ignition DODGE RAM 2003 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 453 of 2895

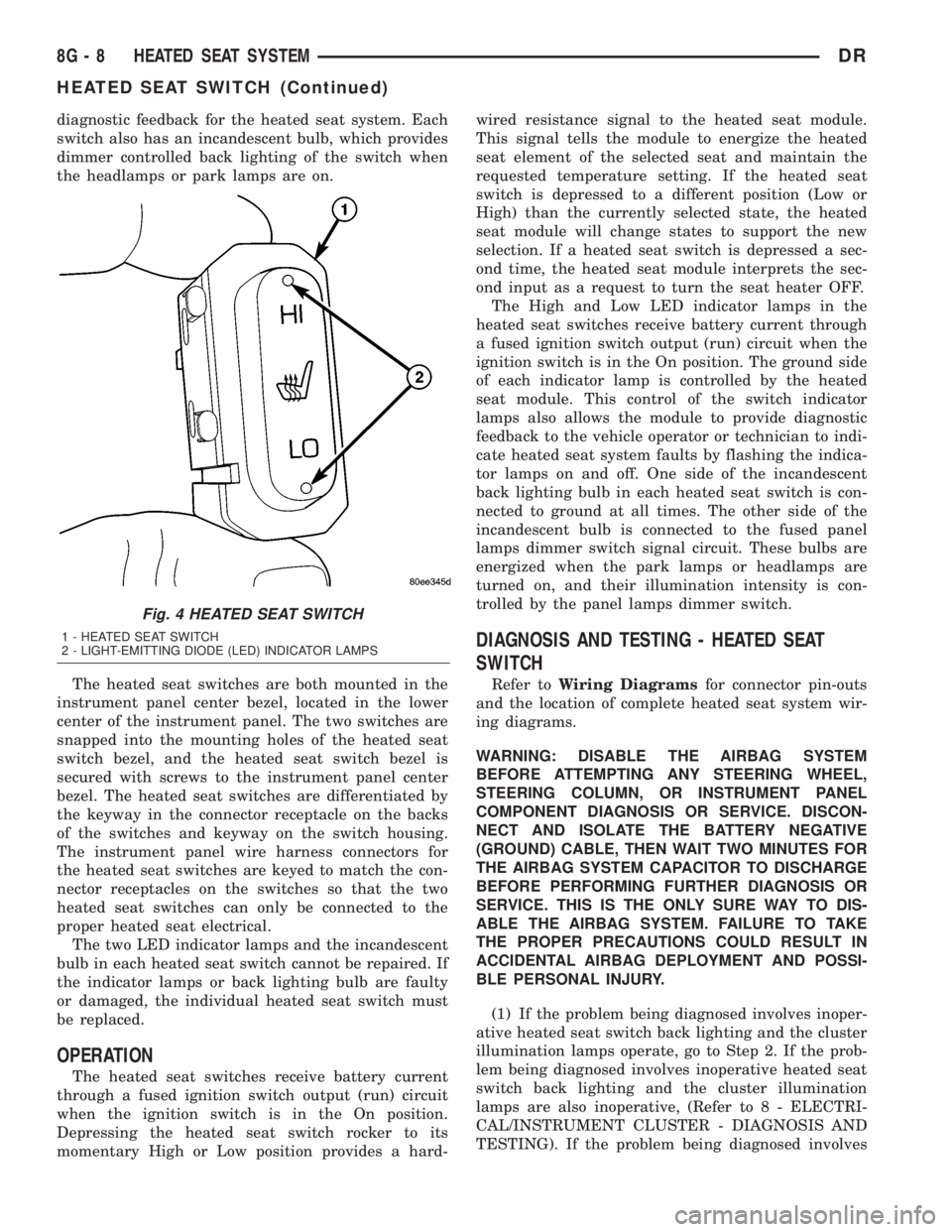

diagnostic feedback for the heated seat system. Each

switch also has an incandescent bulb, which provides

dimmer controlled back lighting of the switch when

the headlamps or park lamps are on.

The heated seat switches are both mounted in the

instrument panel center bezel, located in the lower

center of the instrument panel. The two switches are

snapped into the mounting holes of the heated seat

switch bezel, and the heated seat switch bezel is

secured with screws to the instrument panel center

bezel. The heated seat switches are differentiated by

the keyway in the connector receptacle on the backs

of the switches and keyway on the switch housing.

The instrument panel wire harness connectors for

the heated seat switches are keyed to match the con-

nector receptacles on the switches so that the two

heated seat switches can only be connected to the

proper heated seat electrical.

The two LED indicator lamps and the incandescent

bulb in each heated seat switch cannot be repaired. If

the indicator lamps or back lighting bulb are faulty

or damaged, the individual heated seat switch must

be replaced.

OPERATION

The heated seat switches receive battery current

through a fused ignition switch output (run) circuit

when the ignition switch is in the On position.

Depressing the heated seat switch rocker to its

momentary High or Low position provides a hard-wired resistance signal to the heated seat module.

This signal tells the module to energize the heated

seat element of the selected seat and maintain the

requested temperature setting. If the heated seat

switch is depressed to a different position (Low or

High) than the currently selected state, the heated

seat module will change states to support the new

selection. If a heated seat switch is depressed a sec-

ond time, the heated seat module interprets the sec-

ond input as a request to turn the seat heater OFF.

The High and Low LED indicator lamps in the

heated seat switches receive battery current through

a fused ignition switch output (run) circuit when the

ignition switch is in the On position. The ground side

of each indicator lamp is controlled by the heated

seat module. This control of the switch indicator

lamps also allows the module to provide diagnostic

feedback to the vehicle operator or technician to indi-

cate heated seat system faults by flashing the indica-

tor lamps on and off. One side of the incandescent

back lighting bulb in each heated seat switch is con-

nected to ground at all times. The other side of the

incandescent bulb is connected to the fused panel

lamps dimmer switch signal circuit. These bulbs are

energized when the park lamps or headlamps are

turned on, and their illumination intensity is con-

trolled by the panel lamps dimmer switch.

DIAGNOSIS AND TESTING - HEATED SEAT

SWITCH

Refer toWiring Diagramsfor connector pin-outs

and the location of complete heated seat system wir-

ing diagrams.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCON-

NECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE AIRBAG SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE AIRBAG SYSTEM. FAILURE TO TAKE

THE PROPER PRECAUTIONS COULD RESULT IN

ACCIDENTAL AIRBAG DEPLOYMENT AND POSSI-

BLE PERSONAL INJURY.

