Actuator DODGE RAM 2003 Service Manual Online

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2605 of 2895

DOOR GLASS

REMOVAL

(1) Remove the glass run channels. (Refer to 23 -

BODY/DOORS - REAR/GLASS RUN CHANNEL -

REMOVAL)

(2) Remove the glass support and place the glass

into the bottom of the door.

(3) Separate the glass run weatherstrip from the

rear of the window opening.

(4) Remove the inner belt molding. (Refer to 23 -

BODY/WEATHERSTRIP/SEALS/FRONT DOOR

INNER BELT WEATHERSTRIP - REMOVAL)

(5) Remove the glass from the window opening.

INSTALLATION

(1) Install the glass through the window opening

and pace the glass into the bottom of the door.

(2) Install the inner belt molding. (Refer to 23 -

BODY/WEATHERSTRIP/SEALS/FRONT DOOR

INNER BELT WEATHERSTRIP - INSTALLATION)

(3) Stuff the glass run weatherstrip into the win-

dow frame.

(4) Secure the glass in the up position using a

wood wedge or equivalent.

(5) Install the glass run channels. (Refer to 23 -

BODY/DOORS - REAR/GLASS RUN CHANNEL -

INSTALLATION)

EXTERIOR HANDLE

REMOVAL

(1) Remove the front glass run channel. (Refer to

23 - BODY/DOORS - REAR/GLASS RUN CHANNEL

- REMOVAL)

(2) Disconnect the latch actuator rod. (Fig. 2)

(3) Remove the nuts and remove the handle.

INSTALLATION

(1) Install the latch and install the nuts.

(2) Connect the latch actuator rod.

(3) Install the front glass run channel. (Refer to 23

- BODY/DOORS - REAR/GLASS RUN CHANNEL -

INSTALLATION)

GLASS RUN CHANNEL

REMOVAL

(1) Remove the window regulator. (Refer to 23 -

BODY/DOORS - REAR/WINDOW REGULATOR -

REMOVAL)

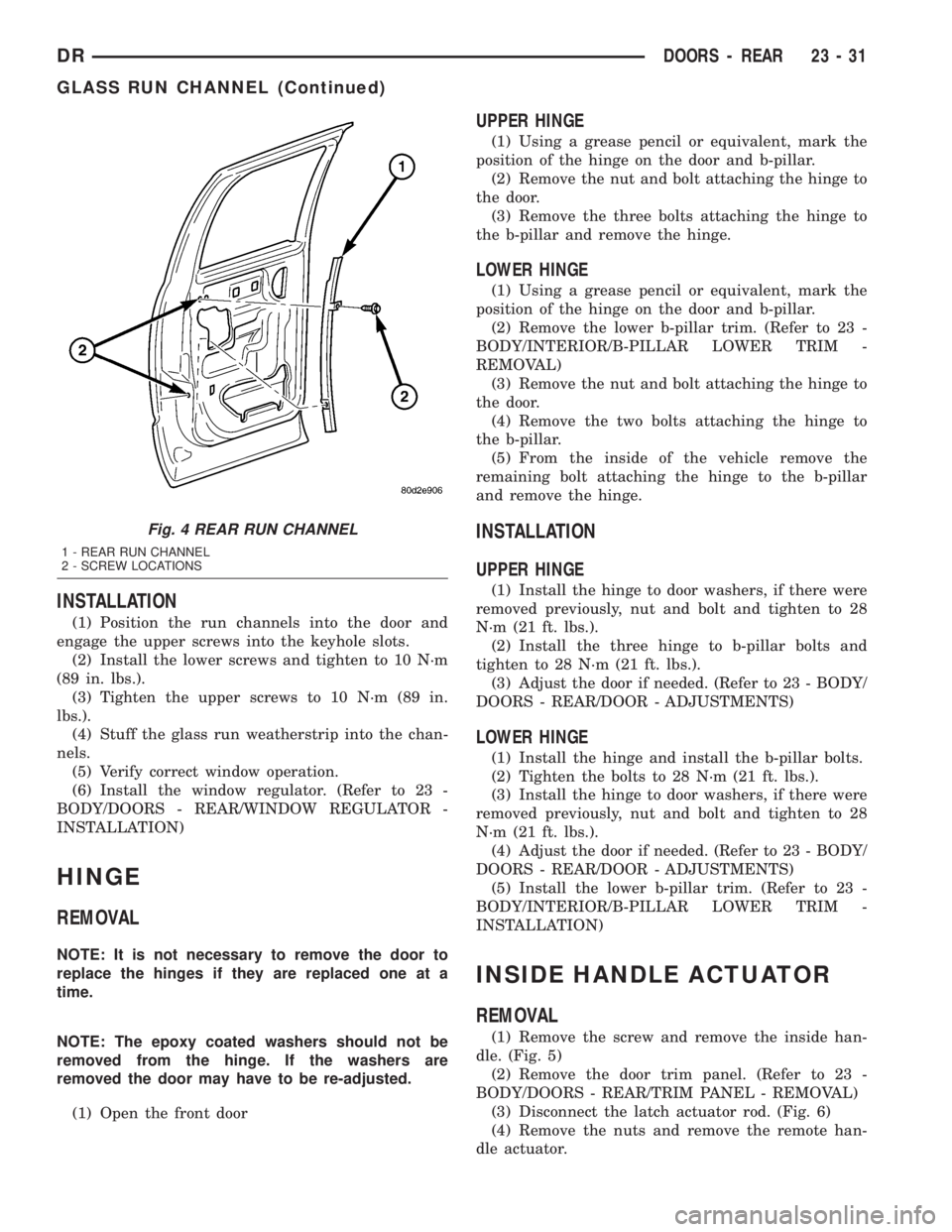

(2) Remove the bottom screws and loosen the top

screws from bolt channels. (Fig. 3) and (Fig. 4)(3) Slide the channels up to disengage from the

keyhole slots.

(4) Separate the glass run weatherstrip from the

channel and remove the channels.

Fig. 2 EXTERIOR HANDLE

1 - LATCH ACTUATOR ROD

2-LATCH

3 - NUTS (2)

Fig. 3 FRONT RUN CHANNEL

1 - BOLTS

2 - FRONT RUN CHANNEL

23 - 30 DOORS - REARDR

Page 2606 of 2895

INSTALLATION

(1) Position the run channels into the door and

engage the upper screws into the keyhole slots.

(2) Install the lower screws and tighten to 10 N´m

(89 in. lbs.).

(3) Tighten the upper screws to 10 N´m (89 in.

lbs.).

(4) Stuff the glass run weatherstrip into the chan-

nels.

(5) Verify correct window operation.

(6) Install the window regulator. (Refer to 23 -

BODY/DOORS - REAR/WINDOW REGULATOR -

INSTALLATION)

HINGE

REMOVAL

NOTE: It is not necessary to remove the door to

replace the hinges if they are replaced one at a

time.

NOTE: The epoxy coated washers should not be

removed from the hinge. If the washers are

removed the door may have to be re-adjusted.

(1) Open the front door

UPPER HINGE

(1) Using a grease pencil or equivalent, mark the

position of the hinge on the door and b-pillar.

