warning DODGE RAM 2500 GAS 2008 3.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2008, Model line: RAM 2500 GAS, Model: DODGE RAM 2500 GAS 2008 3.GPages: 554, PDF Size: 9.93 MB

Page 404 of 554

CAUTION!

Using 1500 Model vehicles for snowplow applica-

tions can cause damage to the vehicle.

NOTE:Before installation of a snowplow, it is highly

recommended that the owner/installer obtain and follow

the recommendations contained within the current

Dodge BODY BUILDER'S GUIDE. See your authorized

dealer, installer or snowplow manufacturer for this infor-

mation. There are unique electrical systems that must be

connected to properly assure operator safety, and to

prevent overloading vehicle systems.

WARNING!

Attaching a snowplow to this vehicle could adversely

affect performance of the airbag system in an acci-

dent. Do not expect that the airbag will perform as

described earlier in this manual

CAUTION!

The ªLamp Outº indicator could illuminate if exte-

rior lamps are not properly installed.

402 STARTING AND OPERATING

Page 410 of 554

CAUTION!

Damage to the automatic transmission may occur if

the transmission is shifted into PARK with the trans-

fer case in NEUTRAL and the engine running. With

the transfer case in NEUTRAL ensure that the engine

is OFF prior to shifting the transmission into PARK.

Returning to Normal Operation Ð Manual Shift

Transfer Case

Use the following procedure to prepare your vehicle for

normal usage:

1. Bring the vehicle to a complete stop.

2. Apply the parking brake.

3. Shut OFF the engine.

4. Depress the brake pedal.5. Shift automatic transmission to NEUTRAL, or depress

the clutch on manual transmissions.

6. Shift transfer case lever to desired position.

7. Shift automatic transmission into PARK.

WARNING!

You or others could be injured if you leave the

vehicle unattended with the transfer case in the

NEUTRAL position without first fully engaging the

parking brake. The transfer case NEUTRAL position

disengages both the front and rear driveshafts from

the powertrain and will allow the vehicle to move,

regardless of the transmission position. The parking

brake should always be applied when the driver is

not in the vehicle.

408 STARTING AND OPERATING

Page 414 of 554

NOTE:Steps 1 through 5 are requirements that must be

met prior to depressing the transfer case Neutral (N)

button, and must continue to be met until one second

elapses and the shift has been completed. If any of these

requirements (with the exception of step 3 - key ON) are

not met prior to depressing the Neutral (N) button, or are

no longer met during the one second time, then all of the

mode position indicator lights will flash continuously

until all requirements are met, or until the Neutral (N)

button is released.

NOTE:The ignition key must be ON for a transfer case

shift to take place and for the position indicator lights to

be operable. If the key is not ON, the shift will not take

place and no position indicator lights will be on or

flashing.NOTE:Flashing Neutral position indicator light indi-

cates that shift requirements have not been met.

WARNING!

You or others could be injured if you leave the

vehicle unattended with the transfer case in the

NEUTRAL position without first fully engaging the

parking brake. The transfer case NEUTRAL position

disengages both the front and rear driveshafts from

the powertrain and will allow the vehicle to move

despite the transmission position. The parking brake

should always be applied when the driver is not in

the vehicle.

412 STARTING AND OPERATING

Page 417 of 554

WHAT TO DO IN EMERGENCIES

CONTENTS

mHazard Warning Flasher..................416

mJacking And Tire Changing................417

NJack Location........................417

NReinstalling The Scissors-Type Jack And Tools

(1500 Models)........................419

mJacking Instructions.....................422

NRemoving The Spare Tire................422

NTire Changing Procedure................423mHoisting.............................434

mJump-Starting Procedures.................434

mFreeing A Stuck Vehicle..................437

mEmergency Tow Hooks Ð If Equipped........438

mTowing A Disabled Vehicle................439

N4-Wheel Drive Vehicles.................439

N2±Wheel Drive Vehicles.................439

6

Page 418 of 554

HAZARD WARNING FLASHER

The Hazard Warning switch is mounted on the top of the

steering column as shown in the illustration.To engage the Hazard Warning lights, depress the button

on the top of the steering column. When the Hazard

Warning switch is activated, all directional turn signals

will flash off and on to warn oncoming traffic of an

emergency. Push the button a second time to turn off the

flashers.

This is an emergency warning system and should not be

used when the vehicle is in motion. Use it when your

vehicle is disabled and is creating a safety hazard for

other motorists.

