warning DODGE RAM 2500 POWER WAGON 2008 3.G Manual Online

[x] Cancel search | Manufacturer: DODGE, Model Year: 2008, Model line: RAM 2500 POWER WAGON, Model: DODGE RAM 2500 POWER WAGON 2008 3.GPages: 504, PDF Size: 8.17 MB

Page 299 of 504

point. Using tow straps requires coordination between

the two drivers. Good communication and line of sight

are required for a safe recovery. First connect the tow

strap to the correct attachment points on both vehicles.

There should be a least 20 to 30 feet between the

vehicles to allow for a safe recovery. If necessary join

two tow straps together using a 1

1¤2inch hard wood

dowel. This will keep the straps from becoming knot-

ted and is safer than using a clevis pin if the strap

breaks. Next have the tow vehicle backup, leaving 2 to

3 feet worth of slack in the strap. Then the tow vehicle,

using light throttle, should accelerate tightening the

strap providing the pulling force needed to free the

vehicle. The vehicle being recovered should assist in

the recovery, at the time of the snap, by slowly

spinning the tires in the same direction as the pulling

vehicle. After the vehicle becomes free, the driver of

the previously stuck vehicle should signal they are free

and should hit their brakes stopping both vehicles.The driver of the pulling vehicle should let off the

throttle without using the brakes, once signaled by the

other driver. This sequence is important to avoid

having the recovered vehicle hit the pulling vehicle.

WARNING!

Never use tow straps with end hooks or link two

straps with a clevis pin. These heavy metal objects

could become projectiles if a strap breaks, which

could cause severe injury. Never leave more than 2 or

3 feet of slack in the strap. More slack than this

greatly increases the risk of injury and vehicle dam-

age. Always keep everyone at least 30 feet away from

a strapping or winching situation.

STARTING AND OPERATING 299

5

Page 301 of 504

WARNING!

Winch cables are under high tension when in use and

can become a projectile if they fail. Never stand over

or straddle the winch cable. Never jerk or overload

the winch cable. Never stand in front of the vehicle

while winching. Failure to follow these instructions

can result in serious or fatal injury.

After Driving Off-Road

Off-road operation puts more stress on your vehicle than

does most on-road driving. After driving off-road, it is

always a good idea to check for damage.

²Completely inspect the underbody of your vehicle.

Check tires, body structure, steering, suspension, and

exhaust system for damage.

²Check threaded fasteners for looseness, particularly on

the chassis, drivetrain components, steering, and sus-

pension. Retighten them, if required, and torque to the

values specified in the Service Manual.

²Check for accumulations of plants or brush. These

things could be a fire hazard, or they might hide

damage to fuel lines, brake hoses, axle pinion seals,

and propeller shafts.

²After extended operation in mud, sand, water, or

similar dirty conditions, have brake drums and rotors,

brake linings, and axle yokes inspected and cleaned as

soon as possible.

²If you experience unusual vibration after driving in

mud, slush or similar conditions, check the wheels for

packed material. Packed foreign material can cause a

wheel imbalance and cleaning the wheels will correct

the situation.

STARTING AND OPERATING 301

5

Page 302 of 504

WARNING!

Abrasive material in any part of the brakes may cause

excessive wear or unpredictable braking. You might

not have full braking power when you need it to

prevent an accident. If you have been operating your

vehicle in dirty conditions, get your brakes checked

and cleaned as necessary. Failure to do so may result

is serious injury.

WINCH USAGE ± IF EQUIPPED

Things To Know Before Using Your Winch

General Winch Information

Your vehicle is equipped with an electric vehicle recovery

winch. This winch uses the electrical power from the

vehicle charging system to power a motor that windswire rope into the winch drum via planetary gear reduc-

tion. By nature, a winch is capable of generating very

high forces and should be used with care. Do not operate

the winch without reading and understanding the com-

plete winch owner's manual.

Tensioning the Wire Rope

The winch rope must be properly tensioned before use.

Follow the instructions below to tension the rope:

1. Un-spool the wire rope leaving 5 wraps of rope on the

winch drum.