(2) Remove the nut and bolt attaching the hinge to

the door.

(3) Remove the three bolts attaching the hinge to

the b-pillar and remove the hinge.

LOWER HINGE

(1) Using a grease pencil or equivalent, mark the

position of the hinge on the door and b-pillar.

(2) Remove the lower b-pillar trim. (Refer to 23 -

BODY/INTERIOR/B-PILLAR LOWER TRIM -

REMOVAL)

(3) Remove the nut and bolt attaching the hinge to

the door.

(4) Remove the two bolts attaching the hinge to

the b-pillar.

(5) From the inside of the vehicle remove the

remaining bolt attaching the hinge to the b-pillar

and remove the hinge.

INSTALLATION

UPPER HINGE

(1) Install the hinge to door washers, if there were

removed previously, nut and bolt and tighten to 28

N´m (21 ft. lbs.).

(2) Install the three hinge to b-pillar bolts and

tighten to 28 N´m (21 ft. lbs.).

(3) Adjust the door if needed. (Refer to 23 - BODY/

DOORS - REAR/DOOR - ADJUSTMENTS)

LOWER HINGE

(1) Install the hinge and install the b-pillar bolts.

(2) Tighten the bolts to 28 N´m (21 ft. lbs.).

(3) Install the hinge to door washers, if there were

removed previously, nut and bolt and tighten to 28

N´m (21 ft. lbs.).

(4) Adjust the door if needed. (Refer to 23 - BODY/

DOORS - REAR/DOOR - ADJUSTMENTS)

(5) Install the lower b-pillar trim. (Refer to 23 -

BODY/INTERIOR/B-PILLAR LOWER TRIM -

INSTALLATION)

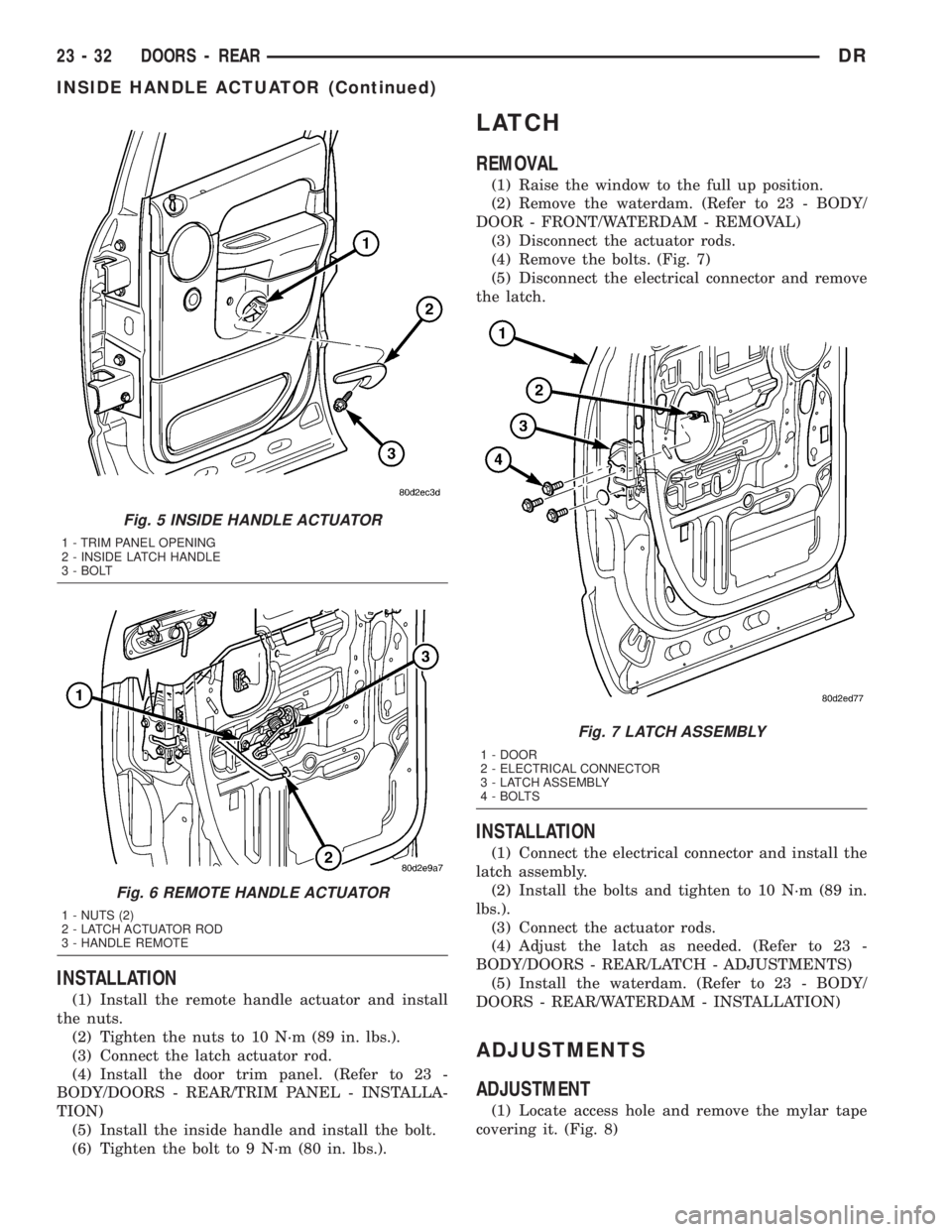

INSIDE HANDLE ACTUATOR

REMOVAL

(1) Remove the screw and remove the inside han-

dle. (Fig. 5)

(2) Remove the door trim panel. (Refer to 23 -

BODY/DOORS - REAR/TRIM PANEL - REMOVAL)

(3) Disconnect the latch actuator rod. (Fig. 6)

(4) Remove the nuts and remove the remote han-

dle actuator.

Fig. 4 REAR RUN CHANNEL

1 - REAR RUN CHANNEL

2 - SCREW LOCATIONS

DRDOORS - REAR 23 - 31

GLASS RUN CHANNEL (Continued)

Page 2607 of 2895

INSTALLATION

(1) Install the remote handle actuator and install

the nuts.

(2) Tighten the nuts to 10 N´m (89 in. lbs.).

(3) Connect the latch actuator rod.

(4) Install the door trim panel. (Refer to 23 -

BODY/DOORS - REAR/TRIM PANEL - INSTALLA-

TION)

(5) Install the inside handle and install the bolt.

(6) Tighten the bolt to 9 N´m (80 in. lbs.).

LATCH

REMOVAL

(1) Raise the window to the full up position.

(2) Remove the waterdam. (Refer to 23 - BODY/

DOOR - FRONT/WATERDAM - REMOVAL)

(3) Disconnect the actuator rods.

(4) Remove the bolts. (Fig. 7)

(5) Disconnect the electrical connector and remove

the latch.

INSTALLATION

(1) Connect the electrical connector and install the

latch assembly.

(2) Install the bolts and tighten to 10 N´m (89 in.

lbs.).

(3) Connect the actuator rods.

