Engine system DODGE RAM 2003 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 387 of 2895

DIAGNOSIS AND TESTING - FRONT CONTROL

MODULE

The front control module is a printed circuit board

based module with a on-board micro-processor. The

front control module interfaces with other electronic

modules in the vehicle via the Programmable Com-

munications Interface (PCI) data bus (J1850). In

order to obtain conclusive testing the Programmable

Communications Interface (PCI) data bus network

and all of the electronic modules that provide inputs

to, or receive outputs from the front control module

must be checked. All PCI (J1850) communication

faults must be resolved prior to further diagnosing

any front control module related issues.

The front control module was designed to be diag-

nosed with an appropriate diagnostic scan tool, such

as the DRB IIIt. The most reliable, efficient, and

accurate means to diagnose the front control module

requires the use of a DRB IIItscan tool and the

proper Body Diagnostic Procedures manual.

Before any testing of the front control module is

attempted, the battery should be fully charged and

all wire harness and ground connections inspected

around the affected areas on the vehicle.

REMOVAL

(1) Disconnect the positive and negative battery

cables from the battery.

(2) Partially remove the integrated power module

from the engine compartment (Refer to 8 - ELECTRI-

CAL/POWER DISTRIBUTION/INTEGRATED

POWER MODULE - REMOVAL).

(3) Remove the front control module retaining

screws.

(4) Using both hands, pull the front control module

straightfrom the integrated power module assembly

to disconnect the 49-way electrical connector and

remove the front control module from the vehicle.

INSTALLATION

(1) Install the front control module on the inte-

grated power module assembly by pushing the

49-way electrical connector straight in.

(2) Install the front control module retaining

screws. Torque the screws to 7 in. lbs.

(3) Install the integrated power module (Refer to 8

- ELECTRICAL/POWER DISTRIBUTION/INTE-

GRATED POWER MODULE - INSTALLATION).

(4) Connect the positive and negative battery

cables.

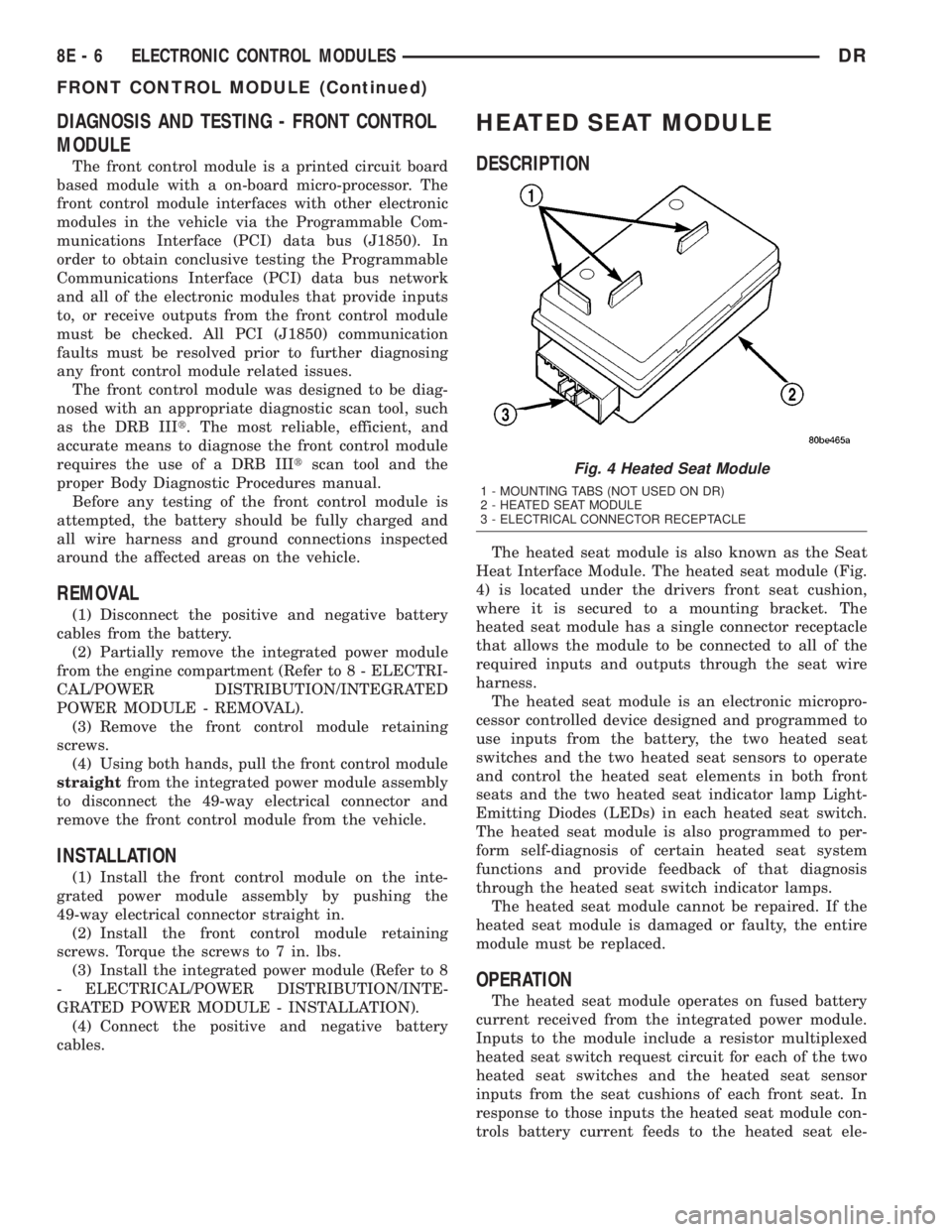

HEATED SEAT MODULE

DESCRIPTION

The heated seat module is also known as the Seat

Heat Interface Module. The heated seat module (Fig.

4) is located under the drivers front seat cushion,

where it is secured to a mounting bracket. The

heated seat module has a single connector receptacle

that allows the module to be connected to all of the

required inputs and outputs through the seat wire

harness.

The heated seat module is an electronic micropro-

cessor controlled device designed and programmed to

use inputs from the battery, the two heated seat

switches and the two heated seat sensors to operate

and control the heated seat elements in both front

seats and the two heated seat indicator lamp Light-

Emitting Diodes (LEDs) in each heated seat switch.