2. Attach the hook to a suitable anchor point.

CAUTION!

Be certain the anchor will withstand the load re-

quired to tension the wire rope.

302 STARTING AND OPERATING

Page 307 of 504

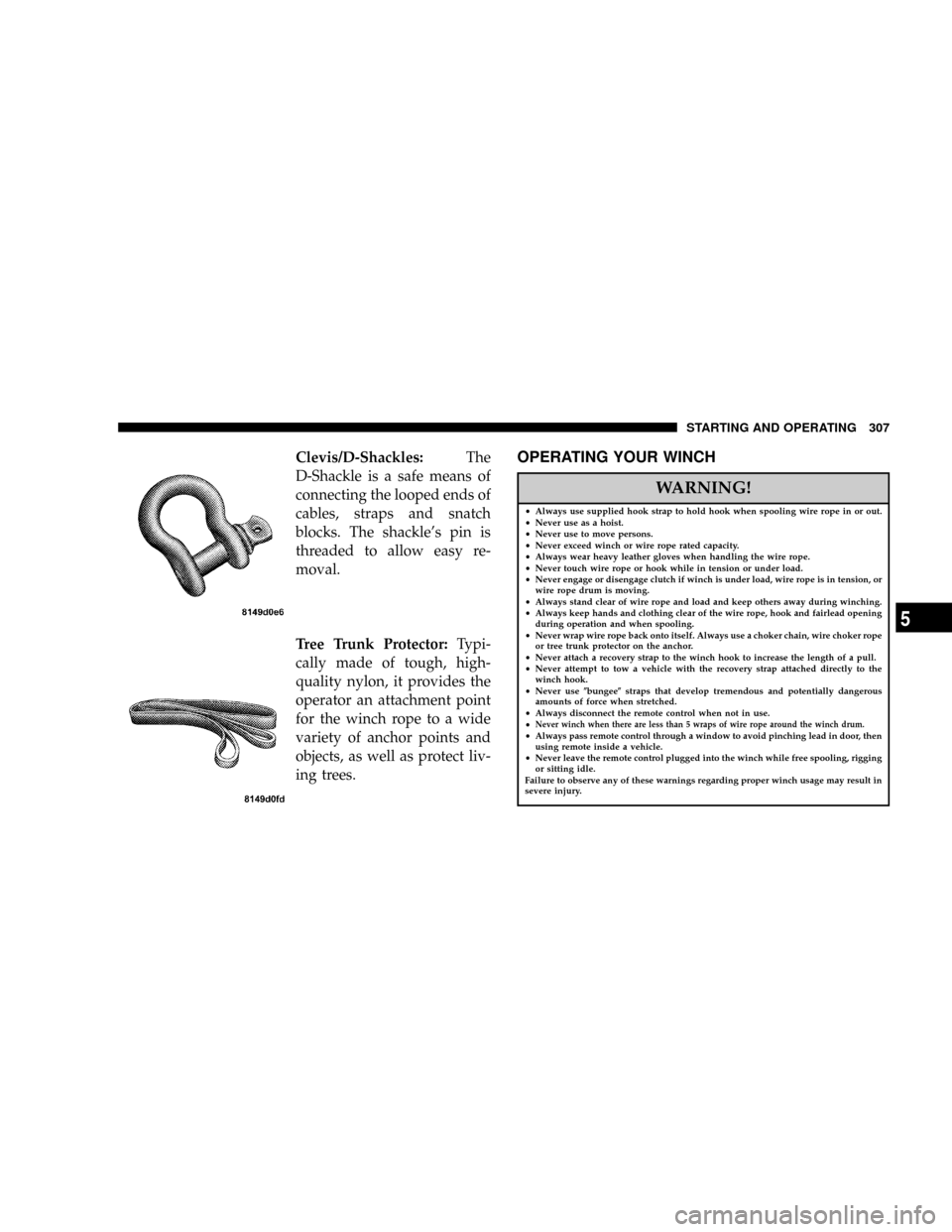

Clevis/D-Shackles:The

D-Shackle is a safe means of

connecting the looped ends of

cables, straps and snatch

blocks. The shackle's pin is

threaded to allow easy re-

moval.

