

Driver Door Module C1 BL In Left Front Door 42

Driver Door Module C2 BL In Left Front Door 42

Engine Control Module C1 BK Left Engine 10

Engine Control Module C2 BK Left Engine 10

Engine Coolant Temperature

SensorBK Near Generator 4, 7, 9

Engine Oil Pressure Sensor BK Lower Left Side of Engine 4, 6, 8, 9, 11

Evap/Purge Solenoid BK Left Fender Side Shield 26, 28

Evaporator Temperature Sensor BK Right Side of HVAC N/S

Fog Lamp-Left WT Left Front Facia N/S

Fog Lamp-Right WT Right Front Facia N/S

Fuel Control Actuator (Diesel) BK Left Rear Engine 23

Fuel Heater (Diesel) BK Left Side Engine 10

Fuel Injector No.1 BK At Fuel Injector 4, 8

Fuel Injector No. 2 BK At Fuel Injector 3, 7

Fuel Injector No. 3 BK At Fuel Injector 4, 8

Fuel Injector No. 4 BK At Fuel Injector 3, 7

Fuel Injector No. 5 BK At Fuel Injector 4, 8

Fuel Injector No. 6 BK At Fuel Injector 3, 7

Fuel Injector No. 7 BK At Fuel Injector 4, 8

Fuel Injector No. 8 BK At Fuel Injector 3, 7

Fuel Pump Module LT GY At Fuel Tank 48

Fuel Pump Motor (Diesel) BK Left Side Engine 10

Generator BK Front of Engine 4, 6, 7, 10

Glove Box Lamp and Switch BK At Glove Box 37, 40

Governor Pressure Sensor BK Left Rear of Transmission N/S

Headlamp Switch BK Left Side of Instrument Panel 34, 37, 39

Headlamp-Left BL At Headlamp 26, 30, 31

8W - 91 - 4 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONDR

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1183 of 2895

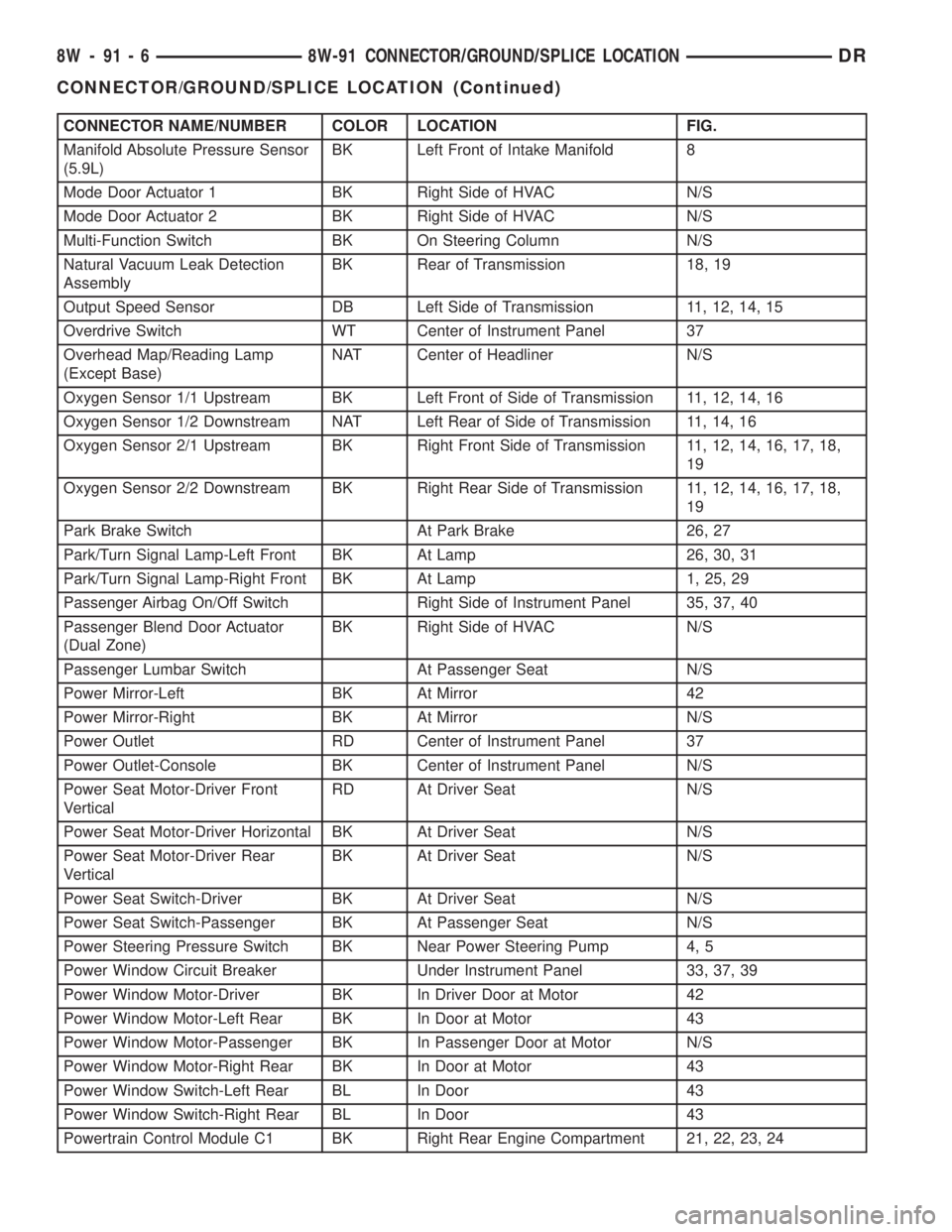

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Manifold Absolute Pressure Sensor

