ignition DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 3286 of 5267

NOTE: The readings should be within ±14 kPa or 2.0 psi on the scan tool of the pressure reading specified

on Transmission Simulator.

Does the 3 line pressures on the scan tool match the Line pressure readings on the Transmission Sim-

ulator?

Ye s>>

Replace the Line Pressure Sensor per the Service Information.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Go To 3

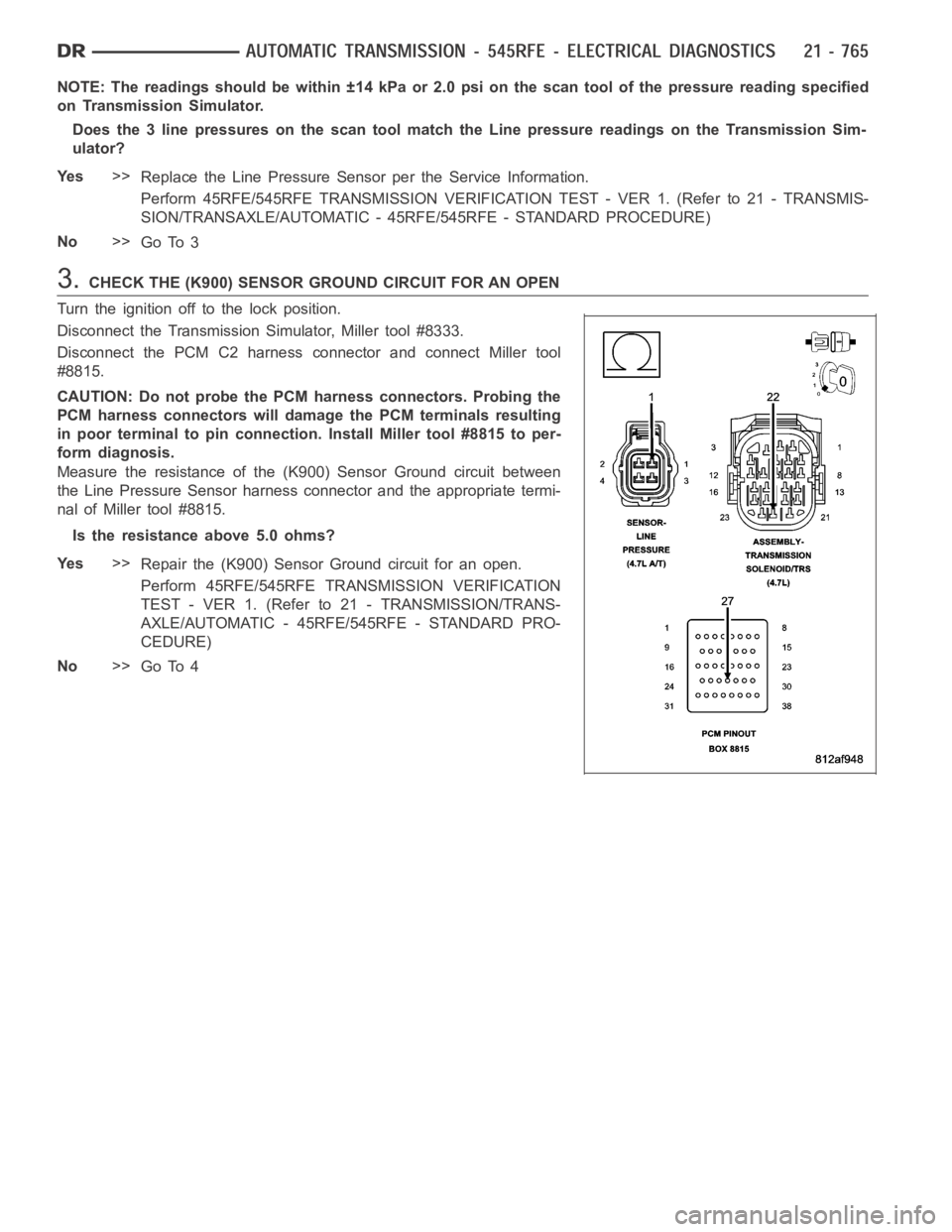

3.CHECK THE (K900) SENSOR GROUND CIRCUIT FOR AN OPEN

Turn the ignition off to the lock position.

Disconnect the Transmission Simulator, Miller tool #8333.

Disconnect the PCM C2 harness connector and connect Miller tool

#8815.

CAUTION: Do not probe the PCM harness connectors. Probing the

PCM harness connectors will damage the PCM terminals resulting

in poor terminal to pin connection. Install Miller tool #8815 to per-

form diagnosis.

Measure the resistance of the (K900) Sensor Ground circuit between

the Line Pressure Sensor harness connector and the appropriate termi-

nal of Miller tool #8815.

Is the resistance above 5.0 ohms?

Ye s>>

Repair the (K900) Sensor Ground circuit for an open.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

