engine DODGE RAM 3500 DIESEL 2008 3.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2008, Model line: RAM 3500 DIESEL, Model: DODGE RAM 3500 DIESEL 2008 3.GPages: 527, PDF Size: 8.88 MB

Page 443 of 527

The radiator normally remains completely full, so there is

no need to remove the radiator cap unless checking for

coolant freeze point or replacing coolant. Advise your

service attendant of this. As long as the engine operating

temperature is satisfactory, the coolant bottle need only

be checked once a month.

When additional coolant is needed to maintain the

proper level, it should be added to the coolant bottle. Do

not overfill.

Points To Remember

NOTE:When the vehicle is stopped after a few miles (a

few kilometers) of operation, you may observe vapor

coming from the front of the engine compartment. This is

normally a result of moisture from rain, snow, or high

humidity accumulating on the radiator and being vapor-

ized when the thermostat opens, allowing hot coolant to

enter the radiator.If an examination of your engine compartment shows no

evidence of radiator or hose leaks, the vehicle may be

safely driven. The vapor will soon dissipate.

²Do not overfill the coolant recovery bottle.

²Check coolant freeze point in the radiator and in the

coolant recovery bottle. If antifreeze needs to be

added, contents of coolant recovery bottle must also be

protected against freezing.

²If frequent coolant additions are required, or if the

level in the coolant recovery bottle does not drop when

the engine cools, the cooling system should be pres-

sure tested for leaks.

²Maintain coolant concentration at 50% HOAT engine

coolant (minimum) and distilled water for proper

corrosion protection of your engine which contains

aluminum components.

MAINTAINING YOUR VEHICLE 441

7

Page 444 of 527

²Make sure that the radiator and coolant recovery

bottle overflow hoses are not kinked or obstructed.

²Keep the front of the radiator clean. If your vehicle is

equipped with air conditioning, keep the front of the

condenser clean also.

²Do not change the thermostat for summer or winter

operation. If replacement is ever necessary, install

ONLY the correct type thermostat. Other designs may

result in unsatisfactory coolant performance, poor gas

mileage, and increased emissions.

Fan

Inspection

Check the fan for cracks and bent or broken blades. If any

of these conditions exist, you must replace the fan. Make

sure it is securely mounted.NOTE:This service procedure must be performed by a

trained service technician. Make arrangements with your

authorized dealer for this inspection.

Charge Air Cooler (Inter-Cooler)

The charge air cooler is positioned between the radiator

and the air conditioner condenser. Air enters the engine

through the air cleaner and passes through the turbo-

charger where it is pressurized. This pressurized air

rapidly reaches high temperature. The air is then directed

through a hose to the charge air cooler and through

another hose to the intake manifold of the engine. The air

entering the engine has been cooled by about 50 to 100

degrees Fahrenheit. This cooling process enables more

efficient burning of fuel resulting in fewer emissions.

442 MAINTAINING YOUR VEHICLE

Page 445 of 527

To guarantee optimum performance of the system, keep

the surfaces of the charge air cooler, condenser and

radiator clean and free of debris. Periodically check the

hoses leading to and from the charge air cooler for cracks

or loose clamps resulting in loss of pressure and reduced

engine performance.

Hoses And Vacuum/Vapor Harnesses

Inspect surfaces of hoses and nylon tubing for evidence

of heat and mechanical damage. Hard or soft spots,

brittle rubber, cracking, tears, cuts, abrasions, and exces-

sive swelling indicate deterioration of the rubber.

Pay particular attention to those hoses nearest to high

heat sources such as the exhaust manifold. Inspect hose

routing to be sure hoses do not come in contact with any

heat source or moving component that may cause heat

damage or mechanical wear.Insure nylon tubing in these areas has not melted or

collapsed.

Inspect all hose connections such as clamps and cou-

plings to make sure they are secure and no leaks are

present.

Components should be replaced immediately if there is

any evidence of wear or damage that could cause failure.

