warning DODGE RAM 2500 POWER WAGON 2008 3.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2008, Model line: RAM 2500 POWER WAGON, Model: DODGE RAM 2500 POWER WAGON 2008 3.GPages: 504, PDF Size: 8.17 MB

Page 351 of 504

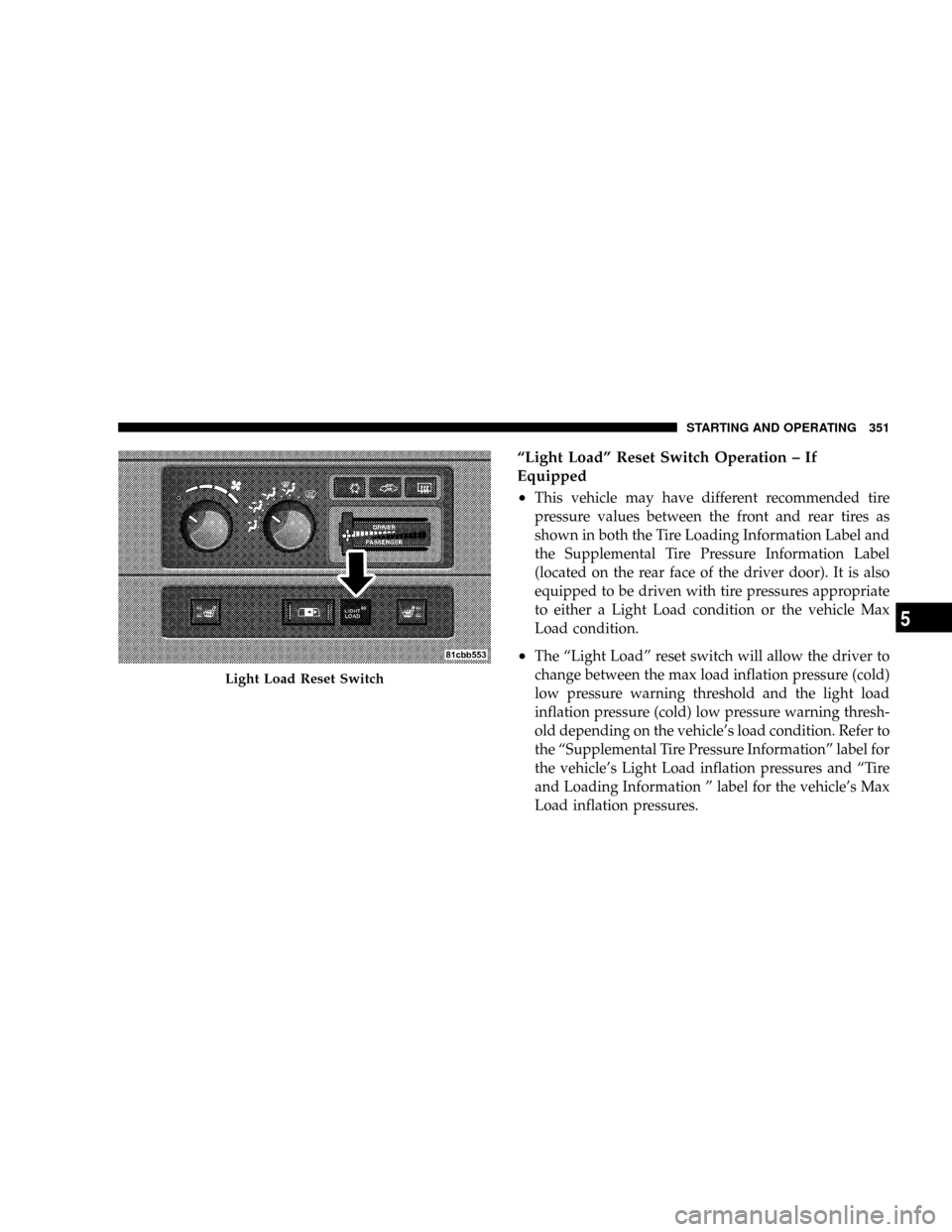

ªLight Loadº Reset Switch Operation ± If

Equipped

²

This vehicle may have different recommended tire

pressure values between the front and rear tires as

shown in both the Tire Loading Information Label and

the Supplemental Tire Pressure Information Label

(located on the rear face of the driver door). It is also

equipped to be driven with tire pressures appropriate

to either a Light Load condition or the vehicle Max

Load condition.

