height DODGE RAM 2003 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2664 of 2895

(4) Apply clear glass primer 25 mm (1 in.) wide

around perimeter of windshield and wipe with a new

clean and dry lint- free cloth.

(5) Apply black-out primer onto the glass using the

windshield molding as a guide. The primer should be

15 mm (5/8 in.) wide on the top and sides of the glass

and 25 mm (1 in.) on the bottom of windshield. Allow

at least three minutes drying time.

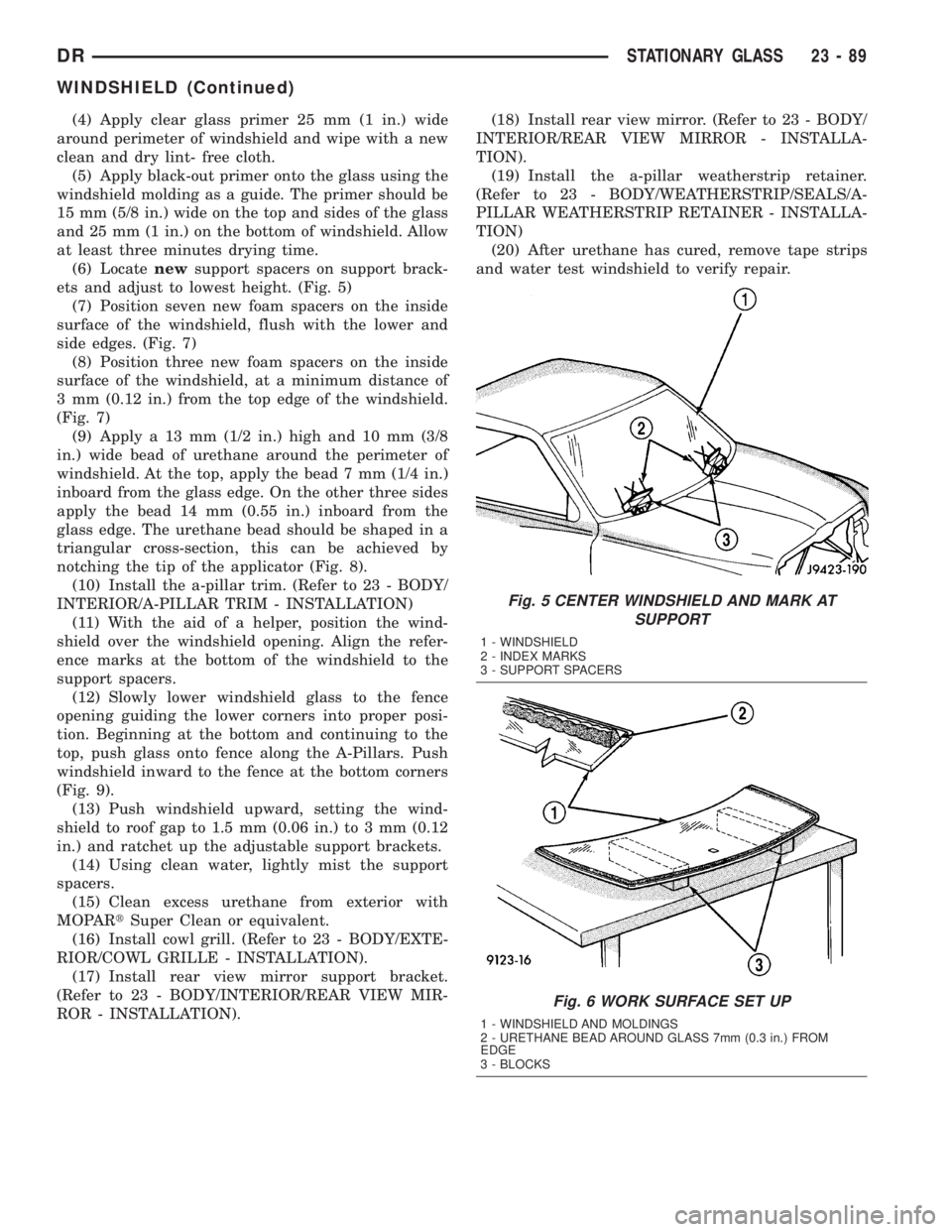

(6) Locatenewsupport spacers on support brack-

ets and adjust to lowest height. (Fig. 5)

(7) Position seven new foam spacers on the inside

surface of the windshield, flush with the lower and

side edges. (Fig. 7)

(8) Position three new foam spacers on the inside

surface of the windshield, at a minimum distance of

3 mm (0.12 in.) from the top edge of the windshield.

