sensor DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 3715 of 5267

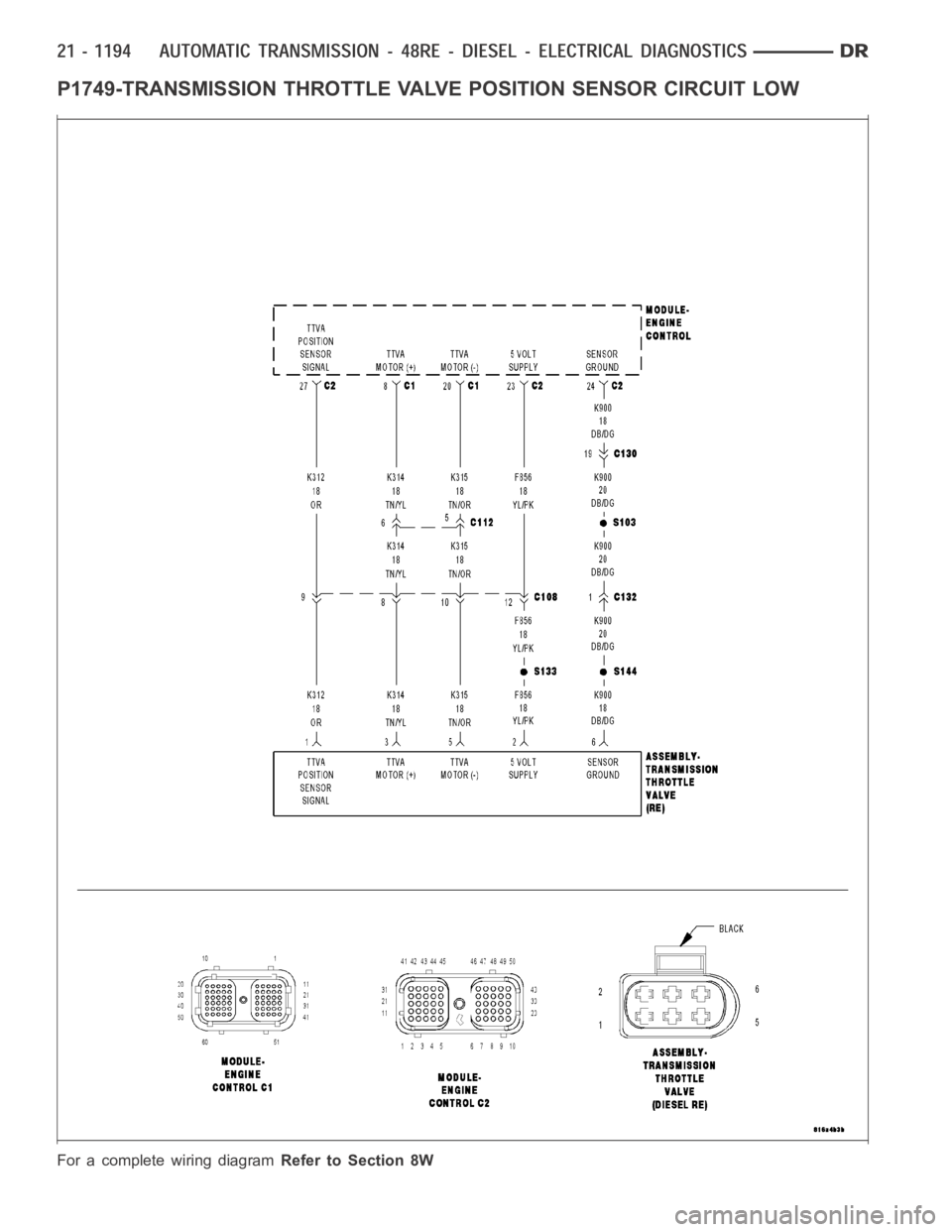

P1749-TRANSMISSION THROTTLE VALVE POSITION SENSOR CIRCUIT LOW

For a complete wiring diagramRefer to Section 8W

Page 3716 of 5267

Theory of Operation

The transmission throttle valve cable has been replace by the transmission throttle valve actuator (TTVA). The TTVA

consists of an electric DC motor, two potentiometers, and a gear drive system. The TTVA is mechanically connected

to the transmission throttle valve in the valve body by the “D” shaped opening in the bottom of the TTVA shaft.

The Transmission Throttle Valve Actuator (TTVA) does not require any mechanical adjustments. All changes in throt-

tle valve position are controlled by the Engine Control Module (ECM).

The TTVA does require an initialization period after the actuator has beenremoved or replaced. After the actuator

has been removed or replaced, move the ignition to the ON position for thirty (30) seconds. This will allow the ECM

sufficient time to perform the internal calibration procedures to learn the TTVA’s current “zero” position.

When Monitored:

Continuously with the ignition on.

Set Condition:

When the Engine Control Module (ECM) detects the monitored Transmission Throttle Valve Position Sensor

voltage drops below a predetermined value.

