Heating and cooling DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1 of 2895

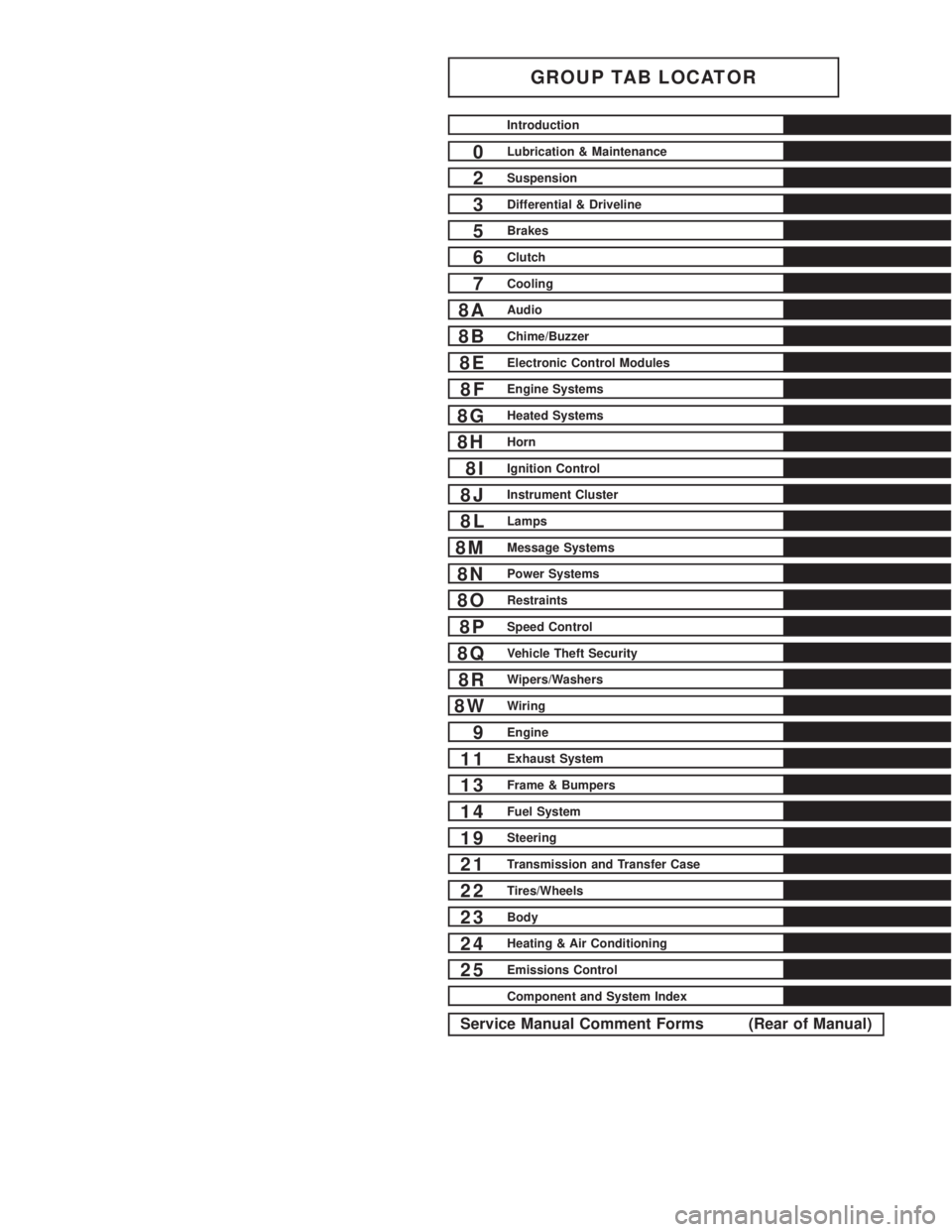

GROUP TAB LOCATOR

Introduction

0Lubrication & Maintenance

2Suspension

3Differential & Driveline

5Brakes

6Clutch

7Cooling

8AAudio

8BChime/Buzzer

8EElectronic Control Modules

8FEngine Systems

8GHeated Systems

8HHorn

8IIgnition Control

8JInstrument Cluster

8LLamps

8MMessage Systems

8NPower Systems

8ORestraints

8PSpeed Control

8QVehicle Theft Security

8RWipers/Washers

8WWiring

9Engine

11Exhaust System

13Frame & Bumpers

14Fuel System

19Steering

21Transmission and Transfer Case

22Tires/Wheels

23Body

24Heating & Air Conditioning

25Emissions Control

Component and System Index

Service Manual Comment Forms (Rear of Manual)

Page 18 of 2895

FLUID ADDITIVES

DaimlerChrysler strongly recommends against the

addition of any fluids to the transmission, other than

those automatic transmission fluids listed above.

Exceptions to this policy are the use of special dyes

to aid in detecting fluid leaks.

Various ªspecialº additives and supplements exist

that claim to improve shift feel and/or quality. These

additives and others also claim to improve converter

clutch operation and inhibit overheating, oxidation,

varnish, and sludge. These claims have not been sup-

ported to the satisfaction of DaimlerChrysler and

these additivesmust not be used.The use of trans-

mission ªsealersº should also be avoided, since they

may adversely affect the integrity of transmission

seals.

OPERATION - AUTOMATIC TRANSMISSION

FLUID

The automatic transmission fluid is selected based

upon several qualities. The fluid must provide a high

level of protection for the internal components by

providing a lubricating film between adjacent metal

components. The fluid must also be thermally stable

so that it can maintain a consistent viscosity through

a large temperature range. If the viscosity stays con-

stant through the temperature range of operation,

transmission operation and shift feel will remain con-

sistent. Transmission fluid must also be a good con-

ductor of heat. The fluid must absorb heat from the

internal transmission components and transfer that

heat to the transmission case.