(Fig. 7)

(9) Apply a 13 mm (1/2 in.) high and 10 mm (3/8

in.) wide bead of urethane around the perimeter of

windshield. At the top, apply the bead 7 mm (1/4 in.)

inboard from the glass edge. On the other three sides

apply the bead 14 mm (0.55 in.) inboard from the

glass edge. The urethane bead should be shaped in a

triangular cross-section, this can be achieved by

notching the tip of the applicator (Fig. 8).

(10) Install the a-pillar trim. (Refer to 23 - BODY/

INTERIOR/A-PILLAR TRIM - INSTALLATION)

(11) With the aid of a helper, position the wind-

shield over the windshield opening. Align the refer-

ence marks at the bottom of the windshield to the

support spacers.

(12) Slowly lower windshield glass to the fence

opening guiding the lower corners into proper posi-

tion. Beginning at the bottom and continuing to the

top, push glass onto fence along the A-Pillars. Push

windshield inward to the fence at the bottom corners

(Fig. 9).

(13) Push windshield upward, setting the wind-

shield to roof gap to 1.5 mm (0.06 in.) to 3 mm (0.12

in.) and ratchet up the adjustable support brackets.

(14) Using clean water, lightly mist the support

spacers.

(15) Clean excess urethane from exterior with

MOPARtSuper Clean or equivalent.

(16) Install cowl grill. (Refer to 23 - BODY/EXTE-

RIOR/COWL GRILLE - INSTALLATION).

(17) Install rear view mirror support bracket.

(Refer to 23 - BODY/INTERIOR/REAR VIEW MIR-

ROR - INSTALLATION).(18) Install rear view mirror. (Refer to 23 - BODY/

INTERIOR/REAR VIEW MIRROR - INSTALLA-

TION).

(19) Install the a-pillar weatherstrip retainer.

(Refer to 23 - BODY/WEATHERSTRIP/SEALS/A-

PILLAR WEATHERSTRIP RETAINER - INSTALLA-

TION)

(20) After urethane has cured, remove tape strips

and water test windshield to verify repair.

