seats DODGE RAM 2003 Service Manual Online

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1818 of 2895

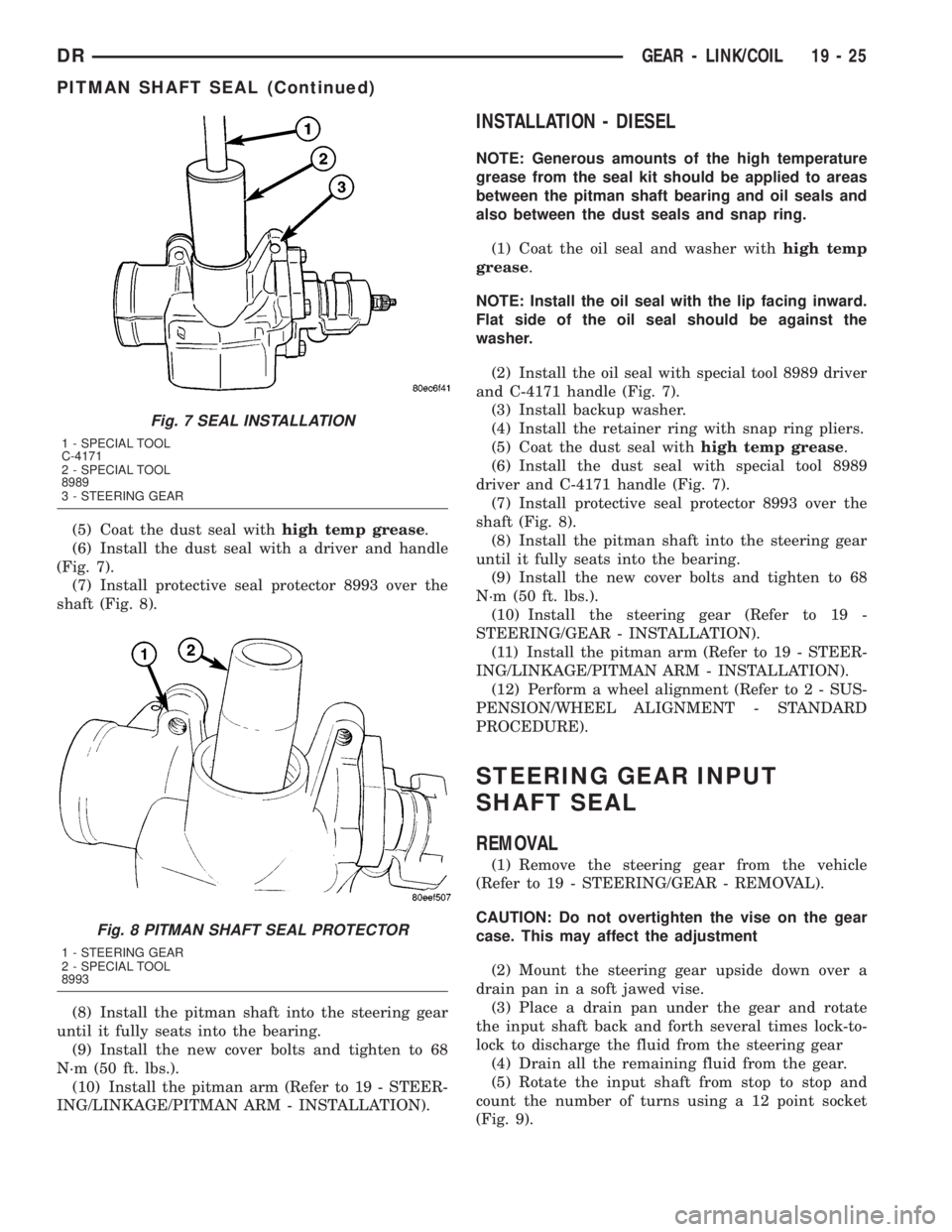

(5) Coat the dust seal withhigh temp grease.

(6) Install the dust seal with a driver and handle

(Fig. 7).

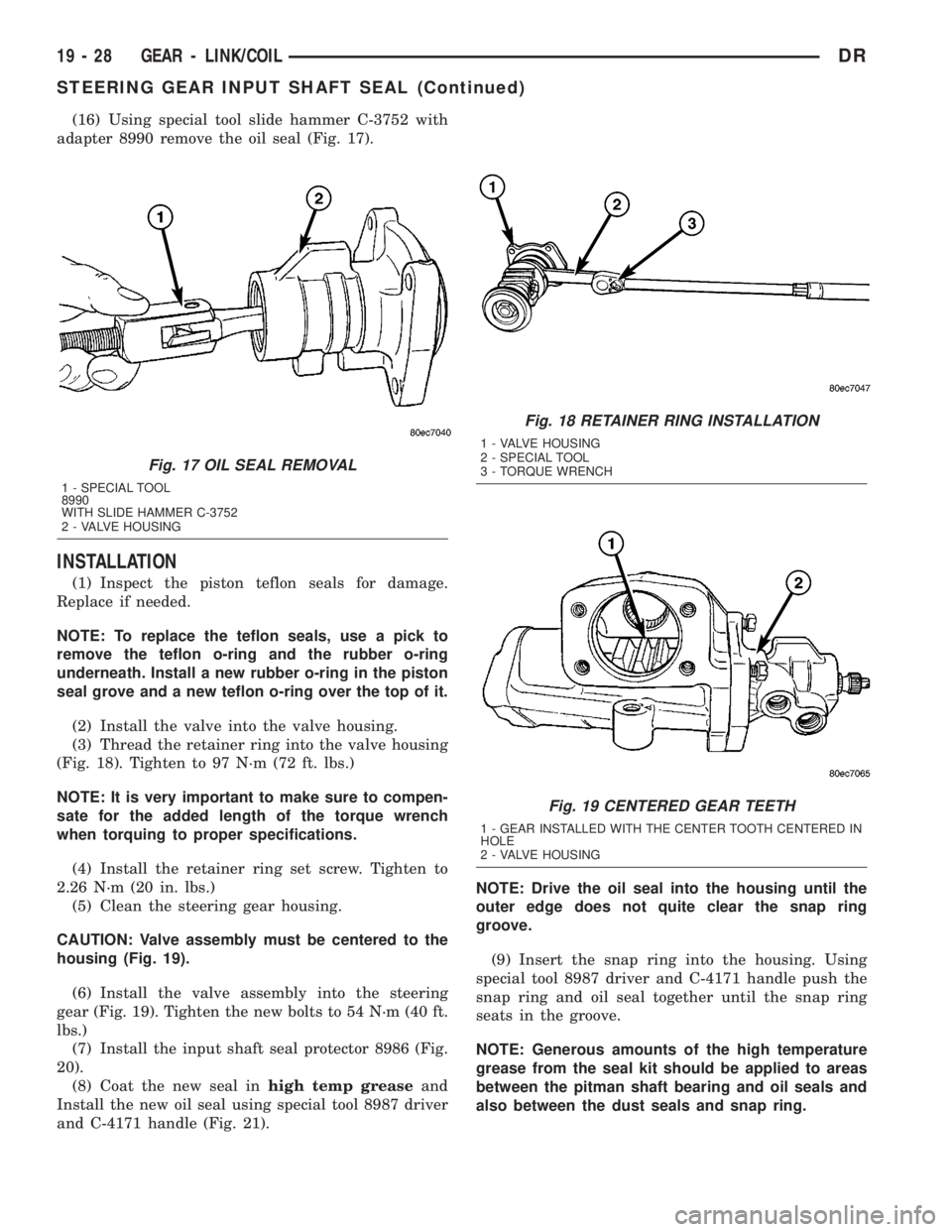

(7) Install protective seal protector 8993 over the

shaft (Fig. 8).

(8) Install the pitman shaft into the steering gear

until it fully seats into the bearing.

(9) Install the new cover bolts and tighten to 68

N´m (50 ft. lbs.).