No>>

Go To 4

Page 3287 of 5267

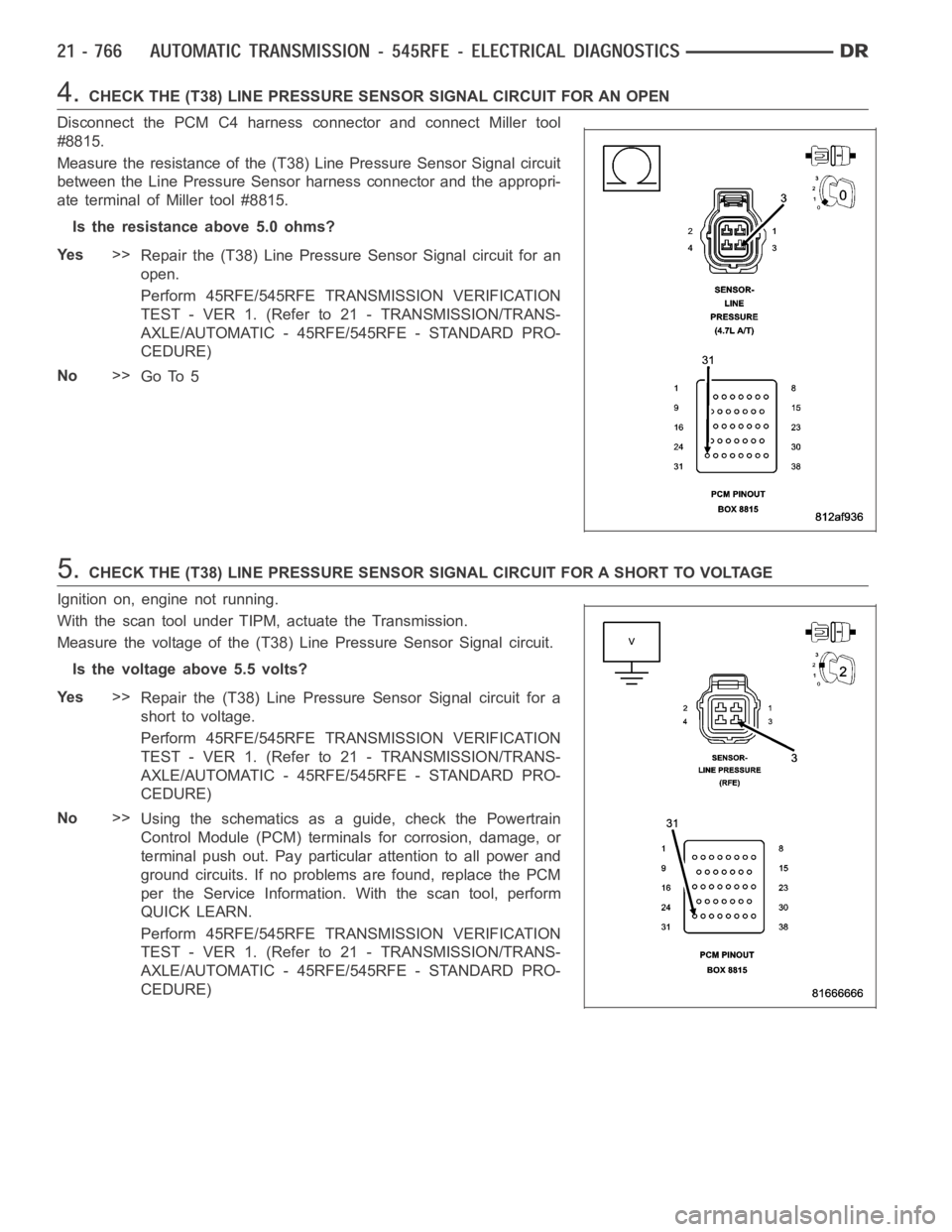

4.CHECK THE (T38) LINE PRESSURE SENSOR SIGNAL CIRCUIT FOR AN OPEN

Disconnect the PCM C4 harness connector and connect Miller tool

#8815.

Measure the resistance of the (T38) Line Pressure Sensor Signal circuit

between the Line Pressure Sensor harness connector and the appropri-

ate terminal of Miller tool #8815.

Is the resistance above 5.0 ohms?

Ye s>>

Repair the (T38) Line Pressure Sensor Signal circuit for an

open.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

No>>

Go To 5

5.CHECK THE (T38) LINE PRESSURE SENSOR SIGNAL CIRCUIT FOR A SHORT TO VOLTAGE

Ignition on, engine not running.

With the scan tool under TIPM, actuate the Transmission.

Measure the voltage of the (T38) Line Pressure Sensor Signal circuit.

Is the voltage above 5.5 volts?

Ye s>>

Repair the (T38) Line Pressure Sensor Signal circuit for a

short to voltage.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

No>>

Using the schematics as a guide, check the Powertrain

Control Module (PCM) terminals for corrosion, damage, or

terminal push out. Pay particular attention to all power and

ground circuits. If no problems are found, replace the PCM

per the Service Information.With the scan tool, perform

QUICK LEARN.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

Page 3293 of 5267

2.CHECK FOR DTCS

With the scan tool, check Transmission DTCs.

Is the DTC P0770 also present?

Ye s>>

Refer to the symptom list and perform diagnostics for P0770.

No>>

Go To 3

3.OTHER DTCS PRESENT

With the scan tool, check for other transmission DTC’s

Are the DTCs P0988 and/or P1736 present also?

Ye s>>

Go To 12

No>>

Go To 4

4.CHECK TO SEE IF DTC IS CURRENT

With the scan tool, check if the DTC P0987-4C HYDRAULIC PRESSURE TEST FAILURE is active or stored.

Is the DTC P0987-4C HYDRAULIC PRESSURE TEST FAILURE active?