The heated seat module is also programmed to per-

form self-diagnosis of certain heated seat system

functions and provide feedback of that diagnosis

through the heated seat switch indicator lamps.

The heated seat module cannot be repaired. If the

heated seat module is damaged or faulty, the entire

module must be replaced.

OPERATION

The heated seat module operates on fused battery

current received from the integrated power module.

Inputs to the module include a resistor multiplexed

heated seat switch request circuit for each of the two

heated seat switches and the heated seat sensor

inputs from the seat cushions of each front seat. In

response to those inputs the heated seat module con-

trols battery current feeds to the heated seat ele-

Fig. 4 Heated Seat Module

1 - MOUNTING TABS (NOT USED ON DR)

2 - HEATED SEAT MODULE

3 - ELECTRICAL CONNECTOR RECEPTACLE

8E - 6 ELECTRONIC CONTROL MODULESDR

FRONT CONTROL MODULE (Continued)

Page 389 of 2895

POWERTRAIN CONTROL

MODULE

DESCRIPTION

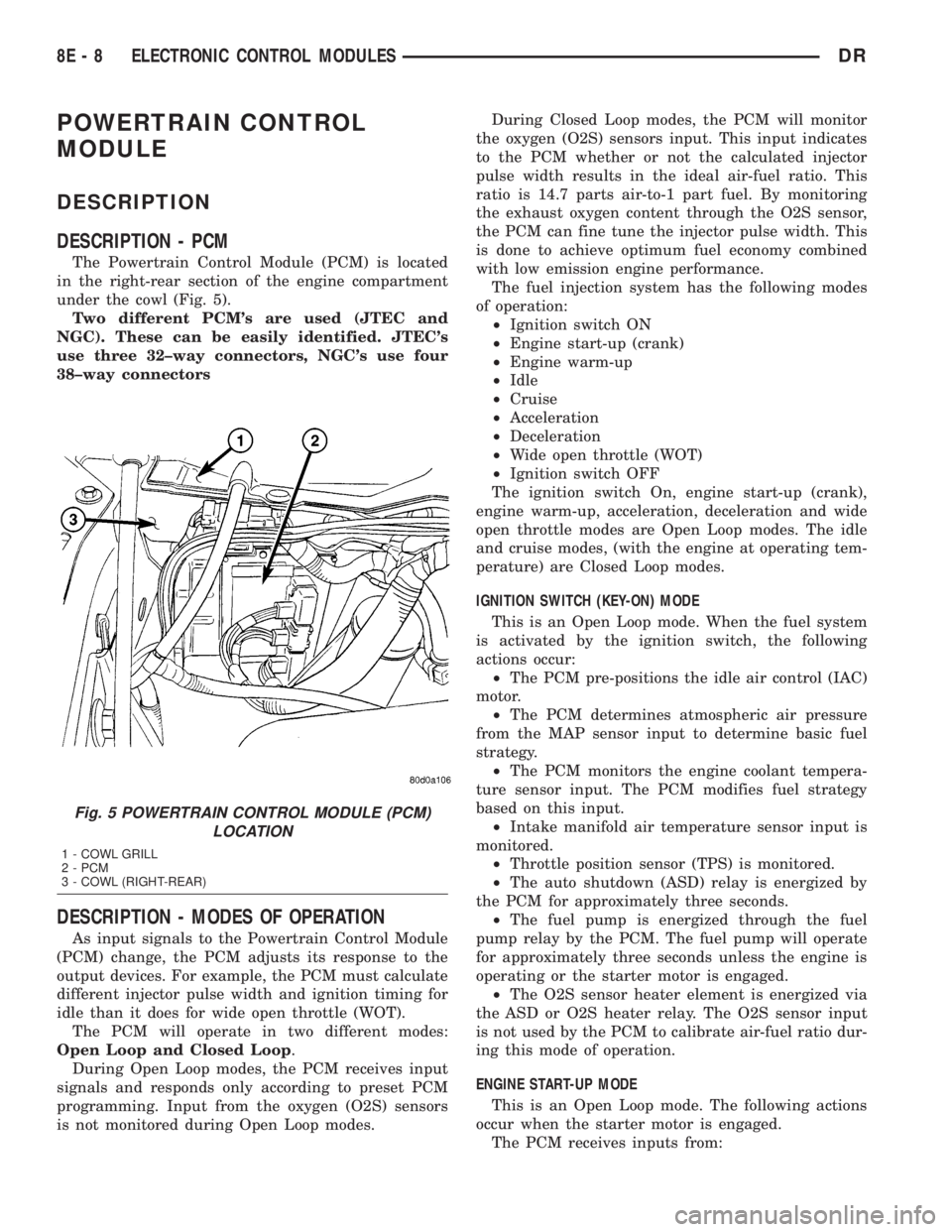

DESCRIPTION - PCM

The Powertrain Control Module (PCM) is located

in the right-rear section of the engine compartment

under the cowl (Fig. 5).

Two different PCM's are used (JTEC and

NGC). These can be easily identified. JTEC's

use three 32±way connectors, NGC's use four

38±way connectors

DESCRIPTION - MODES OF OPERATION

As input signals to the Powertrain Control Module

(PCM) change, the PCM adjusts its response to the

output devices. For example, the PCM must calculate

different injector pulse width and ignition timing for

idle than it does for wide open throttle (WOT).

The PCM will operate in two different modes:

Open Loop and Closed Loop.

During Open Loop modes, the PCM receives input

signals and responds only according to preset PCM

programming. Input from the oxygen (O2S) sensors

is not monitored during Open Loop modes.During Closed Loop modes, the PCM will monitor

the oxygen (O2S) sensors input. This input indicates

to the PCM whether or not the calculated injector

pulse width results in the ideal air-fuel ratio. This

ratio is 14.7 parts air-to-1 part fuel. By monitoring

the exhaust oxygen content through the O2S sensor,

the PCM can fine tune the injector pulse width. This

is done to achieve optimum fuel economy combined

with low emission engine performance.

The fuel injection system has the following modes

of operation:

²Ignition switch ON

²Engine start-up (crank)

²Engine warm-up

²Idle

²Cruise

²Acceleration

²Deceleration

²Wide open throttle (WOT)

²Ignition switch OFF

The ignition switch On, engine start-up (crank),

engine warm-up, acceleration, deceleration and wide

open throttle modes are Open Loop modes. The idle

and cruise modes, (with the engine at operating tem-

perature) are Closed Loop modes.

