torque DODGE RAM 2500 DIESEL 2008 3.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2008, Model line: RAM 2500 DIESEL, Model: DODGE RAM 2500 DIESEL 2008 3.GPages: 527, PDF Size: 8.88 MB

Page 6 of 527

INTRODUCTION

This Owner's Manual has been prepared with the assis-

tance of service and engineering specialists to acquaint

you with the operation and maintenance of your vehicle.

It is supplemented by a Warranty Information Booklet

and various customer-oriented documents. You are

urged to read these publications carefully. Following the

instructions and recommendations in this manual will

help assure safe and enjoyable operation of your vehicle.

NOTE: After you read the manual, it should be stored

in the vehicle for convenient reference and remain with

the vehicle when sold, so that the new owner will be

aware of all safety warnings.

When it comes to service, remember that your authorized

dealer knows your vehicle best, has the factory-trained

technicians and genuine Mopartparts, and is interested

in your satisfaction.

A MESSAGE FROM DAIMLERCHRYSLER

CORPORATION

DaimlerChrysler Corporation and Cumminstwelcome

you as a CumminstTurbo Diesel-powered truck owner.

Almost 100% of the heavy duty trucks in the United

States and Canada are diesel powered because of the fuel

economy, rugged durability, and high torque which per-

mits pulling heavy loads. Cumminst, engines power

well over half of these trucks. Now this same technology

and proven performance is yours in your truck equipped

with the Cumminst, turbocharged, charge air cooled,

diesel engine.

Your diesel truck will sound, feel, drive, and operate

differently from a gasoline-powered truck. It is important

that you read and understand this manual. You may find

that some of the starting, operating, and maintenance

procedures are different. However, they are simple to

4 INTRODUCTION

Page 200 of 527

CAUTION!

The TPMS has been optimized for the original

equipment tires and wheels. TPMS pressures and

warning have been established for the tire size

equipped on your vehicle. Undesirable system opera-

tion or sensor damage may result when using re-

placement equipment that is not of the same size,

type, and/or style. Aftermarket wheels can cause

sensor damage. Do not use tire sealant from a can, or

balance beads if your vehicle is equipped with a

TPMS, as damage to the sensors may result.

TPMS ªLight Loadº Reset Switch ± If Equipped

The TPMS ºLight Loadº reset switch allows you to

choose between Light Load vehicle conditions and Max

Load vehicle conditions tire pressures and related TPMS

warning levels. The switch is located in the instrumentpanel, below the climate control panel. For additional

information refer to ªTire Pressure Monitoring System

(TPMS) Ð If Equippedº in section 5 of this manual.

25. Transmission Oil Temperature Warning Light

(Automatic Transmissions Only)

This light indicates that there is excessive trans-

mission fluid temperature that might occur

with severe usage such as trailer towing. It may

also occur when operating the vehicle in a high

torque converter slip condition, such as 4-wheel drive

operation (e.g., snow plowing, off-road operation). If this

light comes on, stop the vehicle and run the engine at idle

or faster, with the transmission in NEUTRAL until the

light goes off.

26. Wait To Start Indicator

The Wait To Start indicator will illuminate when

the ignition is turned to the run position and the

intake manifold temperature is below 66ÉF (19ÉC).

198 UNDERSTANDING YOUR INSTRUMENT PANEL

Page 284 of 527

²Up Steep Hills Ð

select a lower transmission gear, but try and keep the

torque converter clutch engaged.

²Air Conditioning Ð

turn it off temporarily.

Do Not Operate The Engine With Low Oil

Pressure

When the engine is at normal operating temperature, the

minimum oil pressures required are:

Idle 700 to 800 RPM............... 10psi(69kPa)

Full speed and load.............. 30psi(207 kPa)

CAUTION!

If oil pressure falls to less than normal readings, shut

the engine off immediately. Failure to do so could

result in immediate and severe engine damage.

Do Not Operate The Engine With Failed Parts

Practically all failures give some warning before the parts

fail. Be on the alert for changes in performance, sounds,

and visual evidence that the engine requires service.

