sensor DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 3876 of 5267

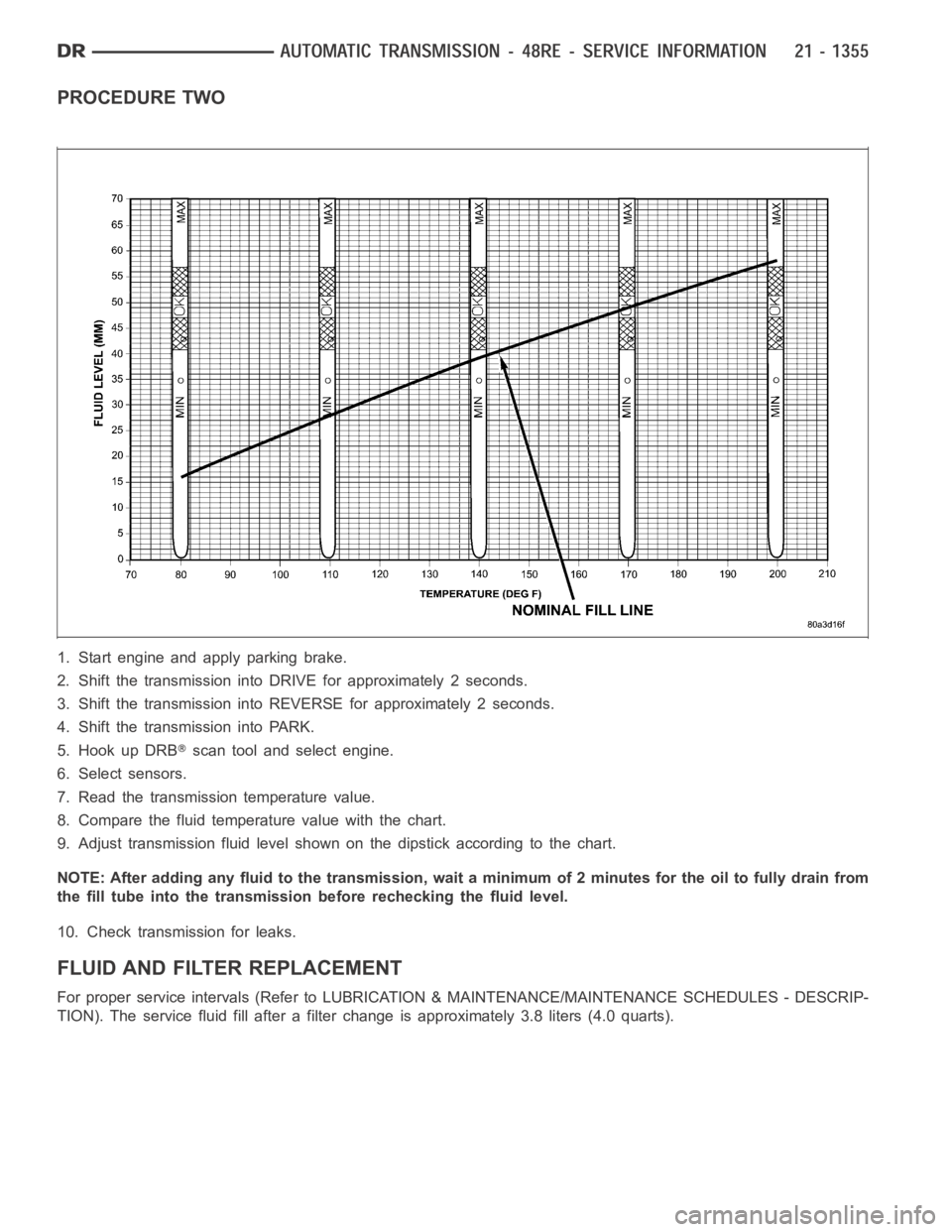

PROCEDURE TWO

1. Start engine and apply parking brake.

2. Shift the transmission into DRIVE for approximately 2 seconds.

3. Shift the transmission into REVERSE for approximately 2 seconds.

4. Shift the transmission into PARK.

5. Hook up DRB

scan tool and select engine.

6. Select sensors.

7. Read the transmission temperature value.

8. Compare the fluid temperature value with the chart.

9. Adjust transmission fluid level shown on the dipstick according to the chart.

NOTE: After adding any fluid to the transmission, wait a minimum of 2 minutes for the oil to fully drain from

the fill tube into the transmission before rechecking the fluid level.

10. Check transmission for leaks.

FLUID AND FILTER REPLACEMENT

For proper service intervals (Refer to LUBRICATION & MAINTENANCE/MAINTENANCE SCHEDULES - DESCRIP-

TION). The service fluid fill after a filter change is approximately 3.8 liters (4.0 quarts).