Fig. 5 CENTER WINDSHIELD AND MARK AT

SUPPORT

1 - WINDSHIELD

2 - INDEX MARKS

3 - SUPPORT SPACERS

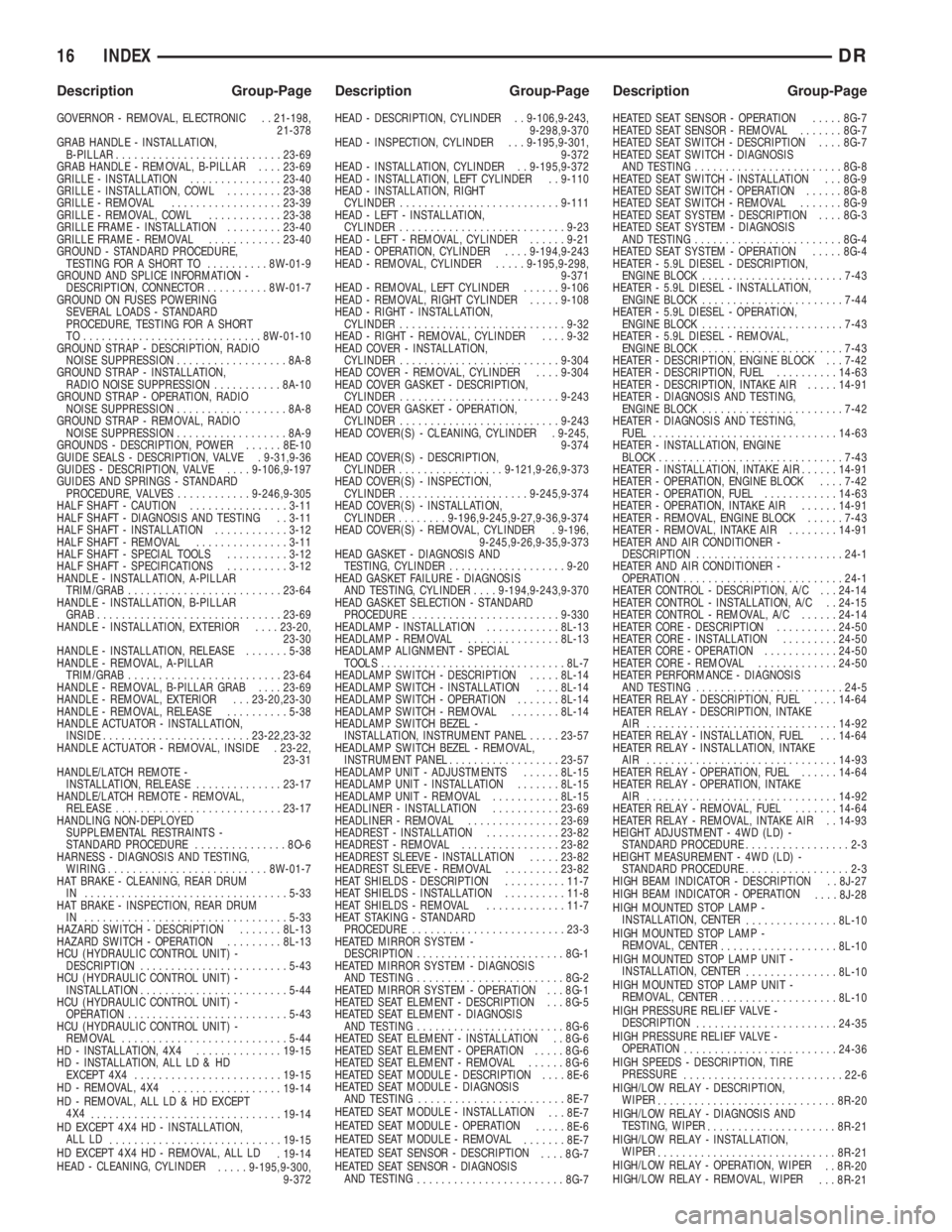

Fig. 6 WORK SURFACE SET UP

1 - WINDSHIELD AND MOLDINGS

2 - URETHANE BEAD AROUND GLASS 7mm (0.3 in.) FROM

EDGE

3 - BLOCKS

DRSTATIONARY GLASS 23 - 89

WINDSHIELD (Continued)

