cooling DODGE RAM 2003 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 355 of 2895

INSPECTION

Visually inspect the water pump and replace if it

has any of the following conditions:

²The body is cracked or damaged

²Water leaks from the shaft seal. This is evident

by traces of coolant below the vent hole

²Loose or rough turning bearing.

²Impeller rubbing the pump body

INSTALLATION

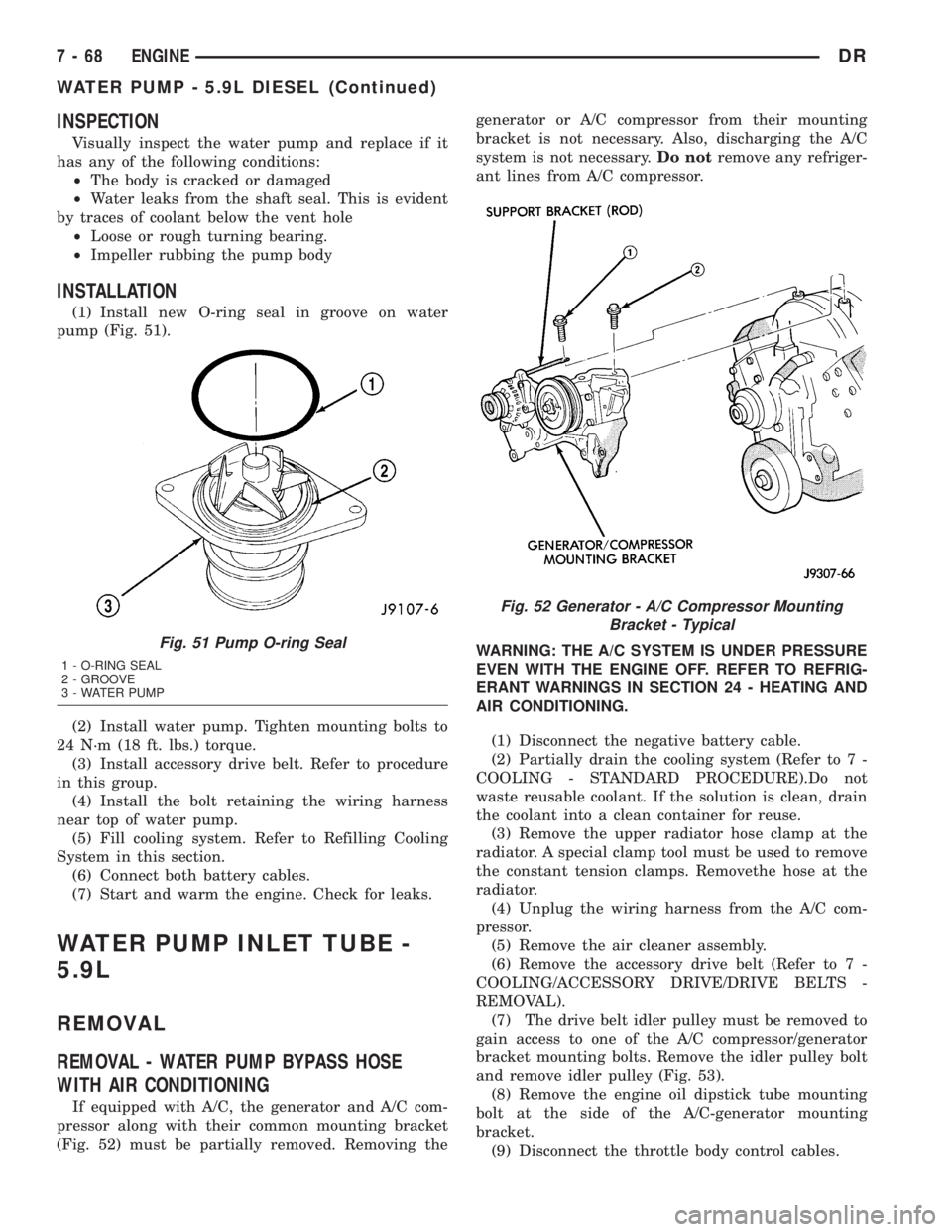

(1) Install new O-ring seal in groove on water

pump (Fig. 51).

(2) Install water pump. Tighten mounting bolts to

24 N´m (18 ft. lbs.) torque.

(3) Install accessory drive belt. Refer to procedure

in this group.

(4) Install the bolt retaining the wiring harness

near top of water pump.

(5) Fill cooling system. Refer to Refilling Cooling

System in this section.

(6) Connect both battery cables.

(7) Start and warm the engine. Check for leaks.

WATER PUMP INLET TUBE -

5.9L

REMOVAL

REMOVAL - WATER PUMP BYPASS HOSE

WITH AIR CONDITIONING

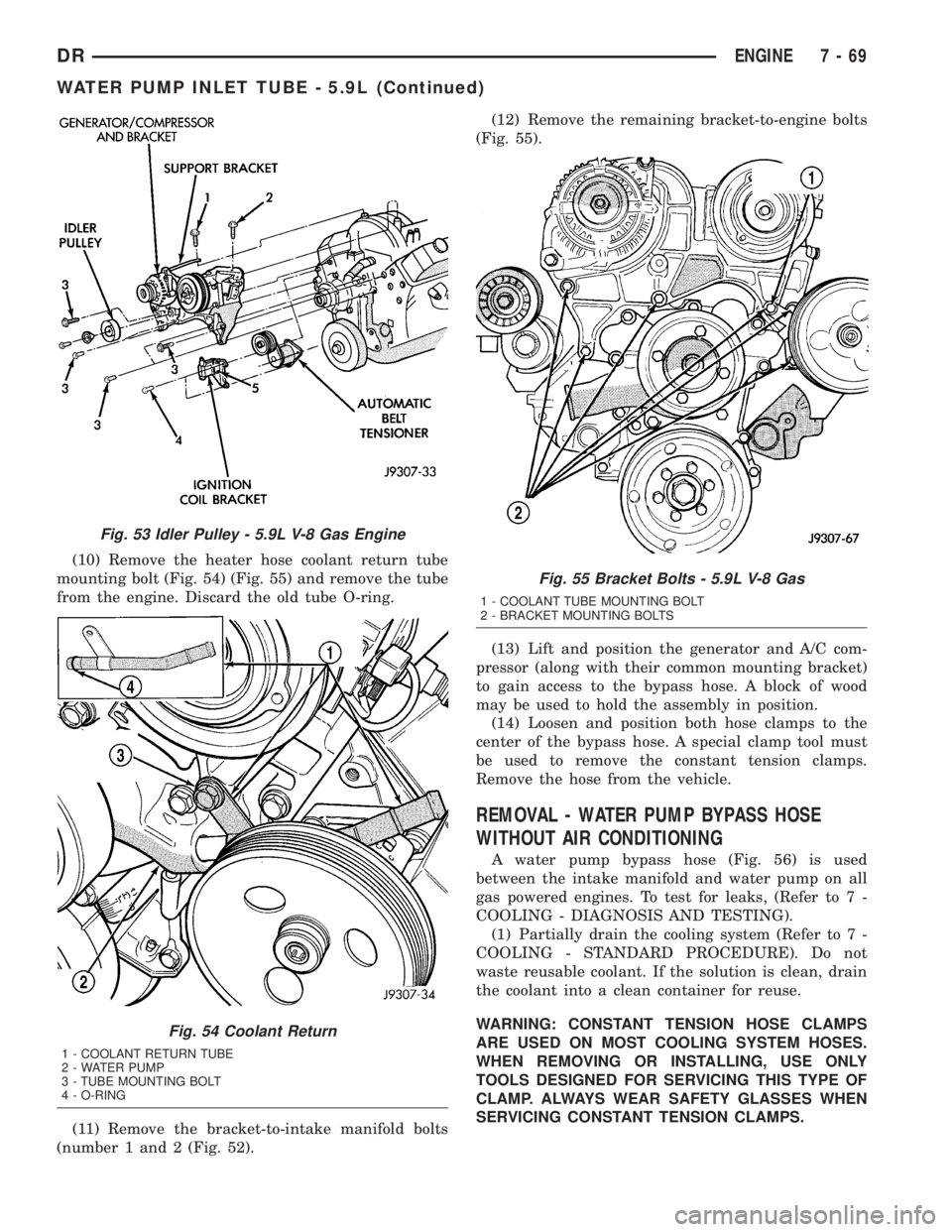

If equipped with A/C, the generator and A/C com-

pressor along with their common mounting bracket

(Fig. 52) must be partially removed. Removing thegenerator or A/C compressor from their mounting

bracket is not necessary. Also, discharging the A/C

system is not necessary.Do notremove any refriger-

ant lines from A/C compressor.