When you must leave the vehicle to seek assistance, the

Hazard Warning lights will continue to operate even

though the ignition switch is OFF.

NOTE:With extended use, the Hazard Warning lights

may discharge your battery.

Hazard Light Warning Switch

416 WHAT TO DO IN EMERGENCIES

Page 419 of 554

JACKING AND TIRE CHANGING

WARNING!

²Being under a jacked-up vehicle is dangerous. The

vehicle could slip off the jack and fall on you. You

could be crushed. Never put any part of your body

under a vehicle that is on a jack. Never start or run

the engine while the vehicle is on a jack. If you need

to get under a raised vehicle, take it to an authorized

service center where it can be raised on a lift.

²The jack is designed to use as a tool for changing

tires only. The jack should not be used to lift the

vehicle for service purposes. The vehicle should

be jacked on a firm level surface only. Avoid ice or

slippery areas.

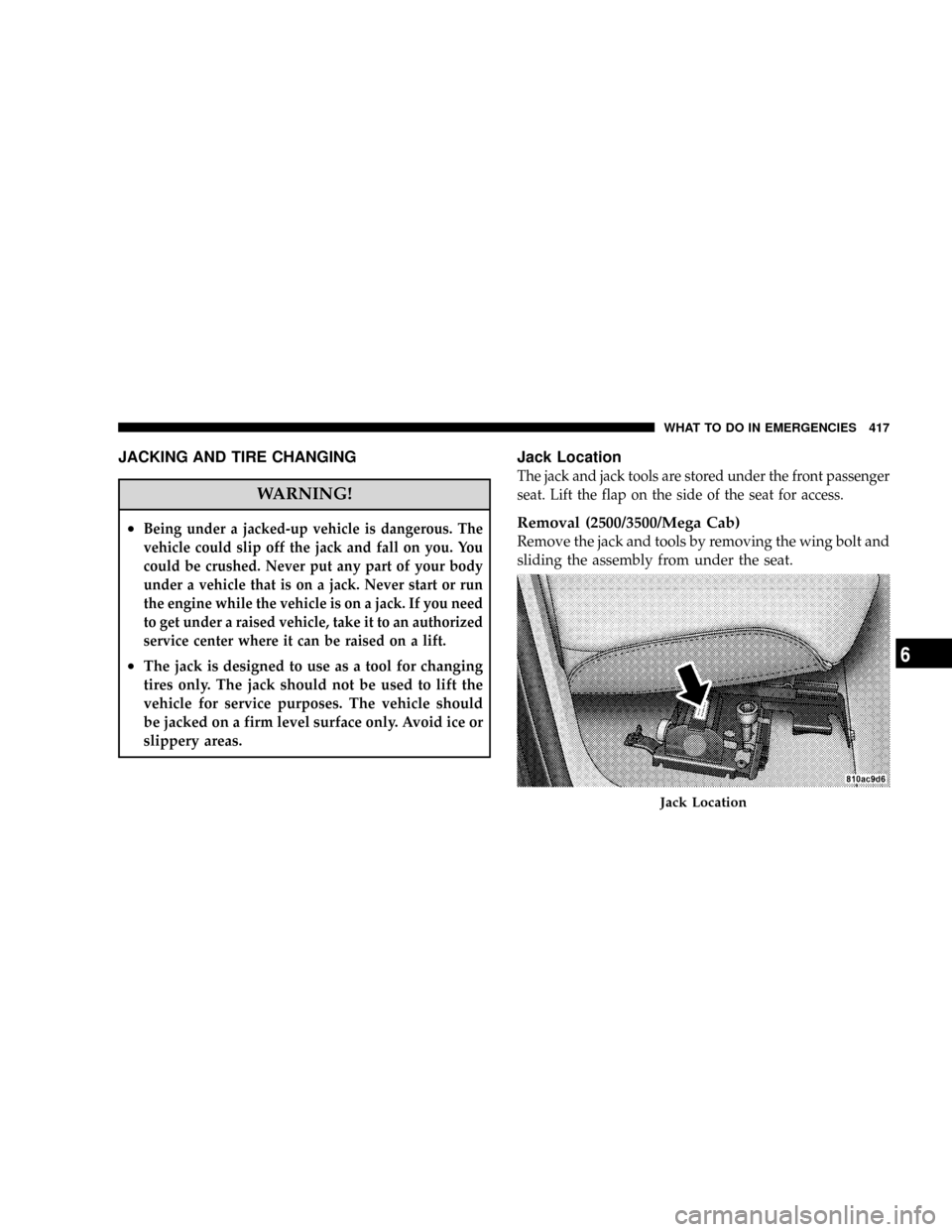

Jack Location

The jack and jack tools are stored under the front passenger

seat. Lift the flap on the side of the seat for access.