(10) Install the pitman arm (Refer to 19 - STEER-

ING/LINKAGE/PITMAN ARM - INSTALLATION).

INSTALLATION - DIESEL

NOTE: Generous amounts of the high temperature

grease from the seal kit should be applied to areas

between the pitman shaft bearing and oil seals and

also between the dust seals and snap ring.

(1) Coat the oil seal and washer withhigh temp

grease.

NOTE: Install the oil seal with the lip facing inward.

Flat side of the oil seal should be against the

washer.

(2) Install the oil seal with special tool 8989 driver

and C-4171 handle (Fig. 7).

(3) Install backup washer.

(4) Install the retainer ring with snap ring pliers.

(5) Coat the dust seal withhigh temp grease.

(6) Install the dust seal with special tool 8989

driver and C-4171 handle (Fig. 7).

(7) Install protective seal protector 8993 over the

shaft (Fig. 8).

(8) Install the pitman shaft into the steering gear

until it fully seats into the bearing.

(9) Install the new cover bolts and tighten to 68

N´m (50 ft. lbs.).

(10) Install the steering gear (Refer to 19 -

STEERING/GEAR - INSTALLATION).

(11) Install the pitman arm (Refer to 19 - STEER-

ING/LINKAGE/PITMAN ARM - INSTALLATION).

(12) Perform a wheel alignment (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

STEERING GEAR INPUT

SHAFT SEAL

REMOVAL

(1) Remove the steering gear from the vehicle

(Refer to 19 - STEERING/GEAR - REMOVAL).

CAUTION: Do not overtighten the vise on the gear

case. This may affect the adjustment

(2) Mount the steering gear upside down over a

drain pan in a soft jawed vise.

(3) Place a drain pan under the gear and rotate

the input shaft back and forth several times lock-to-

lock to discharge the fluid from the steering gear

(4) Drain all the remaining fluid from the gear.

(5) Rotate the input shaft from stop to stop and

count the number of turns using a 12 point socket

(Fig. 9).

Fig. 7 SEAL INSTALLATION

1 - SPECIAL TOOL

C-4171

2 - SPECIAL TOOL

8989

3 - STEERING GEAR

Fig. 8 PITMAN SHAFT SEAL PROTECTOR

1 - STEERING GEAR

2 - SPECIAL TOOL

8993

DRGEAR - LINK/COIL 19 - 25

PITMAN SHAFT SEAL (Continued)

Page 1821 of 2895

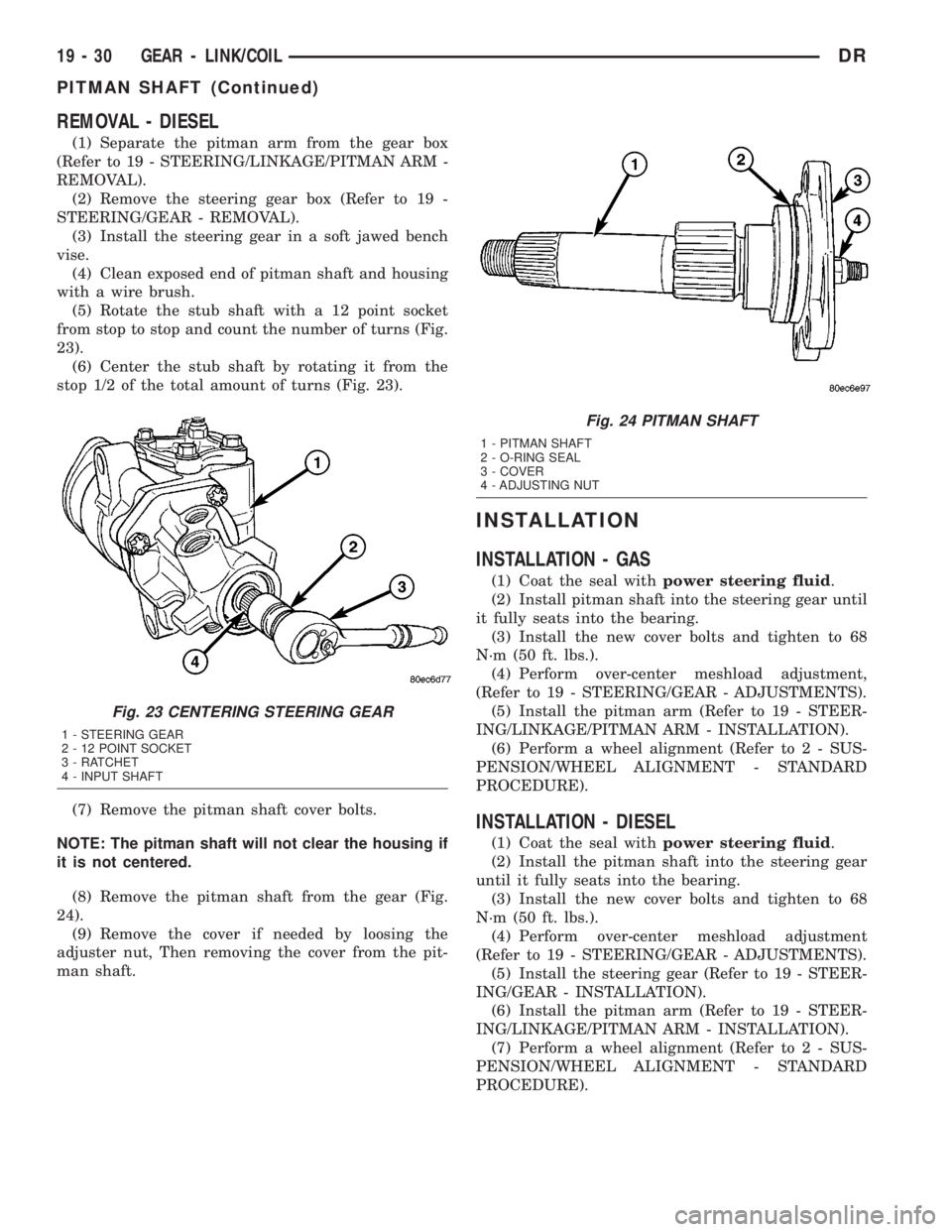

(16) Using special tool slide hammer C-3752 with

adapter 8990 remove the oil seal (Fig. 17).

INSTALLATION

(1) Inspect the piston teflon seals for damage.

Replace if needed.

NOTE: To replace the teflon seals, use a pick to

remove the teflon o-ring and the rubber o-ring

underneath. Install a new rubber o-ring in the piston

seal grove and a new teflon o-ring over the top of it.

(2) Install the valve into the valve housing.

(3) Thread the retainer ring into the valve housing

(Fig. 18). Tighten to 97 N´m (72 ft. lbs.)

NOTE: It is very important to make sure to compen-

sate for the added length of the torque wrench

when torquing to proper specifications.

(4) Install the retainer ring set screw. Tighten to

2.26 N´m (20 in. lbs.)

(5) Clean the steering gear housing.

CAUTION: Valve assembly must be centered to the

housing (Fig. 19).

(6) Install the valve assembly into the steering

gear (Fig. 19). Tighten the new bolts to 54 N´m (40 ft.

lbs.)

(7) Install the input shaft seal protector 8986 (Fig.

20).

(8) Coat the new seal inhigh temp greaseand

Install the new oil seal using special tool 8987 driver

and C-4171 handle (Fig. 21).NOTE: Drive the oil seal into the housing until the

outer edge does not quite clear the snap ring

groove.

(9) Insert the snap ring into the housing. Using

special tool 8987 driver and C-4171 handle push the

snap ring and oil seal together until the snap ring

seats in the groove.

NOTE: Generous amounts of the high temperature

grease from the seal kit should be applied to areas

between the pitman shaft bearing and oil seals and

also between the dust seals and snap ring.