Page 3888 of 5267

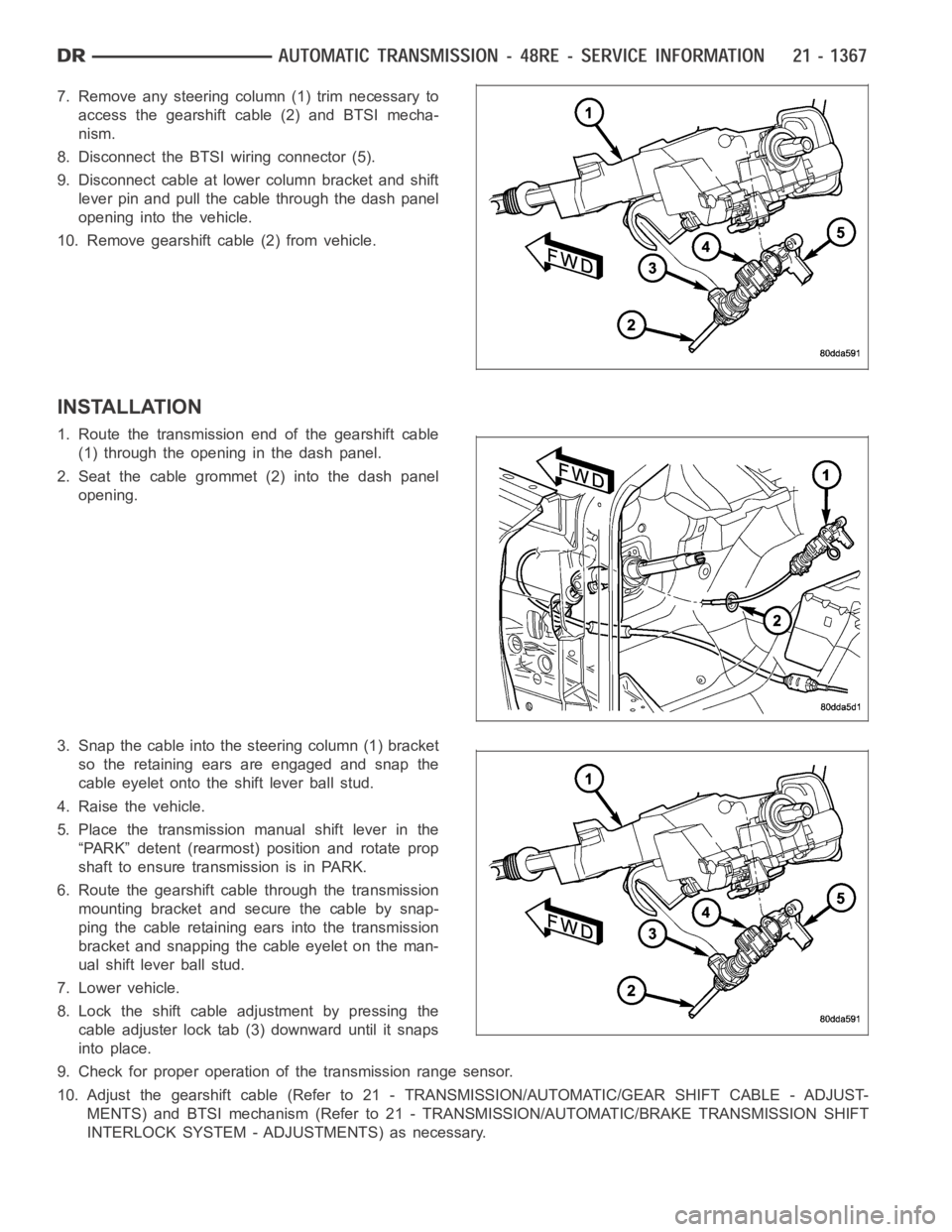

7. Remove any steering column (1) trim necessary to

access the gearshift cable (2) and BTSI mecha-

nism.

8. Disconnect the BTSI wiring connector (5).

9. Disconnect cable at lower column bracket and shift

lever pin and pull the cable through the dash panel

opening into the vehicle.

10. Remove gearshift cable (2) from vehicle.

INSTALLATION

1. Route the transmission end of the gearshift cable

(1) through the opening in the dash panel.

2. Seat the cable grommet (2) into the dash panel

opening.

3. Snap the cable into the steering column (1) bracket

so the retaining ears are engaged and snap the

cable eyelet onto the shift lever ball stud.

4. Raise the vehicle.

5. Place the transmission manual shift lever in the

“PARK” detent (rearmost) position and rotate prop

shaft to ensure transmission is in PARK.

6. Route the gearshift cable through the transmission

mounting bracket and secure the cable by snap-

ping the cable retaining ears into the transmission

bracket and snapping the cable eyelet on the man-

ual shift lever ball stud.

7. Lower vehicle.

8. Lock the shift cable adjustment by pressing the

cable adjuster lock tab (3) downward until it snaps

into place.

9. Check for proper operation of the transmission range sensor.

10. Adjust the gearshift cable (Refer to 21 - TRANSMISSION/AUTOMATIC/GEAR SHIFT CABLE - ADJUST-

MENTS) and BTSI mechanism (Refer to 21 - TRANSMISSION/AUTOMATIC/BRAKE TRANSMISSION SHIFT

INTERLOCK SYSTEM - ADJUSTMENTS) as necessary.

Page 3889 of 5267

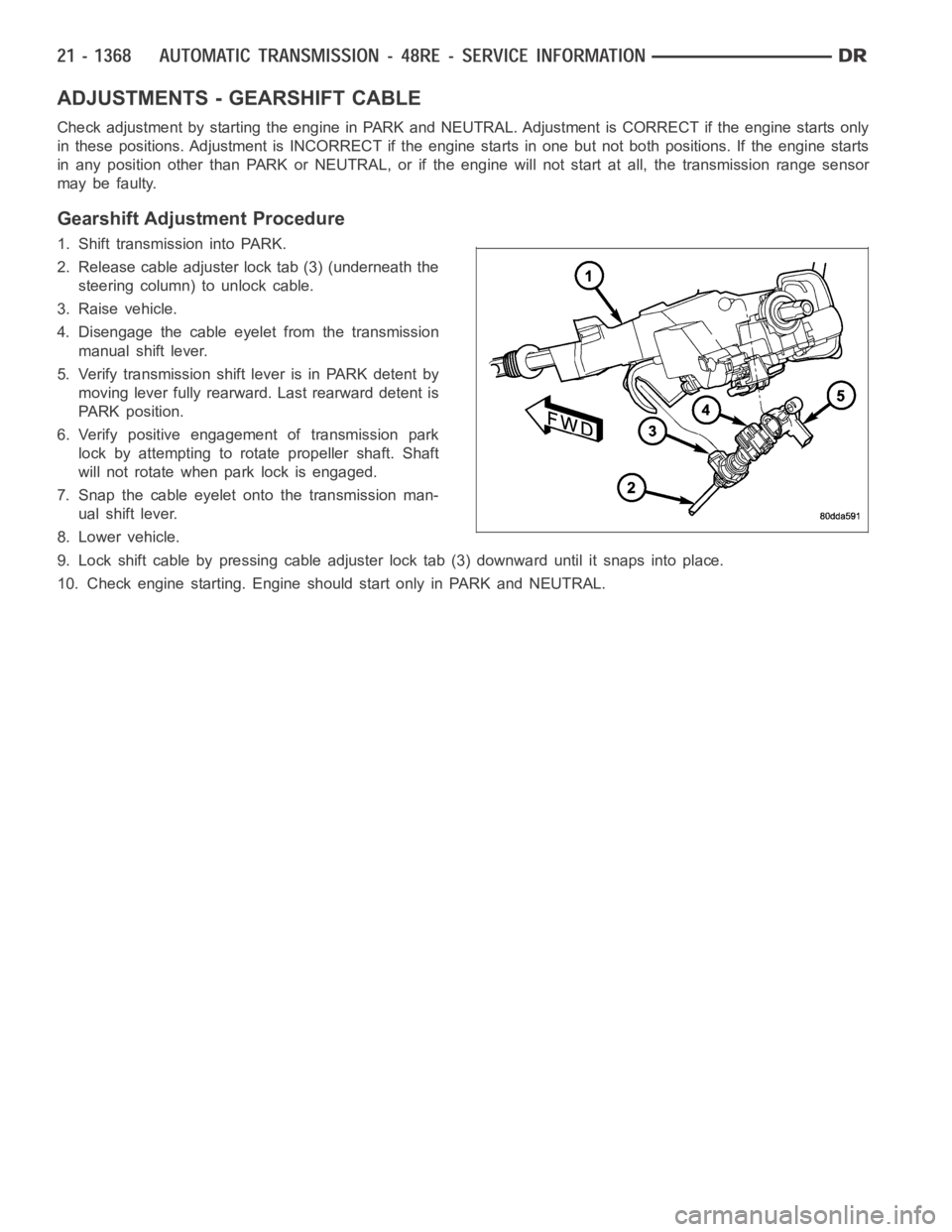

ADJUSTMENTS - GEARSHIFT CABLE

Check adjustment by starting the engine in PARK and NEUTRAL. Adjustment isCORRECT if the engine starts only