(1) If the problem being diagnosed involves inoper-

ative heated seat switch back lighting and the cluster

illumination lamps operate, go to Step 2. If the prob-

lem being diagnosed involves inoperative heated seat

switch back lighting and the cluster illumination

lamps are also inoperative, (Refer to 8 - ELECTRI-

CAL/INSTRUMENT CLUSTER - DIAGNOSIS AND

TESTING). If the problem being diagnosed involves

Fig. 4 HEATED SEAT SWITCH

1 - HEATED SEAT SWITCH

2 - LIGHT-EMITTING DIODE (LED) INDICATOR LAMPS

8G - 8 HEATED SEAT SYSTEMDR

HEATED SEAT SWITCH (Continued)

Page 454 of 2895

inoperative heated seat switch indicator lamps and

the heated seat elements do not heat, proceed. If the

problem being diagnosed involves inoperative heated

seat switch indicator lamps and the heated seat ele-

ments do heat, go to Step 6. If the problem being

diagnosed involves a heated seat switch indicator

lamp that remains illuminated after the heated seat

has been turned Off, (Refer to 8 - ELECTRICAL/

ELECTRONIC CONTROL MODULES/MEMORY

HEATED SEAT/MIRROR MODULE - DIAGNOSIS

AND TESTING).

(2) Disconnect and isolate the battery negative

cable. Remove the heated seat switch and bezel unit

from the instrument panel. Disconnect the heated

seat switch to be tested. Check for continuity

between the ground circuit cavity of the heated seat

switch and a good ground. There should be continu-

ity. If OK, go to Step 3. If not OK, repair the open

ground circuit to ground as required.

(3) Reconnect the battery negative cable. Turn the

park lamps on with the headlamp switch. Rotate the

panel lamps dimmer thumb wheel on the headlamp

switch upward to just before the interior lamps

detent. Check for battery voltage at the fused panel

lamps dimmer circuit cavity of the heated seat

switch. If OK, go to Step 4. If not OK, repair the

open fused panel lamps dimmer switch signal circuit

to the fuse in the Integrated Power Module as

required.

(4) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run) circuit cavity of the heated seat switch.

If OK, go to Step 5. If not OK, repair the open fused

ignition switch output (run) circuit as required.

(5) Check the continuity and resistance values of

the heated seat switch in the Neutral, Low and High

positions as shown in the Heated Seat Switch Conti-

nuity chart. If OK, refer to Step 6. If not OK, replace

the faulty heated seat switch.

HEATED SEAT SWITCH CONTINUITY

Switch PositionContinuity

BetweenResistance

Neutral 4 & 6 2.2 Kilohms

Low 4 & 6 .415 Kilohms

High 4 & 6 33 Ohms(6) Replace the inoperative heated seat switch

with a known good unit and test the operation of the

switch indicator lamps. If OK, discard the faulty

heated seat switch. If not OK, (Refer to 8 - ELEC-

TRICAL/ELECTRONIC CONTROL MODULES/

MEMORY HEATED SEAT/MIRROR MODULE -

DIAGNOSIS AND TESTING).

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Wait two minutes for the system reserve capac-

itor to discharge before beginning any airbag or

instrument panel service.

(3) Remove the center bezel from the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL - REMOV-

AL).

(4) Remove the screws that secure the heated seat

switch bezel to the instrument panel center bezel.

(5) Remove the heated seat switch bezel and both

switches from the instrument panel as a unit.

(6) From the back of the heated seat switch bezel,

gently pry the switch free and push the heated seat

switch out through the front of the bezel.

INSTALLATION

NOTE: When installing the heated seat switches, be

certain they are installed in the proper mounting

holes of the heated seat switch bezel. The heated

seat switches are differentiated by the keyway in

the connector receptacle on the backs of the

switches and keyway on the switch housing (Fig.

4).

(1) From the back of the heated seat switch bezel,

gently push the heated seat switch in through the

front of the bezel.

(2) Position the heated seat switch bezel to the

instrument panel center bezel and install the retain-

ing screws.

(3) Install the center bezel on the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL - INSTAL-

LATION).

(4) Connect the battery negative cable.

(5) Verify vehicle and system operation.

DRHEATED SEAT SYSTEM 8G - 9

HEATED SEAT SWITCH (Continued)

Page 456 of 2895

HORN

TABLE OF CONTENTS

page page

HORN SYSTEM

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING - HORN SYSTEM . . . 1

HORN

DIAGNOSIS AND TESTING - HORN..........1REMOVAL.............................2

INSTALLATION..........................2

HORN SWITCH

DESCRIPTION..........................2

DIAGNOSIS AND TESTING - HORN SWITCH . . . 2

HORN SYSTEM

DESCRIPTION

The dual-note horn system features dual electro-

magnetic horn units. The horn system includes the

following major components:

²Horn- The two horns are located on the left

side of the engine compartment below the Integrated

Power Module (IPM).

²Horn Switch- The horn switch is molded into

the driver airbag trim cover.

OPERATION

The horn system operates on battery current

received through a fuse in the Integrated Power

Module (IPM). The horn system circuit is designed so

that the system will remain operational, regardless

of the ignition switch position.

DIAGNOSIS AND TESTING - HORN SYSTEM

The most reliable, efficient, and accurate

means to diagnose the horn system requires the

use of a DRBIIItscan tool and the proper Diag-

nostic Procedures manual. The DRBIIItscan

tool can provide confirmation that the PCI data

bus is functional, that all of the electronic mod-

ules are sending and receiving the proper mes-

sages on the PCI data bus, and that the horns

are being sent the proper hard wired outputs

for them to perform their functions.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

In most cases, any problem involving continually

sounding horns can be quickly alleviated by removing

the horn fuse from the Integrated Power Module

(IPM).WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

HORN

DIAGNOSIS AND TESTING - HORN

The most reliable, efficient, and accurate

means to diagnose the horn system requires the

use of a DRBIIItscan tool and the proper Diag-

nostic Procedures manual. The DRBIIItscan

tool can provide confirmation that the PCI data

bus is functional, that all of the electronic mod-

ules are sending and receiving the proper mes-

sages on the PCI data bus, and that the horns

are being sent the proper hard wired outputs

for them to perform their functions.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

