ECU DODGE RAM 2500 POWER WAGON 2008 3.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2008, Model line: RAM 2500 POWER WAGON, Model: DODGE RAM 2500 POWER WAGON 2008 3.GPages: 504, PDF Size: 8.17 MB

Page 168 of 504

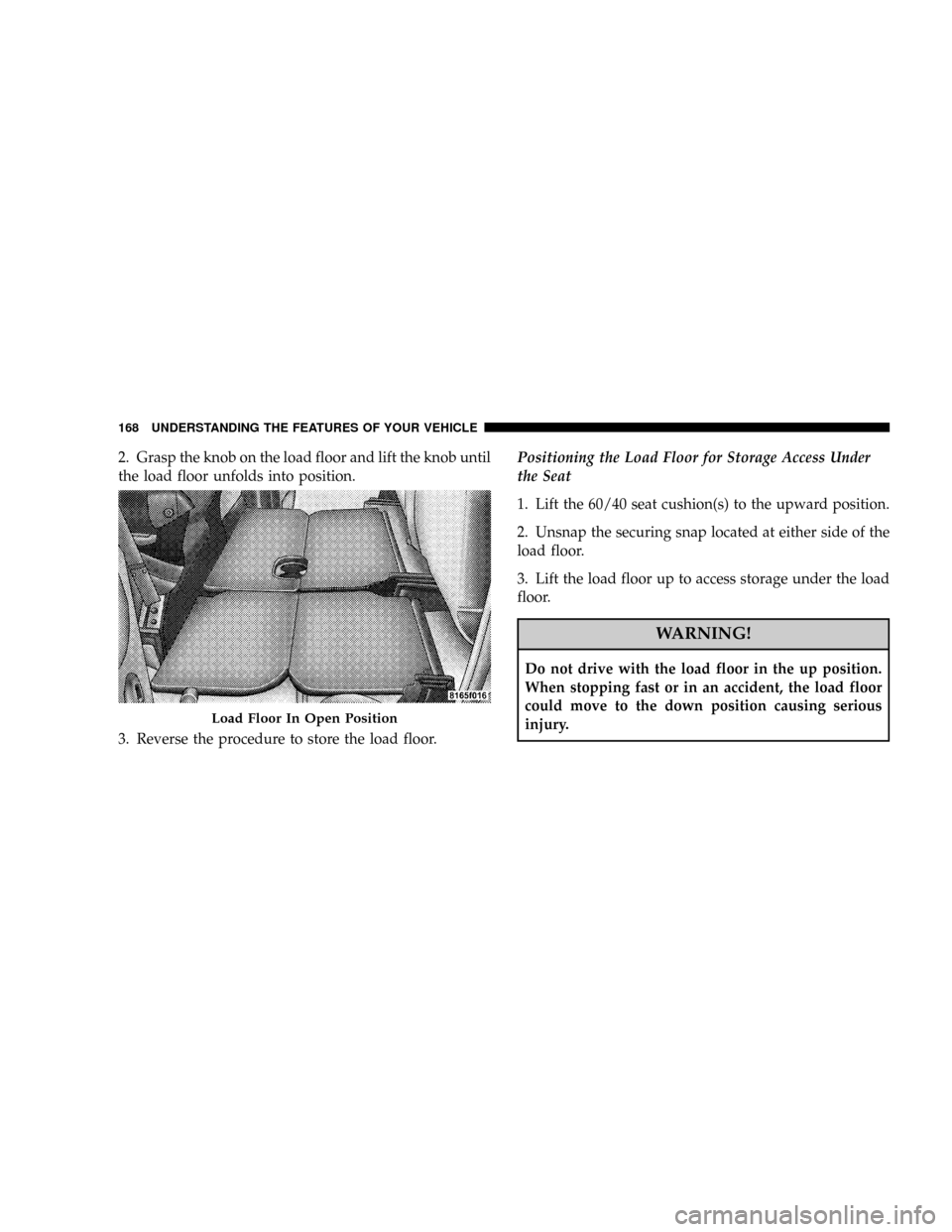

2. Grasp the knob on the load floor and lift the knob until

the load floor unfolds into position.