in these positions. Adjustment is INCORRECT if the engine starts in one butnot both positions. If the engine starts

in any position other than PARK or NEUTRAL, or if the engine will not start atall, the transmission range sensor

may be faulty.

Gearshift Adjustment Procedure

1. Shift transmission into PARK.

2. Release cable adjuster lock tab (3) (underneath the

steering column) to unlock cable.

3. Raise vehicle.

4. Disengage the cable eyelet from the transmission

manual shift lever.

5. Verify transmission shift lever is in PARK detent by

moving lever fully rearward. Last rearward detent is

PARK position.

6. Verify positive engagement of transmission park

lock by attempting to rotate propeller shaft. Shaft

will not rotate when park lock is engaged.

7. Snap the cable eyelet onto the transmission man-

ual shift lever.

8. Lower vehicle.

9. Lock shift cable by pressing cable adjuster lock tab (3) downward until it snaps into place.

10. Check engine starting. Engine should start only in PARK and NEUTRAL.

Page 3900 of 5267

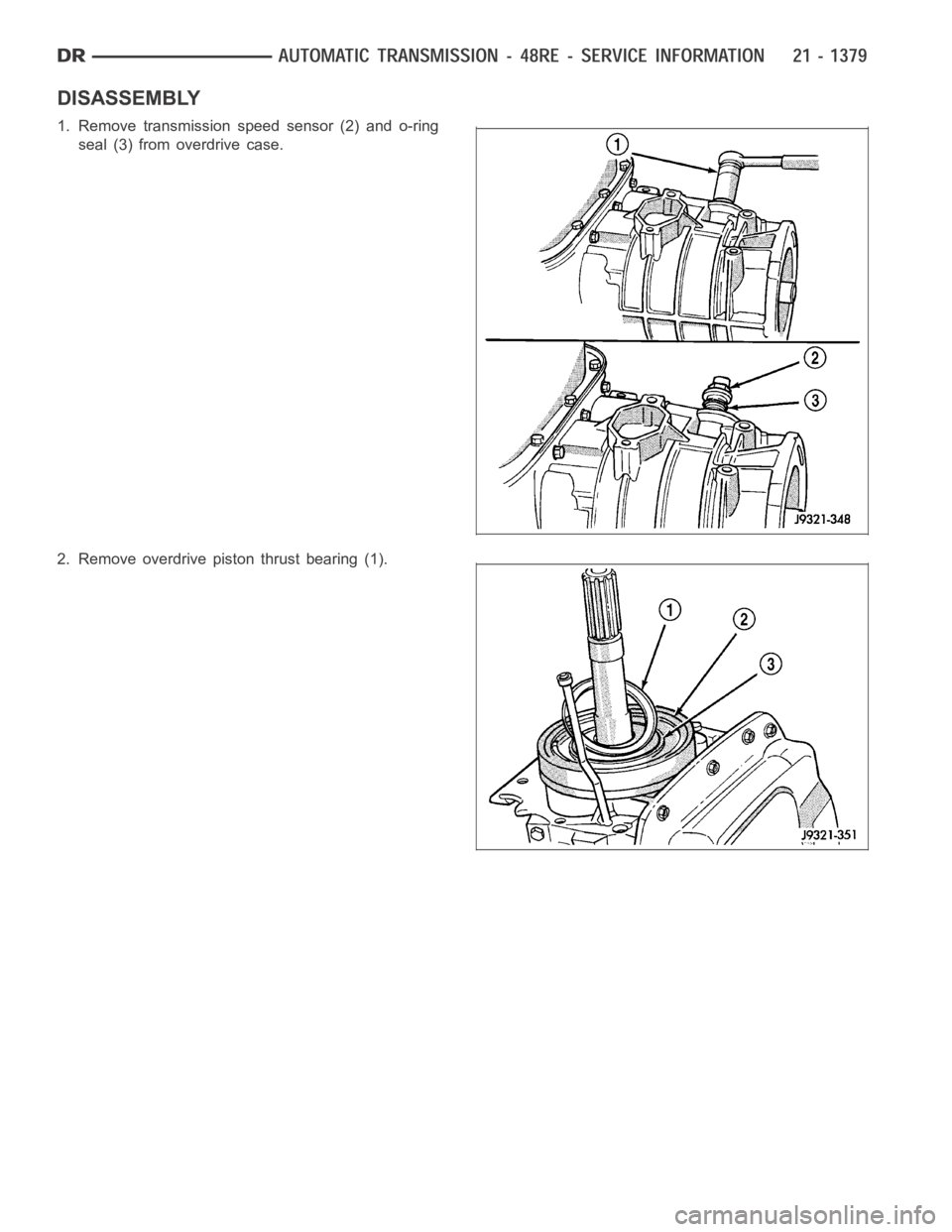

DISASSEMBLY

1. Remove transmission speed sensor (2) and o-ring

seal (3) from overdrive case.

2. Remove overdrive piston thrust bearing (1).

Page 3920 of 5267

3. Select proper thickness end play spacer from

spacer chart based on distance measured.