DRHORN 8H - 1

Page 458 of 2895

IGNITION CONTROL

TABLE OF CONTENTS

page page

IGNITION CONTROL

DESCRIPTION..........................1

SPECIFICATIONS

SPECIFICATIONS - TORQUE - IGNITION....3

ENGINE FIRING ORDER - 3.7L V-6.........4

ENGINE FIRING ORDER ± 4.7L V-8........4

FIRING ORDER / CABLE ROUTING ± 5.7L

V-8 ENGINE...........................4

ENGINE FIRING ORDER - 5.9L V-8.........4

SPARK PLUG CABLE ORDER ± 8.0L V-10

ENGINE..............................5

SPARK PLUG CABLE RESISTANCE........5

SPARK PLUGS........................5

IGNITION COIL RESISTANCE - 3.7L V-6.....6

IGNITION COIL RESISTANCE - 4.7L V-8.....6

IGNITION COIL RESISTANCE - 5.7L V-8.....6

IGNITION COIL RESISTANCE - 5.9L........6

IGNITION COIL RESISTANCE ± 8.0L V-10

ENGINE..............................6

IGNITION TIMING......................6

AUTOMATIC SHUT DOWN RELAY

DESCRIPTION - PCM OUTPUT.............6

OPERATION

OPERATION - PCM OUTPUT.............6

OPERATION - ASD SENSE - PCM INPUT....6

DIAGNOSIS AND TESTING - ASD AND FUEL

PUMP RELAYS........................7

REMOVAL.............................7

INSTALLATION..........................8

CAMSHAFT POSITION SENSOR

DESCRIPTION..........................8

OPERATION............................8

REMOVAL.............................11

INSTALLATION.........................14

DISTRIBUTOR

DESCRIPTION.........................16

OPERATION...........................16

REMOVAL.............................17INSTALLATION.........................18

DISTRIBUTOR CAP

DIAGNOSIS AND TESTING - DISTRIBUTOR

CAP - 5.9L V-8........................18

DISTRIBUTOR ROTOR

DIAGNOSIS AND TESTING - DISTRIBUTOR

ROTOR - 5.9L V-8.....................19

IGNITION COIL

DESCRIPTION.........................19

OPERATION...........................20

REMOVAL.............................23

INSTALLATION.........................24

KNOCK SENSOR

DESCRIPTION.........................25

OPERATION...........................25

REMOVAL.............................25

INSTALLATION.........................26

SPARK PLUG

DESCRIPTION.........................27

DIAGNOSIS AND TESTING - SPARK PLUG

CONDITIONS.........................27

REMOVAL.............................30

CLEANING

CLEANING AND ADJUSTMENT...........31

INSTALLATION.........................31

IGNITION COIL CAPACITOR

DESCRIPTION.........................33

OPERATION...........................33

REMOVAL.............................33

INSTALLATION.........................33

SPARK PLUG CABLE

DESCRIPTION.........................33

OPERATION...........................33

DIAGNOSIS AND TESTING - SPARK PLUG

CABLES............................33

REMOVAL.............................34

INSTALLATION.........................35

IGNITION CONTROL

DESCRIPTION

The ignition system is controlled by the Powertrain

Control Module (PCM) on all engines.

3.7L V-6 ENGINE

The 3.7L V-6 engine uses a separate ignition coil

for each cylinder. The one-piece coil bolts directly tothe cylinder head. Rubber boots seal the secondary

terminal ends of the coils to the top of all 6 spark

plugs. A separate electrical connector is used for each

coil.

Because of coil design, spark plug cables (second-

ary cables) are not used. A distributor is not used

with the 3.7L engine.

Two knock sensors (one for each cylinder bank) are

used to help control spark knock.

DRIGNITION CONTROL 8I - 1

Page 459 of 2895

The Auto Shutdown (ASD) relay provides battery

voltage to each ignition coil.

The ignition system consists of:

²6 Spark Plugs

²6 Separate Ignition Coils

²2 Knock Sensors

²Powertrain Control Module (PCM)

²Also to be considered part of the ignition system

are certain inputs from the Crankshaft Position,

Camshaft Position, Throttle Position, 2 knock and

MAP Sensors

4.7L V-8 ENGINE

The 4.7L V-8 engine uses a separate ignition coil for

each cylinder. The one-piece coil bolts directly to the

cylinder head. Rubber boots seal the secondary termi-

nal ends of the coils to the top of all 8 spark plugs. A

separate electrical connector is used for each coil.

Because of coil design, spark plug cables (second-

ary cables) are not used. A distributor is not used

with the 4.7L engine.

Two knock sensors (one for each cylinder bank) are

used to help control spark knock.

The Auto Shutdown (ASD) relay provides battery

voltage to each ignition coil.

The ignition system consists of:

²8 Spark Plugs

²8 Separate Ignition Coils

²2 Knock Sensors

²Powertrain Control Module (PCM)

²Also to be considered part of the ignition system

are certain inputs from the Crankshaft Position,

Camshaft Position, Throttle Position, 2 knock and

MAP Sensors

5.7L V-8 ENGINE

For additional information, also refer to Igni-

tion Coil Description and Operation.