Ye s>>

Go To 5

No>>

Go To 17

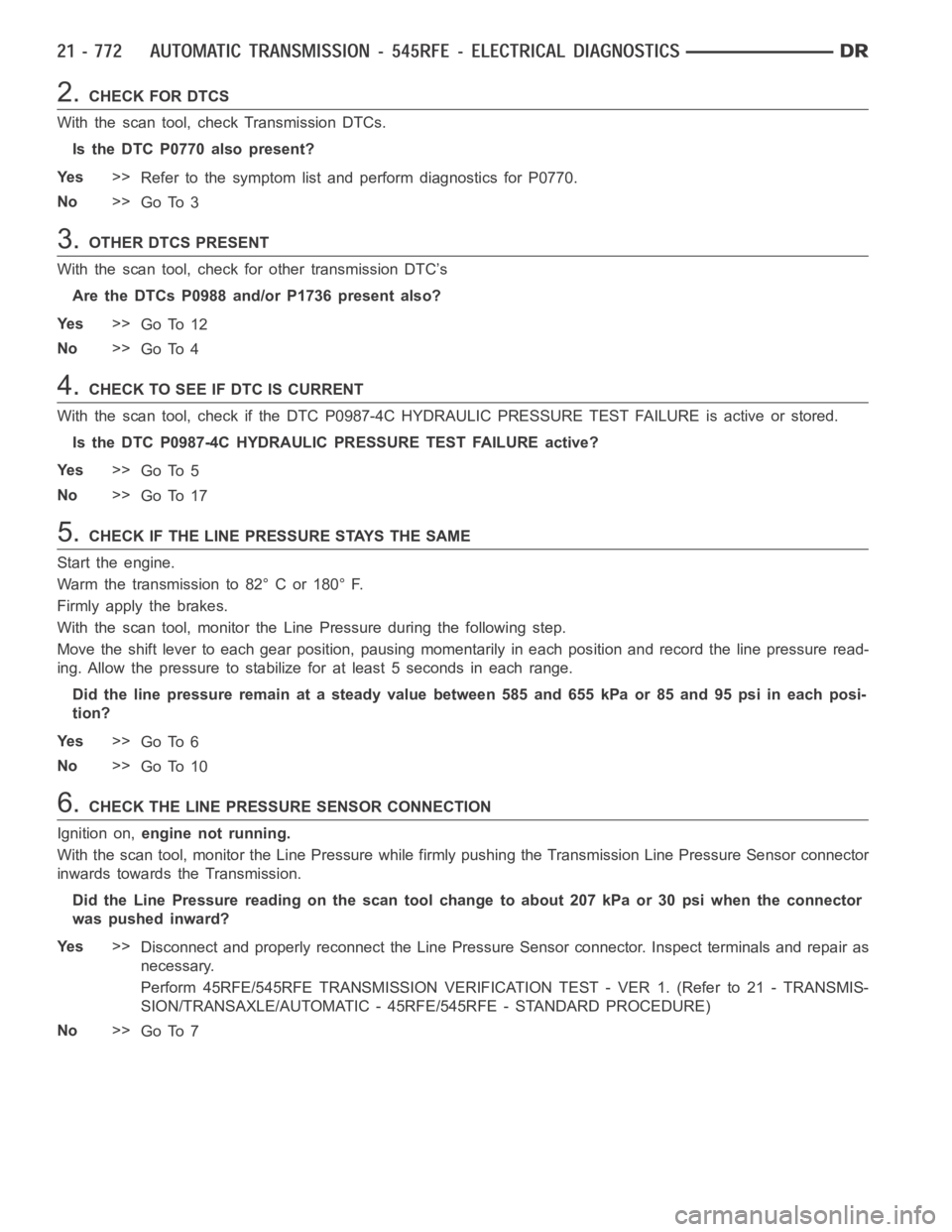

5.CHECK IF THE LINE PRESSURE STAYS THE SAME

Start the engine.

Warm the transmission to 82° C or 180° F.

Firmly apply the brakes.

With the scan tool, monitor the Line Pressure during the following step.

Move the shift lever to each gear position, pausing momentarily in each position and record the line pressure read-

ing. Allow the pressure to stabilize for at least 5 seconds in each range.

Did the line pressure remain at a steady value between 585 and 655 kPa or 85 and 95 psi in each posi-

tion?

Ye s>>

Go To 6

No>>

Go To 10

6.CHECK THE LINE PRESSURE SENSOR CONNECTION

Ignition on,engine not running.

Withthescantool,monitortheLinePressure while firmly pushing the Transmission Line Pressure Sensor connector

inwards towards the Transmission.

Did the Line Pressure reading on the scan tool change to about 207 kPa or 30 psi when the connector

was pushed inward?

Ye s>>

Disconnect and properly reconnect the Line Pressure Sensor connector. Inspect terminals and repair as

necessary.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Go To 7

Page 3294 of 5267

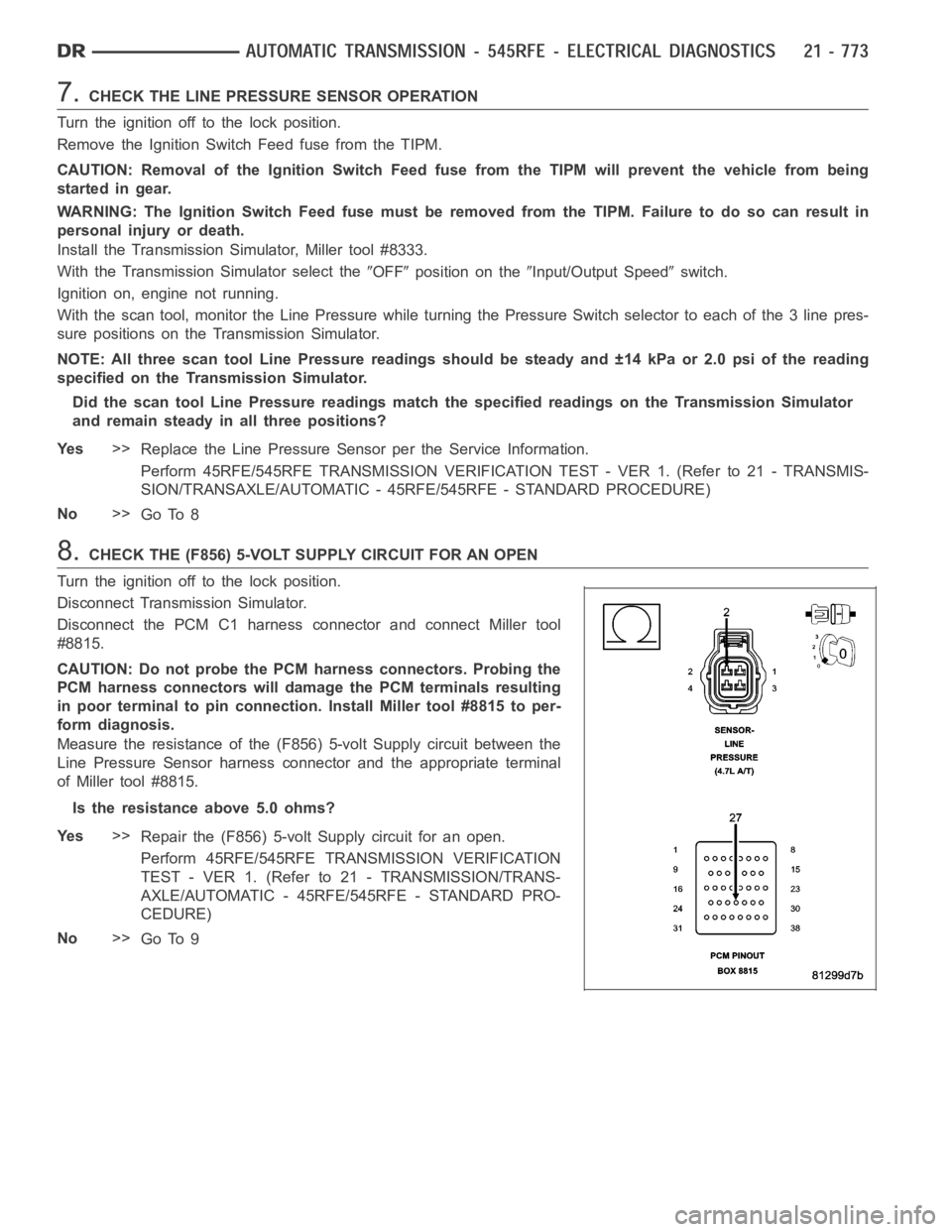

7.CHECK THE LINE PRESSURE SENSOR OPERATION

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install the Transmission Simulator, Miller tool #8333.