(5.9L)BK Left Front of Intake Manifold 8

Mode Door Actuator 1 BK Right Side of HVAC N/S

Mode Door Actuator 2 BK Right Side of HVAC N/S

Multi-Function Switch BK On Steering Column N/S

Natural Vacuum Leak Detection

AssemblyBK Rear of Transmission 18, 19

Output Speed Sensor DB Left Side of Transmission 11, 12, 14, 15

Overdrive Switch WT Center of Instrument Panel 37

Overhead Map/Reading Lamp

(Except Base)NAT Center of Headliner N/S

Oxygen Sensor 1/1 Upstream BK Left Front of Side of Transmission 11, 12, 14, 16

Oxygen Sensor 1/2 Downstream NAT Left Rear of Side of Transmission 11, 14, 16

Oxygen Sensor 2/1 Upstream BK Right Front Side of Transmission 11, 12, 14, 16, 17, 18,

19

Oxygen Sensor 2/2 Downstream BK Right Rear Side of Transmission 11, 12, 14, 16, 17, 18,

19

Park Brake Switch At Park Brake 26, 27

Park/Turn Signal Lamp-Left Front BK At Lamp 26, 30, 31

Park/Turn Signal Lamp-Right Front BK At Lamp 1, 25, 29

Passenger Airbag On/Off Switch Right Side of Instrument Panel 35, 37, 40

Passenger Blend Door Actuator

(Dual Zone)BK Right Side of HVAC N/S

Passenger Lumbar Switch At Passenger Seat N/S

Power Mirror-Left BK At Mirror 42

Power Mirror-Right BK At Mirror N/S

Power Outlet RD Center of Instrument Panel 37

Power Outlet-Console BK Center of Instrument Panel N/S

Power Seat Motor-Driver Front

VerticalRD At Driver Seat N/S

Power Seat Motor-Driver Horizontal BK At Driver Seat N/S

Power Seat Motor-Driver Rear

VerticalBK At Driver Seat N/S

Power Seat Switch-Driver BK At Driver Seat N/S

Power Seat Switch-Passenger BK At Passenger Seat N/S

Power Steering Pressure Switch BK Near Power Steering Pump 4, 5

Power Window Circuit Breaker Under Instrument Panel 33, 37, 39

Power Window Motor-Driver BK In Driver Door at Motor 42

Power Window Motor-Left Rear BK In Door at Motor 43

Power Window Motor-Passenger BK In Passenger Door at Motor N/S

Power Window Motor-Right Rear BK In Door at Motor 43

Power Window Switch-Left Rear BL In Door 43

Power Window Switch-Right Rear BL In Door 43

Powertrain Control Module C1 BK Right Rear Engine Compartment 21, 22, 23, 24

8W - 91 - 6 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONDR

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1184 of 2895

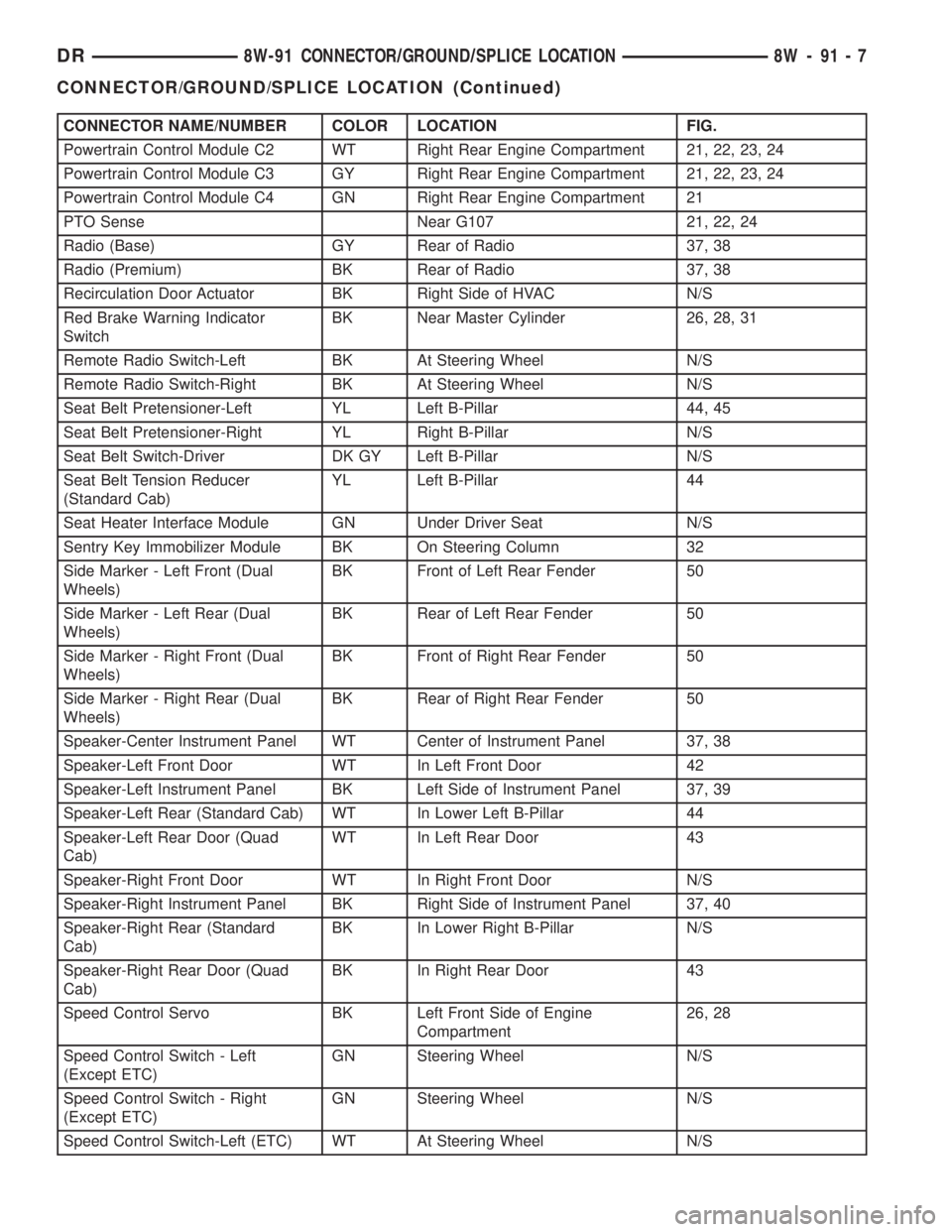

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Powertrain Control Module C2 WT Right Rear Engine Compartment 21, 22, 23, 24