²The ªLight Loadº reset switch will allow the driver to

change between the max load inflation pressure (cold)

low pressure warning threshold and the light load

inflation pressure (cold) low pressure warning thresh-

old depending on the vehicle's load condition. Refer to

the ªSupplemental Tire Pressure Informationº label for

the vehicle's Light Load inflation pressures and ªTire

and Loading Information º label for the vehicle's Max

Load inflation pressures.

Light Load Reset Switch

STARTING AND OPERATING 351

5

Page 352 of 504

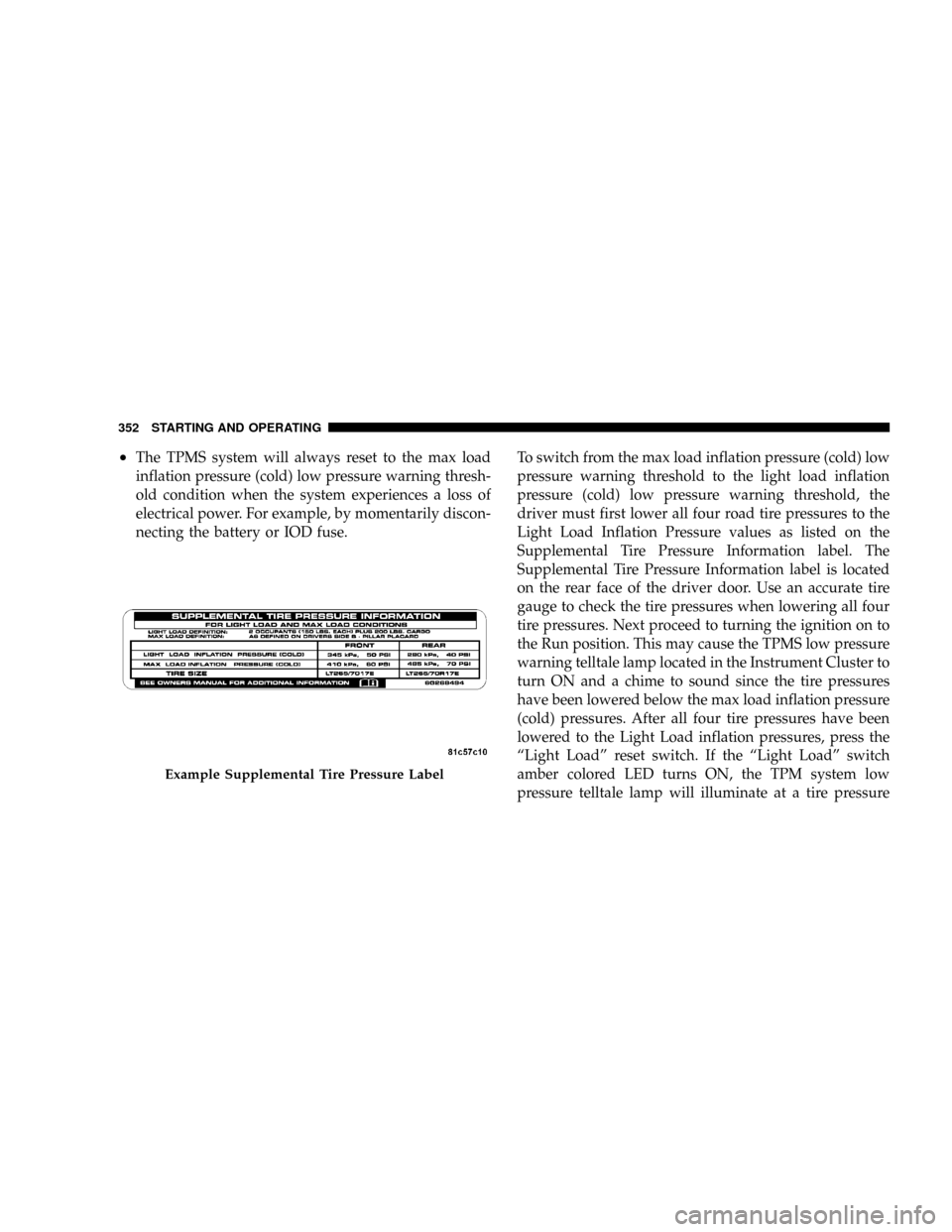

²The TPMS system will always reset to the max load

inflation pressure (cold) low pressure warning thresh-

old condition when the system experiences a loss of

electrical power. For example, by momentarily discon-

necting the battery or IOD fuse.To switch from the max load inflation pressure (cold) low

pressure warning threshold to the light load inflation

pressure (cold) low pressure warning threshold, the

driver must first lower all four road tire pressures to the

Light Load Inflation Pressure values as listed on the

Supplemental Tire Pressure Information label. The

Supplemental Tire Pressure Information label is located

on the rear face of the driver door. Use an accurate tire

gauge to check the tire pressures when lowering all four

tire pressures. Next proceed to turning the ignition on to

the Run position. This may cause the TPMS low pressure

warning telltale lamp located in the Instrument Cluster to

turn ON and a chime to sound since the tire pressures

have been lowered below the max load inflation pressure

(cold) pressures. After all four tire pressures have been

lowered to the Light Load inflation pressures, press the

ªLight Loadº reset switch. If the ªLight Loadº switch

amber colored LED turns ON, the TPM system low

pressure telltale lamp will illuminate at a tire pressure

Example Supplemental Tire Pressure Label

352 STARTING AND OPERATING

Page 354 of 504

WARNING!