Fig. 17 OIL SEAL REMOVAL

1 - SPECIAL TOOL

8990

WITH SLIDE HAMMER C-3752

2 - VALVE HOUSING

Fig. 18 RETAINER RING INSTALLATION

1 - VALVE HOUSING

2 - SPECIAL TOOL

3 - TORQUE WRENCH

Fig. 19 CENTERED GEAR TEETH

1 - GEAR INSTALLED WITH THE CENTER TOOTH CENTERED IN

HOLE

2 - VALVE HOUSING

19 - 28 GEAR - LINK/COILDR

STEERING GEAR INPUT SHAFT SEAL (Continued)

Page 1823 of 2895

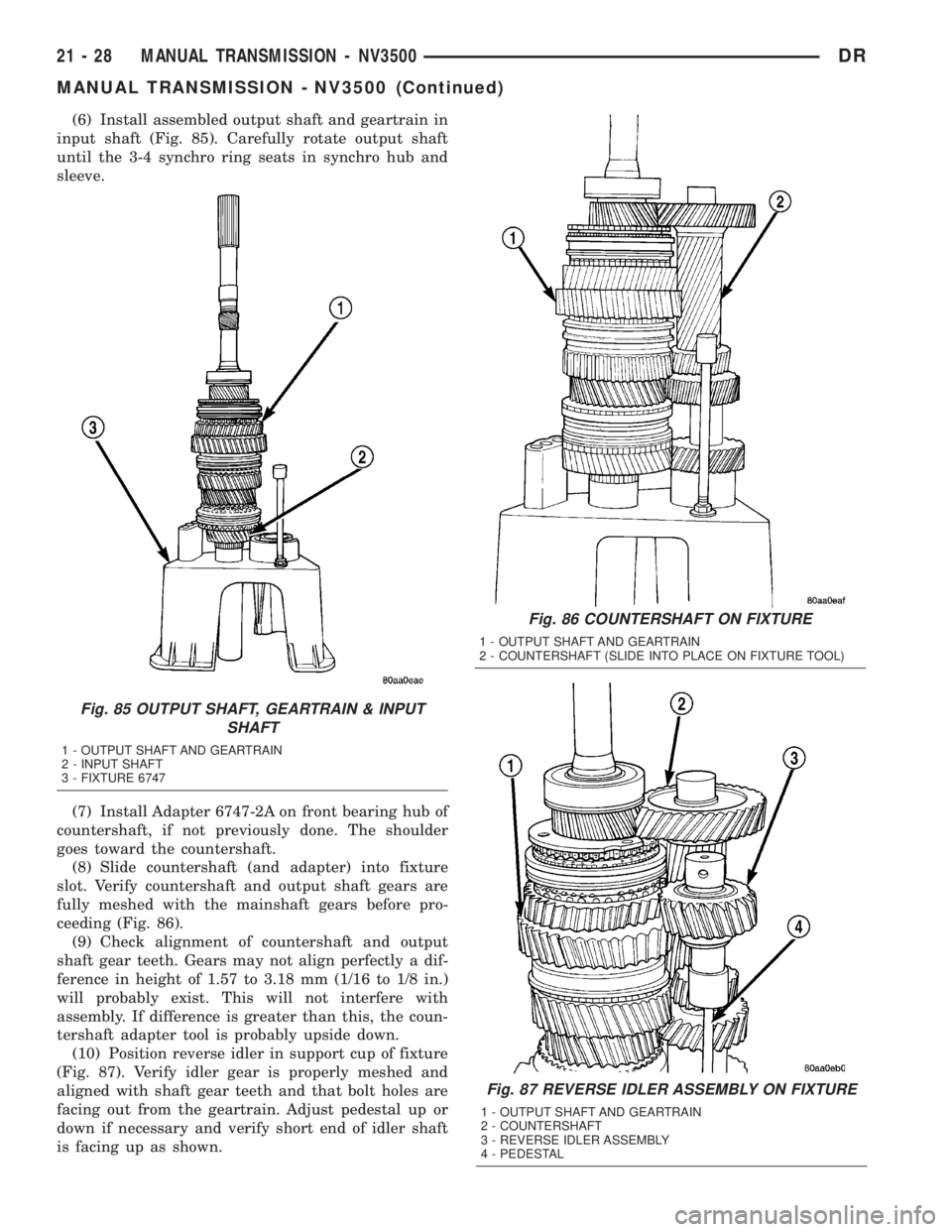

REMOVAL - DIESEL

(1) Separate the pitman arm from the gear box

(Refer to 19 - STEERING/LINKAGE/PITMAN ARM -

REMOVAL).

(2) Remove the steering gear box (Refer to 19 -

STEERING/GEAR - REMOVAL).

(3) Install the steering gear in a soft jawed bench

vise.

(4) Clean exposed end of pitman shaft and housing

with a wire brush.

(5) Rotate the stub shaft with a 12 point socket

from stop to stop and count the number of turns (Fig.

23).

(6) Center the stub shaft by rotating it from the

stop 1/2 of the total amount of turns (Fig. 23).

(7) Remove the pitman shaft cover bolts.

NOTE: The pitman shaft will not clear the housing if

it is not centered.

(8) Remove the pitman shaft from the gear (Fig.

24).

(9) Remove the cover if needed by loosing the

adjuster nut, Then removing the cover from the pit-

man shaft.

INSTALLATION

INSTALLATION - GAS

(1) Coat the seal withpower steering fluid.

(2) Install pitman shaft into the steering gear until

it fully seats into the bearing.

(3) Install the new cover bolts and tighten to 68

N´m (50 ft. lbs.).

(4) Perform over-center meshload adjustment,

(Refer to 19 - STEERING/GEAR - ADJUSTMENTS).

(5) Install the pitman arm (Refer to 19 - STEER-

ING/LINKAGE/PITMAN ARM - INSTALLATION).

(6) Perform a wheel alignment (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

INSTALLATION - DIESEL

(1) Coat the seal withpower steering fluid.

(2) Install the pitman shaft into the steering gear

until it fully seats into the bearing.

(3) Install the new cover bolts and tighten to 68

N´m (50 ft. lbs.).

(4) Perform over-center meshload adjustment

(Refer to 19 - STEERING/GEAR - ADJUSTMENTS).

(5) Install the steering gear (Refer to 19 - STEER-

ING/GEAR - INSTALLATION).

(6) Install the pitman arm (Refer to 19 - STEER-

ING/LINKAGE/PITMAN ARM - INSTALLATION).

(7) Perform a wheel alignment (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

Fig. 23 CENTERING STEERING GEAR

1 - STEERING GEAR

2 - 12 POINT SOCKET

3 - RATCHET

4 - INPUT SHAFT

Fig. 24 PITMAN SHAFT

1 - PITMAN SHAFT

2 - O-RING SEAL

3 - COVER

4 - ADJUSTING NUT

19 - 30 GEAR - LINK/COILDR

PITMAN SHAFT (Continued)

Page 1867 of 2895

(6) Install assembled output shaft and geartrain in

input shaft (Fig. 85). Carefully rotate output shaft

until the 3-4 synchro ring seats in synchro hub and

sleeve.

(7) Install Adapter 6747-2A on front bearing hub of

countershaft, if not previously done. The shoulder

goes toward the countershaft.

(8) Slide countershaft (and adapter) into fixture

slot. Verify countershaft and output shaft gears are

fully meshed with the mainshaft gears before pro-

ceeding (Fig. 86).

(9) Check alignment of countershaft and output

shaft gear teeth. Gears may not align perfectly a dif-

ference in height of 1.57 to 3.18 mm (1/16 to 1/8 in.)

will probably exist. This will not interfere with

assembly. If difference is greater than this, the coun-

tershaft adapter tool is probably upside down.

(10) Position reverse idler in support cup of fixture

(Fig. 87). Verify idler gear is properly meshed and

aligned with shaft gear teeth and that bolt holes are

facing out from the geartrain. Adjust pedestal up or

down if necessary and verify short end of idler shaft

is facing up as shown.