4. Remove Gauge Alignment Tool 6312.

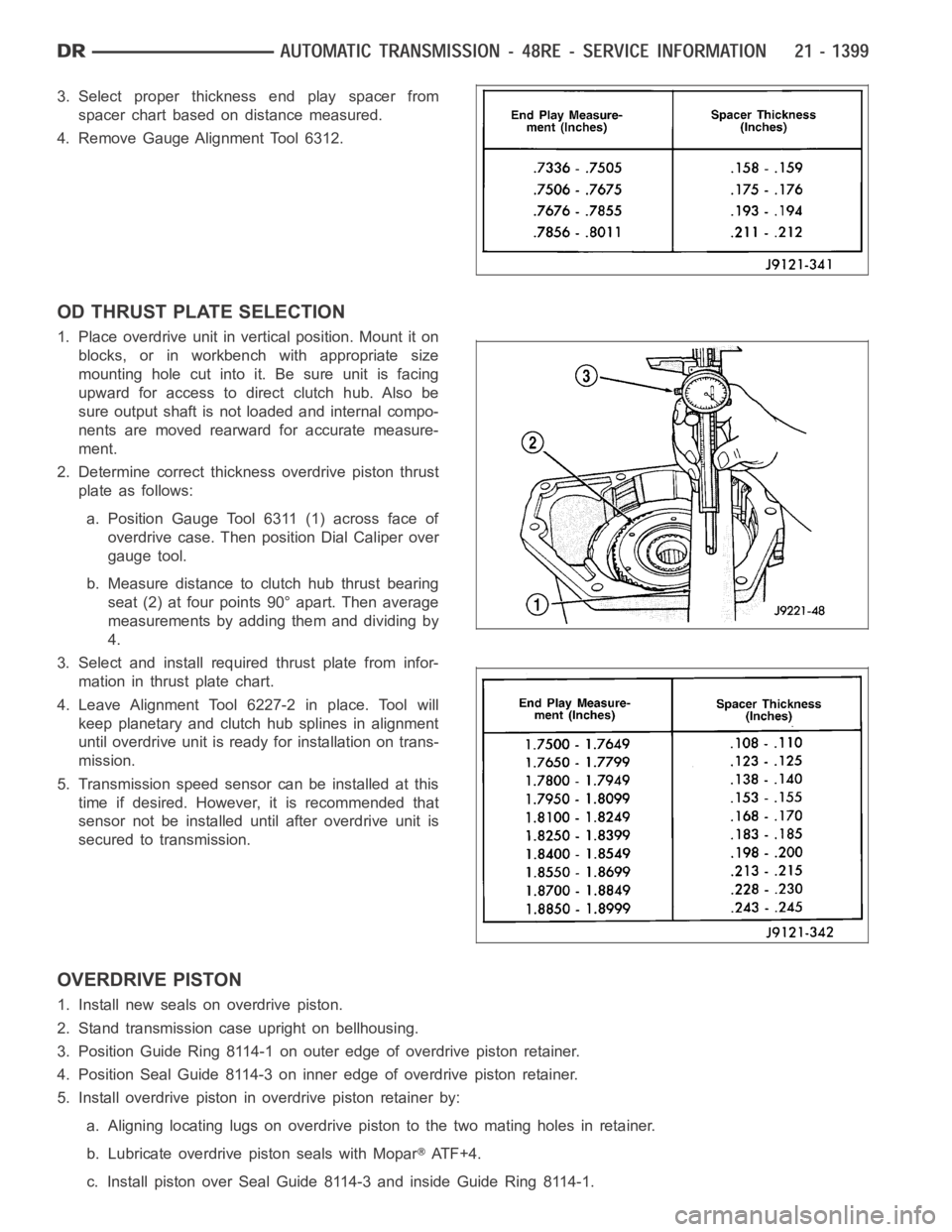

OD THRUST PLATE SELECTION

1. Place overdrive unit in vertical position. Mount it on

blocks, or in workbench with appropriate size

mounting hole cut into it. Be sure unit is facing

upward for access to direct clutch hub. Also be

sure output shaft is not loaded and internal compo-

nents are moved rearward for accurate measure-

ment.

2. Determine correct thickness overdrive piston thrust

plate as follows:

a. Position Gauge Tool 6311 (1) across face of

overdrive case. Then position Dial Caliper over

gauge tool.

b. Measure distance to clutch hub thrust bearing

seat (2) at four points 90° apart. Then average

measurements by adding them and dividing by

4.

3. Select and install required thrust plate from infor-

mation in thrust plate chart.

4. Leave Alignment Tool 6227-2 in place. Tool will

keep planetary and clutch hub splines in alignment

until overdrive unit is ready for installation on trans-

mission.

5. Transmission speed sensor can be installed at this

time if desired. However, it is recommended that

sensor not be installed until after overdrive unit is

secured to transmission.

OVERDRIVE PISTON

1. Install new seals on overdrive piston.

2. Stand transmission case upright on bellhousing.

3. Position Guide Ring 8114-1 on outer edge of overdrive piston retainer.

4. Position Seal Guide 8114-3 on inner edge of overdrive piston retainer.

5. Install overdrive piston in overdrive piston retainer by:

a. Aligning locating lugs on overdrive piston to the two mating holes in retainer.

b. Lubricate overdrive piston seals with Mopar

ATF+4.

c. Install piston over Seal Guide 8114-3 and inside Guide Ring 8114-1.

Page 3921 of 5267

d. Push overdrive piston into position in retainer.

e. Verify that the locating lugs entered the lug bores in the retainer.