WARNING: THE A/C SYSTEM IS UNDER PRESSURE

EVEN WITH THE ENGINE OFF. REFER TO REFRIG-

ERANT WARNINGS IN SECTION 24 - HEATING AND

AIR CONDITIONING.

(1) Disconnect the negative battery cable.

(2) Partially drain the cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE).Do not

waste reusable coolant. If the solution is clean, drain

the coolant into a clean container for reuse.

(3) Remove the upper radiator hose clamp at the

radiator. A special clamp tool must be used to remove

the constant tension clamps. Removethe hose at the

radiator.

(4) Unplug the wiring harness from the A/C com-

pressor.

(5) Remove the air cleaner assembly.

(6) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(7) The drive belt idler pulley must be removed to

gain access to one of the A/C compressor/generator

bracket mounting bolts. Remove the idler pulley bolt

and remove idler pulley (Fig. 53).

(8) Remove the engine oil dipstick tube mounting

bolt at the side of the A/C-generator mounting

bracket.

(9) Disconnect the throttle body control cables.

Fig. 51 Pump O-ring Seal

1 - O-RING SEAL

2 - GROOVE

3 - WATER PUMP

Fig. 52 Generator - A/C Compressor Mounting

Bracket - Typical

7 - 68 ENGINEDR

WATER PUMP - 5.9L DIESEL (Continued)

Page 356 of 2895

(10) Remove the heater hose coolant return tube

mounting bolt (Fig. 54) (Fig. 55) and remove the tube

from the engine. Discard the old tube O-ring.

(11) Remove the bracket-to-intake manifold bolts

(number 1 and 2 (Fig. 52).(12) Remove the remaining bracket-to-engine bolts

(Fig. 55).

(13) Lift and position the generator and A/C com-

pressor (along with their common mounting bracket)

to gain access to the bypass hose. A block of wood

may be used to hold the assembly in position.

(14) Loosen and position both hose clamps to the

center of the bypass hose. A special clamp tool must

be used to remove the constant tension clamps.

Remove the hose from the vehicle.

REMOVAL - WATER PUMP BYPASS HOSE

WITHOUT AIR CONDITIONING

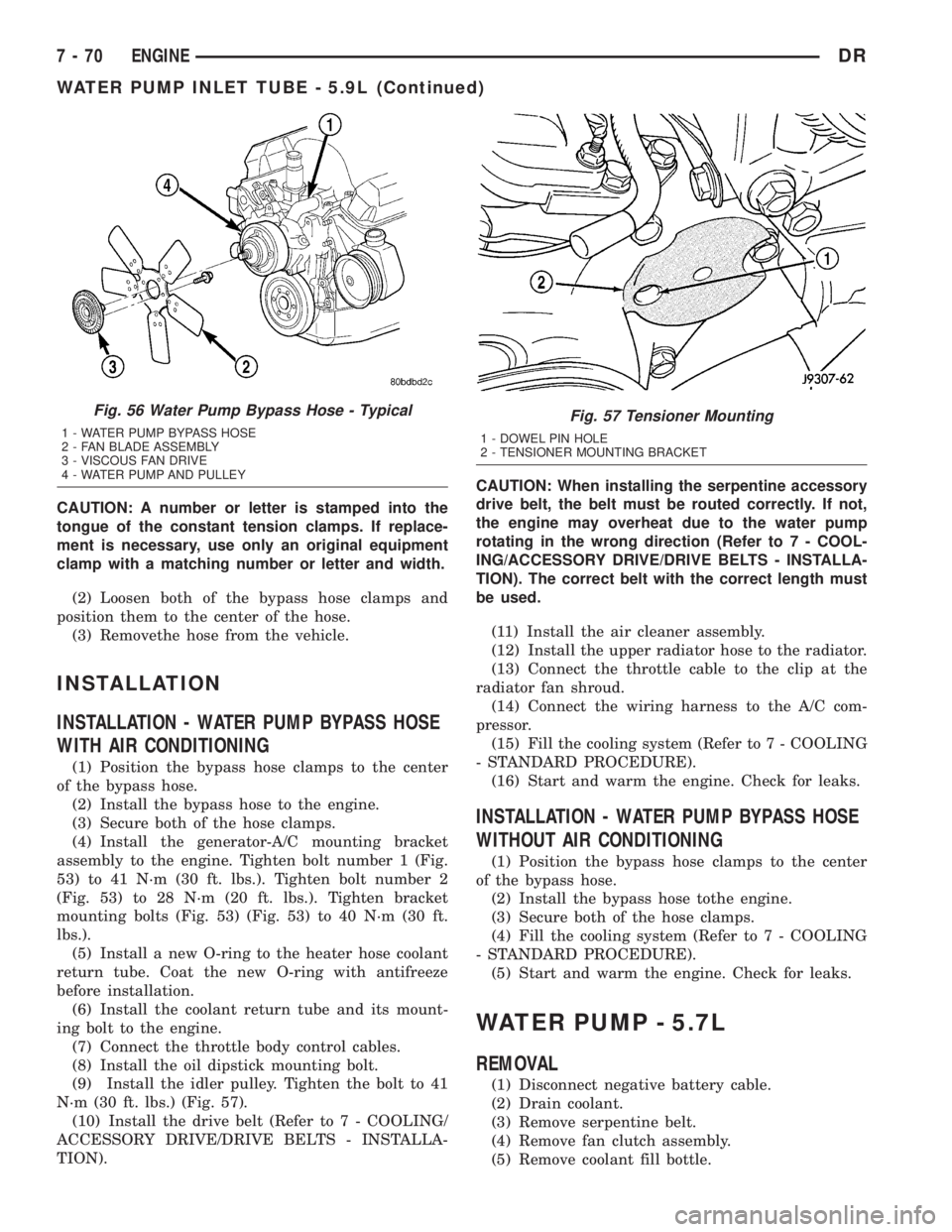

A water pump bypass hose (Fig. 56) is used

between the intake manifold and water pump on all

gas powered engines. To test for leaks, (Refer to 7 -

COOLING - DIAGNOSIS AND TESTING).

(1) Partially drain the cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE). Do not

waste reusable coolant. If the solution is clean, drain

the coolant into a clean container for reuse.

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP. ALWAYS WEAR SAFETY GLASSES WHEN

SERVICING CONSTANT TENSION CLAMPS.

