ABS DODGE RAM 2500 DIESEL 2004 3.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2004, Model line: RAM 2500 DIESEL, Model: DODGE RAM 2500 DIESEL 2004 3.GPages: 426, PDF Size: 7.22 MB

Page 30 of 426

To Disarm the System:

Use the Keyless Entry transmitter or the key to turn the

driver's door lock to the unlock position. If something

has triggered the system in your absence, the horn will

sound three times when you unlock the doors and the

security lamp will flash for 30 seconds. Check the vehicle

for tampering.

The Security system will also disarm, if the vehicle is

started with a programmed Sentry Key. If an unpro-

grammed Sentry Key is used to start a vehicle, the engine

will run for 2 seconds and then the security alarm will be

initiated. To exit alarming mode, press the transmitter

Unlock button, unlock the driver's door using the key

cylinder, or start the vehicle with a programmed Sentry

Key.The Security Alarm System is designed to protect your

vehicle; however, you can create conditions where the

system will arm unexpectedly. If you remain in the

vehicle and lock the doors with the transmitter, the alarm

will sound when you pull the door handle to exit. You

may also accidentally disarm the system by unlocking

the driver's door with the door key and then locking it

manually with the lock plunger. The door will be locked

but the Security Alarm will not arm.

30 THINGS TO KNOW BEFORE STARTING YOUR VEHICLE

Page 146 of 426

12. ABS Warning Light

This light monitors the Anti-Lock Brake System

which is described elsewhere in this manual. This

light will come on when the ignition key is turned to the

ON position and may stay on for five seconds. If the ABS

light remains on or comes on during driving, it indicates

that the anti-lock portion of the brake system is not

functioning and that service is required. See your autho-

rized dealer immediately. The ABS light could also

illuminate during loss of traction and remain illuminated

until the brake pedal is pressed.

13. Temperature Gauge

The temperature gauge indicates engine coolant

temperature. Any reading within the normal

range indicates that the cooling system is operat-

ing satisfactorily. The gauge needle will likely indicate a

higher temperature when driving in hot weather, up

mountain grades, in heavy traffic, or when towing a

trailer. If the needle rises to the ª245ÉFº mark, stop thevehicle, shift into N (Neutral), and increase the engine

idle speed for 2 to 3 minutes. If the temperature reading

does not return to normal, shut your engine OFF and

allow it to cool. Seek authorized service immediately. See

Cooling System information in the section on ªMaintain-

ing Your Vehicle.º

CAUTION!

Do not leave your vehicle unattended with the

engine running as you would not be able to react to

the temperature indicator if the engine overheats.

NOTE:Engine idle speed will automatically increase to

1000 rpm at elevated coolant temperatures to improve

engine cooling.

146 UNDERSTANDING YOUR INSTRUMENT PANEL

Page 147 of 426

NOTE:If the gauge pointer moves to either extreme of

the gauge, the ªCheck Gagesº indicator will illuminate

and a single chime will sound.

14. Security

The light will flash rapidly for approximately 16 seconds

when the vehicle theft alarm is arming. The light will

flash at a slower rate after the alarm is set. The security

light will also come on for about two seconds when the

ignition is first turned ON.

15. Transmission Range Indicator (Automatic

Tranmissions Only)

When the gear selector lever is moved, this indicator

shows the automatic transmission gear range selected.

16. CRUISE Light

This indicator lights when the electronic speed control

system is turned on.17. Water In Fuel Indicator

Indicates there is water detected in the fuel

filter bowl. Refer to the Maintenance section,

Draining Fuel/Water Separator Filter, for water

drain procedure.

18. Brake System Warning Light

This light illuminates when the ignition key is turned to

the ON position and remains on for a few seconds. If the

light stays on longer, it may be an indication that the

parking brake has not been released. This light will

illuminate if the brake fluid is low, especially when

braking or accelerating hard. This light will illuminate if

the ABS indicator light has a malfunction. This light will

flash if the engine is running and the parking brake is on.