3. Reverse the procedure to store the load floor.Positioning the Load Floor for Storage Access Under

the Seat

1. Lift the 60/40 seat cushion(s) to the upward position.

2. Unsnap the securing snap located at either side of the

load floor.

3. Lift the load floor up to access storage under the load

floor.

WARNING!

Do not drive with the load floor in the up position.

When stopping fast or in an accident, the load floor

could move to the down position causing serious

injury.

Load Floor In Open Position

168 UNDERSTANDING THE FEATURES OF YOUR VEHICLE

Page 169 of 504

4. Reverse the procedure to put the load floor back in the

secured down position before you operate the vehicle.

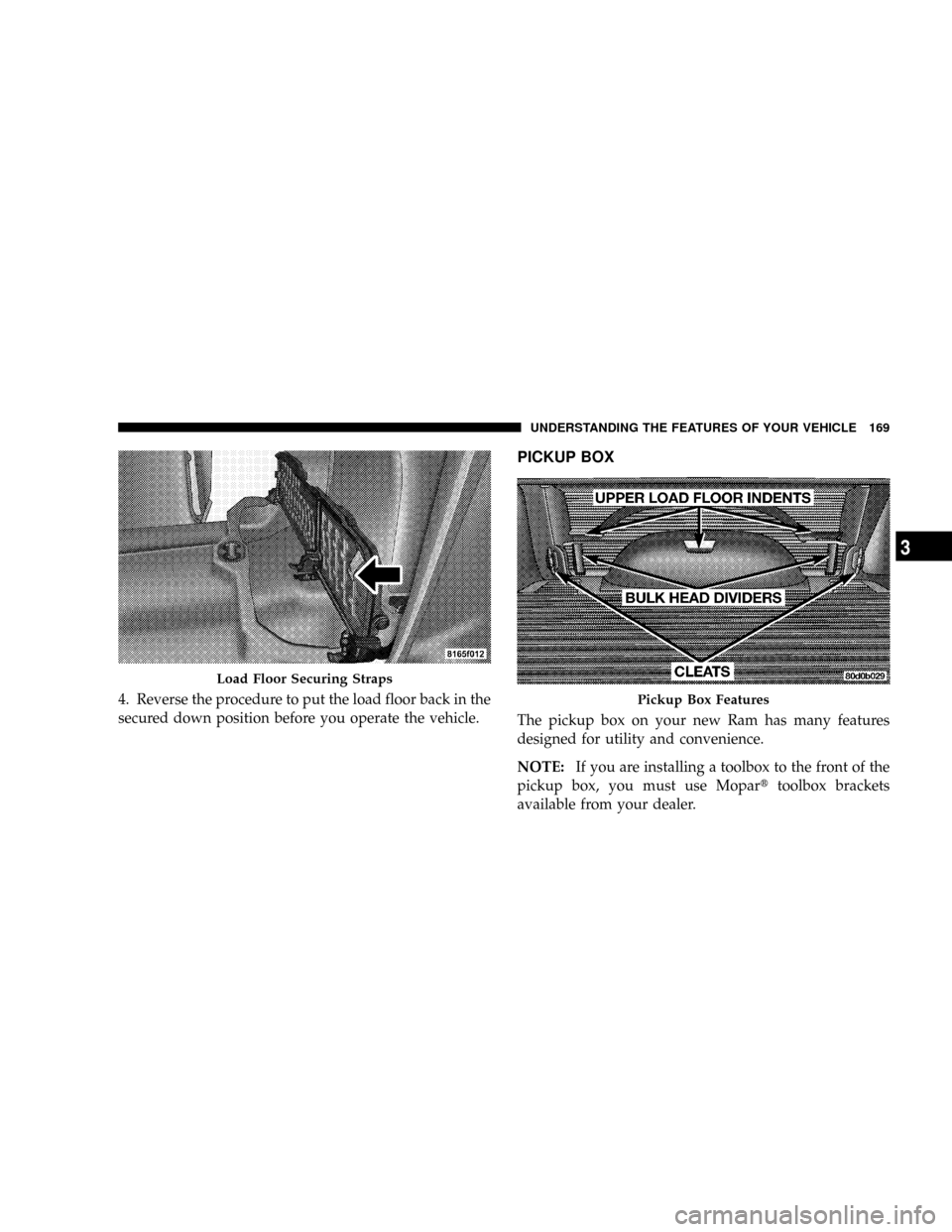

PICKUP BOX

The pickup box on your new Ram has many features

designed for utility and convenience.

NOTE:If you are installing a toolbox to the front of the

pickup box, you must use Moparttoolbox brackets

available from your dealer.

Load Floor Securing Straps

Pickup Box Features

UNDERSTANDING THE FEATURES OF YOUR VEHICLE 169

3

Page 182 of 504

CAUTION!

Do not leave your vehicle unattended with the en-

gine running as you would not be able to react to the

temperature indicator if the engine overheats.

NOTE:Engine idle speed will automatically increase to

1000 rpm at elevated coolant temperatures to improve

engine cooling.

NOTE:If the gauge pointer moves to either extreme of

the gauge, the ªCheck Gagesº indicator will illuminate

and a single chime will sound.

14. Security

The light will flash rapidly for approximately 16 seconds

when the vehicle theft alarm is arming. The light will

flash at a slower rate after the alarm is set. The security

light will also come on for about two seconds when the

ignition is first turned ON.15. Transmission Range Indicator (Automatic

Tranmissions Only)

When the gear selector lever is moved, this indicator

shows the automatic transmission gear range selected.

16. Odometer/Trip Odometer

The odometer shows the total distance the vehicle has

been driven. U.S. federal regulations require that upon

transfer of vehicle ownership, the seller certify to the

purchaser the correct mileage that the vehicle has been