Possible Causes

(K312) TTVA POSITION SENSOR SIGNAL CIRCUIT OPEN

(K312) TTVA POSITION SENSOR SIGNAL CIRCUIT SHORT TO GROUND

(K312) TTVA POSITION SENSOR SIGNAL CIRCUIT SHORT TO ANOTHER CIRCUIT

(F856) 5 VOLT SUPPLY CIRCUIT OPEN

(F856) 5 VOLT SUPPLY CIRCUIT SHORT TO GROUND

(F856) 5 VOLT SUPPLY CIRCUIT SHORT TO ANOTHER CIRCUIT

TRANSMISSION THROTTLE VALVE ACTUATOR

ENGINE CONTROL MODULE

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

Diagnostic Test

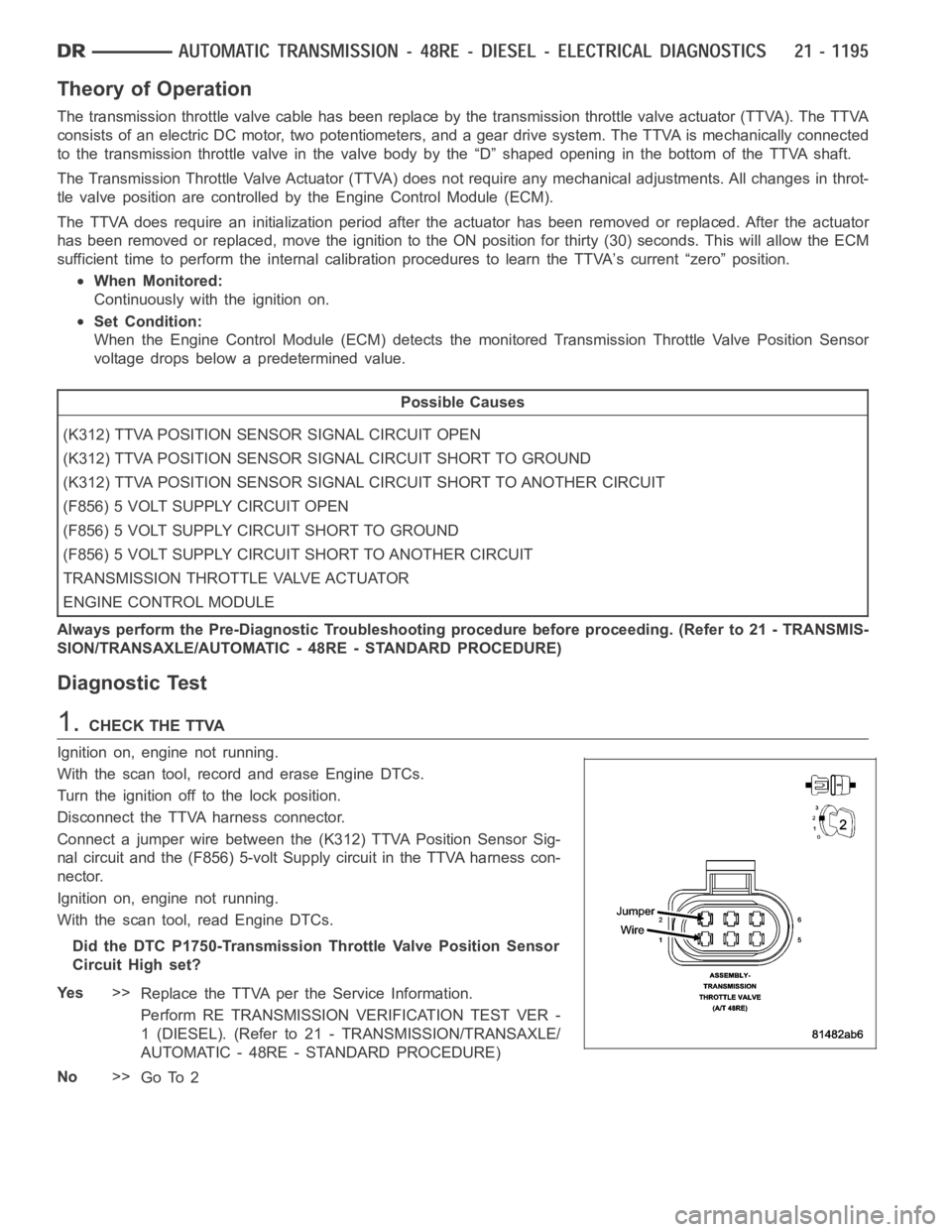

1.CHECK THE TTVA

Ignition on, engine not running.

With the scan tool, record and erase Engine DTCs.

Turn the ignition off to the lock position.

Disconnect the TTVA harness connector.

Connect a jumper wire between the (K312) TTVA Position Sensor Sig-

nal circuit and the (F856) 5-volt Supply circuit in the TTVA harness con-

nector.

Ignition on, engine not running.

With the scan tool, read Engine DTCs.

Did the DTC P1750-Transmission Throttle Valve Position Sensor

Circuit High set?

Ye s>>

Replace the TTVA per the Service Information.

Perform RE TRANSMISSION VERIFICATION TEST VER -

1 (DIESEL). (Refer to 21 - TRANSMISSION/TRANSAXLE/

AUTOMATIC - 48RE - STANDARD PROCEDURE)

No>>

Go To 2

Page 3717 of 5267

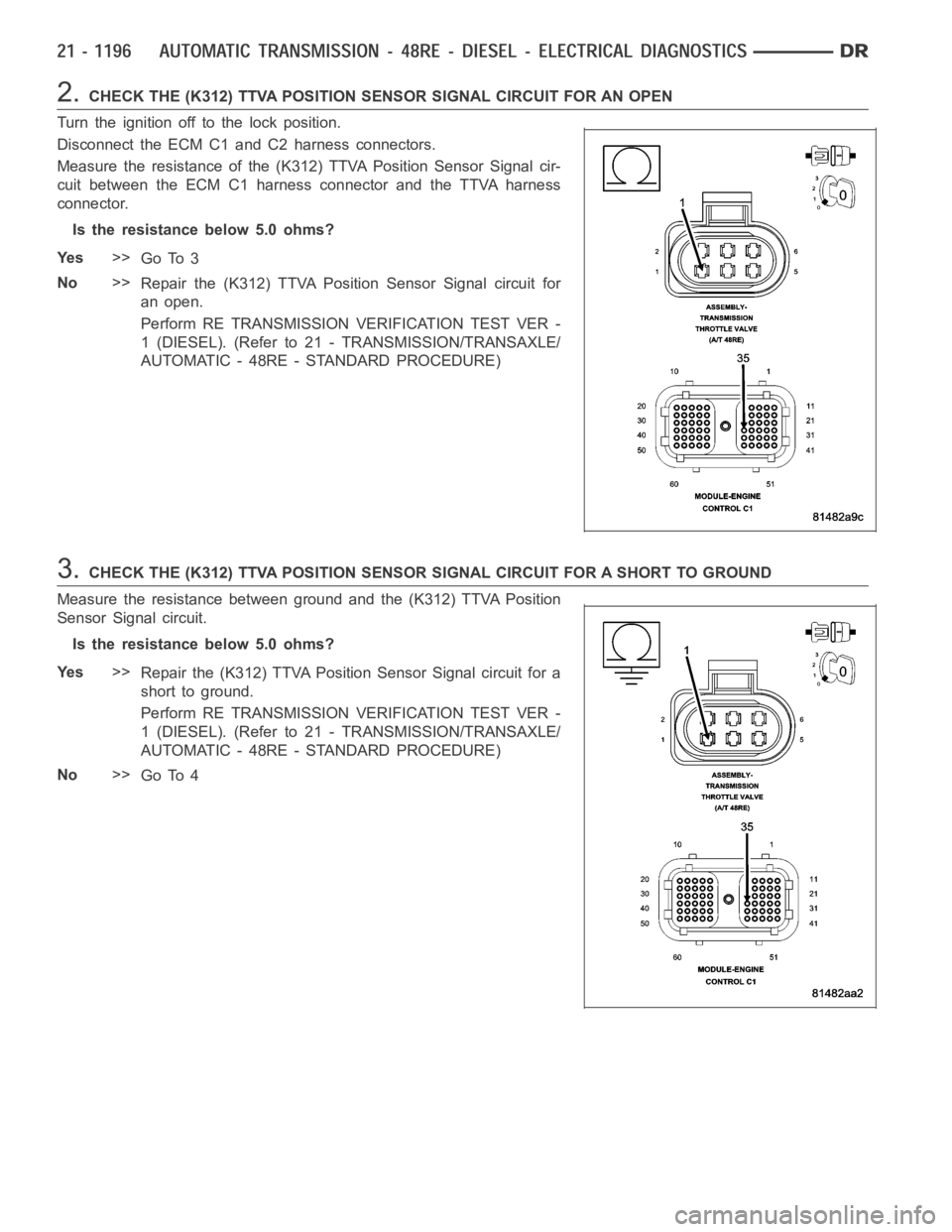

2.CHECK THE (K312) TTVA POSITION SENSOR SIGNAL CIRCUIT FOR AN OPEN

Turn the ignition off to the lock position.