6. Install intermediate shaft spacer on intermediate shaft.

7. Install overdrive piston thrust plate on overdrive piston.

8. Install overdrive piston thrust bearing on overdrive piston.

9. Install transmission speed sensorand o-ring seal in overdrive case.

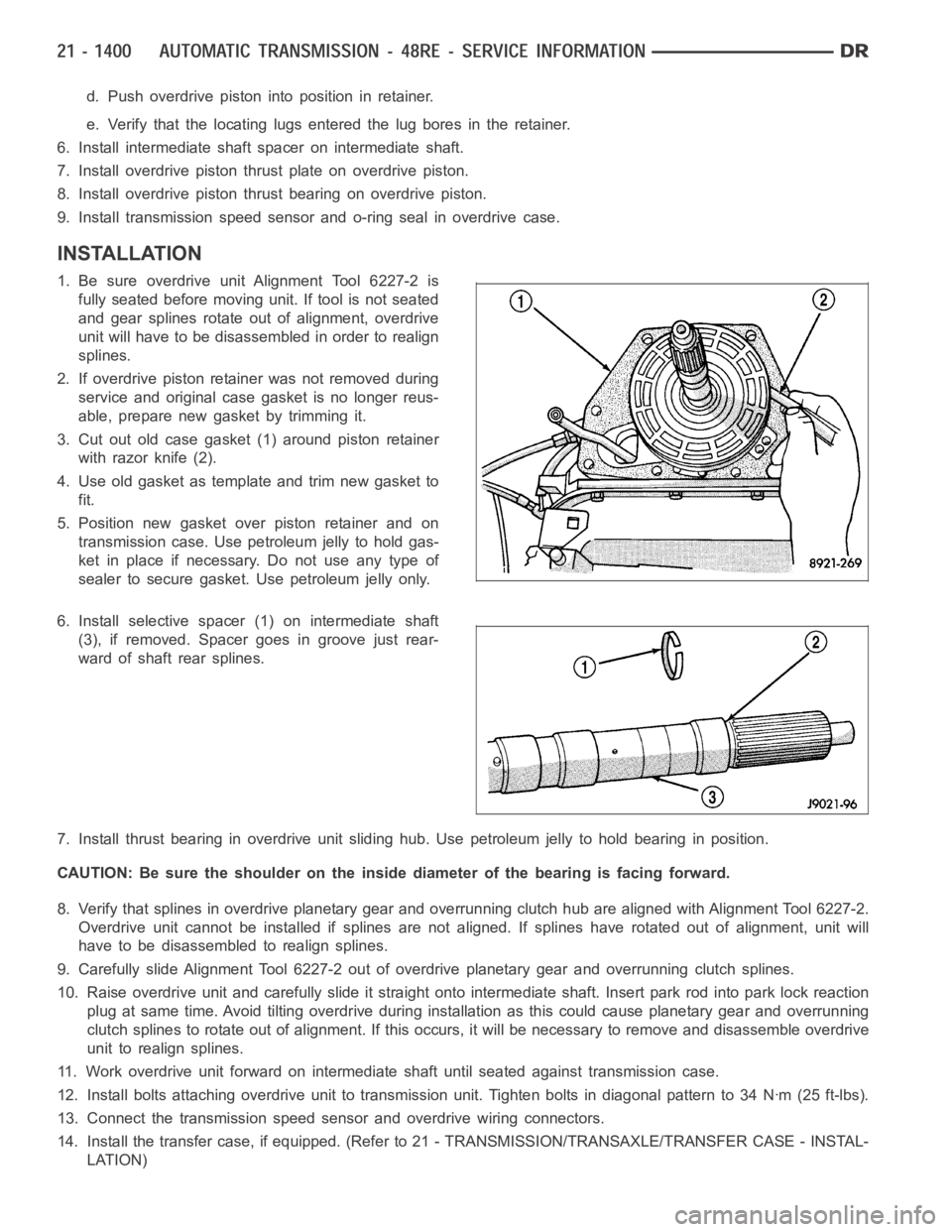

INSTALLATION

1. Be sure overdrive unit Alignment Tool 6227-2 is

fully seated before moving unit. If tool is not seated

and gear splines rotate out of alignment, overdrive

unit will have to be disassembled in order to realign

splines.

2. If overdrive piston retainer was not removed during

service and original case gasket is no longer reus-

able, prepare new gasket by trimming it.

3. Cut out old case gasket (1) around piston retainer

with razor knife (2).

4. Use old gasket as template and trim new gasket to

fit.

5. Position new gasket over piston retainer and on

transmission case. Use petroleum jelly to hold gas-

ket in place if necessary. Do not use any type of

sealer to secure gasket. Use petroleum jelly only.

6. Install selective spacer (1) on intermediate shaft

(3), if removed. Spacer goes in groove just rear-

ward of shaft rear splines.

7. Install thrust bearing in overdrive unit sliding hub. Use petroleum jelly to hold bearing in position.

CAUTION: Be sure the shoulder on the inside diameter of the bearing is facingforward.

8. Verify that splines in overdrive planetary gear and overrunning clutchhub are aligned with Alignment Tool 6227-2.

Overdrive unit cannot be installed if splines are not aligned. If splines have rotated out of alignment, unit will

have to be disassembled to realign splines.

9. Carefully slide Alignment Tool 6227-2 out of overdrive planetary gear and overrunning clutch splines.

10. Raise overdrive unit and carefully slide it straight onto intermediate shaft. Insert park rod into park lock reaction

plug at same time. Avoid tilting overdrive during installation as this could cause planetary gear and overrunning

clutch splines to rotate out of alignment. If this occurs, it will be necessary to remove and disassemble overdrive

unit to realign splines.

11. Work overdrive unit forward on intermediate shaft until seated against transmission case.

12. Install bolts attaching overdrive unit to transmission unit. Tightenbolts in diagonal pattern to 34 Nꞏm (25 ft-lbs).

13. Connect the transmission speed sensor and overdrive wiring connectors.

14. Install the transfer case, if equipped. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER CASE - INSTAL-

LATION)