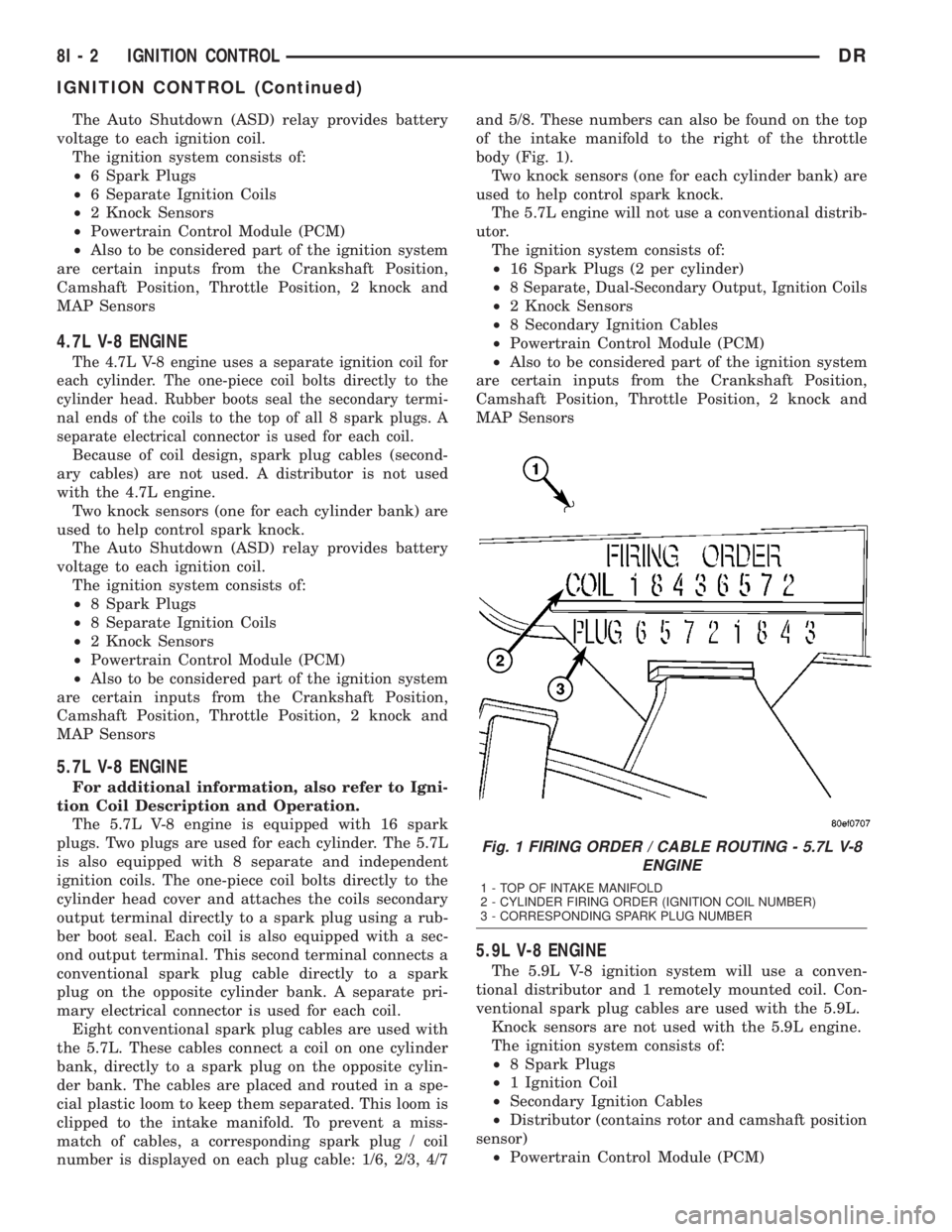

The 5.7L V-8 engine is equipped with 16 spark

plugs. Two plugs are used for each cylinder. The 5.7L

is also equipped with 8 separate and independent

ignition coils. The one-piece coil bolts directly to the

cylinder head cover and attaches the coils secondary

output terminal directly to a spark plug using a rub-

ber boot seal. Each coil is also equipped with a sec-

ond output terminal. This second terminal connects a

conventional spark plug cable directly to a spark

plug on the opposite cylinder bank. A separate pri-

mary electrical connector is used for each coil.

Eight conventional spark plug cables are used with

the 5.7L. These cables connect a coil on one cylinder

bank, directly to a spark plug on the opposite cylin-

der bank. The cables are placed and routed in a spe-

cial plastic loom to keep them separated. This loom is

clipped to the intake manifold. To prevent a miss-

match of cables, a corresponding spark plug / coil

number is displayed on each plug cable: 1/6, 2/3, 4/7and 5/8. These numbers can also be found on the top

of the intake manifold to the right of the throttle

body (Fig. 1).

Two knock sensors (one for each cylinder bank) are

used to help control spark knock.

The 5.7L engine will not use a conventional distrib-

utor.

The ignition system consists of:

²16 Spark Plugs (2 per cylinder)

²

8 Separate, Dual-Secondary Output, Ignition Coils

²2 Knock Sensors

²8 Secondary Ignition Cables

²Powertrain Control Module (PCM)

²Also to be considered part of the ignition system

are certain inputs from the Crankshaft Position,

Camshaft Position, Throttle Position, 2 knock and

MAP Sensors

5.9L V-8 ENGINE

The 5.9L V-8 ignition system will use a conven-

tional distributor and 1 remotely mounted coil. Con-

ventional spark plug cables are used with the 5.9L.

Knock sensors are not used with the 5.9L engine.

The ignition system consists of:

²8 Spark Plugs

²1 Ignition Coil

²Secondary Ignition Cables

²Distributor (contains rotor and camshaft position

sensor)

²Powertrain Control Module (PCM)

Fig. 1 FIRING ORDER / CABLE ROUTING - 5.7L V-8

ENGINE

1 - TOP OF INTAKE MANIFOLD

2 - CYLINDER FIRING ORDER (IGNITION COIL NUMBER)

3 - CORRESPONDING SPARK PLUG NUMBER

8I - 2 IGNITION CONTROLDR

IGNITION CONTROL (Continued)

Page 460 of 2895

²Also to be considered part of the ignition system

are certain inputs from the Crankshaft Position, Cam-

shaft Position, Throttle Position and MAP Sensors

8.0L V-10 ENGINE

. The 8.0L V-10 engine is equipped with 2 remote

coil packs. Conventional spark plug cables are used

with the 8.0L engine. The 8.0L engine will not use a

conventional distributor

The ignition coils are individually fired, but each

coil is a dual output. Refer to Ignition Coil for addi-

tional information.Knock sensors are not used with the 8.0L engine.