Tree Trunk Protector:Typi-

cally made of tough, high-

quality nylon, it provides the

operator an attachment point

for the winch rope to a wide

variety of anchor points and

objects, as well as protect liv-

ing trees.OPERATING YOUR WINCH

WARNING!

²Always use supplied hook strap to hold hook when spooling wire rope in or out.

²Never use as a hoist.

²Never use to move persons.

²Never exceed winch or wire rope rated capacity.

²Always wear heavy leather gloves when handling the wire rope.

²Never touch wire rope or hook while in tension or under load.

²Never engage or disengage clutch if winch is under load, wire rope is in tension, or

wire rope drum is moving.

²Always stand clear of wire rope and load and keep others away during winching.

²Always keep hands and clothing clear of the wire rope, hook and fairlead opening

during operation and when spooling.

²Never wrap wire rope back onto itself. Always use a choker chain, wire choker rope

or tree trunk protector on the anchor.

²Never attach a recovery strap to the winch hook to increase the length of a pull.

²Never attempt to tow a vehicle with the recovery strap attached directly to the

winch hook.

²Never use(bungee(straps that develop tremendous and potentially dangerous

amounts of force when stretched.

²Always disconnect the remote control when not in use.

²

Never winch when there are less than 5 wraps of wire rope around the winch drum.²Always pass remote control through a window to avoid pinching lead in door, then

using remote inside a vehicle.

²Never leave the remote control plugged into the winch while free spooling, rigging

or sitting idle.

Failure to observe any of these warnings regarding proper winch usage may result in

severe injury.