Fig. 53 Idler Pulley - 5.9L V-8 Gas Engine

Fig. 54 Coolant Return

1 - COOLANT RETURN TUBE

2 - WATER PUMP

3 - TUBE MOUNTING BOLT

4 - O-RING

Fig. 55 Bracket Bolts - 5.9L V-8 Gas

1 - COOLANT TUBE MOUNTING BOLT

2 - BRACKET MOUNTING BOLTS

DRENGINE 7 - 69

WATER PUMP INLET TUBE - 5.9L (Continued)

Page 357 of 2895

CAUTION: A number or letter is stamped into the

tongue of the constant tension clamps. If replace-

ment is necessary, use only an original equipment

clamp with a matching number or letter and width.

(2) Loosen both of the bypass hose clamps and

position them to the center of the hose.

(3) Removethe hose from the vehicle.

INSTALLATION

INSTALLATION - WATER PUMP BYPASS HOSE

WITH AIR CONDITIONING

(1) Position the bypass hose clamps to the center

of the bypass hose.

(2) Install the bypass hose to the engine.

(3) Secure both of the hose clamps.

(4) Install the generator-A/C mounting bracket

assembly to the engine. Tighten bolt number 1 (Fig.

53) to 41 N´m (30 ft. lbs.). Tighten bolt number 2

(Fig. 53) to 28 N´m (20 ft. lbs.). Tighten bracket

mounting bolts (Fig. 53) (Fig. 53) to 40 N´m (30 ft.

lbs.).

(5) Install a new O-ring to the heater hose coolant

return tube. Coat the new O-ring with antifreeze

before installation.

(6) Install the coolant return tube and its mount-

ing bolt to the engine.

(7) Connect the throttle body control cables.

(8) Install the oil dipstick mounting bolt.

(9) Install the idler pulley. Tighten the bolt to 41

N´m (30 ft. lbs.) (Fig. 57).

(10) Install the drive belt (Refer to 7 - COOLING/

ACCESSORY DRIVE/DRIVE BELTS - INSTALLA-

TION).CAUTION: When installing the serpentine accessory

drive belt, the belt must be routed correctly. If not,

the engine may overheat due to the water pump

rotating in the wrong direction (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTALLA-

TION). The correct belt with the correct length must

be used.

(11) Install the air cleaner assembly.

(12) Install the upper radiator hose to the radiator.

(13) Connect the throttle cable to the clip at the

radiator fan shroud.

(14) Connect the wiring harness to the A/C com-

pressor.

(15) Fill the cooling system (Refer to 7 - COOLING

- STANDARD PROCEDURE).

(16) Start and warm the engine. Check for leaks.

INSTALLATION - WATER PUMP BYPASS HOSE

WITHOUT AIR CONDITIONING

(1) Position the bypass hose clamps to the center

of the bypass hose.

(2) Install the bypass hose tothe engine.

(3) Secure both of the hose clamps.

(4) Fill the cooling system (Refer to 7 - COOLING

- STANDARD PROCEDURE).

(5) Start and warm the engine. Check for leaks.

WATER PUMP - 5.7L

REMOVAL

(1) Disconnect negative battery cable.

(2) Drain coolant.

(3) Remove serpentine belt.

(4) Remove fan clutch assembly.

(5) Remove coolant fill bottle.

Fig. 56 Water Pump Bypass Hose - Typical

1 - WATER PUMP BYPASS HOSE

2 - FAN BLADE ASSEMBLY

3 - VISCOUS FAN DRIVE

4 - WATER PUMP AND PULLEY

Fig. 57 Tensioner Mounting

1 - DOWEL PIN HOLE

2 - TENSIONER MOUNTING BRACKET

7 - 70 ENGINEDR

WATER PUMP INLET TUBE - 5.9L (Continued)

Page 359 of 2895

TRANSMISSION

TABLE OF CONTENTS

page page

TRANS COOLER

DESCRIPTION

DESCRIPTION........................72

DESCRIPTION........................72

OPERATION...........................72

REMOVAL.............................72

DISASSEMBLY - 5.9L ONLY...............73

ASSEMBLY - 5.9L ONLY..................73

INSTALLATION.........................73TRANS COOLER - 5.9L DIESEL

DESCRIPTION.........................73

OPERATION...........................74

REMOVAL

REMOVALÐAIR TO OIL COOLER.........74

REMOVALÐWATER TO OIL COOLER......74

INSTALLATION

INSTALLATIONÐAIR TO OIL COOLER.....75

INSTALLATION.......................75

TRANS COOLER

DESCRIPTION

DESCRIPTION

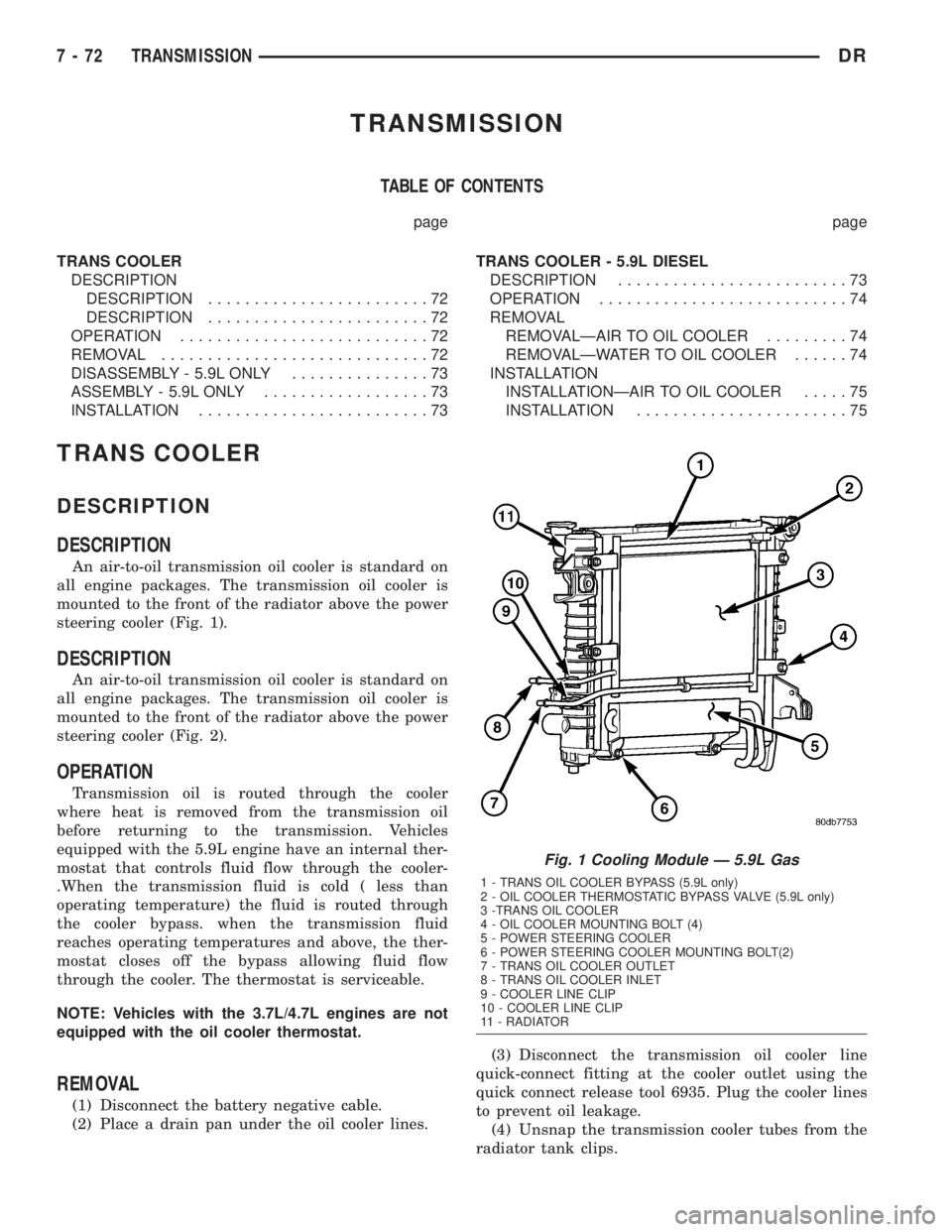

An air-to-oil transmission oil cooler is standard on

all engine packages. The transmission oil cooler is

mounted to the front of the radiator above the power

steering cooler (Fig. 1).