The ignition system consists of:

²10 Spark Plugs

²2 Ignition Coil packs containing 10 individual

coils

²10 Secondary Ignition Cables

²Powertrain Control Module (PCM)

²Also to be considered part of the ignition system

are certain inputs from the Crankshaft Position,

Camshaft Position, Throttle Position and MAP Sen-

sors

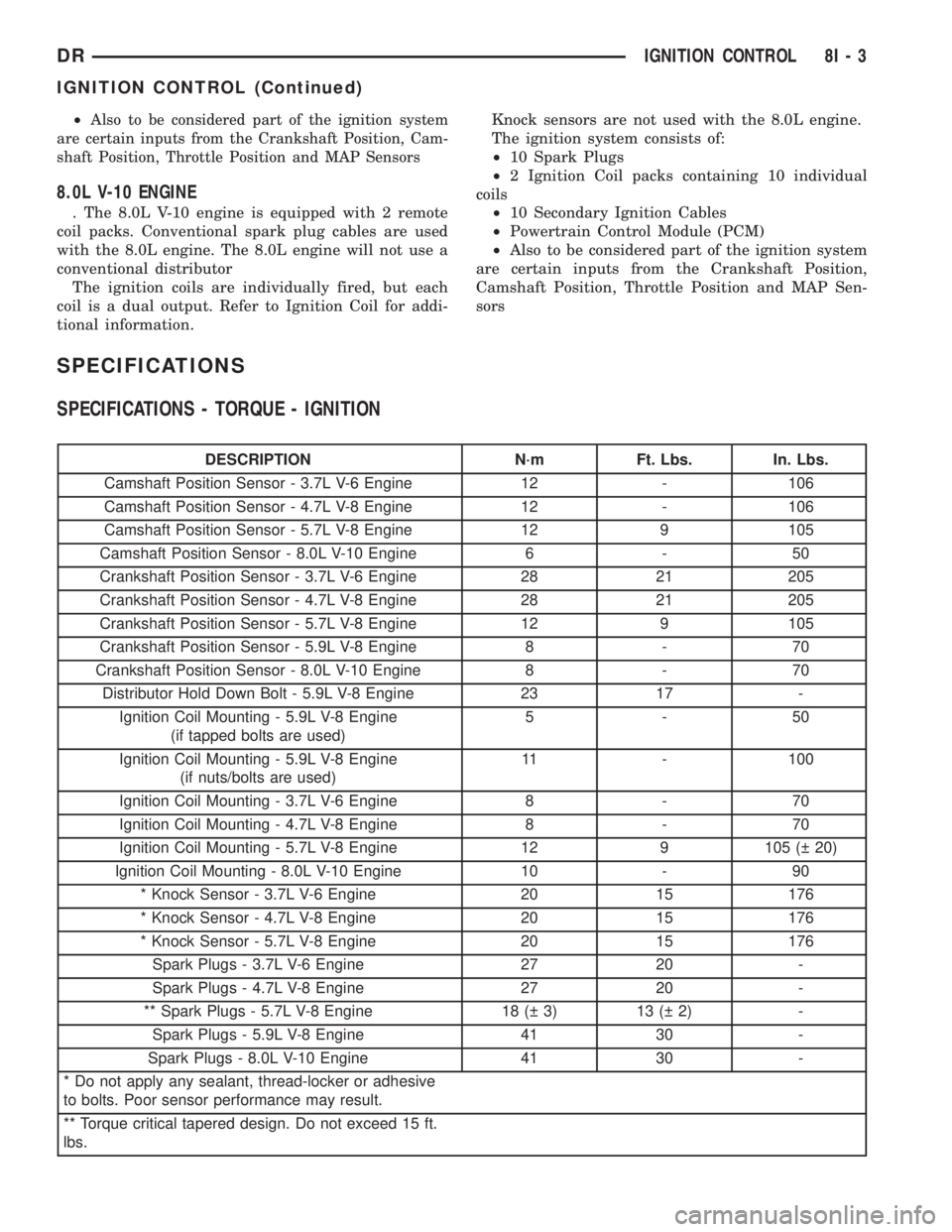

SPECIFICATIONS

SPECIFICATIONS - TORQUE - IGNITION

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Camshaft Position Sensor - 3.7L V-6 Engine 12 - 106

Camshaft Position Sensor - 4.7L V-8 Engine 12 - 106

Camshaft Position Sensor - 5.7L V-8 Engine 12 9 105

Camshaft Position Sensor - 8.0L V-10 Engine 6 - 50

Crankshaft Position Sensor - 3.7L V-6 Engine 28 21 205

Crankshaft Position Sensor - 4.7L V-8 Engine 28 21 205

Crankshaft Position Sensor - 5.7L V-8 Engine 12 9 105

Crankshaft Position Sensor - 5.9L V-8 Engine 8 - 70

Crankshaft Position Sensor - 8.0L V-10 Engine 8 - 70

Distributor Hold Down Bolt - 5.9L V-8 Engine 23 17 -

Ignition Coil Mounting - 5.9L V-8 Engine

(if tapped bolts are used)5-50

Ignition Coil Mounting - 5.9L V-8 Engine

(if nuts/bolts are used)11 - 100

Ignition Coil Mounting - 3.7L V-6 Engine 8 - 70

Ignition Coil Mounting - 4.7L V-8 Engine 8 - 70

Ignition Coil Mounting - 5.7L V-8 Engine 12 9 105 ( 20)

Ignition Coil Mounting - 8.0L V-10 Engine 10 - 90

* Knock Sensor - 3.7L V-6 Engine 20 15 176

* Knock Sensor - 4.7L V-8 Engine 20 15 176

* Knock Sensor - 5.7L V-8 Engine 20 15 176

Spark Plugs - 3.7L V-6 Engine 27 20 -

Spark Plugs - 4.7L V-8 Engine 27 20 -

** Spark Plugs - 5.7L V-8 Engine 18 ( 3) 13 ( 2) -

Spark Plugs - 5.9L V-8 Engine 41 30 -

Spark Plugs - 8.0L V-10 Engine 41 30 -

* Do not apply any sealant, thread-locker or adhesive

to bolts. Poor sensor performance may result.

** Torque critical tapered design. Do not exceed 15 ft.

lbs.