IGNITION SWITCH (KEY-ON) MODE

This is an Open Loop mode. When the fuel system

is activated by the ignition switch, the following

actions occur:

²The PCM pre-positions the idle air control (IAC)

motor.

²The PCM determines atmospheric air pressure

from the MAP sensor input to determine basic fuel

strategy.

²The PCM monitors the engine coolant tempera-

ture sensor input. The PCM modifies fuel strategy

based on this input.

²Intake manifold air temperature sensor input is

monitored.

²Throttle position sensor (TPS) is monitored.

²The auto shutdown (ASD) relay is energized by

the PCM for approximately three seconds.

²The fuel pump is energized through the fuel

pump relay by the PCM. The fuel pump will operate

for approximately three seconds unless the engine is

operating or the starter motor is engaged.

²The O2S sensor heater element is energized via

the ASD or O2S heater relay. The O2S sensor input

is not used by the PCM to calibrate air-fuel ratio dur-

ing this mode of operation.

ENGINE START-UP MODE

This is an Open Loop mode. The following actions

occur when the starter motor is engaged.

The PCM receives inputs from:

Fig. 5 POWERTRAIN CONTROL MODULE (PCM)

LOCATION

1 - COWL GRILL

2 - PCM

3 - COWL (RIGHT-REAR)

8E - 8 ELECTRONIC CONTROL MODULESDR

Page 390 of 2895

²Battery voltage

²Engine coolant temperature sensor

²Crankshaft position sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal

The PCM monitors the crankshaft position sensor.

If the PCM does not receive a crankshaft position

sensor signal within 3 seconds of cranking the

engine, it will shut down the fuel injection system.

The fuel pump is activated by the PCM through

the fuel pump relay.

Voltage is applied to the fuel injectors with the

ASD relay via the PCM. The PCM will then control

the injection sequence and injector pulse width by

turning the ground circuit to each individual injector

on and off.

The PCM determines the proper ignition timing

according to input received from the crankshaft posi-

tion sensor.

ENGINE WARM-UP MODE

This is an Open Loop mode. During engine warm-

up, the PCM receives inputs from:

²Battery voltage

²Crankshaft position sensor

²Engine coolant temperature sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal

²Park/neutral switch (gear indicator signalÐauto.

trans. only)

²Air conditioning select signal (if equipped)

²Air conditioning request signal (if equipped)

Based on these inputs the following occurs:

²Voltage is applied to the fuel injectors with the

ASD relay via the PCM. The PCM will then control

the injection sequence and injector pulse width by

turning the ground circuit to each individual injector

on and off.

²The PCM adjusts engine idle speed through the

idle air control (IAC) motor and adjusts ignition tim-

ing.

²The PCM operates the A/C compressor clutch

through the A/C compressor clutch relay. This is done

if A/C has been selected by the vehicle operator and

specified pressures are met at the high and low±pres-

sure A/C switches. Refer to Heating and Air Condi-

tioning for additional information.

²When engine has reached operating tempera-

ture, the PCM will begin monitoring O2S sensor

input. The system will then leave the warm-up mode

and go into closed loop operation.IDLE MODE

When the engine is at operating temperature, this

is a Closed Loop mode. At idle speed, the PCM

receives inputs from:

²Air conditioning select signal (if equipped)

²Air conditioning request signal (if equipped)

²Battery voltage

²Crankshaft position sensor

²Engine coolant temperature sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal

²Battery voltage

²Park/neutral switch (gear indicator signalÐauto.

trans. only)

²Oxygen sensors

Based on these inputs, the following occurs:

²Voltage is applied to the fuel injectors with the

ASD relay via the PCM. The PCM will then control

injection sequence and injector pulse width by turn-

ing the ground circuit to each individual injector on

and off.

²The PCM monitors the O2S sensor input and

adjusts air-fuel ratio by varying injector pulse width.

It also adjusts engine idle speed through the idle air

control (IAC) motor.

²The PCM adjusts ignition timing by increasing

and decreasing spark advance.

²The PCM operates the A/C compressor clutch

through the A/C compressor clutch relay. This is done

if A/C has been selected by the vehicle operator and

specified pressures are met at the high and low±pres-

sure A/C switches. Refer to Heating and Air Condi-

tioning for additional information.

CRUISE MODE

When the engine is at operating temperature, this

is a Closed Loop mode. At cruising speed, the PCM

receives inputs from:

²Air conditioning select signal (if equipped)

²Air conditioning request signal (if equipped)

²Battery voltage

²Engine coolant temperature sensor

²Crankshaft position sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal

²Park/neutral switch (gear indicator signalÐauto.

trans. only)

²Oxygen (O2S) sensors

Based on these inputs, the following occurs:

²Voltage is applied to the fuel injectors with the

ASD relay via the PCM. The PCM will then adjust

DRELECTRONIC CONTROL MODULES 8E - 9

POWERTRAIN CONTROL MODULE (Continued)

Page 391 of 2895

the injector pulse width by turning the ground circuit

to each individual injector on and off.

²The PCM monitors the O2S sensor input and

adjusts air-fuel ratio. It also adjusts engine idle

speed through the idle air control (IAC) motor.

²The PCM adjusts ignition timing by turning the

ground path to the coil(s) on and off.

²The PCM operates the A/C compressor clutch

through the clutch relay. This happens if A/C has

been selected by the vehicle operator and requested

by the A/C thermostat.

ACCELERATION MODE

This is an Open Loop mode. The PCM recognizes

an abrupt increase in throttle position or MAP pres-

sure as a demand for increased engine output and

vehicle acceleration. The PCM increases injector

pulse width in response to increased throttle opening.

DECELERATION MODE

When the engine is at operating temperature, this

is an Open Loop mode. During hard deceleration, the

PCM receives the following inputs.

²Air conditioning select signal (if equipped)

²Air conditioning request signal (if equipped)

²Battery voltage

²Engine coolant temperature sensor

²Crankshaft position sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal

²Park/neutral switch (gear indicator signalÐauto.

trans. only)

²Vehicle speed

If the vehicle is under hard deceleration with the

proper rpm and closed throttle conditions, the PCM

will ignore the oxygen sensor input signal. The PCM

will enter a fuel cut-off strategy in which it will not

supply a ground to the injectors. If a hard decelera-

tion does not exist, the PCM will determine the

proper injector pulse width and continue injection.