If the light remains on when the parking brake is

released, it indicates a possible brake hydraulic system

malfunction. In this case, the light will remain on until

the cause is corrected.

UNDERSTANDING YOUR INSTRUMENT PANEL 147

4

Page 148 of 426

If brake failure is indicated, immediate repair is necessary

and continued operation of the vehicle in this condition is

dangerous.

Acceleration which causes the rear wheels to slip for a

period of time may result in the red brake light illumi-

nating and a brake switch code being set on ABS

equipped vehicles. Depressing the brake pedal should

extinguish the red brake light.

19. Wait To Start Indicator

The Wait To Start Indicator will illuminate when

the ignition key is first turned to the ON position.

Wait until the Wait To Start Indicator turns OFF then start

the vehicle.

20. Odometer/Trip Odometer

The odometer shows the total distance the vehicle has

been driven.If the odometer reading is changed during repair or

replacement, be sure to keep a record of the reading

before and after the service so that the correct mileage can

be determined.

The trip odometer shows individual trip mileage. To

toggle between the odometer and the trip odometer,

press the Odometer/Trip Odometer Button. To reset the

Trip Odometer, press and hold the button while in trip

mode, until the Trip Odometer resets.

NOTE:There is also an engine hour function. This

indicates the total number of hours the engine has been

running. To display the engine hours perform the follow-

ing: Place the ignition in RUN, but do not start the

engine. With the odometer value displayed, hold the trip

button down for a period of 6 seconds. The odometer will

change to trip value first, then it will display the engine

148 UNDERSTANDING YOUR INSTRUMENT PANEL

Page 239 of 426

WARNING!

²Always fully apply the parking brake when leav-

ing your vehicle, or it may roll and cause damage

or injury. Also be certain to leave an automatic

transmission in Park, a manual transmission in

Reverse or first gear. Failure to do so may allow

the vehicle to roll and cause damage or injury.

²Leaving children in a vehicle unattended is dan-

gerous for a number of reasons. A child or others

could be injured. Children should be warned not

to touch the parking brake or the gear selector

lever. Don't leave the keys in the ignition. A child

could operate power windows, other controls, or

move the vehicle.

²Be sure the parking brake is fully disengaged before

driving, failure to do so can lead to brake problems

due to excessive heating of the rear brakes.

When parking on a hill, turn the front wheels toward the

curb on a downhill grade and away from the curb on an

uphill grade.

The parking brake should always be applied whenever

the driver is not in the vehicle.

BRAKE SYSTEM

If power assist is lost for any reason (for example,

repeated brake applications with the engine off), the

brakes will still function. However, you will experience a

substantial increase in braking effort to stop the vehicle.

If either the front or rear hydraulic systems lose normal

capability, the remaining system will still function with

some loss of overall braking effectiveness. This will be

evident by increased pedal travel during application,

greater pedal force required to slow or stop, and activa-

tion of the BRAKE warning lamp and the ABS lamp (if

equipped) during brake use.

STARTING AND OPERATING 239

5

Page 241 of 426

WARNING!

²Anti-lock system (ABS) cannot prevent the natu-

ral laws of physics from acting on the vehicle, nor

can it increase braking or steering efficiency be-

yond that afforded by the condition of the vehicle

brakes and tires or the traction afforded.

²The ABS cannot prevent accidents, including

those resulting from excessive speed in turns,

following another vehicle too closely, or hydro-

planing. Only a safe, attentive, and skillful driver

can prevent accidents.

²The capabilities of an ABS equipped vehicle must

never be exploited in a reckless or dangerous

manner which could jeopardize the user's safety

or the safety of others.

This Anti-lock Brake System is designed to aid the driver

in maintaining vehicle control under adverse braking

conditions. The system operates with a separate com-

puter to modulate hydraulic pressure to prevent wheel

lockup and help avoid skidding on slippery surfaces.