DRIGNITION CONTROL 8I - 3

IGNITION CONTROL (Continued)

Page 461 of 2895

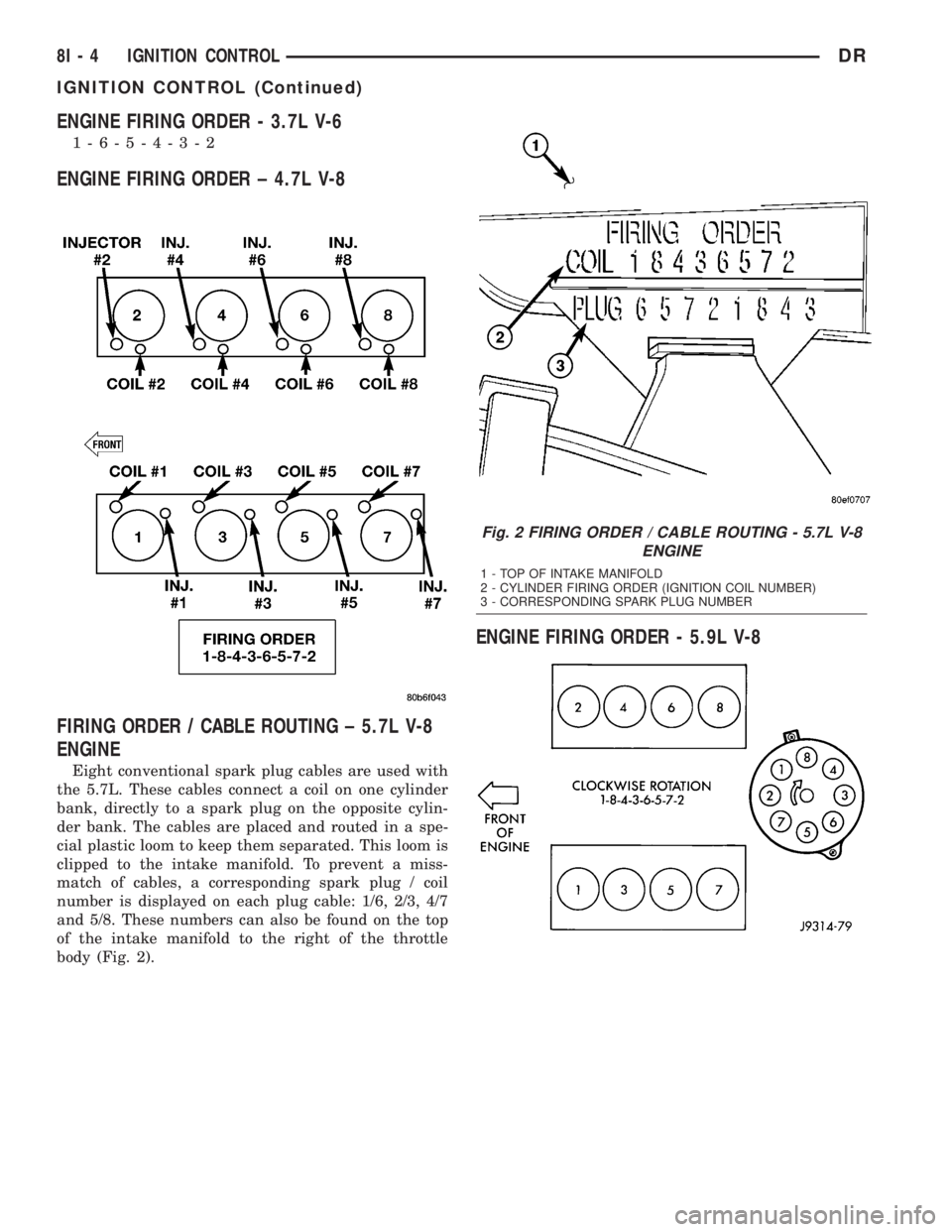

ENGINE FIRING ORDER - 3.7L V-6

1-6-5-4-3-2

ENGINE FIRING ORDER ± 4.7L V-8

FIRING ORDER / CABLE ROUTING ± 5.7L V-8

ENGINE

Eight conventional spark plug cables are used with

the 5.7L. These cables connect a coil on one cylinder

bank, directly to a spark plug on the opposite cylin-

der bank. The cables are placed and routed in a spe-

cial plastic loom to keep them separated. This loom is

clipped to the intake manifold. To prevent a miss-

match of cables, a corresponding spark plug / coil

number is displayed on each plug cable: 1/6, 2/3, 4/7

and 5/8. These numbers can also be found on the top

of the intake manifold to the right of the throttle

body (Fig. 2).

ENGINE FIRING ORDER - 5.9L V-8

Fig. 2 FIRING ORDER / CABLE ROUTING - 5.7L V-8

ENGINE

1 - TOP OF INTAKE MANIFOLD

2 - CYLINDER FIRING ORDER (IGNITION COIL NUMBER)

3 - CORRESPONDING SPARK PLUG NUMBER

8I - 4 IGNITION CONTROLDR

IGNITION CONTROL (Continued)