Page 2871 of 2895

GOVERNOR - REMOVAL, ELECTRONIC . . 21-198,

21-378

GRAB HANDLE - INSTALLATION,

B-PILLAR...........................23-69

GRAB HANDLE - REMOVAL, B-PILLAR....23-69

GRILLE - INSTALLATION...............23-40

GRILLE - INSTALLATION, COWL.........23-38

GRILLE - REMOVAL..................23-39

GRILLE - REMOVAL, COWL............23-38

GRILLE FRAME - INSTALLATION.........23-40

GRILLE FRAME - REMOVAL............23-40

GROUND - STANDARD PROCEDURE,

TESTING FOR A SHORT TO..........8W-01-9

GROUND AND SPLICE INFORMATION -

DESCRIPTION, CONNECTOR..........8W-01-7

GROUND ON FUSES POWERING

SEVERAL LOADS - STANDARD

PROCEDURE, TESTING FOR A SHORT

TO.............................8W-01-10

GROUND STRAP - DESCRIPTION, RADIO

NOISE SUPPRESSION..................8A-8

GROUND STRAP - INSTALLATION,

RADIO NOISE SUPPRESSION...........8A-10

GROUND STRAP - OPERATION, RADIO

NOISE SUPPRESSION..................8A-8

GROUND STRAP - REMOVAL, RADIO

NOISE SUPPRESSION..................8A-9

GROUNDS - DESCRIPTION, POWER......8E-10

GUIDE SEALS - DESCRIPTION, VALVE . 9-31,9-36

GUIDES - DESCRIPTION, VALVE....9-106,9-197

GUIDES AND SPRINGS - STANDARD

PROCEDURE, VALVES............9-246,9-305

HALF SHAFT - CAUTION................3-11

HALF SHAFT - DIAGNOSIS AND TESTING . . 3-11

HALF SHAFT - INSTALLATION............3-12

HALF SHAFT - REMOVAL...............3-11

HALF SHAFT - SPECIAL TOOLS..........3-12

HALF SHAFT - SPECIFICATIONS..........3-12

HANDLE - INSTALLATION, A-PILLAR

TRIM/GRAB.........................23-64

HANDLE - INSTALLATION, B-PILLAR

GRAB..............................23-69

HANDLE - INSTALLATION, EXTERIOR....23-20,

23-30

HANDLE - INSTALLATION, RELEASE.......5-38

HANDLE - REMOVAL, A-PILLAR

TRIM/GRAB.........................23-64

HANDLE - REMOVAL, B-PILLAR GRAB....23-69

HANDLE - REMOVAL, EXTERIOR . . . 23-20,23-30

HANDLE - REMOVAL, RELEASE..........5-38

HANDLE ACTUATOR - INSTALLATION,

INSIDE........................23-22,23-32

HANDLE ACTUATOR - REMOVAL, INSIDE . 23-22,

23-31

HANDLE/LATCH REMOTE -

INSTALLATION, RELEASE..............23-17

HANDLE/LATCH REMOTE - REMOVAL,

RELEASE...........................23-17

HANDLING NON-DEPLOYED

SUPPLEMENTAL RESTRAINTS -

STANDARD PROCEDURE...............8O-6

HARNESS - DIAGNOSIS AND TESTING,

WIRING..........................8W-01-7

HAT BRAKE - CLEANING, REAR DRUM

IN .................................5-33

HAT BRAKE - INSPECTION, REAR DRUM

IN .................................5-33

HAZARD SWITCH - DESCRIPTION.......8L-13

HAZARD SWITCH - OPERATION.........8L-13

HCU (HYDRAULIC CONTROL UNIT) -

DESCRIPTION........................5-43

HCU (HYDRAULIC CONTROL UNIT) -

INSTALLATION........................5-44

HCU (HYDRAULIC CONTROL UNIT) -

OPERATION..........................5-43

HCU (HYDRAULIC CONTROL UNIT) -

REMOVAL...........................5-44

HD - INSTALLATION, 4X4..............19-15

HD - INSTALLATION, ALL LD & HD

EXCEPT 4X4........................19-15

HD - REMOVAL, 4X4

..................19-14

HD - REMOVAL, ALL LD & HD EXCEPT

4X4

...............................19-14

HD EXCEPT 4X4 HD - INSTALLATION,

ALL LD

............................19-15

HD EXCEPT 4X4 HD - REMOVAL, ALL LD

. 19-14

HEAD - CLEANING, CYLINDER

.....9-195,9-300,

9-372HEAD - DESCRIPTION, CYLINDER . . 9-106,9-243,

9-298,9-370

HEAD - INSPECTION, CYLINDER . . . 9-195,9-301,

9-372

HEAD - INSTALLATION, CYLINDER . . 9-195,9-372

HEAD - INSTALLATION, LEFT CYLINDER . . 9-110

HEAD - INSTALLATION, RIGHT

CYLINDER..........................9-111

HEAD - LEFT - INSTALLATION,

CYLINDER...........................9-23

HEAD - LEFT - REMOVAL, CYLINDER......9-21

HEAD - OPERATION, CYLINDER....9-194,9-243

HEAD - REMOVAL, CYLINDER.....9-195,9-298,

9-371

HEAD - REMOVAL, LEFT CYLINDER......9-106

HEAD - REMOVAL, RIGHT CYLINDER.....9-108

HEAD - RIGHT - INSTALLATION,

CYLINDER...........................9-32

HEAD - RIGHT - REMOVAL, CYLINDER....9-32

HEAD COVER - INSTALLATION,

CYLINDER..........................9-304