driven. Therefore, if the odometer reading is changed

during repair or replacement, be sure to keep a record of

the reading before and after the service so that the correct

mileage can be determined.

The two trip odometers show individual trip mileage. To

switch from odometer to trip odometers, press and

release the Trip Odometer button.

182 UNDERSTANDING YOUR INSTRUMENT PANEL

Page 278 of 504

rear axles are unlocked. In the REAR LOCK position, the

rear axle is locked. In the FRONT/REAR position, the

front and rear axles are locked.

NOTE:Even when the axles are in the AXLE UNLOCK

position, the limited slip differential in the rear axle still

provides torque biasing capability for moderate low

traction environments.

During the command to lock the axle, the indicator light

will flash until the axle is locked. After the lock command

has been successfully executed, the light will remain on

solid.

To lock the rear axle, place the vehicle in 4LO by

following the procedure in Four Wheel Drive Operation,

located in this section of the manual. Move the axle

locker switch position to REAR LOCK while traveling

less than 3 MPH (5 KM/H). The RR indicator light will

remain on when the rear axle is locked.NOTE:Left to right wheel speed difference may be

necessary to allow the axle to fully lock. If the indicator

light is flashing after placing the switch in the REAR

LOCK or FRONT/REAR position, drive the vehicle in a

turn or on loose gravel to expedite the locking action.

WARNING!

Do not use the locked axle position for normal

driving. A locked front axle is intended for off-road

driving only. Locking the front axle during on-road

driving will reduce the steering ability. This could

cause an accident and you may be seriously injured.

To lock the front axle move the axle locker switch to

FRONT/REAR while travelingless than 3 MPH (5

KM/H). The indicator light will be solid when the front

axle is locked.

278 STARTING AND OPERATING

Page 286 of 504

CAUTION!

Never park your vehicle over dry grass or other

combustible materials. The heat from your vehicle

exhaust system could cause a fire.

WARNING!

Always wear your seat belt and firmly tie down

cargo. Unsecured cargo can become projectiles in an

off-road situation.