Disconnect the ECM C1 and C2 harness connectors.

Measure the resistance of the (K312) TTVA Position Sensor Signal cir-

cuit between the ECM C1 harness connector and the TTVA harness

connector.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 3

No>>

Repair the (K312) TTVA Position Sensor Signal circuit for

an open.

Perform RE TRANSMISSION VERIFICATION TEST VER -

1 (DIESEL). (Refer to 21 - TRANSMISSION/TRANSAXLE/

AUTOMATIC - 48RE - STANDARD PROCEDURE)

3.CHECK THE (K312) TTVA POSITION SENSOR SIGNAL CIRCUIT FOR A SHORT TO GROUND

Measure the resistance between ground and the (K312) TTVA Position

Sensor Signal circuit.

Is the resistance below 5.0 ohms?

Ye s>>

Repair the (K312) TTVA Position Sensor Signal circuit for a

short to ground.

Perform RE TRANSMISSION VERIFICATION TEST VER -

1 (DIESEL). (Refer to 21 - TRANSMISSION/TRANSAXLE/

AUTOMATIC - 48RE - STANDARD PROCEDURE)

No>>

Go To 4

Page 3718 of 5267

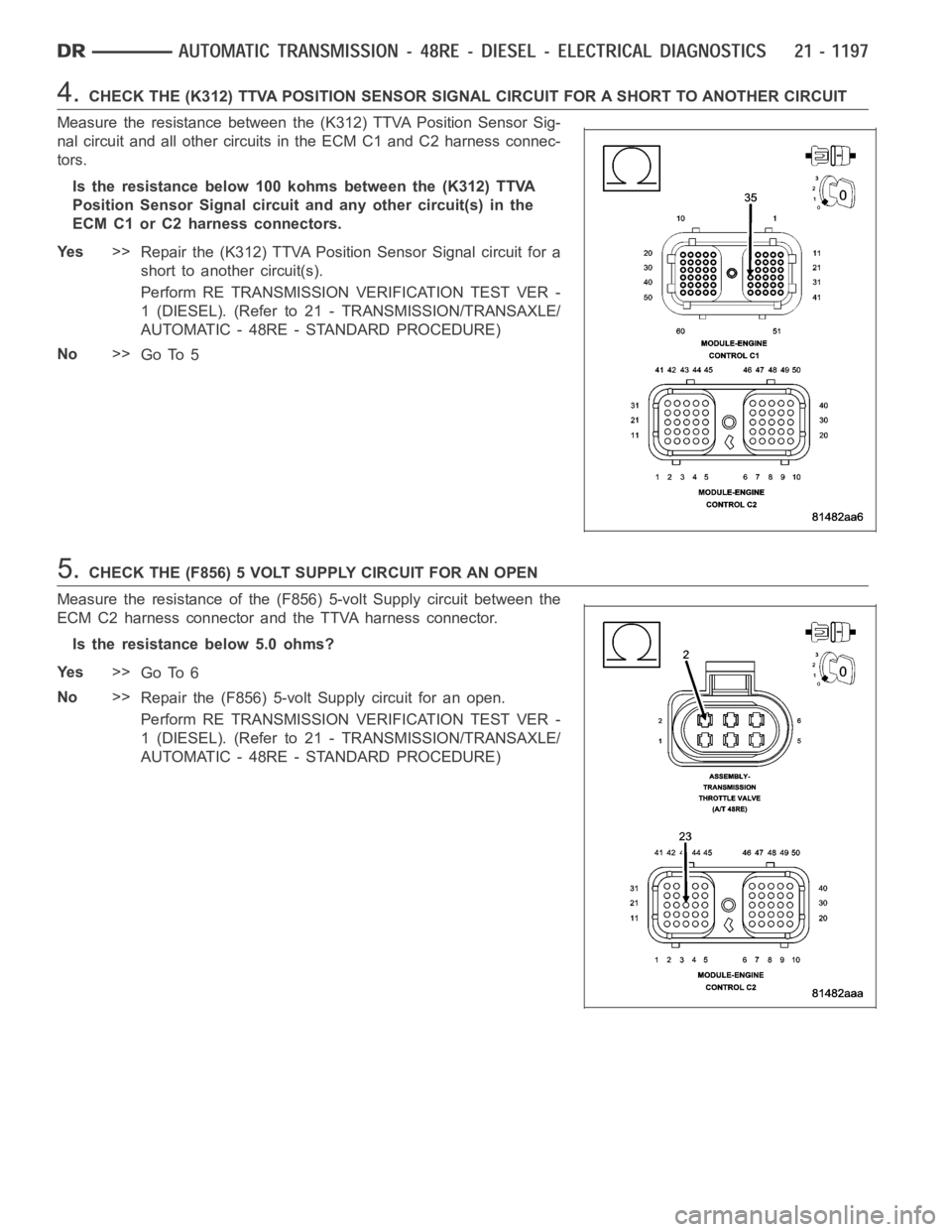

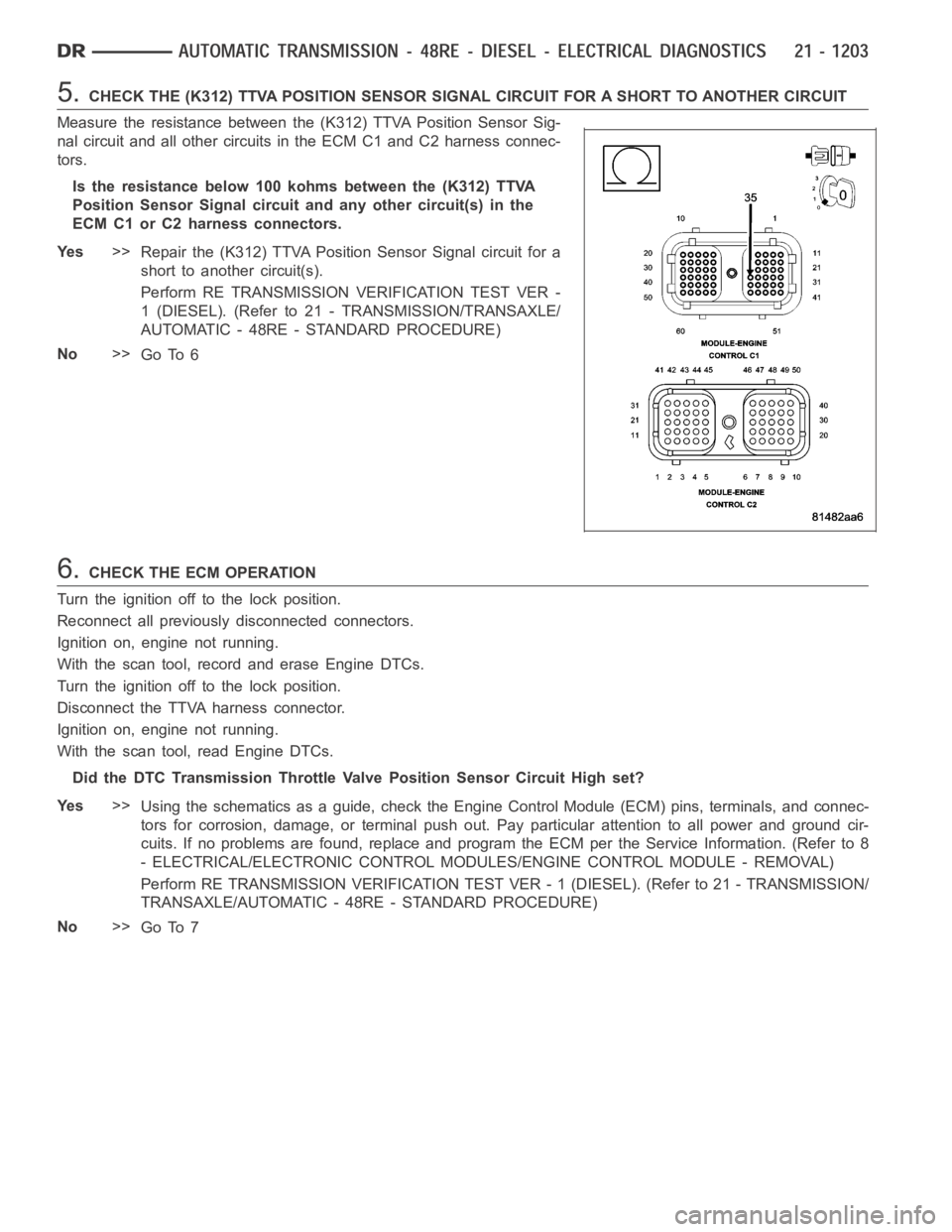