With the Transmission Simulator select the

OFFposition on theInput/Output Speedswitch.

Ignition on, engine not running.

With the scan tool, monitor the Line Pressure while turning the Pressure Switch selector to each of the 3 line pres-

sure positions on the Transmission Simulator.

NOTE: All three scan tool Line Pressure readings should be steady and ±14 kPa or 2.0 psi of the reading

specified on the Transmission Simulator.

Did the scan tool Line Pressure readings match the specified readings on the Transmission Simulator

and remain steady in all three positions?

Ye s>>

Replace the Line Pressure Sensor per the Service Information.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Go To 8

8.CHECK THE (F856) 5-VOLT SUPPLY CIRCUIT FOR AN OPEN

Turn the ignition off to the lock position.

Disconnect Transmission Simulator.

Disconnect the PCM C1 harness connector and connect Miller tool

#8815.

CAUTION: Do not probe the PCM harness connectors. Probing the

PCM harness connectors will damage the PCM terminals resulting

in poor terminal to pin connection. Install Miller tool #8815 to per-

form diagnosis.

Measure the resistance of the (F856) 5-volt Supply circuit between the

Line Pressure Sensor harness connector and the appropriate terminal

of Miller tool #8815.

Is the resistance above 5.0 ohms?

Ye s>>

Repair the (F856) 5-volt Supply circuit for an open.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

No>>

Go To 9

Page 3295 of 5267

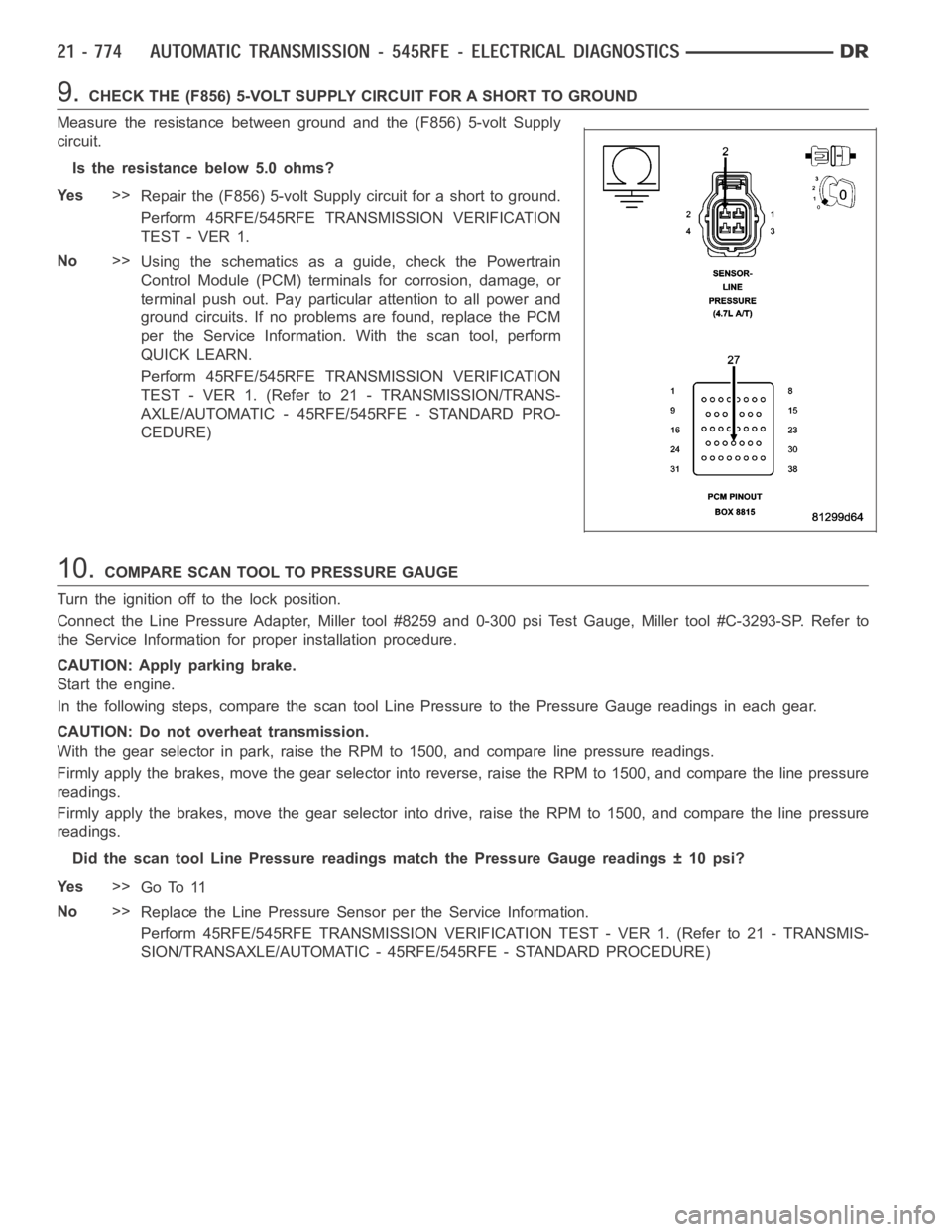

9.CHECK THE (F856) 5-VOLT SUPPLY CIRCUIT FOR A SHORT TO GROUND

Measure the resistance between ground and the (F856) 5-volt Supply

circuit.