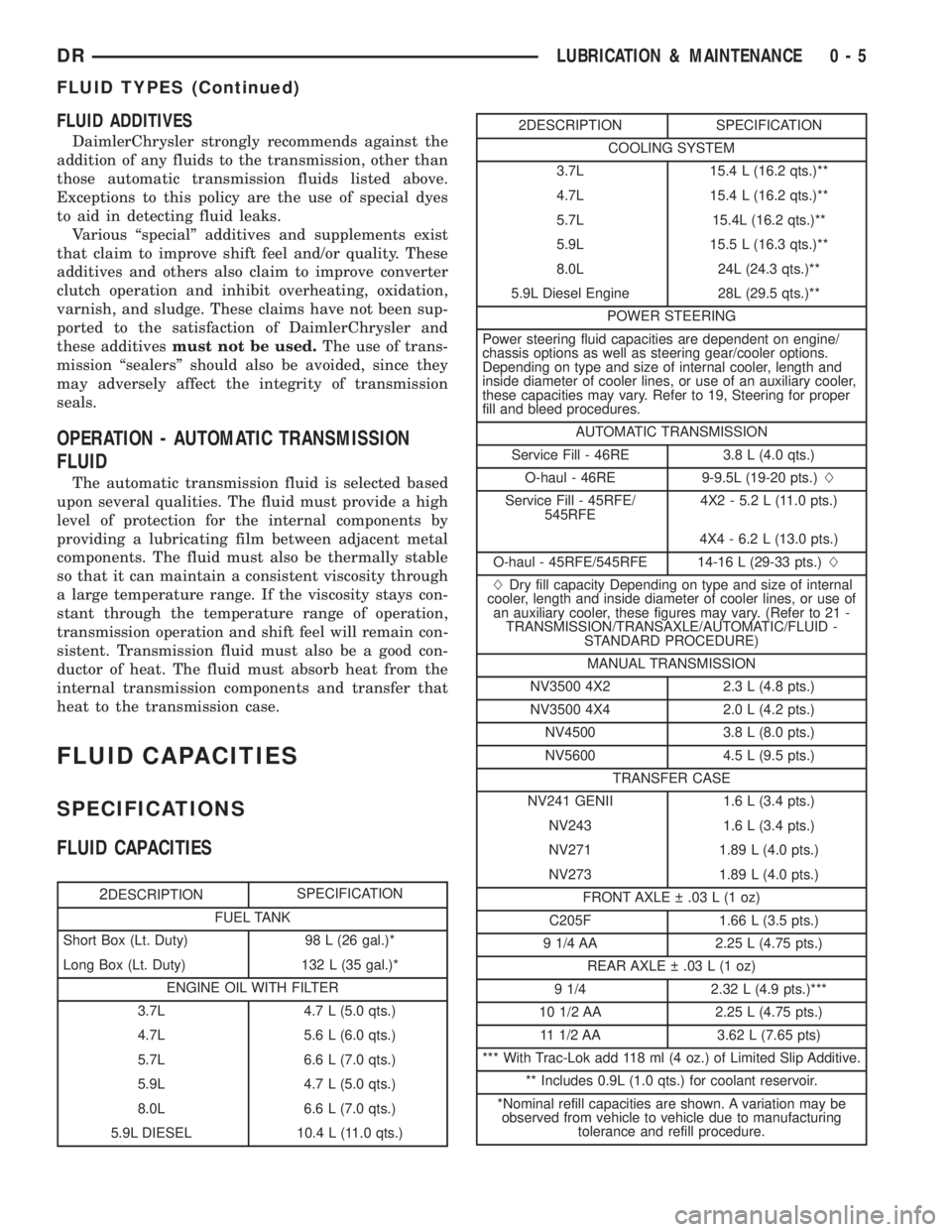

FLUID CAPACITIES

SPECIFICATIONS

FLUID CAPACITIES

2DESCRIPTIONSPECIFICATION

FUEL TANK

Short Box (Lt. Duty) 98 L (26 gal.)*

Long Box (Lt. Duty) 132 L (35 gal.)*

ENGINE OIL WITH FILTER

3.7L 4.7 L (5.0 qts.)

4.7L 5.6 L (6.0 qts.)

5.7L 6.6 L (7.0 qts.)

5.9L 4.7 L (5.0 qts.)

8.0L 6.6 L (7.0 qts.)

5.9L DIESEL 10.4 L (11.0 qts.)

2DESCRIPTION SPECIFICATION

COOLING SYSTEM

3.7L 15.4 L (16.2 qts.)**

4.7L 15.4 L (16.2 qts.)**

5.7L 15.4L (16.2 qts.)**

5.9L 15.5 L (16.3 qts.)**

8.0L 24L (24.3 qts.)**

5.9L Diesel Engine 28L (29.5 qts.)**

POWER STEERING

Power steering fluid capacities are dependent on engine/

chassis options as well as steering gear/cooler options.

Depending on type and size of internal cooler, length and

inside diameter of cooler lines, or use of an auxiliary cooler,

these capacities may vary. Refer to 19, Steering for proper

fill and bleed procedures.

AUTOMATIC TRANSMISSION

Service Fill - 46RE 3.8 L (4.0 qts.)

O-haul - 46RE 9-9.5L (19-20 pts.)L

Service Fill - 45RFE/

545RFE4X2 - 5.2 L (11.0 pts.)

4X4 - 6.2 L (13.0 pts.)

O-haul - 45RFE/545RFE 14-16 L (29-33 pts.)L

LDry fill capacity Depending on type and size of internal

cooler, length and inside diameter of cooler lines, or use of

an auxiliary cooler, these figures may vary. (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC/FLUID -

STANDARD PROCEDURE)

MANUAL TRANSMISSION

NV3500 4X2 2.3 L (4.8 pts.)

NV3500 4X4 2.0 L (4.2 pts.)

NV4500 3.8 L (8.0 pts.)

NV5600 4.5 L (9.5 pts.)