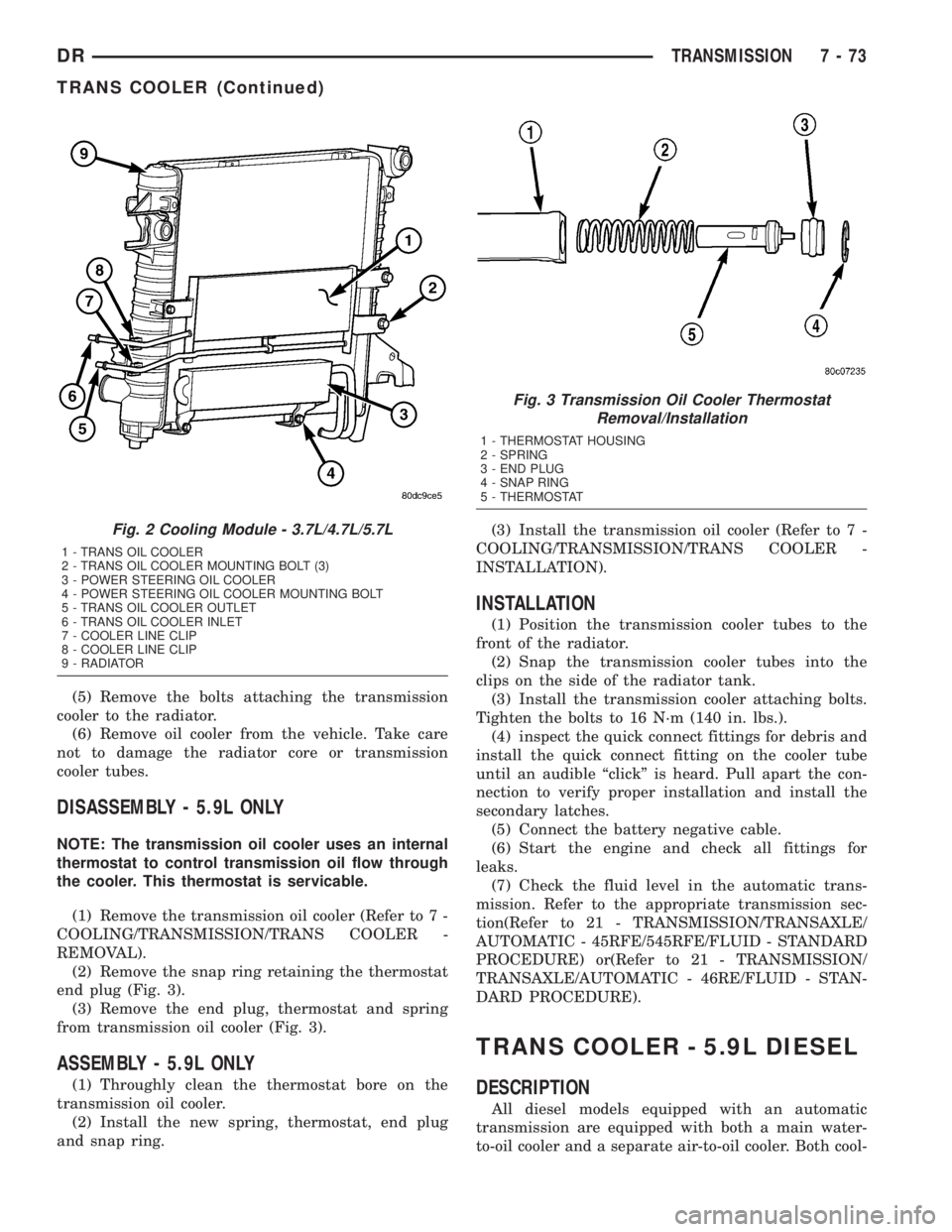

DESCRIPTION

An air-to-oil transmission oil cooler is standard on

all engine packages. The transmission oil cooler is

mounted to the front of the radiator above the power

steering cooler (Fig. 2).

OPERATION

Transmission oil is routed through the cooler

where heat is removed from the transmission oil

before returning to the transmission. Vehicles

equipped with the 5.9L engine have an internal ther-

mostat that controls fluid flow through the cooler-

.When the transmission fluid is cold ( less than

operating temperature) the fluid is routed through

the cooler bypass. when the transmission fluid

reaches operating temperatures and above, the ther-

mostat closes off the bypass allowing fluid flow

through the cooler. The thermostat is serviceable.

NOTE: Vehicles with the 3.7L/4.7L engines are not

equipped with the oil cooler thermostat.

REMOVAL

(1) Disconnect the battery negative cable.

(2) Place a drain pan under the oil cooler lines.(3) Disconnect the transmission oil cooler line

quick-connect fitting at the cooler outlet using the

quick connect release tool 6935. Plug the cooler lines

to prevent oil leakage.

(4) Unsnap the transmission cooler tubes from the

radiator tank clips.

Fig. 1 Cooling Module Ð 5.9L Gas

1 - TRANS OIL COOLER BYPASS (5.9L only)

2 - OIL COOLER THERMOSTATIC BYPASS VALVE (5.9L only)

3 -TRANS OIL COOLER

4 - OIL COOLER MOUNTING BOLT (4)

5 - POWER STEERING COOLER

6 - POWER STEERING COOLER MOUNTING BOLT(2)

7 - TRANS OIL COOLER OUTLET

8 - TRANS OIL COOLER INLET

9 - COOLER LINE CLIP

10 - COOLER LINE CLIP

11 - RADIATOR

7 - 72 TRANSMISSIONDR

Page 360 of 2895

(5) Remove the bolts attaching the transmission

cooler to the radiator.

(6) Remove oil cooler from the vehicle. Take care

not to damage the radiator core or transmission

cooler tubes.