It is the driver 's responsibility to change to the max

load inflation pressure (cold) low pressure warning

threshold condition when not driving in the light

load condition as defined as two occupants ( 150 lbs

each) plus 200 pounds of cargo. The vehicle ªLight

Load Definitionº is found in the Supplemental Tire

Pressure Information Label located on the rear face of

the driver door. Failure to do so may cause you to lose

control resulting in an accident, causing serious or

fatal injury.To switch back to the max load inflation pressure (cold)

low pressure warning threshold, press the ªLight Loadº

reset switch. It is not necessary to first fill the tires to the

max load inflation pressure (cold) values to switch the

TPMS system to the max load inflation pressure (cold)

low pressure warning threshold. If after pressing the

ªLight Loadº reset switch and tire pressures are below

the max load inflation pressure (cold) low pressure

warning thresholds, the TPMS low pressure warning

telltale lamp located in the Instrument Cluster will turn

ON and a chime will sound. The tire pressures are now

required to be inflated to the max load inflation pressure

(cold) values described on the Tire and Loading Informa-

tion label. The Tire and Loading Information label is

located on the drivers side B-pillar. If the ªLight Loadº

reset switch LED turns OFF the TPMS has been reset and

the low pressure telltale lamp will illuminate at tire

pressures 25% or more below the max load inflation

pressure (cold) values.

354 STARTING AND OPERATING

Page 355 of 504

Tire Pressure Monitor System Components

The Tire Pressure Monitor System (TPMS) uses wireless

technology with wheel rim mounted electronic sensors to

monitor tire pressure levels. Sensors, mounted to each

wheel as part of the valve stem, transmit tire pressure

readings to the Receiver Module.

NOTE:It is particularly important, for you to check the

tire pressure in all of your tires regularly and to maintain

the proper pressure.