TRANSFER CASE

NV241 GENII 1.6 L (3.4 pts.)

NV243 1.6 L (3.4 pts.)

NV271 1.89 L (4.0 pts.)

NV273 1.89 L (4.0 pts.)

FRONT AXLE .03 L (1 oz)

C205F 1.66 L (3.5 pts.)

9 1/4 AA 2.25 L (4.75 pts.)

REAR AXLE .03 L (1 oz)

9 1/4 2.32 L (4.9 pts.)***

10 1/2 AA 2.25 L (4.75 pts.)

11 1/2 AA 3.62 L (7.65 pts)

*** With Trac-Lok add 118 ml (4 oz.) of Limited Slip Additive.

** Includes 0.9L (1.0 qts.) for coolant reservoir.

*Nominal refill capacities are shown. A variation may be

observed from vehicle to vehicle due to manufacturing

tolerance and refill procedure.

DRLUBRICATION & MAINTENANCE 0 - 5

FLUID TYPES (Continued)

Page 285 of 2895

bolts when remounting a flywheel and secure the

bolts with Mopar Lock And Seal or equivalent.

Tighten flywheel bolts to specified torque only. Over-

tightening can distort the flywheel hub causing

runout.

REMOVAL

(1) Remove transmission.

(2) Remove pressure plate and clutch.

(3) Remove flywheel bolts and remove flywheel.

DISASSEMBLY

NOTE: If the teeth are worn or damaged, the fly-

wheel should be replaced as an assembly. This is

the recommended repair. In cases where a new fly-

wheel is not readily available, (V10/Diesel Engine

only) a replacement ring gear can be installed. The

following procedure must be observed to avoid

damaging the flywheel and replacement gear.

WARNING: WEAR PROTECTIVE GOGGLES OR

SAFETY GLASSES WHILE CUTTING RING GEAR.

(1) Mark position of the old gear for alignment ref-

erence on the flywheel. Use a scriber for this pur-

pose.

(2) Remove the old gear by cutting most of the way

through it (at one point) with an abrasive cut-off

wheel. Then complete removal with a cold chisel or

punch.

ASSEMBLY

NOTE: The ring gear is a shrink fit on the flywheel.

This means the gear must be expanded by heating

in order to install it. The method of heating and

expanding the gear is extremely important. Every

surface of the gear must be heated at the same

time to produce uniform expansion. An oven or

similar enclosed heating device must be used. Tem-

perature required for uniform expansion is approxi-

mately 375É F.

CAUTION: Do not use an oxy/acetylene torch to

remove the old gear, or to heat and expand a new

gear. The high temperature of the torch flame can

cause localized heating that will damage the fly-

wheel. In addition, using the torch to heat a replace-

ment gear will cause uneven heating and

expansion. The torch flame can also anneal the

gear teeth resulting in rapid wear and damage after

installation.WARNING: WEAR PROTECTIVE GOGGLES OR

SAFETY GLASSES AND HEAT RESISTENT GLOVES

WHEN HANDLING A HEATED RING GEAR.

(1) The heated gear must be installed evenly to

avoid misalignment or distortion.

(2) Position and install the heated ring gear on the

flywheel with a shop press and a suitable press

plates.

(3) Place flywheel on work bench and let it cool in

normal shop air. Allow the ring gear to cool down

completely before installation it on the engine.

CAUTION: Do not use water or compressed air to

cool the flywheel. The rapid cooling produced by

water or compressed air will distort or crack the

new gear.

INSTALLATION

(1) Install flywheel on the crank shaft.

(2) Install flywheel bolts and tighten to 95 N´m (70

ft. lbs.).

(3) Install clutch.

(4) Install transmission.

PILOT BEARING

REMOVAL

(1) Remove transmission.

(2) Remove clutch disc.

(3) Use a suitable blind hole puller to remove pilot

bearing.

INSTALLATION

(1) Clean bearing bore with solvent and wipe dry

with shop towel.

(2) Install new bearing with clutch alignment tool

(Fig. 19). Drive bearing into place with the letter side

of the bearing facing the transmission. Bearing

should be flush with edge of bearing bore.

CAUTION: Do not allow bearing to become cocked

and do not recess bearing.

6 - 12 CLUTCHDR

FLYWHEEL (Continued)