Based on the above inputs, the PCM will adjust

engine idle speed through the idle air control (IAC)

motor.

The PCM adjusts ignition timing by turning the

ground path to the coil on and off.

WIDE OPEN THROTTLE MODE

This is an Open Loop mode. During wide open

throttle operation, the PCM receives the following

inputs.

²Battery voltage

²Crankshaft position sensor

²Engine coolant temperature sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor²Throttle position sensor (TPS)

²Camshaft position sensor signal

During wide open throttle conditions, the following

occurs:

²Voltage is applied to the fuel injectors with the

ASD relay via the PCM. The PCM will then control

the injection sequence and injector pulse width by

turning the ground circuit to each individual injector

on and off. The PCM ignores the oxygen sensor input

signal and provides a predetermined amount of addi-

tional fuel. This is done by adjusting injector pulse

width.

²The PCM adjusts ignition timing by turning the

ground path to the coil(s) on and off.

IGNITION SWITCH OFF MODE

When ignition switch is turned to OFF position,

the PCM stops operating the injectors, ignition coil,

ASD relay and fuel pump relay.

DESCRIPTION - 5 VOLT SUPPLIES

Two different Powertrain Control Module (PCM)

five volt supply circuits are used; primary and sec-

ondary.

DESCRIPTION - IGNITION CIRCUIT SENSE

This circuit ties the ignition switch to the Power-

train Control Module (PCM).

DESCRIPTION - POWER GROUNDS

The Powertrain Control Module (PCM) has 2 main

grounds. Both of these grounds are referred to as

power grounds. All of the high-current, noisy, electri-

cal devices are connected to these grounds as well as

all of the sensor returns. The sensor return comes

into the sensor return circuit, passes through noise

suppression, and is then connected to the power

ground.

The power ground is used to control ground cir-

cuits for the following PCM loads:

²Generator field winding

²Fuel injectors

²Ignition coil(s)

²Certain relays/solenoids

²Certain sensors

DESCRIPTION - SENSOR RETURN

The Sensor Return circuits are internal to the Pow-

ertrain Control Module (PCM).

Sensor Return provides a low±noise ground refer-

ence for all engine control system sensors. Refer to

Power Grounds for more information.

8E - 10 ELECTRONIC CONTROL MODULESDR

POWERTRAIN CONTROL MODULE (Continued)

Page 392 of 2895

OPERATION

OPERATION - PCM

The PCM operates the fuel system. The PCM is a

pre-programmed, triple microprocessor digital com-

puter. It regulates ignition timing, air-fuel ratio,

emission control devices, charging system, certain

transmission features, speed control, air conditioning

compressor clutch engagement and idle speed. The

PCM can adapt its programming to meet changing

operating conditions.

The PCM receives input signals from various

switches and sensors. Based on these inputs, the

PCM regulates various engine and vehicle operations

through different system components. These compo-

nents are referred to as Powertrain Control Module

(PCM) Outputs. The sensors and switches that pro-

vide inputs to the PCM are considered Powertrain

Control Module (PCM) Inputs.

The PCM adjusts ignition timing based upon

inputs it receives from sensors that react to: engine

rpm, manifold absolute pressure, engine coolant tem-

perature, throttle position, transmission gear selec-

tion (automatic transmission), vehicle speed, power

steering pump pressure, and the brake switch.

The PCM adjusts idle speed based on inputs it

receives from sensors that react to: throttle position,

vehicle speed, transmission gear selection, engine

coolant temperature and from inputs it receives from

the air conditioning clutch switch and brake switch.

Based on inputs that it receives, the PCM adjusts

ignition coil dwell. The PCM also adjusts the gener-

ator charge rate through control of the generator

field and provides speed control operation.

NOTE: PCM Inputs:

²ABS module (if equipped)

²A/C request (if equipped with factory A/C)

²A/C select (if equipped with factory A/C)

²A/C pressure transducer

²Auto shutdown (ASD) sense

²Battery temperature sensor

²Battery voltage

²Brake switch

²J1850 bus (+) circuits

²J1850 bus (-) circuits

²Camshaft position sensor signal

²Crankshaft position sensor

²Data link connection for DRB scan tool

²EATX module (if equipped)

²Engine coolant temperature sensor

²Fuel level (through J1850 circuitry)

²Generator (battery voltage) output

²Ignition circuit sense (ignition switch in on/off/

crank/run position)²Intake manifold air temperature sensor

²Knock sensors (2 on 3.7L engine)

²Leak detection pump (switch) sense (if equipped)

²Manifold absolute pressure (MAP) sensor

²Oil pressure

²Oxygen sensors

²Park/neutral switch (auto. trans. only)

²Power ground

²Power steering pressure switch (if equipped)

²Sensor return

²Signal ground

²Speed control multiplexed single wire input

²Throttle position sensor

²Transfer case switch (4WD range position)

²Vehicle speed signal

NOTE: PCM Outputs:

²A/C clutch relay

²Auto shutdown (ASD) relay

²J1850 bus (+/-) circuits for: speedometer, voltme-

ter, fuel gauge, oil pressure gauge/lamp, engine temp.

gauge and speed control warn. lamp

²Data link connection for DRB scan tool

²EGR valve control solenoid (if equipped)

²EVAP canister purge solenoid

²Five volt sensor supply (primary)

²Five volt sensor supply (secondary)

²Fuel injectors

²Fuel pump relay

²Generator field driver (-)

²Generator field driver (+)

²Idle air control (IAC) motor

²Ignition coil(s)

²Leak detection pump (if equipped)

²Malfunction indicator lamp (Check engine lamp).

Driven through J1850 circuits.

²Oxygen sensor heater relays

²Oxygen sensors (pulse width modulated)

²Radiator cooling fan relay (pulse width modu-

lated)

²Speed control vacuum solenoid

²Speed control vent solenoid

²Tachometer (if equipped). Driven through J1850

circuits.

²Transmission convertor clutch circuit. Driven

through J1850 circuits.

OPERATION - 5 VOLT SUPPLIES

Primary 5±volt supply:

²supplies the required 5 volt power source to the

Crankshaft Position (CKP) sensor.

²supplies the required 5 volt power source to the

Camshaft Position (CMP) sensor.

²supplies a reference voltage for the Manifold

Absolute Pressure (MAP) sensor.

DRELECTRONIC CONTROL MODULES 8E - 11

POWERTRAIN CONTROL MODULE (Continued)

Page 394 of 2895

(2) Tighten bolts. Refer to torque specifications.