4.CHECK THE (K312) TTVA POSITION SENSOR SIGNAL CIRCUIT FOR A SHORT TO ANOTHERCIRCUIT

Measure the resistance between the (K312) TTVA Position Sensor Sig-

nal circuit and all other circuits in the ECM C1 and C2 harness connec-

tors.

Is the resistance below 100 kohms between the (K312) TTVA

Position Sensor Signal circuit and any other circuit(s) in the

ECM C1 or C2 harness connectors.

Ye s>>

Repair the (K312) TTVA Position Sensor Signal circuit for a

short to another circuit(s).

Perform RE TRANSMISSION VERIFICATION TEST VER -

1 (DIESEL). (Refer to 21 - TRANSMISSION/TRANSAXLE/

AUTOMATIC - 48RE - STANDARD PROCEDURE)

No>>

Go To 5

5.CHECK THE (F856) 5 VOLT SUPPLY CIRCUIT FOR AN OPEN

Measure the resistance of the (F856) 5-volt Supply circuit between the

ECM C2 harness connector and the TTVA harness connector.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 6

No>>

Repair the (F856) 5-volt Supply circuit for an open.

Perform RE TRANSMISSION VERIFICATION TEST VER -

1 (DIESEL). (Refer to 21 - TRANSMISSION/TRANSAXLE/

AUTOMATIC - 48RE - STANDARD PROCEDURE)