Powertrain Control Module C3 GY Right Rear Engine Compartment 21, 22, 23, 24

Powertrain Control Module C4 GN Right Rear Engine Compartment 21

PTO Sense Near G107 21, 22, 24

Radio (Base) GY Rear of Radio 37, 38

Radio (Premium) BK Rear of Radio 37, 38

Recirculation Door Actuator BK Right Side of HVAC N/S

Red Brake Warning Indicator

SwitchBK Near Master Cylinder 26, 28, 31

Remote Radio Switch-Left BK At Steering Wheel N/S

Remote Radio Switch-Right BK At Steering Wheel N/S

Seat Belt Pretensioner-Left YL Left B-Pillar 44, 45

Seat Belt Pretensioner-Right YL Right B-Pillar N/S

Seat Belt Switch-Driver DK GY Left B-Pillar N/S

Seat Belt Tension Reducer

(Standard Cab)YL Left B-Pillar 44

Seat Heater Interface Module GN Under Driver Seat N/S

Sentry Key Immobilizer Module BK On Steering Column 32

Side Marker - Left Front (Dual

Wheels)BK Front of Left Rear Fender 50

Side Marker - Left Rear (Dual

Wheels)BK Rear of Left Rear Fender 50

Side Marker - Right Front (Dual

Wheels)BK Front of Right Rear Fender 50

Side Marker - Right Rear (Dual

Wheels)BK Rear of Right Rear Fender 50

Speaker-Center Instrument Panel WT Center of Instrument Panel 37, 38

Speaker-Left Front Door WT In Left Front Door 42

Speaker-Left Instrument Panel BK Left Side of Instrument Panel 37, 39

Speaker-Left Rear (Standard Cab) WT In Lower Left B-Pillar 44

Speaker-Left Rear Door (Quad

Cab)WT In Left Rear Door 43

Speaker-Right Front Door WT In Right Front Door N/S

Speaker-Right Instrument Panel BK Right Side of Instrument Panel 37, 40

Speaker-Right Rear (Standard

Cab)BK In Lower Right B-Pillar N/S

Speaker-Right Rear Door (Quad

Cab)BK In Right Rear Door 43

Speed Control Servo BK Left Front Side of Engine

Compartment26, 28

Speed Control Switch - Left

(Except ETC)GN Steering Wheel N/S

Speed Control Switch - Right

(Except ETC)GN Steering Wheel N/S

Speed Control Switch-Left (ETC) WT At Steering Wheel N/S

DR8W-91 CONNECTOR/GROUND/SPLICE LOCATION 8W - 91 - 7

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1187 of 2895

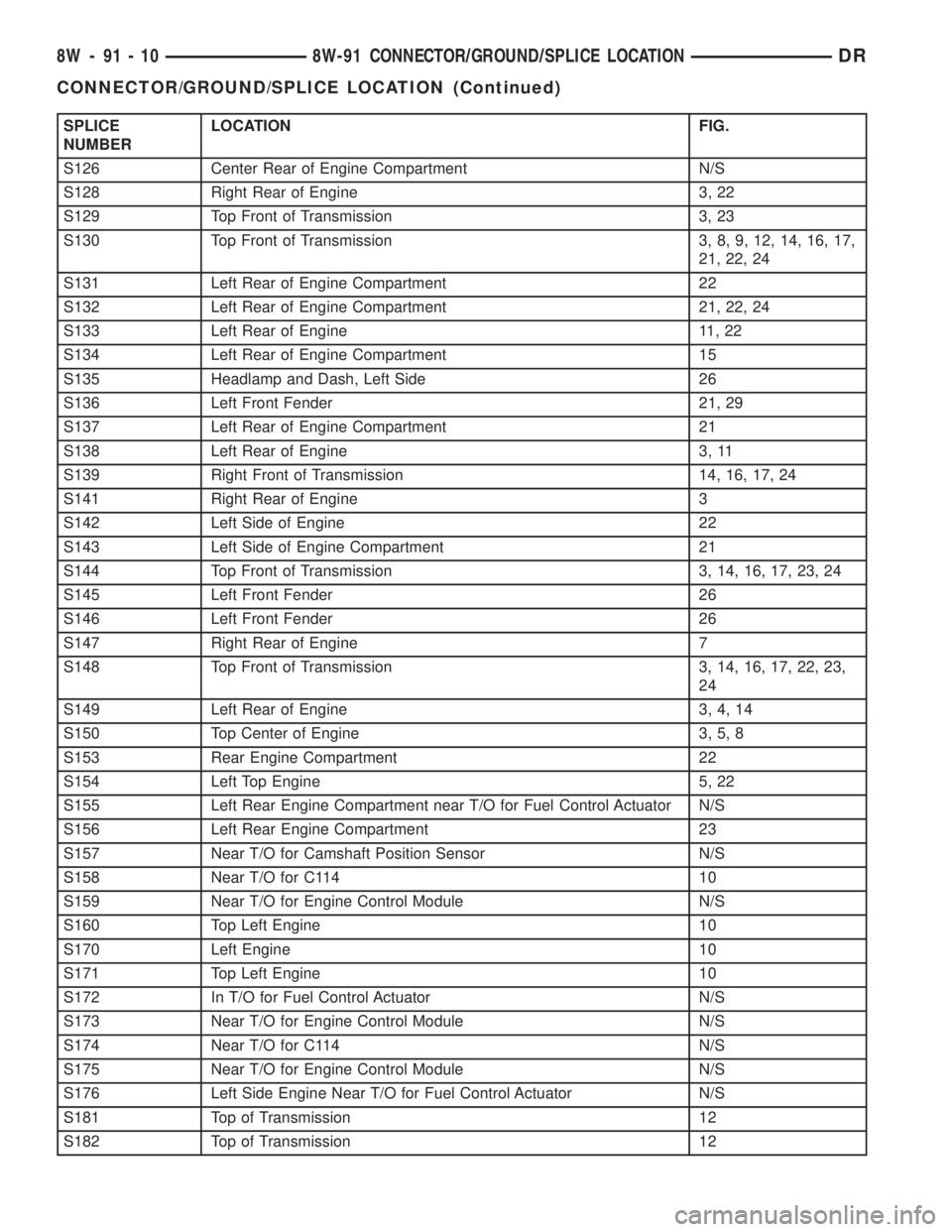

SPLICE

NUMBERLOCATION FIG.