Fig. 86 COUNTERSHAFT ON FIXTURE

1 - OUTPUT SHAFT AND GEARTRAIN

2 - COUNTERSHAFT (SLIDE INTO PLACE ON FIXTURE TOOL)

Fig. 87 REVERSE IDLER ASSEMBLY ON FIXTURE

1 - OUTPUT SHAFT AND GEARTRAIN

2 - COUNTERSHAFT

3 - REVERSE IDLER ASSEMBLY

4 - PEDESTAL

Fig. 85 OUTPUT SHAFT, GEARTRAIN & INPUT

SHAFT

1 - OUTPUT SHAFT AND GEARTRAIN

2 - INPUT SHAFT

3 - FIXTURE 6747

21 - 28 MANUAL TRANSMISSION - NV3500DR

MANUAL TRANSMISSION - NV3500 (Continued)

Page 1875 of 2895

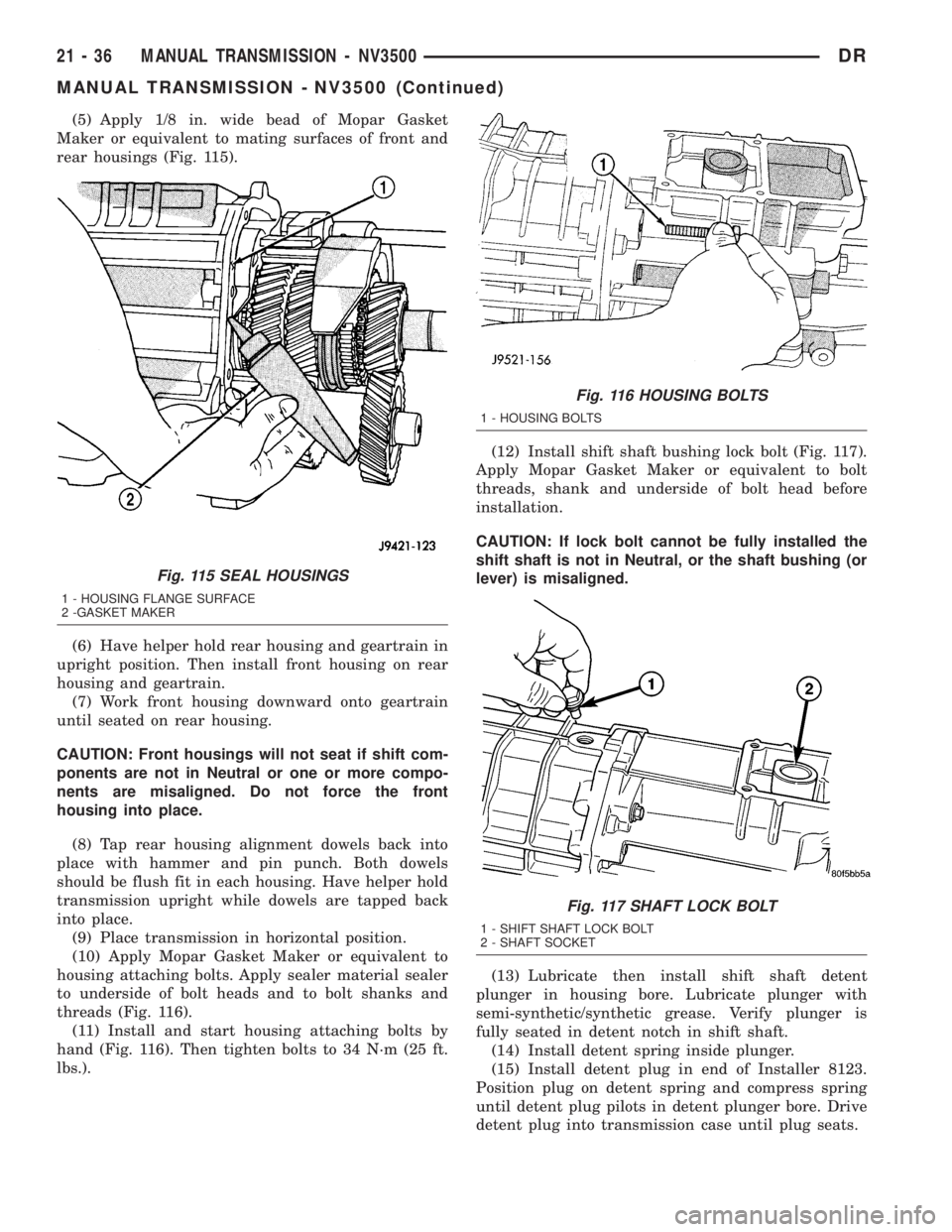

(5) Apply 1/8 in. wide bead of Mopar Gasket

Maker or equivalent to mating surfaces of front and

rear housings (Fig. 115).

(6) Have helper hold rear housing and geartrain in

upright position. Then install front housing on rear

housing and geartrain.

(7) Work front housing downward onto geartrain

until seated on rear housing.

CAUTION: Front housings will not seat if shift com-

ponents are not in Neutral or one or more compo-

nents are misaligned. Do not force the front

housing into place.

(8) Tap rear housing alignment dowels back into

place with hammer and pin punch. Both dowels

should be flush fit in each housing. Have helper hold

transmission upright while dowels are tapped back

into place.

(9) Place transmission in horizontal position.

(10) Apply Mopar Gasket Maker or equivalent to

housing attaching bolts. Apply sealer material sealer

to underside of bolt heads and to bolt shanks and

threads (Fig. 116).

(11) Install and start housing attaching bolts by

hand (Fig. 116). Then tighten bolts to 34 N´m (25 ft.

lbs.).(12) Install shift shaft bushing lock bolt (Fig. 117).

Apply Mopar Gasket Maker or equivalent to bolt

threads, shank and underside of bolt head before

installation.

CAUTION: If lock bolt cannot be fully installed the

shift shaft is not in Neutral, or the shaft bushing (or

lever) is misaligned.

(13) Lubricate then install shift shaft detent

plunger in housing bore. Lubricate plunger with

semi-synthetic/synthetic grease. Verify plunger is

fully seated in detent notch in shift shaft.

(14) Install detent spring inside plunger.

(15) Install detent plug in end of Installer 8123.

Position plug on detent spring and compress spring

until detent plug pilots in detent plunger bore. Drive

detent plug into transmission case until plug seats.

Fig. 115 SEAL HOUSINGS

1 - HOUSING FLANGE SURFACE

2 -GASKET MAKER

Fig. 116 HOUSING BOLTS

1 - HOUSING BOLTS

Fig. 117 SHAFT LOCK BOLT

1 - SHIFT SHAFT LOCK BOLT

2 - SHAFT SOCKET

21 - 36 MANUAL TRANSMISSION - NV3500DR

MANUAL TRANSMISSION - NV3500 (Continued)

Page 2012 of 2895

CAUTION: If the condition of the transmission

before the overhaul procedure caused excessive

metallic or fiber contamination in the fluid, replace

the torque converter. Fluid contamination and trans-

mission failure can result if not done.

(6) Install torque converter. Use C-clamp or metal

strap to hold converter in place for installation.

BAND ADJUSTMENT AND FINAL

(1) Adjust front and rear bands as follows:

(a) Loosen locknut on each band adjusting screw

4-5 turns.

(b) Tighten both adjusting screws to 8 N´m (72

in. lbs.).

(c) Back off front band adjusting screw 2-7/8

turns.

(d) Back off rear band adjusting screw 2 turns.

(e) Hold each adjusting screw in position and

tighten locknut to 34 N´m (25 ft. lbs.) torque.

(2) Install magnet in oil pan. Magnet seats on

small protrusion at corner of pan.

(3) Position new oil pan gasket on case and install

oil pan. Tighten pan bolts to 17 N´m (13 ft. lbs.).

(4) Install throttle valve and shift selector levers

on valve body manual lever shaft.