Page 3720 of 5267

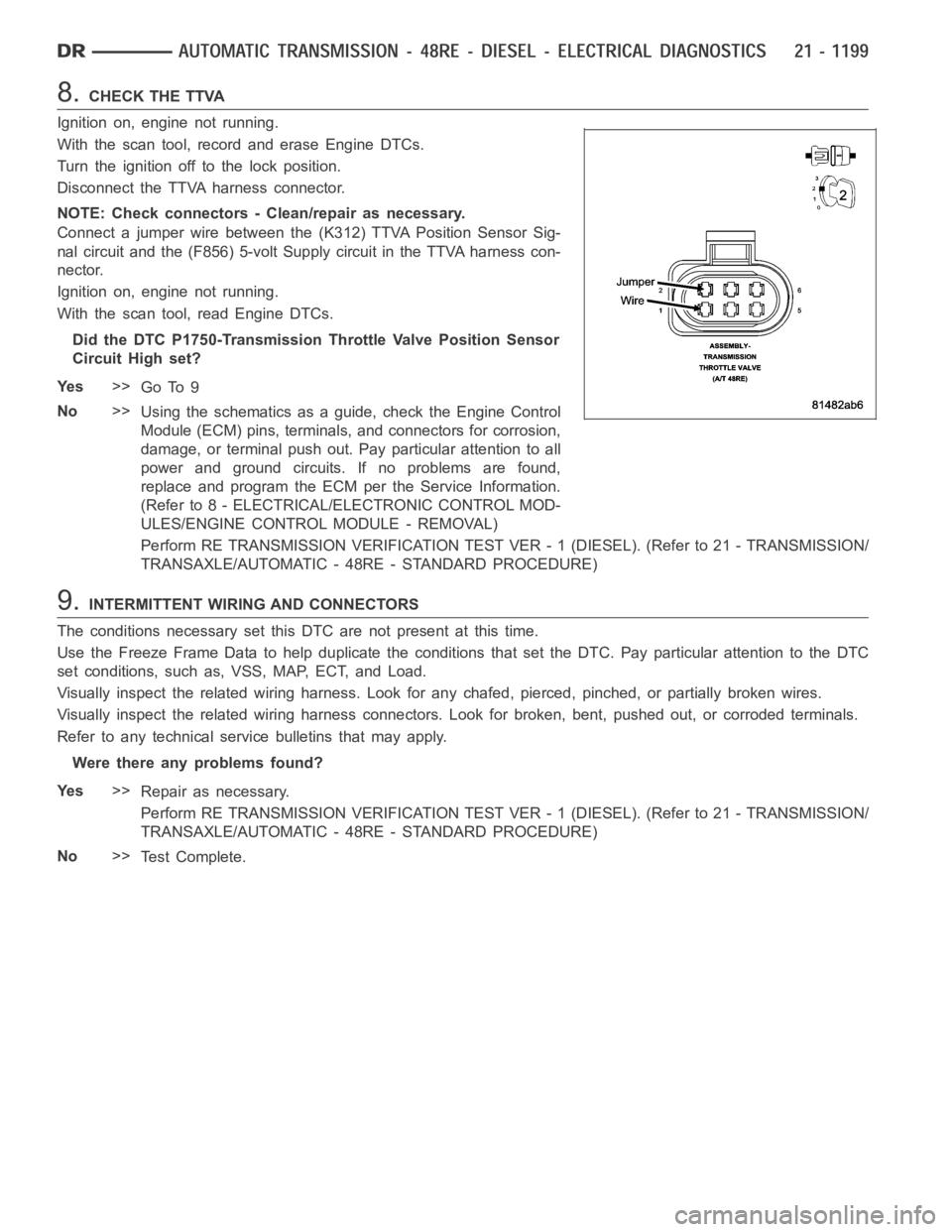

8.CHECK THE TTVA

Ignition on, engine not running.

With the scan tool, record and erase Engine DTCs.

Turn the ignition off to the lock position.

Disconnect the TTVA harness connector.

NOTE: Check connectors - Clean/repair as necessary.

Connect a jumper wire between the (K312) TTVA Position Sensor Sig-

nal circuit and the (F856) 5-volt Supply circuit in the TTVA harness con-

nector.

Ignition on, engine not running.

With the scan tool, read Engine DTCs.

Did the DTC P1750-Transmission Throttle Valve Position Sensor

Circuit High set?

Ye s>>

Go To 9

No>>

Using the schematics as a guide, check the Engine Control

Module (ECM) pins, terminals, and connectors for corrosion,

damage, or terminal push out. Pay particular attention to all

power and ground circuits. If no problems are found,

replace and program the ECM per the Service Information.

(Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/ENGINE CONTROL MODULE - REMOVAL)

Perform RE TRANSMISSION VERIFICATION TEST VER - 1 (DIESEL). (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

9.INTERMITTENT WIRING AND CONNECTORS

The conditions necessary set this DTC are not present at this time.

Use the Freeze Frame Data to help duplicate the conditions that set the DTC.Pay particular attention to the DTC

set conditions, such as, VSS, MAP, ECT, and Load.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken,bent, pushed out, or corroded terminals.

Refer to any technical service bulletins that may apply.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform RE TRANSMISSION VERIFICATION TEST VER - 1 (DIESEL). (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

No>>

Te s t C o m p l e t e .

Page 3721 of 5267

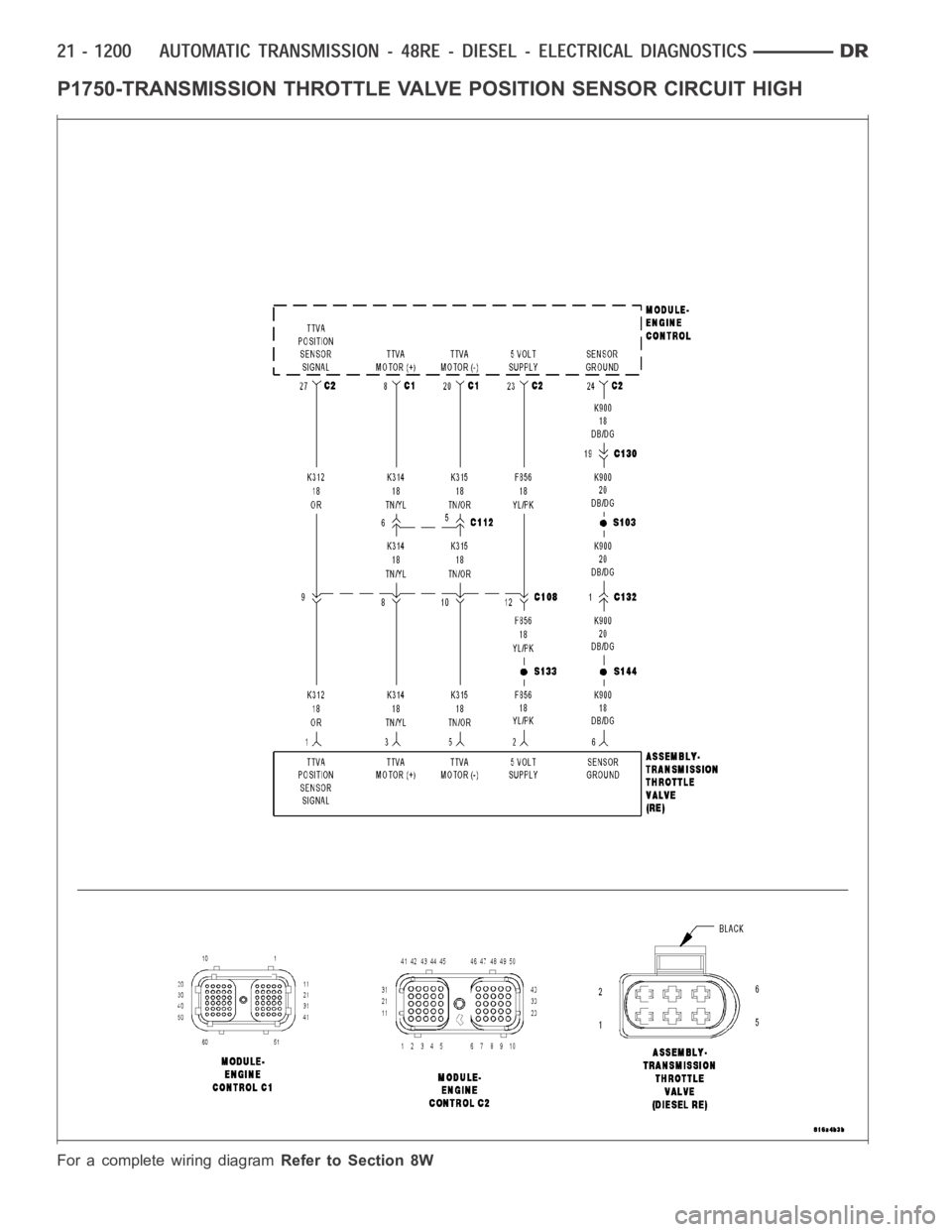

P1750-TRANSMISSION THROTTLE VALVE POSITION SENSOR CIRCUIT HIGH

For a complete wiring diagramRefer to Section 8W

Page 3722 of 5267

Theory of Operation

The transmission throttle valve cable has been replace by the transmission throttle valve actuator (TTVA). The TTVA

consists of an electric DC motor, two potentiometers, and a gear drive system. The TTVA is mechanically connected

to the transmission throttle valve in the valve body by the “D” shaped opening in the bottom of the TTVA shaft.