(4) Adjust the latch as needed. (Refer to 23 -

BODY/DOORS - REAR/LATCH - ADJUSTMENTS)

(5) Install the waterdam. (Refer to 23 - BODY/

DOORS - REAR/WATERDAM - INSTALLATION)

ADJUSTMENTS

ADJUSTMENT

(1) Locate access hole and remove the mylar tape

covering it. (Fig. 8)

Fig. 5 INSIDE HANDLE ACTUATOR

1 - TRIM PANEL OPENING

2 - INSIDE LATCH HANDLE

3 - BOLT

Fig. 6 REMOTE HANDLE ACTUATOR

1 - NUTS (2)

2 - LATCH ACTUATOR ROD

3 - HANDLE REMOTE

Fig. 7 LATCH ASSEMBLY

1 - DOOR

2 - ELECTRICAL CONNECTOR

3 - LATCH ASSEMBLY

4 - BOLTS

23 - 32 DOORS - REARDR

INSIDE HANDLE ACTUATOR (Continued)

Page 2609 of 2895

WATERDAM

REMOVAL

(1) Remove the inside handle actuator. (Refer to 23

- BODY/DOORS - REAR/INSIDE HANDLE ACTUA-

TOR - REMOVAL)

(2) Remove the speaker. (Refer to 8 - ELECTRI-

CAL/AUDIO/SPEAKER - REMOVAL)

(3) Separate the waterdam from the inner door

panel and off of the latch linkages.

INSTALLATION

(1) Position the wire harness and actuator rods

through the holes in the waterdam.

(2) Secure the waterdam to the inner door panel.

(3) Install the speaker. (Refer to 8 - ELECTRICAL/

AUDIO/SPEAKER - INSTALLATION)

(4) Install the inside handle actuator. (Refer to 23 -

BODY/DOORS - REAR/INSIDE HANDLE ACTUA-

TOR - INSTALLATION)

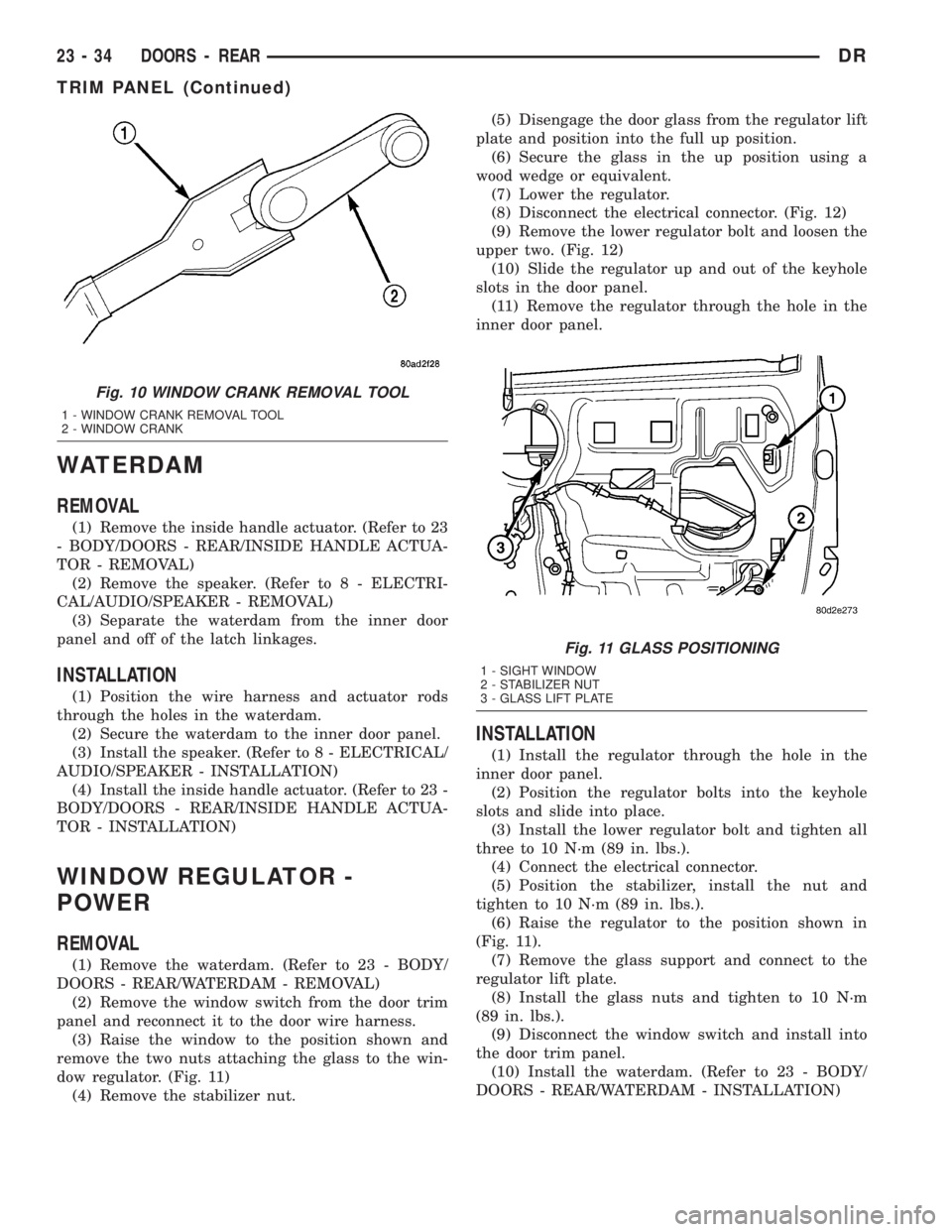

WINDOW REGULATOR -

POWER

REMOVAL

(1) Remove the waterdam. (Refer to 23 - BODY/

DOORS - REAR/WATERDAM - REMOVAL)

(2) Remove the window switch from the door trim

panel and reconnect it to the door wire harness.

(3) Raise the window to the position shown and

remove the two nuts attaching the glass to the win-

dow regulator. (Fig. 11)

(4) Remove the stabilizer nut.(5) Disengage the door glass from the regulator lift

plate and position into the full up position.

(6) Secure the glass in the up position using a

wood wedge or equivalent.

(7) Lower the regulator.

(8) Disconnect the electrical connector. (Fig. 12)

(9) Remove the lower regulator bolt and loosen the

upper two. (Fig. 12)

(10) Slide the regulator up and out of the keyhole

slots in the door panel.

(11) Remove the regulator through the hole in the

inner door panel.

INSTALLATION

(1) Install the regulator through the hole in the

inner door panel.

(2) Position the regulator bolts into the keyhole

slots and slide into place.

(3) Install the lower regulator bolt and tighten all

three to 10 N´m (89 in. lbs.).

(4) Connect the electrical connector.

(5) Position the stabilizer, install the nut and

tighten to 10 N´m (89 in. lbs.).

(6) Raise the regulator to the position shown in

(Fig. 11).

(7) Remove the glass support and connect to the

regulator lift plate.

(8) Install the glass nuts and tighten to 10 N´m

(89 in. lbs.).

(9) Disconnect the window switch and install into

the door trim panel.