S126 Center Rear of Engine Compartment N/S

S128 Right Rear of Engine 3, 22

S129 Top Front of Transmission 3, 23

S130 Top Front of Transmission 3, 8, 9, 12, 14, 16, 17,

21, 22, 24

S131 Left Rear of Engine Compartment 22

S132 Left Rear of Engine Compartment 21, 22, 24

S133 Left Rear of Engine 11, 22

S134 Left Rear of Engine Compartment 15

S135 Headlamp and Dash, Left Side 26

S136 Left Front Fender 21, 29

S137 Left Rear of Engine Compartment 21

S138 Left Rear of Engine 3, 11

S139 Right Front of Transmission 14, 16, 17, 24

S141 Right Rear of Engine 3

S142 Left Side of Engine 22

S143 Left Side of Engine Compartment 21

S144 Top Front of Transmission 3, 14, 16, 17, 23, 24

S145 Left Front Fender 26

S146 Left Front Fender 26

S147 Right Rear of Engine 7

S148 Top Front of Transmission 3, 14, 16, 17, 22, 23,

24

S149 Left Rear of Engine 3, 4, 14

S150 Top Center of Engine 3, 5, 8

S153 Rear Engine Compartment 22

S154 Left Top Engine 5, 22

S155 Left Rear Engine Compartment near T/O for Fuel Control Actuator N/S

S156 Left Rear Engine Compartment 23

S157 Near T/O for Camshaft Position Sensor N/S

S158 Near T/O for C114 10

S159 Near T/O for Engine Control Module N/S

S160 Top Left Engine 10

S170 Left Engine 10

S171 Top Left Engine 10

S172 In T/O for Fuel Control Actuator N/S

S173 Near T/O for Engine Control Module N/S

S174 Near T/O for C114 N/S

S175 Near T/O for Engine Control Module N/S

S176 Left Side Engine Near T/O for Fuel Control Actuator N/S

S181 Top of Transmission 12

S182 Top of Transmission 12

8W - 91 - 10 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONDR

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1667 of 2895

²Improved operating economy

²Altitude compensation

²Noise reduction.

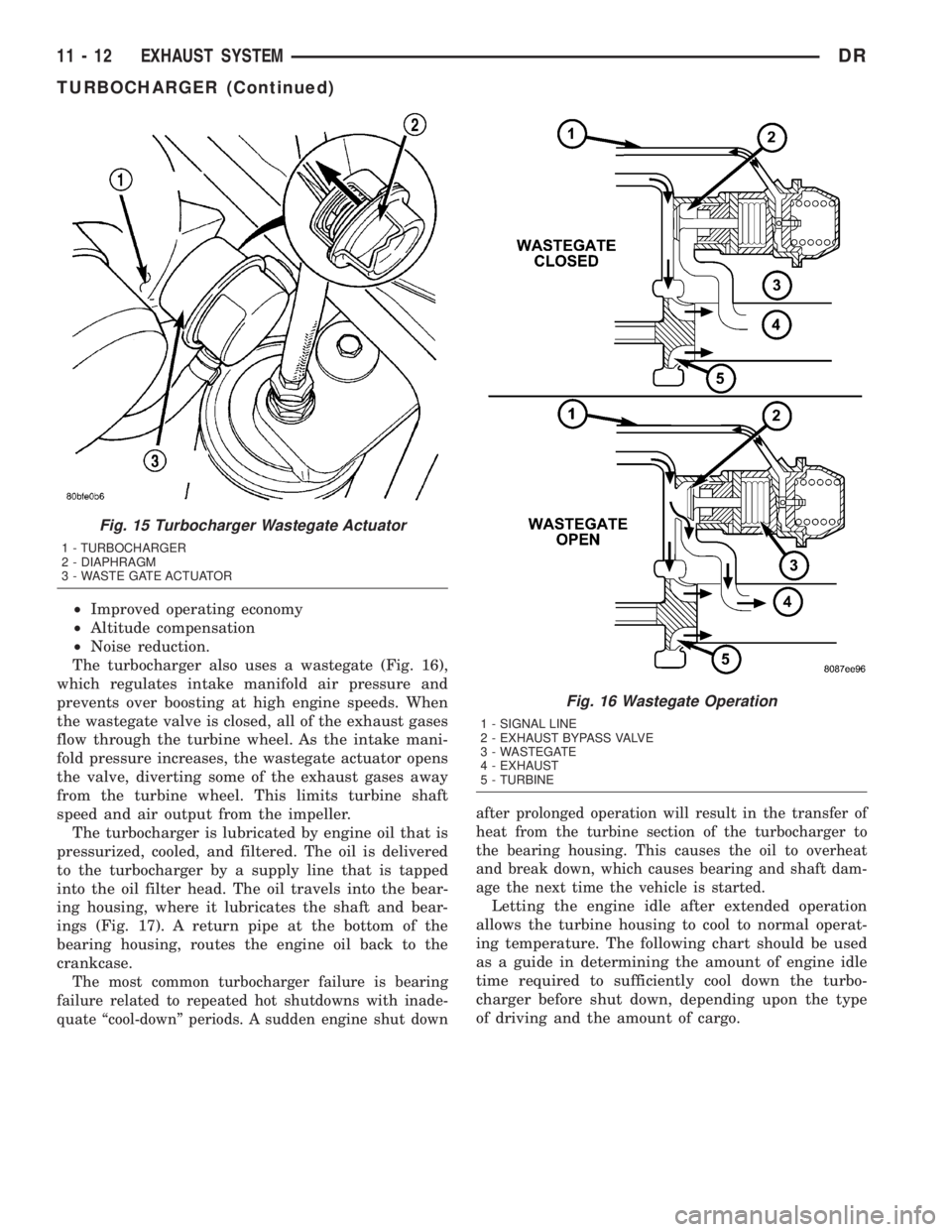

The turbocharger also uses a wastegate (Fig. 16),

which regulates intake manifold air pressure and

prevents over boosting at high engine speeds. When

the wastegate valve is closed, all of the exhaust gases

flow through the turbine wheel. As the intake mani-

fold pressure increases, the wastegate actuator opens

the valve, diverting some of the exhaust gases away

from the turbine wheel. This limits turbine shaft

speed and air output from the impeller.