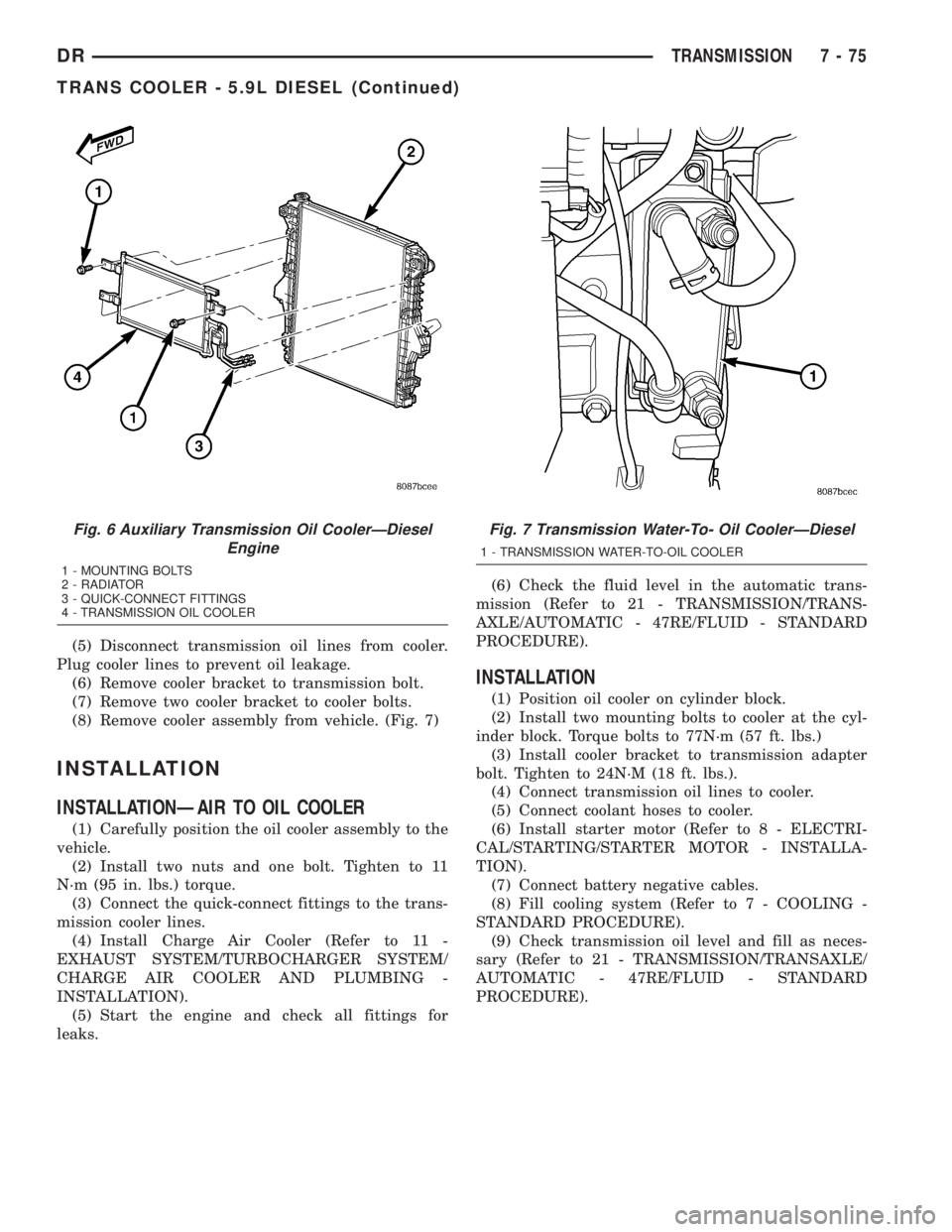

DISASSEMBLY - 5.9L ONLY

NOTE: The transmission oil cooler uses an internal

thermostat to control transmission oil flow through

the cooler. This thermostat is servicable.

(1) Remove the transmission oil cooler (Refer to 7 -

COOLING/TRANSMISSION/TRANS COOLER -

REMOVAL).

(2) Remove the snap ring retaining the thermostat

end plug (Fig. 3).

(3) Remove the end plug, thermostat and spring

from transmission oil cooler (Fig. 3).

ASSEMBLY - 5.9L ONLY

(1) Throughly clean the thermostat bore on the

transmission oil cooler.

(2) Install the new spring, thermostat, end plug

and snap ring.(3) Install the transmission oil cooler (Refer to 7 -

COOLING/TRANSMISSION/TRANS COOLER -

INSTALLATION).

INSTALLATION

(1) Position the transmission cooler tubes to the

front of the radiator.

(2) Snap the transmission cooler tubes into the

clips on the side of the radiator tank.

(3) Install the transmission cooler attaching bolts.

Tighten the bolts to 16 N´m (140 in. lbs.).

(4) inspect the quick connect fittings for debris and

install the quick connect fitting on the cooler tube

until an audible ªclickº is heard. Pull apart the con-

nection to verify proper installation and install the

secondary latches.

(5) Connect the battery negative cable.

(6) Start the engine and check all fittings for

leaks.

(7) Check the fluid level in the automatic trans-

mission. Refer to the appropriate transmission sec-

tion(Refer to 21 - TRANSMISSION/TRANSAXLE/

AUTOMATIC - 45RFE/545RFE/FLUID - STANDARD

PROCEDURE) or(Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 46RE/FLUID - STAN-

DARD PROCEDURE).

TRANS COOLER - 5.9L DIESEL

DESCRIPTION

All diesel models equipped with an automatic

transmission are equipped with both a main water-

to-oil cooler and a separate air-to-oil cooler. Both cool-

Fig. 2 Cooling Module - 3.7L/4.7L/5.7L

1 - TRANS OIL COOLER

2 - TRANS OIL COOLER MOUNTING BOLT (3)

3 - POWER STEERING OIL COOLER

4 - POWER STEERING OIL COOLER MOUNTING BOLT

5 - TRANS OIL COOLER OUTLET

6 - TRANS OIL COOLER INLET

7 - COOLER LINE CLIP

8 - COOLER LINE CLIP

9 - RADIATOR

Fig. 3 Transmission Oil Cooler Thermostat

Removal/Installation

1 - THERMOSTAT HOUSING

2 - SPRING

3 - END PLUG

4 - SNAP RING

5 - THERMOSTAT

DRTRANSMISSION 7 - 73

TRANS COOLER (Continued)

Page 361 of 2895

ers are supplied as standard equipment on diesel

engine powered models when equipped with an auto-

matic transmission.

The main water-to-oil transmission oil cooler is

mounted to a bracket on the intake side of the engine

(Fig. 4).

The air-to-oil cooler is located in front of and to the

left side of the radiator (Fig. 5).

OPERATION

The transmission oil is routed through the main

cooler first, then the auxiliary cooler where addi-

tional heat is removed from the transmission oil

before returning to the transmission. The cooler has

an internal thermostat that controls fluid flow

through the cooler. When the transmission fluid is

cold (less then operating temperature), the fluid is

routed through the cooler bypass. When the trans-

mission fluid reaches operating temperatures and

above, the thermostat closes off the bypass allowing

fluid flow through the cooler. The thermostat is ser-

vicable.

