gas tank size DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 292 of 2895

system is pressurized and uses a centrifugal water

pump to circulate coolant throughout the system.

5.9L, 5.9L Diesel, and 8.0L engines utilize an

ambient overflow bottle for coolant recovery/reserve.

The 3.7L and 4.7L engines utilize a pressurized

degas bottle for coolant deaeration and reserve. This

degas bottle has coolant flowing through it continu-

ously, supplied by a vent in the hot side radiator

tank and returning to the heater return hose.

An optional factory installed maximum duty cool-

ing package is available on most models. This pack-

age will provide additional cooling capacity for

vehicles used under extreme conditions such as

trailer towing in high ambient temperatures.

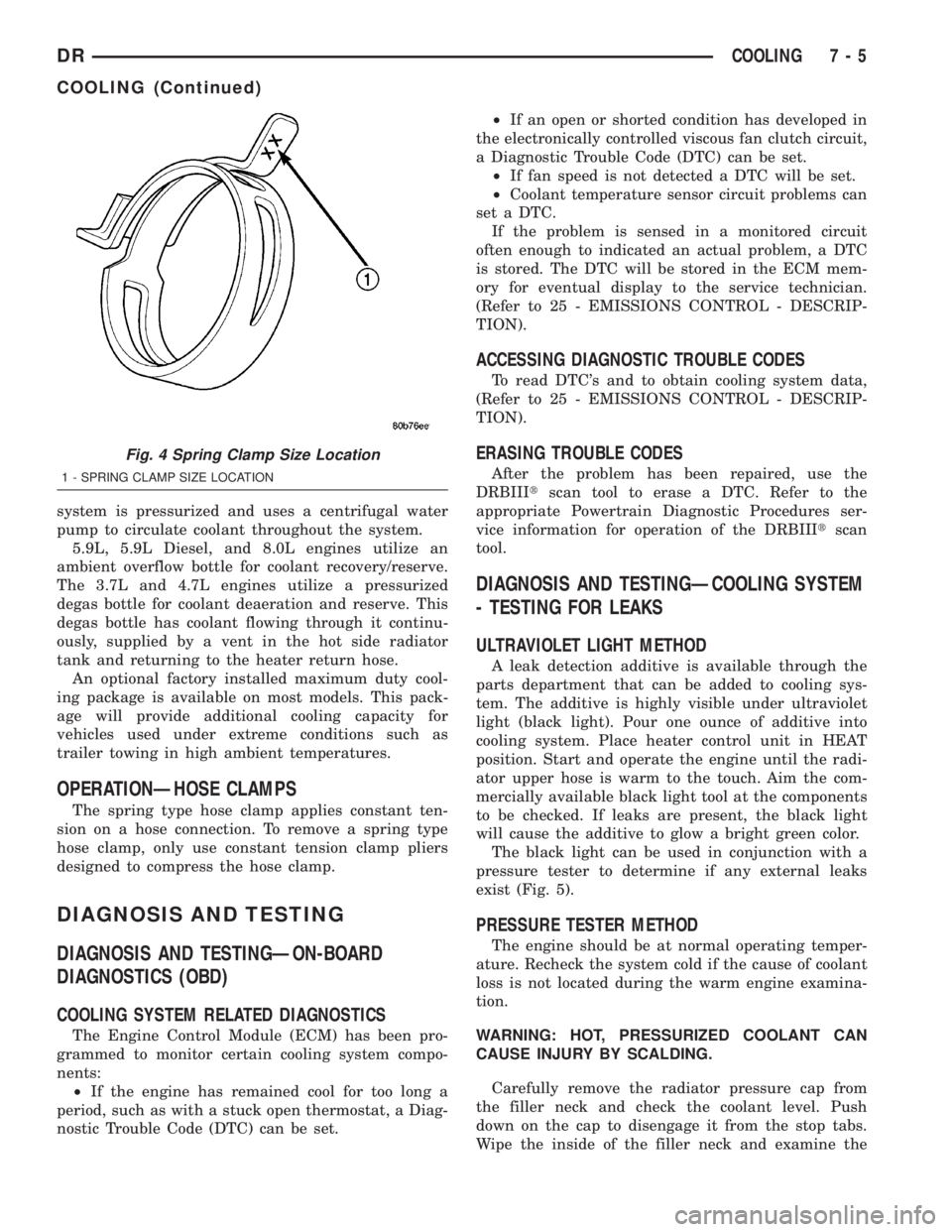

OPERATIONÐHOSE CLAMPS

The spring type hose clamp applies constant ten-

sion on a hose connection. To remove a spring type

hose clamp, only use constant tension clamp pliers

designed to compress the hose clamp.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTINGÐON-BOARD