(5) Apply small quantity of dielectric grease to ter-

minal pins of solenoid case connector and transmis-

sion range sensor.

(6) Fill transmission with recommended fluid.

Refer to Service Procedures section of this group.

INSTALLATION

(1) Check torque converter hub and hub drive

notches for sharp edges burrs, scratches, or nicks.

Polish the hub and notches with 320/400 grit paper

and crocus cloth if necessary. The hub must be

smooth to avoid damaging pump seal at installation.

(2) Lubricate pocket in the rear oil pump seal lip

with transmission fluid.

(3) Lubricate converter pilot hub of the crankshaft

with a light coating of MopartHigh Temp Grease.

(4) Align and install converter in oil pump.

(5) Carefully insert converter in oil pump. Then

rotate converter back and forth until fully seated in

pump gears.

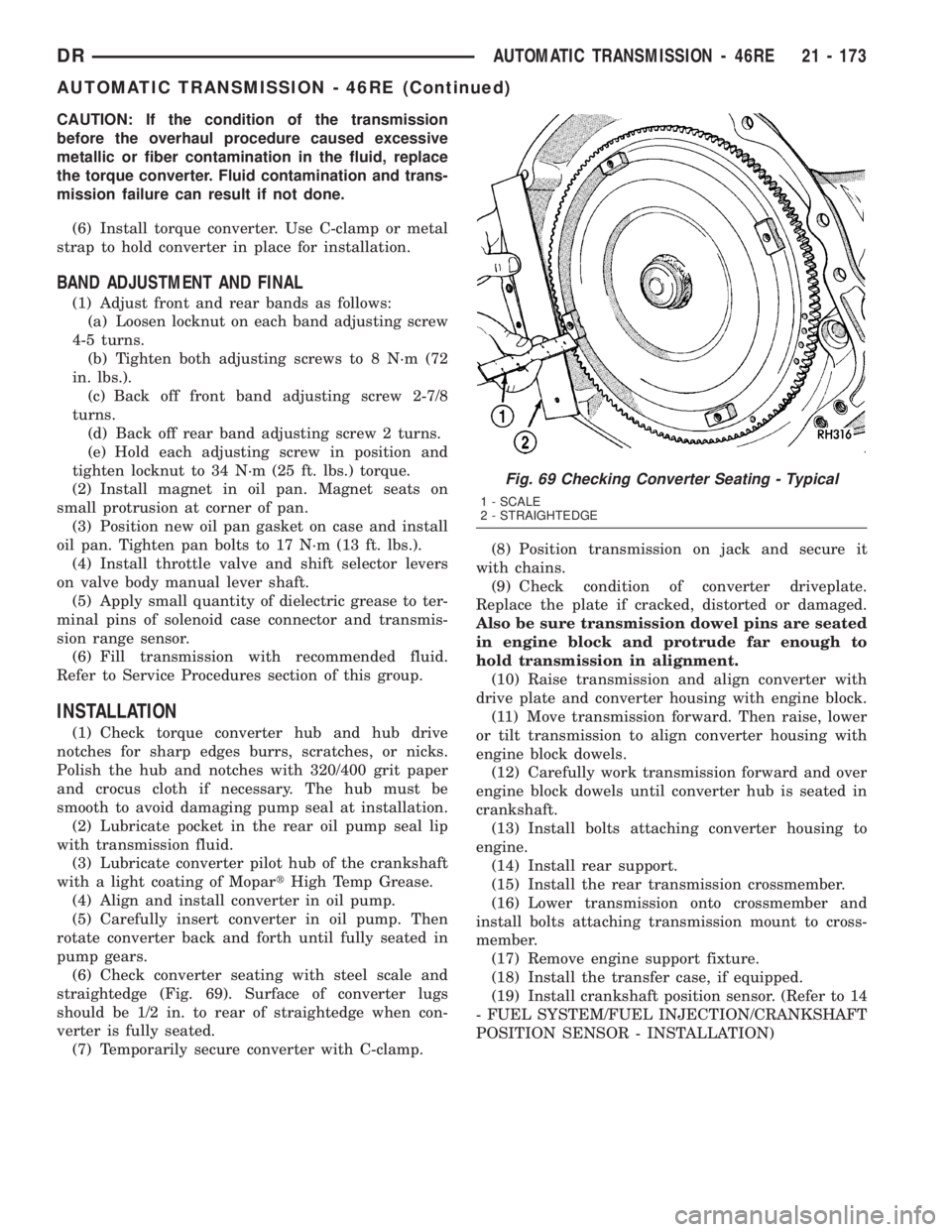

(6) Check converter seating with steel scale and

straightedge (Fig. 69). Surface of converter lugs

should be 1/2 in. to rear of straightedge when con-

verter is fully seated.

(7) Temporarily secure converter with C-clamp.(8) Position transmission on jack and secure it

with chains.

(9) Check condition of converter driveplate.

Replace the plate if cracked, distorted or damaged.

Also be sure transmission dowel pins are seated

in engine block and protrude far enough to

hold transmission in alignment.

(10) Raise transmission and align converter with

drive plate and converter housing with engine block.

(11) Move transmission forward. Then raise, lower

or tilt transmission to align converter housing with

engine block dowels.

(12) Carefully work transmission forward and over

engine block dowels until converter hub is seated in

crankshaft.

(13) Install bolts attaching converter housing to

engine.

(14) Install rear support.

(15) Install the rear transmission crossmember.

(16) Lower transmission onto crossmember and

install bolts attaching transmission mount to cross-

member.

(17) Remove engine support fixture.

(18) Install the transfer case, if equipped.

(19) Install crankshaft position sensor. (Refer to 14

- FUEL SYSTEM/FUEL INJECTION/CRANKSHAFT

POSITION SENSOR - INSTALLATION)

Fig. 69 Checking Converter Seating - Typical

1 - SCALE

2 - STRAIGHTEDGE

DRAUTOMATIC TRANSMISSION - 46RE 21 - 173

AUTOMATIC TRANSMISSION - 46RE (Continued)

Page 2137 of 2895

CLEANING

Clean the valve housings, valves, plugs, springs,

and separator plates with a standard parts cleaning

solution only. Do not use gasoline, kerosene, or any

type of caustic solution.

Do not immerse any of the electrical components in

cleaning solution. Clean the governor solenoid and

sensor and the dual solenoid and harness assembly

by wiping them off with dry shop towels only.

Dry all except the electrical parts with compressed

air. Make sure all passages are clean and free from

obstructions.Do not use rags or shop towels to

dry or wipe off valve body components. Lint

from these materials can stick to valve body

parts, interfere with valve operation, and clog

filters and fluid passages.

Wipe the governor pressure sensor and solenoid

valve with dry, lint free shop towels only. The O-rings

on the sensor and solenoid valve are the only service-

able components. Be sure the vent ports in the sole-

noid valve are open and not blocked by dirt or debris.

Replace the valve and/or sensor only when DRB scan

tool diagnosis indicates this is necessary. Or, if either

part has sustained physical damage (dented,

deformed, broken, etc.).

CAUTION: Do not turn the small screw at the end of

the solenoid valve for any reason. Turning the

screw in either direction will ruin solenoid calibra-

tion and result in solenoid failure. In addition, thefilter on the solenoid valve is NOT serviceable. Do

not try to remove the filter as this will damage the

valve housing.

INSPECTION

Inspect the throttle and manual valve levers and

shafts. Do not attempt to straighten a bent shaft or

correct a loose lever. Replace these components if

worn, bent, loose or damaged in any way.

Inspect all of the valve body mating surfaces for

scratches, nicks, burrs, or distortion. Use a straight-

edge to check surface flatness. Minor scratches may

be removed with crocus cloth using only very light

pressure.

Minor distortion of a valve body mating surface

may be corrected by smoothing the surface with a

sheet of crocus cloth. Position the crocus cloth on a

surface plate, sheet of plate glass or equally flat sur-

face. If distortion is severe or any surfaces are

heavily scored, the valve body will have to be

replaced.