REMOVAL

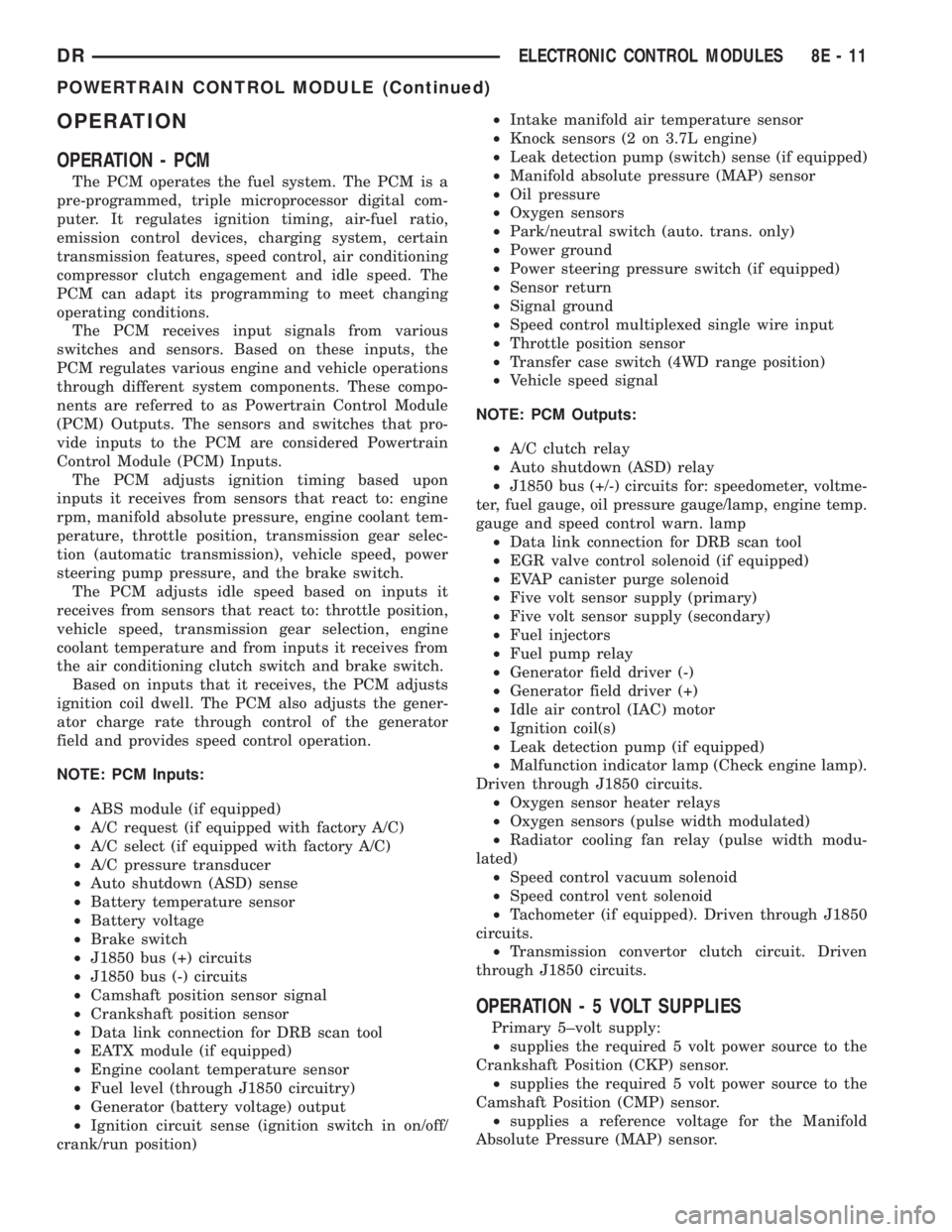

REMOVALÐAIR TO OIL COOLER

(1) Remove Charge Air Cooler (Refer to 11 -

EXHAUST SYSTEM/TURBOCHARGER SYSTEM/

CHARGE AIR COOLER AND PLUMBING -

REMOVAL).(2) Place a drain pan under the oil cooler.

(3) Raise the vehicle.

(4) Disconnect the oil cooler quick-connect fittings

from the transmission lines.

(5) Remove the charge air cooler-to-oil cooler bolt

(Fig. 6).

(6) Remove two mounting nuts.

(7) Remove the oil cooler and line assembly

towards the front of vehicle. Cooler must be rotated

and tilted into position while removing.

REMOVALÐWATER TO OIL COOLER

CAUTION: If a leak should occur in the water-to-oil

cooler mounted to the side of the engine block,

engine coolant may become mixed with transmis-

sion fluid. Transmission fluid may also enter engine

cooling system. Both cooling system and transmis-

sion should be drained and inspected in case of oil

cooler leakage.

(1) Disconnect both battery negative cables.

(2) Remove starter (Refer to 8 - ELECTRICAL/

STARTING/STARTER MOTOR - REMOVAL).

(3) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(4) Disconnect coolant lines from cooler.

Fig. 4 Transmission Water-To-Oil CoolerÐDiesel

EngineÐTypical

1 - TRANSMISSION WATER-TO-OIL COOLER

Fig. 5 Auxiliary Transmission Oil CoolerÐDiesel

Engine

1 - MOUNTING BOLTS

2 - RADIATOR

3 - QUICK-CONNECT FITTINGS

4 - TRANSMISSION OIL COOLER

7 - 74 TRANSMISSIONDR

TRANS COOLER - 5.9L DIESEL (Continued)

Page 362 of 2895

(5) Disconnect transmission oil lines from cooler.

Plug cooler lines to prevent oil leakage.

(6) Remove cooler bracket to transmission bolt.

(7) Remove two cooler bracket to cooler bolts.

(8) Remove cooler assembly from vehicle. (Fig. 7)

INSTALLATION

INSTALLATIONÐAIR TO OIL COOLER

(1) Carefully position the oil cooler assembly to the

vehicle.

(2) Install two nuts and one bolt. Tighten to 11

N´m (95 in. lbs.) torque.

(3) Connect the quick-connect fittings to the trans-

mission cooler lines.

(4) Install Charge Air Cooler (Refer to 11 -

EXHAUST SYSTEM/TURBOCHARGER SYSTEM/

CHARGE AIR COOLER AND PLUMBING -

INSTALLATION).

(5) Start the engine and check all fittings for

leaks.(6) Check the fluid level in the automatic trans-

mission (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 47RE/FLUID - STANDARD

PROCEDURE).

INSTALLATION

(1) Position oil cooler on cylinder block.

(2) Install two mounting bolts to cooler at the cyl-

inder block. Torque bolts to 77N´m (57 ft. lbs.)

(3) Install cooler bracket to transmission adapter

bolt. Tighten to 24N´M (18 ft. lbs.).

(4) Connect transmission oil lines to cooler.

(5) Connect coolant hoses to cooler.

(6) Install starter motor (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - INSTALLA-

TION).

(7) Connect battery negative cables.

(8) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(9) Check transmission oil level and fill as neces-

sary (Refer to 21 - TRANSMISSION/TRANSAXLE/

AUTOMATIC - 47RE/FLUID - STANDARD

PROCEDURE).

Fig. 6 Auxiliary Transmission Oil CoolerÐDiesel

Engine

1 - MOUNTING BOLTS

2 - RADIATOR

3 - QUICK-CONNECT FITTINGS

4 - TRANSMISSION OIL COOLER

Fig. 7 Transmission Water-To- Oil CoolerÐDiesel

1 - TRANSMISSION WATER-TO-OIL COOLER

DRTRANSMISSION 7 - 75

TRANS COOLER - 5.9L DIESEL (Continued)

Page 392 of 2895

OPERATION

OPERATION - PCM

The PCM operates the fuel system. The PCM is a

pre-programmed, triple microprocessor digital com-

puter. It regulates ignition timing, air-fuel ratio,

emission control devices, charging system, certain

transmission features, speed control, air conditioning

compressor clutch engagement and idle speed. The

PCM can adapt its programming to meet changing

operating conditions.

The PCM receives input signals from various

switches and sensors. Based on these inputs, the

PCM regulates various engine and vehicle operations

through different system components. These compo-

nents are referred to as Powertrain Control Module

(PCM) Outputs. The sensors and switches that pro-

vide inputs to the PCM are considered Powertrain

Control Module (PCM) Inputs.

The PCM adjusts ignition timing based upon

inputs it receives from sensors that react to: engine

rpm, manifold absolute pressure, engine coolant tem-

perature, throttle position, transmission gear selec-

tion (automatic transmission), vehicle speed, power

steering pump pressure, and the brake switch.

The PCM adjusts idle speed based on inputs it

receives from sensors that react to: throttle position,

vehicle speed, transmission gear selection, engine

coolant temperature and from inputs it receives from

the air conditioning clutch switch and brake switch.

Based on inputs that it receives, the PCM adjusts

ignition coil dwell. The PCM also adjusts the gener-

ator charge rate through control of the generator

field and provides speed control operation.