DIAGNOSTICS (OBD)

COOLING SYSTEM RELATED DIAGNOSTICS

The Engine Control Module (ECM) has been pro-

grammed to monitor certain cooling system compo-

nents:

²If the engine has remained cool for too long a

period, such as with a stuck open thermostat, a Diag-

nostic Trouble Code (DTC) can be set.²If an open or shorted condition has developed in

the electronically controlled viscous fan clutch circuit,

a Diagnostic Trouble Code (DTC) can be set.

²If fan speed is not detected a DTC will be set.

²Coolant temperature sensor circuit problems can

set a DTC.

If the problem is sensed in a monitored circuit

often enough to indicated an actual problem, a DTC

is stored. The DTC will be stored in the ECM mem-

ory for eventual display to the service technician.

(Refer to 25 - EMISSIONS CONTROL - DESCRIP-

TION).

ACCESSING DIAGNOSTIC TROUBLE CODES

To read DTC's and to obtain cooling system data,

(Refer to 25 - EMISSIONS CONTROL - DESCRIP-

TION).

ERASING TROUBLE CODES

After the problem has been repaired, use the

DRBIIItscan tool to erase a DTC. Refer to the

appropriate Powertrain Diagnostic Procedures ser-

vice information for operation of the DRBIIItscan

tool.

DIAGNOSIS AND TESTINGÐCOOLING SYSTEM

- TESTING FOR LEAKS

ULTRAVIOLET LIGHT METHOD

A leak detection additive is available through the

parts department that can be added to cooling sys-

tem. The additive is highly visible under ultraviolet

light (black light). Pour one ounce of additive into

cooling system. Place heater control unit in HEAT

position. Start and operate the engine until the radi-

ator upper hose is warm to the touch. Aim the com-

mercially available black light tool at the components

to be checked. If leaks are present, the black light

will cause the additive to glow a bright green color.

The black light can be used in conjunction with a

pressure tester to determine if any external leaks

exist (Fig. 5).

PRESSURE TESTER METHOD

The engine should be at normal operating temper-

ature. Recheck the system cold if the cause of coolant

loss is not located during the warm engine examina-

tion.

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING.

Carefully remove the radiator pressure cap from

the filler neck and check the coolant level. Push

down on the cap to disengage it from the stop tabs.

Wipe the inside of the filler neck and examine the

Fig. 4 Spring Clamp Size Location

1 - SPRING CLAMP SIZE LOCATION

DRCOOLING 7 - 5

COOLING (Continued)