STARTING AND OPERATING 307

5

Page 317 of 504

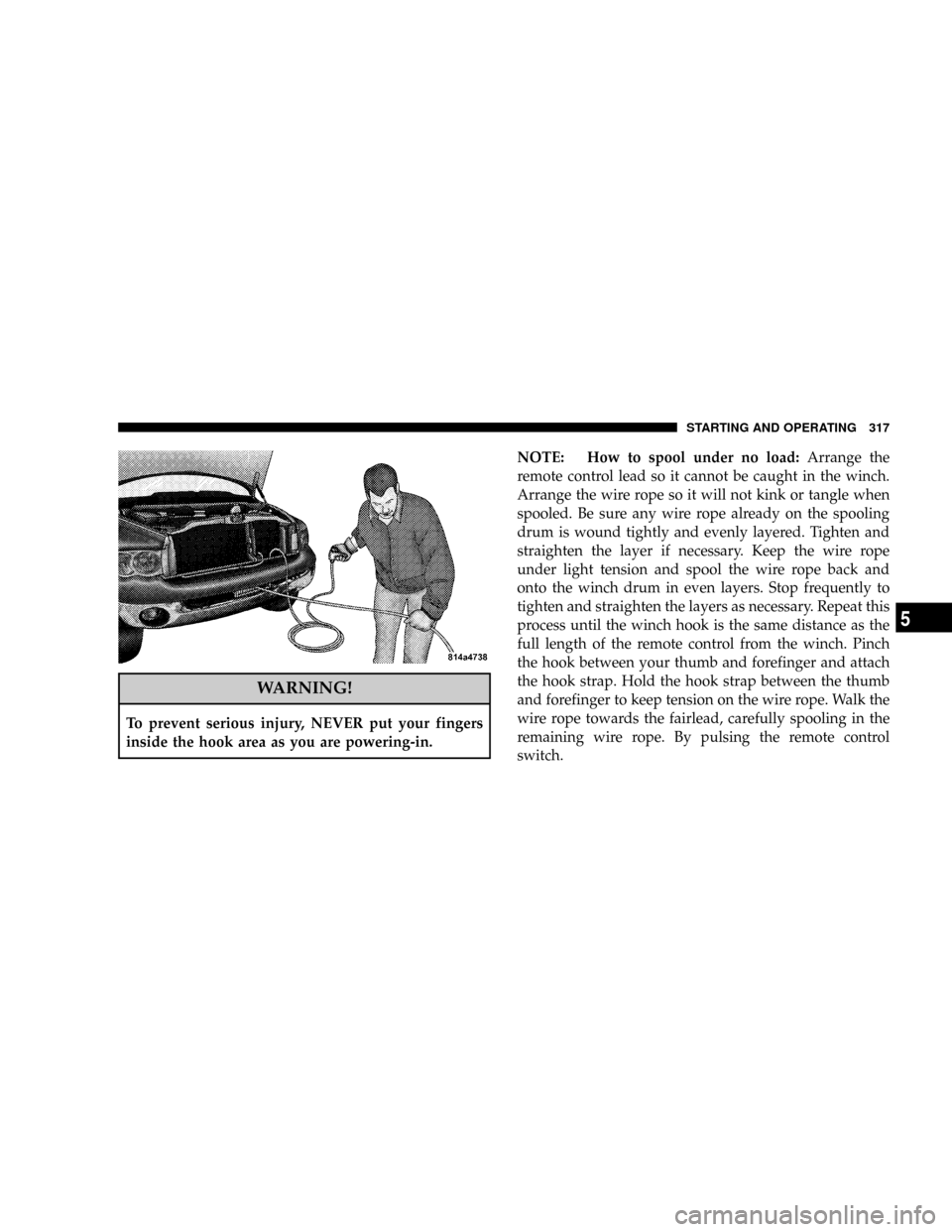

WARNING!

To prevent serious injury, NEVER put your fingers

inside the hook area as you are powering-in.NOTE: How to spool under no load:Arrange the

remote control lead so it cannot be caught in the winch.

Arrange the wire rope so it will not kink or tangle when

spooled. Be sure any wire rope already on the spooling

drum is wound tightly and evenly layered. Tighten and

straighten the layer if necessary. Keep the wire rope

under light tension and spool the wire rope back and

onto the winch drum in even layers. Stop frequently to

tighten and straighten the layers as necessary. Repeat this

process until the winch hook is the same distance as the

full length of the remote control from the winch. Pinch

the hook between your thumb and forefinger and attach

the hook strap. Hold the hook strap between the thumb

and forefinger to keep tension on the wire rope. Walk the

wire rope towards the fairlead, carefully spooling in the

remaining wire rope. By pulsing the remote control

switch.

STARTING AND OPERATING 317

5

Page 321 of 504

vehicle's frame/tow hook and run the wire rope through

a snatch block. Disengage the clutch and, using the

snatch block, pull out enough wire to reach your anchor

point. Do not attach hook to mounting kit. Secure to the

anchor point with a tree trunk protector or choker chain.

Attach the clevis/shackle. Attach the shackle to the two

ends of the strap/chain, being careful not to over tighten

(tighten and back-off 1/2 turn).

