Operation DODGE RAM 2500 DIESEL 2004 3.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2004, Model line: RAM 2500 DIESEL, Model: DODGE RAM 2500 DIESEL 2004 3.GPages: 426, PDF Size: 7.22 MB

Page 232 of 426

NOTE:Before retrying a selection, make certain that all

the necessary requirements for selecting a new transfer

case position have been met. To retry the selection, turn

the control knob back to the current position, wait five (5)

seconds, and retry selection. To find the shift require-

ments, refer to the9Shifting Procedure9for your transfer

case, located in this section of the owner's manual.

The ªSERVICE 4WDº warning light monitors the electric

shift 4WD system. If this light remains on after engine

start up or illuminates during driving, it means that the

4WD system is not functioning properly and that service

is required.

WARNING!

Always engage the parking brake when powering

down the vehicle if the(Service 4WD(light is illu-

minated. Not engaging the parking brake may allow

the vehicle to roll which may cause personal injury.

NOTE:Do not attempt to make a shift while only the

front or rear wheels are spinning. The transfer case is not

equipped with a synchronizer and therefore the front and

rear driveshaft speeds must be equal for the shift to take

place. Shifting while only the front or rear wheels are

spinning can cause damage to the transfer case.

When operating your vehicle in 4LO, the engine speed is

approximately three times that of the 2WD/AWD or 4HI

positions at a given road speed. Take care not to over-

speed the engine and do not exceed 25 mph (40 km/h).

Proper operation of 4 wheel drive vehicles depends on

tires of equal size, type and circumference on each wheel.

Any difference in tire size can cause damage to the

transfer case.

Because 4 wheel drive provides improved traction, there

is a tendency to exceed safe turning and stopping speeds.

Do not go faster than road conditions permit.

232 STARTING AND OPERATING

Page 240 of 426

Brake Noise

During normal operation of the brake system certain

noises may be present from time to time. Occasional

9groan9or9squeal9noises may occur during normal

operation of the brake system which may not be indica-

tive of a problem. These noises may be heard at any time

the brakes are applied but may be more noticeable during

the first few brake applications in the morning. Moisture,

hot or cold temperature, dust, and or other debris may

also contribute to the noise condition. Repeated or con-

tinuous noises during braking may be an indication that

the brake linings are worn and in need of replacement.

Four-Wheel Anti-Lock Brake System

WARNING!

Anti-Lock Brake Systems contain sophisticated elec-

tronic equipment. It may be susceptible to interfer-

ence caused by improperly installed or high output

radio transmitting equipment. This interference can

cause possible loss of anti-lock braking capability.

Installation of such equipment should be performed

by qualified professionals.

240 STARTING AND OPERATING

Page 241 of 426

WARNING!

²Anti-lock system (ABS) cannot prevent the natu-

ral laws of physics from acting on the vehicle, nor

can it increase braking or steering efficiency be-

yond that afforded by the condition of the vehicle

brakes and tires or the traction afforded.

²The ABS cannot prevent accidents, including

those resulting from excessive speed in turns,

following another vehicle too closely, or hydro-

planing. Only a safe, attentive, and skillful driver

can prevent accidents.

²The capabilities of an ABS equipped vehicle must

never be exploited in a reckless or dangerous

manner which could jeopardize the user's safety

or the safety of others.

This Anti-lock Brake System is designed to aid the driver

in maintaining vehicle control under adverse braking

conditions. The system operates with a separate com-

puter to modulate hydraulic pressure to prevent wheel

lockup and help avoid skidding on slippery surfaces.

The system's pump motor runs during an ABS stop to

provide regulated hydraulic pressure. The pump motor

makes a low humming noise during operation. This is

normal.

When you are in a severe braking condition involving

use of the Anti-lock Brake System, you will experience

some pedal drop as the vehicle comes to a complete stop.

This is the result of the system reverting to the base brake

system and is normal.

Engagement of the Anti-lock Brake System may be

accompanied by a pulsing sensation. You may also hear a

clicking noise. These occurrences are normal, and indi-

cate that the system is functioning.

STARTING AND OPERATING 241

5

Page 251 of 426

WARNING!