Page 288 of 2895

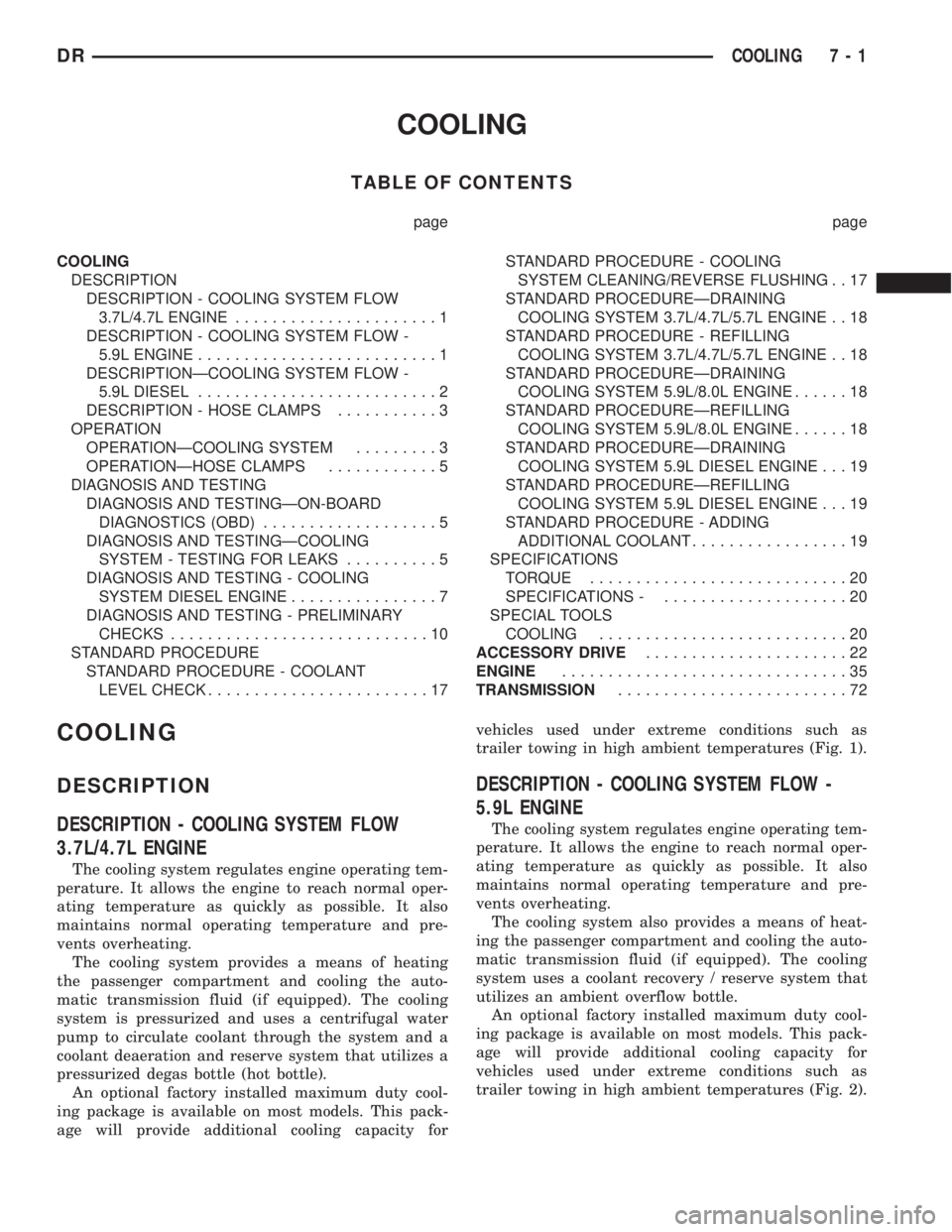

COOLING

TABLE OF CONTENTS

page page

COOLING

DESCRIPTION

DESCRIPTION - COOLING SYSTEM FLOW

3.7L/4.7L ENGINE......................1

DESCRIPTION - COOLING SYSTEM FLOW -

5.9L ENGINE..........................1

DESCRIPTIONÐCOOLING SYSTEM FLOW -

5.9L DIESEL..........................2

DESCRIPTION - HOSE CLAMPS...........3

OPERATION

OPERATIONÐCOOLING SYSTEM.........3

OPERATIONÐHOSE CLAMPS............5

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTINGÐON-BOARD

DIAGNOSTICS (OBD)...................5

DIAGNOSIS AND TESTINGÐCOOLING

SYSTEM - TESTING FOR LEAKS..........5

DIAGNOSIS AND TESTING - COOLING

SYSTEM DIESEL ENGINE................7

DIAGNOSIS AND TESTING - PRELIMINARY

CHECKS............................10

STANDARD PROCEDURE

STANDARD PROCEDURE - COOLANT

LEVEL CHECK........................17STANDARD PROCEDURE - COOLING

SYSTEM CLEANING/REVERSE FLUSHING . . 17

STANDARD PROCEDUREÐDRAINING

COOLING SYSTEM 3.7L/4.7L/5.7L ENGINE . . 18

STANDARD PROCEDURE - REFILLING

COOLING SYSTEM 3.7L/4.7L/5.7L ENGINE . . 18

STANDARD PROCEDUREÐDRAINING

COOLING SYSTEM 5.9L/8.0L ENGINE......18

STANDARD PROCEDUREÐREFILLING

COOLING SYSTEM 5.9L/8.0L ENGINE......18

STANDARD PROCEDUREÐDRAINING

COOLING SYSTEM 5.9L DIESEL ENGINE . . . 19

STANDARD PROCEDUREÐREFILLING

COOLING SYSTEM 5.9L DIESEL ENGINE . . . 19

STANDARD PROCEDURE - ADDING

ADDITIONAL COOLANT.................19

SPECIFICATIONS

TORQUE............................20

SPECIFICATIONS -....................20

SPECIAL TOOLS

COOLING...........................20

ACCESSORY DRIVE......................22

ENGINE...............................35

TRANSMISSION.........................72

COOLING

DESCRIPTION

DESCRIPTION - COOLING SYSTEM FLOW

3.7L/4.7L ENGINE

The cooling system regulates engine operating tem-

perature. It allows the engine to reach normal oper-

ating temperature as quickly as possible. It also

maintains normal operating temperature and pre-

vents overheating.

The cooling system provides a means of heating

the passenger compartment and cooling the auto-

matic transmission fluid (if equipped). The cooling

system is pressurized and uses a centrifugal water

pump to circulate coolant through the system and a

coolant deaeration and reserve system that utilizes a

pressurized degas bottle (hot bottle).

An optional factory installed maximum duty cool-

ing package is available on most models. This pack-

age will provide additional cooling capacity forvehicles used under extreme conditions such as

trailer towing in high ambient temperatures (Fig. 1).