The Tire Pressure Monitoring System (TPMS) consists of

the following components:

²Receiver Module

²4 Wheel Sensors

²2 Trigger Modules (mounted in the front wheel-wells)

²ªLight Loadº Reset Switch (located in the instrument

panel)

²Tire Pressure Monitoring Telltale Lamp

Tire Pressure Monitoring Low Pressure Warnings

The Tire Pressure Monitoring Telltale Lamp will

illuminate in the instrument cluster, and an au-

dible chime will be activated when one or more of

the four active road tire pressures are low. Should this

occur, you should stop as soon as possible, check the

inflation pressure of each tire on your vehicle and inflate

each tire to the vehicle's recommended cold placard

pressure value. The system will automatically update

and the Tire Pressure Monitoring Lamp will extinguish

once the updated tire pressures have been received. The

vehicle may need to be driven for up to 10 minutes above

15 mph (25 km/h) to receive this information.

Check TPMS Warnings

The Tire Pressure Monitoring Telltale Warning Light

located in the Instrument Cluster will flash on and off for

75 seconds and will remain on solid when a system fault

is detected. The system fault will also sound a chime. If

STARTING AND OPERATING 355

5

Page 356 of 504

the ignition key is cycled, this sequence will repeat,

providing the system fault still exists. A system fault can

occur by any of the following scenarios:

1. Signal interference due to electronic devices or driving

next to facilities emitting the same Radio Frequencies as

the TPM sensors.

2. Installing aftermarket window tinting that affects ra-

dio wave signals.

3. Accumulation of snow or ice around the wheels or

wheel housings.

4. Using tire chains on the vehicle.

5. Using wheels/tires not equipped with TPM sensors.

6. Loss of communication with the trigger modules or

tire pressure monitoring sensors.

NOTE: Your vehicle is equipped with a non-matching

full size spare wheel and tire assembly.1. This spare tire does not have a tire pressure monitor-

ing sensor. Therefore, the TPMS will not monitor the tire

pressure in the spare tire.

2. If you install the full size spare tire in place of a road

tire that has a pressure below the low-pressure warning

limit, upon the next ignition key cycle, a chime will

sound and the TPM Telltale Light will still turn ON due

to the low tire.

3. However, after driving the vehicle for up to 10 min-

utes above 15 mph (25 km/h), the TPM Telltale Light will

flash on and off for 75 seconds and then remain on solid.

4. For each subsequent ignition key cycle, a chime will

sound and the TPM Telltale Light will flash on and off for

75 seconds and then remain on solid.

5. Once you repair or replace the original road tire, and

reinstall it on the vehicle in place of the full size spare tire,

the TPMS will update automatically and the TPM Telltale

356 STARTING AND OPERATING

Page 357 of 504

Light will turn OFF, as long as no tire pressure is below

the low-pressure warning limit in any of the four active

road tires. The vehicle may need to be driven for up to 10

minutes above 15 mph (25 km/h) in order for the TPMS

to receive this information.

General Information

This device complies with part 15 of the FCC rules and

RSS 210 of Industry Canada. Operation is subject to the

following conditions:

²This device may not cause harmful interference.

²This device must accept any interference received, includ-

ing interference that may cause undesired operation.

The tire pressure sensors are covered under one of the

following licenses:

United States.....................KR5S120123

Canada........................2671-S120123

FUEL REQUIREMENTS

The 5.7L engine is designed to meet all

emissions regulations and provide satisfac-

tory fuel economy and performance when

using high quality unleaded gasoline hav-

ing an octane range of 87 to 89. The manu-

facturer recommends the use of 89 octane

for optimum performance.The routine use

of premium gasoline is not recommended. The use of

premium gasoline will provide no benefit over high

quality regular and mid-grade gasolines, and in some

circumstances may result in poorer performance.

Light spark knock at low engine speeds is not harmful to

your engine. However, continued heavy spark knock at

high speeds can cause damage and immediate service is

required.

5.7L Engines

STARTING AND OPERATING 357

5

Page 361 of 504

²The use of fuel additives which are now being sold as

octane enhancers is not recommended. Many of these

products contain high concentrations of methanol.