(10) Install the waterdam. (Refer to 23 - BODY/

DOORS - REAR/WATERDAM - INSTALLATION)

Fig. 10 WINDOW CRANK REMOVAL TOOL

1 - WINDOW CRANK REMOVAL TOOL

2 - WINDOW CRANK

Fig. 11 GLASS POSITIONING

1 - SIGHT WINDOW

2 - STABILIZER NUT

3 - GLASS LIFT PLATE

23 - 34 DOORS - REARDR

TRIM PANEL (Continued)

Page 2629 of 2895

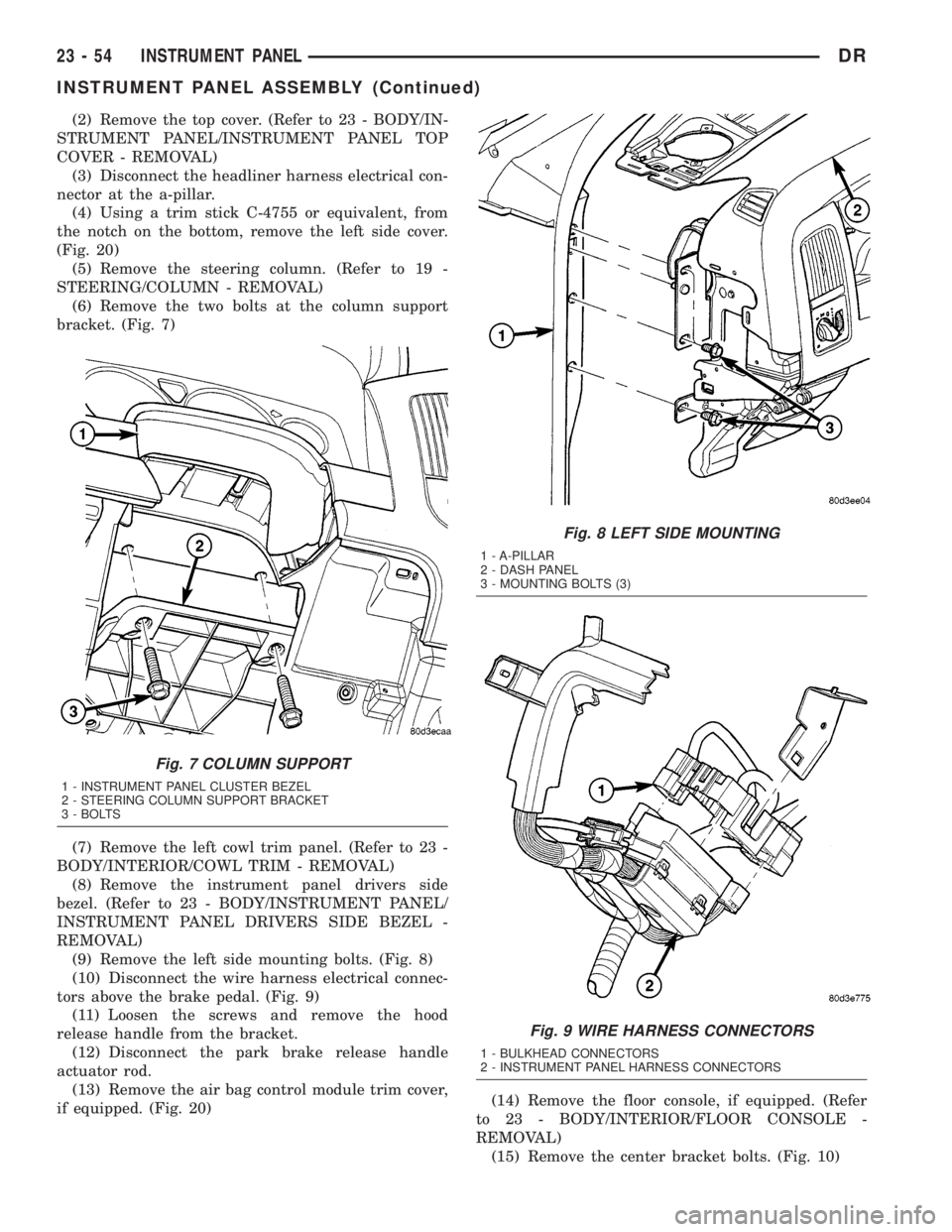

(2) Remove the top cover. (Refer to 23 - BODY/IN-

STRUMENT PANEL/INSTRUMENT PANEL TOP

COVER - REMOVAL)

(3) Disconnect the headliner harness electrical con-

nector at the a-pillar.

(4) Using a trim stick C-4755 or equivalent, from

the notch on the bottom, remove the left side cover.

(Fig. 20)

(5) Remove the steering column. (Refer to 19 -

STEERING/COLUMN - REMOVAL)

(6) Remove the two bolts at the column support

bracket. (Fig. 7)

(7) Remove the left cowl trim panel. (Refer to 23 -

BODY/INTERIOR/COWL TRIM - REMOVAL)

(8) Remove the instrument panel drivers side

bezel. (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL DRIVERS SIDE BEZEL -

REMOVAL)

(9) Remove the left side mounting bolts. (Fig. 8)

(10) Disconnect the wire harness electrical connec-

tors above the brake pedal. (Fig. 9)

(11) Loosen the screws and remove the hood

release handle from the bracket.

(12) Disconnect the park brake release handle

actuator rod.

(13) Remove the air bag control module trim cover,

if equipped. (Fig. 20)(14) Remove the floor console, if equipped. (Refer

to 23 - BODY/INTERIOR/FLOOR CONSOLE -

REMOVAL)

(15) Remove the center bracket bolts. (Fig. 10)

Fig. 7 COLUMN SUPPORT

1 - INSTRUMENT PANEL CLUSTER BEZEL

2 - STEERING COLUMN SUPPORT BRACKET

3 - BOLTS

Fig. 8 LEFT SIDE MOUNTING

1 - A-PILLAR

2 - DASH PANEL

3 - MOUNTING BOLTS (3)

Fig. 9 WIRE HARNESS CONNECTORS

1 - BULKHEAD CONNECTORS

2 - INSTRUMENT PANEL HARNESS CONNECTORS

23 - 54 INSTRUMENT PANELDR

INSTRUMENT PANEL ASSEMBLY (Continued)

Page 2776 of 2895

HEATING & AIR CONDITIONING

TABLE OF CONTENTS

page page

HEATING & AIR CONDITIONING

DESCRIPTION

DESCRIPTION - HEATER AND AIR

CONDITIONER........................1

DESCRIPTION - COOLING SYSTEM

REQUIREMENTS.......................1

DESCRIPTION - REFRIGERANT SYSTEM

SERVICE PORT........................1

OPERATION

OPERATION - HEATER AND AIR

CONDITIONER........................1

OPERATION - REFRIGERANT SYSTEM

SERVICE PORT........................2DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - A/C