Brake System

Power Disc Brakes (Front and Rear)

Disc brakes do not require adjustment; however, several

hard stops during the break-in period are recommended

to seat the linings and wear off any foreign material.

MAINTAINING YOUR VEHICLE 443

7

Page 447 of 527

WARNING!

Overfilling the brake fluid reservoir can result in

spilling brake fluid on hot engine parts and the

brake fluid catching fire.

Use only brake fluid that has been in a tightly closed

container to avoid contamination from foreign matter or

moisture.

CAUTION!

Do not allow a petroleum-base fluid to contaminate

the brake fluid. Seal damage and loss of brake

performance may result.

Brake Hoses

Inspection should be performed whenever the brake

system is serviced or at intervals specified. Inspect hy-

draulic brake hoses for surface cracking, scuffing or worn

spots. If there is any evidence of cracking, scuffing, or

worn spots, the hose should be replaced immediately!

Eventual deterioration of the hose can take place with

possible burst failure.

Clutch Linkage

If the clutch pedal linkage begins to squeak or grunt, the

clutch pedal pivot bushings should be lubricated. Refer

to Fluids, Lubricants and Genuine Parts for the correct

lubricant type. Multipurpose Grease, NLGI Grade 2 E.P.

Clutch Hydraulic System

The clutch hydraulic system is a sealed maintenance-free

system. In the event of leakage or other malfunction, the

system must be replaced.

MAINTAINING YOUR VEHICLE 445

7

Page 450 of 527

CAUTION!

Using a transmission fluid other than the manufac-

turers recommended fluid may cause deterioration in

transmission shift quality and/or torque converter

shudder. Using a transmission fluid other than the

manufacturers recommended fluid will result in

more frequent fluid and filter changes. Refer to

Fluids, Lubricants and Genuine Parts for correct

fluid type.

Fluid Level Check

If equipped with a dipstick, use the following procedure.

If your vehicle has a capped dipstick tube, it is sealed and

should not be tampered with. Your authorized dealer has

the proper tools to ensure that the fluid level is set

properly. The fluid level should be checked when theengine is fully warmed up and the fluid in the transmis-

sion is at normal operating temperature. Operation of the

transmission with an improper fluid level will greatly

reduce the life of the transmission and of the fluid. Check

the fluid level whenever the vehicle is serviced.

Procedure For Checking Fluid Level

To properly check the automatic transmission fluid level,

the following procedure must be used:

1. Operate the engine at idle speed and normal operating

temperature.

2. The vehicle must be on level ground.

3. Fully apply the parking brake and press the brake

pedal.

4. Place the gear selector momentarily in each gear

position ending with the lever in PARK.

448 MAINTAINING YOUR VEHICLE

Page 452 of 527

Automatic Transmission Fluid and Filter Change

To obtain best performance and long life for automatic

transmissions, the manufacturer recommends that they

be given regular maintenance service by an authorized

dealer or Service Center. It is important that the trans-

mission fluid is maintained at the correct level, and that

it is drained and refilled as specified.

Use only manufacturer 's recommended transmission

fluid; for correct fluid type, refer to ªAutomatic Trans-

missionº under ªFluids, Lubricants and Genuine Partsº

in this section. It is important that the transmission fluid

be maintained at the prescribed level using the recom-

mended fluid..

The fluid and filter(s) should be changed as specified in

the Maintenance Schedule (Section 8).

NOTE:If the transmission is disassembled for any

reason, the fluid and filter should be changed.

Special Additives

Automatic Transmission Fluid (ATF) is an engineered

product and its performance may be impaired by supple-

mental additives. Therefore, do not add any fluid addi-

tives to the transmission. The only exception to this

policy is the use of special dyes to aid in detecting fluid

leaks. In addition, avoid using transmission sealers as

they may adversely affect seals.

Front Wheel Bearings

Front wheel bearings for your vehicle are sealed-for-life.

They do not require greasing or seal replacement. In

some instances, these bearings will ªpurgeº excess grease

and the bearing housing will look slightly wet. This is

normal.

²Periodic inspection for excess play is recommended.