Page 3944 of 5267

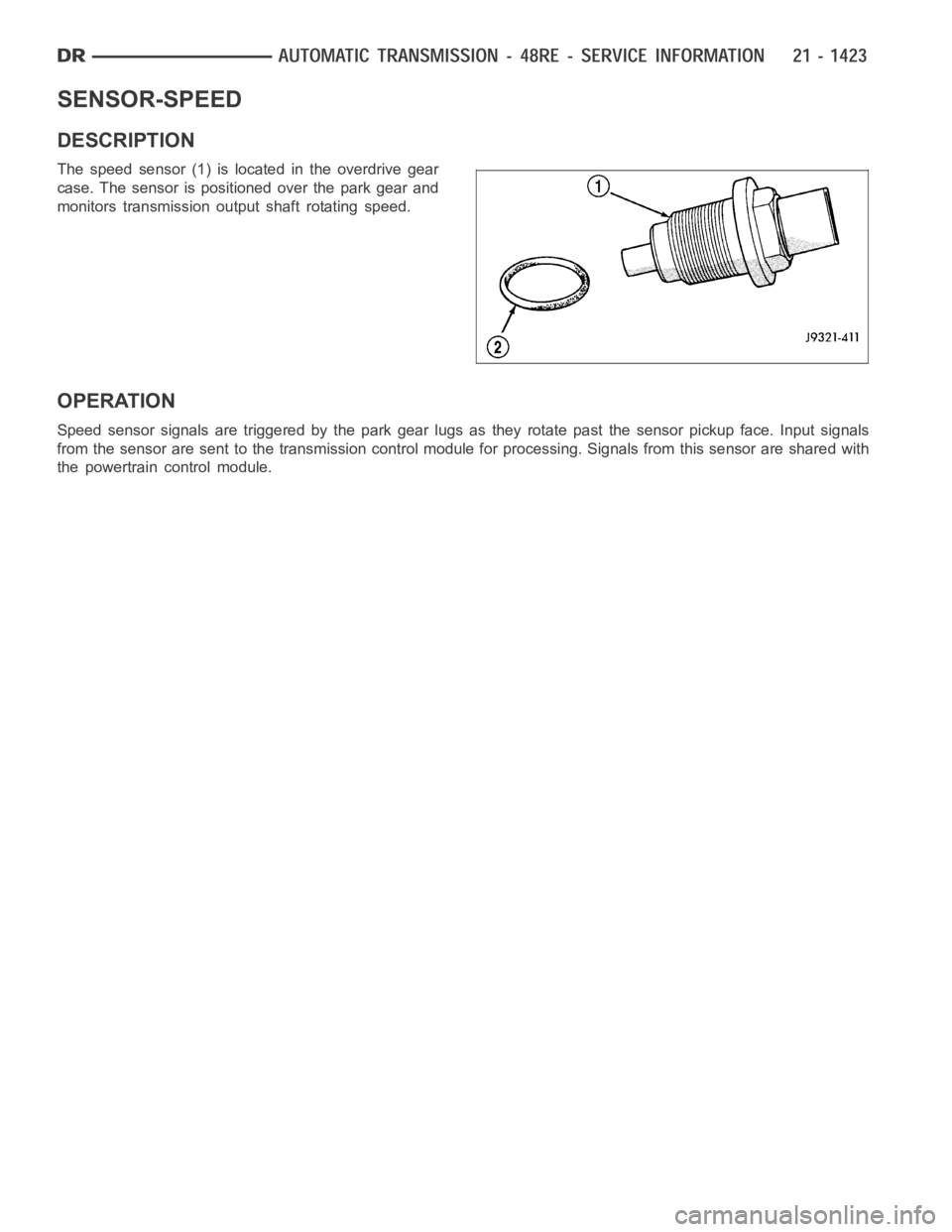

SENSOR-SPEED

DESCRIPTION

The speed sensor (1) is located in the overdrive gear

case. The sensor is positioned over the park gear and

monitors transmission output shaft rotating speed.

OPERATION

Speed sensor signals are triggered by the park gear lugs as they rotate pastthe sensor pickup face. Input signals

from the sensor are sent to the transmission control module for processing. Signals from this sensor are shared with

the powertrain control module.

Page 3963 of 5267

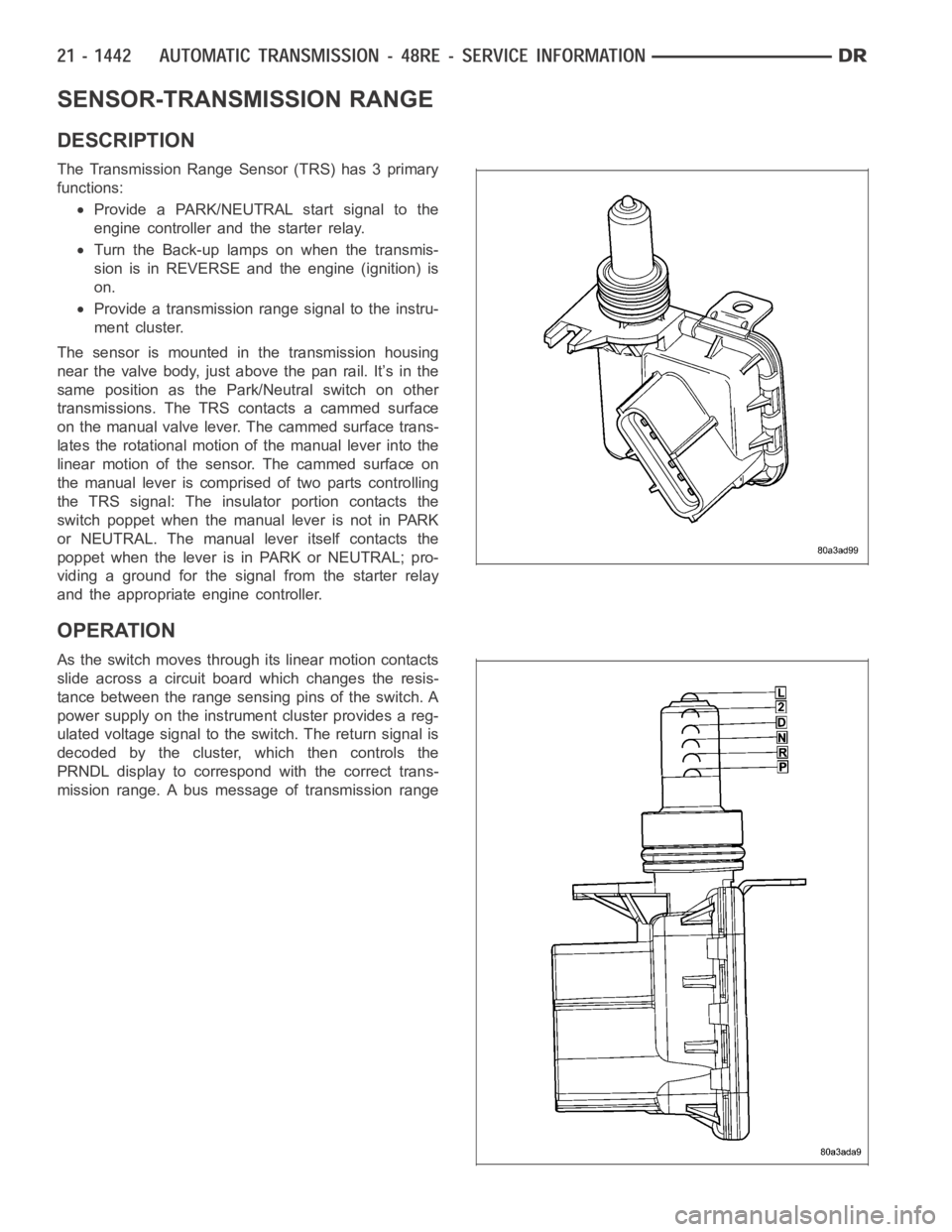

SENSOR-TRANSMISSION RANGE

DESCRIPTION

The Transmission Range Sensor (TRS) has 3 primary

functions:

Provide a PARK/NEUTRAL start signal to the

engine controller and the starter relay.

Turn the Back-up lamps on when the transmis-

sion is in REVERSE and the engine (ignition) is

on.

Provide a transmission range signal to the instru-

ment cluster.