Removal (2500/3500/Mega Cab)

Remove the jack and tools by removing the wing bolt and

sliding the assembly from under the seat.

Jack Location

WHAT TO DO IN EMERGENCIES 417

6

Page 421 of 554

WARNING!

After using the jack and tools, always reinstall them

in the original carrier and location. While driving

you may experience abrupt stopping, rapid accelera-

tion, or sharp turns. A loose jack, tools, bracket or

other objects in the vehicle may move around with

force, resulting in serious injury.

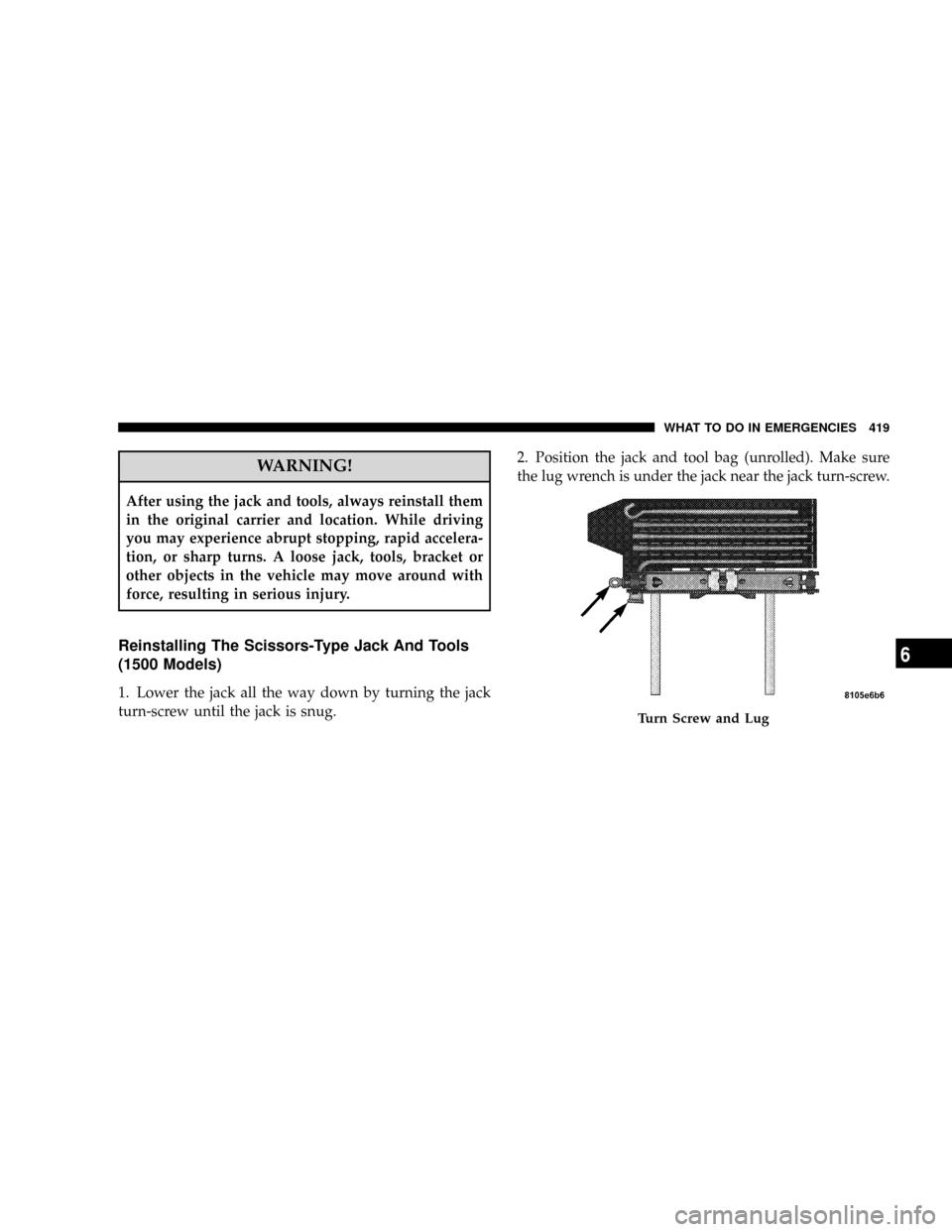

Reinstalling The Scissors-Type Jack And Tools

(1500 Models)

1. Lower the jack all the way down by turning the jack

turn-screw until the jack is snug.2. Position the jack and tool bag (unrolled). Make sure

the lug wrench is under the jack near the jack turn-screw.