Fuel system damage or vehicle performance problems

resulting from the use of such fuels or additives is not

the responsibility of the manufacturer.

NOTE:Intentional tampering with emissions control

systems can result in civil penalties being assessed

against you.

Carbon Monoxide Warnings

WARNING!

Carbon monoxide (CO) in exhaust gases is deadly.

Follow the precautions below to prevent carbon

monoxide poisoning:

²Do not inhale exhaust gases. They contain carbon

monoxide, a colorless and odorless gas which can kill.

Never run the engine in a closed area, such as a

garage, and never sit in a parked vehicle with the

engine running for an extended period. If the vehicle is

stopped in an open area with the engine running for

more than a short period, adjust the ventilation system

to force fresh, outside air into the vehicle.

²Guard against carbon monoxide with proper mainte-

nance. Have the exhaust system inspected every time

the vehicle is raised. Have any abnormal conditions

repaired promptly. Until repaired, drive with all side

windows fully open.

²Keep the liftgate closed when driving your vehicle to

prevent carbon monoxide and other poisonous ex-

haust gases from entering the vehicle.

STARTING AND OPERATING 361

5

Page 363 of 504

WARNING!

²Never have any smoking materials lit in or near

the vehicle when the gas cap is removed or the

tank filled.

²Never add fuel to the vehicle when the engine is

running. This is in violation of most state and

federal fire regulations and will cause the Mal-

function Indicator Light to turn on.

NOTE:Tighten the gas cap 1/4 turn until you hear one

click. This is an indication that the cap is properly

tightened.

If the gas cap is not tightened properly, the Malfunction

Indicator Light will come on, Be sure the gas cap is

tightened every time the vehicle is refueled.

WARNING!

A fire may result if gasoline is pumped into a

portable container that is inside of a vehicle. You

could be burned. Always place gas containers on the

ground while filling.

Loose Fuel Filler Cap (Gas Cap) Message

If the vehicles diagnostic system determines that the fuel

filler cap in loose, improperly installed, or damaged, a

GASCAP message will be displayed in the instrument

cluster. Tighten the gas cap until a ªclickingº sound is

heard. This is an indication that the gas cap is properly

tightened. Press the odometer reset button to turn the

message off. If the problem persists, the message will

appear the next time the vehicle is started. This might

indicate a damaged cap. If the problem is detected twice

STARTING AND OPERATING 363

5

Page 368 of 504

Gross Trailer Weight (GTW)

The gross trailer weight (GTW) is the weight of the trailer

plus the weight of all cargo, consumables and equipment

(permanent or temporary) loaded in or on the trailer in its

9loaded and ready for operation9condition. The recom-

mended way to measure GTW is to put your fully loaded

trailer on a vehicle scale. The entire weight of the trailer

must be supported by the scale.

Gross Combination Weight Rating (GCWR)

The gross combination weight rating (GCWR) is the total

permissible weight of your vehicle and trailer when

weighed in combination. (Note that GCWR ratings in-

clude a 68 kg (150 lbs) allowance for the presence of a

driver).

Gross Axle Weight Rating (GAWR)

The GAWR is the maximum capacity of the front and rear

axles. Distribute the load over the front and rear axles

evenly. Make sure that you do not exceed either front or

rear GAWR.

WARNING!

It is important that you do not exceed the maximum

front or rear GAWR. A dangerous driving condition

can result if either rating is exceeded. You could lose

control of the vehicle and have an accident.

Tongue Weight (TW)

The downward force exerted on the hitch ball by the

trailer. In most cases it should not be less than 10% or

more than 15% of the trailer load. You must consider this

as part of the load on your vehicle.