The turbocharger is lubricated by engine oil that is

pressurized, cooled, and filtered. The oil is delivered

to the turbocharger by a supply line that is tapped

into the oil filter head. The oil travels into the bear-

ing housing, where it lubricates the shaft and bear-

ings (Fig. 17). A return pipe at the bottom of the

bearing housing, routes the engine oil back to the

crankcase.

The most common turbocharger failure is bearing

failure related to repeated hot shutdowns with inade-

quate ªcool-downº periods. A sudden engine shut downafter prolonged operation will result in the transfer of

heat from the turbine section of the turbocharger to

the bearing housing. This causes the oil to overheat

and break down, which causes bearing and shaft dam-

age the next time the vehicle is started.

Letting the engine idle after extended operation

allows the turbine housing to cool to normal operat-

ing temperature. The following chart should be used

as a guide in determining the amount of engine idle

time required to sufficiently cool down the turbo-

charger before shut down, depending upon the type

of driving and the amount of cargo.

Fig. 15 Turbocharger Wastegate Actuator

1 - TURBOCHARGER

2 - DIAPHRAGM

3 - WASTE GATE ACTUATOR

Fig. 16 Wastegate Operation

1 - SIGNAL LINE

2 - EXHAUST BYPASS VALVE

3 - WASTEGATE

4 - EXHAUST

5 - TURBINE

11 - 12 EXHAUST SYSTEMDR

TURBOCHARGER (Continued)

Page 1754 of 2895

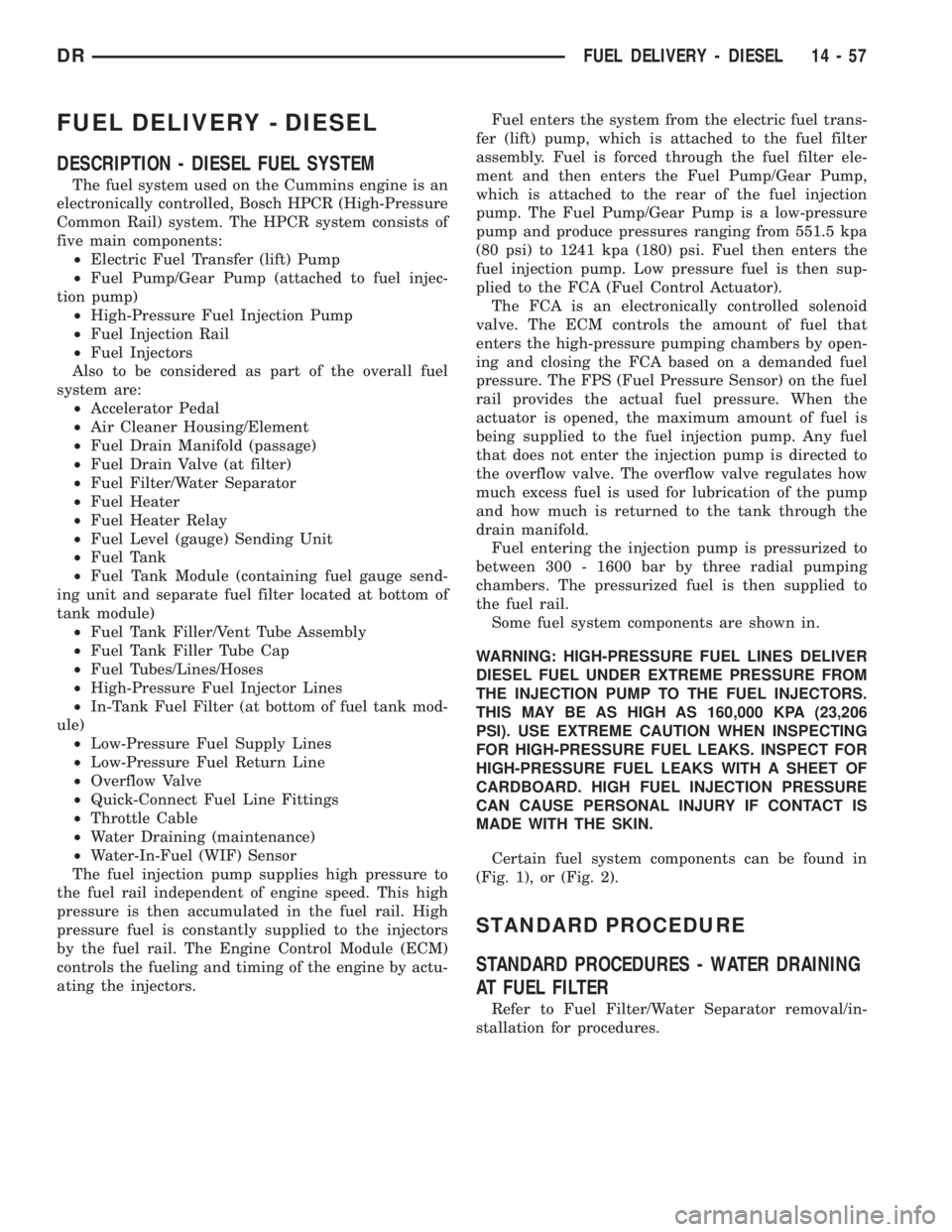

FUEL DELIVERY - DIESEL

DESCRIPTION - DIESEL FUEL SYSTEM

The fuel system used on the Cummins engine is an

electronically controlled, Bosch HPCR (High-Pressure

Common Rail) system. The HPCR system consists of

five main components:

²Electric Fuel Transfer (lift) Pump

²Fuel Pump/Gear Pump (attached to fuel injec-

tion pump)

²High-Pressure Fuel Injection Pump

²Fuel Injection Rail

²Fuel Injectors

Also to be considered as part of the overall fuel

system are:

²Accelerator Pedal

²Air Cleaner Housing/Element

²Fuel Drain Manifold (passage)

²Fuel Drain Valve (at filter)

²Fuel Filter/Water Separator

²Fuel Heater

²Fuel Heater Relay

²Fuel Level (gauge) Sending Unit

²Fuel Tank

²Fuel Tank Module (containing fuel gauge send-

ing unit and separate fuel filter located at bottom of

tank module)

²Fuel Tank Filler/Vent Tube Assembly

²Fuel Tank Filler Tube Cap

²Fuel Tubes/Lines/Hoses

²High-Pressure Fuel Injector Lines

²In-Tank Fuel Filter (at bottom of fuel tank mod-

ule)

²Low-Pressure Fuel Supply Lines

²Low-Pressure Fuel Return Line

²Overflow Valve

²Quick-Connect Fuel Line Fittings

²Throttle Cable

²Water Draining (maintenance)

²Water-In-Fuel (WIF) Sensor

The fuel injection pump supplies high pressure to

the fuel rail independent of engine speed. This high

pressure is then accumulated in the fuel rail. High

pressure fuel is constantly supplied to the injectors

by the fuel rail. The Engine Control Module (ECM)

controls the fueling and timing of the engine by actu-

ating the injectors.Fuel enters the system from the electric fuel trans-

fer (lift) pump, which is attached to the fuel filter

assembly. Fuel is forced through the fuel filter ele-

ment and then enters the Fuel Pump/Gear Pump,

which is attached to the rear of the fuel injection

pump. The Fuel Pump/Gear Pump is a low-pressure

pump and produce pressures ranging from 551.5 kpa

(80 psi) to 1241 kpa (180) psi. Fuel then enters the

fuel injection pump. Low pressure fuel is then sup-

plied to the FCA (Fuel Control Actuator).

The FCA is an electronically controlled solenoid

valve. The ECM controls the amount of fuel that

enters the high-pressure pumping chambers by open-

ing and closing the FCA based on a demanded fuel

pressure. The FPS (Fuel Pressure Sensor) on the fuel

rail provides the actual fuel pressure. When the

actuator is opened, the maximum amount of fuel is

being supplied to the fuel injection pump. Any fuel

that does not enter the injection pump is directed to

the overflow valve. The overflow valve regulates how

much excess fuel is used for lubrication of the pump

and how much is returned to the tank through the

drain manifold.

Fuel entering the injection pump is pressurized to

between 300 - 1600 bar by three radial pumping

chambers. The pressurized fuel is then supplied to

the fuel rail.

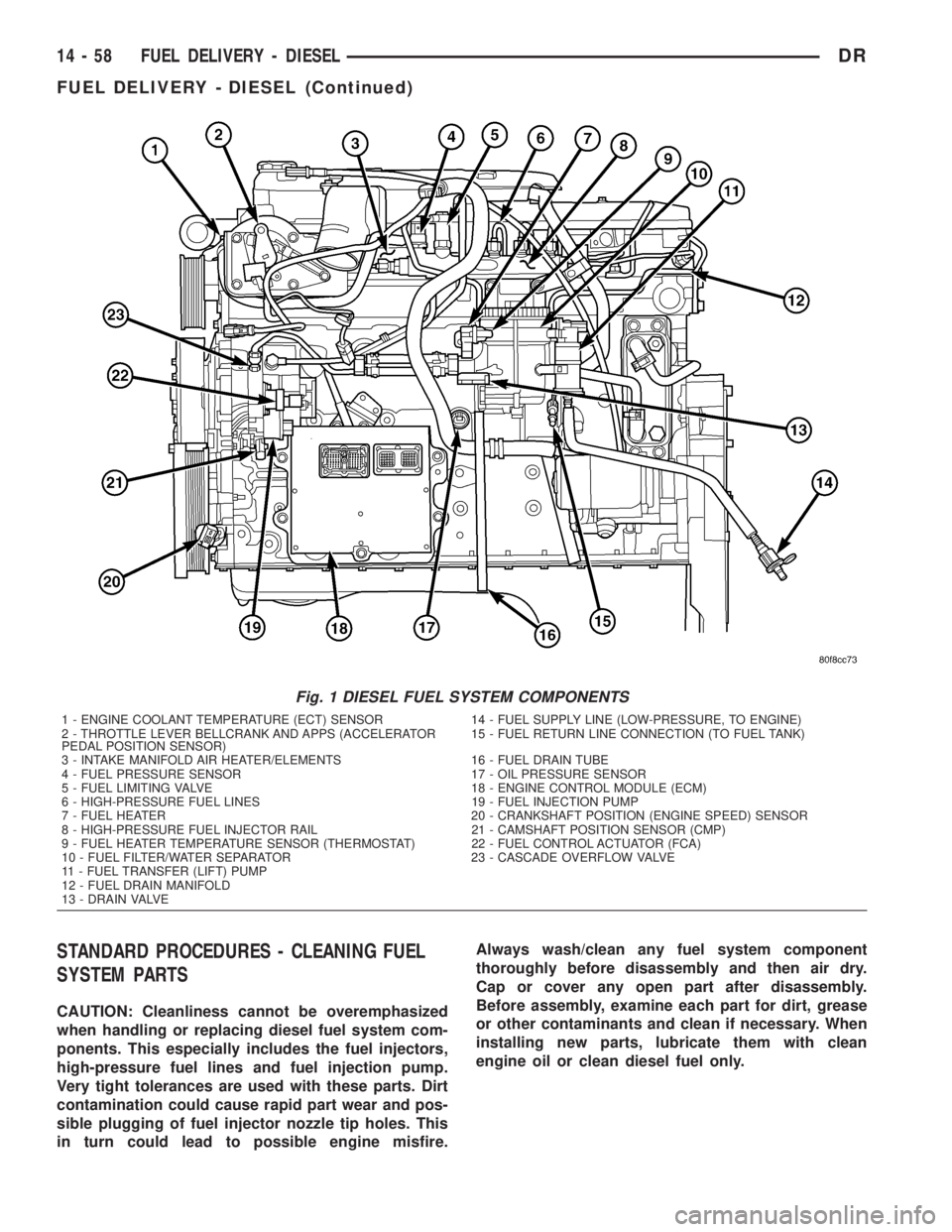

Some fuel system components are shown in.