The system's pump motor runs during an ABS stop to

provide regulated hydraulic pressure. The pump motor

makes a low humming noise during operation. This is

normal.

When you are in a severe braking condition involving

use of the Anti-lock Brake System, you will experience

some pedal drop as the vehicle comes to a complete stop.

This is the result of the system reverting to the base brake

system and is normal.

Engagement of the Anti-lock Brake System may be

accompanied by a pulsing sensation. You may also hear a

clicking noise. These occurrences are normal, and indi-

cate that the system is functioning.

STARTING AND OPERATING 241

5

Page 242 of 426

ABS Warning Light

The Anti-lock Brake System includes an amber warning

light, located in the instrument cluster. When the light is

illuminated, the Anti-lock Brake System is not function-

ing. The system reverts to standard non-anti-lock brakes.

WARNING!

Pumping of the anti-lock brakes will diminish their

effectiveness and may lead to an accident. Pumping

makes the stopping distance longer. Just press firmly

on your brake pedal when you need to slow down or

stop.

POWER STEERING

Your power steering system will provide mechanical

steering capability if power assist is lost.

If for any reason the hydraulic pressure is interrupted, it

will still be possible to steer your vehicle. Under these

conditions you will experience a substantial increase in

steering effort.

242 STARTING AND OPERATING

Page 243 of 426

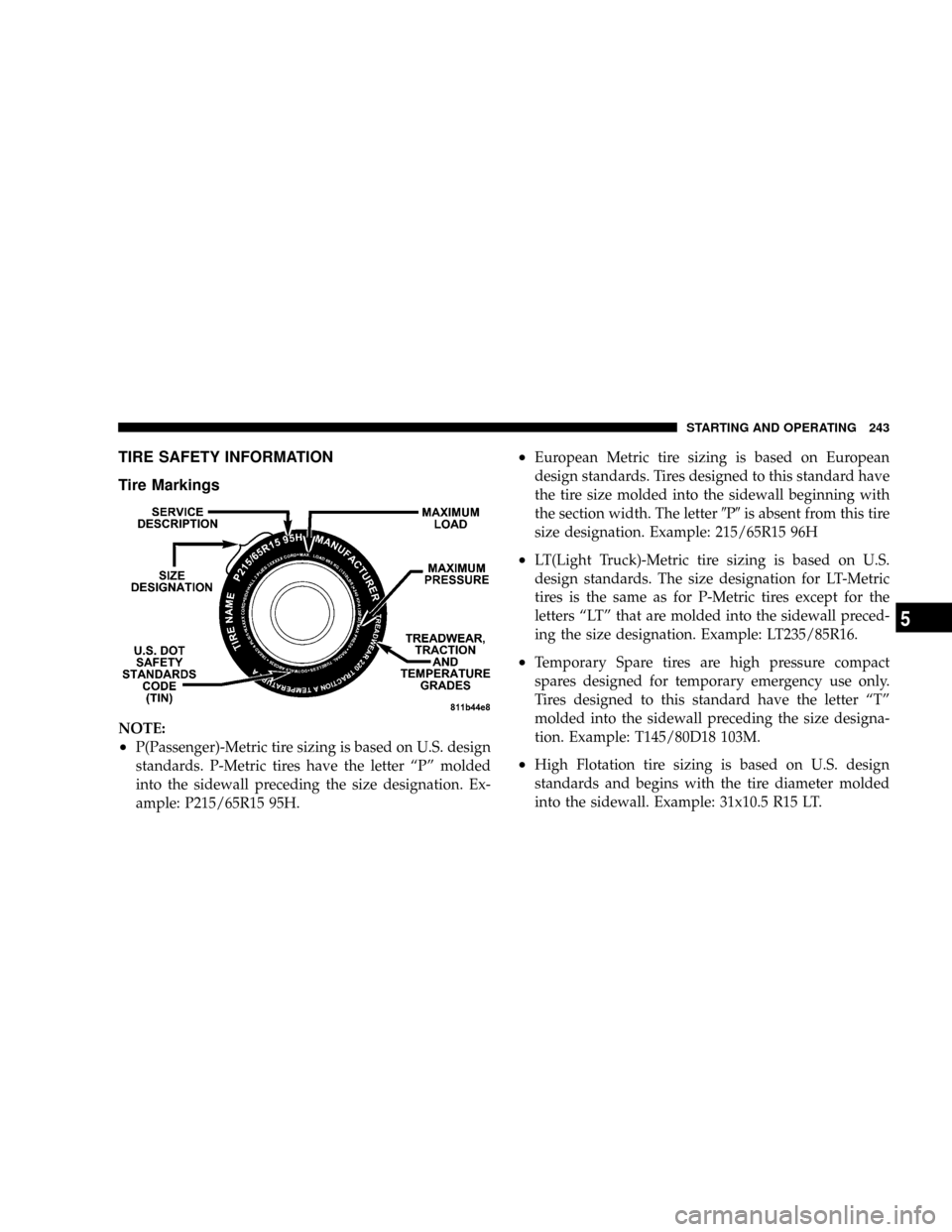

TIRE SAFETY INFORMATION

Tire Markings

NOTE:

²P(Passenger)-Metric tire sizing is based on U.S. design

standards. P-Metric tires have the letter ªPº molded

into the sidewall preceding the size designation. Ex-

ample: P215/65R15 95H.

²European Metric tire sizing is based on European