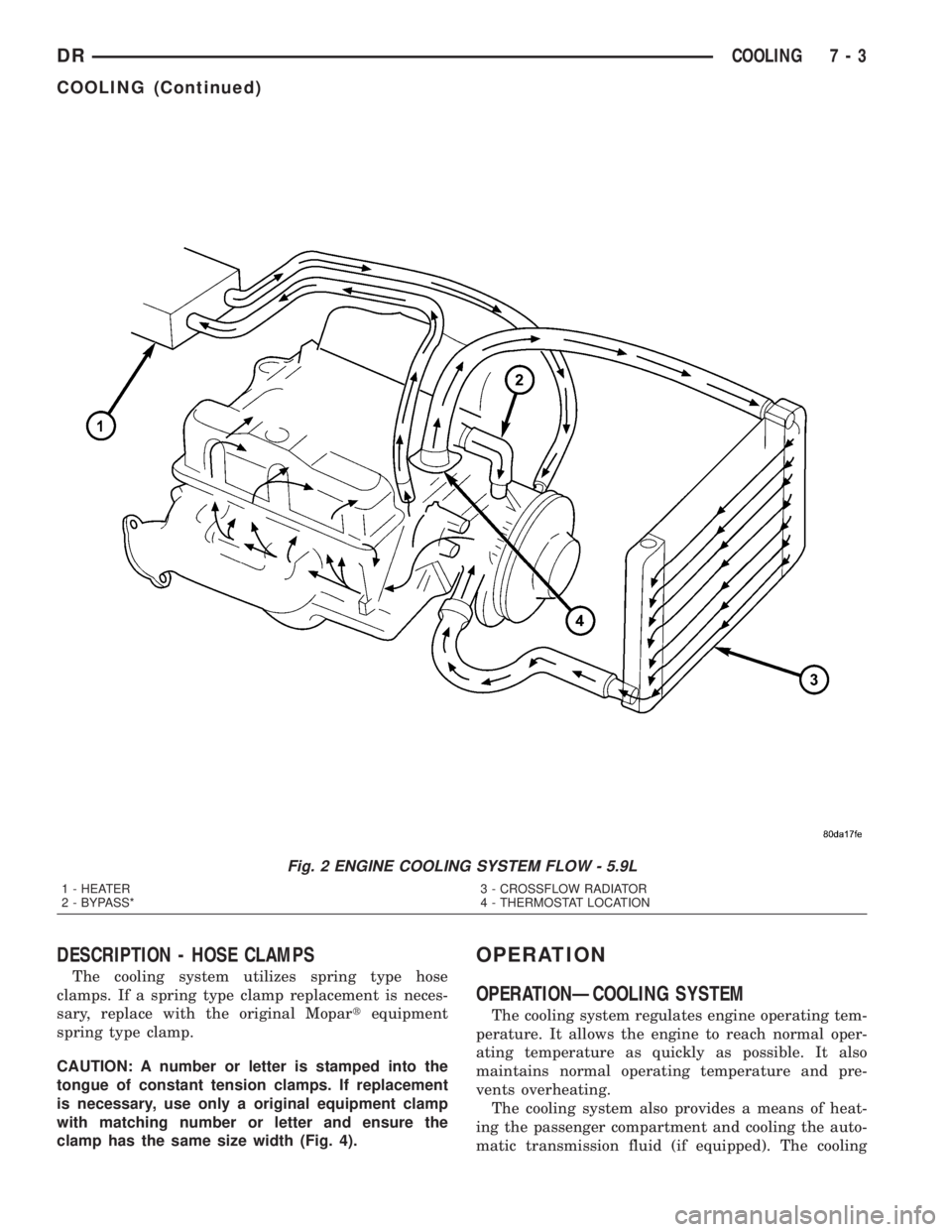

DESCRIPTION - COOLING SYSTEM FLOW -

5.9L ENGINE

The cooling system regulates engine operating tem-

perature. It allows the engine to reach normal oper-

ating temperature as quickly as possible. It also

maintains normal operating temperature and pre-

vents overheating.

The cooling system also provides a means of heat-

ing the passenger compartment and cooling the auto-

matic transmission fluid (if equipped). The cooling

system uses a coolant recovery / reserve system that

utilizes an ambient overflow bottle.

An optional factory installed maximum duty cool-

ing package is available on most models. This pack-

age will provide additional cooling capacity for

vehicles used under extreme conditions such as

trailer towing in high ambient temperatures (Fig. 2).

DRCOOLING 7 - 1

Page 290 of 2895

DESCRIPTION - HOSE CLAMPS

The cooling system utilizes spring type hose

clamps. If a spring type clamp replacement is neces-

sary, replace with the original Mopartequipment

spring type clamp.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only a original equipment clamp

with matching number or letter and ensure the

clamp has the same size width (Fig. 4).

OPERATION

OPERATIONÐCOOLING SYSTEM

The cooling system regulates engine operating tem-

perature. It allows the engine to reach normal oper-

ating temperature as quickly as possible. It also

maintains normal operating temperature and pre-

vents overheating.

The cooling system also provides a means of heat-

ing the passenger compartment and cooling the auto-

matic transmission fluid (if equipped). The cooling

Fig. 2 ENGINE COOLING SYSTEM FLOW - 5.9L

1 - HEATER

2 - BYPASS*3 - CROSSFLOW RADIATOR

4 - THERMOSTAT LOCATION

DRCOOLING 7 - 3

COOLING (Continued)

Page 294 of 2895

WARNING: DO NOT REMOVE CYLINDER BLOCK

DRAIN PLUGS OR LOOSEN RADIATOR DRAIN-

COCK WITH SYSTEM HOT AND UNDER PRESSURE.

SERIOUS BURNS FROM COOLANT CAN OCCUR.

Drain sufficient coolant to allow thermostat

removal. (Refer to 7 - COOLING/ENGINE/ENGINE

COOLANT THERMOSTAT - REMOVAL). Remove

accessory drive belt (Refer to 7 - COOLING/ACCES-

SORY DRIVE/DRIVE BELTS - REMOVAL).

Add coolant to radiator to bring level to within 6.3

mm (1/4 in) of the top of the thermostat housing.CAUTION: Avoid overheating. Do not operate

engine for an excessive period of time. Open drain-

cock immediately after test to eliminate boil over.

Start engine and accelerate rapidly three times, to

approximately 3000 rpm while observing coolant. If

internal engine combustion gases are leaking into

cooling system, bubbles will appear in coolant. If bub-

bles do not appear, internal combustion gas leakage

is not present.