PERFORMANCE.......................2

DIAGNOSIS AND TESTING - HEATER

PERFORMANCE.......................5

STANDARD PROCEDURE - DIODE

REPLACEMENT.......................7

SPECIFICATIONS

A/C APPLICATION TABLE................7

SPECIFICATIONS......................8

CONTROLS.............................9

DISTRIBUTION..........................24

PLUMBING.............................31

HEATING & AIR

CONDITIONING

DESCRIPTION

DESCRIPTION - HEATER AND AIR

CONDITIONER

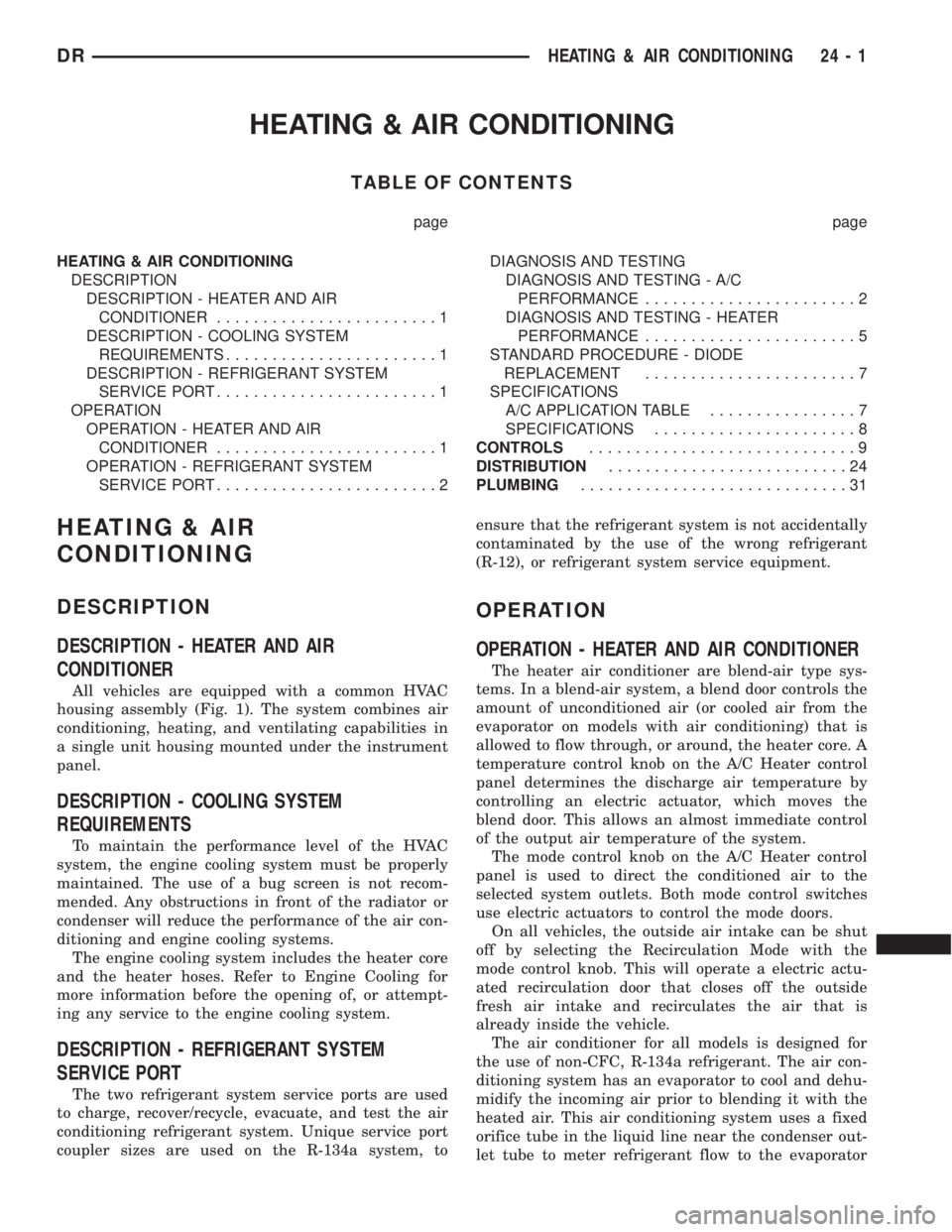

All vehicles are equipped with a common HVAC

housing assembly (Fig. 1). The system combines air

conditioning, heating, and ventilating capabilities in

a single unit housing mounted under the instrument

panel.

DESCRIPTION - COOLING SYSTEM

REQUIREMENTS

To maintain the performance level of the HVAC

system, the engine cooling system must be properly

maintained. The use of a bug screen is not recom-

mended. Any obstructions in front of the radiator or

condenser will reduce the performance of the air con-

ditioning and engine cooling systems.

The engine cooling system includes the heater core

and the heater hoses. Refer to Engine Cooling for

more information before the opening of, or attempt-

ing any service to the engine cooling system.

DESCRIPTION - REFRIGERANT SYSTEM

SERVICE PORT

The two refrigerant system service ports are used

to charge, recover/recycle, evacuate, and test the air

conditioning refrigerant system. Unique service port

coupler sizes are used on the R-134a system, toensure that the refrigerant system is not accidentally

contaminated by the use of the wrong refrigerant

(R-12), or refrigerant system service equipment.

OPERATION

OPERATION - HEATER AND AIR CONDITIONER

The heater air conditioner are blend-air type sys-

tems. In a blend-air system, a blend door controls the

amount of unconditioned air (or cooled air from the

evaporator on models with air conditioning) that is

allowed to flow through, or around, the heater core. A

temperature control knob on the A/C Heater control

panel determines the discharge air temperature by

controlling an electric actuator, which moves the

blend door. This allows an almost immediate control

of the output air temperature of the system.

The mode control knob on the A/C Heater control

panel is used to direct the conditioned air to the

selected system outlets. Both mode control switches

use electric actuators to control the mode doors.

On all vehicles, the outside air intake can be shut

off by selecting the Recirculation Mode with the

mode control knob. This will operate a electric actu-

ated recirculation door that closes off the outside

fresh air intake and recirculates the air that is

already inside the vehicle.

The air conditioner for all models is designed for

the use of non-CFC, R-134a refrigerant. The air con-

ditioning system has an evaporator to cool and dehu-

midify the incoming air prior to blending it with the

heated air. This air conditioning system uses a fixed

orifice tube in the liquid line near the condenser out-

let tube to meter refrigerant flow to the evaporator

DRHEATING & AIR CONDITIONING 24 - 1

Page 2777 of 2895

coil. To maintain minimum evaporator temperature

and prevent evaporator freezing, the A/C Fin Probe

which is located in the evaporator cycles the com-

pressor clutch by sending an A/C request to the

JTEC which in turn processes this piece of informa-

tion and if all conditions are met cycles the compres-

sor clutch.

OPERATION - REFRIGERANT SYSTEM SERVICE

PORT

The low pressure service port is located on the suc-

tion refrigerant line, near the accumulator. The high

pressure service port is located on the liquid line at

the passenger side of the engine compartment, near

the condenser.

Each of the service ports has a threaded plastic

protective cap installed over it from the factory. After

servicing the refrigerant system, always reinstall

both of the service port caps.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - A/C

PERFORMANCE

The air conditioning system is designed to provide

the passenger compartment with low temperature

and low humidity air. The evaporator, located in the

HVAC housing on the dash panel below the instru-

ment panel, is cooled to temperatures near the freez-

ing point. As warm damp air passes through the

cooled evaporator, the air transfers its heat to the

refrigerant in the evaporator and the moisture in the

air condenses on the evaporator fins. During periods

of high heat and humidity, an air conditioning sys-

tem will be more effective in the Recirculation Mode.