Turn Screw and Lug

WHAT TO DO IN EMERGENCIES 419

6

Page 425 of 554

Tire Changing Procedure

WARNING!

Getting under a jacked-up vehicle is dangerous. The

vehicle could slip off the jack and fall on you. You

could be crushed. Never get any part of your body

under a vehicle that is on a jack. Never start or run

the engine while the vehicle is on a jack. If you need

to get under a raised vehicle, take it to an authorized

service center where it can be raised on a lift.

Do not raise this vehicle using a bumper jack. The jack is

designed as a tool for changing tires on this vehicle only.

It is not recommended that the jack be used for service

purposes or to lift more than one wheel at a time.

Preparations

Park the vehicle on a firm level surface, avoiding ice or

slippery areas. Set the parking brake and place the gear

selector in PARK (automatic transmission) or REVERSE

(manual transmission). On four-wheel drive vehicles,

shift the transfer case to the 4L position.

WARNING!

Do not attempt to change a tire on the side of the

vehicle close to moving traffic. Pull far enough off

the road to avoid the danger of being hit when

operating the jack or changing the wheel.

²Turn on the Hazard Warning Flasher.

WHAT TO DO IN EMERGENCIES 423

6

Page 426 of 554

²Block both the front and rear

of the wheel diagonally oppo-

site the jacking position. For

example, if the right front

wheel is being changed, block

the left rear wheel.

²Passengers should not remain in the vehicle when the

vehicle is being jacked.

Instructions

WARNING!

Carefully follow these tire changing warnings to help prevent

personal injury or damage to your vehicle:

²Always park on a firm, level surface as far from the edge of the

roadway as possible before raising the vehicle.

²Block the wheel diagonally opposite the wheel to be raised.

²Set the parking brake firmly and set an automatic transmis-

sion in park; a manual transmission in reverse.

²Never start or run the engine with the vehicle on a jack.

²Do not let anyone sit in the vehicle when it is on a jack.

²Do not get under the vehicle when it is on a jack.

²Only use the jack in the positions indicated and for lifting this

vehicle during a tire change.

²If working on or near a roadway, be extremely careful of motor

traffic.

²To assure that spare tires, flat or inflated are securely stowed,

spares must be stowed with the valve stem facing the ground.

²Turn on the Hazard warning flasher.

Jack Warning Label

424 WHAT TO DO IN EMERGENCIES

Page 430 of 554

²Connect the jack tube extension and wheel wrench.

Before raising the wheel off the ground, make sure

that the jack will not damage surrounding truck

parts and adjust the jack position as required.

NOTE:If the 2500/3500 bottle jack will not lower by

turning the dial (thumbwheel) by hand, it may be neces-

sary to use the jack drive tube in order to lower the jack.

4. By rotating the wheel wrench clockwise, raise the

vehicle until the wheel just clears the surface.

WARNING!

Raising the vehicle higher than necessary can make

the vehicle unstable and cause an accident. It could

slip off the jack and hurt someone near it. Raise the

vehicle only enough to remove the tire.5. Remove the wheel nuts and pull the wheel off. Install

the spare wheel and wheel nuts with the cone shaped end

of the nuts toward the wheel on 1500/2500/3500 single

rear-wheel (SRW) models. On 3500 dual rear-wheel mod-

els (DRW) the lug nuts are a two-piece assembly with a

flat face. Lightly tighten the nuts. To avoid risk of forcing

the vehicle off the jack, do not fully tighten the nuts until

the vehicle has been lowered.

6. Using the wheel wrench, finish tightening the nuts

using a crisscross pattern. Correct nut tightness is 135 ft

lbs (183 N´m) torque for 1500/2500/3500 single-rear

wheel (SRW) models, and 145 ft lbs (197 N´m) for 3500

dual rear-wheel models. If in doubt about the correct

tightness, have them checked with a torque wrench by

your authorized dealer or at a service station.

428 WHAT TO DO IN EMERGENCIES