design standards. Tires designed to this standard have

the tire size molded into the sidewall beginning with

the section width. The letter9P9is absent from this tire

size designation. Example: 215/65R15 96H

²LT(Light Truck)-Metric tire sizing is based on U.S.

design standards. The size designation for LT-Metric

tires is the same as for P-Metric tires except for the

letters ªLTº that are molded into the sidewall preced-

ing the size designation. Example: LT235/85R16.

²Temporary Spare tires are high pressure compact

spares designed for temporary emergency use only.

Tires designed to this standard have the letter ªTº

molded into the sidewall preceding the size designa-

tion. Example: T145/80D18 103M.

²High Flotation tire sizing is based on U.S. design

standards and begins with the tire diameter molded

into the sidewall. Example: 31x10.5 R15 LT.

STARTING AND OPERATING 243

5

Page 245 of 426

EXAMPLE:

Service Description:

95= Load Index

ÐA numerical code associated with the maximum load a tire can carry.

H= Speed Symbol

ÐA symbol indicating the range of speeds at which a tire can carry a load corresponding

to its load index under certain operating conditions.

ÐThe maximum speed corresponding to the Speed Symbol should only be achieved un-

der specified operating conditions. (ie. tire pressure, vehicle loading, road conditions and

posted speed limits).

Load Identification:

(....blank....(= Absence of any text on sidewall of the tire indicates a Standard Load (SL) Tire

Extra Load (XL)= Extra Load (or Reinforced) Tire

Light Load= Light Load Tire

C,D,E= Load range associated with the maximum load a tire can carry at a specified pressure

Maximum LoadÐ Maximum Load indicates the maximum load this tire is designed to carry.

Maximum PressureÐ

Maximum Pressure indicates the maximum permissible cold tire inflation pressure for this tire.