Is the resistance below 5.0 ohms?

Ye s>>

Repair the (F856) 5-volt Supply circuit for a short to ground.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1.

No>>

Using the schematics as a guide, check the Powertrain

Control Module (PCM) terminals for corrosion, damage, or

terminal push out. Pay particular attention to all power and

ground circuits. If no problems are found, replace the PCM

per the Service Information.With the scan tool, perform

QUICK LEARN.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

10.COMPARE SCAN TOOL TO PRESSURE GAUGE

Turn the ignition off to the lock position.

Connect the Line Pressure Adapter, Miller tool #8259 and 0-300 psi Test Gauge, Miller tool #C-3293-SP. Refer to

the Service Information for proper installation procedure.

CAUTION: Apply parking brake.

Start the engine.

In the following steps, compare thescan tool Line Pressure to the PressureGauge readings in each gear.

CAUTION: Do not overheat transmission.

With the gear selector in park, raise the RPM to 1500, and compare line pressure readings.

Firmly apply the brakes, move the gear selector into reverse, raise the RPMto 1500, and compare the line pressure

readings.

Firmly apply the brakes, move the gear selector into drive, raise the RPM to1500, and compare the line pressure

readings.

Did the scan tool Line Pressure readings match the Pressure Gauge readings±10psi?

Ye s>>

Go To 11

No>>

Replace the Line Pressure Sensor per the Service Information.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Page 3296 of 5267

11 .CHECK PCM AND WIRING

Turn the ignition off to the lock position.

Remove the Line Pressure Adapter, Miller tool #8259 and 0-300 psi Test Gauge, Miller tool #C-3293-SP.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install the Transmission Simulator, Miller tool #8333.

On the Transmission Simulator, turn the Pressure Switch selector switch to4C.

Ignition on, engine not running.

With the scan tool, monitor the 4C Pressure Switch state while pressing andholding the Pressure Switch test button

and wiggling the wire harness and connectors that pertain to the 4C PressureSwitch.

Did the 4C Pressure Switch state change to closed and remain closed while wiggling the wires?

Ye s>>

Go To 12

No>>

Go To 14

12.CHECK FOR EXCESSIVE DEBRIS

Turn the ignition off to the lock position.

Remove the Transmission Simulator, Miller tool #8333.

Remove and inspect the Transmission Oil Pan per the Service Information.

Does the Transmission Oil Pan contain excessive debris or contamination?

Ye s>>

Repair the cause of the excessive debris in the Transmission Oil Pan. Referto the Service Information

for the proper procedures.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Go To 13

13.CHECK 4C HYDRAULIC CLUTCH CIRCUIT

Remove the Valve Body and air check the 4C hydraulic clutch circuit (in the case) for leakage per the Service

Information.

NOTE: The 4C hydraulic clutch circuit contains a small bleed orifice. A small amount of air leakage is nor-

mal.

Was there excessive air leakage noticed during the air check?

Ye s>>

Repair as necessary. Check the 4C clutch piston, piston seals and bleed orifice assembly.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Disassemble and inspect the Valve Body and repair as necessary. Inspect the 4C Accumulator piston

and seals. If no problems are found in the Valve Body, replace the Transmission Solenoid/TRS Assem-

bly per the Service Information.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Page 3297 of 5267