WARNING: HIGH-PRESSURE FUEL LINES DELIVER

DIESEL FUEL UNDER EXTREME PRESSURE FROM

THE INJECTION PUMP TO THE FUEL INJECTORS.

THIS MAY BE AS HIGH AS 160,000 KPA (23,206

PSI). USE EXTREME CAUTION WHEN INSPECTING

FOR HIGH-PRESSURE FUEL LEAKS. INSPECT FOR

HIGH-PRESSURE FUEL LEAKS WITH A SHEET OF

CARDBOARD. HIGH FUEL INJECTION PRESSURE

CAN CAUSE PERSONAL INJURY IF CONTACT IS

MADE WITH THE SKIN.

Certain fuel system components can be found in

(Fig. 1), or (Fig. 2).

STANDARD PROCEDURE

STANDARD PROCEDURES - WATER DRAINING

AT FUEL FILTER

Refer to Fuel Filter/Water Separator removal/in-

stallation for procedures.

DRFUEL DELIVERY - DIESEL 14 - 57

Page 1755 of 2895

STANDARD PROCEDURES - CLEANING FUEL

SYSTEM PARTS

CAUTION: Cleanliness cannot be overemphasized

when handling or replacing diesel fuel system com-

ponents. This especially includes the fuel injectors,

high-pressure fuel lines and fuel injection pump.

Very tight tolerances are used with these parts. Dirt

contamination could cause rapid part wear and pos-

sible plugging of fuel injector nozzle tip holes. This

in turn could lead to possible engine misfire.Always wash/clean any fuel system component

thoroughly before disassembly and then air dry.

Cap or cover any open part after disassembly.

Before assembly, examine each part for dirt, grease

or other contaminants and clean if necessary. When

installing new parts, lubricate them with clean

engine oil or clean diesel fuel only.

Fig. 1 DIESEL FUEL SYSTEM COMPONENTS

1 - ENGINE COOLANT TEMPERATURE (ECT) SENSOR 14 - FUEL SUPPLY LINE (LOW-PRESSURE, TO ENGINE)

2 - THROTTLE LEVER BELLCRANK AND APPS (ACCELERATOR

PEDAL POSITION SENSOR)15 - FUEL RETURN LINE CONNECTION (TO FUEL TANK)

3 - INTAKE MANIFOLD AIR HEATER/ELEMENTS 16 - FUEL DRAIN TUBE

4 - FUEL PRESSURE SENSOR 17 - OIL PRESSURE SENSOR

5 - FUEL LIMITING VALVE 18 - ENGINE CONTROL MODULE (ECM)

6 - HIGH-PRESSURE FUEL LINES 19 - FUEL INJECTION PUMP

7 - FUEL HEATER 20 - CRANKSHAFT POSITION (ENGINE SPEED) SENSOR

8 - HIGH-PRESSURE FUEL INJECTOR RAIL 21 - CAMSHAFT POSITION SENSOR (CMP)

9 - FUEL HEATER TEMPERATURE SENSOR (THERMOSTAT) 22 - FUEL CONTROL ACTUATOR (FCA)

10 - FUEL FILTER/WATER SEPARATOR 23 - CASCADE OVERFLOW VALVE

11 - FUEL TRANSFER (LIFT) PUMP

12 - FUEL DRAIN MANIFOLD

13 - DRAIN VALVE

14 - 58 FUEL DELIVERY - DIESELDR

FUEL DELIVERY - DIESEL (Continued)

Page 1762 of 2895

pump. The Fuel Pump/Gear Pump is a low-pressure

pump and produce pressures ranging from 551.5 kpa

(80 psi) to 1241 kpa (180) psi. Fuel then enters the

fuel injection pump. Low pressure fuel is then sup-

plied to the FAC (Fuel Control Actuator).

The FAC is an electronically controlled solenoid

valve. The ECM controls the amount of fuel that

enters the high-pressure pumping chambers by open-

ing and closing the FAC based on a demanded fuel

pressure. The FPS (Fuel Pressure Sensor) on the fuel

rail provides the actual fuel pressure. When the

actuator is opened, the maximum amount of fuel is

being supplied to the fuel injection pump. Any fuel

that does not enter the injection pump is directed to

the overflow valve. The overflow valve regulates how

much excess fuel is used for lubrication of the pump

and how much is returned to the tank through the

drain manifold.

Fuel entering the injection pump is pressurized to

between 300 - 1600 bar by three radial pumping

chambers. The pressurized fuel is then supplied to

the fuel rail.

DIAGNOSIS AND TESTING - FUEL INJECTION

PUMP TIMING

With the Bosch injection pump, there are no

mechanical adjustments needed or necessary to

accomplish fuel injection timing. All timing and fuel

adjustments are electrically made by the engine

mounted Engine Control Module (ECM).

REMOVAL

CAUTION: Cleanliness cannot be overemphasized

when handling or replacing diesel fuel system com-

ponents. This especially includes the fuel injectors,

high-pressure fuel lines and fuel injection pump.

Very tight tolerances are used with these parts. Dirt

contamination could cause rapid part wear and pos-

sible plugging of fuel injector nozzle tip holes. This

in turn could lead to possible engine misfire.