DIAGNOSIS AND TESTING - COOLING SYSTEM

DIESEL ENGINE

COOLING SYSTEM DIAGNOSISÐDIESEL ENGINE

CONDITION POSSIBLE CAUSES CORRECTION

TEMPERATURE GAUGE READS

LOWNOTE:

Information on dash cluster is

displayed based on broadcast data

from ECM. DTC will be set for

engine sensor circuit concern.1. Vehicle is equipped with a heavy

duty cooling system.1. None. System operating normally.

2. Thermostat stuck open 2. Inspect and test thermostat.

3. Coolant level low. 3. Fill cooling system. (Refer to 7 -

COOLING - STANDARD

PROCEDURE)

4. Temperature gauge not

functioning correctly.4. Check cluster (Refer to 8 -

ELECTRICAL/INSTRUMENT

CLUSTER - DIAGNOSIS AND

TESTING)

DRCOOLING 7 - 7

COOLING (Continued)

Page 297 of 2895

CONDITION POSSIBLE CAUSES CORRECTION

INADEQUATE AIR CONDITIONER

PERFORMANCE (COOLING

SYSTEM SUSPECTED)1. Radiator and/or A/C condenser

air flow obstructed.1. Remove obstruction and/or clean.

2. Electronically controlled viscous

fan drive not working.2. Check fan drive. (Refer to 7 -

COOLING/ENGINE/FAN DRIVE

VISCOUS CLUTCH - DIAGNOSIS

AND TESTING)

3. Air seals around radiator

damaged or missing.3. Inspect air seals, repair or

replace as necessary.

INADEQUATE HEATER

PERFORMANCE. GAUGE MAY OR

MAY NOT READ LOW.1. Heavy duty cooling system, and

cooler ambient temperatures.1. None. Normal condition.

2. Obstruction in heater hoses. 2. Remove hoses, remove

obstruction.

3. Electronically controlled viscous

fan stuck onCheck fan drive. (Refer to 7 -

COOLING/ENGINE/FAN DRIVE

VISCOUS CLUTCH - DIAGNOSIS

AND TESTING)

4. Water pump damaged. 4. Replace water pump.

HEAT ODOR 1. Damaged or missing drive line

heat shields.1. Repair or replace damaged or

missing heat shields.

2. Electronically controlled viscous

fan drive damaged.2. Check thermal viscous fan drive.

(Refer to 7 - COOLING/ENGINE/

FAN DRIVE VISCOUS CLUTCH -

DIAGNOSIS AND TESTING)

DIAGNOSIS AND TESTING - PRELIMINARY

CHECKS

ENGINE COOLING SYSTEM OVERHEATING

Establish what driving conditions caused the com-

plaint. Abnormal loads on the cooling system such as

the following may be the cause:

²PROLONGED IDLE

²VERY HIGH AMBIENT TEMPERATURE

²SLIGHT TAIL WIND AT IDLE

²SLOW TRAFFIC

²TRAFFIC JAMS

²HIGH SPEED OR STEEP GRADES

Driving techniques that avoid overheating are:

²Idle with A/C off when temperature gauge is at

end of normal range.

²Increasing engine speed for more air flow is rec-

ommended.

TRAILER TOWING:

Consult Trailer Towing section of owners manual.

Do not exceed limits.RECENT SERVICE OR ACCIDENT REPAIR:

Determine if any recent service has been per-

formed on vehicle that may effect the cooling system.

This may be:

²Engine adjustments (incorrect timing)

²Slipping engine accessory drive belt(s)

²Brakes (possibly dragging)

²Changed parts. Incorrect water pump or pump

rotating in wrong direction due to belt not correctly

routed

²Reconditioned radiator or cooling system refill-

ing (possibly under filled or air trapped in system).

²Service to electrically controlled viscous fan

clutch

NOTE: If investigation reveals none of the previous

items as a cause for an engine overheating com-

plaint, refer to COOLING SYSTEM DIAGNOSIS

CHART BELOW.

These charts are to be used as a quick-reference

only. Refer to COOLING SYSTEM DIAGNOSIS

CHART

7 - 10 COOLINGDR

COOLING (Continued)

Page 298 of 2895

COOLING SYSTEM DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

TEMPERATURE GAUGE

READS LOW1. Has a Diagnostic Trouble

Code (DTC) been set indicating

a stuck open thermostat?1. (Refer to 25 - EMISSIONS CONTROL -

DESCRIPTION) for On-Board Diagnostics

and DTC information. Replace thermostat

if necessary.

2. Is the temperature sending

unit connected?2. Check the temperature sensor

connector. (Refer to 8 - ELECTRICAL/

INSTRUMENT CLUSTER - SCHEMATIC -

ELECTRICAL) Repair connector if

necessary.

3. Is the temperature gauge

operating OK?3. Check gauge operation. (Refer to 8 -

ELECTRICAL/INSTRUMENT CLUSTER/

ENGINE TEMPERATURE GAUGE -

DESCRIPTION). Repair as necessary.

4. Coolant level low in cold

ambient temperatures

accompanied with poor heater

performance.4. Check coolant level in the coolant

reserve/overflow tank or degas bottle and

the radiator. Inspect system for leaks.

Repair leaks as necessary. Refer to the

Coolant section of the manual text for

WARNINGS and CAUTIONS associated

with removing the radiator cap.

5. Improper operation of internal

heater doors or heater controls.5. Inspect heater and repair as necessary.

(Refer to 24 - HEATING & AIR

CONDITIONING - DIAGNOSIS AND

TESTING) for procedures.