When To Use Low Range

When driving off-road, shift into 4L (Low range) for

additional traction or to improve handling and control on

slippery or difficult terrain. Due to the lower gearing, low

range will allow the engine to operate in a higher powerrange. This will allow you to idle over obstacles and

down hills, with improved control and less effort. Also,

use 4L (Low range) in rain, ice, snow, mud, sand, to get

heavy loads rolling, improve traction, or whenever 4H

(High range) traction will not do the job.

Driving in Snow, Mud and Sand

There is a drastic reduction in traction when driving in

snow, mud or sand. The vehicle will be less responsive to

steering, acceleration and braking inputs. Therefore you

should accelerate slowly, leave greater stopping distances

and avoid abrupt vehicle maneuvers. You want to keep a

slow constant steady pace. The key is to maintain the

vehicle's momentum.

²Snow± In heavy snow or for additional control and

traction at slower speeds, shift the transmission to a

low gear and shift the transfer case to 4L (Low) if

necessary. Don't shift to a lower gear than necessary to

maintain headway. Over-revving the engine can spin

286 STARTING AND OPERATING

Page 311 of 504

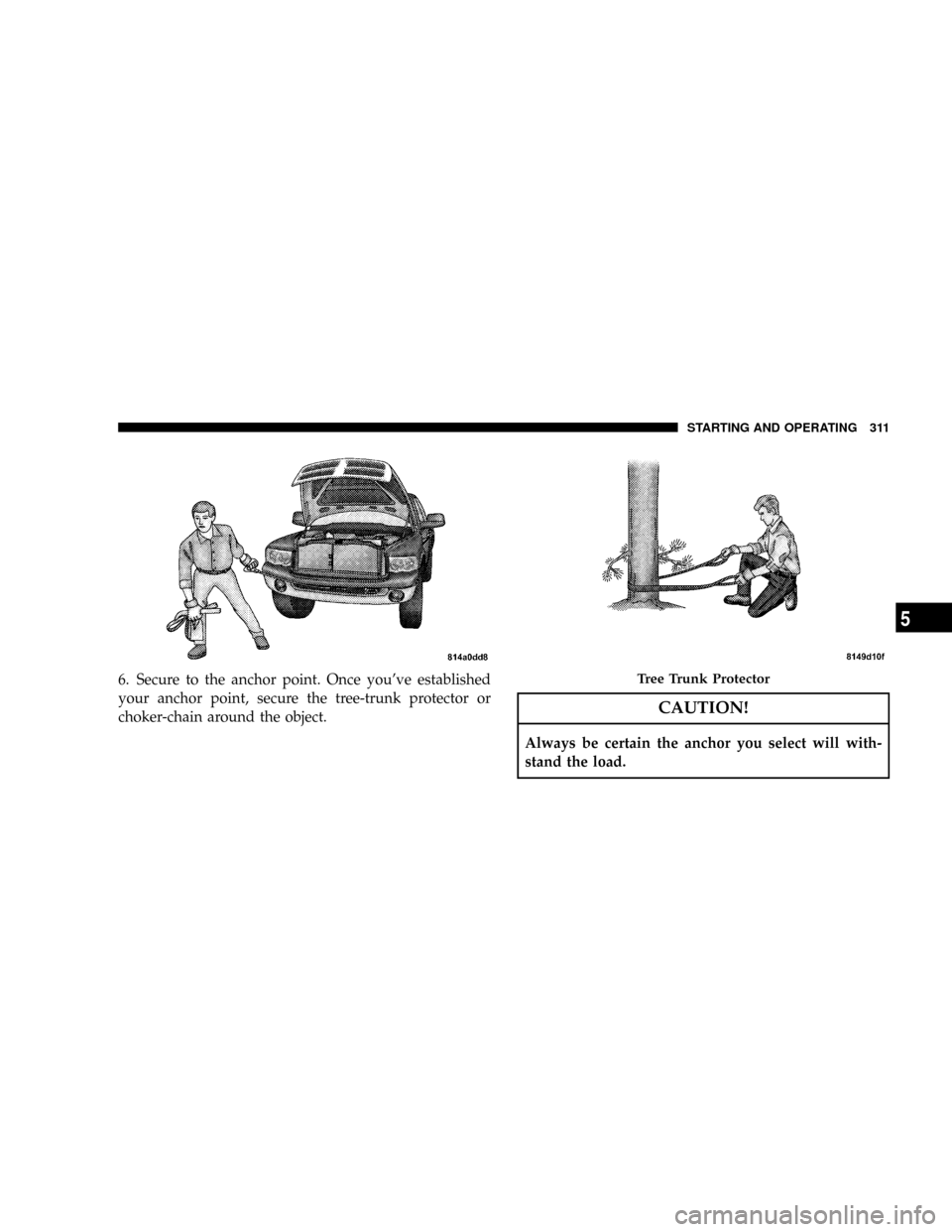

6. Secure to the anchor point. Once you've established

your anchor point, secure the tree-trunk protector or

choker-chain around the object.

CAUTION!

Always be certain the anchor you select will with-

stand the load.

Tree Trunk Protector

STARTING AND OPERATING 311

5

Page 312 of 504

NOTE: How to choose an anchor point:A secure

anchor is critical to winching operations. An anchor must

be strong enough to hold while winching. Natural an-

chors include trees, stumps and rocks. Hook the cable as

low as possible. If no natural anchors are available when

recovering another vehicle, your vehicle becomes the

anchor point. In this case, be sure to put the transmission

in neutral, apply the hand brake and block its wheels to

prevent your vehicle from moving. Ideally, you'll want

an anchor point that will enable you to pull straight in the

direction the vehicle will move. This allows the wire rope

to wind tightly and evenly onto the spooling drum. An

anchor point as far away as possible will provide the

winch with its greatest pulling power.