(3) Check pin connectors in the PCM and the three

32±way connectors (four 38±way connectors if

equipped with NGC) for corrosion or damage. Also,

the pin heights in connectors should all be same.

Repair as necessary before installing connectors.

(4) Install three 32±way connectors (four 38±way

connectors if equipped with NGC).

(5) Install cover over electrical connectors. Cover

snaps onto PCM.

(6) Install negative battery cable.

(7) Use the DRB scan tool to reprogram new PCM

with vehicles original Vehicle Identification Number

(VIN) and original vehicle mileage.

SENTRY KEY IMMOBILIZER

MODULE

DESCRIPTION

The Sentry Key Immobilizer Module (SKIM) con-

tains a Radio Frequency (RF) transceiver and a cen-

tral processing unit, which includes the Sentry Key

Immobilizer System (SKIS) program logic. The SKIS

programming enables the SKIM to program and

retain in memory the codes of at least two, but no

more than eight electronically coded Sentry Key

transponders. The SKIS programming also enables

the SKIM to communicate over the Programmable

Communication Interface (PCI) bus network with the

Powertrain Control Module (PCM), and/or the

DRBIIItscan tool.

OPERATION

The SKIM transmits and receives RF signals

through a tuned antenna enclosed within a molded

plastic ring that is integral to the SKIM housing.

When the SKIM is properly installed on the steering

column, the antenna ring is oriented around the igni-

tion lock cylinder housing. This antenna ring must be

located within eight millimeters (0.31 inches) of the

Sentry Key in order to ensure proper RF communica-

tion between the SKIM and the Sentry Key tran-

sponder.

For added system security, each SKIM is pro-

grammed with a unique ªSecret Keyº code and a

security code. The SKIM keeps the ªSecret Keyº code

in memory. The SKIM also sends the ªSecret Keyº

code to each of the programmed Sentry Key tran-

sponders. The security code is used by the assembly

plant to access the SKIS for initialization, or by the

dealer technician to access the system for service.

The SKIM also stores in its memory the Vehicle

Identification Number (VIN), which it learns through

a PCI bus message from the PCM during initializa-

tion.The SKIM and the PCM both use software that

includes a rolling code algorithm strategy, which

helps to reduce the possibility of unauthorized SKIS

disarming. The rolling code algorithm ensures secu-

rity by preventing an override of the SKIS through

the unauthorized substitution of the SKIM or the

PCM. However, the use of this strategy also means

that replacement of either the SKIM or the PCM

units will require a system initialization procedure to

restore system operation.

When the ignition switch is turned to the ON or

START positions, the SKIM transmits an RF signal

to excite the Sentry Key transponder. The SKIM then

listens for a return RF signal from the transponder

of the Sentry Key that is inserted in the ignition lock

cylinder. If the SKIM receives an RF signal with

valid ªSecret Keyº and transponder identification

codes, the SKIM sends a ªvalid keyº message to the

PCM over the PCI bus. If the SKIM receives an

invalid RF signal or no response, it sends ªinvalid

keyº messages to the PCM. The PCM will enable or

disable engine operation based upon the status of the

SKIM messages.

The SKIM also sends messages to the Instrument

Cluster which controls the VTSS indicator LED. The

SKIM sends messages to the Instrument Cluster to

turn the LED on for about three seconds when the

ignition switch is turned to the ON position as a bulb

test. After completion of the bulb test, the SKIM

sends bus messages to keep the LED off for a dura-

tion of about one second. Then the SKIM sends mes-

sages to turn the LED on or off based upon the

results of the SKIS self-tests. If the VTSS indicator

LED comes on and stays on after the bulb test, it

indicates that the SKIM has detected a system mal-

function and/or that the SKIS has become inopera-

tive.

If the SKIM detects an invalid key when the igni-

tion switch is turned to the ON position, it sends

messages to flash the VTSS indicator LED. The

SKIM can also send messages to flash the LED as an

indication to the customer that the SKIS has been

placed in it's ªCustomer Learnº programming mode.

See Sentry Key Immobilizer System Transponder

Programming in this section for more information on

the ªCustomer Learnº programming mode.

For diagnosis or initialization of the SKIM and the

PCM, a DRBIIItscan tool and the proper Powertrain

Diagnostic Procedures manual are required. The

SKIM cannot be repaired and, if faulty or damaged,

the unit must be replaced.

DRELECTRONIC CONTROL MODULES 8E - 13

POWERTRAIN CONTROL MODULE (Continued)

Page 395 of 2895

STANDARD PROCEDURE - PCM/SKIM

PROGRAMMING

NOTE: There are two procedures for transfering the

secret key to the SKIM:

²When ONLY the SKIM module is replaced, the

secret key is transfered from the PCM to the SKIM.

The ORGINAL KEYS may then be programmed to

the SKIM.

²When ONLY the PCM is replaced, then the

secret key is transfered from the SKIM to the PCM.

The ORGINAL KEYS may be used.

²When BOTH the SKIM and the PCM are

replaced the secret key is transferred from the

SKIM to the PCM, and NEW KEYS must be pro-

grammed.

NOTE: Before replacing the Powertrain Control

Module (PCM) for a failed driver, control circuit, or

ground circuit, be sure to check the related compo-

nent/circuit integrity for failures not detected due to

a double fault in the circuit. Most PCM driver/con-

trol circuit failures are caused by internal compo-

nent failures (i.e. relay and solenoids) and shorted

circuits (i.e. pull-ups, drivers and switched circuits).

These failures are difficult to detect when a double

fault has occurred and only one Diagnostic Trouble

Code (DTC) has set.

When a PCM (SBEC) and the Sentry Key Immobi-

lizer Module (SKIM) are replaced at the same time

perform the following steps in order:

(1) Program the new PCM (SBEC).

(2) Program the new SKIM.

(3) Replace all ignition keys and program them to

the new SKIM.

PROGRAMMING THE PCM (SBEC)

The Sentry Key Immobilizer System (SKIS) Secret

Key is an ID code that is unique to each SKIM. This

code is programmed and stored in the SKIM, PCM

and transponder chip (ignition keys). When replacing

the PCM it is necessary to program the secret key

into the new PCM using the DRBIIItscan tool. Per-

form the following steps to program the secret key

into the PCM.

(1) Turn the ignition switch on (transmission in

park/neutral).