With the system in the Recirculation Mode, only air

from the passenger compartment passes through the

evaporator. As the passenger compartment air dehu-

midifies, the air conditioning system performance

levels improve.

Humidity has an important bearing on the temper-

ature of the air delivered to the interior of the vehi-

cle. It is important to understand the effect that

humidity has on the performance of the air condition-

ing system. When humidity is high, the evaporator

has to perform a double duty. It must lower the air

temperature, and it must lower the temperature of

the moisture in the air that condenses on the evapo-

rator fins. Condensing the moisture in the air trans-

fers heat energy into the evaporator fins and tubing.

This reduces the amount of heat the evaporator can

absorb from the air. High humidity greatly reduces

the ability of the evaporator to lower the temperature

of the air.

However, evaporator capacity used to reduce the

amount of moisture in the air is not wasted. Remov-

ing some of the moisture out of the air entering the

vehicle adds to the comfort of the passengers.

Although, an owner may expect too much from the

air conditioning system on humid days. A perfor-

mance test is the best way to determine whether the

system is performing up to standard. This test also

provides valuable clues as to the possible cause of

trouble with the air conditioning system.

Before proceeding, (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - WARNING) and

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - CAUTION). The air temperature in

the test room and in the vehicle must be a minimum

of 21É C (70É F) for this test.

(1) Connect a tachometer and a manifold gauge set

or A/C recycling/charging station.

(2) Set the A/C Heater mode control switch knob in

the Recirculation Mode position, the temperature

control knob in the full cool position, and the blower

motor switch knob in the highest speed position.

Fig. 1 HVAC Housing - Dual Zone Shown (Typical -

Single Zone)

1 - Mounting Nut

2 - Passenger Blend Door Actuator (dual zone)

3 - Mounting Nut

4 - Air Intake Spacer

5 - Recirculation Door Actuator

6 - Recirculation Door Assembly

7 - Driver Side Blend Door Actuator

8 - HVAC Housing

9 - Mounting Screw

10 - Defroster Door Actuator

11 - Panel Actuator

24 - 2 HEATING & AIR CONDITIONINGDR

HEATING & AIR CONDITIONING (Continued)

Page 2779 of 2895

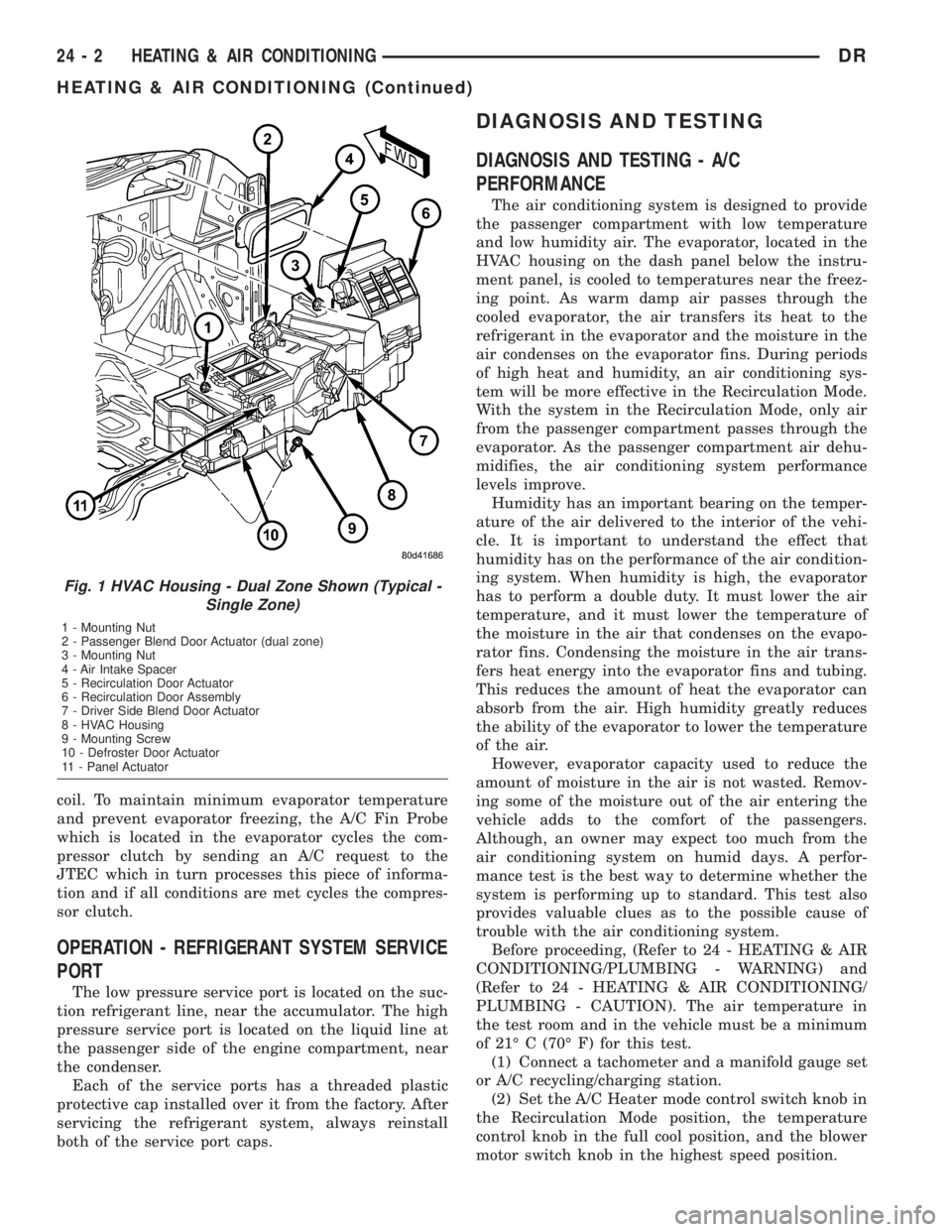

Pressure Diagnosis

Condition Possible Causes Correction

4. Faulty a/c compressor

clutch relay.4. See A/C Compressor Clutch Relay/Diagnosis

and Testing - Compressor Clutch Relay in this

group. Test the compressor clutch relay and relay

circuits. Repair the circuits or replace the relay, if

required.

5. Improperly installed or

faulty Fin Sensor.5. See Fin Sensor/Diagnosis and Testing in this

group. Reinstall or replace the Fin Sensor as

required.

6. Faulty a/c high pressure

transducer.6. See A/C High Pressure Transducer/Diagnosis

and Testing in this group. Test the a/c high

pressure transducer and replace, if required.

7. Faulty Powertrain Control

Module (PCM).7. (Refer to Appropriate Diagnostic Information).

Test the PCM and replace, if required.

Normal pressures, but A/C

Performance Test air

temperatures at center panel

outlet are too high.1. Excessive refrigerant oil in

system.1. See Refrigerant Oil/Standard Procedure -

Refrigerant Oil Level in this group. Recover the

refrigerant from the refrigerant system and

inspect the refrigerant oil content. Restore the

refrigerant oil to the proper level, if required.