Page 462 of 2895

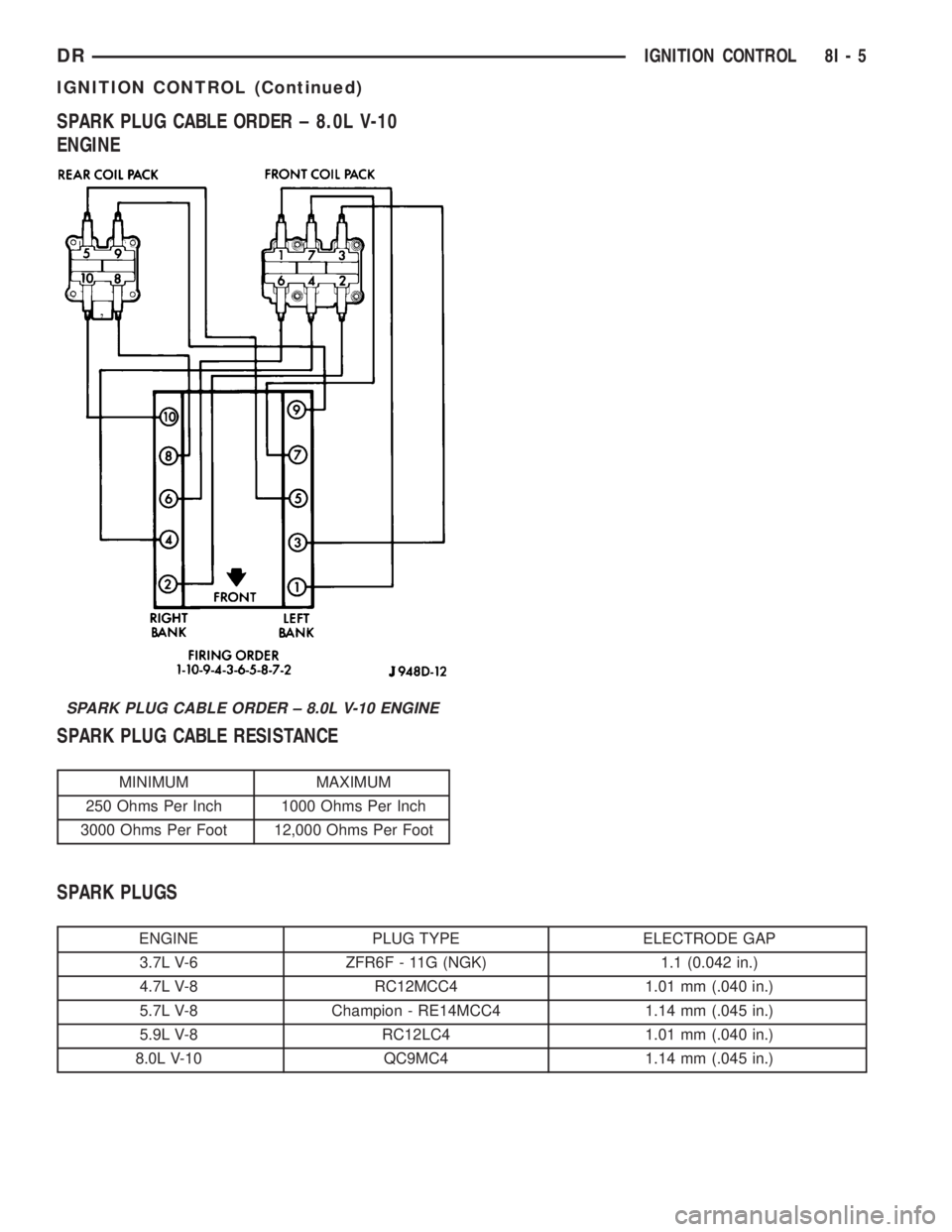

SPARK PLUG CABLE ORDER ± 8.0L V-10

ENGINE

SPARK PLUG CABLE RESISTANCE

MINIMUM MAXIMUM

250 Ohms Per Inch 1000 Ohms Per Inch

3000 Ohms Per Foot 12,000 Ohms Per Foot

SPARK PLUGS

ENGINE PLUG TYPE ELECTRODE GAP

3.7L V-6 ZFR6F - 11G (NGK) 1.1 (0.042 in.)

4.7L V-8 RC12MCC4 1.01 mm (.040 in.)

5.7L V-8 Champion - RE14MCC4 1.14 mm (.045 in.)

5.9L V-8 RC12LC4 1.01 mm (.040 in.)

8.0L V-10 QC9MC4 1.14 mm (.045 in.)

SPARK PLUG CABLE ORDER ± 8.0L V-10 ENGINE

DRIGNITION CONTROL 8I - 5

IGNITION CONTROL (Continued)

Page 463 of 2895

IGNITION COIL RESISTANCE - 3.7L V-6

PRIMARY RESISTANCE

21-27ÉC (70-80ÉF)SECONDARY

RESISTANCE 21-27ÉC

(70-80ÉF)

0.6 - 0.9 Ohms 6,000 - 9,000 Ohms

IGNITION COIL RESISTANCE - 4.7L V-8

PRIMARY

RESISTANCE 21-27ÉC

(70-80ÉF)SECONDARY

RESISTANCE 21-27ÉC

(70-80ÉF)

0.6 - 0.9 Ohms 6,000 - 9,000 Ohms

IGNITION COIL RESISTANCE - 5.7L V-8

PRIMARY RESISTANCE @ 21-27ÉC (70-80ÉF)

0.558 - 0.682 Ohms

(Plus or Minus 10% @ 70-80É F)

IGNITION COIL RESISTANCE - 5.9L

COIL MANUFACTURERPRIMARY RESISTANCE

21-27ÉC (70-80ÉF)SECONDARY RESISTANCE 21-27ÉC

(70-80ÉF)

Diamond 0.97 - 1.18 Ohms 11,300 - 15,300 Ohms

Toyodenso 0.95 - 1.20 Ohms 11,300 - 13,300 Ohms

IGNITION COIL RESISTANCE ± 8.0L V-10

ENGINE

Primary Resistance: 0.53-0.65 Ohms. Test across the

primary connector. Refer to text for test procedures.

Secondary Resistance: 10.9-14.7K Ohms. Test across

the individual coil towers. Refer to text for test

procedures.

IGNITION TIMING

Ignition timing is not adjustable on any engine.

AUTOMATIC SHUT DOWN

RELAY

DESCRIPTION - PCM OUTPUT

The 5±pin, 12±volt, Automatic Shutdown (ASD)

relay is located in the Power Distribution Center

(PDC). Refer to label on PDC cover for relay location.

OPERATION

OPERATION - PCM OUTPUT

The ASD relay supplies battery voltage (12+ volts)

to the fuel injectors and ignition coil(s). With certain

emissions packages it also supplies 12±volts to the

oxygen sensor heating elements.The ground circuit for the coil within the ASD

relay is controlled by the Powertrain Control Module

(PCM). The PCM operates the ASD relay by switch-

ing its ground circuit on and off.

The ASD relay will be shut±down, meaning the

12±volt power supply to the ASD relay will be de-ac-

tivated by the PCM if:

²the ignition key is left in the ON position. This

is if the engine has not been running for approxi-

mately 1.8 seconds.

²there is a crankshaft position sensor signal to

the PCM that is lower than pre-determined values.

OPERATION - ASD SENSE - PCM INPUT

A 12 volt signal at this input indicates to the PCM

that the ASD has been activated. The relay is used to

connect the oxygen sensor heater element, ignition

coil and fuel injectors to 12 volt + power supply.

This input is used only to sense that the ASD relay

is energized. If the Powertrain Control Module

(PCM) does not see 12 volts at this input when the

ASD should be activated, it will set a Diagnostic

Trouble Code (DTC).