²If a bearing assembly is accidentally separated when

servicing the brake rotors, it should be replaced.

450 MAINTAINING YOUR VEHICLE

Page 455 of 527

Among those acts presumed to constitute tampering are

the acts listed below.

²AIR CLEANER

þRemoval of the air cleaner.

þRemoval of the air cleaner filter element from the air

cleaner housing.

þRemoval of the air ducting.

²EXHAUST SYSTEM

þRemoval or rendering inoperative exhaust system

components, including the muffler or tailpipe.

²ENGINE COOLING SYSTEM

þRemoval or rendering inoperative the fan clutch.

þRemoval of the fan shroud.

Noise Emission Warranty

The manufacturer warrants that this vehicle as manufac-

tured by the manufacturer, was designed, built and

equipped to conform at the time it left the manufacturer's

control with all applicable U.S. EPA Noise Control Regu-

lations.

This warranty covers this vehicle as designed, built and

equipped by the manufacturer, and is not limited to any

particular part, component or system of the vehicle

manufactured by the manufacturer. Defects in design,

assembly or in any part, component or system of the

vehicle as manufactured by the manufacturer, which, at

the time it left the manufacturer's control, caused noise

emissions to exceed Federal standards, are covered by

this warranty for the life of the vehicle.

MAINTAINING YOUR VEHICLE 453

7

Page 456 of 527