Page 2870 of 2895

FUEL INJECTOR RAIL - DESCRIPTION....14-89

FUEL INJECTOR RAIL - INSTALLATION....14-90

FUEL INJECTOR RAIL - OPERATION......14-89

FUEL INJECTOR RAIL - REMOVAL.......14-89

FUEL LEVEL SENDING UNIT / SENSOR -

DESCRIPTION...................14-68,14-7

FUEL LEVEL SENDING UNIT / SENSOR -

INSTALLATION........................14-8

FUEL LEVEL SENDING UNIT / SENSOR -

OPERATION.....................14-68,14-7

FUEL LEVEL SENDING UNIT / SENSOR -

REMOVAL...........................14-7

FUEL LINE LEAKS - DIAGNOSIS AND

TESTING, HIGH-PRESSURE.............14-69

FUEL LINES - DESCRIPTION........14-69,14-8

FUEL LINES - INSTALLATION...........14-71

FUEL LINES - OPERATION..............14-69

FUEL LINES - REMOVAL...............14-69

FUEL PRESSURE LIMITING VALVE -

DESCRIPTION.......................14-72

FUEL PRESSURE LIMITING VALVE -

INSTALLATION.......................14-73

FUEL PRESSURE LIMITING VALVE -

OPERATION.........................14-72

FUEL PRESSURE LIMITING VALVE -

REMOVAL..........................14-72

FUEL PRESSURE SENSOR -

DESCRIPTION.......................14-72

FUEL PRESSURE SENSOR -

INSTALLATION.......................14-72

FUEL PRESSURE SENSOR - OPERATION....14-72

FUEL PRESSURE SENSOR - REMOVAL....14-72

FUEL PUMP - DESCRIPTION............14-12

FUEL PUMP - OPERATION.............14-12

FUEL PUMP MODULE - DESCRIPTION....14-12

FUEL PUMP MODULE - INSTALLATION . . . 14-13

FUEL PUMP MODULE - OPERATION......14-12

FUEL PUMP MODULE - REMOVAL.......14-12

FUEL PUMP RELAY - DESCRIPTION......14-33

FUEL PUMP RELAY - INSTALLATION.....14-33

FUEL PUMP RELAY - OPERATION........14-33

FUEL PUMP RELAY - REMOVAL.........14-33

FUEL PUMP RELAYS - DIAGNOSIS AND

TESTING, ASD........................8I-7

FUEL RAIL - DESCRIPTION.............14-13

FUEL RAIL - INSTALLATION............14-18

FUEL RAIL - OPERATION...............14-13

FUEL RAIL - REMOVAL................14-13

FUEL REQUIREMENTS - DIESEL ENGINE

- DESCRIPTION........................0-1

FUEL SENSOR - DESCRIPTION, WATER

IN ................................14-77

FUEL SENSOR - OPERATION, WATER IN . . 14-78

FUEL SENSOR - REMOVAL, WATER IN....14-78

FUEL SYSTEM - DESCRIPTION, DIESEL . . . 14-57

FUEL SYSTEM - TORQUE...............14-3

FUEL SYSTEM PARTS - STANDARD

PROCEDURES, CLEANING..............14-58

FUEL SYSTEM PRESSURE, DIESEL.......14-60

FUEL SYSTEM PRESSURE RELEASE -

STANDARD PROCEDURE................14-2

FUEL SYSTEM PRESSURE,

SPECIFICATIONS......................14-3

FUEL SYSTEM PRIMING - STANDARD

PROCEDURE........................14-59

FUEL SYSTEM, SPECIAL TOOLS..........14-5

FUEL SYSTEM, SPECIAL TOOLS -

DIESEL............................14-60

FUEL TANK - DESCRIPTION............14-20

FUEL TANK - OPERATION..............14-20

FUEL TANK MODULE - DESCRIPTION.....14-75

FUEL TANK MODULE - INSTALLATION....14-75

FUEL TANK MODULE - OPERATION......14-75

FUEL TANK MODULE - REMOVAL........14-75

FUEL TRANSFER PUMP - DESCRIPTION . . 14-75

FUEL TRANSFER PUMP - INSTALLATION . . 14-76

FUEL TRANSFER PUMP - OPERATION....14-76

FUEL TRANSFER PUMP - REMOVAL......14-76

FULL SIZE, SPARE WHEEL WITH

MATCHING TIRE - DESCRIPTION........22-15

FUNCTIONS - DESCRIPTION, CIRCUIT . . 8W-01-6

FUSE - DESCRIPTION, IOD

...........8W-97-6

FUSE - INSTALLATION, IOD

..........8W-97-7

FUSE - OPERATION, IOD

.............8W-97-6

FUSE - REMOVAL, IOD