8I - 6 IGNITION CONTROLDR

IGNITION CONTROL (Continued)

Page 464 of 2895

DIAGNOSIS AND TESTING - ASD AND FUEL

PUMP RELAYS

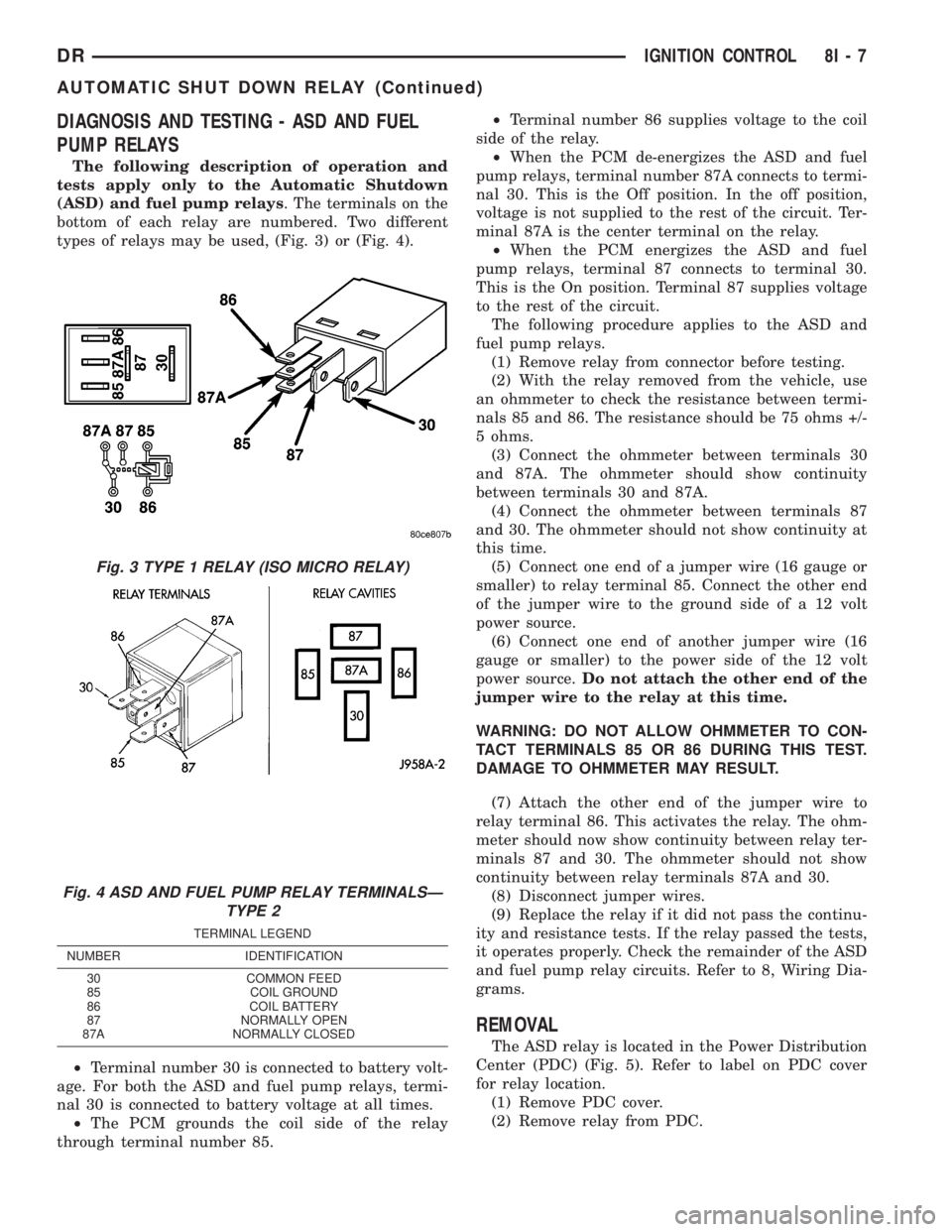

The following description of operation and

tests apply only to the Automatic Shutdown

(ASD) and fuel pump relays. The terminals on the

bottom of each relay are numbered. Two different

types of relays may be used, (Fig. 3) or (Fig. 4).

²Terminal number 30 is connected to battery volt-

age. For both the ASD and fuel pump relays, termi-

nal 30 is connected to battery voltage at all times.

²The PCM grounds the coil side of the relay

through terminal number 85.²Terminal number 86 supplies voltage to the coil

side of the relay.

²When the PCM de-energizes the ASD and fuel

pump relays, terminal number 87A connects to termi-

nal 30. This is the Off position. In the off position,

voltage is not supplied to the rest of the circuit. Ter-

minal 87A is the center terminal on the relay.

²When the PCM energizes the ASD and fuel

pump relays, terminal 87 connects to terminal 30.

This is the On position. Terminal 87 supplies voltage

to the rest of the circuit.

The following procedure applies to the ASD and

fuel pump relays.

(1) Remove relay from connector before testing.

(2) With the relay removed from the vehicle, use

an ohmmeter to check the resistance between termi-

nals 85 and 86. The resistance should be 75 ohms +/-

5 ohms.

(3) Connect the ohmmeter between terminals 30

and 87A. The ohmmeter should show continuity

between terminals 30 and 87A.

(4) Connect the ohmmeter between terminals 87

and 30. The ohmmeter should not show continuity at

this time.

(5) Connect one end of a jumper wire (16 gauge or

smaller) to relay terminal 85. Connect the other end

of the jumper wire to the ground side of a 12 volt

power source.

(6) Connect one end of another jumper wire (16

gauge or smaller) to the power side of the 12 volt

power source.Do not attach the other end of the

jumper wire to the relay at this time.

WARNING: DO NOT ALLOW OHMMETER TO CON-

TACT TERMINALS 85 OR 86 DURING THIS TEST.

DAMAGE TO OHMMETER MAY RESULT.

(7) Attach the other end of the jumper wire to

relay terminal 86. This activates the relay. The ohm-

meter should now show continuity between relay ter-

minals 87 and 30. The ohmmeter should not show

continuity between relay terminals 87A and 30.

(8) Disconnect jumper wires.

(9) Replace the relay if it did not pass the continu-

ity and resistance tests. If the relay passed the tests,

it operates properly. Check the remainder of the ASD

and fuel pump relay circuits. Refer to 8, Wiring Dia-

grams.

REMOVAL

The ASD relay is located in the Power Distribution

Center (PDC) (Fig. 5). Refer to label on PDC cover

for relay location.

(1) Remove PDC cover.

(2) Remove relay from PDC.

Fig. 3 TYPE 1 RELAY (ISO MICRO RELAY)

Fig. 4 ASD AND FUEL PUMP RELAY TERMINALSÐ

TYPE 2

TERMINAL LEGEND

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

DRIGNITION CONTROL 8I - 7

AUTOMATIC SHUT DOWN RELAY (Continued)