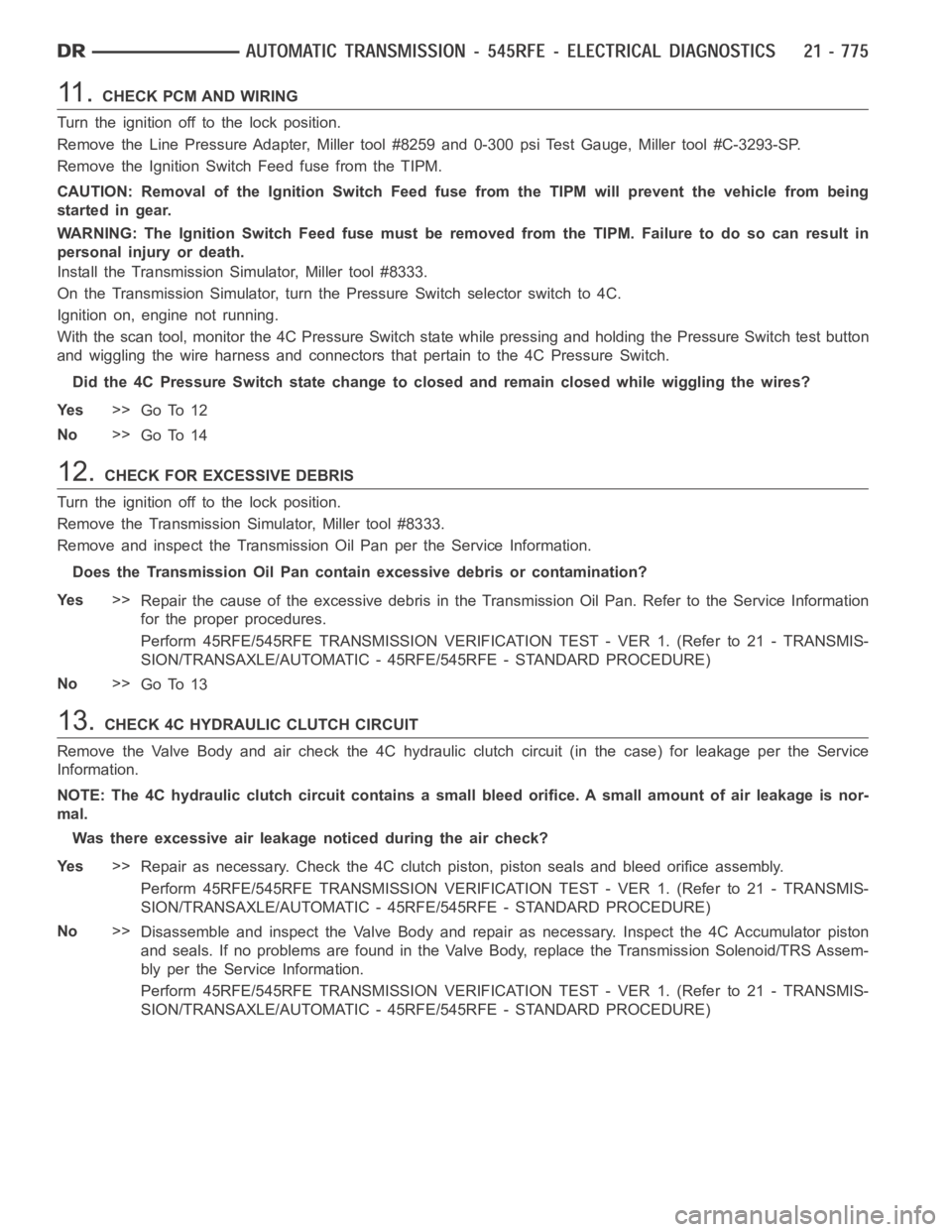

14.CHECK THE (T48) 4C PRESSURE SWITCH SENSE CIRCUIT FOR AN OPEN

Turn the ignition off to the lock position.

Remove the Transmission Simulator, Miller tool #8333 and connect

Miller tool #8815.

Disconnect the PCM C4 harness connector.

Measure the resistance of the (T48) 4C Pressure Switch Sense circuit

between the Transmission Solenoid/TRS Assembly harness connector

and the appropriate terminal of Miller tool #8815.

Is the resistance above 5.0 ohms?

Ye s>>

Repair the (T48) 4C Pressure Switch Sense circuit for an

open.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

No>>

Go To 15

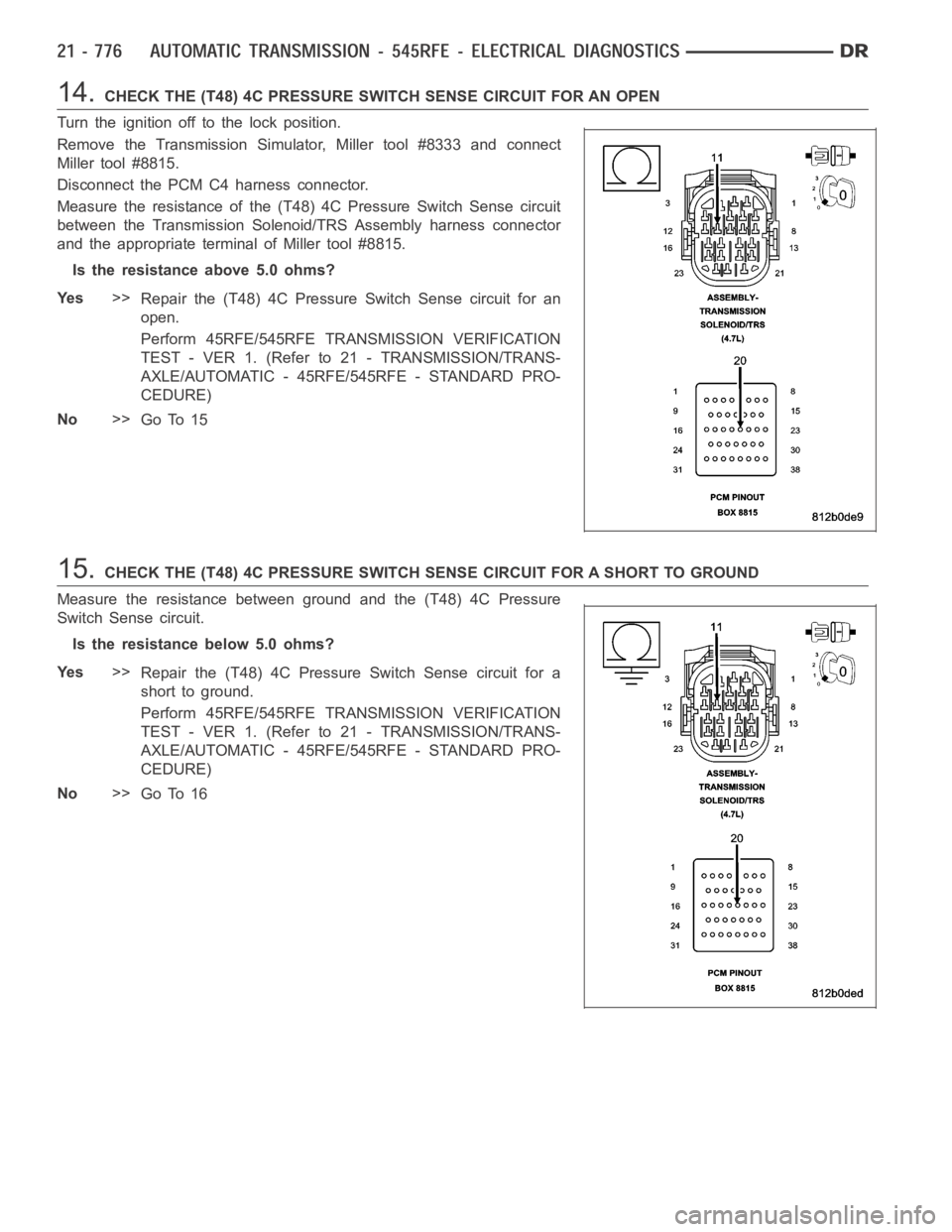

15.CHECK THE (T48) 4C PRESSURE SWITCH SENSE CIRCUIT FOR A SHORT TO GROUND

Measure the resistance between ground and the (T48) 4C Pressure

Switch Sense circuit.

Is the resistance below 5.0 ohms?