HEAD COVER - REMOVAL, CYLINDER....9-304

HEAD COVER GASKET - DESCRIPTION,

CYLINDER..........................9-243

HEAD COVER GASKET - OPERATION,

CYLINDER..........................9-243

HEAD COVER(S) - CLEANING, CYLINDER . 9-245,

9-374

HEAD COVER(S) - DESCRIPTION,

CYLINDER.................9-121,9-26,9-373

HEAD COVER(S) - INSPECTION,

CYLINDER.....................9-245,9-374

HEAD COVER(S) - INSTALLATION,

CYLINDER........9-196,9-245,9-27,9-36,9-374

HEAD COVER(S) - REMOVAL, CYLINDER . 9-196,

9-245,9-26,9-35,9-373

HEAD GASKET - DIAGNOSIS AND

TESTING, CYLINDER...................9-20

HEAD GASKET FAILURE - DIAGNOSIS

AND TESTING, CYLINDER....9-194,9-243,9-370

HEAD GASKET SELECTION - STANDARD

PROCEDURE........................9-330

HEADLAMP - INSTALLATION............8L-13

HEADLAMP - REMOVAL...............8L-13

HEADLAMP ALIGNMENT - SPECIAL

TOOLS..............................8L-7

HEADLAMP SWITCH - DESCRIPTION.....8L-14

HEADLAMP SWITCH - INSTALLATION....8L-14

HEADLAMP SWITCH - OPERATION.......8L-14

HEADLAMP SWITCH - REMOVAL........8L-14

HEADLAMP SWITCH BEZEL -

INSTALLATION, INSTRUMENT PANEL.....23-57

HEADLAMP SWITCH BEZEL - REMOVAL,

INSTRUMENT PANEL..................23-57

HEADLAMP UNIT - ADJUSTMENTS......8L-15

HEADLAMP UNIT - INSTALLATION.......8L-15

HEADLAMP UNIT - REMOVAL...........8L-15

HEADLINER - INSTALLATION...........23-69

HEADLINER - REMOVAL...............23-69

HEADREST - INSTALLATION............23-82

HEADREST - REMOVAL................23-82

HEADREST SLEEVE - INSTALLATION.....23-82

HEADREST SLEEVE - REMOVAL.........23-82

HEAT SHIELDS - DESCRIPTION..........11-7

HEAT SHIELDS - INSTALLATION..........11-8

HEAT SHIELDS - REMOVAL.............11-7

HEAT STAKING - STANDARD

PROCEDURE.........................23-3

HEATED MIRROR SYSTEM -

DESCRIPTION........................8G-1

HEATED MIRROR SYSTEM - DIAGNOSIS

AND TESTING........................8G-2

HEATED MIRROR SYSTEM - OPERATION . . . 8G-1

HEATED SEAT ELEMENT - DESCRIPTION . . . 8G-5

HEATED SEAT ELEMENT - DIAGNOSIS

AND TESTING........................8G-6

HEATED SEAT ELEMENT - INSTALLATION . . 8G-6

HEATED SEAT ELEMENT - OPERATION.....8G-6

HEATED SEAT ELEMENT - REMOVAL......8G-6

HEATED SEAT MODULE - DESCRIPTION....8E-6

HEATED SEAT MODULE - DIAGNOSIS

AND TESTING........................8E-7

HEATED SEAT MODULE - INSTALLATION

. . . 8E-7

HEATED SEAT MODULE - OPERATION

.....8E-6

HEATED SEAT MODULE - REMOVAL

.......8E-7

HEATED SEAT SENSOR - DESCRIPTION

....8G-7

HEATED SEAT SENSOR - DIAGNOSIS

AND TESTING

........................8G-7HEATED SEAT SENSOR - OPERATION.....8G-7

HEATED SEAT SENSOR - REMOVAL.......8G-7

HEATED SEAT SWITCH - DESCRIPTION....8G-7

HEATED SEAT SWITCH - DIAGNOSIS

AND TESTING........................8G-8

HEATED SEAT SWITCH - INSTALLATION . . . 8G-9

HEATED SEAT SWITCH - OPERATION......8G-8

HEATED SEAT SWITCH - REMOVAL.......8G-9

HEATED SEAT SYSTEM - DESCRIPTION....8G-3

HEATED SEAT SYSTEM - DIAGNOSIS

AND TESTING........................8G-4

HEATED SEAT SYSTEM - OPERATION.....8G-4

HEATER - 5.9L DIESEL - DESCRIPTION,

ENGINE BLOCK.......................7-43

HEATER - 5.9L DIESEL - INSTALLATION,

ENGINE BLOCK.......................7-44

HEATER - 5.9L DIESEL - OPERATION,

ENGINE BLOCK.......................7-43

HEATER - 5.9L DIESEL - REMOVAL,

ENGINE BLOCK.......................7-43

HEATER - DESCRIPTION, ENGINE BLOCK . . . 7-42

HEATER - DESCRIPTION, FUEL..........14-63

HEATER - DESCRIPTION, INTAKE AIR.....14-91

HEATER - DIAGNOSIS AND TESTING,

ENGINE BLOCK.......................7-42

HEATER - DIAGNOSIS AND TESTING,

FUEL..............................14-63

HEATER - INSTALLATION, ENGINE

BLOCK..............................7-43

HEATER - INSTALLATION, INTAKE AIR......14-91

HEATER - OPERATION, ENGINE BLOCK....7-42

HEATER - OPERATION, FUEL............14-63

HEATER - OPERATION, INTAKE AIR......14-91

HEATER - REMOVAL, ENGINE BLOCK......7-43

HEATER - REMOVAL, INTAKE AIR........14-91