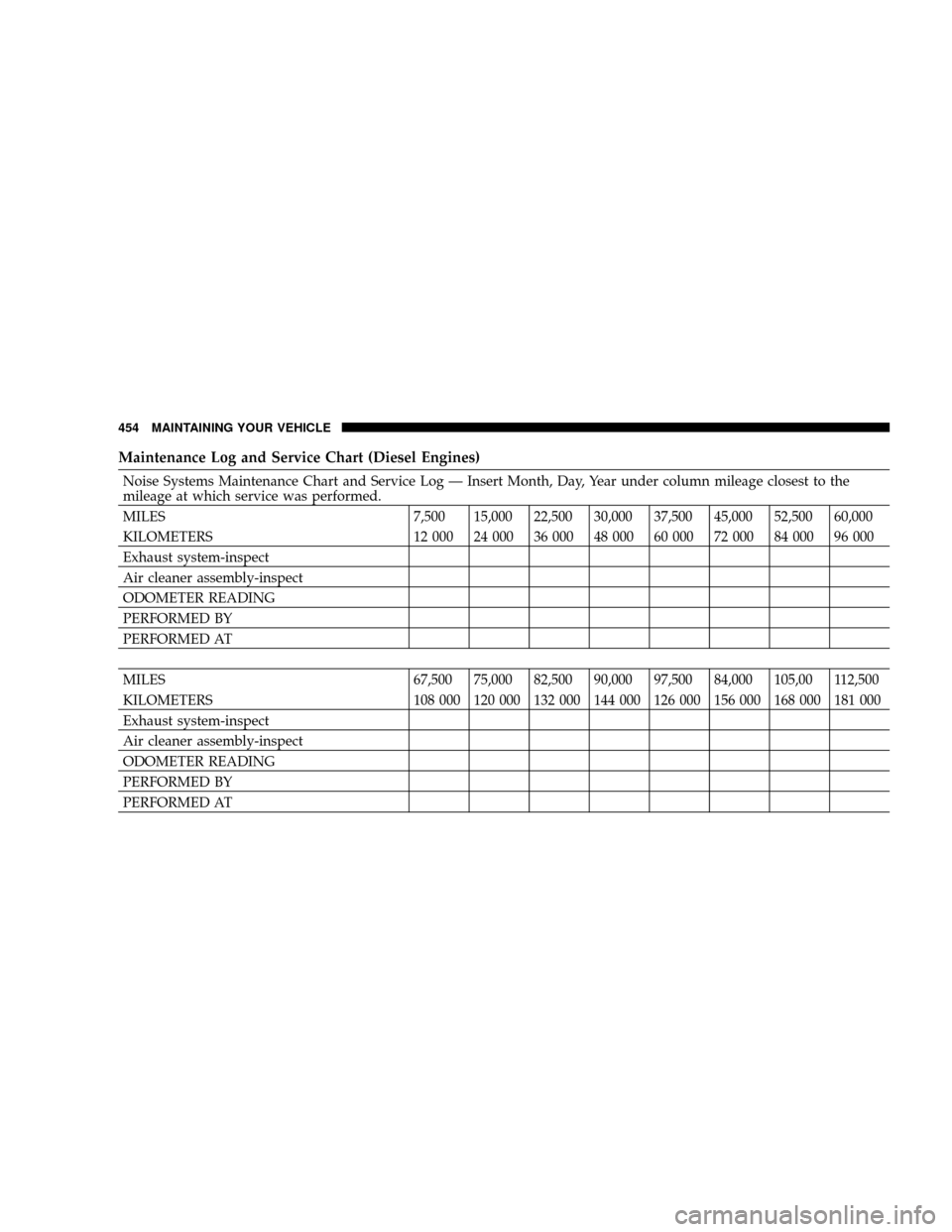

Maintenance Log and Service Chart (Diesel Engines)

Noise Systems Maintenance Chart and Service Log Ð Insert Month, Day, Year under column mileage closest to the

mileage at which service was performed.

MILES 7,500 15,000 22,500 30,000 37,500 45,000 52,500 60,000

KILOMETERS 12 000 24 000 36 000 48 000 60 000 72 000 84 000 96 000

Exhaust system-inspect

Air cleaner assembly-inspect

ODOMETER READING

PERFORMED BY

PERFORMED AT

MILES 67,500 75,000 82,500 90,000 97,500 84,000 105,00 112,500

KILOMETERS 108 000 120 000 132 000 144 000 126 000 156 000 168 000 181 000

Exhaust system-inspect

Air cleaner assembly-inspect

ODOMETER READING

PERFORMED BY

PERFORMED AT

454 MAINTAINING YOUR VEHICLE

Page 461 of 527

1. Clean with a wet soft rag. A mild soap solution may be

used, but do not use high alcohol content or abrasive

cleaners. If soap is used, wipe clean with a clean damp

rag.

2. Dry with a soft tissue.

Seat Belt Maintenance

Do not bleach, dye or clean the belts with chemical

solvents or abrasive cleaners. This will weaken the fabric.

Sun damage can also weaken the fabric.

If the belts need cleaning, use a mild soap solution or

lukewarm water. Do not remove the belts from the car to

wash them.

Replace the belts if they appear frayed or worn or if the

buckles do not work properly.

Dry with a soft tissue.