Overloading of your tire is dangerous. Overloading

can cause tire failure, affect vehicle handling, and

increase your stopping distance. Use tires of the

recommended load capacity for your vehicle. Never

overload them.

TIRESÐGENERAL INFORMATION

Tire Pressure

Proper tire inflation pressure is essential to the safe and

satisfactory operation of your vehicle. Three primary

areas are affected by improper tire pressure:1. SafetyÐ

WARNING!

Improperly inflated tires are dangerous and can

cause accidents.

²Under inflation increases tire flexing and can result

in tire failure.

²Over inflation reduces a tire's ability to cushion

shock. Objects on the road and chuck holes can cause

damage that results in tire failure.

²Unequal tire pressures can cause steering prob-

lems. You could lose control of your vehicle.

²Over inflated or under inflated tires can affect

vehicle handling and can fail suddenly, resulting in

loss of vehicle control.

²Unequal tire pressures from one side of the vehicle

to the other can cause the vehicle to drift to the right

or left.

Always drive with each tire inflated to the recom-

mended cold tire inflation pressure.

STARTING AND OPERATING 251

5

Page 253 of 426

check tire pressure. Do not make a visual judgement

when determining proper inflation. Radial tires may look

properly inflated even when they are underinflated.

CAUTION!

After inspecting or adjusting the tire pressure al-

ways reinstall the valve stem cap±if equipped. This

will prevent moisture and dirt from entering the

valve stem, which could damage the valve stem.

Inflation pressures specified on the placard are always

ªcold tire inflation pressureº. Cold tire inflation pressure

is defined as the tire pressure after the vehicle has not

been driven for at least 3 hours, or driven less than 1mile

(1 km) after a 3 hour period. The cold tire inflation

pressure must not exceed the maximum inflation pres-

sure molded into the tire side wall.Check tire pressures more often if subject to a wide range

of outdoor temperatures, as tire pressures vary with

temperature changes.

Tire pressures change by approximately 1 psi (7 kPa) per

12É F (7É C) of air temperature change. Keep this in mind

when checking tire pressure inside a garage especially in

the winter.

Example: If garage temperature = 68É F (20É C) and the

outside temperature = 32É F (0É C) then the cold tire

inflation pressure should be increased by 3 psi (21 kPa),

which equals 1 psi (7 kPa) for every 12É F (7É C) for this

outside temperature condition.

Tire pressure may increase from 2 to 6 psi (13 to 40 kPa)

during operation. DO NOT reduce this normal pressure

build up or your tire pressure will be too low.

STARTING AND OPERATING 253

5

Page 254 of 426

Tire Pressures for High Speed Operation

The manufacturer advocates driving at safe speeds

within posted speed limits. Where speed limits or condi-

tions are such that the vehicle can be driven at high

speeds, maintaining correct tire inflation pressure is very

important. Increased tire pressure and reduced vehicle

loading may be required for high speed vehicle opera-

tion. Refer to original equipment or an authorized tire

dealer for recommended safe operating speeds, loading

and cold tire inflation pressures.WARNING!

High speed driving with your vehicle under maxi-

mum load is dangerous. The added strain on your

tires could cause them to fail. You could have a

serious accident. Don't drive a vehicle loaded to the

maximum capacity at continuous speeds above 75

mph (120 km/h).

254 STARTING AND OPERATING

Page 267 of 426

Avoid Using Contaminated Fuel

Fuel that is contaminated by water or dirt can cause

severe damage to the engine fuel system which is not

covered by the warranty. Proper maintenance of the

engine fuel filter and fuel tank is essential. (See Section 7

for Maintenance Procedures).

NOTE:Climatized diesel fuel is a blend of Number 2

and Number 1 Diesel fuel which reduces the temperature

at which wax crystals form in the fuel.

Bulk Fuel Storage

If you store quantities of fuel, good maintenance of the

stored fuel is also essential. Fuel contaminated with

water will promote the growth of ªmicrobes.º These

microbes form ªslimeº that will clog fuel filters and lines.

Drain condensation from the supply tank and change the

line filter on a regular basis.