Some important clues are:

²engine misfiring or vibrating severely

²sudden loss of power

²unusual engine noises

²fuel, oil or coolant leaks

²sudden change, outside the normal operating range, in

the engine operating temperature

²excessive smoke

²oil pressure drop

282 STARTING AND OPERATING

Page 286 of 527

WARNING!

Do not use the Exhaust Brake feature when driving

in icy or slippery conditions as the increased engine

braking can cause the rear wheels to slide and the

vehicle to swing around with the possible loss of

vehicle control, which may cause an accident possi-

bly resulting in personal injury or death.

NOTE:For optimum braking power it is recommended

to use the Exhaust Brake while in Tow/Haul Mode.

The purpose of the exhaust brake (engine braking) fea-

ture is to supply negative (braking) torque to the engine.

Typically, the engine braking is used for, but not limited

to, vehicle towing applications where vehicle braking can

be achieved by the internal engine power, thereby spar-

ing the mechanical brakes of the vehicle.Benefits of the exhaust brake are:²vehicle driving control

²reduced brake fade

²longer brake life

²faster cab warm-up.

The exhaust brake feature can also be used to reduce the

engine warm up time. To use the exhaust brake as a

warm-up device, the vehicle must be moving less than 5

mph (8 km/h), the exhaust brake switch must be in the

ON position, and the coolant temperature must below

180ÉF (82ÉC) and ambient temperature below 60ÉF (16ÉC).

284 STARTING AND OPERATING

Page 289 of 527

Upshifts into both overdrive gears, 5th and 6th, will be

delayed when the transmission fluid temperature is

below 40É F (4.5É C) or above 240É F (115.5É C).

NOTE:Use caution when operating a heavily loaded

vehicle in 2nd or 1st gear in high ambients as torque

converter slip can impose significant additional heat load

on the cooling system.

WARNING!

Never use Park position on an automatic transmis-

sion as a substitute for the parking brake. Always

apply parking brake fully when parked to guard

against vehicle movement and possible injury or

damage.

Overdrive Operation

The overdrive automatic transmission contains an elec-

tronically controlled 5th and 6th (Overdrive). The trans-

mission will automatically shift from Drive to Overdrive

if the following conditions are present:

²the transmission selector is in DRIVE;

²the engine coolant has reached normal operating tem-

perature;

²vehicle speed is above approximately 30 mph (48

km/h);

²the ªTOW HAUL O/D OFFº switch has not been

activated;

²transmission has reached normal operating tempera-

ture.

STARTING AND OPERATING 287

5

Page 290 of 527

NOTE:If the vehicle is started in extremely cold tem-

peratures, the transmission may not shift into Overdrive

and will automatically select the most desirable gear for

operation at this temperature. Normal operation will

resume when the transmission fluid temperature has

risen to a suitable level. Refer also to the Note under

torque converter clutch, later in this section.

If the transmission temperature gets extremely hot, the

transmission will automatically select the most desirable

gear for operation at this temperature. If the transmission

temperature becomes hot enough the TRANS TEMP light

may illuminate and the transmission may downshift out

of Overdrive until the transmission cools down. After

cooldown, the transmission will resume normal opera-

tion.