The sensor is mounted in the transmission housing

near the valve body, just above the pan rail. It’s in the

same position as the Park/Neutral switch on other

transmissions. The TRS contacts a cammed surface

on the manual valve lever. The cammed surface trans-

lates the rotational motion of the manual lever into the

linear motion of the sensor. The cammed surface on

the manual lever is comprised of two parts controlling

the TRS signal: The insulator portion contacts the

switch poppet when the manual lever is not in PARK

or NEUTRAL. The manual lever itself contacts the

poppet when the lever is in PARK or NEUTRAL; pro-

viding a ground for the signal from the starter relay

and the appropriate engine controller.

OPERATION

As the switch moves through its linear motion contacts

slide across a circuit board which changes the resis-

tance between the range sensing pins of the switch. A

power supply on the instrument cluster provides a reg-

ulated voltage signal to the switch. The return signal is

decoded by the cluster, which then controls the

PRNDL display to correspond with the correct trans-

mission range. A bus message of transmission range

Page 3964 of 5267

is also sent by the cluster. In REVERSE range a second contact set closes thecircuit providing power to the

reverse lamps.

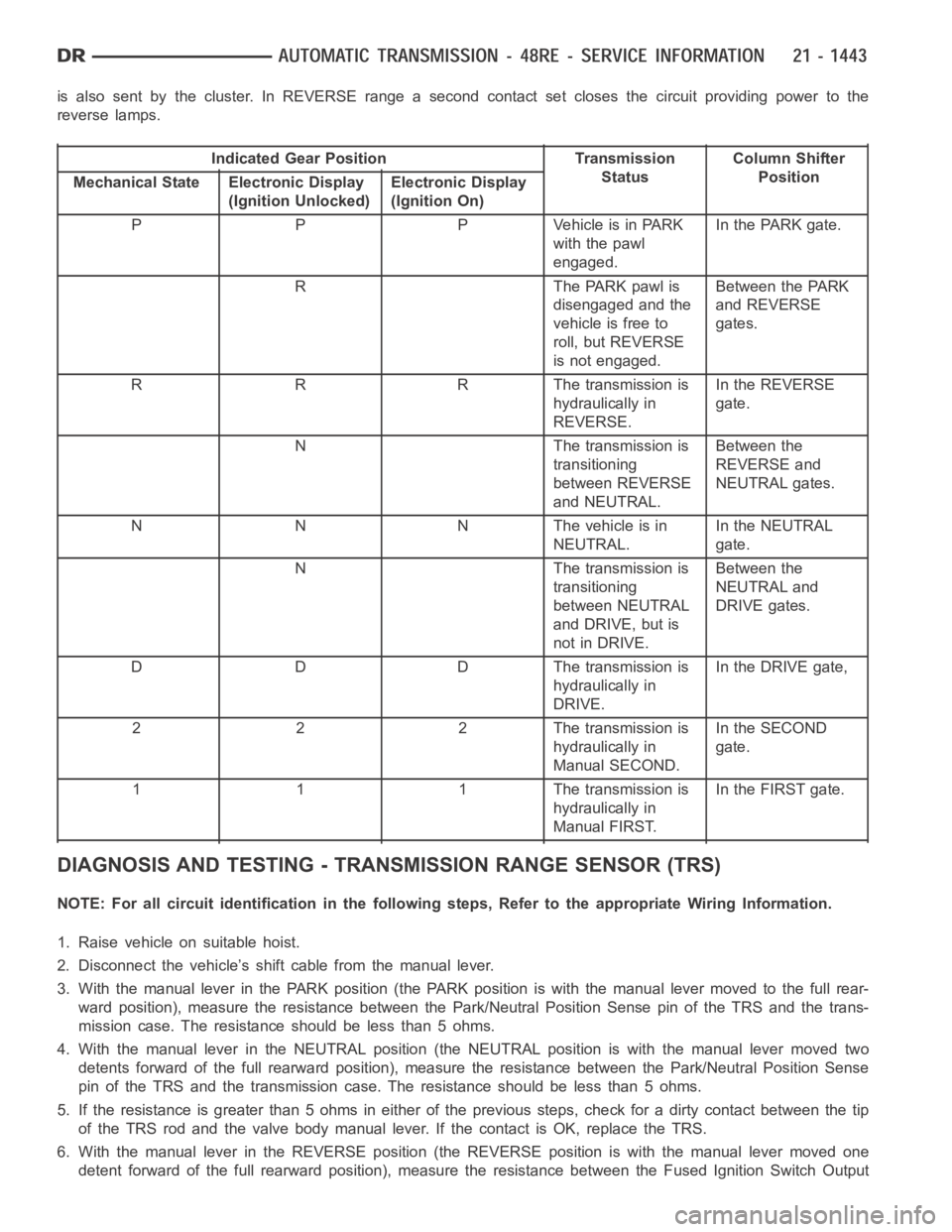

Indicated Gear Position Transmission

StatusColumn Shifter

Position

Mechanical State Electronic Display

(Ignition Unlocked)Electronic Display

(Ignition On)

P P P Vehicle is in PARK

with the pawl

engaged.In the PARK gate.

R The PARK pawl is

disengaged and the

vehicle is free to

roll, but REVERSE

is not engaged.Between the PARK

and REVERSE

gates.

R R R The transmission is

hydraulically in

REVERSE.In the REVERSE

gate.

N The transmission is

transitioning

between REVERSE

and NEUTRAL.Between the

REVERSE and

NEUTRAL gates.

N N N The vehicle is in

NEUTRAL.In the NEUTRAL

gate.

N The transmission is

transitioning

between NEUTRAL

and DRIVE, but is

not in DRIVE.Between the

NEUTRAL and

DRIVE gates.

D D D The transmission is

hydraulically in

DRIVE.In the DRIVE gate,

2 2 2 The transmission is

hydraulically in

Manual SECOND.In the SECOND

gate.

1 1 1 The transmission is

hydraulically in

Manual FIRST.In the FIRST gate.

DIAGNOSIS AND TESTING - TRANSMISSION RANGE SENSOR (TRS)

NOTE: For all circuit identification in the following steps, Refer to the appropriate Wiring Information.

1. Raise vehicle on suitable hoist.

2. Disconnect the vehicle’s shift cable from the manual lever.

3. With the manual lever in the PARK position (the PARK position is with the manual lever moved to the full rear-

ward position), measure the resistance between the Park/Neutral PositionSensepinoftheTRSandthetrans-

mission case. The resistance should be less than 5 ohms.

4. With the manual lever in the NEUTRAL position (the NEUTRAL position is with the manual lever moved two

detents forward of the full rearward position), measure the resistance between the Park/Neutral Position Sense

pin of the TRS and the transmission case. The resistance should be less than5ohms.