(2) Use the DRBIIItscan tool and select THEFT

ALARM, SKIM then MISCELLANEOUS.

(3) Select PCM REPLACED (GAS ENGINE).

(4) Enter secured access mode by entering the

vehicle four-digit PIN.

(5) Select ENTER to update PCM VIN.NOTE: If three attempts are made to enter secure

access mode using an incorrect PIN, secured

access mode will be locked out for one hour. To

exit this lockout mode, turn the ignition to the RUN

position for one hour then enter the correct PIN.

(Ensure all accessories are turned OFF. Also moni-

tor the battery state and connect a battery charger

if necessary).

(6) Press ENTER to transfer the secret key (the

SKIM will send the secret key to the PCM).

(7) Press Page Back to get to the Select System

menu and select ENGINE, MISCELLANEOUS, and

SRI MEMORY CHECK.

(8) The DRBIIItscan tool will ask, Is odometer

reading between XX and XX? Select the YES or NO

button on the DRB IIItscan tool. If NO is selected,

the DRBIIItscan tool will read, Enter odometer

Reading

reading from the instrument cluster and press

ENTER.

PROGRAMMING THE SKIM

(1) Turn the ignition switch on (transmission in

park/neutral).

(2) Use the DRBIIItscan tool and select THEFT

ALARM, SKIM then MISCELLANEOUS.

(3) Select SKIM REPLACED (GAS ENGINE).

(4) Program the vehicle four-digit PIN into SKIM.

(5) Select COUNTRY CODE and enter the correct

country.

NOTE: Be sure to enter the correct country code. If

the incorrect country code is programmed into the

SKIM, the SKIM must be replaced.

(6) Select YES to update the VIN (the SKIM will

learn the VIN from the PCM).

(7) Press ENTER to transfer the secret key (the

PCM will send the secret key information to the

SKIM).

(8) Program ignition keys to the SKIM.

NOTE: If the PCM and the SKIM are replaced at the

same time, all vehicle keys will need to be replaced

and programmed to the new SKIM.

PROGRAMMING IGNITION KEYS TO THE SKIM

(1) Turn the ignition switch on (transmission in

park/neutral).

(2) Use the DRBIIItscan tool and select THEFT

ALARM, SKIM then MISCELLANEOUS.

(3) Select PROGRAM IGNITION KEY'S.

(4) Enter secured access mode by entering the

vehicle four-digit PIN.

8E - 14 ELECTRONIC CONTROL MODULESDR

SENTRY KEY IMMOBILIZER MODULE (Continued)

Page 400 of 2895

SHIFT ATTEMPT LIMIT

To protect the transfer case system, the TCCM will

impose a limit on the number of shifts that can occur

over a calibrated time period. The system will monitor

the number of 'D' channel segment transitions that

occur in any 30 second time period. If the number of

segment transitions is 30 or greater, the system will go

into a default mode. The default mode of operation for

shifting is that the number of allowed 'D' channel tran-

sitions permitted to occur will be 3 over each 15 second

100 msec calibrated window of time. After 5 minutes

100 msec, the motor can be assumed to have cooled

down and the system will revert to normal operation.

The following rules also apply to the shift limit:

²The attempt limit will not prevent shifts coming

out of NEUTRAL, they will be allowed regardless of

the counter/timer.

²Any shift that is in progress when the counter

reaches a maximum count in time will be allowed to

complete before the default mode is entered. D-chan-

nel transitions during this period will not be counted

towards the default mode limit.

²A block, regardless of the direction, whether

towards destination or back towards reversal target

(shift timer expiring), will count as a value of 2 tran-

sitions towards the 30 segment transitions to go into

default mode as defined above. Current attempt limit

values are 30 transitions in 30 seconds and default

mode values are 3 transitions every 15 seconds for 5

minutes.