CAUTION: Many of the valves and plugs, such as

the throttle valve, shuttle valve plug, 1-2 shift valve

and 1-2 governor plug, are made of coated alumi-

num. Aluminum components are identified by the

dark color of the special coating applied to the sur-

face (or by testing with a magnet). Do not sand alu-

minum valves or plugs under any circumstances.

This practice could damage the special coating

causing the valves/plugs to stick and bind.

Inspect the valves and plugs for scratches, burrs,

nicks, or scores. Minor surface scratches on steel

valves and plugs can be removed with crocus cloth

butdo not round off the edges of the valve or

plug lands.Maintaining sharpness of these edges is

vitally important. The edges prevent foreign matter

from lodging between the valves and plugs and the

bore.

Inspect all the valve and plug bores in the valve

body. Use a penlight to view the bore interiors.

Replace the valve body if any bores are distorted or

scored. Inspect all of the valve body springs. The

springs must be free of distortion, warpage or broken

coils.

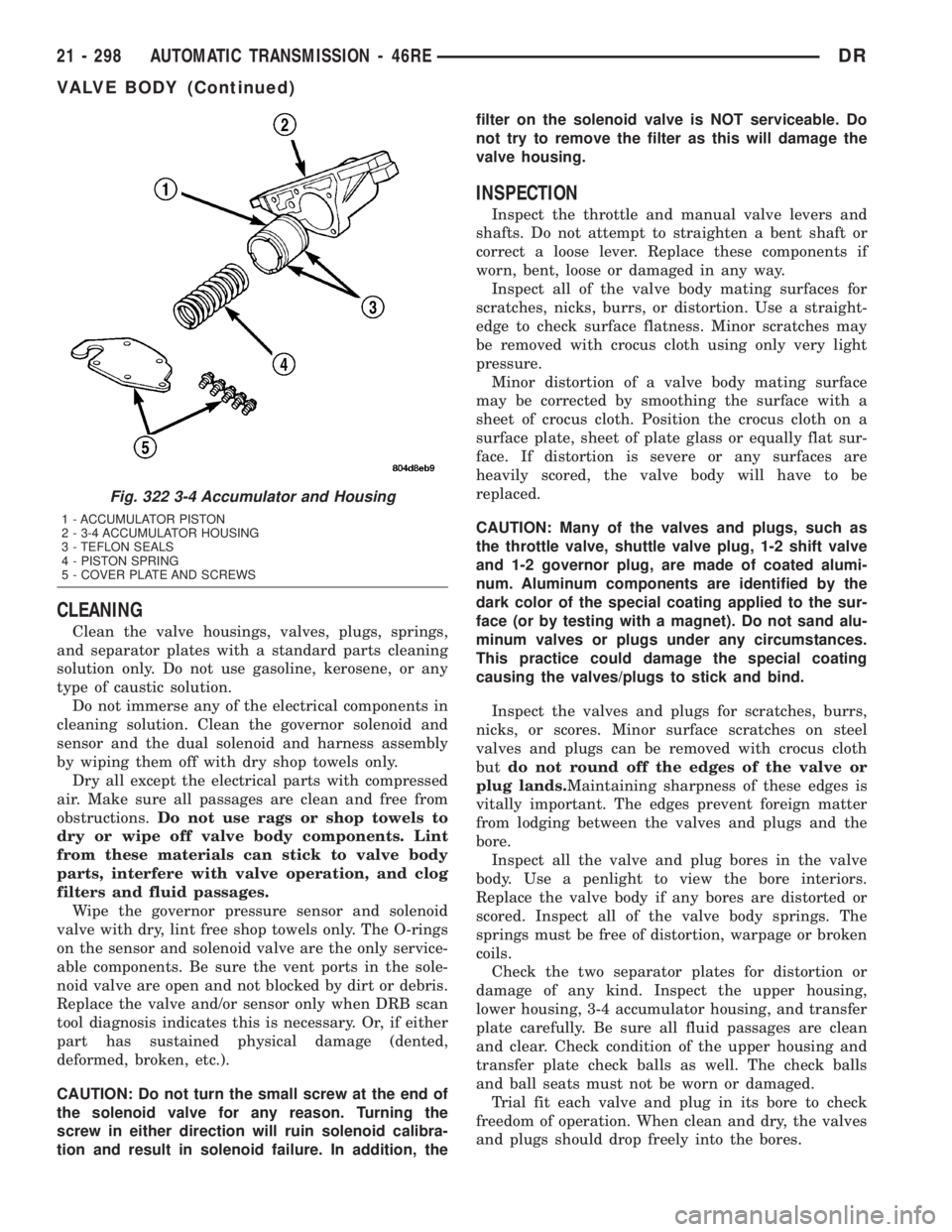

Check the two separator plates for distortion or

damage of any kind. Inspect the upper housing,

lower housing, 3-4 accumulator housing, and transfer

plate carefully. Be sure all fluid passages are clean

and clear. Check condition of the upper housing and

transfer plate check balls as well. The check balls

and ball seats must not be worn or damaged.

Trial fit each valve and plug in its bore to check

freedom of operation. When clean and dry, the valves

and plugs should drop freely into the bores.

Fig. 322 3-4 Accumulator and Housing

1 - ACCUMULATOR PISTON

2 - 3-4 ACCUMULATOR HOUSING

3 - TEFLON SEALS

4 - PISTON SPRING

5 - COVER PLATE AND SCREWS

21 - 298 AUTOMATIC TRANSMISSION - 46REDR

VALVE BODY (Continued)