HEATER AND AIR CONDITIONER -

DESCRIPTION........................24-1

HEATER AND AIR CONDITIONER -

OPERATION..........................24-1

HEATER CONTROL - DESCRIPTION, A/C . . . 24-14

HEATER CONTROL - INSTALLATION, A/C . . 24-15

HEATER CONTROL - REMOVAL, A/C......24-14

HEATER CORE - DESCRIPTION..........24-50

HEATER CORE - INSTALLATION.........24-50

HEATER CORE - OPERATION............24-50

HEATER CORE - REMOVAL.............24-50

HEATER PERFORMANCE - DIAGNOSIS

AND TESTING........................24-5

HEATER RELAY - DESCRIPTION, FUEL....14-64

HEATER RELAY - DESCRIPTION, INTAKE

AIR ...............................14-92

HEATER RELAY - INSTALLATION, FUEL . . . 14-64

HEATER RELAY - INSTALLATION, INTAKE

AIR ...............................14-93

HEATER RELAY - OPERATION, FUEL......14-64

HEATER RELAY - OPERATION, INTAKE

AIR ...............................14-92

HEATER RELAY - REMOVAL, FUEL.......14-64

HEATER RELAY - REMOVAL, INTAKE AIR . . 14-93

HEIGHT ADJUSTMENT - 4WD (LD) -

STANDARD PROCEDURE.................2-3

HEIGHT MEASUREMENT - 4WD (LD) -

STANDARD PROCEDURE.................2-3

HIGH BEAM INDICATOR - DESCRIPTION . . 8J-27

HIGH BEAM INDICATOR - OPERATION

....8J-28

HIGH MOUNTED STOP LAMP -

INSTALLATION, CENTER

...............8L-10

HIGH MOUNTED STOP LAMP -

REMOVAL, CENTER

...................8L-10

HIGH MOUNTED STOP LAMP UNIT -

INSTALLATION, CENTER

...............8L-10

HIGH MOUNTED STOP LAMP UNIT -

REMOVAL, CENTER

...................8L-10

HIGH PRESSURE RELIEF VALVE -

DESCRIPTION

.......................24-35

HIGH PRESSURE RELIEF VALVE -

OPERATION

.........................24-36

HIGH SPEEDS - DESCRIPTION, TIRE

PRESSURE

..........................22-6

HIGH/LOW RELAY - DESCRIPTION,

WIPER

.............................8R-20

HIGH/LOW RELAY - DIAGNOSIS AND

TESTING, WIPER

.....................8R-21

HIGH/LOW RELAY - INSTALLATION,

WIPER

.............................8R-21

HIGH/LOW RELAY - OPERATION, WIPER

. . 8R-20

HIGH/LOW RELAY - REMOVAL, WIPER

. . . 8R-21

16 INDEXDR

Description Group-Page Description Group-Page Description Group-Page

Page 2876 of 2895

MANUAL TRANSMISSION -

DESCRIPTION.........................0-4

MANUAL TRANSMISSION - NV3500 -

ASSEMBLY..........................21-17

MANUAL TRANSMISSION - NV3500 -

CLEANING..........................21-15

MANUAL TRANSMISSION - NV3500 -

DESCRIPTION........................21-1

MANUAL TRANSMISSION - NV3500 -

DIAGNOSIS AND TESTING..............21-3

MANUAL TRANSMISSION - NV3500 -

DISASSEMBLY........................21-4

MANUAL TRANSMISSION - NV3500 -

INSPECTION........................21-15

MANUAL TRANSMISSION - NV3500 -

INSTALLATION.......................21-38

MANUAL TRANSMISSION - NV3500 -

OPERATION..........................21-1

MANUAL TRANSMISSION - NV3500 -

REMOVAL...........................21-3

MANUAL TRANSMISSION - NV3500 -

SPECIAL TOOLS.....................21-40

MANUAL TRANSMISSION - NV3500 -

SPECIFICATIONS.....................21-39

MANUAL TRANSMISSION - NV4500 -

ASSEMBLY..........................21-61

MANUAL TRANSMISSION - NV4500 -

CLEANING..........................21-60

MANUAL TRANSMISSION - NV4500 -

DESCRIPTION.......................21-42

MANUAL TRANSMISSION - NV4500 -

DIAGNOSIS AND TESTING.............21-43

MANUAL TRANSMISSION - NV4500 -

DISASSEMBLY........................21-44

MANUAL TRANSMISSION - NV4500 -

INSPECTION........................21-60

MANUAL TRANSMISSION - NV4500 -

INSTALLATION.......................21-77

MANUAL TRANSMISSION - NV4500 -

OPERATION.........................21-42

MANUAL TRANSMISSION - NV4500 -

REMOVAL..........................21-43

MANUAL TRANSMISSION - NV4500 -

SPECIAL TOOLS.....................21-79

MANUAL TRANSMISSION - NV4500 -

SPECIFICATIONS.....................21-79

MANUAL TRANSMISSION - NV5600 -

ASSEMBLY.........................21-105

MANUAL TRANSMISSION - NV5600 -

DESCRIPTION.......................21-87

MANUAL TRANSMISSION - NV5600 -

DIAGNOSIS AND TESTING.............21-89