The transmission will downshift from Overdrive to Drive

if the accelerator pedal is fully depressed at vehicle

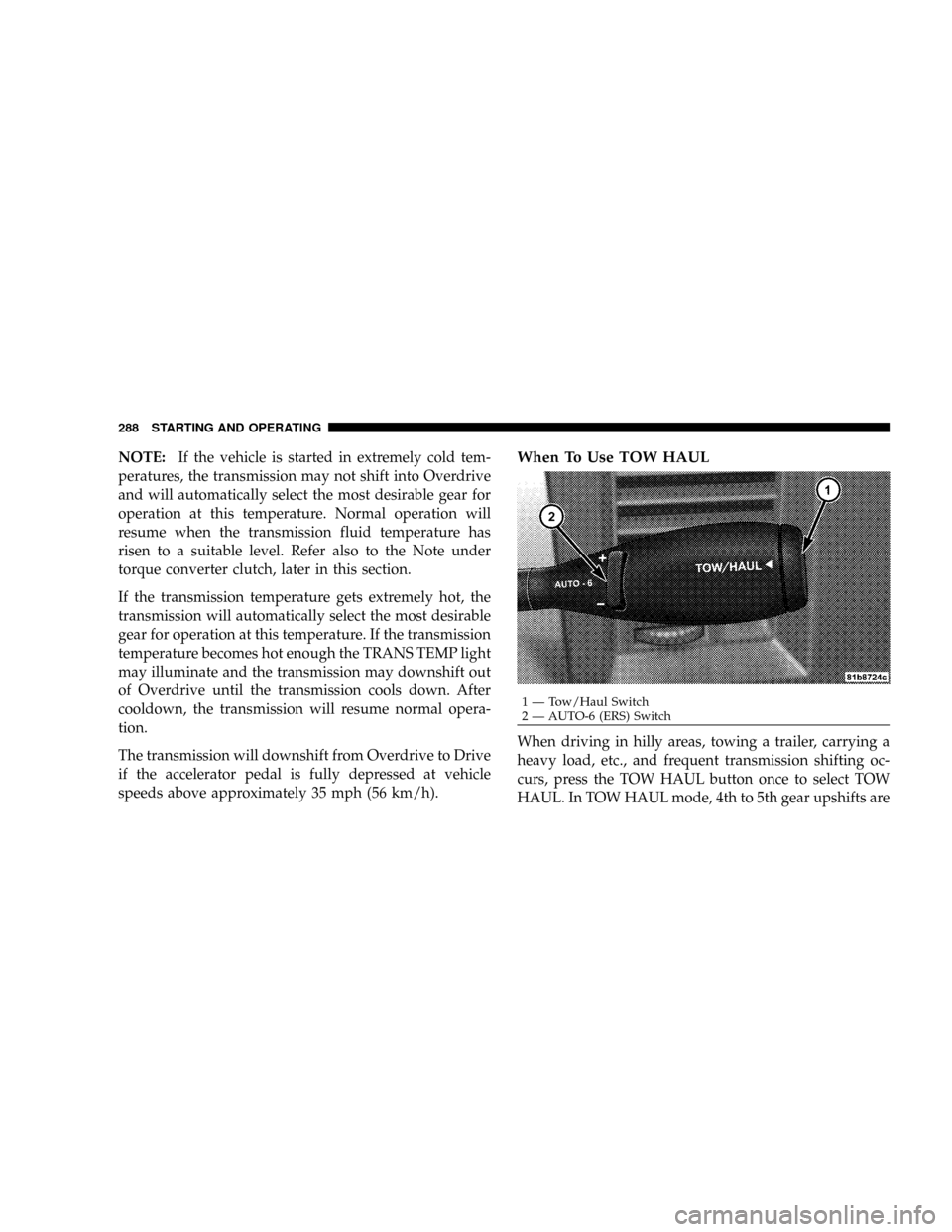

speeds above approximately 35 mph (56 km/h).When To Use TOW HAUL

When driving in hilly areas, towing a trailer, carrying a

heavy load, etc., and frequent transmission shifting oc-

curs, press the TOW HAUL button once to select TOW

HAUL. In TOW HAUL mode, 4th to 5th gear upshifts are

1 Ð Tow/Haul Switch

2 Ð AUTO-6 (ERS) Switch 288 STARTING AND OPERATING

Page 292 of 527

NOTE:To select the proper gear position for maximum

deceleration (engine braking), simply press and hold the

switch down (-). The transmission will shift to the range

from which the vehicle can best be slowed down.

Torque Converter Clutch

A feature designed to improve fuel economy has been

included in the automatic transmission on your vehicle.

A clutch within the torque converter engages automati-

cally at calibrated speeds. This may result in a slightly

different feeling or response during normal operation in

the upper gears. When the vehicle speed drops or during

acceleration when the transmission downshifts to second

gear, the clutch automatically disengages.NOTE:The torque converter clutch will not engage

until the transmission fluid and engine coolant are warm

[usually after 1-3 miles (1.6 - 4.8 km) of driving]. Because

the engine speed is higher when the torque converter

clutch is not engaged, it may seem as if the transmission

is not shifting into Overdrive when cold. This is normal.