Page 2139 of 2895

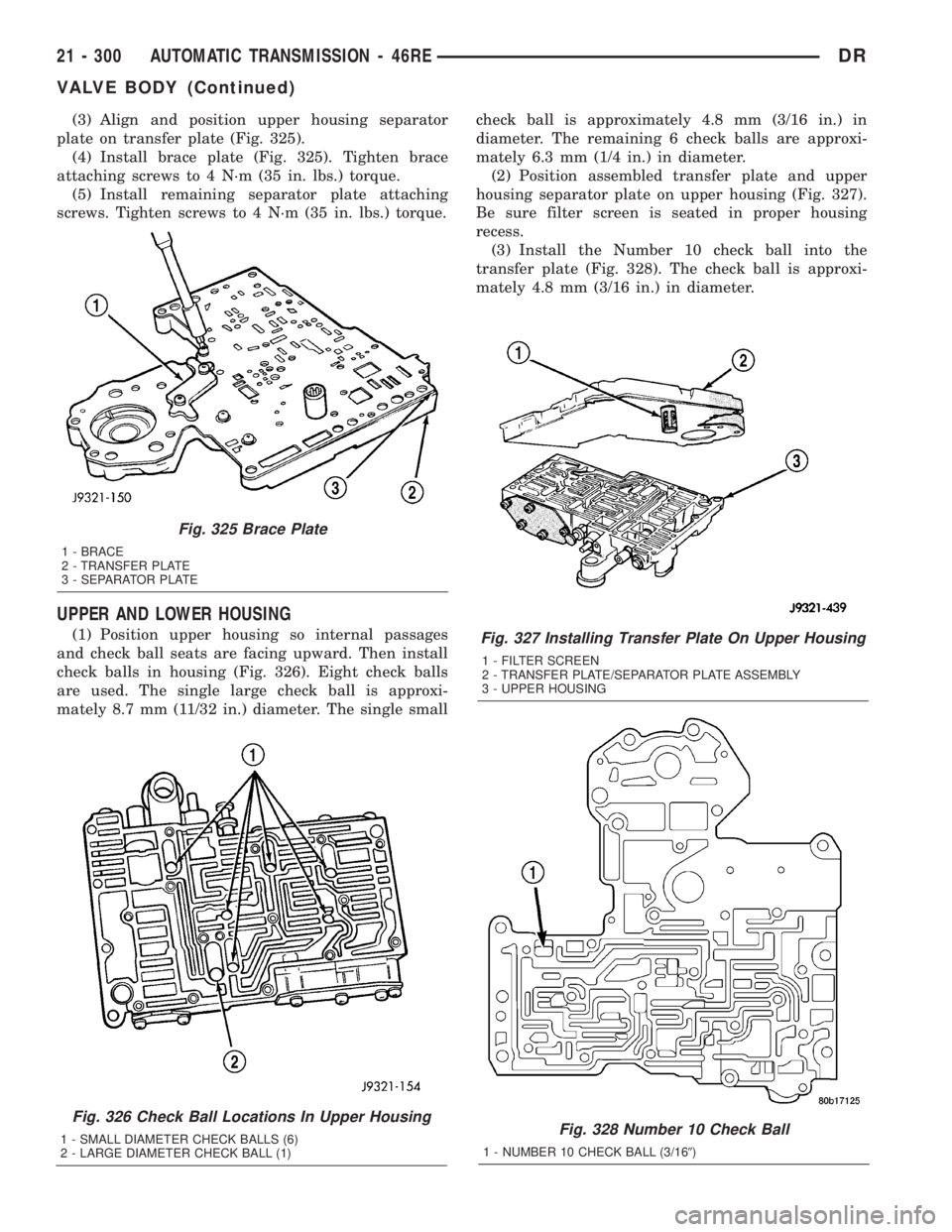

(3) Align and position upper housing separator

plate on transfer plate (Fig. 325).

(4) Install brace plate (Fig. 325). Tighten brace

attaching screws to 4 N´m (35 in. lbs.) torque.

(5) Install remaining separator plate attaching

screws. Tighten screws to 4 N´m (35 in. lbs.) torque.

UPPER AND LOWER HOUSING

(1) Position upper housing so internal passages

and check ball seats are facing upward. Then install

check balls in housing (Fig. 326). Eight check balls

are used. The single large check ball is approxi-

mately 8.7 mm (11/32 in.) diameter. The single smallcheck ball is approximately 4.8 mm (3/16 in.) in

diameter. The remaining 6 check balls are approxi-

mately 6.3 mm (1/4 in.) in diameter.

(2) Position assembled transfer plate and upper

housing separator plate on upper housing (Fig. 327).

Be sure filter screen is seated in proper housing

recess.

(3) Install the Number 10 check ball into the

transfer plate (Fig. 328). The check ball is approxi-

mately 4.8 mm (3/16 in.) in diameter.

Fig. 326 Check Ball Locations In Upper Housing

1 - SMALL DIAMETER CHECK BALLS (6)

2 - LARGE DIAMETER CHECK BALL (1)

Fig. 327 Installing Transfer Plate On Upper Housing

1 - FILTER SCREEN

2 - TRANSFER PLATE/SEPARATOR PLATE ASSEMBLY

3 - UPPER HOUSING

Fig. 328 Number 10 Check Ball

1 - NUMBER 10 CHECK BALL (3/169)

Fig. 325 Brace Plate

1 - BRACE

2 - TRANSFER PLATE

3 - SEPARATOR PLATE

21 - 300 AUTOMATIC TRANSMISSION - 46REDR

VALVE BODY (Continued)

Page 2192 of 2895

(10) Install torque converter. Use C-clamp or metal

strap to hold converter in place for installation.

BAND ADJUSTMENT AND FINAL

(1) Adjust front and rear bands as follows:

(a) Loosen locknut on each band adjusting screw

4-5 turns.

(b) Tighten both adjusting screws to 8 N´m (72

in. lbs.).

(c) Back off front band adjusting screw 1-3/4

turns.

(d) Back off rear band adjusting screw 3 turns.

(e) Hold each adjusting screw in position and

tighten locknut to 34 N´m (25 ft. lbs.) torque.

(2) Install magnet in oil pan. Magnet seats on

small protrusion at corner of pan.

(3) Position new oil pan gasket on case and install

oil pan. Tighten pan bolts to 13.6 N´m (125 in. lbs.).

(4) Install throttle valve and shift selector levers

on valve body manual lever shaft.

(5) Apply small quantity of dielectric grease to ter-

minal pins of solenoid case connector and neutral

switch.

(6) Fill transmission with recommended fluid.

INSTALLATION

(1) Check torque converter hub inner and outer

diameters and hub drive notches for sharp edges

burrs, scratches, or nicks. Polish the hub and notches

with 320/400 grit paper and crocus cloth if necessary.

The hub must be smooth to avoid damaging pump

seal at installation.

(2) Lubricate pocket in the rear oil pump seal lip

with transmission fluid.

(3) Lubricate converter pilot hub of the crankshaft

with a light coating of MopartHigh Temp Grease.

(4) Align and install converter in oil pump.

(5) Carefully insert converter in oil pump. Then

rotate converter back and forth until fully seated in

pump gears.

(6) Check converter seating with steel scale and

straightedge (Fig. 65). Surface of converter lugs

should be 19mm (0.75 in.) to rear of straightedge

when converter is fully seated.

(7) Temporarily secure converter with C-clamp.

(8) Position transmission on jack and secure it

with chains.

(9) Check condition of converter driveplate.

Replace the plate if cracked, distorted or damaged.

Also be sure transmission dowel pins are seated

in engine block and protrude far enough to

hold transmission in alignment.

(10) Raise transmission and align converter with

drive plate and converter housing with engine block.

(11) Move transmission forward. Then raise, lower

or tilt transmission to align converter housing with

engine block dowels.