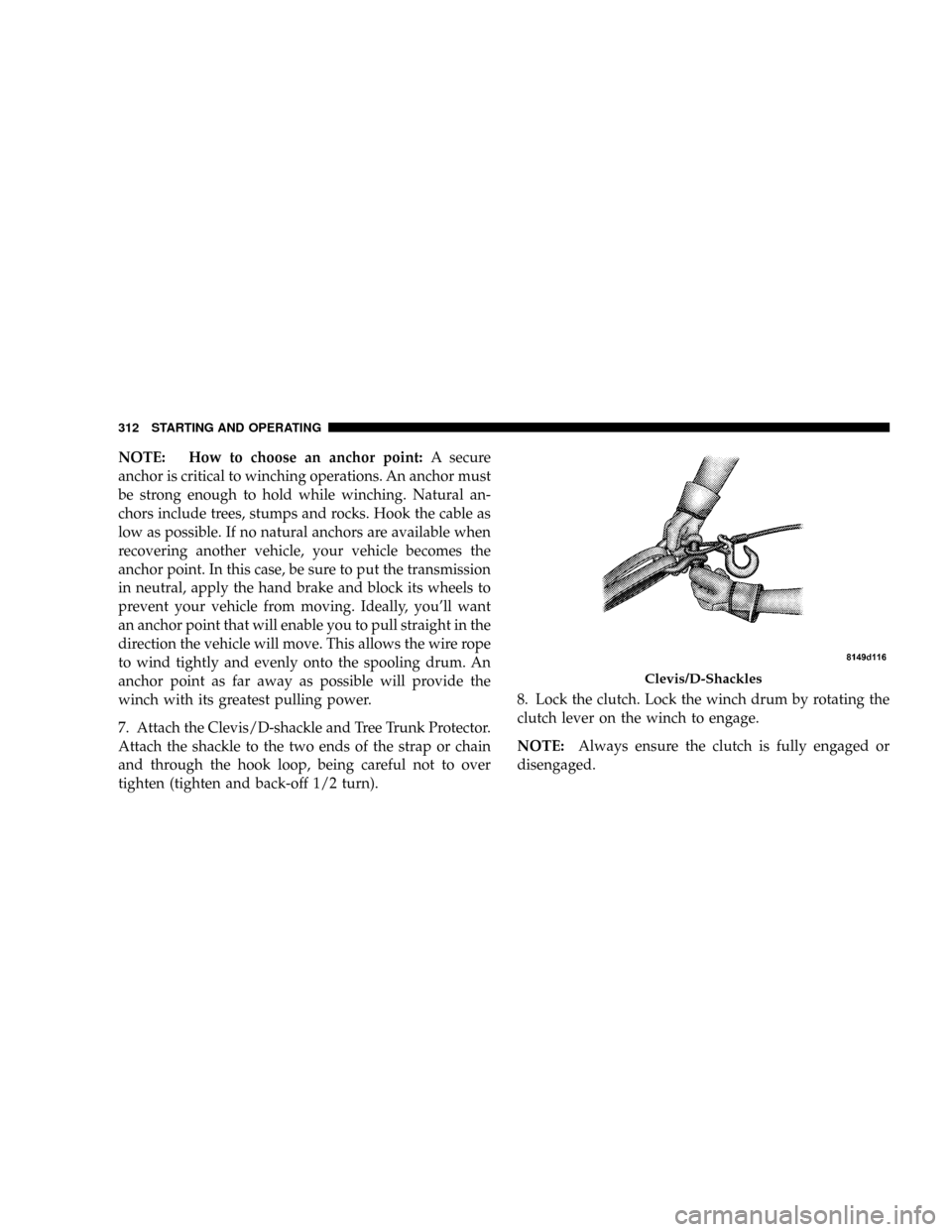

7. Attach the Clevis/D-shackle and Tree Trunk Protector.

Attach the shackle to the two ends of the strap or chain

and through the hook loop, being careful not to over

tighten (tighten and back-off 1/2 turn).8. Lock the clutch. Lock the winch drum by rotating the

clutch lever on the winch to engage.

NOTE:Always ensure the clutch is fully engaged or

disengaged.