DRCOOLING 7 - 11

COOLING (Continued)

Page 299 of 2895

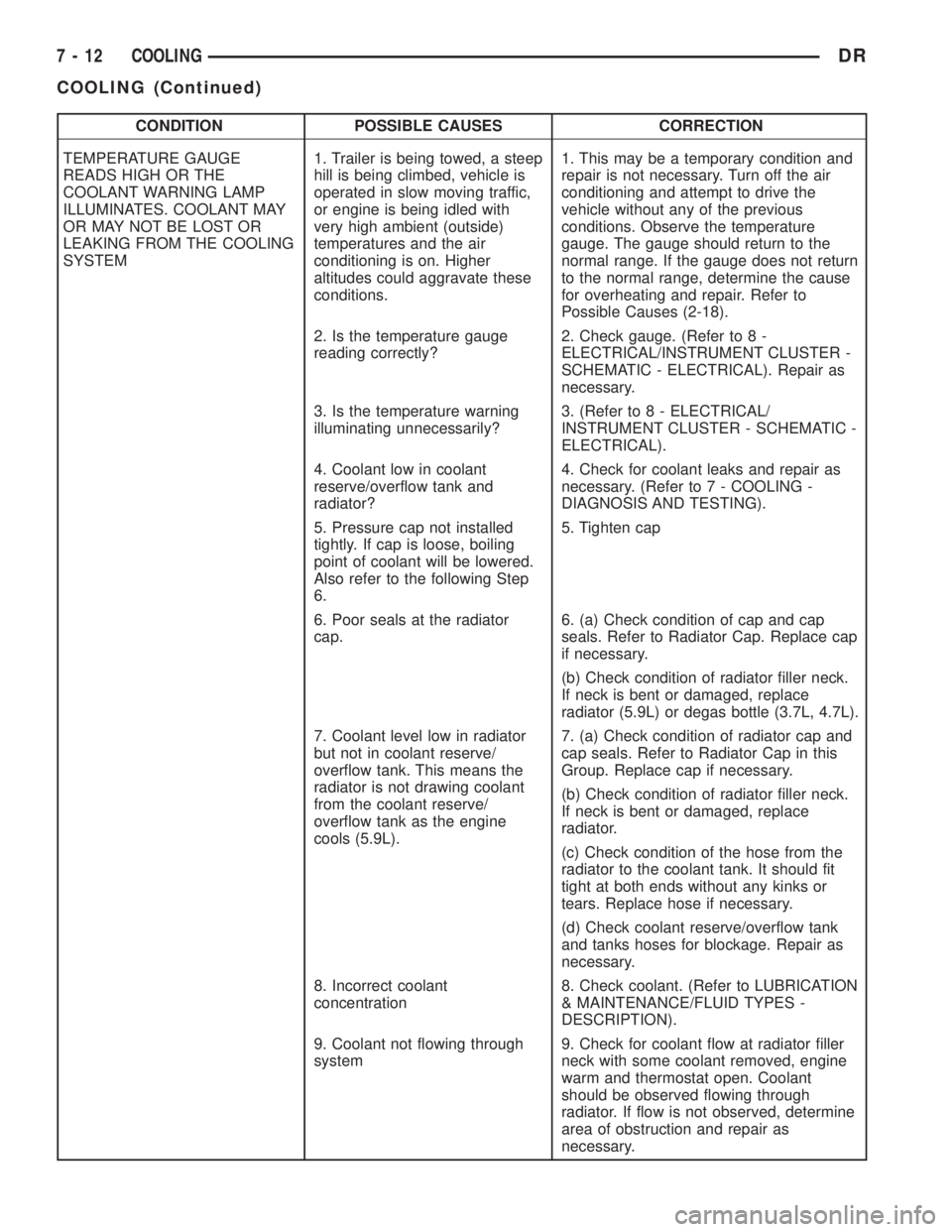

CONDITION POSSIBLE CAUSES CORRECTION

TEMPERATURE GAUGE

READS HIGH OR THE

COOLANT WARNING LAMP

ILLUMINATES. COOLANT MAY

OR MAY NOT BE LOST OR

LEAKING FROM THE COOLING

SYSTEM1. Trailer is being towed, a steep

hill is being climbed, vehicle is

operated in slow moving traffic,

or engine is being idled with

very high ambient (outside)

temperatures and the air

conditioning is on. Higher

altitudes could aggravate these

conditions.1. This may be a temporary condition and

repair is not necessary. Turn off the air

conditioning and attempt to drive the

vehicle without any of the previous

conditions. Observe the temperature

gauge. The gauge should return to the

normal range. If the gauge does not return

to the normal range, determine the cause

for overheating and repair. Refer to

Possible Causes (2-18).

2. Is the temperature gauge

reading correctly?2. Check gauge. (Refer to 8 -

ELECTRICAL/INSTRUMENT CLUSTER -

SCHEMATIC - ELECTRICAL). Repair as

necessary.

3. Is the temperature warning

illuminating unnecessarily?3. (Refer to 8 - ELECTRICAL/

INSTRUMENT CLUSTER - SCHEMATIC -

ELECTRICAL).

4. Coolant low in coolant

reserve/overflow tank and

radiator?4. Check for coolant leaks and repair as

necessary. (Refer to 7 - COOLING -

DIAGNOSIS AND TESTING).

5. Pressure cap not installed

tightly. If cap is loose, boiling

point of coolant will be lowered.

Also refer to the following Step

6.5. Tighten cap

6. Poor seals at the radiator

cap.6. (a) Check condition of cap and cap

seals. Refer to Radiator Cap. Replace cap

if necessary.

(b) Check condition of radiator filler neck.

If neck is bent or damaged, replace

radiator (5.9L) or degas bottle (3.7L, 4.7L).

7. Coolant level low in radiator

but not in coolant reserve/

overflow tank. This means the

radiator is not drawing coolant

from the coolant reserve/

overflow tank as the engine

cools (5.9L).7. (a) Check condition of radiator cap and

cap seals. Refer to Radiator Cap in this

Group. Replace cap if necessary.

(b) Check condition of radiator filler neck.

If neck is bent or damaged, replace

radiator.

(c) Check condition of the hose from the

radiator to the coolant tank. It should fit

tight at both ends without any kinks or

tears. Replace hose if necessary.