Fuel Specifications

The Cummins Turbocharged, Charge Air Cooled, Diesel

engine has been developed to take advantage of the high

energy content and generally lower cost No. 2 diesel fuel

or No. 2 climatized diesel fuels. Experience has shown

that it also operates on No. 1 diesel fuels or other fuels

within the specifications in the following chart.

NOTE:As sufficient testing has not been completed,

organically blended diesel fuels (e.g. biodiesel, ethanol,

and methanol blends) are not recommended or approved

for use with your Cummins Diesel equipped Dodge Ram

Truck.

NOTE:In addition, commercially available fuel addi-

tives are not necessary for the proper operation of your

Cummins Diesel equipped Dodge Ram Truck.

NOTE:No. 1 diesel fuel should only be used where

extended arctic conditions (-10ÉF or 23ÉC) exist.

STARTING AND OPERATING 267

5

Page 270 of 426

Tire Size

This is the minimum allowable tire size for your vehicle.

Replacement tires must be equal to the load capacity of

this tire size.

Rim Size

This is the rim size that is appropriate for the tire size

listed.

Inflation Pressure

This is the cold tire inflation pressure for your vehicle for

all loading conditions up to full GAWR.

Curb Weight

The curb weight of a vehicle is defined as the total weight

of the vehicle with all fluids, including vehicle fuel, at full

capacity conditions, and with no occupants or cargo

loaded into the vehicle. The front and rear curb weight

values are determined by weighing your vehicle on a

commercial scale before any occupants or cargo are

added.

Loading

The actual total weight and the weight of the front and

rear of your vehicle at the ground can best be determined

by weighing it when it is loaded and ready for operation.

The entire vehicle should first be weighed on a commer-

cial scale to insure that the GVWR has not been exceeded.

The weight on the front and rear of the vehicle should

then be determined separately to be sure that the load is

properly distributed over front and rear axle. Weighing

the vehicle may show that the GAWR of either the front

or rear axles has been exceeded but the total load is

within the specified GVWR. If so, weight must be shifted

from front to rear or rear to front as appropriate until the

specified weight limitations are met. Store the heavier

items down low and be sure that the weight is distributed

equally. Stow all loose items securely before driving.