The Transmission Throttle Valve Actuator (TTVA) does not require any mechanical adjustments. All changes in throt-

tle valve position are controlled by the Engine Control Module (ECM).

The TTVA does require an initialization period after the actuator has beenremoved or replaced. After the actuator

has been removed or replaced, move the ignition to the ON position for thirty (30) seconds. This will allow the ECM

sufficient time to perform the internal calibration procedures to learn the TTVA’s current “zero” position.

When Monitored:

Continuously with the ignition on.

Set Condition:

When the Engine Control Module (ECM) detects the monitored Transmission Throttle Valve Position Sensor

voltage rises above a predetermined value.

Possible Causes

(K312) TTVA POSITION SENSOR SIGNAL CIRCUIT SHORT TO VOLTAGE

(K312) TTVA POSITION SENSOR SIGNAL CIRCUIT SHORT TO ANOTHER CIRCUIT

(K900) SENSOR GROUND CIRCUIT OPEN

TRANSMISSION THROTTLE VALVE ACTUATOR

ENGINE CONTROL MODULE

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

Diagnostic Test

1.CHECK IF THE DTC IS CURRENT

Ignition on, engine not running.

With the scan tool, read Engine DTCs.

Record the Freeze Frame data for the reported DTC.

With the scan tool, erase DTCs.

Turn the ignition off to the lock position.

Using the Freeze Frame data recorded earlier, try to duplicate the conditions in which the DTC originally set.

NOTE: It may be necessary to road test the vehicle to duplicate the originalset conditions.

With the scan tool, read Engine DTCs.

Did the DTC reset?

Ye s>>

Go To 2

No>>

Go To 7

2.CHECK THE TTVA

With the scan tool, record and erase Engine DTCs.

Turn the ignition off to the lock position.

Disconnect the TTVA harness connector.

Ignition on, engine not running.

With the scan tool, read Engine DTCs.

Did the DTC Transmission Throttle Valve Position Sensor Circuit High set?

Ye s>>

Go To 4

No>>

Go To 3

Page 3723 of 5267

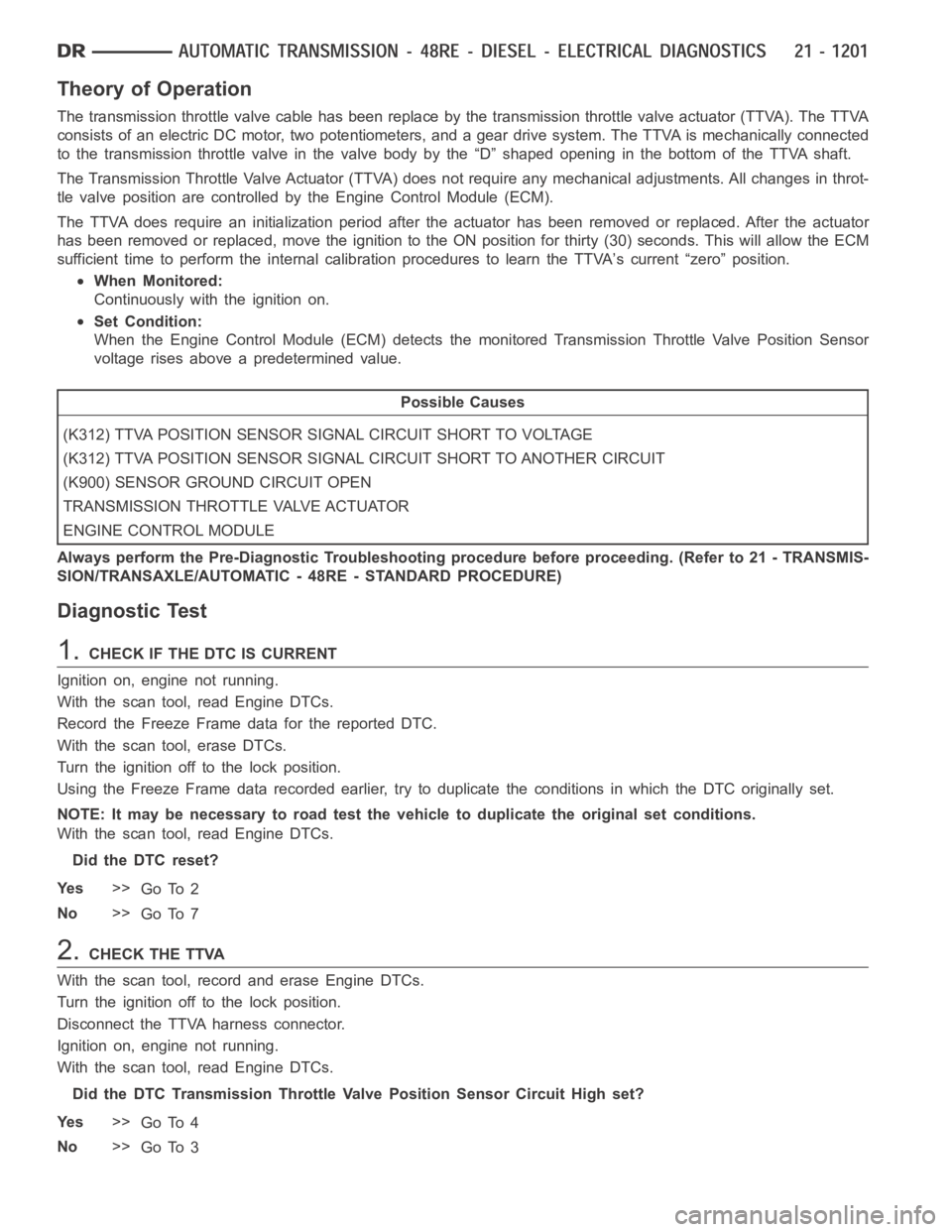

3.CHECK THE (K900) SENSOR GROUND CIRCUIT FOR AN OPEN

Ignition on, engine not running.

With the scan tool, record and erase Engine DTCs.

Turn the ignition off to the lock position.

Disconnect the TTVA harness connector.