NOTE: PCM Inputs:

²ABS module (if equipped)

²A/C request (if equipped with factory A/C)

²A/C select (if equipped with factory A/C)

²A/C pressure transducer

²Auto shutdown (ASD) sense

²Battery temperature sensor

²Battery voltage

²Brake switch

²J1850 bus (+) circuits

²J1850 bus (-) circuits

²Camshaft position sensor signal

²Crankshaft position sensor

²Data link connection for DRB scan tool

²EATX module (if equipped)

²Engine coolant temperature sensor

²Fuel level (through J1850 circuitry)

²Generator (battery voltage) output

²Ignition circuit sense (ignition switch in on/off/

crank/run position)²Intake manifold air temperature sensor

²Knock sensors (2 on 3.7L engine)

²Leak detection pump (switch) sense (if equipped)

²Manifold absolute pressure (MAP) sensor

²Oil pressure

²Oxygen sensors

²Park/neutral switch (auto. trans. only)

²Power ground

²Power steering pressure switch (if equipped)

²Sensor return

²Signal ground

²Speed control multiplexed single wire input

²Throttle position sensor

²Transfer case switch (4WD range position)

²Vehicle speed signal

NOTE: PCM Outputs:

²A/C clutch relay

²Auto shutdown (ASD) relay

²J1850 bus (+/-) circuits for: speedometer, voltme-

ter, fuel gauge, oil pressure gauge/lamp, engine temp.

gauge and speed control warn. lamp

²Data link connection for DRB scan tool

²EGR valve control solenoid (if equipped)

²EVAP canister purge solenoid

²Five volt sensor supply (primary)

²Five volt sensor supply (secondary)

²Fuel injectors

²Fuel pump relay

²Generator field driver (-)

²Generator field driver (+)

²Idle air control (IAC) motor

²Ignition coil(s)

²Leak detection pump (if equipped)

²Malfunction indicator lamp (Check engine lamp).

Driven through J1850 circuits.

²Oxygen sensor heater relays

²Oxygen sensors (pulse width modulated)

²Radiator cooling fan relay (pulse width modu-

lated)

²Speed control vacuum solenoid

²Speed control vent solenoid

²Tachometer (if equipped). Driven through J1850

circuits.

²Transmission convertor clutch circuit. Driven

through J1850 circuits.

OPERATION - 5 VOLT SUPPLIES

Primary 5±volt supply:

²supplies the required 5 volt power source to the

Crankshaft Position (CKP) sensor.

²supplies the required 5 volt power source to the

Camshaft Position (CMP) sensor.

²supplies a reference voltage for the Manifold

Absolute Pressure (MAP) sensor.

DRELECTRONIC CONTROL MODULES 8E - 11

POWERTRAIN CONTROL MODULE (Continued)

Page 425 of 2895

²a faulty or improperly adjusted switch that

allows a lamp to stay on. Refer to Ignition-Off Draw

Test in 8, Battery for more information.

INSPECTION

The PCM (Powertrain Control Module), or ECM

(Diesel) monitors critical input and output circuits of

the charging system, making sure they are opera-

tional. A Diagnostic Trouble Code (DTC) is assigned

to each input and output circuit monitored by the

On-Board Diagnostic (OBD) system. Some charging

system circuits are checked continuously, and some

are checked only under certain conditions.

Refer to Diagnostic Trouble Codes in; Powertrain

Control Module; Electronic Control Modules for more

DTC information. This will include a complete list of

DTC's including DTC's for the charging system.

To perform a complete test of the charging system,

refer to the appropriate Powertrain Diagnostic Proce-

dures service manual and the DRBtscan tool. Per-

form the following inspections before attaching the

scan tool.

(1) Inspect the battery condition. Refer to 8, Bat-

tery for procedures.(2) Inspect condition of battery cable terminals,

battery posts, connections at engine block, starter

solenoid and relay. They should be clean and tight.

Repair as required.

(3) Inspect all fuses in both the fuseblock and

Power Distribution Center (PDC) for tightness in

receptacles. They should be properly installed and

tight. Repair or replace as required.

(4) Inspect generator mounting bolts for tightness.

Replace or tighten bolts if required. Refer to the Gen-

erator Removal/Installation section of this group for

torque specifications.

(5) Inspect generator drive belt condition and ten-

sion. Tighten or replace belt as required. Refer to

Belt Tension Specifications in 7, Cooling System.

(6) Inspect automatic belt tensioner (if equipped).

Refer to 7, Cooling System for information.

(7) Inspect generator electrical connections at gen-

erator field, battery output, and ground terminal (if

equipped). Also check generator ground wire connec-

tion at engine (if equipped). They should all be clean

and tight. Repair as required.

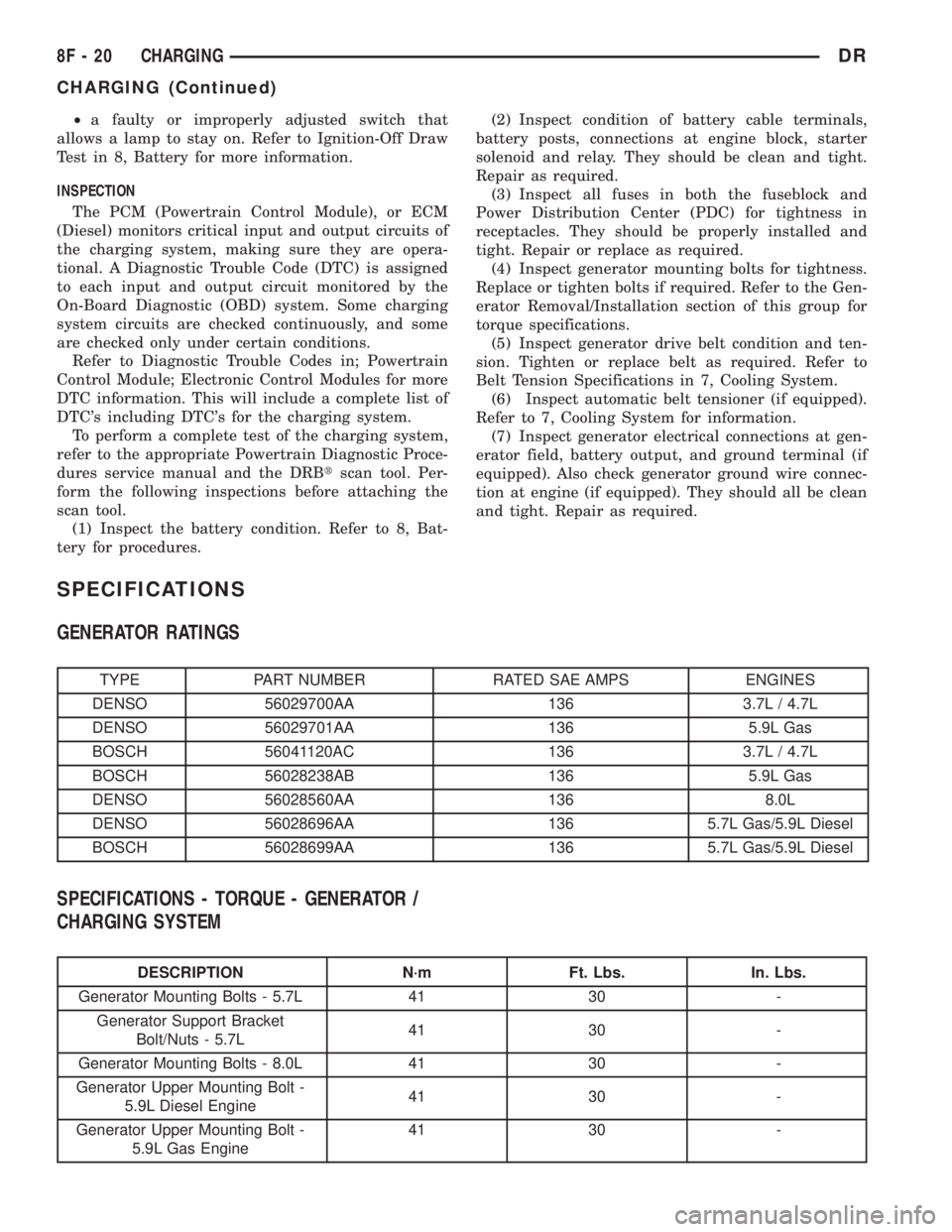

SPECIFICATIONS

GENERATOR RATINGS

TYPE PART NUMBER RATED SAE AMPS ENGINES

DENSO 56029700AA 136 3.7L / 4.7L

DENSO 56029701AA 136 5.9L Gas

BOSCH 56041120AC 136 3.7L / 4.7L

BOSCH 56028238AB 136 5.9L Gas

DENSO 56028560AA 136 8.0L

DENSO 56028696AA 136 5.7L Gas/5.9L Diesel

BOSCH 56028699AA 136 5.7L Gas/5.9L Diesel

SPECIFICATIONS - TORQUE - GENERATOR /

CHARGING SYSTEM

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Generator Mounting Bolts - 5.7L 41 30 -