5. If the resistance is greater than 5 ohms in either of the previous steps, check for a dirty contact between the tip

of the TRS rod and the valve body manual lever. If the contact is OK, replace the TRS.

6. With the manual lever in the REVERSE position (the REVERSE position is with the manual lever moved one

detent forward of the full rearward position), measure the resistance between the Fused Ignition Switch Output

Page 3965 of 5267

and the Back-up Lamp feed pins of the TRS. The resistance should be less than5 ohms. If the resistance is

greater than 5 ohms, replace the TRS.

7. With the manual lever in the PARK position (the PARK position is with the manual lever moved to the full rear-

ward position), measure the resistance between the Transmission Range Sensor MUX and the Transmission

Range Sensor 5V Supply pins of the TRS. The resistance should be 522.2 ohms.If the resistance is not correct,

replace the TRS.

8. With the manual lever in the REVERSE position (the REVERSE position is with the manual lever moved one

detent forward of the full rearward position), measure the resistance between the Transmission Range Sensor

MUX and the Transmission Range Sensor 5V Supply pins of the TRS. The resistance should be 206.2 ohms. If

the resistance is not correct, replace the TRS.

9. With the manual lever in the NEUTRAL position (the NEUTRAL position is with the manual lever moved two

detents forward of the full rearward position), measure the resistance between the Transmission Range Sensor

MUX and the Transmission Range Sensor 5V Supply pins of the TRS. The resistance should be 108.6 ohms. If

the resistance is not correct, replace the TRS.

10. With the manual lever in the DRIVE position (the DRIVE position is with the manual lever moved three detents

forward of the full rearward position), measure the resistance between the Transmission Range Sensor MUX

and the Transmission Range Sensor 5V Supply pins of the TRS. The resistanceshould be 59.9 ohms. If the

resistance is not correct, replace the TRS.

11. With the manual lever in the SECOND position (the SECOND position is with the manual lever moved one

detent rearward of the full forward position), measure the resistance between the Transmission Range Sensor

MUX and the Back-up Lamp feed pins of the TRS. The resistance should be 31.9 ohms. If the resistance is not

correct, replace the TRS.

12. With the manual lever in the LOW position (the LOW position is with the manual lever moved to the full forward

position), measure the resistance between the Transmission Range SensorMUX and the Back-up Lamp feed

pins of the TRS. The resistance should be 13.7 ohms. If the resistance is notcorrect, replace the TRS.

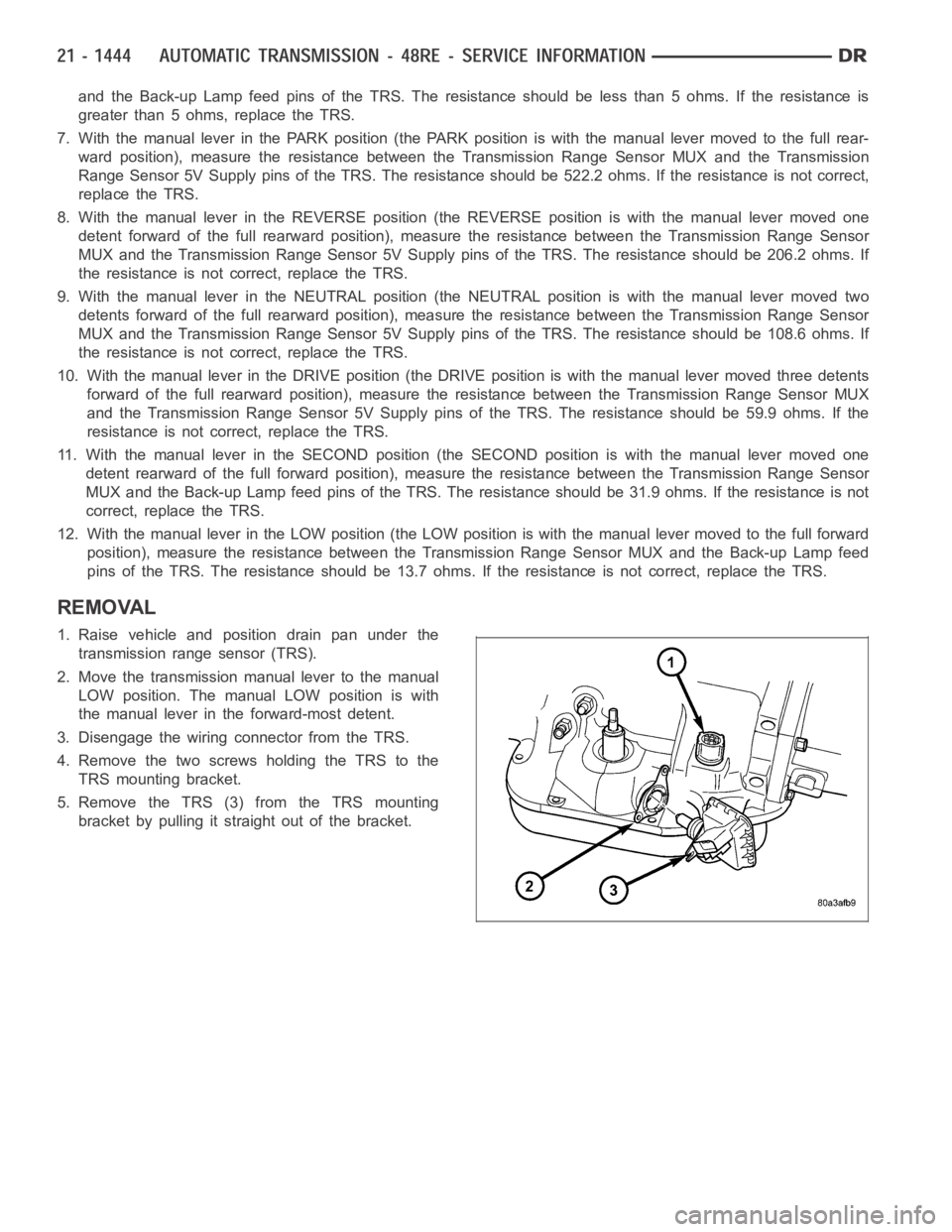

REMOVAL

1. Raise vehicle and position drain pan under the

transmission range sensor (TRS).

2. Move the transmission manual lever to the manual

LOW position. The manual LOW position is with

the manual lever in the forward-most detent.

3. Disengage the wiring connector from the TRS.

4. Remove the two screws holding the TRS to the

TRS mounting bracket.

5. Remove the TRS (3) from the TRS mounting

bracket by pulling it straight out of the bracket.