Pressing the TOW HAUL O/D OFF button, when the

transmission is sufficiently warm, will demonstrate that

the transmission is able to shift into and out of Overdrive.

NOTE:If the vehicle has not been driven in several

days, the first few seconds of operation after shifting the

transmission into gear may seem sluggish. This is due to

the fluid partially draining from the torque converter into

the transmission. This condition is normal and will not

cause damage to the transmission. The torque converter

will refill within five seconds of shifting from PARK into

any other gear position.

290 STARTING AND OPERATING

Page 394 of 527

6. Using the wheel wrench, finish tightening the nuts

using a crisscross pattern. Correct nut tightness is 135 ft.

lbs. (183 N´m) torque for 2500/3500 single rear wheel

(SRW) models and 145 ft. lbs. (197 N´m) for 3500 dual rear

wheel models. If in doubt about the correct tightness,

have them checked with a torque wrench by your dealer

or at a service station.

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could injure someone in the vehicle. Al-

ways stow the jack parts and the extra tire and wheel

in the places provided.

7. Install wheel center cap and remove wheel blocks. Do

not install chrome or aluminum wheel center caps on the

spare wheel. This may result in cap damage.8. Lower the jack to its fully closed position. If the jack

will not lower by turning the dial (thumbwheel) by hand,

it may be necessary to use the jack drive tube in order to

lower the jack. Stow the replaced tire, jack, and tools as

previously described.

9. Adjust the tire pressure when possible.

NOTE:Do not oil wheel studs. For chrome wheels, do

not substitute with chrome plated wheel nuts.Hub Caps/Wheel Covers

The hub caps must be removed before raising the vehicle

off the ground.

For 2500/3500 single rear wheel (SRW) models, use the

blade on the end of the lug wrench to pry the hub cap off.

Insert the blade end into the pryoff notch and carefully

pop off the hub cap with a back and forth motion.

392 WHAT TO DO IN EMERGENCIES

Page 397 of 527

These dual rear wheels should be tightened as follows:1. Tighten the wheel nuts in the numbered sequence to a

snug fit.

2. Retighten the wheel nuts in the same sequence to the

torques listed in the table. Go through the sequence a

second time to verify that specific torque has been

achieved. Retighten to specifications at 100 mi(160 km)

and after 500 mi (800 km).

It is recommended that wheel stud nuts be kept torqued

to specifications at all times. Torque wheel stud nuts to

specifications at each lubrication interval.

Wheel Nuts

All wheel nuts should be tightened occasionally to elimi-

nate the possibility of wheel studs being sheared or the

bolt holes in the wheels becoming elongated. This is

especially important during the first few hundred miles/

kilometers of operation to allow the wheel nuts to

become properly set. All nuts should first be firmly

seated against the wheel. The nuts should then be

WHAT TO DO IN EMERGENCIES 395

6

Page 398 of 527

tightened to recommended torque. Tighten the nuts to

final torque in increments. Progress around the bolt

circle, tightening the nut opposite to the nut just previ-

ously tightened until final torque is achieved. Recom-

mended torques are shown in the following chart.

Disc

WheelsType Nut Stud Size Torque

Ft. Lbs.Torque

Newton

Meters

Cone 9/16-18 120-150 160-200

Flanged 9/16-18 130-160 190-220

To Stow The Flat Or Spare

Turn the wheel so that the valve stem is down. Slide the

wheel retainer through the center of the wheel and

position it properly across the wheel opening.

For convenience in checking the spare tire inflation, stow

with the valve stem toward the rear of the vehicle.Attach the wheel wrench to the extension tube. Rotate the

winch mechanism until the wheel is drawn into place

against the underside of the vehicle. Continue to rotate

until you feel the winch mechanism slip or click three or

four times. It cannot be overtightened. Push against the

tire several times to be sure it is firmly in place.

HOISTING

A conventional floor jack may be used at the jacking

locations. Refer to the graphics that show jacking loca-

tions. However, a floor jack or frame hoist must never be

used on any other parts or the underbody.

CAUTION!

Never use a floor jack directly under the differential

housing of a loaded truck or damage to your vehicle

may result.

396 WHAT TO DO IN EMERGENCIES