270 STARTING AND OPERATING

Page 271 of 426

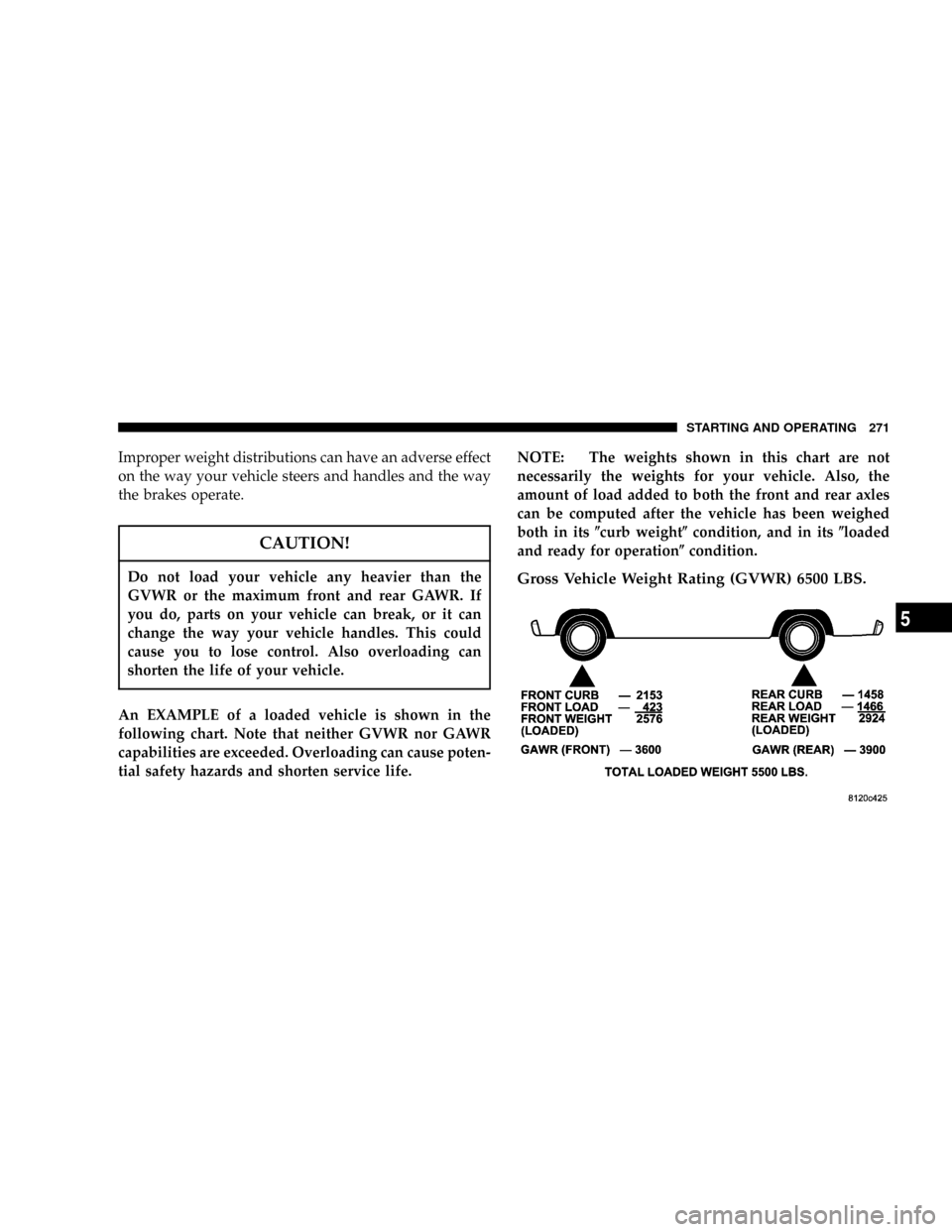

Improper weight distributions can have an adverse effect

on the way your vehicle steers and handles and the way

the brakes operate.

CAUTION!

Do not load your vehicle any heavier than the

GVWR or the maximum front and rear GAWR. If

you do, parts on your vehicle can break, or it can

change the way your vehicle handles. This could

cause you to lose control. Also overloading can

shorten the life of your vehicle.

An EXAMPLE of a loaded vehicle is shown in the

following chart. Note that neither GVWR nor GAWR

capabilities are exceeded. Overloading can cause poten-

tial safety hazards and shorten service life.NOTE: The weights shown in this chart are not

necessarily the weights for your vehicle. Also, the

amount of load added to both the front and rear axles

can be computed after the vehicle has been weighed

both in its(curb weight(condition, and in its(loaded

and ready for operation(condition.

Gross Vehicle Weight Rating (GVWR) 6500 LBS.

STARTING AND OPERATING 271

5

Page 272 of 426

TRAILER TOWING

All Dodge Ram Pickup trucks are intended to tow trailers

up to 2,000 lbs (907 kg) without added equipment or

alterations to standard equipment. Your vehicle may be

factory equipped for safe towing of trailers weighing

over 2,000 lbs (907 kg) with the optional Trailer Tow Prep

Package. See your Dodge dealer for package content.

To Maintain Warranty Coverage

Follow the requirements and recommendations in this

manual concerning vehicles used for trailer towing.

Definitions

The following trailer towing related terminology defini-

tions will assist in understanding the subsequent sec-

tions:

GROSS COMBINATION WEIGHT RATING (GCWR)

is the total permissible weight of your vehicle and trailer

when weighed in combination. (Note that GCWR ratingsinclude a 68 kg (150 lb.) allowance for the presence of a

driver.) Tongue Weight (of a trailer) is the weight placed

on a vehicle's trailer hitch by the trailer.

GROSS TRAILER WEIGHT (GTW)is the weight of the

trailer plus the weight of all cargo, consumables and

equipment (permanent or temporary) loaded in or on the

trailer in its9loaded and ready for operation9condition.

TRAILER SWAY CONTROLis a telescoping link that

can be installed between the hitch receiver and the trailer

tongue that typically provides adjustable friction associ-

ated with the telescoping motion to dampen any un-

wanted trailer swaying motions while traveling.

272 STARTING AND OPERATING