Ye s>>

Repair the (T48) 4C Pressure Switch Sense circuit for a

short to ground.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

No>>

Go To 16

Page 3300 of 5267

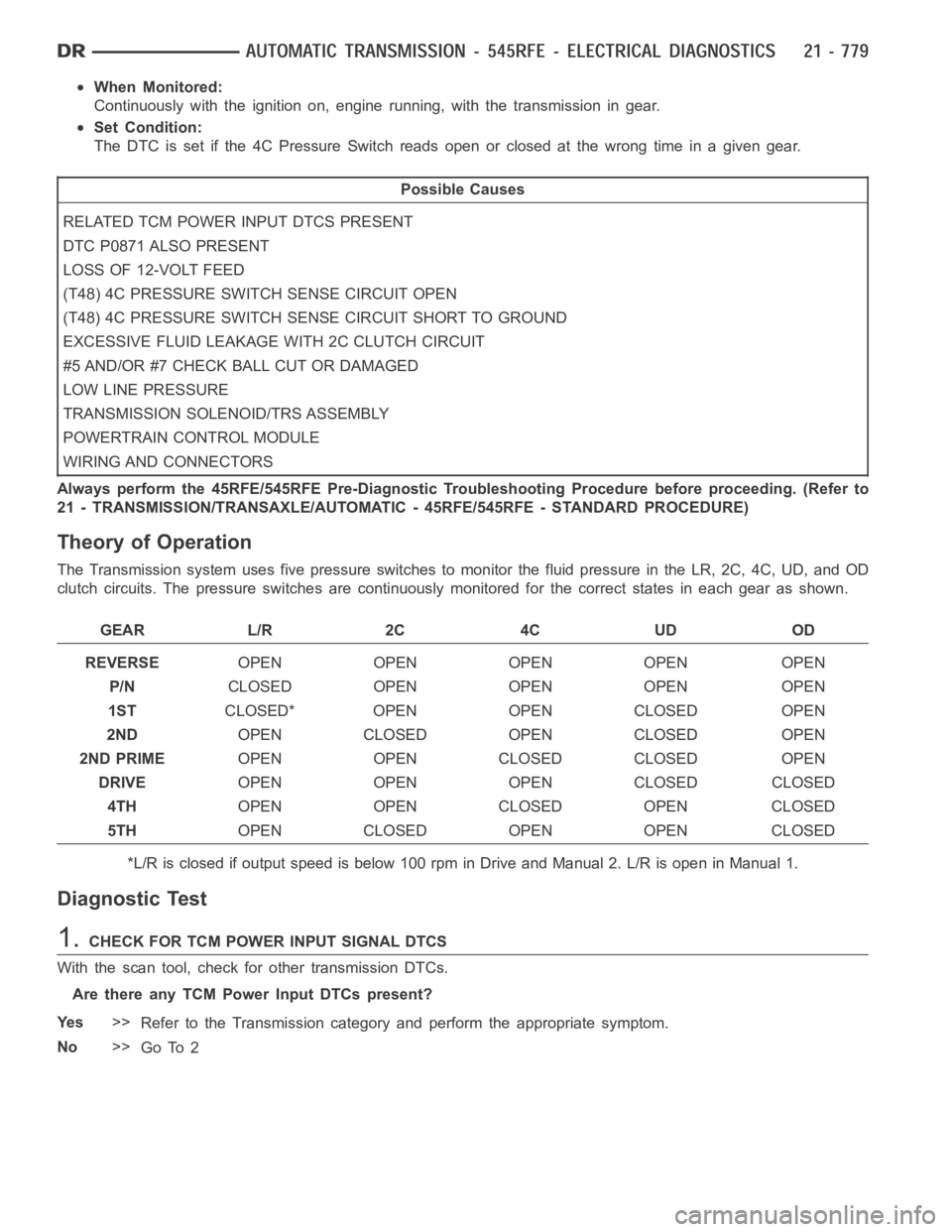

When Monitored:

Continuously with the ignition on, engine running, with the transmissionin gear.

Set Condition:

The DTC is set if the 4C Pressure Switchreadsopenorclosedatthewrongtimein a given gear.

Possible Causes

RELATED TCM POWER INPUT DTCS PRESENT

DTC P0871 ALSO PRESENT

LOSS OF 12-VOLT FEED

(T48) 4C PRESSURE SWITCH SENSE CIRCUIT OPEN

(T48) 4C PRESSURE SWITCH SENSE CIRCUIT SHORT TO GROUND

EXCESSIVE FLUID LEAKAGE WITH 2C CLUTCH CIRCUIT

#5 AND/OR #7 CHECK BALL CUT OR DAMAGED

LOW LINE PRESSURE

TRANSMISSION SOLENOID/TRS ASSEMBLY

POWERTRAIN CONTROL MODULE

WIRING AND CONNECTORS

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

The Transmission system uses five pressure switches to monitor the fluid pressure in the LR, 2C, 4C, UD, and OD

clutch circuits. The pressure switches are continuously monitored for the correct states in each gear as shown.

GEAR L/R 2C 4C UD OD

REVERSEOPEN OPEN OPEN OPEN OPEN

P/NCLOSED OPEN OPEN OPEN OPEN

1STCLOSED* OPEN OPEN CLOSED OPEN

2NDOPEN CLOSED OPEN CLOSED OPEN

2ND PRIMEOPEN OPEN CLOSED CLOSED OPEN

DRIVEOPEN OPEN OPEN CLOSED CLOSED

4THOPEN OPEN CLOSED OPEN CLOSED

5THOPEN CLOSED OPEN OPEN CLOSED

*L/R is closed if output speed is below 100 rpm in Drive and Manual 2. L/R is open in Manual 1.

Diagnostic Test

1.CHECK FOR TCM POWER INPUT SIGNAL DTCS

With the scan tool, check for other transmission DTCs.

Are there any TCM Power Input DTCs present?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom.

No>>

Go To 2

Page 3302 of 5267

7.CHECK IF THE DTC P0871 ALSO SET

With the scan tool, check Transmission DTCs.

Is the DTC P0871 also present?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom.

No>>

Go To 8

8.CHECK IF THE DTC SET IN PARK, REVERSE OR NEUTRAL

With the scan tool, check the DTC EVENT DATA for P0988.

NOTE: Make sure to record all DTC EVENT DATA stored in the scan tool for future reference in this test

procedure.

Does the DTC EVENT DATA show the DTC set in Park, Neutral, or Reverse for P0988?

Ye s>>

Go To 13

No>>

Go To 9

9.CHECK IF THE DTC EVENT DATA READS CLOSED

With the scan tool, check the DTC EVENT DATA for P0988.

NOTE: Make sure to record all DTC EVENT DATA stored in the scan tool for future reference in this test

procedure.

Does the DTC EVENT DATA show the 4C Pressure Switch reading CLOSED?