..............8W-97-6

FUSES POWERING SEVERAL LOADS -

STANDARD PROCEDURE, TESTING

FOR A SHORT TO GROUND ON

......8W-01-10GAP AND FLUSH - SPECIFICATIONS......23-95

GAS - DESCRIPTION, FUEL DELIVERY.....14-1

GAS - INSTALLATION............19-30,19-41

GAS - OPERATION, FUEL DELIVERY.......14-2

GAS - REMOVAL................19-29,19-40

GAS ENGINE - DIAGNOSIS AND TESTING . . 11-2

GAS ENGINE - INSTALLATION...........19-24

GAS ENGINE - REMOVAL..............19-23

GASKET - DESCRIPTION, CYLINDER

HEAD COVER........................9-243

GASKET - DIAGNOSIS AND TESTING,

CYLINDER HEAD......................9-20

GASKET - OPERATION, CYLINDER HEAD

COVER.............................9-243

GASKET FAILURE - DIAGNOSIS AND

TESTING, CYLINDER HEAD . . . 9-194,9-243,9-370

GASKET SELECTION - STANDARD

PROCEDURE, HEAD...................9-330

GASKET SURFACE PREPARATION -

STANDARD PROCEDURE, ENGINE........9-10

GASKETS AND SEALERS - STANDARD

PROCEDURE, FORM-IN-PLACE....9-232,9-289,

9-360,9-9,9-93

GAUGE - DESCRIPTION, ENGINE

TEMPERATURE......................8J-23

GAUGE - DESCRIPTION, FUEL...........8J-25

GAUGE - DESCRIPTION, OIL PRESSURE . . 8J-32

GAUGE - DESCRIPTION, VOLTAGE.......8J-40

GAUGE - OPERATION, ENGINE

TEMPERATURE......................8J-23

GAUGE - OPERATION, FUEL............8J-26

GAUGE - OPERATION, OIL PRESSURE....8J-32

GAUGE - OPERATION, VOLTAGE.........8J-41

GAUGES - DIAGNOSIS AND TESTING,

PRESSURE..........................22-7

GAUGES INDICATOR - DESCRIPTION,

CHECK.............................8J-21

GAUGES INDICATOR - OPERATION,

CHECK.............................8J-21

GEAR - DESCRIPTION, CRANKSHAFT.....9-322

GEAR - INDEPENDENT FRONT

SUSPENSION - DESCRIPTION...........19-16

GEAR - INDEPENDENT FRONT

SUSPENSION - INSTALLATION..........19-17

GEAR - INDEPENDENT FRONT

SUSPENSION - REMOVAL..............19-16

GEAR - INSTALLATION................9-322

GEAR - INSTALLATION, PINION

GEAR/RING......................3-42,3-66

GEAR - LINK/COIL - DESCRIPTION.......19-19

GEAR - LINK/COIL - INSTALLATION......19-20

GEAR - LINK/COIL - OPERATION........19-19

GEAR - LINK/COIL - REMOVAL..........19-19

GEAR - REMOVAL....................9-322

GEAR - REMOVAL, PINION GEAR/RING....3-40,

3-65

GEAR HOUSING - INSTALLATION........9-349

GEAR HOUSING - REMOVAL............9-348

GEAR HOUSING COVER - INSTALLATION . . 9-350

GEAR HOUSING COVER - REMOVAL.....9-349

GEAR INPUT SHAFT SEAL -

INSTALLATION, STEERING.............19-28

GEAR INPUT SHAFT SEAL - REMOVAL,

STEERING..........................19-25

GEAR SELECTOR INDICATOR -

DESCRIPTION.......................8J-26

GEAR SELECTOR INDICATOR -

OPERATION.........................8J-27

GEAR SHIFT LEVER - INSTALLATION.....19-12

GEAR SHIFT LEVER - REMOVAL.........19-12

GEAR, SPECIAL TOOLS - POWER

STEERING..........................19-22

GEAR, SPECIFICATIONS - POWER

STEERING..........................19-21

GEAR TO COOLER - INSTALLATION,

RETURN HOSE.................19-43,19-44

GEAR TO COOLER - REMOVAL, RETURN

HOSE..............................19-43

GEAR/RING GEAR - INSTALLATION,

PINION

.........................3-42,3-66

GEAR/RING GEAR - REMOVAL, PINION

....3-40,

3-65

GEAR/RING GEAR/TONE RING -

INSTALLATION, PINION

.......3-123,3-150,3-96

GEAR/RING GEAR/TONE RING -

REMOVAL, PINION

..........3-122,3-149,3-94

GEARSHIFT CABLE - DIAGNOSIS AND