Clevis/D-Shackles

312 STARTING AND OPERATING

Page 313 of 504

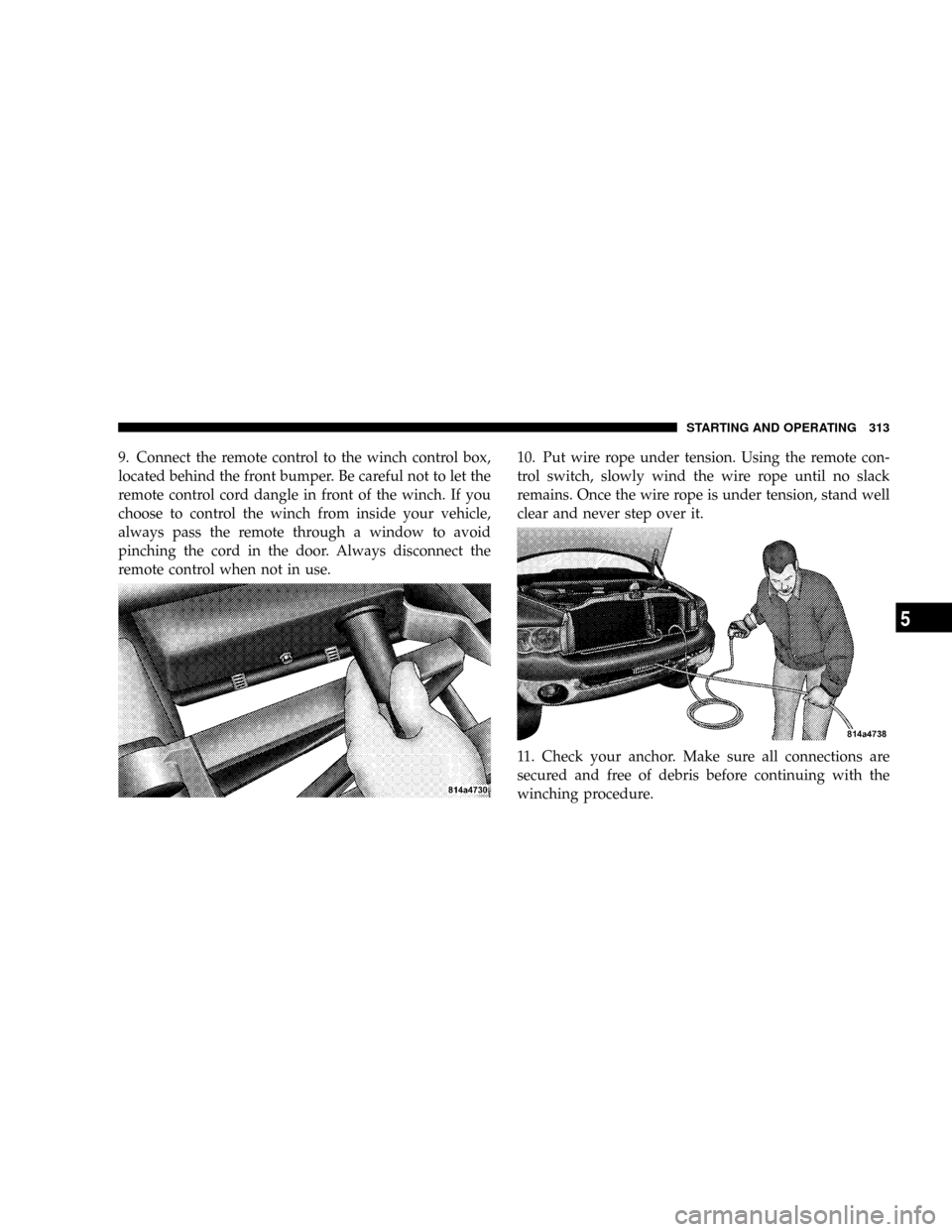

9. Connect the remote control to the winch control box,

located behind the front bumper. Be careful not to let the

remote control cord dangle in front of the winch. If you

choose to control the winch from inside your vehicle,

always pass the remote through a window to avoid

pinching the cord in the door. Always disconnect the

remote control when not in use.10. Put wire rope under tension. Using the remote con-

trol switch, slowly wind the wire rope until no slack

remains. Once the wire rope is under tension, stand well

clear and never step over it.

11. Check your anchor. Make sure all connections are

secured and free of debris before continuing with the

winching procedure.

STARTING AND OPERATING 313

5

Page 316 of 504

NOTE:Avoid overheating the winch motor. For ex-

tended winching, stop at reasonable intervals to allow

the winch motor to cool down.

NOTE: What to look for under load:The wire rope

must always spool onto the drum as indicated by the

drum rotation decal on the winch. As you power-in,

make sure the wire rope winds evenly and tightly on the

drum. This prevents the outer wire wraps from drawing

into the inner wraps, binding and damaging the wire

rope. Avoid shock loads by using the control switch

intermittently to take up wire rope slack. Shock loads can

momentarily far exceed the winch and wire rope ratings.

During side pulls the wire rope tends to stack up at one

end of the drum. This stack can become large enough to

cause serious damage to the winch. So, line up pulls as

straight ahead as possible and stop winching if the wire

rope comes close to the tie rods or mounting plate. To fixan uneven stack, spool out that section of the rope and

reposition it to the opposite end of the drum, which will

free up space for continued winching.

16. Secure vehicle. Once recovery of the vehicle is com-

plete, be sure to secure the vehicle's brakes and put the

transmission in9park9(automatic) or9low9gear for

9manual9transmissions. Release tension in the wire rope.

17. Disconnect wire rope. Disconnect from the anchor.

18. Rewind wire rope. The person handling the wire

rope should walk the rope in and not let it slide through

the hand, control the winch at all times.