368 STARTING AND OPERATING

Page 370 of 504

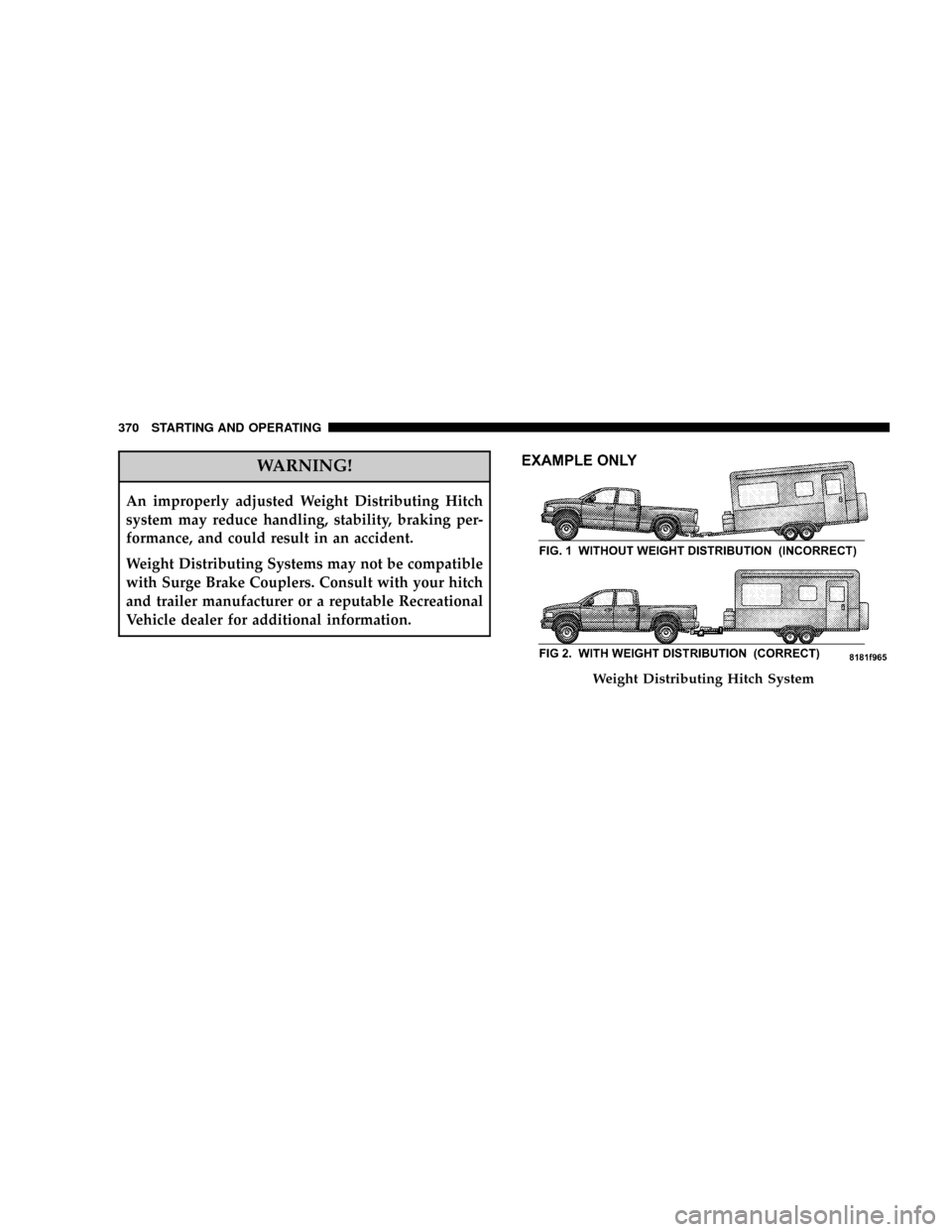

WARNING!

An improperly adjusted Weight Distributing Hitch

system may reduce handling, stability, braking per-

formance, and could result in an accident.

Weight Distributing Systems may not be compatible

with Surge Brake Couplers. Consult with your hitch

and trailer manufacturer or a reputable Recreational

Vehicle dealer for additional information.

Weight Distributing Hitch System

370 STARTING AND OPERATING