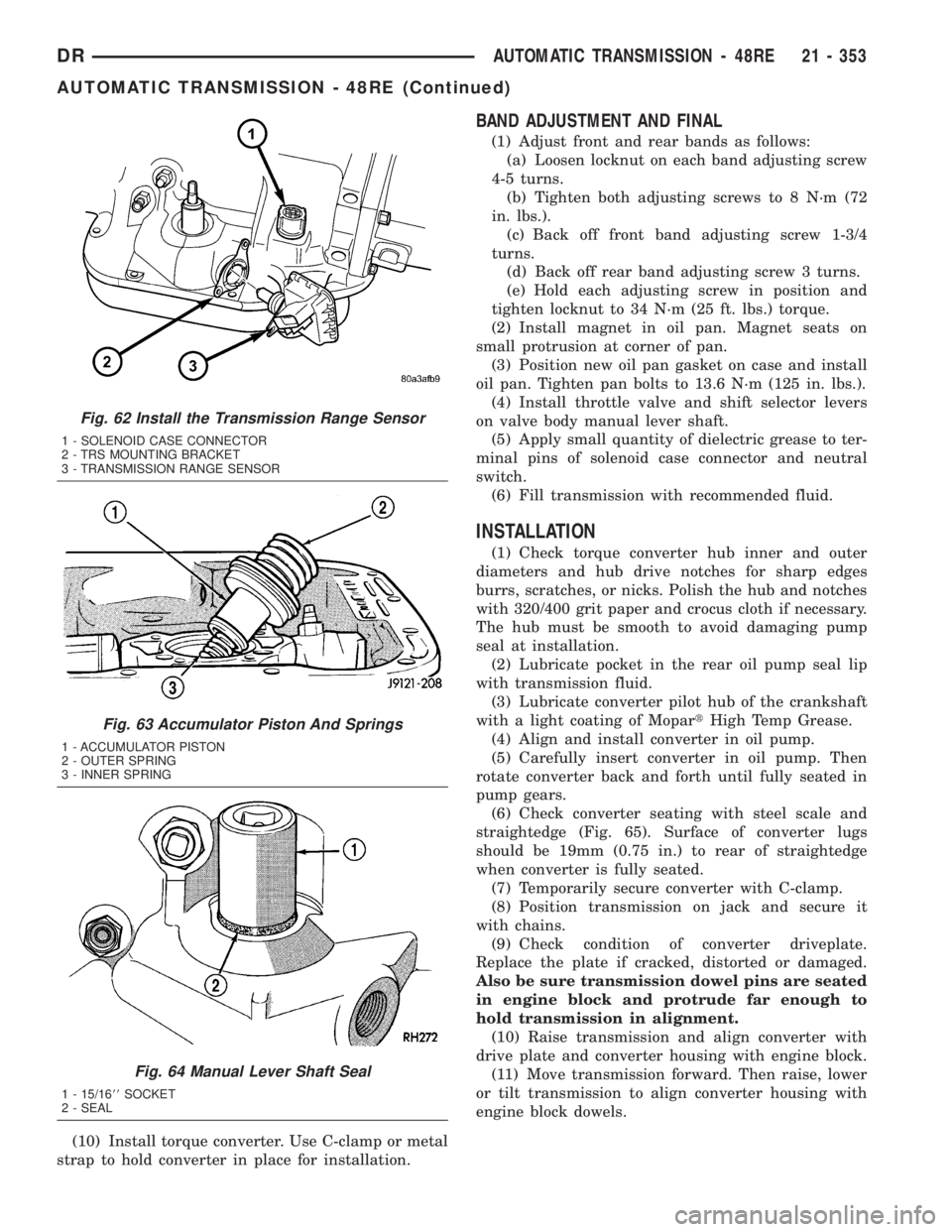

Fig. 62 Install the Transmission Range Sensor

1 - SOLENOID CASE CONNECTOR

2 - TRS MOUNTING BRACKET

3 - TRANSMISSION RANGE SENSOR

Fig. 63 Accumulator Piston And Springs

1 - ACCUMULATOR PISTON

2 - OUTER SPRING

3 - INNER SPRING

Fig. 64 Manual Lever Shaft Seal

1 - 15/1688SOCKET

2 - SEAL

DRAUTOMATIC TRANSMISSION - 48RE 21 - 353

AUTOMATIC TRANSMISSION - 48RE (Continued)

Page 2316 of 2895

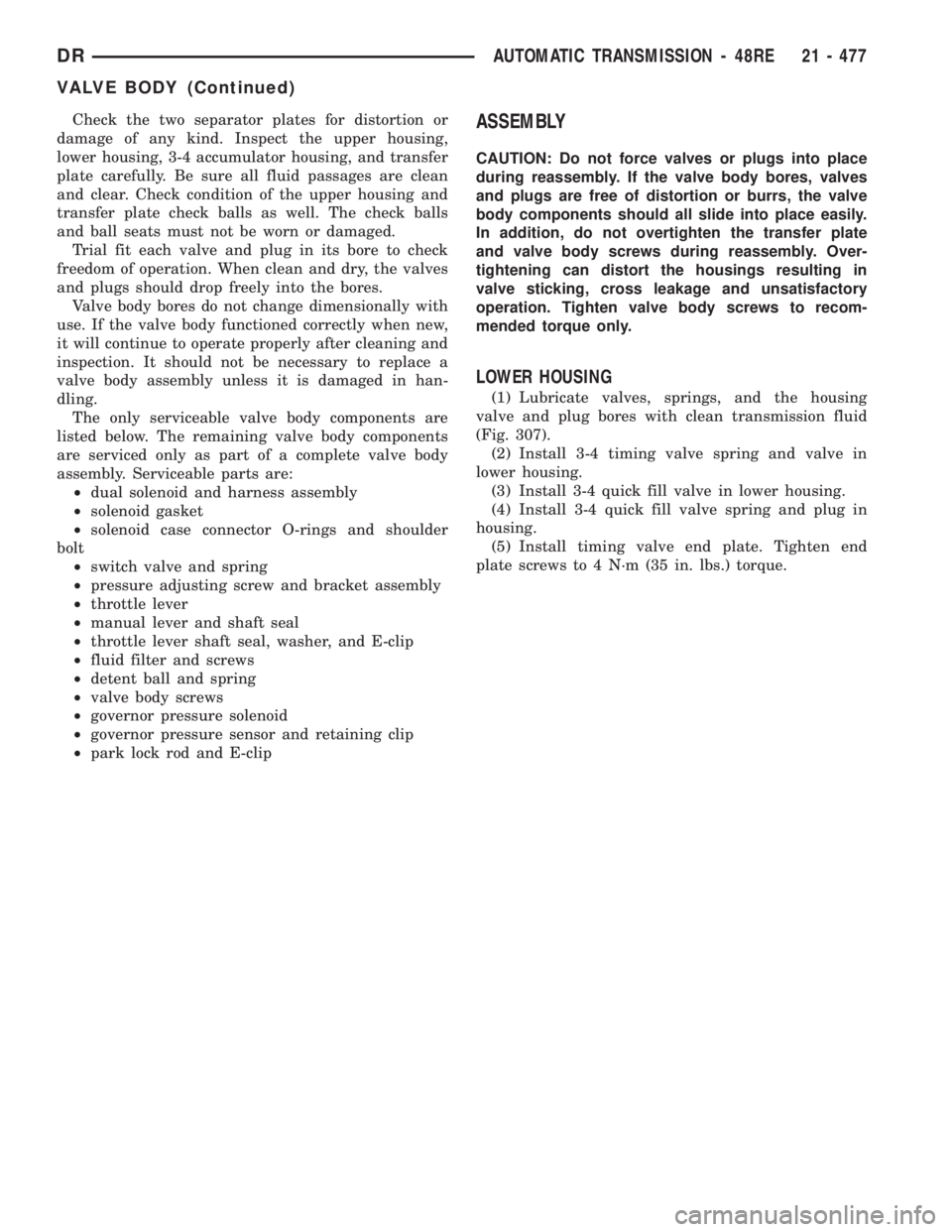

Check the two separator plates for distortion or

damage of any kind. Inspect the upper housing,

lower housing, 3-4 accumulator housing, and transfer

plate carefully. Be sure all fluid passages are clean

and clear. Check condition of the upper housing and

transfer plate check balls as well. The check balls

and ball seats must not be worn or damaged.

Trial fit each valve and plug in its bore to check

freedom of operation. When clean and dry, the valves

and plugs should drop freely into the bores.

Valve body bores do not change dimensionally with

use. If the valve body functioned correctly when new,

it will continue to operate properly after cleaning and

inspection. It should not be necessary to replace a

valve body assembly unless it is damaged in han-

dling.

The only serviceable valve body components are

listed below. The remaining valve body components

are serviced only as part of a complete valve body

assembly. Serviceable parts are:

²dual solenoid and harness assembly

²solenoid gasket

²solenoid case connector O-rings and shoulder

bolt

²switch valve and spring

²pressure adjusting screw and bracket assembly

²throttle lever

²manual lever and shaft seal

²throttle lever shaft seal, washer, and E-clip

²fluid filter and screws

²detent ball and spring

²valve body screws

²governor pressure solenoid

²governor pressure sensor and retaining clip

²park lock rod and E-clipASSEMBLY

CAUTION: Do not force valves or plugs into place

during reassembly. If the valve body bores, valves

and plugs are free of distortion or burrs, the valve

body components should all slide into place easily.

In addition, do not overtighten the transfer plate

and valve body screws during reassembly. Over-

tightening can distort the housings resulting in

valve sticking, cross leakage and unsatisfactory

operation. Tighten valve body screws to recom-

mended torque only.

LOWER HOUSING

(1) Lubricate valves, springs, and the housing

valve and plug bores with clean transmission fluid

(Fig. 307).

(2) Install 3-4 timing valve spring and valve in

lower housing.

(3) Install 3-4 quick fill valve in lower housing.

(4) Install 3-4 quick fill valve spring and plug in

housing.

(5) Install timing valve end plate. Tighten end

plate screws to 4 N´m (35 in. lbs.) torque.

DRAUTOMATIC TRANSMISSION - 48RE 21 - 477

VALVE BODY (Continued)