TRANSMISSION CONTROL

MODULE

DESCRIPTION

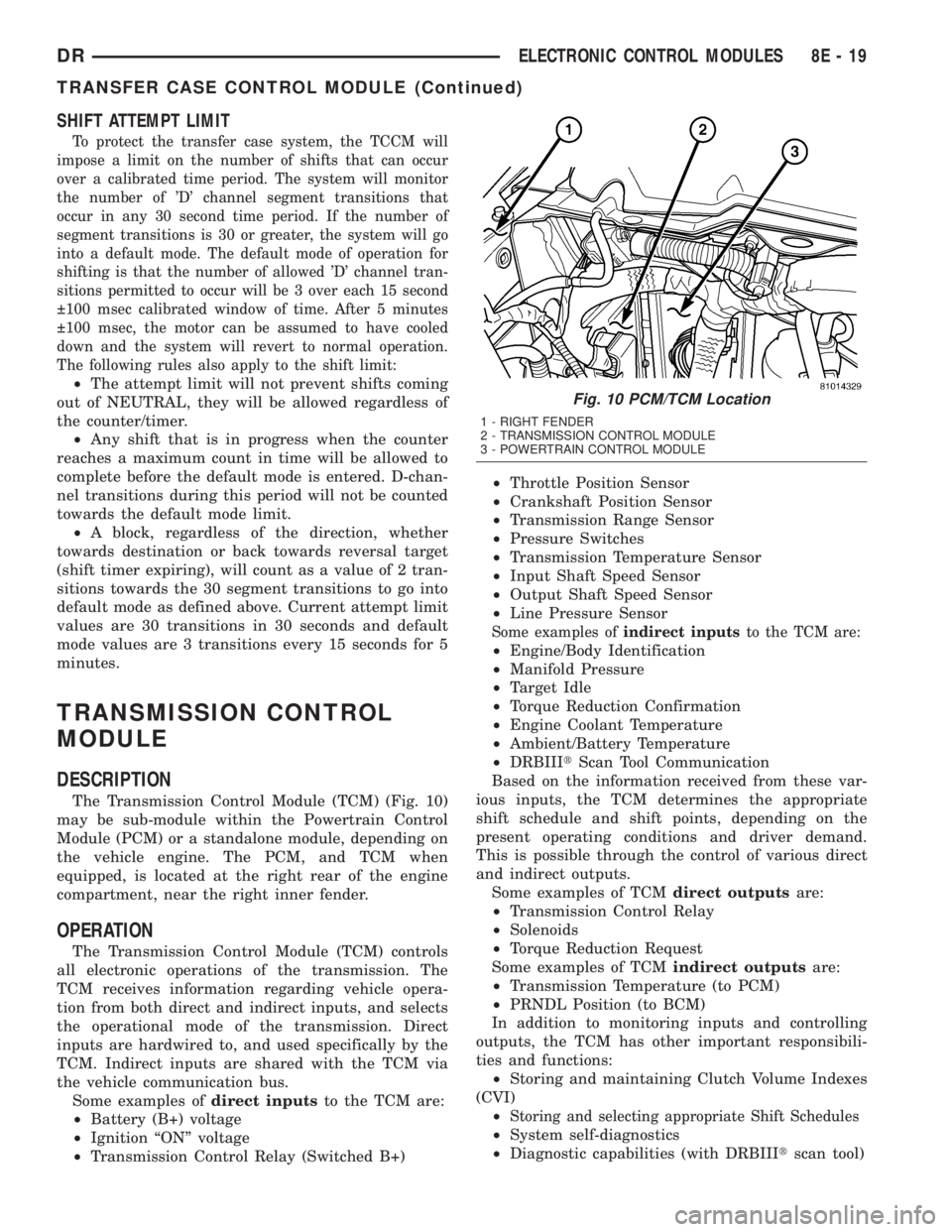

The Transmission Control Module (TCM) (Fig. 10)

may be sub-module within the Powertrain Control

Module (PCM) or a standalone module, depending on

the vehicle engine. The PCM, and TCM when

equipped, is located at the right rear of the engine

compartment, near the right inner fender.

OPERATION

The Transmission Control Module (TCM) controls

all electronic operations of the transmission. The

TCM receives information regarding vehicle opera-

tion from both direct and indirect inputs, and selects

the operational mode of the transmission. Direct

inputs are hardwired to, and used specifically by the

TCM. Indirect inputs are shared with the TCM via

the vehicle communication bus.

Some examples ofdirect inputsto the TCM are:

²Battery (B+) voltage

²Ignition ªONº voltage

²Transmission Control Relay (Switched B+)²Throttle Position Sensor

²Crankshaft Position Sensor

²Transmission Range Sensor

²Pressure Switches

²Transmission Temperature Sensor

²Input Shaft Speed Sensor

²Output Shaft Speed Sensor

²Line Pressure Sensor

Some examples ofindirect inputsto the TCM are:

²Engine/Body Identification

²Manifold Pressure

²Target Idle

²Torque Reduction Confirmation

²Engine Coolant Temperature

²Ambient/Battery Temperature

²DRBIIItScan Tool Communication

Based on the information received from these var-

ious inputs, the TCM determines the appropriate

shift schedule and shift points, depending on the

present operating conditions and driver demand.

This is possible through the control of various direct

and indirect outputs.

Some examples of TCMdirect outputsare:

²Transmission Control Relay

²Solenoids

²Torque Reduction Request

Some examples of TCMindirect outputsare:

²Transmission Temperature (to PCM)

²PRNDL Position (to BCM)

In addition to monitoring inputs and controlling

outputs, the TCM has other important responsibili-

ties and functions:

²Storing and maintaining Clutch Volume Indexes

(CVI)

²

Storing and selecting appropriate Shift Schedules

²System self-diagnostics

²Diagnostic capabilities (with DRBIIItscan tool)

Fig. 10 PCM/TCM Location

1 - RIGHT FENDER

2 - TRANSMISSION CONTROL MODULE

3 - POWERTRAIN CONTROL MODULE

DRELECTRONIC CONTROL MODULES 8E - 19

TRANSFER CASE CONTROL MODULE (Continued)