MANUAL TRANSMISSION - NV5600 -

DISASSEMBLY.......................21-90

MANUAL TRANSMISSION - NV5600 -

INSPECTION.......................21-104

MANUAL TRANSMISSION - NV5600 -

INSTALLATION......................21-120

MANUAL TRANSMISSION - NV5600 -

OPERATION.........................21-89

MANUAL TRANSMISSION - NV5600 -

REMOVAL..........................21-89

MANUAL TRANSMISSION - NV5600 -

SPECIAL TOOLS....................21-122

MAP SENSOR - DESCRIPTION.....14-39,14-94

MAP SENSOR - INSTALLATION..........14-42

MAP SENSOR - OPERATION............14-39

MAP SENSOR - REMOVAL.............14-40

MASTER CYLINDER - DESCRIPTION......5-19

MASTER CYLINDER - OPERATION........5-20

MASTER CYLINDER BLEEDING -

STANDARD PROCEDURE................5-20

MASTER CYLINDER/POWER BOOSTER -

DIAGNOSIS AND TESTING..............5-20

MATCH MOUNTING - STANDARD

PROCEDURE.........................22-3

MATCHING TIRE - DESCRIPTION, FULL

SIZE, SPARE WHEEL WITH.............22-15

MATS - INSTALLATION, CARPETS AND

FLOOR

.............................23-66

MATS - REMOVAL, CARPETS AND

FLOOR

.............................23-66

MEASUREMENT - 4WD (LD) -

STANDARD PROCEDURE, HEIGHT

.........2-3

MEASURING TIMING CHAIN STRETCH -

INSPECTION

...................9-279,9-405

MEASURING TIMING CHAIN WEAR -

STANDARD PROCEDURE

...............9-165MEASURING TIMING CHAIN WEAR,

STANDARD PROCEDURE................9-76

MECHANICAL - DIAGNOSIS AND

TESTING, ENGINE DIAGNOSIS.....9-181,9-184,

9-228,9-283,9-356,9-6,9-91

MECHANISM - DESCRIPTION, SHIFT....21-253,

21-430,21-574

MECHANISM - INSTALLATION, SHIFT.....21-85

MECHANISM - OPERATION, SHIFT......21-253,

21-430,21-574

MECHANISM - REMOVAL, SHIFT........21-84

MEMBER BUSHING - INSTALLATION,

TORSION BAR CROSS..................2-14

METRIC SYSTEM - DESCRIPTION......Intro.-9

MICRO 420 BATTERY TESTER -

STANDARD PROCEDURE, USING........8F-12

MICRO RELAY - DESCRIPTION........8W-97-9

MICRO RELAY - INSTALLATION......8W-97-10

MICRO RELAY - OPERATION.........8W-97-9

MICRO RELAY - REMOVAL..........8W-97-10

MICRO-RELAY - DIAGNOSIS AND

TESTING.........................8W-97-9

MILE, SPECIFICATIONS - TIRE

REVOLUTIONS PER...................22-10

MINI-TRIP COMPUTER - DIAGNOSIS

AND TESTING, COMPASS..............8M-7

MIRROR - DESCRIPTION, AUTOMATIC

DAY / NIGHT........................8N-12

MIRROR - DIAGNOSIS AND TESTING,

AUTOMATIC DAY / NIGHT..............8N-12

MIRROR - INSTALLATION, SIDE VIEW....23-41

MIRROR - OPERATION, AUTOMATIC DAY

/ NIGHT............................8N-12

MIRROR - REMOVAL, AUTOMATIC DAY /

NIGHT.............................8N-13

MIRROR - REMOVAL, REAR VIEW.......23-71

MIRROR - REMOVAL, SIDE VIEW........23-41

MIRROR - REMOVAL, SIDEVIEW........8N-13

MIRROR FLAG - INSTALLATION, SIDE

VIEW..............................23-27

MIRROR FLAG - REMOVAL, SIDE VIEW . . . 23-27

MIRROR GLASS - INSTALLATION, SIDE

VIEW..............................23-44

MIRROR GLASS - REMOVAL, SIDE VIEW . . 23-42

MIRROR SUPPORT BRACKET -

INSTALLATION, REARVIEW.............23-71

MIRROR SWITCH - DIAGNOSIS AND

TESTING, POWER....................8N-13

MIRROR SWITCH - REMOVAL, POWER . . . 8N-13

MIRROR SYSTEM - DESCRIPTION,

HEATED.............................8G-1

MIRROR SYSTEM - DIAGNOSIS AND

TESTING, HEATED.....................8G-2

MIRROR SYSTEM - OPERATION, HEATED . . 8G-1

MIRRORS - DESCRIPTION, POWER......8N-11

MIRRORS - DIAGNOSIS AND TESTING,

POWER............................8N-11

MIRRORS - OPERATION, POWER........8N-11

MODE - DESCRIPTION, CIRCUIT

ACTUATION TEST.....................25-1

MODE - DESCRIPTION, STATE DISPLAY

TEST...............................25-1

MODE DOOR ACTUATOR - DESCRIPTION . . 24-20

MODE DOOR ACTUATOR -

INSTALLATION.......................24-22

MODE DOOR ACTUATOR - OPERATION . . . 24-21

MODE DOOR ACTUATOR - REMOVAL.....24-21

MODE SENSOR - DESCRIPTION

. . 21-684,21-718

MODE SENSOR - OPERATION

....21-684,21-718

MODES OF OPERATION - DESCRIPTION