STARTING AND OPERATING 245

5

Page 303 of 426

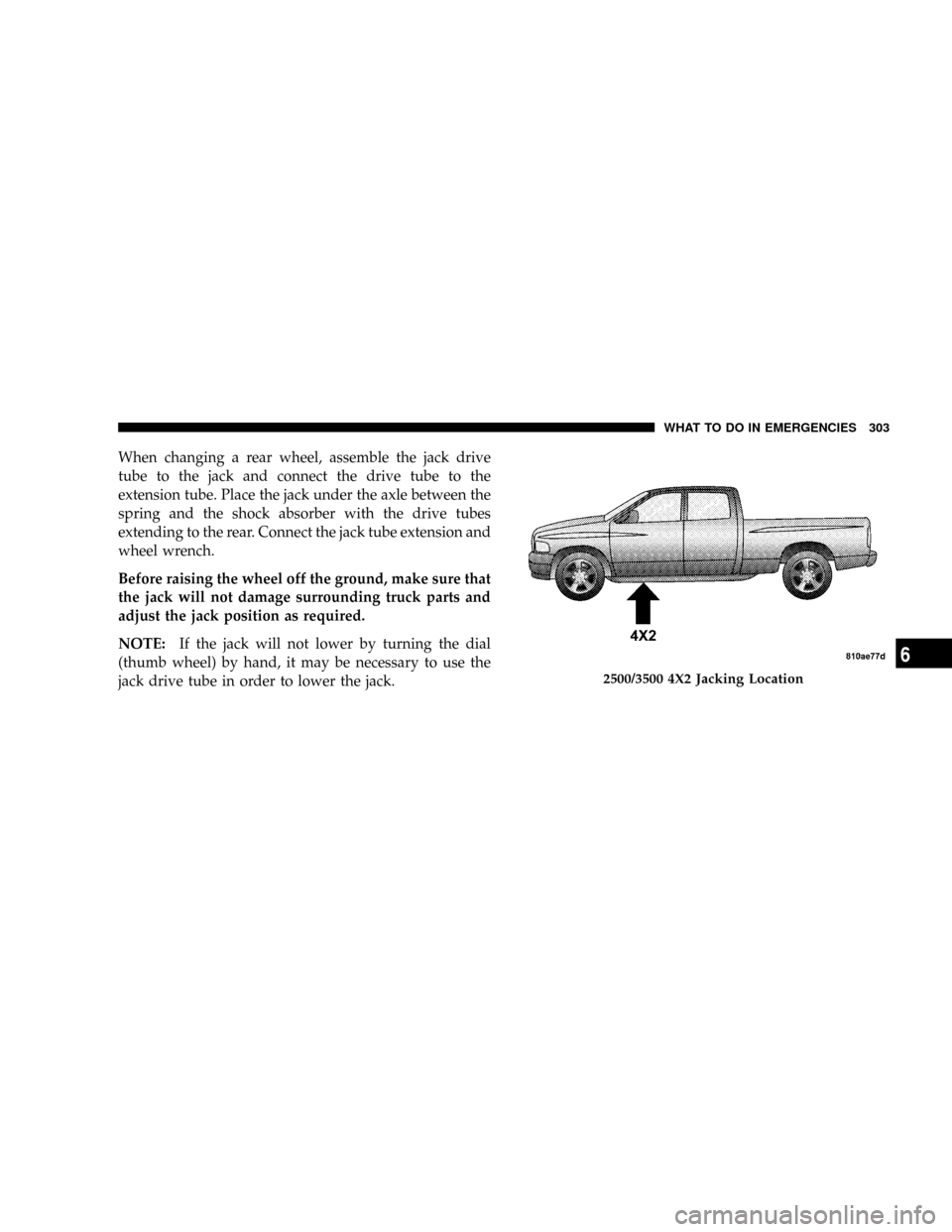

When changing a rear wheel, assemble the jack drive

tube to the jack and connect the drive tube to the

extension tube. Place the jack under the axle between the

spring and the shock absorber with the drive tubes

extending to the rear. Connect the jack tube extension and

wheel wrench.

Before raising the wheel off the ground, make sure that

the jack will not damage surrounding truck parts and

adjust the jack position as required.

NOTE:If the jack will not lower by turning the dial

(thumb wheel) by hand, it may be necessary to use the

jack drive tube in order to lower the jack.

2500/3500 4X2 Jacking Location

WHAT TO DO IN EMERGENCIES 303

6