NOTE: Check connectors - Clean/repair as necessary.

Connect a jumper wire between the (K900) Sensor Ground circuit and

the (F856) 5-volt Supply circuit in the TTVA harness connector.

Ignition on, engine not running.

With the scan tool, read Engine DTCs.

Did either P0642 or P0652 Sensor Supply Voltage DTC set?

Ye s>>

Replace the TTVA per the Service Information.

Perform RE TRANSMISSION VERIFICATION TEST VER -

1 (DIESEL). (Refer to 21 - TRANSMISSION/TRANSAXLE/

AUTOMATIC - 48RE - STANDARD PROCEDURE)

No>>

Repair the (K900) TTVA Sensor Ground circuit for an open.

Perform RE TRANSMISSION VERIFICATION TEST VER - 1 (DIESEL). (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

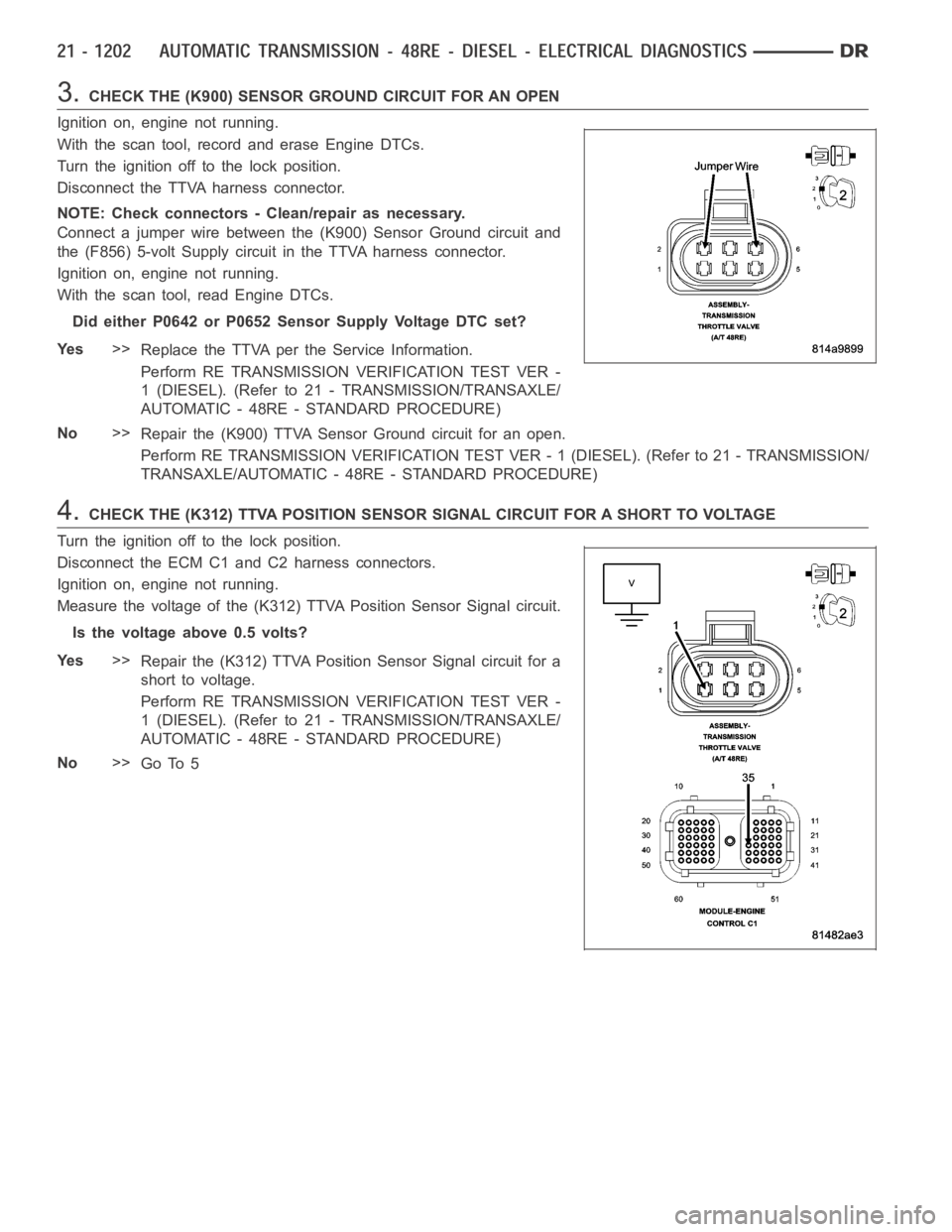

4.CHECK THE (K312) TTVA POSITION SENSOR SIGNAL CIRCUIT FOR A SHORT TO VOLTAGE

Turn the ignition off to the lock position.

Disconnect the ECM C1 and C2 harness connectors.

Ignition on, engine not running.

Measure the voltage of the (K312) TTVA Position Sensor Signal circuit.

Is the voltage above 0.5 volts?

Ye s>>

Repair the (K312) TTVA Position Sensor Signal circuit for a

short to voltage.

Perform RE TRANSMISSION VERIFICATION TEST VER -

1 (DIESEL). (Refer to 21 - TRANSMISSION/TRANSAXLE/

AUTOMATIC - 48RE - STANDARD PROCEDURE)

No>>

Go To 5

Page 3724 of 5267

5.CHECK THE (K312) TTVA POSITION SENSOR SIGNAL CIRCUIT FOR A SHORT TO ANOTHERCIRCUIT

Measure the resistance between the (K312) TTVA Position Sensor Sig-

nal circuit and all other circuits in the ECM C1 and C2 harness connec-

tors.

Is the resistance below 100 kohms between the (K312) TTVA

Position Sensor Signal circuit and any other circuit(s) in the

ECM C1 or C2 harness connectors.

Ye s>>

Repair the (K312) TTVA Position Sensor Signal circuit for a

short to another circuit(s).

Perform RE TRANSMISSION VERIFICATION TEST VER -

1 (DIESEL). (Refer to 21 - TRANSMISSION/TRANSAXLE/

AUTOMATIC - 48RE - STANDARD PROCEDURE)

No>>

Go To 6

6.CHECK THE ECM OPERATION

Turn the ignition off to the lock position.

Reconnect all previously disconnected connectors.

Ignition on, engine not running.

With the scan tool, record and erase Engine DTCs.

Turn the ignition off to the lock position.

Disconnect the TTVA harness connector.

Ignition on, engine not running.

With the scan tool, read Engine DTCs.

Did the DTC Transmission Throttle Valve Position Sensor Circuit High set?