Always wash/clean any fuel system component

thoroughly before disassembly and then air dry.

Cap or cover any open part after disassembly.

Before assembly, examine each part for dirt, grease

or other contaminants and clean if necessary. When

installing new parts, lubricate them with clean

engine oil or clean diesel fuel only.

(1) Disconnect both negative battery cables at both

batteries. Cover and isolate ends of both cables.

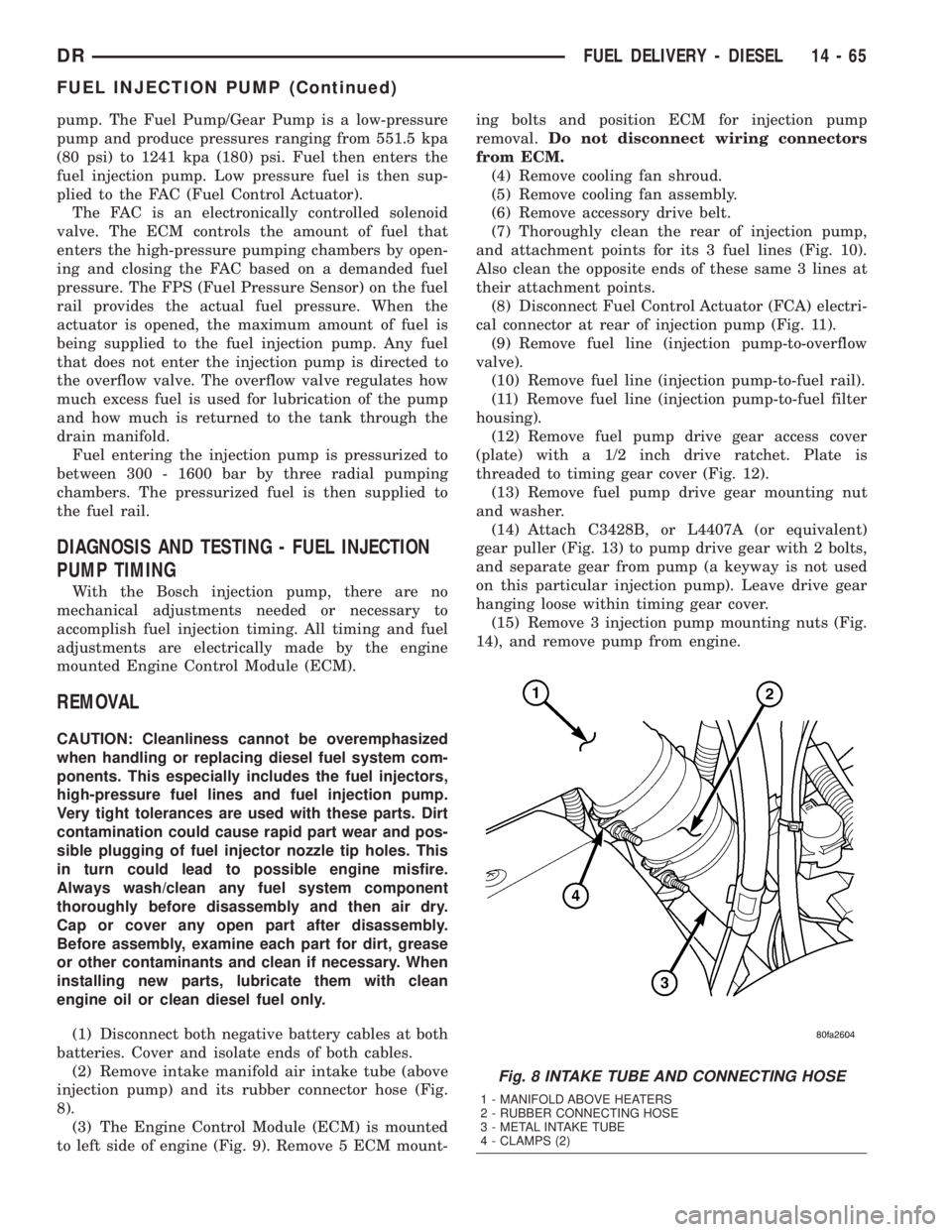

(2) Remove intake manifold air intake tube (above

injection pump) and its rubber connector hose (Fig.

8).

(3) The Engine Control Module (ECM) is mounted

to left side of engine (Fig. 9). Remove 5 ECM mount-ing bolts and position ECM for injection pump

removal.Do not disconnect wiring connectors

from ECM.

(4) Remove cooling fan shroud.

(5) Remove cooling fan assembly.

(6) Remove accessory drive belt.

(7) Thoroughly clean the rear of injection pump,

and attachment points for its 3 fuel lines (Fig. 10).

Also clean the opposite ends of these same 3 lines at

their attachment points.

(8) Disconnect Fuel Control Actuator (FCA) electri-

cal connector at rear of injection pump (Fig. 11).

(9) Remove fuel line (injection pump-to-overflow

valve).

(10) Remove fuel line (injection pump-to-fuel rail).

(11) Remove fuel line (injection pump-to-fuel filter

housing).

(12) Remove fuel pump drive gear access cover

(plate) with a 1/2 inch drive ratchet. Plate is

threaded to timing gear cover (Fig. 12).

(13) Remove fuel pump drive gear mounting nut

and washer.

(14) Attach C3428B, or L4407A (or equivalent)

gear puller (Fig. 13) to pump drive gear with 2 bolts,

and separate gear from pump (a keyway is not used

on this particular injection pump). Leave drive gear

hanging loose within timing gear cover.

(15) Remove 3 injection pump mounting nuts (Fig.

14), and remove pump from engine.

Fig. 8 INTAKE TUBE AND CONNECTING HOSE

1 - MANIFOLD ABOVE HEATERS

2 - RUBBER CONNECTING HOSE

3 - METAL INTAKE TUBE

4 - CLAMPS (2)

DRFUEL DELIVERY - DIESEL 14 - 65

FUEL INJECTION PUMP (Continued)