(d) Check coolant reserve/overflow tank

and tanks hoses for blockage. Repair as

necessary.

8. Incorrect coolant

concentration8. Check coolant. (Refer to LUBRICATION

& MAINTENANCE/FLUID TYPES -

DESCRIPTION).

9. Coolant not flowing through

system9. Check for coolant flow at radiator filler

neck with some coolant removed, engine

warm and thermostat open. Coolant

should be observed flowing through

radiator. If flow is not observed, determine

area of obstruction and repair as

necessary.

7 - 12 COOLINGDR

COOLING (Continued)

Page 300 of 2895

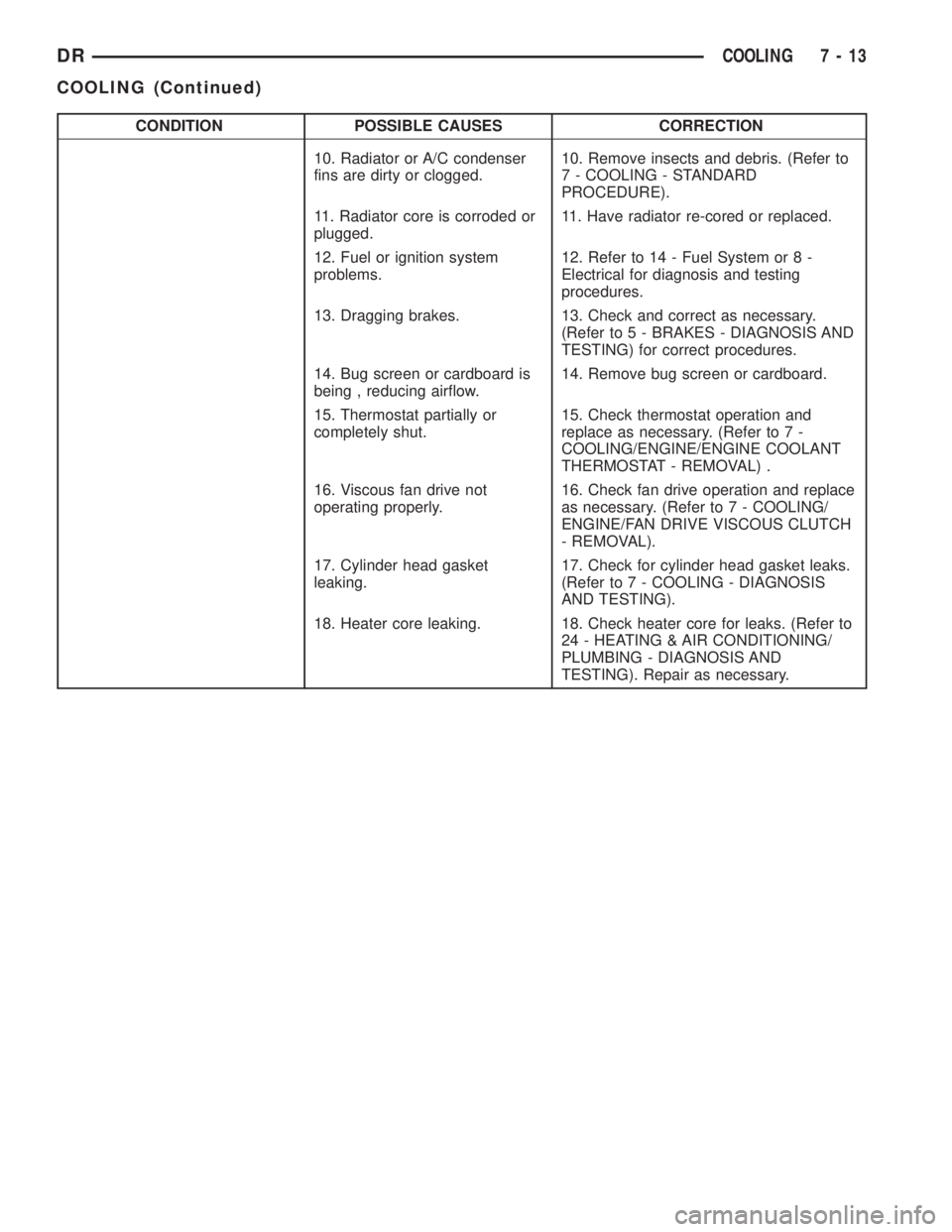

CONDITION POSSIBLE CAUSES CORRECTION

10. Radiator or A/C condenser

fins are dirty or clogged.10. Remove insects and debris. (Refer to

7 - COOLING - STANDARD

PROCEDURE).

11. Radiator core is corroded or

plugged.11. Have radiator re-cored or replaced.

12. Fuel or ignition system

problems.12. Refer to 14 - Fuel System or 8 -

Electrical for diagnosis and testing

procedures.

13. Dragging brakes. 13. Check and correct as necessary.

(Refer to 5 - BRAKES - DIAGNOSIS AND

TESTING) for correct procedures.

14. Bug screen or cardboard is

being , reducing airflow.14. Remove bug screen or cardboard.

15. Thermostat partially or

completely shut.15. Check thermostat operation and

replace as necessary. (Refer to 7 -

COOLING/ENGINE/ENGINE COOLANT

THERMOSTAT - REMOVAL) .

16. Viscous fan drive not

operating properly.16. Check fan drive operation and replace

as necessary. (Refer to 7 - COOLING/

ENGINE/FAN DRIVE VISCOUS CLUTCH

- REMOVAL).

17. Cylinder head gasket

leaking.17. Check for cylinder head gasket leaks.

(Refer to 7 - COOLING - DIAGNOSIS

AND TESTING).

18. Heater core leaking. 18. Check heater core for leaks. (Refer to

24 - HEATING & AIR CONDITIONING/

PLUMBING - DIAGNOSIS AND

TESTING). Repair as necessary.

DRCOOLING 7 - 13

COOLING (Continued)