....8E-8

MODES, STANDARD PROCEDURE -

CONFIGURING A NEW MODULE /

SWITCH OPERATING

...................8Q-3

MODULE - DESCRIPTION, AIRBAG

CONTROL

..........................8O-10

MODULE - DESCRIPTION, DRIVER DOOR

. . 8N-5

MODULE - DESCRIPTION, FRONT

CONTROL

........................8W-97-4

MODULE - DESCRIPTION, FRONT

CONTROL

...........................8E-5

MODULE - DESCRIPTION, FUEL PUMP

....14-12

MODULE - DESCRIPTION, FUEL TANK

....14-75

MODULE - DESCRIPTION, HEATED SEAT

. . . 8E-6

MODULE - DESCRIPTION, INTEGRATED

POWER

..........................8W-97-3

MODULE - DESCRIPTION, REMOTE

KEYLESS ENTRY

......................8N-7MODULE - DESCRIPTION, SENTRY KEY

IMMOBILIZER.......................8E-13

MODULE - DESCRIPTION, SIDE IMPACT

AIRBAG CONTROL...................8O-53

MODULE - DESCRIPTION, TRANSFER

CASE CONTROL......................8E-15

MODULE - DESCRIPTION,

TRANSMISSION CONTROL.............8E-19

MODULE - DESCRIPTION, WIPER.......8R-22

MODULE - DIAGNOSIS AND TESTING,

DRIVER DOOR.......................8N-6

MODULE - DIAGNOSIS AND TESTING,

FRONT CONTROL..................8W-97-5

MODULE - DIAGNOSIS AND TESTING,

FRONT CONTROL.....................8E-6

MODULE - DIAGNOSIS AND TESTING,

HEATED SEAT ........................8E-7

MODULE - DIAGNOSIS AND TESTING,

REMOTE KEYLESS ENTRY..............8N-8

MODULE - INSTALLATION, AIRBAG

CONTROL..........................8O-12

MODULE - INSTALLATION, DRIVER

DOOR..............................8N-7

MODULE - INSTALLATION, ENGINE

CONTROL...........................8E-5

MODULE - INSTALLATION, FRONT

CONTROL........................8W-97-5

MODULE - INSTALLATION, FRONT

CONTROL...........................8E-6

MODULE - INSTALLATION, FUEL PUMP . . . 14-13

MODULE - INSTALLATION, FUEL TANK....14-75

MODULE - INSTALLATION, HEATED SEAT . . . 8E-7

MODULE - INSTALLATION, INTEGRATED

POWER..........................8W-97-4

MODULE - INSTALLATION, REMOTE

KEYLESS ENTRY......................8N-8

MODULE - INSTALLATION, SENTRY KEY

IMMOBILIZER.......................8E-15

MODULE - INSTALLATION, WIPER.......8R-23

MODULE - OPERATION, AIRBAG

CONTROL..........................8O-10

MODULE - OPERATION, DRIVER DOOR....8N-5

MODULE - OPERATION, FRONT

CONTROL........................8W-97-5

MODULE - OPERATION, FRONT

CONTROL...........................8E-5

MODULE - OPERATION, FUEL PUMP.....14-12

MODULE - OPERATION, FUEL TANK......14-75

MODULE - OPERATION, HEATED SEAT.....8E-6

MODULE - OPERATION, INTEGRATED

POWER..........................8W-97-3

MODULE - OPERATION, REMOTE

KEYLESS ENTRY......................8N-8

MODULE - OPERATION, SENTRY KEY

IMMOBILIZER.......................8E-13

MODULE - OPERATION, SIDE IMPACT

AIRBAG CONTROL...................8O-54

MODULE - OPERATION, TRANSFER CASE

CONTROL..........................8E-15

MODULE - OPERATION, TRANSMISSION

CONTROL..........................8E-19

MODULE - OPERATION, WIPER.........8R-23

MODULE - REMOVAL, AIRBAG CONTROL . 8O-11

MODULE - REMOVAL, DRIVER DOOR.....8N-7

MODULE - REMOVAL, ENGINE CONTROL . . . 8E-4

MODULE - REMOVAL, FRONT CONTROL . 8W-97-5

MODULE - REMOVAL, FRONT CONTROL . . . 8E-6

MODULE - REMOVAL, FUEL PUMP.......14-12

MODULE - REMOVAL, FUEL TANK.......14-75

MODULE - REMOVAL, HEATED SEAT......8E-7

MODULE - REMOVAL, INTEGRATED

POWER..........................8W-97-3

MODULE - REMOVAL, REMOTE KEYLESS

ENTRY..............................8N-8

MODULE - REMOVAL, SENTRY KEY

IMMOBILIZER.......................8E-15

MODULE - REMOVAL, WIPER...........8R-23

MODULE / SWITCH OPERATING MODES,

STANDARD PROCEDURE -

CONFIGURING A NEW

.................8Q-3

MODULE LAMP REPLACEMENT -

STANDARD PROCEDURE

...............8M-3

MODULE LENS REPLACEMENT -

STANDARD PROCEDURE

...............8M-3

MOLDING - INSTALLATION, FRONT

DOOR INNER BELT

...................23-93

MOLDING - INSTALLATION, FRONT

DOOR OUTER BELT

...................23-93

DRINDEX 21

Description Group-Page Description Group-Page Description Group-Page