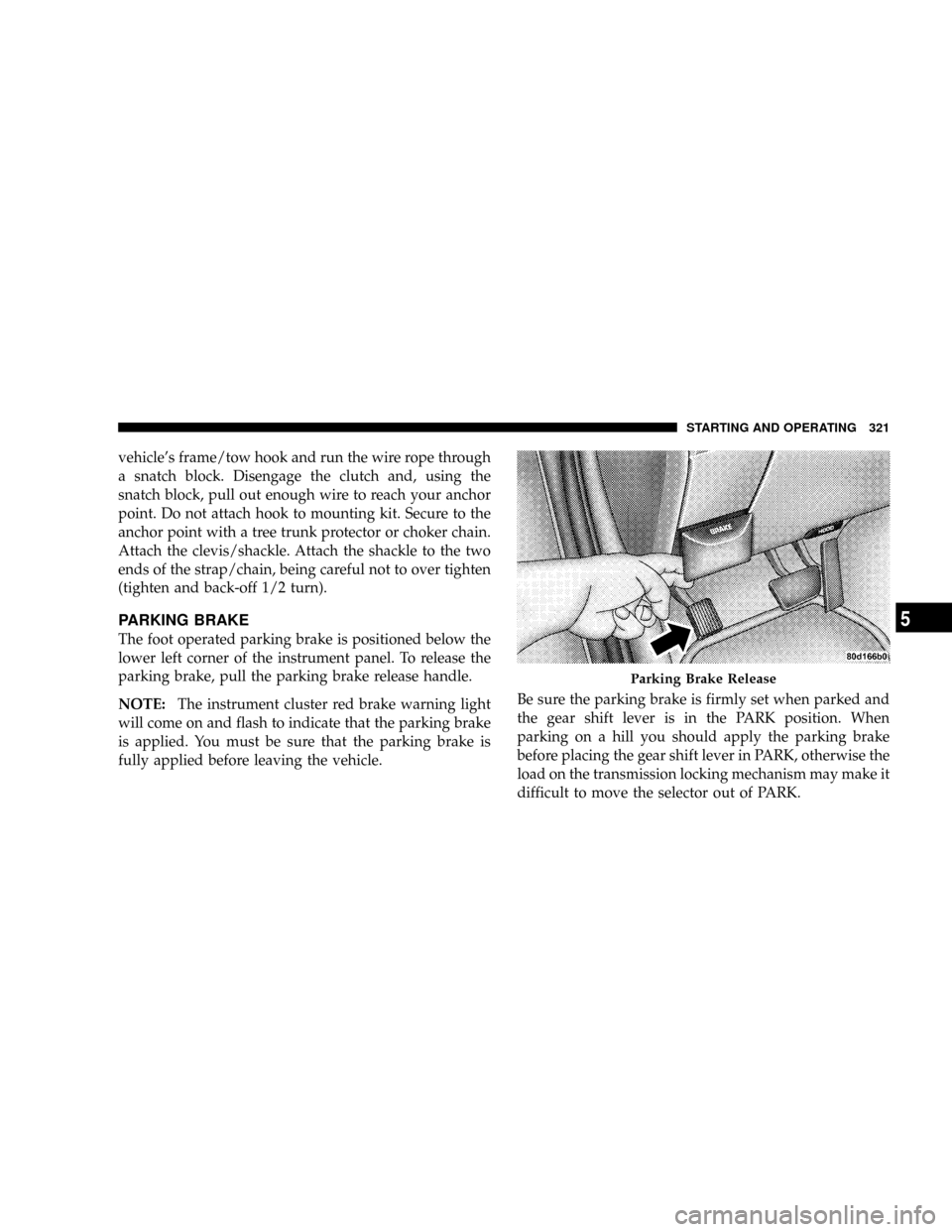

PARKING BRAKE

The foot operated parking brake is positioned below the

lower left corner of the instrument panel. To release the

parking brake, pull the parking brake release handle.

NOTE:The instrument cluster red brake warning light

will come on and flash to indicate that the parking brake

is applied. You must be sure that the parking brake is

fully applied before leaving the vehicle.Be sure the parking brake is firmly set when parked and

the gear shift lever is in the PARK position. When

parking on a hill you should apply the parking brake

before placing the gear shift lever in PARK, otherwise the

load on the transmission locking mechanism may make it

difficult to move the selector out of PARK.

Parking Brake Release

STARTING AND OPERATING 321

5

Page 322 of 504

WARNING!

²Always fully apply the parking brake when leav-

ing your vehicle, or it may roll and cause damage

or injury. Also be certain to leave an automatic

transmission in Park, a manual transmission in

Reverse or First gear. Failure to do so may allow

the vehicle to roll and cause damage or injury.

²Never leave children alone in a vehicle. Leaving

children in a vehicle unattended is dangerous for a

number of reasons. A child or others could be

seriously or fatally injured. Don't leave the keys in

the ignition. A child could operate power win-

dows, other controls, or move the vehicle.

²Be sure the parking brake is fully disengaged

before driving, failure to do so can lead to brake

problems due to excessive heating of the rear

brakes.When parking on a hill, turn the front wheels toward the

curb on a downhill grade and away from the curb on an

uphill grade.

The parking brake should always be applied whenever

the driver is not in the vehicle.