2. Blend door inoperative or

sealing improperly.2. See Blend Door in this group. Inspect the

blend door for proper operation and sealing and

correct, if required.

3. Blend door actuator faulty

or inoperative.3. Perform blend door actuator diagnosis, replace

if faulty.

The low side pressure is

normal or slightly low, and

the high side pressure is too

low.1. Low refrigerant system

charge.1. See Plumbing/Diagnosis and Testing -

Refrigerant System Leaks in this group. Test the

refrigerant system for leaks. Repair, evacuate and

charge the refrigerant system, if required.

2. Refrigerant flow through

the accumulator is restricted.2. See Accumulator in this group. Replace the

restricted accumulator, if required.

3. Refrigerant flow through

the evaporator coil is

restricted.3. See A/C Evaporator in this group. Replace the

restricted evaporator coil, if required.

4. Faulty compressor. 4. See A/C Compressor in this group. Replace

the compressor, if required.

The low side pressure is

normal or slightly high, and

the high side pressure is too

high.1. Condenser air flow

restricted.1. Check the condenser for damaged fins, foreign

objects obstructing air flow through the condenser

fins, and missing or improperly installed air seals.

Refer to Cooling for more information on air

seals. Clean, repair, or replace components as

required.

2. Inoperative cooling fan. 2. Refer to Cooling for more information. Test the

cooling fan and replace, if required.

3. Refrigerant system

overcharged.3. See Plumbing/Standard Procedure -

Refrigerant System Charge in this group. Recover

the refrigerant from the refrigerant system.

Charge the refrigerant system to the proper level,

if required.

24 - 4 HEATING & AIR CONDITIONINGDR

HEATING & AIR CONDITIONING (Continued)

Page 2781 of 2895

If the floor outlet air temperature is too low, refer

to Cooling to check the engine coolant temperature

specifications. Both of the heater hoses should be hot

to the touch. The coolant return heater hose should

be slightly cooler than the coolant supply heater

hose. If the return hose is much cooler than the sup-

ply hose, locate and repair the engine coolant flow

obstruction in the cooling system. Refer to Cooling

for the procedures.

An alternate method of checking heater perfor-

mance is to use a DRBIIItscan tool to monitor the

engine coolant temperature. The floor outlet air tem-

perature reading should be no more than 4.5É C (40É

F) lower than the engine coolant temperature read-

ing.

OBSTRUCTED COOLANT FLOW Possible loca-

tions or causes of obstructed coolant flow:

²Faulty water pump.

²Faulty thermostat.

²Pinched or kinked heater hoses.

²Improper heater hose routing.

²Plugged heater hoses or supply and return ports

at the cooling system connections.

²A plugged heater core.If proper coolant flow through the cooling system is

verified, and heater outlet air temperature is still

low, a mechanical problem may exist.

MECHANICAL PROBLEMS Possible locations or

causes of insufficient heat:

²An obstructed cowl air intake.

²Obstructed heater system outlets.

²A faulty, obstructed or improperly installed

blend door.

²A faulty blower system.

²A faulty a/c heater control.

TEMPERATURE CONTROL

If the heater outlet air temperature cannot be

adjusted with the temperature control knob on the

a/c heater control panel, the following could require

service:

²A faulty a/c heater control.

²A faulty blend door actuator.

²A faulty, obstructed or improperly installed

blend door.

²An obstructed cowl air intake.

²The engine cooling system.

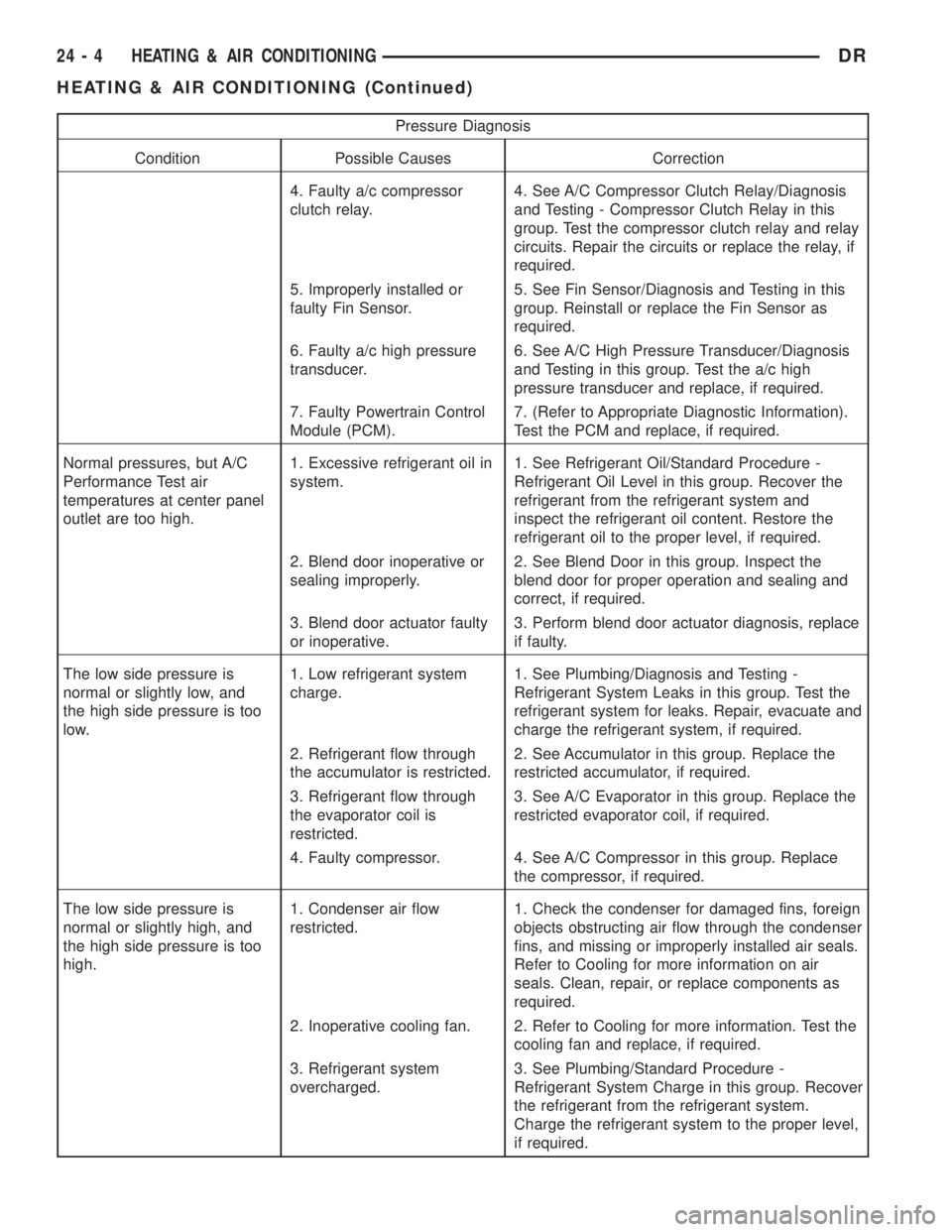

Heater Diagnosis

CONDITION POSSIBLE CAUSE CORRECTION

INSUFFICIENT HEATER

OUTPUT.1. Incorrect engine

coolant level.1. Check the engine coolant level. Refer to Cooling for

the procedures.