Ye s>>

Using the schematics as a guide, check the Engine Control Module (ECM) pins, terminals, and connec-

tors for corrosion, damage, or terminal push out. Pay particular attentiontoallpowerandgroundcir-

cuits. If no problems are found, replace and program the ECM per the ServiceInformation. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/ENGINE CONTROL MODULE - REMOVAL)

Perform RE TRANSMISSION VERIFICATION TEST VER - 1 (DIESEL). (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

No>>

Go To 7

Page 3736 of 5267

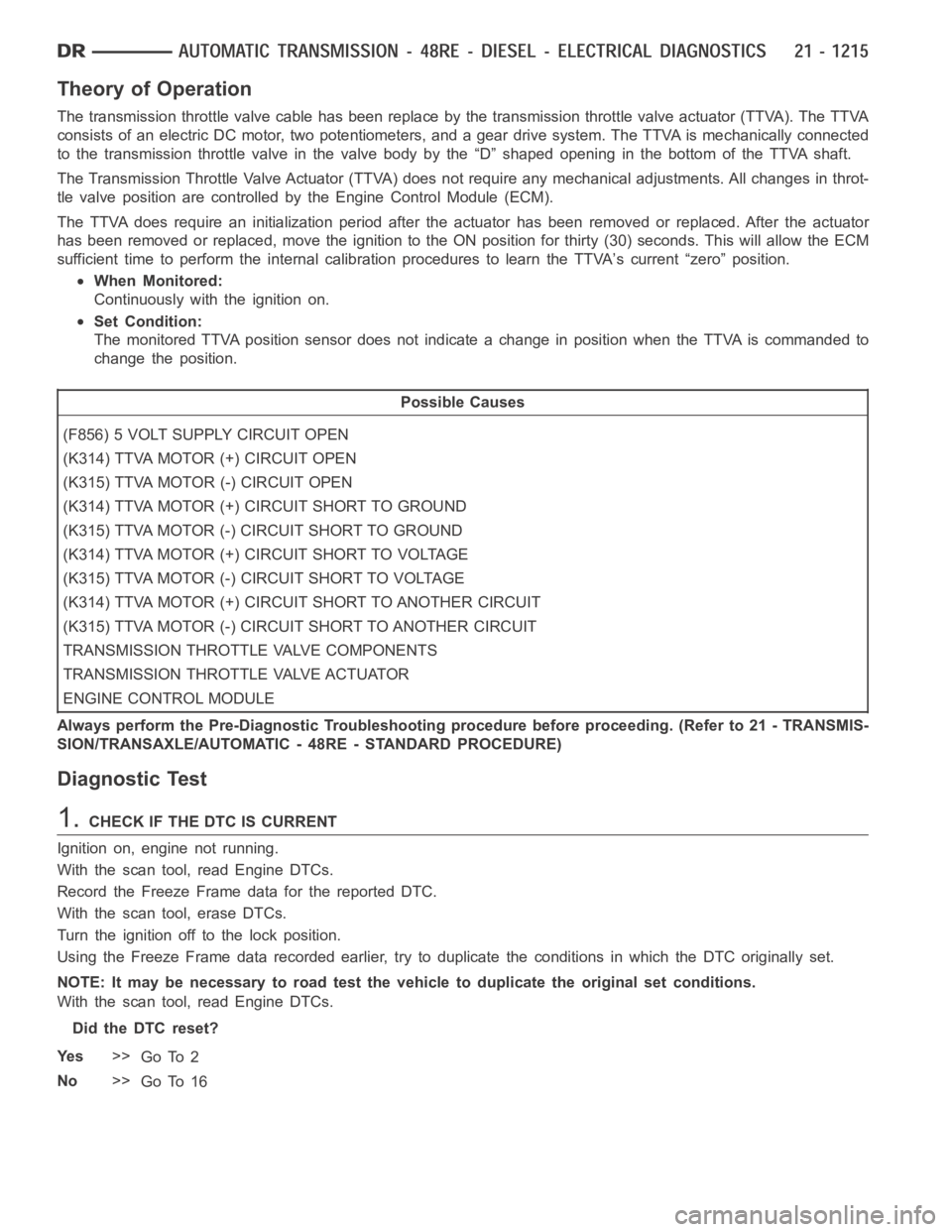

Theory of Operation

The transmission throttle valve cable has been replace by the transmission throttle valve actuator (TTVA). The TTVA

consists of an electric DC motor, two potentiometers, and a gear drive system. The TTVA is mechanically connected

to the transmission throttle valve in the valve body by the “D” shaped opening in the bottom of the TTVA shaft.

The Transmission Throttle Valve Actuator (TTVA) does not require any mechanical adjustments. All changes in throt-

tle valve position are controlled by the Engine Control Module (ECM).

The TTVA does require an initialization period after the actuator has beenremoved or replaced. After the actuator

has been removed or replaced, move the ignition to the ON position for thirty (30) seconds. This will allow the ECM

sufficient time to perform the internal calibration procedures to learn the TTVA’s current “zero” position.

When Monitored:

Continuously with the ignition on.

Set Condition:

The monitored TTVA position sensor does not indicate a change in position when the TTVA is commanded to

change the position.

Possible Causes

(F856) 5 VOLT SUPPLY CIRCUIT OPEN

(K314) TTVA MOTOR (+) CIRCUIT OPEN

(K315) TTVA MOTOR (-) CIRCUIT OPEN

(K314) TTVA MOTOR (+) CIRCUIT SHORT TO GROUND

(K315) TTVA MOTOR (-) CIRCUIT SHORT TO GROUND

(K314) TTVA MOTOR (+) CIRCUIT SHORT TO VOLTAGE

(K315) TTVA MOTOR (-) CIRCUIT SHORT TO VOLTAGE

(K314) TTVA MOTOR (+) CIRCUIT SHORT TO ANOTHER CIRCUIT

(K315) TTVA MOTOR (-) CIRCUIT SHORT TO ANOTHER CIRCUIT

TRANSMISSION THROTTLE VALVE COMPONENTS

TRANSMISSION THROTTLE VALVE ACTUATOR

ENGINE CONTROL MODULE

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

Diagnostic Test

1.CHECK IF THE DTC IS CURRENT

Ignition on, engine not running.

With the scan tool, read Engine DTCs.

Record the Freeze Frame data for the reported DTC.

With the scan tool, erase DTCs.

Turn the ignition off to the lock position.

Using the Freeze Frame data recorded earlier, try to duplicate the conditions in which the DTC originally set.

NOTE: It may be necessary to road test the vehicle to duplicate the originalset conditions.

With the scan tool, read Engine DTCs.

Did the DTC reset?

Ye s>>

Go To 2

No>>

Go To 16