BRAKE SYSTEM

If power assist is lost for any reason (for example,

repeated brake applications with the engine off), the

brakes will still function. However, you will experience a

substantial increase in braking effort to stop the vehicle.

If either the front or rear hydraulic systems lose normal

capability, the remaining system will still function with

some loss of overall braking effectiveness. This will be

evident by increased pedal travel during application,

greater pedal force required to slow or stop, and activa-

tion of the BRAKE warning lamp and the ABS lamp (if

equipped) during brake use.

322 STARTING AND OPERATING

Page 323 of 504

Brake Noise

During normal operation of the brake system certain

noises may be present from time to time. Occasional

9groan9or9squeal9noises may occur during normal

operation of the brake system which may not be indica-

tive of a problem. These noises may be heard at any time

the brakes are applied but may be more noticeable during

the first few brake applications in the morning. Moisture,

hot or cold temperature, dust, and or other debris may

also contribute to the noise condition. Repeated or con-

tinuous noises during braking may be an indication that

the brake linings are worn and in need of replacement.

Four-Wheel Anti-Lock Brake System (ABS) ± If

Equipped

This Anti-lock Brake System is designed to aid the driver

in maintaining vehicle control under adverse braking

conditions. The system operates with a separate com-

puter to modulate hydraulic pressure to prevent wheel

lockup and help avoid skidding on slippery surfaces.The system's pump motor runs during an ABS stop to

provide regulated hydraulic pressure. The pump motor

makes a low humming noise during operation. This is

normal.

When you are in a severe braking condition involving

use of the Anti-lock Brake System, you will experience

some pedal drop as the vehicle comes to a complete stop.

This is the result of the system reverting to the base brake

system and is normal.

Engagement of the Anti-lock Brake System may be

accompanied by a pulsing sensation. You may also hear a

clicking noise. These occurrences are normal, and indi-

cate that the system is functioning.ABS Warning Light

The Anti-lock Brake System includes an amber warning

light. When the light is illuminated, the Anti-lock Brake

System is not functioning. The system reverts to standard

non-anti-lock brakes.

STARTING AND OPERATING 323

5

Page 324 of 504

WARNING!

Pumping of the anti-lock brakes will diminish their

effectiveness and may lead to an accident. Pumping

makes the stopping distance longer. Just press firmly

on your brake pedal when you need to slow down or

stop.

WARNING!

²Anti-lock system (ABS) cannot prevent the natural

laws of physics from acting on the vehicle, nor can

it increase braking or steering efficiency beyond

that afforded by the condition of the vehicle

brakes and tires or the traction afforded.

²The ABS cannot prevent accidents, including

those resulting from excessive speed in turns,

following another vehicle too closely, or hydro-

planing. Only a safe, attentive, and skillful driver

can prevent accidents.

²The capabilities of an ABS equipped vehicle must

never be exploited in a reckless or dangerous

manner which could jeopardize the user's safety

or the safety of others.

324 STARTING AND OPERATING

Page 325 of 504

POWER STEERING

The standard power steering system will give you good

vehicle response and increased ease of maneuverability

in tight spaces. The system will provide mechanical

steering capability if power assist is lost.

If for some reason, the power assist is interrupted, it will

still be possible to steer your vehicle. Under these condi-

tions you will observe a substantial increase in steering

effort, especially at very low vehicle speeds and during

parking maneuvers.

NOTE:Increased noise levels at the end of the steering

wheel travel are considered normal and does not indicate

that there is a problem with the power steering system.

Upon initial start-up in cold weather, the power steering

pump may make noise for a short period of time. This is

due to the cold, thick fluid in the steering system. This

noise should be considered normal, and does not in any

way damage the steering system.WARNING!

Continued operation with reduced power steering

assist could pose a safety risk to yourself and others.

Service should be obtained as soon as possible.

CAUTION!

Prolonged operation of the steering system at the end

of the steering wheel travel will increase the steering

fluid temperature and should be avoided when pos-

sible. Damage to the power steering pump may occur.

STARTING AND OPERATING 325

5