316 STARTING AND OPERATING

Page 319 of 504

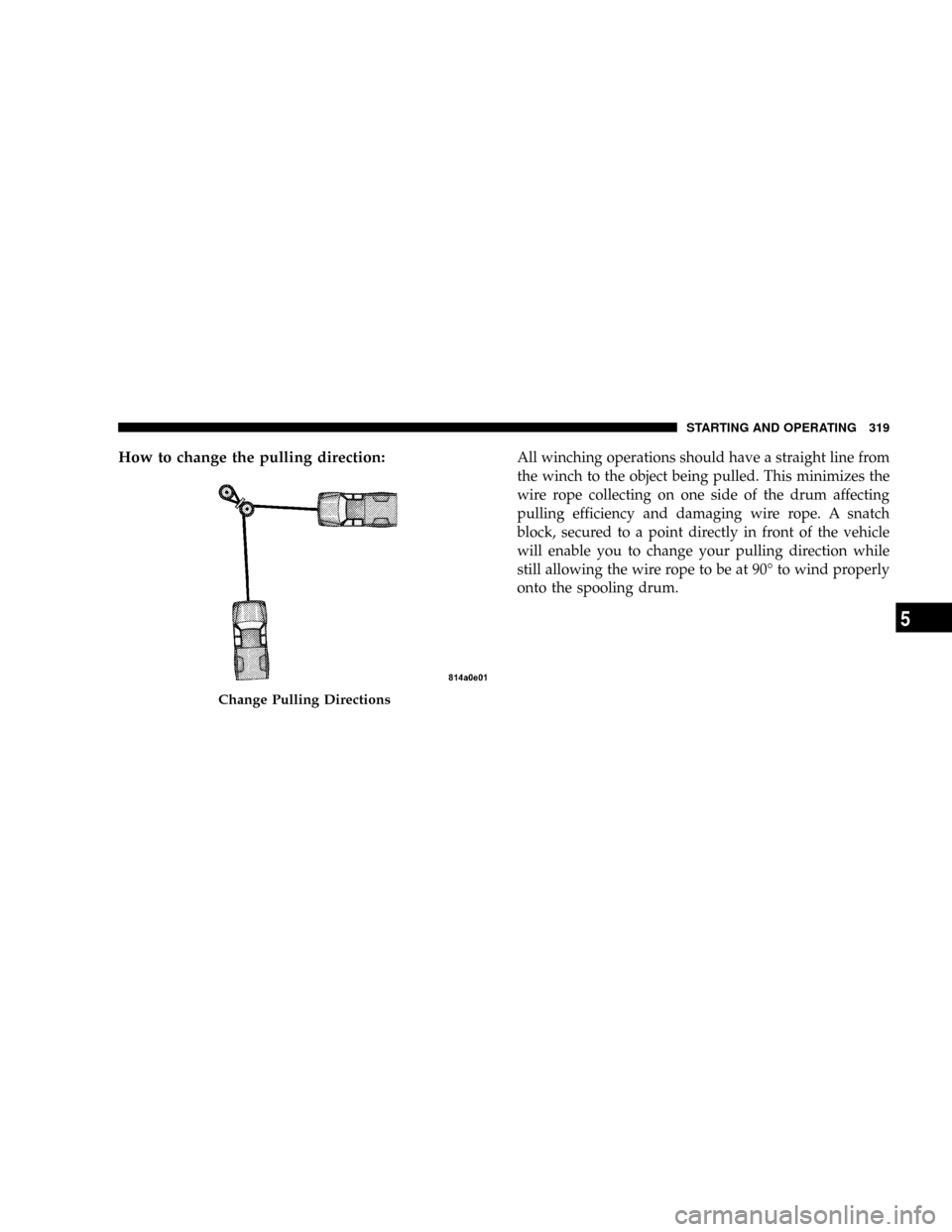

How to change the pulling direction:All winching operations should have a straight line from

the winch to the object being pulled. This minimizes the

wire rope collecting on one side of the drum affecting

pulling efficiency and damaging wire rope. A snatch

block, secured to a point directly in front of the vehicle

will enable you to change your pulling direction while

still allowing the wire rope to be at 90É to wind properly

onto the spooling drum.

Change Pulling Directions

STARTING AND OPERATING 319

5