2. Air trapped in engine

cooling system.2. Check the operation of the coolant reserve/recovery

system. Refer to Cooling for the procedures.

3. Incorrect engine

coolant temperature.3. Check the performance and operation of the engine

cooling system including: thermostat, water pump, fan

drive, accessory drive belt, coolant flow (plugged radiator

or heater core, plugged or kinked coolant hoses), air flow

(missing or improperly installed radiator air seals or fan

shroud). Refer to Cooling for the procedures.

4. Blend door actuator

inoperative or defective.4. (Refer to Controls/Blend Door Actuator) in this group.

5. Blend door not

operating properly.5. Check for a damaged, obstructed or improperly

installed blend door or seals. (Refer to Controls/Blend

Door Actuator) in this group.

6. Insufficient air flow

through heater housing.6. Remove foreign material or obstructions from cowl air

intake.

7. Improper blower motor

operation.7. (Refer to Distribution/Blower Motor/ Diagnosis and

Testing) in this group.

24 - 6 HEATING & AIR CONDITIONINGDR

HEATING & AIR CONDITIONING (Continued)

Page 2782 of 2895

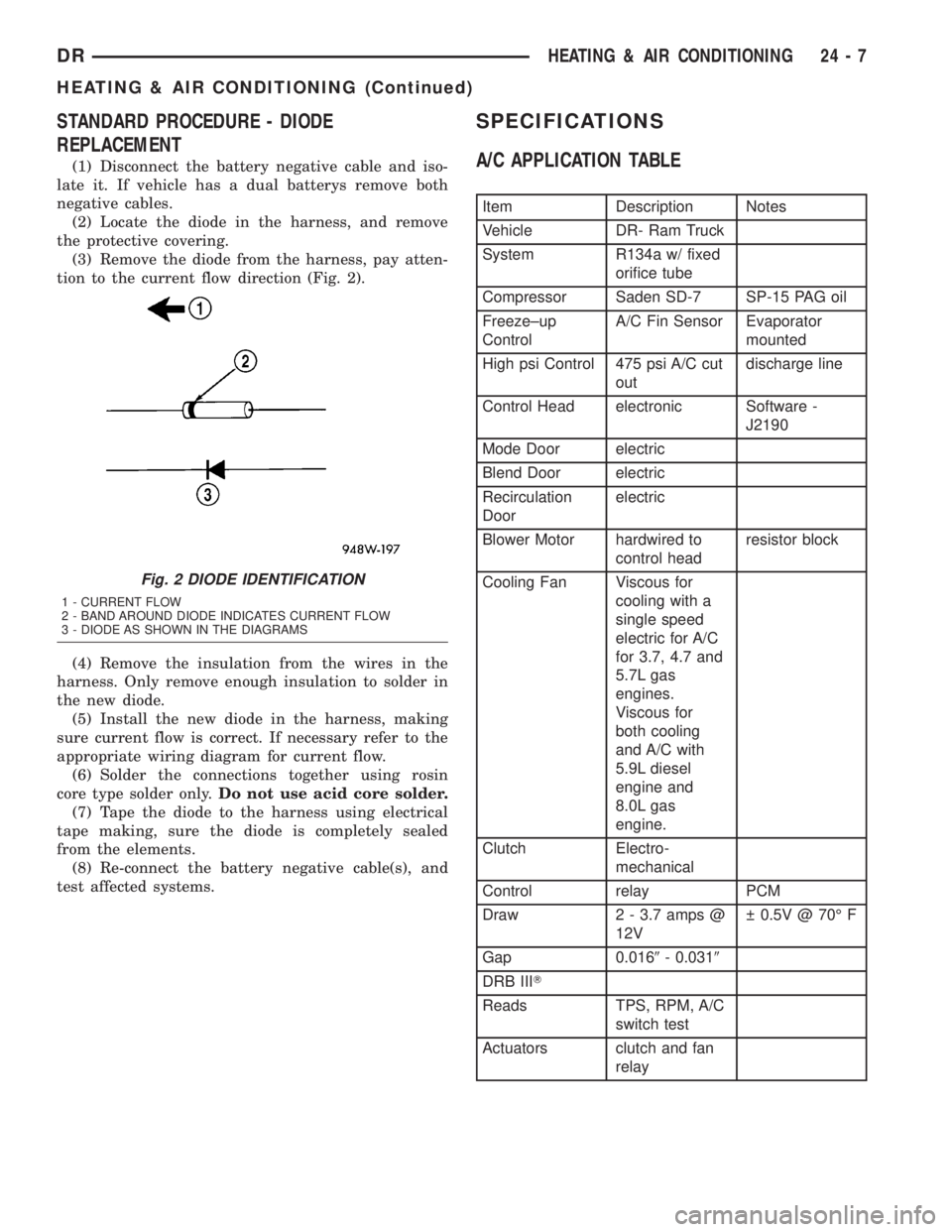

STANDARD PROCEDURE - DIODE

REPLACEMENT

(1) Disconnect the battery negative cable and iso-

late it. If vehicle has a dual batterys remove both

negative cables.

(2) Locate the diode in the harness, and remove

the protective covering.

(3) Remove the diode from the harness, pay atten-

tion to the current flow direction (Fig. 2).

(4) Remove the insulation from the wires in the

harness. Only remove enough insulation to solder in

the new diode.

(5) Install the new diode in the harness, making

sure current flow is correct. If necessary refer to the

appropriate wiring diagram for current flow.

(6) Solder the connections together using rosin

core type solder only.Do not use acid core solder.

(7) Tape the diode to the harness using electrical

tape making, sure the diode is completely sealed

from the elements.

(8) Re-connect the battery negative cable(s), and

test affected systems.

SPECIFICATIONS

A/C APPLICATION TABLE

Item Description Notes

Vehicle DR- Ram Truck

System R134a w/ fixed

orifice tube

Compressor Saden SD-7 SP-15 PAG oil

Freeze±up

ControlA/C Fin Sensor Evaporator

mounted

High psi Control 475 psi A/C cut

outdischarge line

Control Head electronic Software -

J2190

Mode Door electric

Blend Door electric

Recirculation

Doorelectric

Blower Motor hardwired to

control headresistor block

Cooling Fan Viscous for

cooling with a

single speed

electric for A/C

for 3.7, 4.7 and

5.7L gas

engines.

Viscous for

both cooling

and A/C with

5.9L diesel

engine and

8.0L gas

engine.

Clutch Electro-

mechanical

Control relay PCM

Draw 2 - 3.7 amps @

12V 0.5V @ 70É F

Gap 0.0169- 0.0319

DRB IIIT

Reads TPS, RPM, A/C

switch test

Actuators clutch and fan

relay

Fig. 2 DIODE IDENTIFICATION

1 - CURRENT FLOW

2 - BAND AROUND DIODE INDICATES CURRENT FLOW

3 - DIODE AS SHOWN IN THE DIAGRAMS

DRHEATING & AIR CONDITIONING 24 - 7

HEATING & AIR CONDITIONING (Continued)