Ye s>>

Go To 11

No>>

Go To 10

10.CHECK THE PRIMARY OIL FILTER SEAL

In the DTC EVENT DATA recorded earlier,compare the Line Pressure and the Desired Line Pressure.

Is the Line Pressure less than 40 psi, and significantly below the Desired Line Pressure?

Ye s>>

Repair as necessary to correct low line pressure. Check fluid level and adjustasnecessary.Iffluidlevel

is OK, check the Primary Oil Filter seal for a split, crack, or improperly installed. If the filter and seal are

OK, check the Main Regulator Valve in the Oil Pump. Refer to the Service Information for the above

procedures.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Go To 15

11 .CHECK THE PCM AND WIRING

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install the Transmission Simulator, Miller tool #8333.

Ignition on, engine not running.

With the Transmission Simulator, turn the Pressure Switch selector switchtothe4Cposition.

Page 3303 of 5267

With the scan tool, monitor the 4C Pressure Switch while pressing the Pressure Switch test button on the Trans-

mission Simulator.

Did the state of the 4C Pressure Switch change while pressing the Pressure Switch Test button?

Ye s>>

Go To 12

No>>

Go To 13

12.CHECK THE TRANSMISSION SOLENOID/TRS ASSEMBLY

Using the schematics as a guide, inspect the wiring and connectors specifictothiscircuit.

Wiggle the wires while checking for shorted and open circuits.

Where there any problems found?

Ye s>>

Repair as necessary.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Replace the Transmission Solenoid/TRS Assembly per the Service Information.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

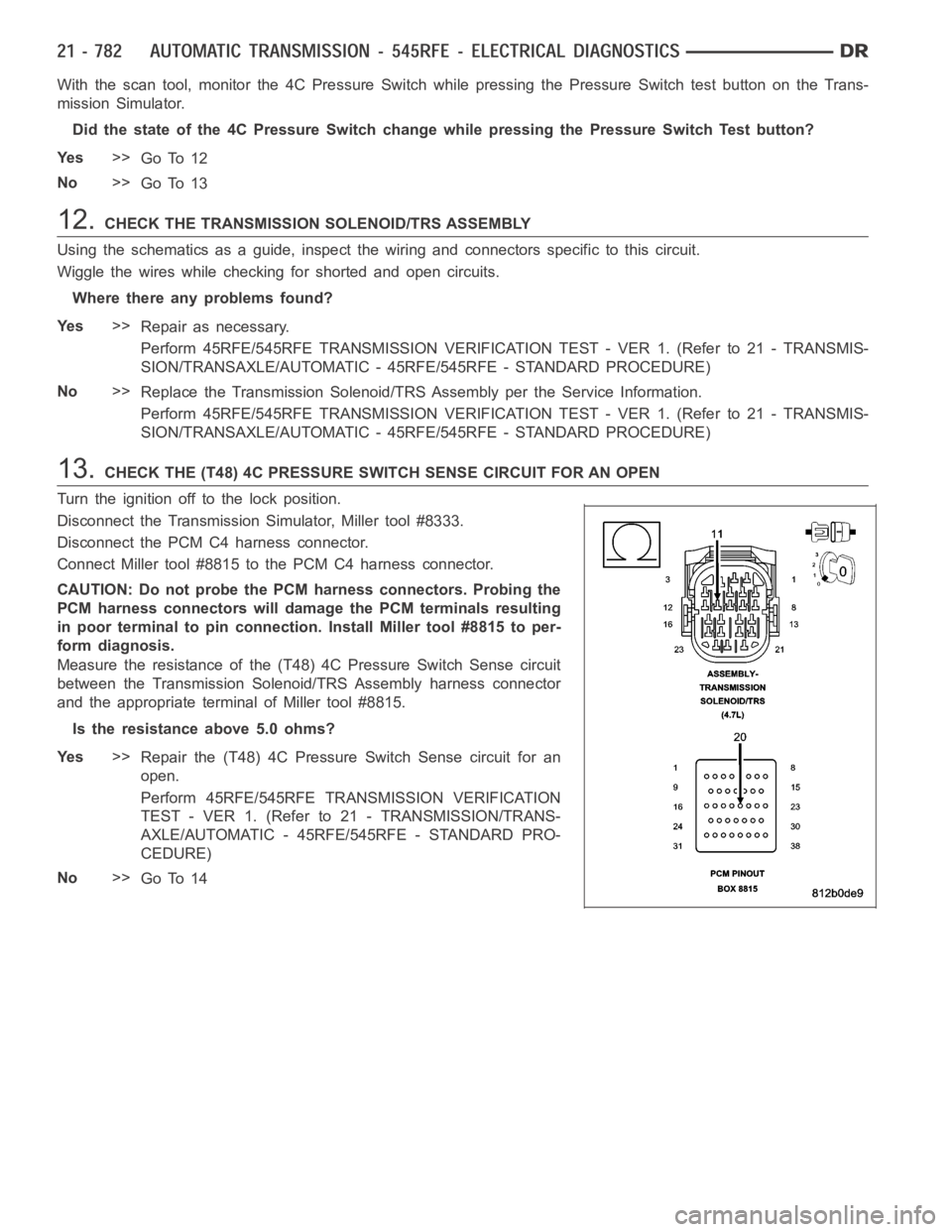

13.CHECK THE (T48) 4C PRESSURE SWITCH SENSE CIRCUIT FOR AN OPEN

Turn the ignition off to the lock position.

Disconnect the Transmission Simulator, Miller tool #8333.

Disconnect the PCM C4 harness connector.

Connect Miller tool #8815 to the PCM C4 harness connector.

CAUTION: Do not probe the PCM harness connectors. Probing the

PCM harness connectors will damage the PCM terminals resulting

in poor terminal to pin connection. Install Miller tool #8815 to per-

form diagnosis.

Measure the resistance of the (T48) 4C Pressure Switch Sense circuit

between the Transmission Solenoid/TRS Assembly harness connector

and the appropriate terminal of Miller tool #8815.

Is the resistance above 5.0 ohms?

Ye s>>

Repair the (T48) 4C Pressure Switch Sense circuit for an

open.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

No>>

Go To 14