Page 402 of 2895

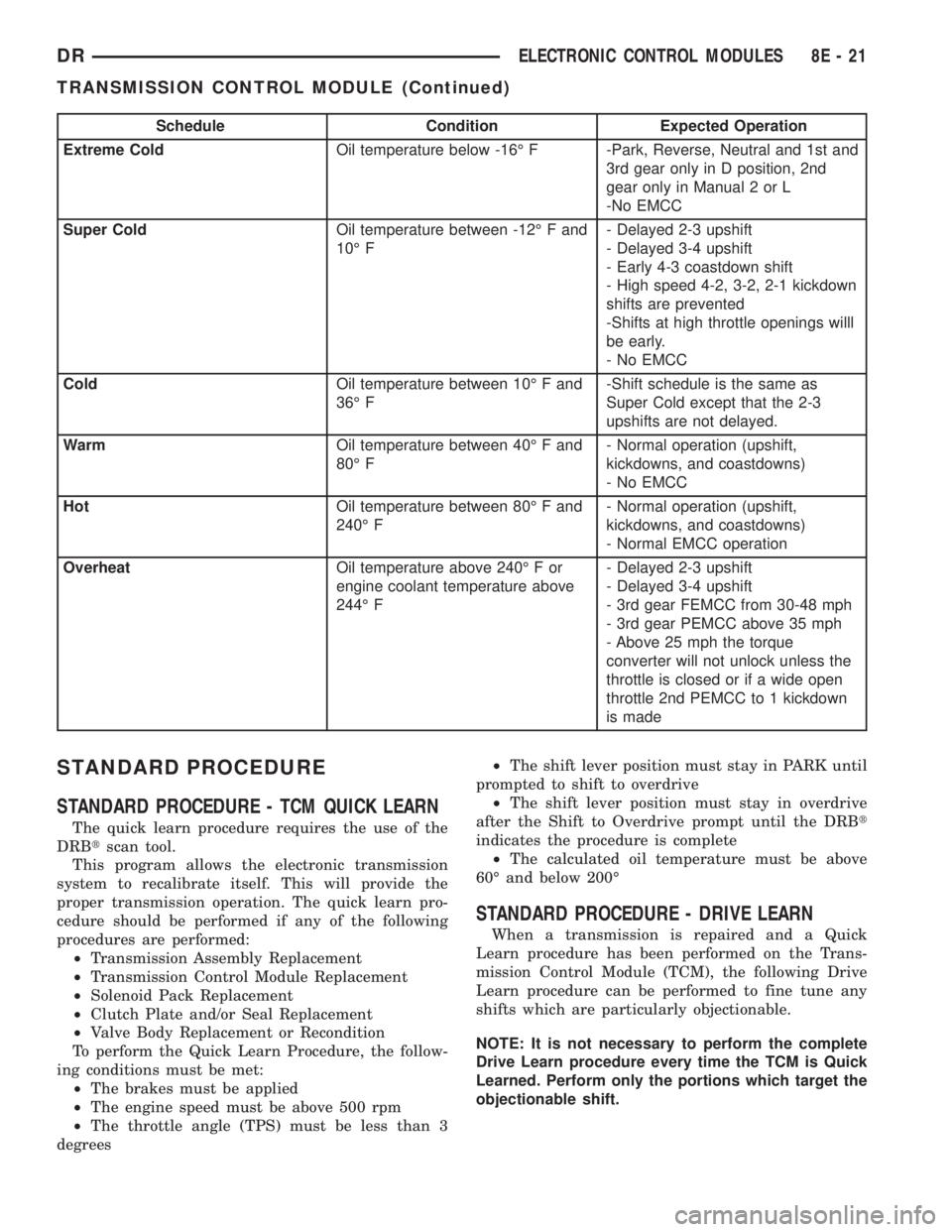

Schedule Condition Expected Operation

Extreme ColdOil temperature below -16É F -Park, Reverse, Neutral and 1st and

3rd gear only in D position, 2nd

gear only in Manual 2 or L

-No EMCC

Super ColdOil temperature between -12É F and

10É F- Delayed 2-3 upshift

- Delayed 3-4 upshift

- Early 4-3 coastdown shift

- High speed 4-2, 3-2, 2-1 kickdown

shifts are prevented

-Shifts at high throttle openings willl

be early.

- No EMCC

ColdOil temperature between 10É F and

36É F-Shift schedule is the same as

Super Cold except that the 2-3

upshifts are not delayed.

WarmOil temperature between 40É F and

80É F- Normal operation (upshift,

kickdowns, and coastdowns)

- No EMCC

HotOil temperature between 80É F and

240É F- Normal operation (upshift,

kickdowns, and coastdowns)

- Normal EMCC operation

OverheatOil temperature above 240É F or

engine coolant temperature above

244É F- Delayed 2-3 upshift

- Delayed 3-4 upshift

- 3rd gear FEMCC from 30-48 mph

- 3rd gear PEMCC above 35 mph

- Above 25 mph the torque

converter will not unlock unless the

throttle is closed or if a wide open

throttle 2nd PEMCC to 1 kickdown

is made

STANDARD PROCEDURE

STANDARD PROCEDURE - TCM QUICK LEARN

The quick learn procedure requires the use of the

DRBtscan tool.

This program allows the electronic transmission

system to recalibrate itself. This will provide the

proper transmission operation. The quick learn pro-

cedure should be performed if any of the following

procedures are performed:

²Transmission Assembly Replacement

²Transmission Control Module Replacement

²Solenoid Pack Replacement

²Clutch Plate and/or Seal Replacement

²Valve Body Replacement or Recondition

To perform the Quick Learn Procedure, the follow-

ing conditions must be met:

²The brakes must be applied

²The engine speed must be above 500 rpm

²The throttle angle (TPS) must be less than 3

degrees²The shift lever position must stay in PARK until

prompted to shift to overdrive

²The shift lever position must stay in overdrive

after the Shift to Overdrive prompt until the DRBt

indicates the procedure is complete

²The calculated oil temperature must be above

60É and below 200É

STANDARD PROCEDURE - DRIVE LEARN

When a transmission is repaired and a Quick

Learn procedure has been performed on the Trans-

mission Control Module (TCM), the following Drive

Learn procedure can be performed to fine tune any

shifts which are particularly objectionable.

NOTE: It is not necessary to perform the complete

Drive Learn procedure every time the TCM is Quick

Learned. Perform only the portions which target the

objectionable shift.

DRELECTRONIC CONTROL MODULES 8E - 21

TRANSMISSION CONTROL MODULE (Continued)

Page 406 of 2895

ENGINE SYSTEMS

TABLE OF CONTENTS

page page

BATTERY SYSTEM......................... 1

CHARGING.............................. 19STARTING............................... 28

BATTERY SYSTEM

TABLE OF CONTENTS

page page

BATTERY SYSTEM

DESCRIPTION..........................1

OPERATION............................2

DIAGNOSIS AND TESTING - BATTERY

SYSTEM.............................2

CLEANING.............................4

INSPECTION...........................6

SPECIFICATIONS........................6

SPECIAL TOOLS

BATTERY SYSTEM SPECIAL TOOLS.......7

BATTERY

DESCRIPTION..........................7

DIAGNOSIS AND TESTING - BATTERY.......7

STANDARD PROCEDURE

STANDARD PROCEDURE - BATTERY

CHARGING...........................8

STANDARD PROCEDURE - BUILT-IN

INDICATOR TEST.....................10

STANDARD PROCEDURE - OPEN-CIRCUIT

VOLTAGE TEST.......................10

STANDARD PROCEDURE - IGNITION-OFF

DRAW TEST.........................11STANDARD PROCEDURE - USING MICRO

420 BATTERY TESTER.................12

REMOVAL.............................13

INSTALLATION.........................14

BATTERY HOLDDOWN

DESCRIPTION.........................14

OPERATION...........................14

REMOVAL.............................14

INSTALLATION.........................14

BATTERY CABLES

DESCRIPTION.........................14

OPERATION...........................14

DIAGNOSIS AND TESTING - BATTERY

CABLES............................15

REMOVAL.............................16

INSTALLATION.........................17

BATTERY TRAY

DESCRIPTION.........................17

OPERATION...........................17

REMOVAL.............................17

INSTALLATION.........................18

BATTERY SYSTEM

DESCRIPTION

A single 12-volt battery is standard factory-in-

stalled equipment on gasoline engine equipped mod-

els. Diesel engine equipped vehicles utilize two

12-volt batteries connected in parallel. All of the com-

ponents of the battery system are located within the

engine compartment of the vehicle. The battery sys-

tem for this vehicle, covers the following related com-

ponents, which are covered in further detail later in

this section of the service manual:²Battery- The storage battery provides a reli-

able means of storing a renewable source of electrical

energy within the vehicle.

²Battery Cables- The battery cables connect

the battery terminal posts to the vehicle electrical

system.

²Battery Holddown- The battery holddown

hardware secures the battery in the battery tray in

the engine compartment.

²Battery Tray- The battery tray provides a

secure mounting location in the vehicle for the bat-

tery and an anchor point for the battery holddown

hardware.

DRENGINE SYSTEMS 8F - 1