TESTING

..............21-209,21-389,21-544GEARSHIFT CABLE - INSTALLATION....21-210,

21-390,21-545

GEARSHIFT CABLE - REMOVAL . . 21-209,21-389,

21-544

GEARSHIFT CABLE, ADJUSTMENTS.....21-211,

21-391,21-546

GEAR/TONE RING - INSTALLATION,

PINION GEAR/RING..........3-123,3-150,3-96

GEAR/TONE RING - REMOVAL, PINION

GEAR/RING................3-122,3-149,3-94

GEARTRAIN - ASSEMBLY, PLANETARY . . . 21-573

GEARTRAIN - CLEANING, PLANETARY . . . 21-573

GEARTRAIN - DESCRIPTION,

PLANETARY........................21-571

GEARTRAIN - DISASSEMBLY,

PLANETARY........................21-573

GEARTRAIN - INSPECTION, PLANETARY . 21-573

GEARTRAIN - OPERATION, PLANETARY . . 21-571

GEARTRAIN/OUTPUT SHAFT -

ASSEMBLY, PLANETARY........21-245,21-423

GEARTRAIN/OUTPUT SHAFT -

DESCRIPTION, PLANETARY......21-242,21-420

GEARTRAIN/OUTPUT SHAFT -

DISASSEMBLY, PLANETARY.....21-243,21-421

GEARTRAIN/OUTPUT SHAFT -

INSPECTION, PLANETARY.......21-245,21-422

GEARTRAIN/OUTPUT SHAFT -

OPERATION, PLANETARY.......21-243,21-420

GENERAL - WARNINGS.............8W-01-7

GENERATOR / CHARGING SYSTEM -

SPECIFICATIONS, TORQUE.............8F-20

GENERATOR - DESCRIPTION.............8F-22

GENERATOR - INSTALLATION...........8F-25

GENERATOR - OPERATION.............8F-22

GENERATOR - REMOVAL...............8F-22

GENERATOR RATINGS, SPECIFICATIONS . . 8F-20

GENII - ASSEMBLY, TRANSFER CASE -

NV241............................21-604

GENII - CLEANING, TRANSFER CASE -

NV241............................21-602

GENII - DESCRIPTION, TRANSFER CASE

- NV241..............................0-4

GENII - DESCRIPTION, TRANSFER CASE

- NV241...........................21-591

GENII - DIAGNOSIS AND TESTING,

TRANSFER CASE - NV241.............21-592

GENII - DISASSEMBLY, TRANSFER CASE

- NV241...........................21-593

GENII - INSPECTION, TRANSFER CASE -

NV241............................21-602

GENII - INSTALLATION, TRANSFER CASE

- NV241...........................21-614

GENII - OPERATION, TRANSFER CASE -

NV241............................21-591

GENII - REMOVAL, TRANSFER CASE -

NV241............................21-593

GENII - TRANSFER CASE, NV241.......21-614

GLASS - INSTALLATION, BACKLITE VENT . 23-87

GLASS - INSTALLATION, DOOR....23-20,23-30

GLASS - INSTALLATION, SIDE VIEW

MIRROR...........................23-44

GLASS - REMOVAL, BACKLITE VENT.....23-87

GLASS - REMOVAL, DOOR........23-20,23-30

GLASS - REMOVAL, SIDE VIEW MIRROR . . 23-42

GLASS RUN CHANNEL - INSTALLATION . . 23-21,

23-31

GLASS RUN CHANNEL - REMOVAL . 23-21,23-30

GLASS RUN WEATHERSTRIP -

INSTALLATION, FRONT DOOR...........23-92

GLASS RUN WEATHERSTRIP -

INSTALLATION, REAR DOOR............23-93

GLASS RUN WEATHERSTRIP -

REMOVAL, FRONT DOOR..............23-92

GLASS RUN WEATHERSTRIP -

REMOVAL, REAR DOOR...............23-93

GLOVE BOX - INSTALLATION...........23-53

GLOVE BOX - REMOVAL...............23-53

GLOVE BOX LAMP/SWITCH -

INSTALLATION.......................8L-25

GLOVE BOX LAMP/SWITCH - REMOVAL . . . 8L-25

GLOVE BOX LATCH - INSTALLATION

.....23-53

GLOVE BOX LATCH - REMOVAL

.........23-53

GOVERNOR - DESCRIPTION,

ELECTRONIC

.................21-196,21-376

GOVERNOR - INSTALLATION,

ELECTRONIC

.................21-199,21-379

GOVERNOR - OPERATION, ELECTRONIC

. 21-196,

21-377

DRINDEX 15

Description Group-Page Description Group-Page Description Group-Page