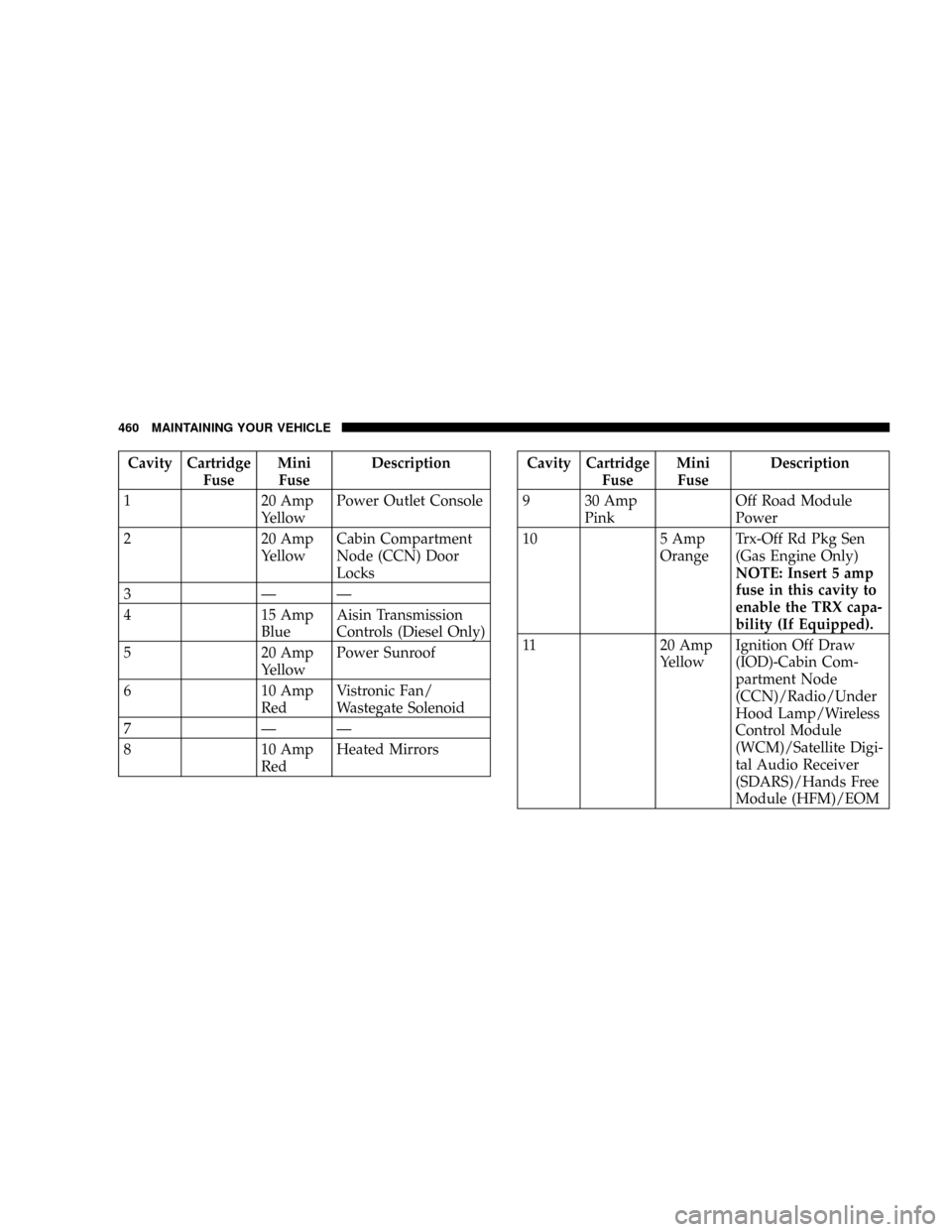

FUSES (INTEGRATED POWER MODULE)

An integrated power module is located in the engine

compartment near the battery. This center contains car-

tridge fuses and mini fuses. A description of each fuse

and component may be stamped on the inside cover,

otherwise the cavity number of each fuse is stamped on

the inside cover that corresponds to the following chart.

Integrated Power Module Location

MAINTAINING YOUR VEHICLE 459

7

Page 462 of 527

Cavity Cartridge

FuseMini

FuseDescription

1 20 Amp

YellowPower Outlet Console

2 20 Amp

YellowCabin Compartment

Node (CCN) Door

Locks

3ÐÐ

4 15 Amp

BlueAisin Transmission

Controls (Diesel Only)

5 20 Amp

YellowPower Sunroof

6 10 Amp

RedVistronic Fan/

Wastegate Solenoid

7ÐÐ

8 10 Amp

RedHeated MirrorsCavity Cartridge

FuseMini

FuseDescription

9 30 Amp

PinkOff Road Module

Power

10 5 Amp

OrangeTrx-Off Rd Pkg Sen

(Gas Engine Only)

NOTE: Insert 5 amp

fuse in this cavity to

enable the TRX capa-

bility (If Equipped).

11 20 Amp

YellowIgnition Off Draw

(IOD)-Cabin Com-

partment Node

(CCN)/Radio/Under

Hood Lamp/Wireless

Control Module

(WCM)/Satellite Digi-

tal Audio Receiver

(SDARS)/Hands Free

Module (HFM)/EOM

460 MAINTAINING YOUR VEHICLE