Generator Support Bracket

Bolt/Nuts - 5.7L41 30 -

Generator Mounting Bolts - 8.0L 41 30 -

Generator Upper Mounting Bolt -

5.9L Diesel Engine41 30 -

Generator Upper Mounting Bolt -

5.9L Gas Engine41 30 -

8F - 20 CHARGINGDR

CHARGING (Continued)

Page 430 of 2895

(8) Remove generator from vehicle.

INSTALLATION

3.7L / 4.7L

(1) Position generator to engine and install 2 hor-

izontal bolts and 1 vertical bolt.

(2) Tighten all 3 bolts. Refer to Torque Specifica-

tions.

(3) Snap field wire connector into rear of genera-

tor.

(4) Install B+ terminal eyelet to generator output

stud. Tighten mounting nut. Refer to Torque Specifi-

cations.

CAUTION: Never force a belt over a pulley rim

using a screwdriver. The synthetic fiber of the belt

can be damaged.

CAUTION: When installing a serpentine accessory

drive belt, the belt MUST be routed correctly. The

water pump may be rotating in the wrong direction

if the belt is installed incorrectly, causing the

engine to overheat. Refer to belt routing label in

engine compartment, or refer to Belt Schematics in

7, Cooling System.

(5) Install generator drive belt. Refer to 7, Cooling

System for procedure.

(6) Install negative battery cable to battery.

5.7L

(1) Position generator to engine and install 2

mounting bolts.

(2) Tighten bolts. Refer to Torque Specifications.

(3) Position support bracket to front of generator

and install bolt and nuts. Tighten bolt / nuts. Refer

to Torque Specifications.

(4) Snap field wire connector into rear of genera-

tor.

(5) Install B+ terminal eyelet to generator output

stud. Tighten mounting nut. Refer to Torque Specifi-

cations.

CAUTION: Never force a belt over a pulley rim

using a screwdriver. The synthetic fiber of the belt

can be damaged.

CAUTION: When installing a serpentine accessory

drive belt, the belt MUST be routed correctly. The

water pump may be rotating in the wrong direction

if the belt is installed incorrectly, causing the

engine to overheat. Refer to belt routing label in

engine compartment, or refer to Belt Schematics in

7, Cooling System.

(6) Install generator drive belt. Refer to 7, Cooling

System for procedure.

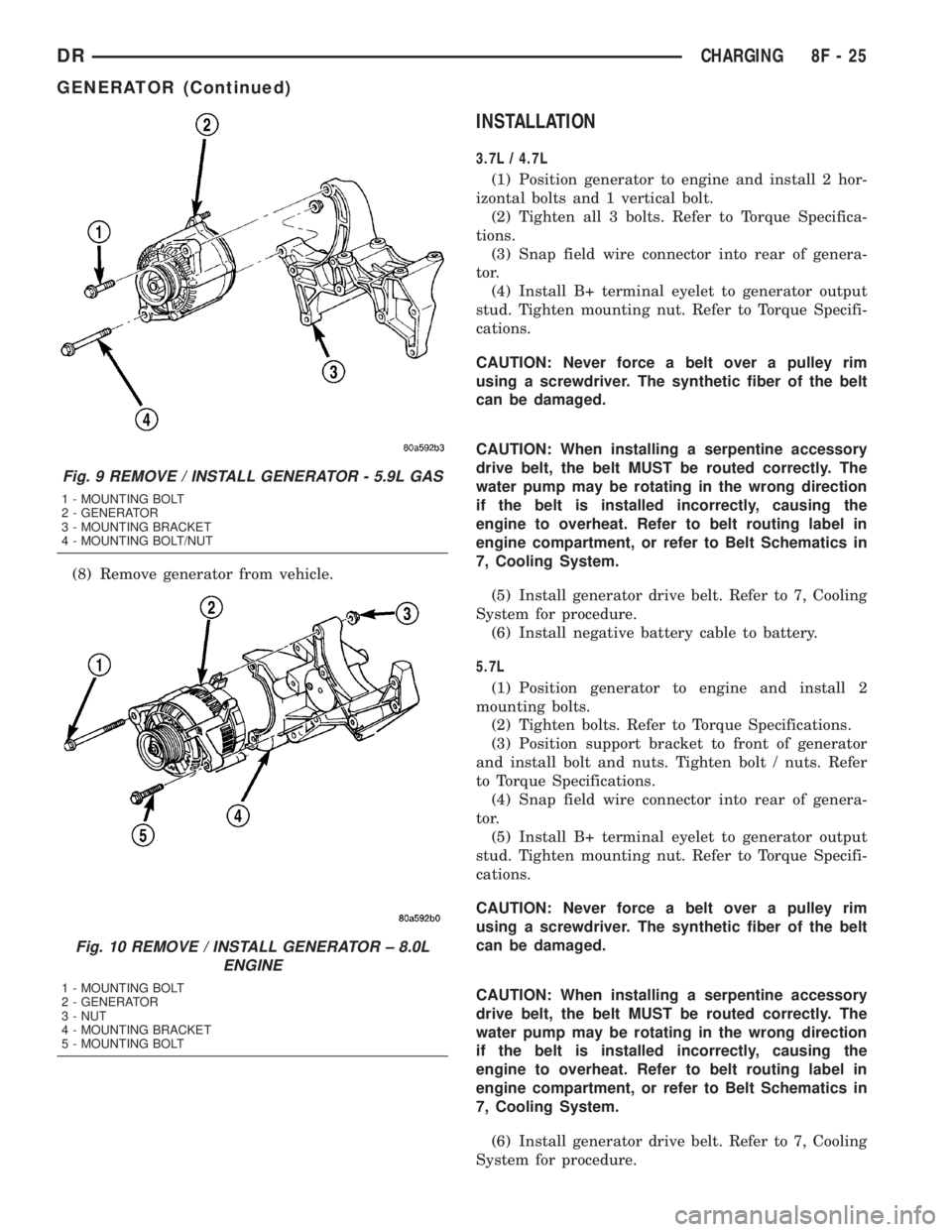

Fig. 9 REMOVE / INSTALL GENERATOR - 5.9L GAS

1 - MOUNTING BOLT

2 - GENERATOR

3 - MOUNTING BRACKET

4 - MOUNTING BOLT/NUT

Fig. 10 REMOVE / INSTALL GENERATOR ± 8.0L

ENGINE

1 - MOUNTING BOLT

2 - GENERATOR

3 - NUT

4 - MOUNTING BRACKET

5 - MOUNTING BOLT

DRCHARGING 8F - 25

GENERATOR (Continued)